Performance of a Single Source of Low-Grade Clay in a Limestone Calcined Clay Cement Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Mix Proportion and Sample Preparation

2.2.2. Experimental Methods

3. Results and Discussion

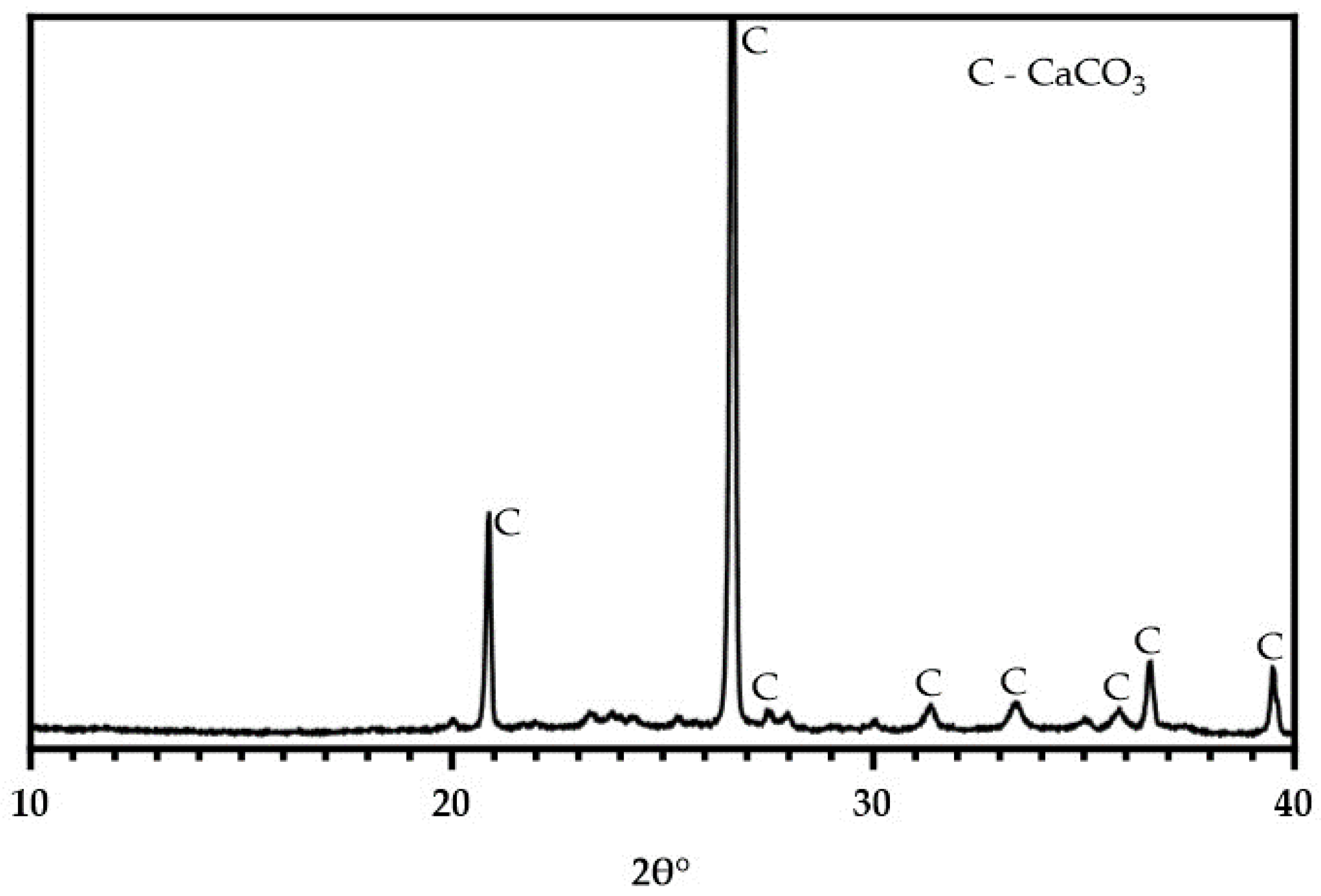

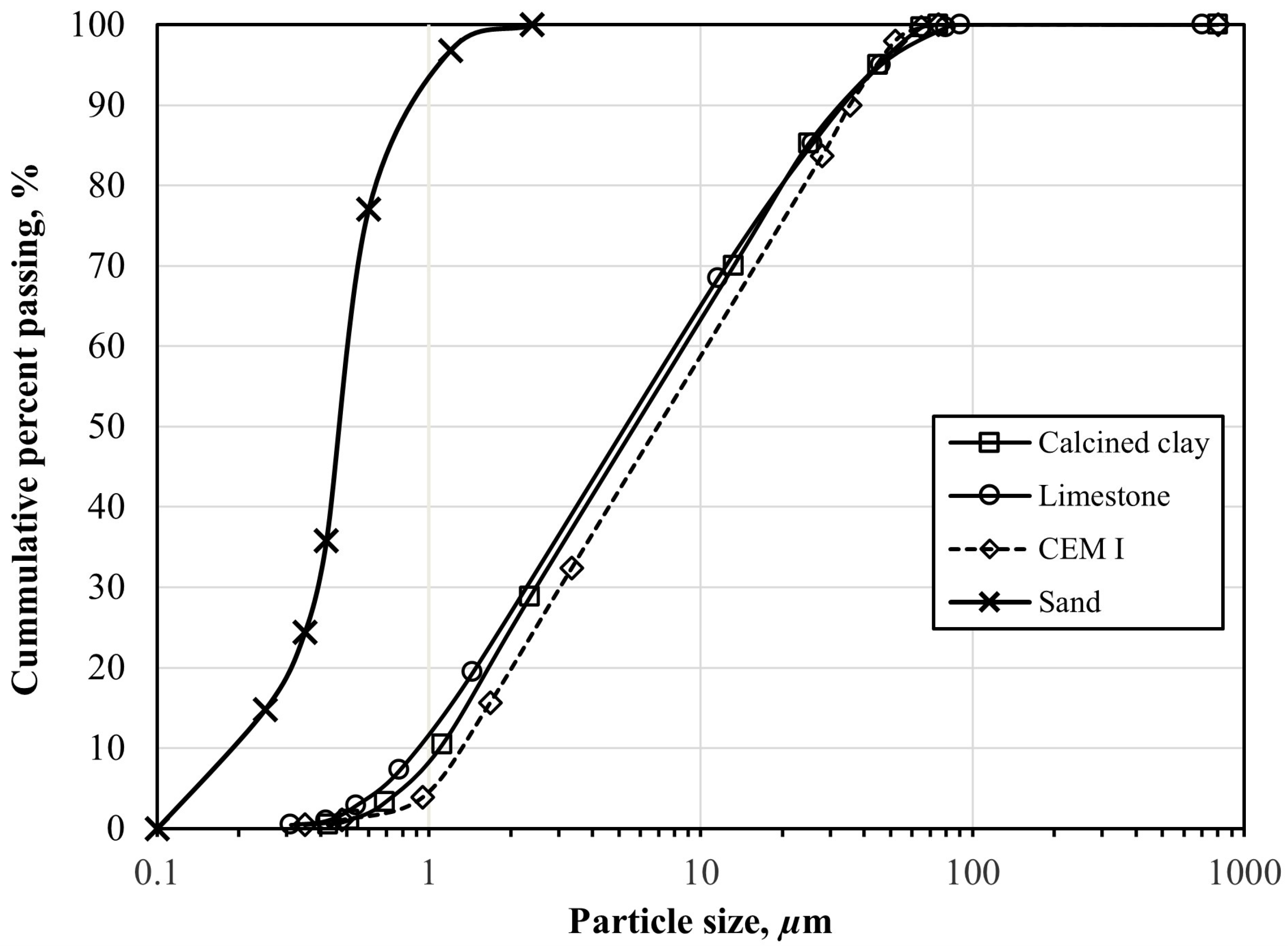

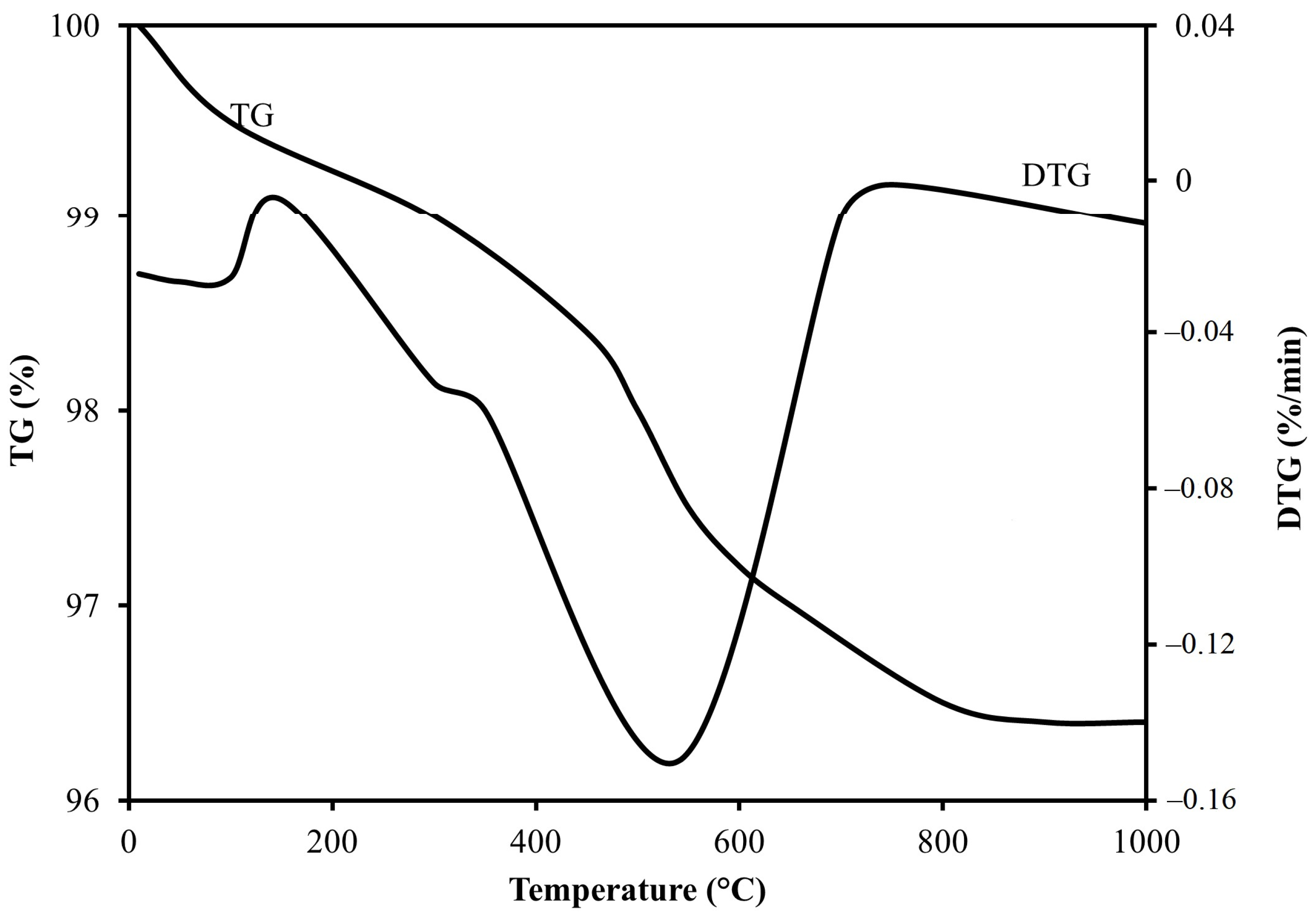

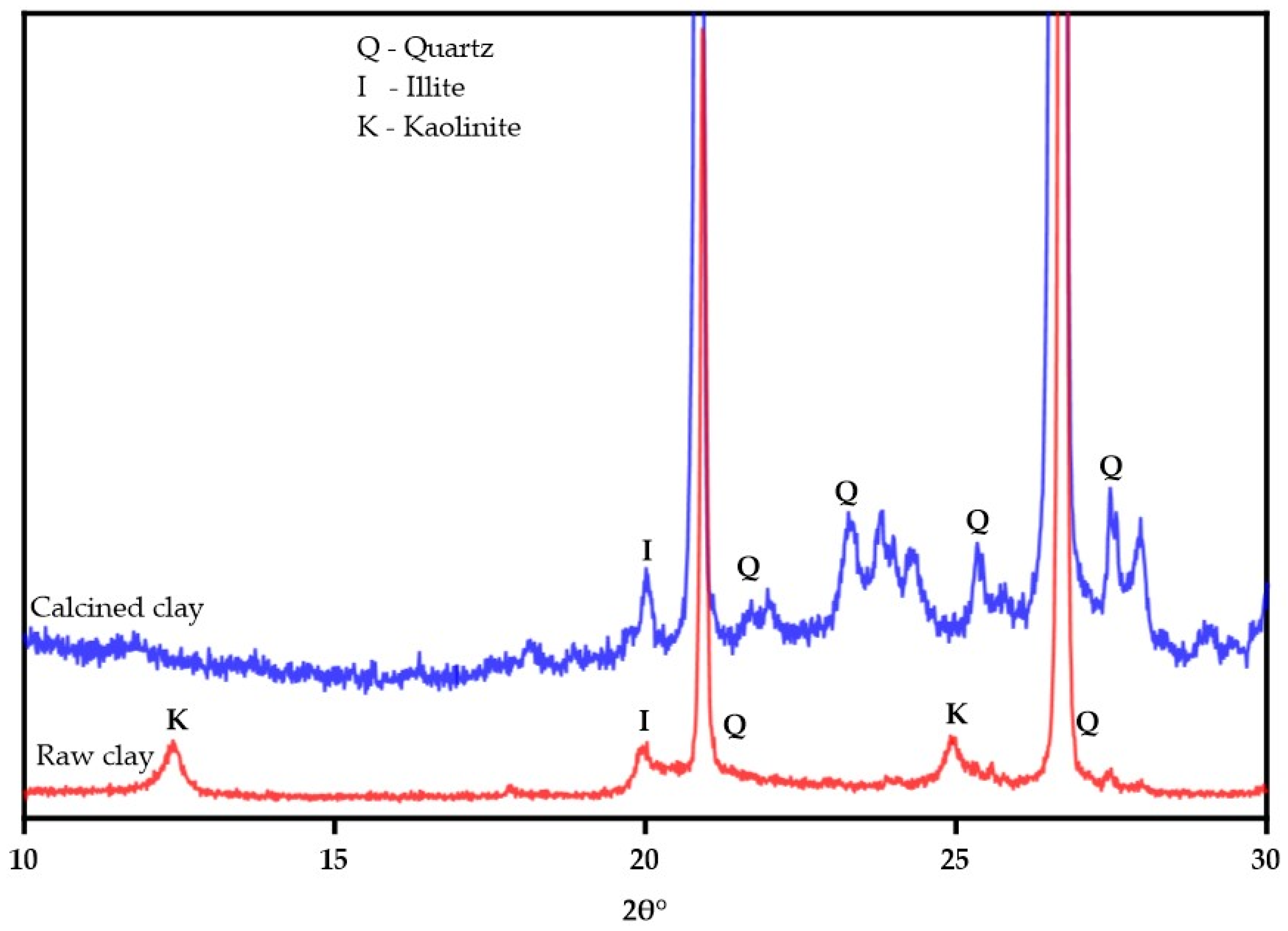

3.1. Characterization of Raw Materials

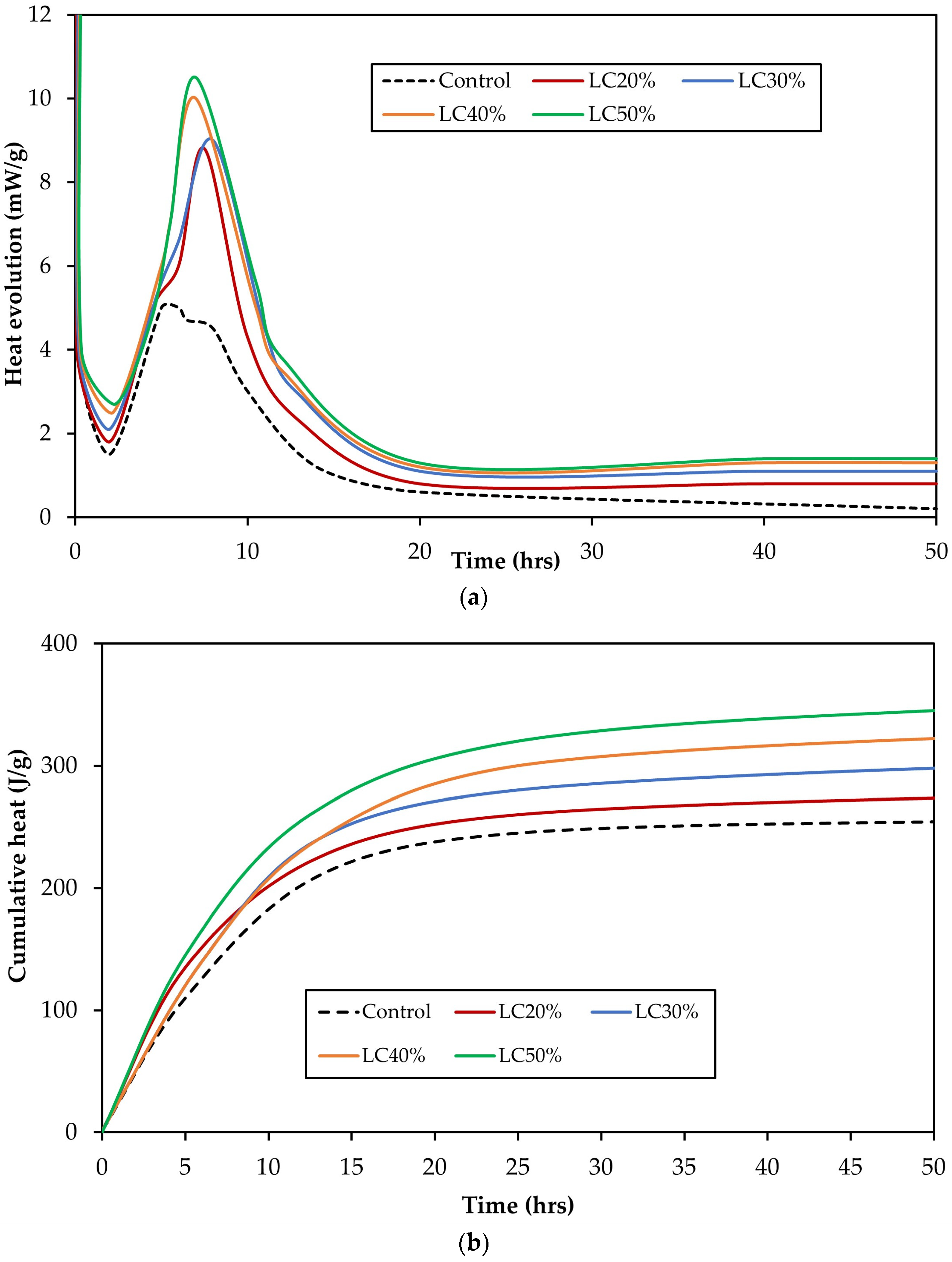

3.2. Heat of Hydration and Reaction Mechanics

3.3. Thermogravimetric Analysis

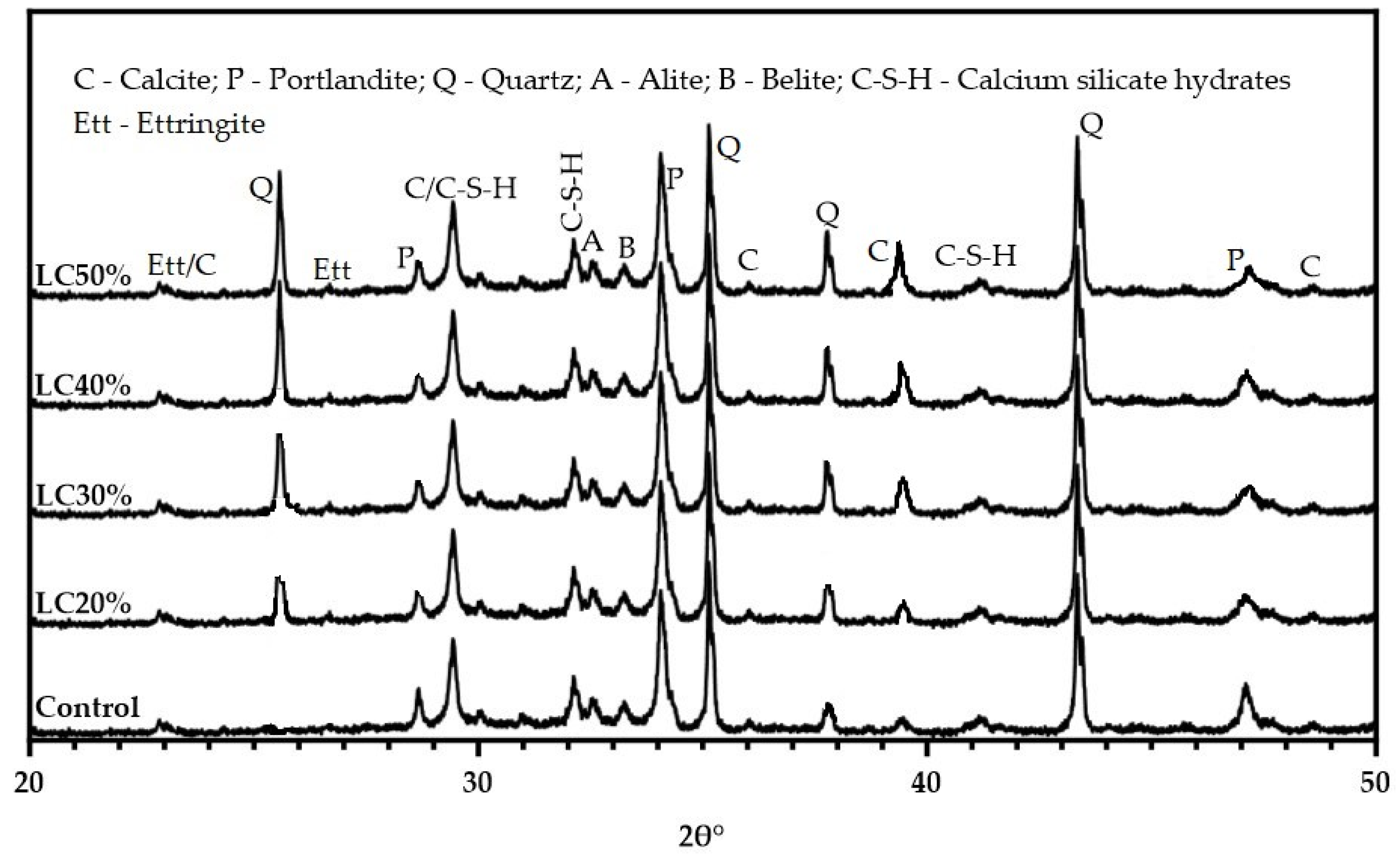

3.4. Hydration Kinetics via XRD

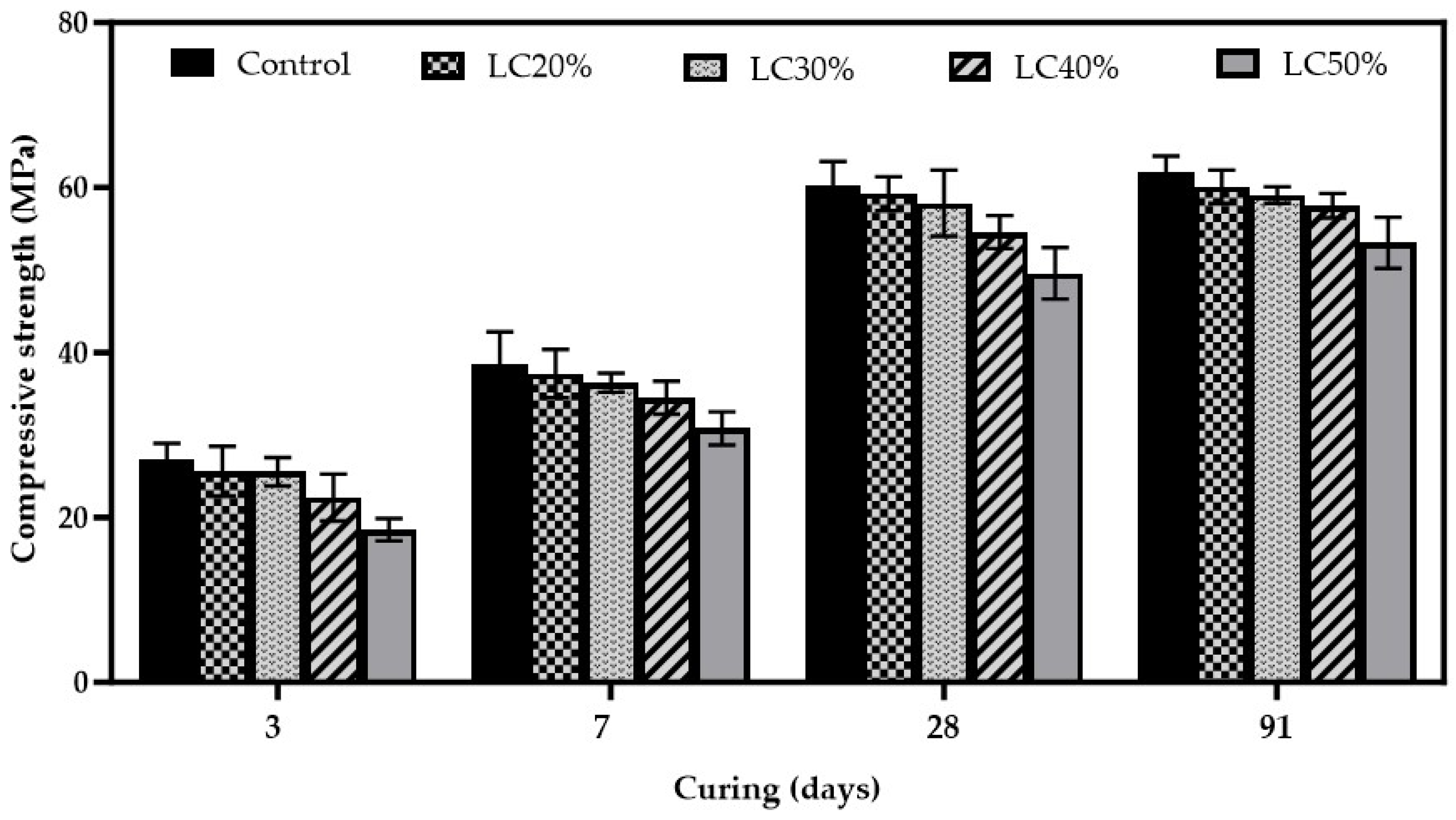

