Circular Material Usage Strategies and Principles in Buildings: A Review

Abstract

1. Introduction

2. Methodology

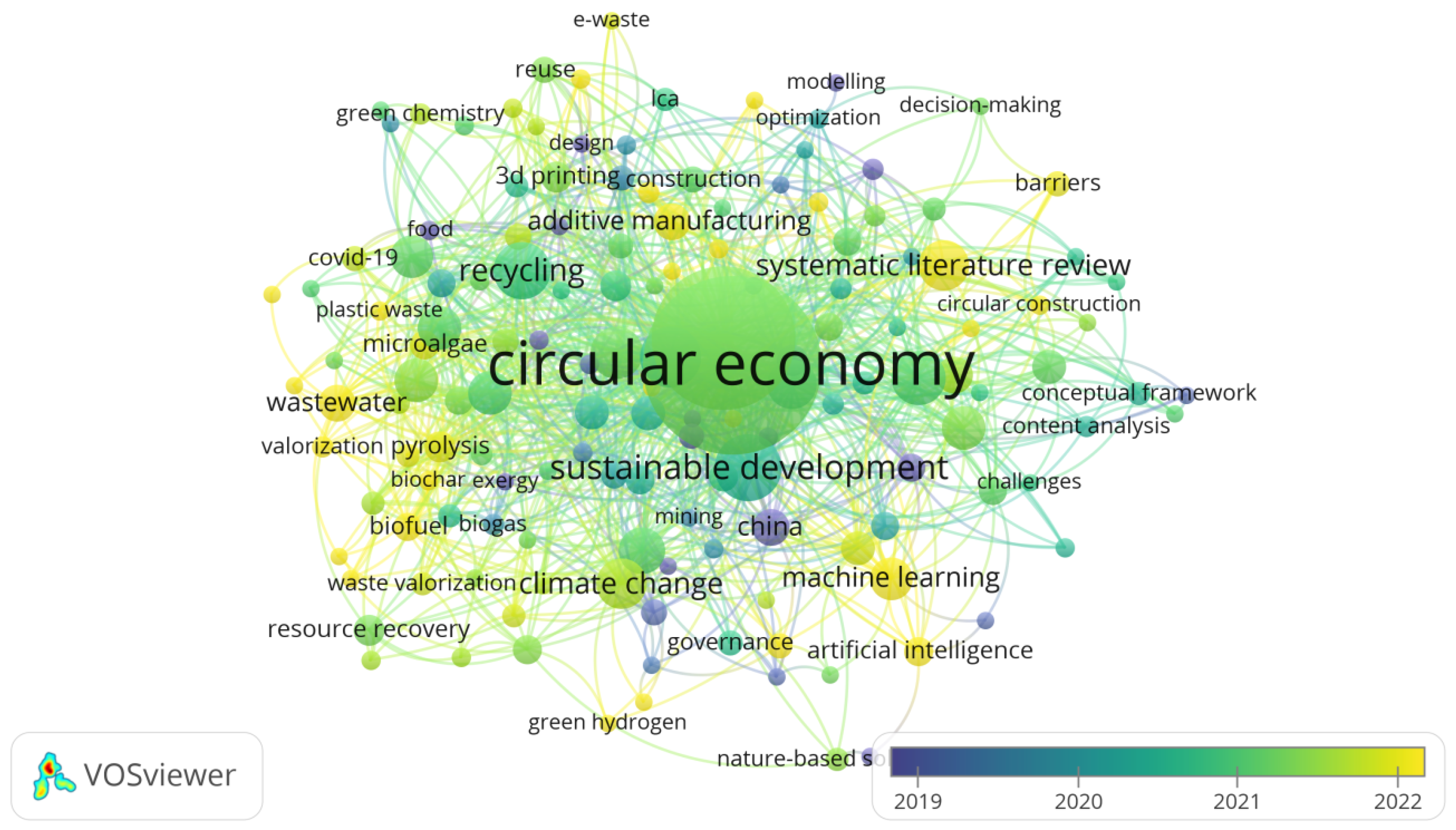

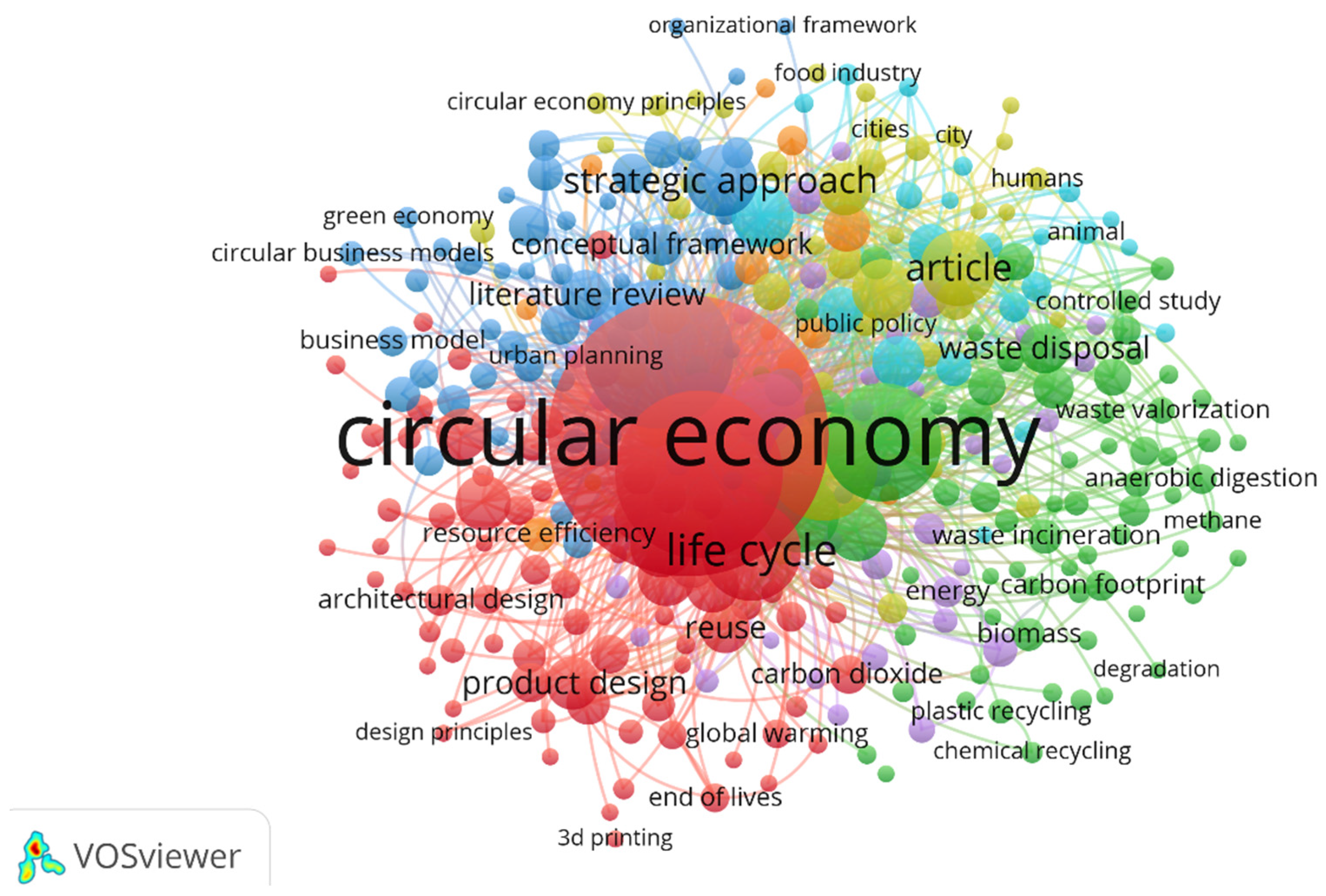