3.5. Compressive Strength

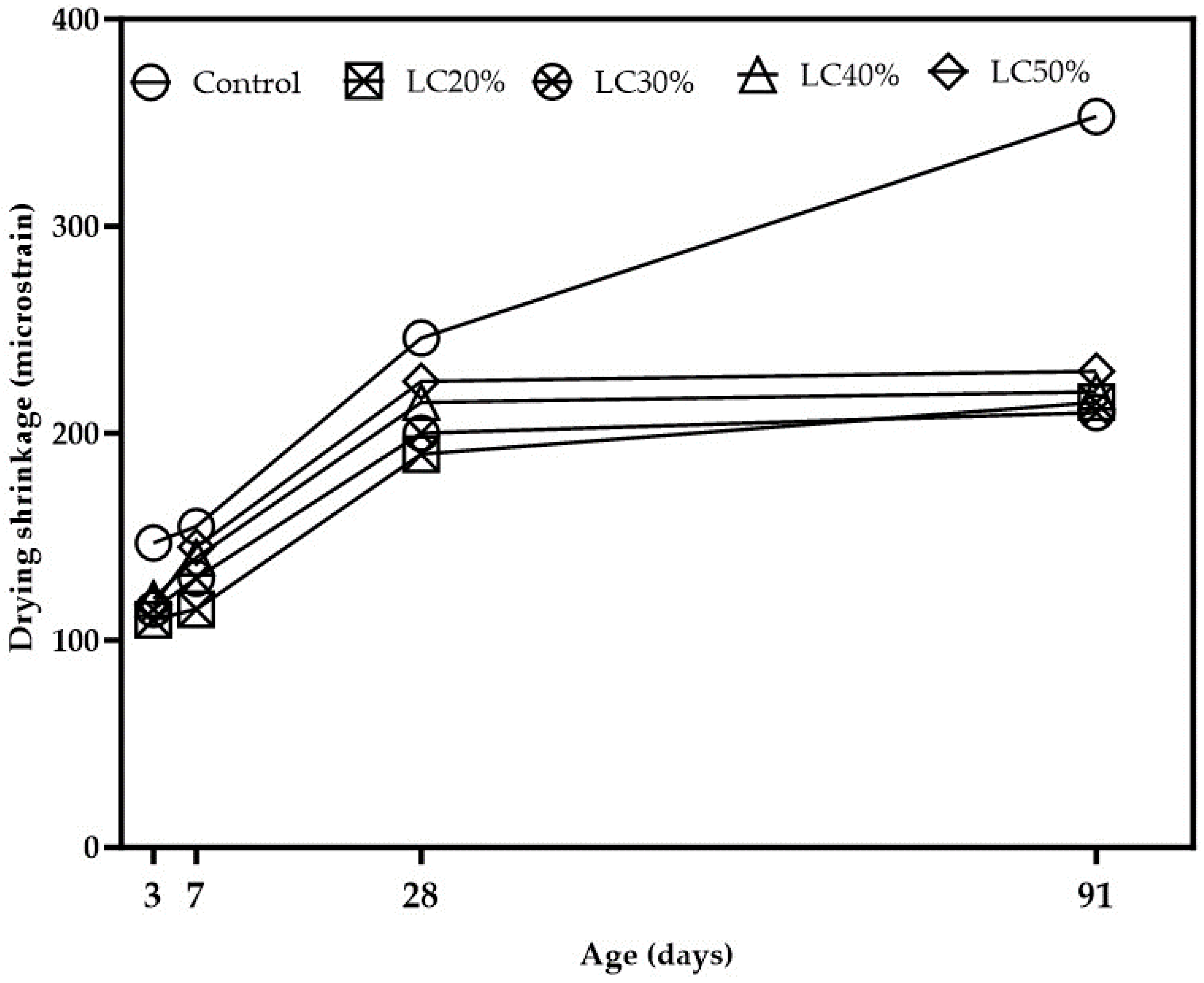

3.6. Drying Shrinkage

3.7. Chloride Penetration Resistance and Water Absorption

4. Conclusions

- In the LC3 systems, the addition of calcined clay and limestone reduced the induction period and raised the slope of the acceleration period due to the filler effect. This led to the creation of additional room for the cement particles to react and generate nucleation sites for the development of hydration products (C-S-H). The rate of reaction and cumulative heat increased with increasing calcined clay and limestone content in the LC3 mixes.

- X-ray diffraction (XRD) and thermogravimetric analysis (TGA) confirmed the decomposition of monosulphates and carboaluminates in the LC3 specimens. Contrary to what was expected, lower amounts of portlandite were consumed, which could potentially affect the formation of C-(A)-S-H. The more limestone powder in the mix, the greater the calcite peak intensity.

- LC3 mortar specimens obtained relatively lower compressive strength at 3 and 7 days compared with the reference cement. There was a slight improvement in strength as the curing age increased to 28 and 91 days but it was not enough to match the results of the reference mortar.

- LC3 mortar specimens (LC20%, LC30%, LC40%, and LC50%) trailed the control sample by 1.2%, 4%, 9.8%, and 18%, respectively, at 28 days and 1.6%, 2.3%, 3.6%, and 5.5%, respectively, at 91 days. Even though strength values were found to be lower than the control, there appeared to be a significant improvement at 91 days.

- The optimum replacement of OPC clinker, calcined clay and limestone, was 20% (LC20%).

- Drying shrinkage values recorded for all the LC3 samples were found within the range of 215 and 230 micro-strains. Drying shrinkage in the LC3 samples was about 34.5% lower than that of the reference cement mortar. LC3 specimens showed lower amounts of total charge passed at 28 days compared with the reference mortar, demonstrating significant chloride penetration resistance.