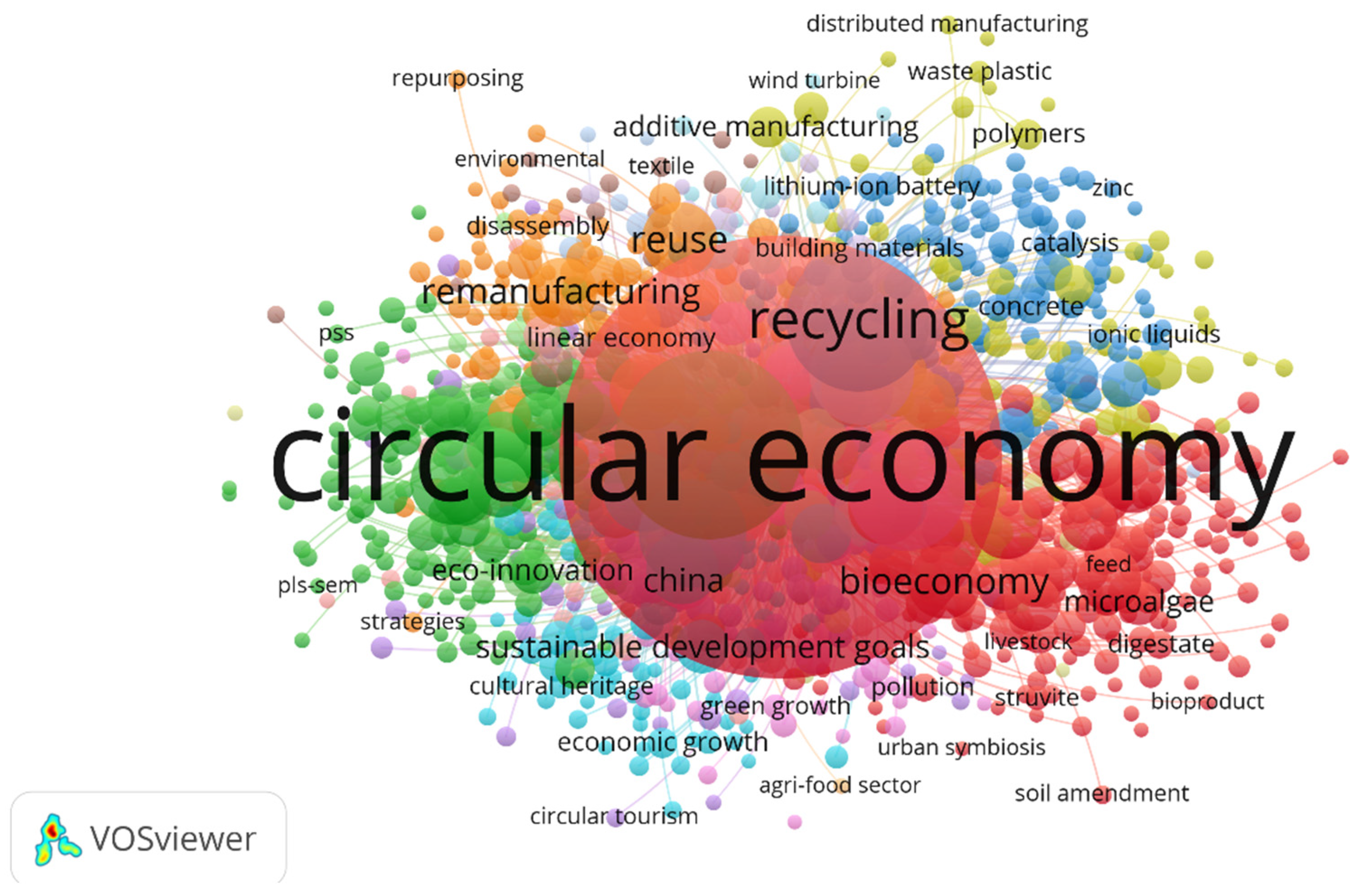

2.1. Bibliometrics Search

2.2. Scientometric Analysis

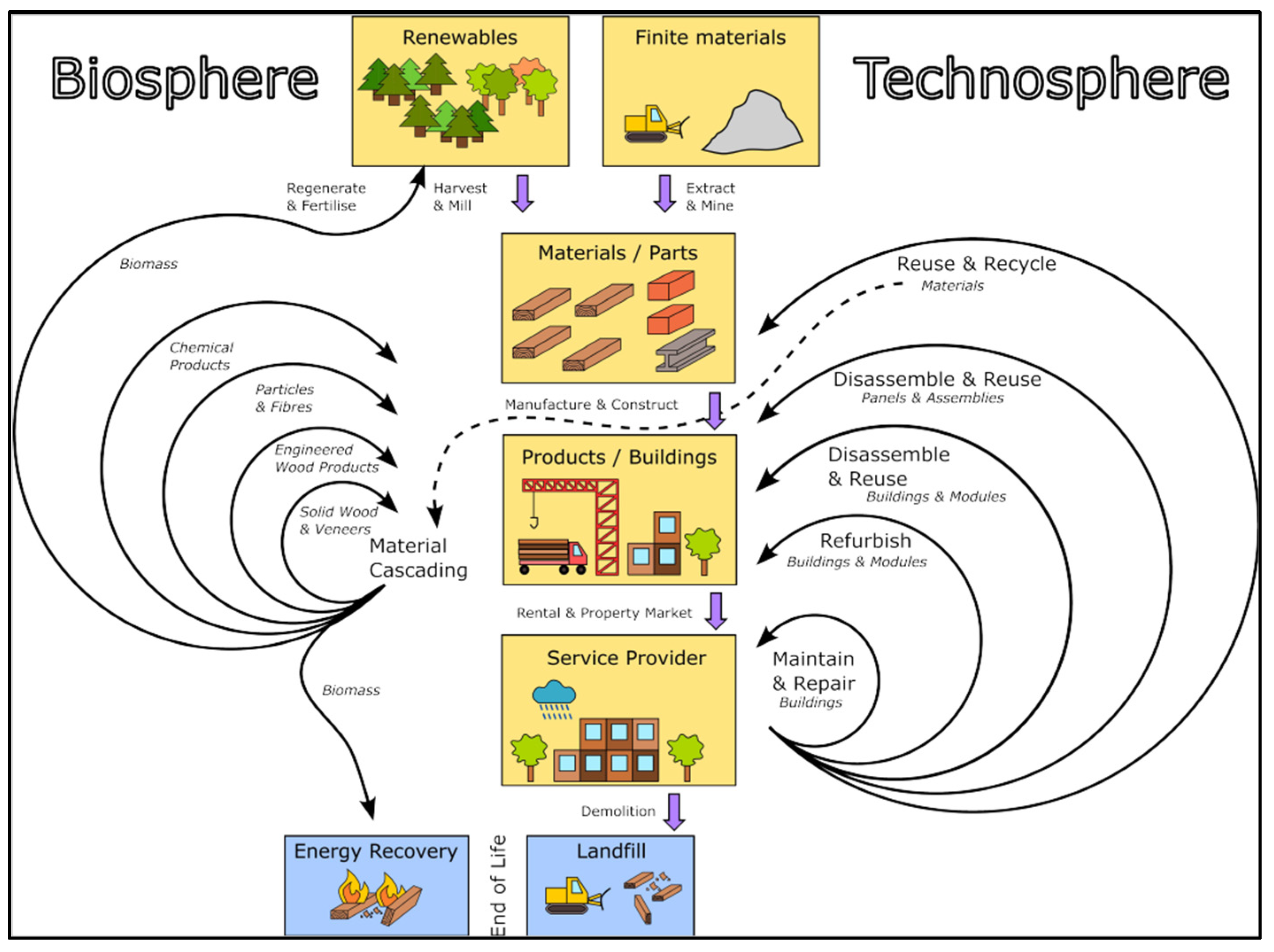

3. Understanding the Circular Economy and Material Usage