- The incorporation of calcined clay and limestone, with an added advantage of filler effect in the LC3 mortar specimens resulted in a reduced number of pores and, consequently, minimal absorption. This demonstrates how the LC3 binder system enhances resistance to capillary absorption.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. The reaction between metakaolin and limestone and its effect in porosity refinement and mechanical properties. Cem. Concr. Res. 2021, 140, 106307. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

- Sui, S.; Wilson, W.; Georget, F.; Maraghechi, H.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Quantification methods for chloride binding in Portland cement and limestone systems. Cem. Concr. Res. 2019, 125, 105864. [Google Scholar] [CrossRef]

- Cardinaud, G.; Rozière, E.; Martinage, O.; Loukili, A.; Barnes-Davin, L.; Paris, M.; Deneele, D. Calcined clay—Limestone cements: Hydration processes with high and low-grade kaolinite clays. Constr. Build. Mater. 2021, 277, 122271. [Google Scholar] [CrossRef]

- Hay, R.; Celik, K. Performance enhancement and characterization of limestone calcined clay cement (LC3) produced with low-reactivity kaolinitic clay. Constr. Build. Mater. 2023, 392, 131831. [Google Scholar] [CrossRef]

- Blouch, N.; Rashid, K.; Ju, M. Exploring low-grade clay minerals diving into limestone calcined clay cement (LC3): Characterization—Hydration—Performance. J. Clean. Prod. 2023, 426, 139065. [Google Scholar] [CrossRef]

- Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Dunster, A.; Ehsani, A.; Tyrer, M. Mechanochemical characterisation of calcined impure kaolinitic clay as a composite binder in cementitious mortars. J. Compos. Sci. 2022, 6, 134. [Google Scholar] [CrossRef]

- ASTM C. 778; Standard Specification for Standard Sand. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2006; p. 4.

- ASTM C. 191; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2013.