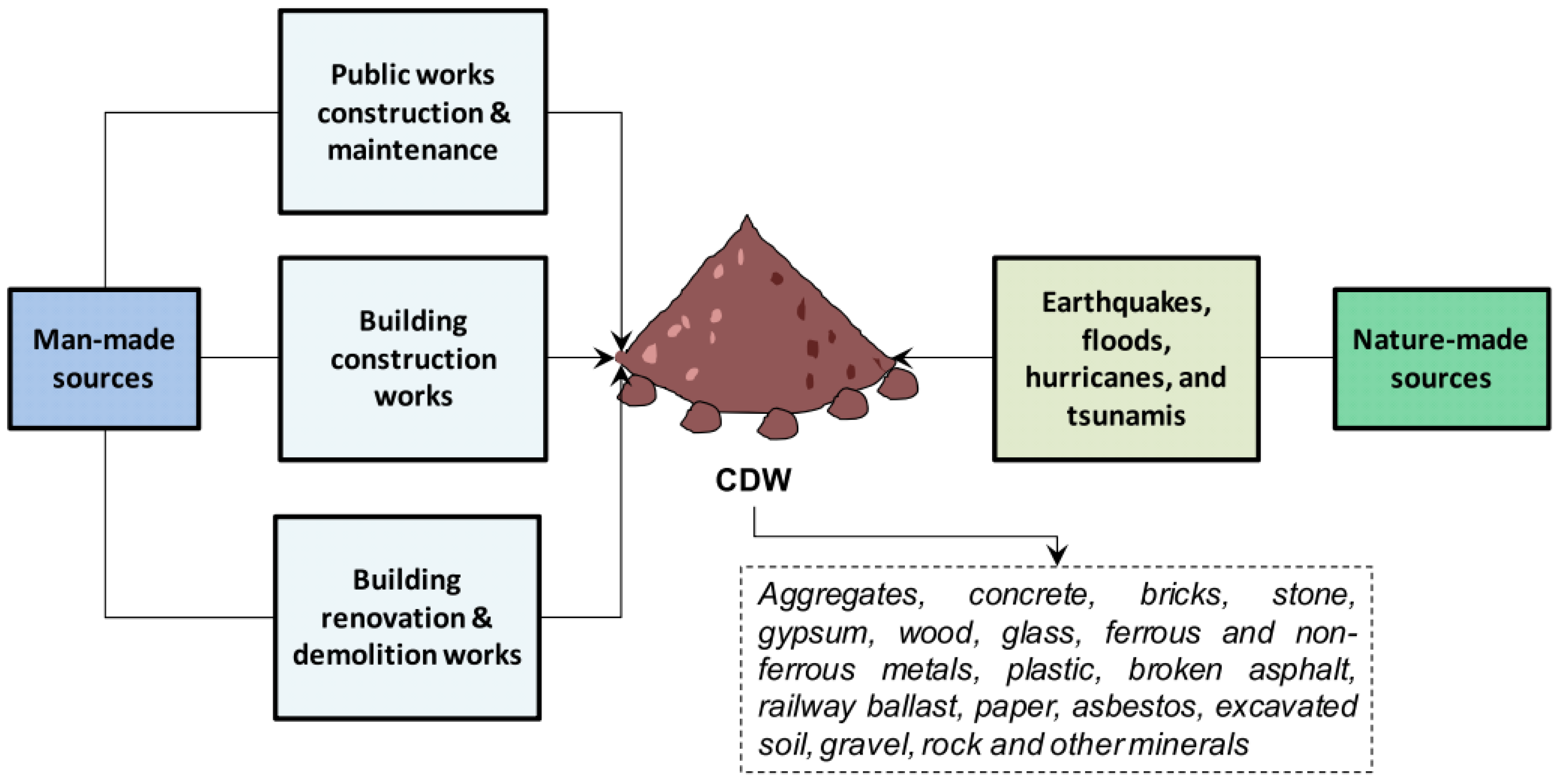

3.1. Eliminating Waste and Pollution

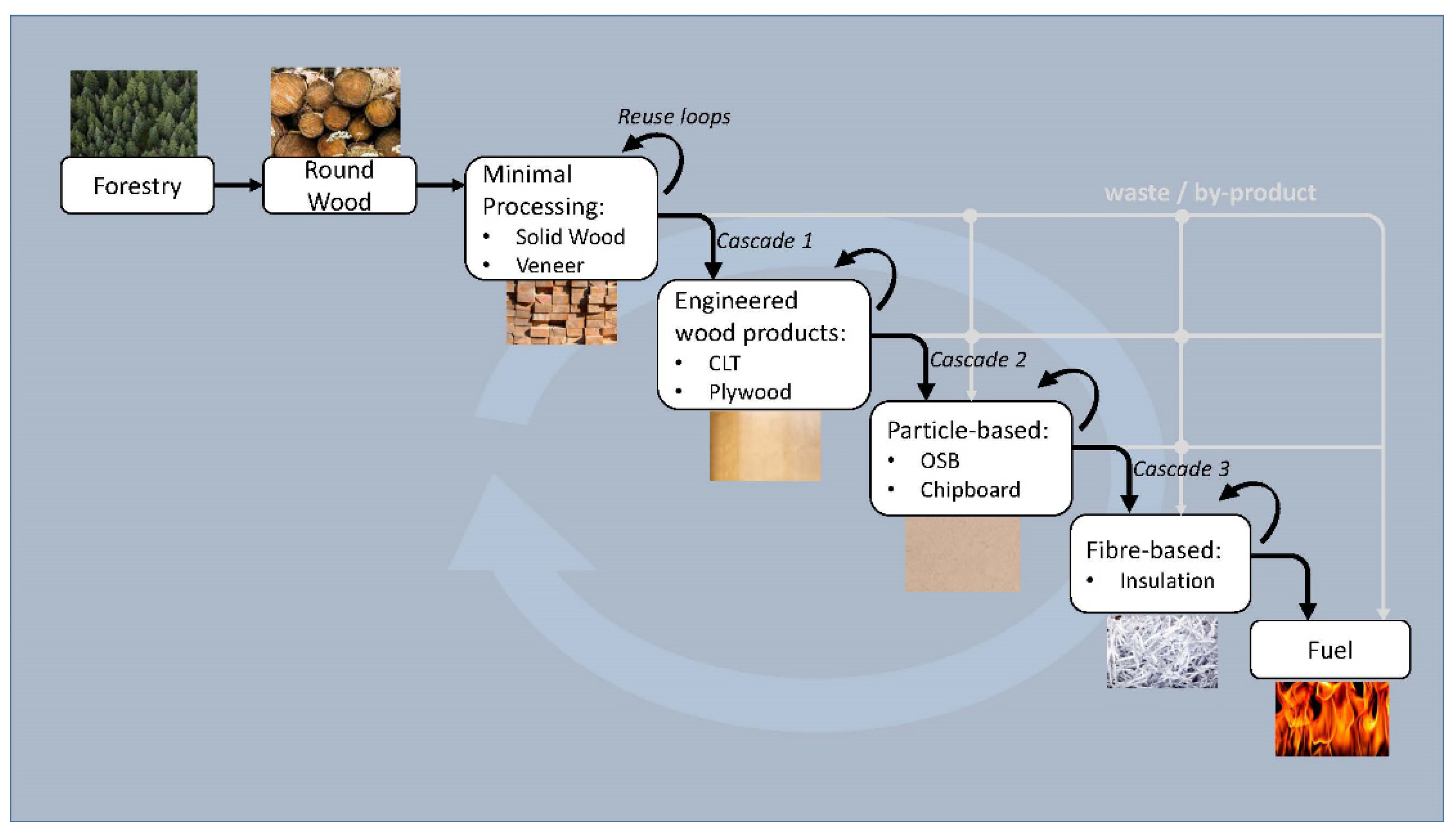

3.2. Use of Circular Products and Materials

3.3. Regenerate Nature

3.4. Challenge Areas

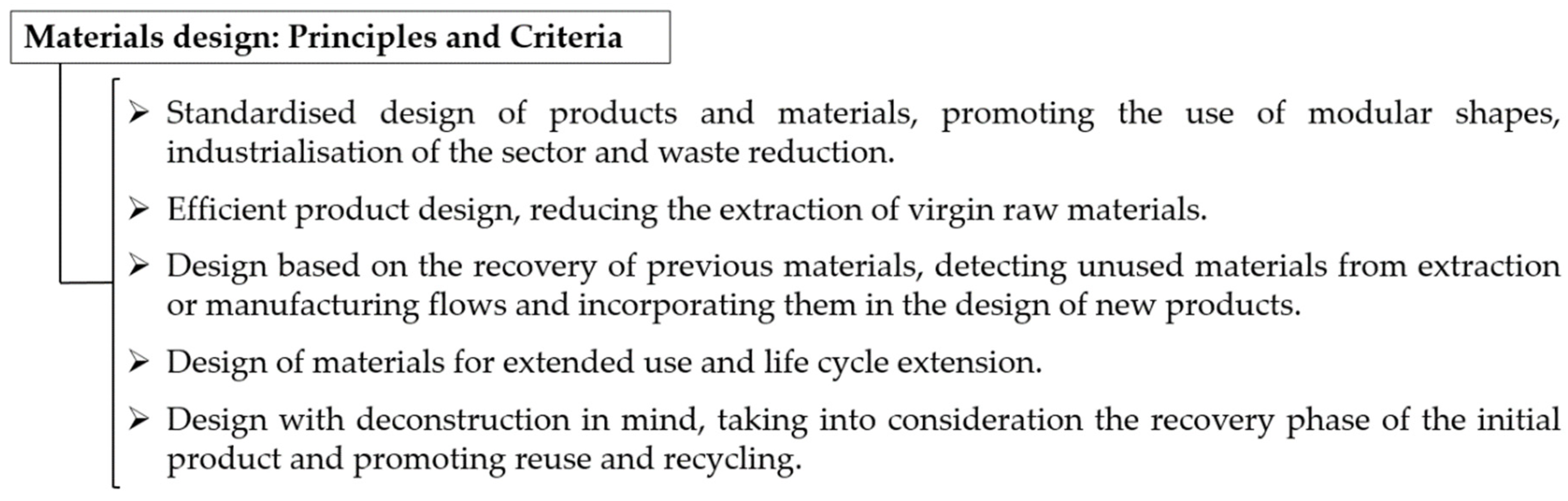

4. Design Principles for Circular Material Usage

4.1. Designing for Circularity

4.2. Material Selection and Management

4.2.1. Criteria for Selecting Circular Materials

4.2.2. Sustainable Material Sourcing

4.2.3. Material Efficiency and Recycling Techniques

- Waste prevention;

- Design oriented toward the economy of materials and energy;

- Use of recycled materials;

- Use of recyclable and renewable materials;

- Easy disassembly and replacement of materials and components.