- Standard B. BS EN 196-3; 1995-Methods of Testing Cement-Part 3: Determination of Setting Time and Soundness. BSI: London, UK, 1999.

- ASTM C. 305; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 1995; pp. 188–190.

- ASTM C. 157/C 157M-08; Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C. 1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C. 642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete, Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2006; p. 4.

- Du, H.; Pang, S.D. High-performance concrete incorporating calcined kaolin clay and limestone as cement substitute. Constr. Build. Mater. 2020, 264, 120152. [Google Scholar] [CrossRef]

- Tagbor, T.A.; Boakye, K.A.; Sarfo-Ansah, J.; Atiemo, E. A study of the pozzolanic properties of Anfoega Kaolin. Int. J. Eng. Res. Appl. 2015, 5, 28–33. [Google Scholar]

- Scrivener, K.L.; Lothenbach, B.; De Belie, N.; Gruyaert, E.; Skibsted Snellings, R.; Vollpracht, A. TC 238-SCM: Hydration and microstructure of concrete with SCMs. Mater. Struct. 2015, 48, 835–862. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Celik, K.; Hay, R.; Hargis, C.W.; Moon, J. Effect of volcanic ash pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 2019, 197, 803–812. [Google Scholar] [CrossRef]

- Yanguatin, H.; Ramírez, J.H.; Tironi, A.; Tobón, J.I. Effect of thermal treatment on pozzolanic activity of excavated waste clays. Constr. Build. Mater. 2019, 211, 814–823. [Google Scholar] [CrossRef]

- Kaminskas RKubiliute, R.; Prialgauskaite, B. Smectite clay waste as an additive for Portland cement. Cem. Concr. Comp. 2020, 113, 103710. [Google Scholar] [CrossRef]

- Trojer, F.J. The crystal structure of parawollastonite. Z. Krist.-Cryst. Mater. 1968, 127, 291–308. [Google Scholar]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

| Composition, % | SiO2 | A12O3 | Fe2O3 | MgO | CaO | Na2O | K2O | MnO | TiO2 | P2O5 | Cl | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calcined clay | 62.7 | 18.72 | 11.69 | 1.88 | 0.26 | 0.02 | 2.1 | 0.45 | 0.4 | 0.02 | – | 0.2 | 1.55 |

| Limestone | 0.45 | 0.05 | 0.06 | 1.05 | 85.6 | – | – | – | – | 0.07 | – | 0.2 | 12.6 |

| CEM I | 18.9 | 3.56 | 3.35 | 1.88 | 59.65 | 4.6 | 2.1 | 0.15 | 0.2 | 0.23 | 0 | 4.9 | 0.52 |

| Materials (kg/m3) | Control | LC20% | LC30% | LC40% | LC50% |

|---|---|---|---|---|---|

| OPC | 600 | 480 | 420 | 360 | 300 |

| Calcined clay | – | 80 | 120 | 160 | 200 |

| Limestone | – | 40 | 60 | 80 | 100 |

| Total binder | 600 | 600 | 600 | 600 | 600 |

| Fine aggregate | 1800 | 1800 | 1800 | 1800 | 1800 |

| Water-to-binder ratio | 0.48 | 0.48 | 0.48 | 0.48 | 0.48 |

| Water | 288 | 288 | 288 | 288 | 288 |

| Physical Properties | Control | LC20% | LC30% | LC40% | LC50% |

|---|---|---|---|---|---|

| Normal consistency (%) | 29.5 | 32.5 | 32.9 | 33.4 | 34.7 |

| Initial setting time (min) | 128 | 135 | 148 | 153 | 158 |

| Final setting time (min) | 251 | 289 | 315 | 328 | 335 |

| Soundness (mm) | 0.8 | 0.2 | 0.3 | 0.2 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boakye, K.; Khorami, M.; Saidani, M.; Ganjian, E.; Tyrer, M.; Dunster, A. Performance of a Single Source of Low-Grade Clay in a Limestone Calcined Clay Cement Mortar. Buildings 2024, 14, 93. https://doi.org/10.3390/buildings14010093

Boakye K, Khorami M, Saidani M, Ganjian E, Tyrer M, Dunster A. Performance of a Single Source of Low-Grade Clay in a Limestone Calcined Clay Cement Mortar. Buildings. 2024; 14(1):93. https://doi.org/10.3390/buildings14010093

Chicago/Turabian StyleBoakye, Kwabena, Morteza Khorami, Messaoud Saidani, Eshmaiel Ganjian, Mark Tyrer, and Andrew Dunster. 2024. "Performance of a Single Source of Low-Grade Clay in a Limestone Calcined Clay Cement Mortar" Buildings 14, no. 1: 93. https://doi.org/10.3390/buildings14010093

APA StyleBoakye, K., Khorami, M., Saidani, M., Ganjian, E., Tyrer, M., & Dunster, A. (2024). Performance of a Single Source of Low-Grade Clay in a Limestone Calcined Clay Cement Mortar. Buildings, 14(1), 93. https://doi.org/10.3390/buildings14010093