4.2.4. Lifecycle Assessment and Material Management

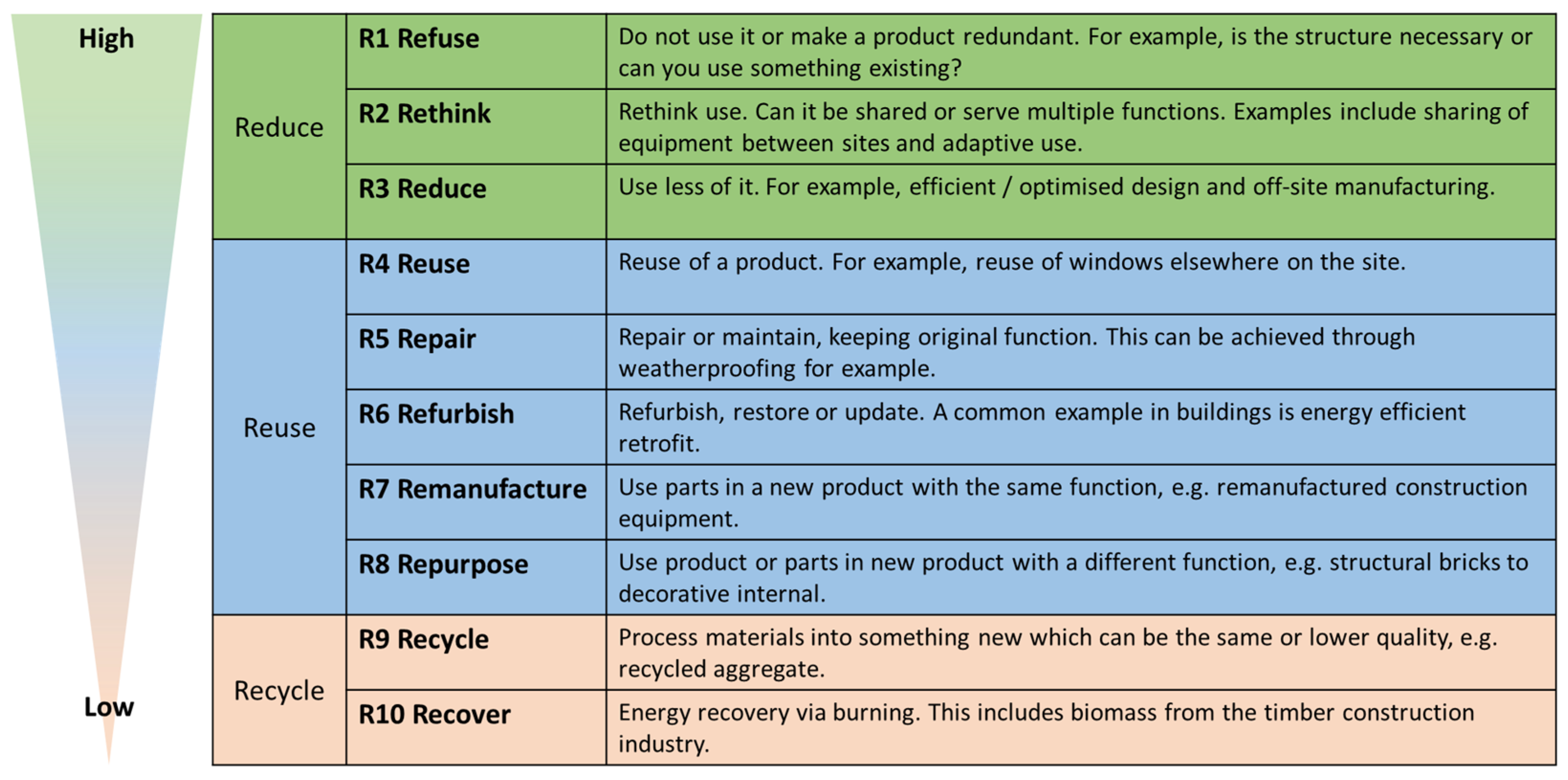

5. Principles and Strategies for the Circular Use of Materials in Construction Operations

5.1. Extending Product Lifespan and End-of-Life Strategies

- Minimization of material usage through design and specification;

- Creation of long-lasting designs to enhance durability;

- Emphasis on maintenance, repair, and refurbishing;

- Adoption of practices for reuse and remanufacturing;

- Incorporation of recycling methods.

5.1.1. Extending Product Lifespan

- -

- Increasing durability through maintenance, repair, and refurbishment

5.1.2. End-of-Life Strategies

- -

- Remanufacturing and Upgrading

- -

- Reuse, Reverse Logistics, and Take-Back Programs

- -

- Material Recovery

- -

- Material Recycling

5.2. Collaborative Approaches and Business Models

5.2.1. Circular Supply Chains and Networks

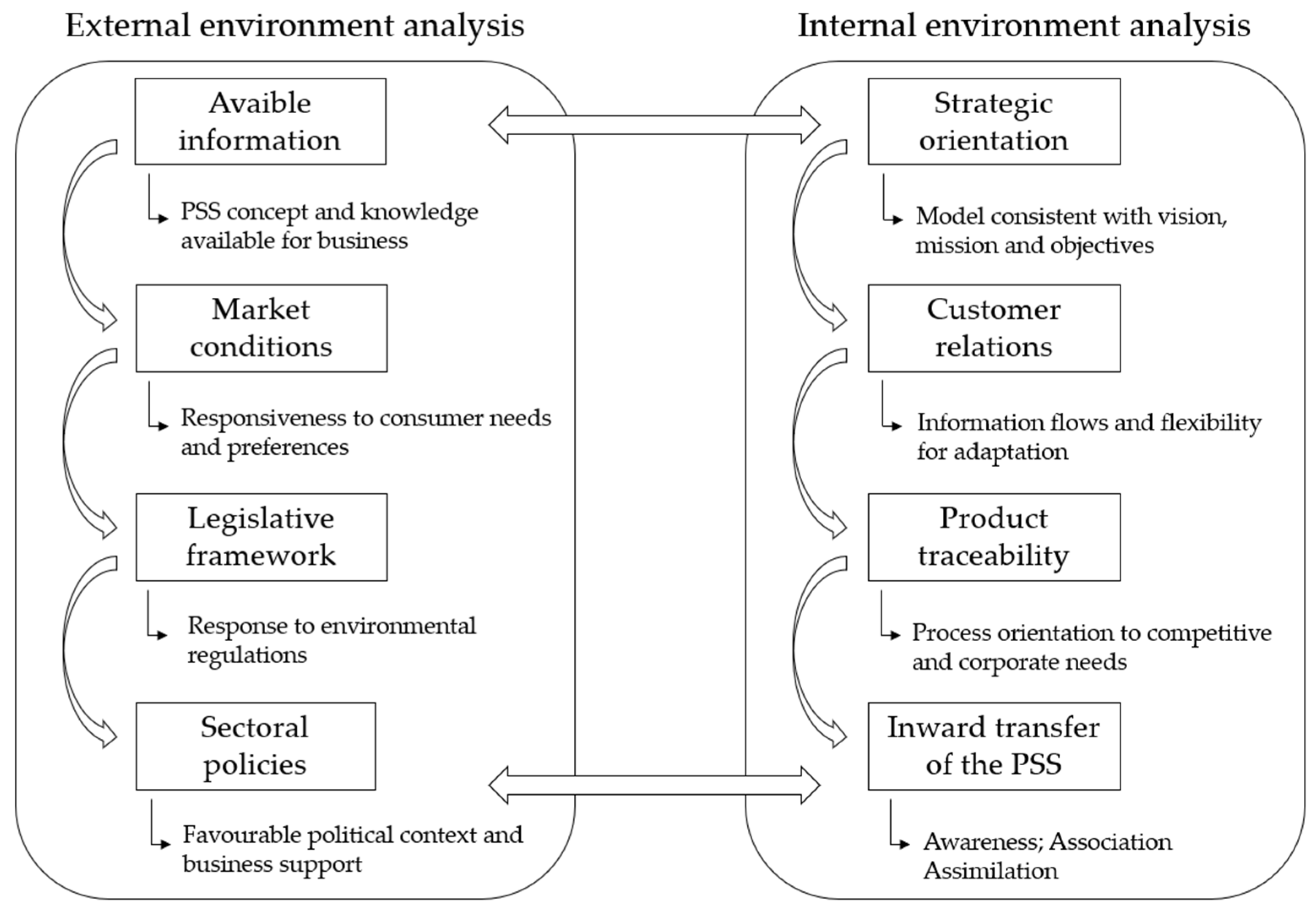

5.2.2. Sharing Economy and Product-as-a-Service Models

5.2.3. Extended Product Responsibility

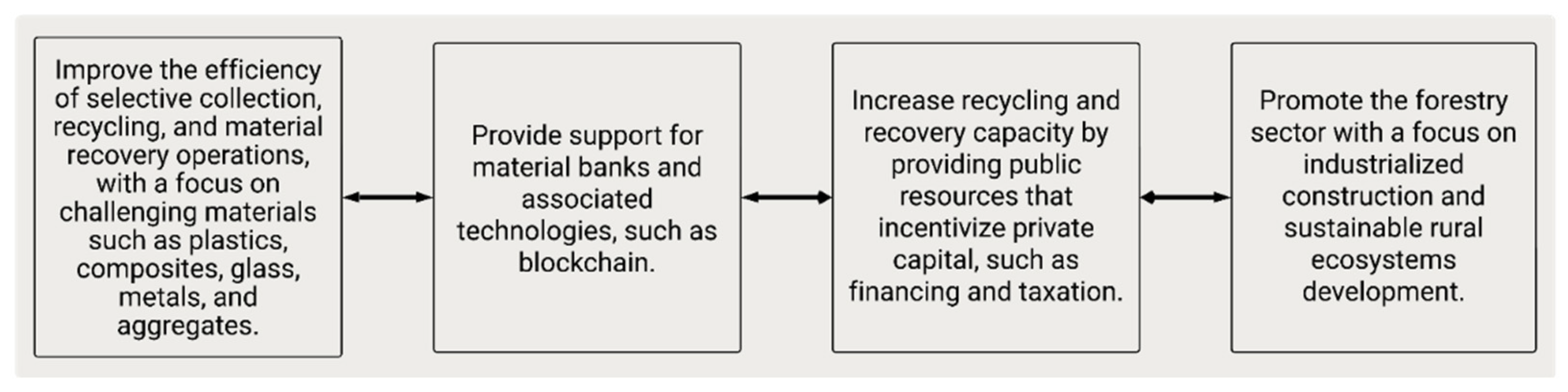

5.2.4. Public–Private Partnerships and Policy Implications

5.3. Technological Innovations for Circular Material Usage

5.3.1. Recycling Technologies

5.3.2. Revolutionizing Material Sorting and Separation Systems

5.3.3. The Transformational Power of Digitalization and Blockchain Applications

5.3.4. Robotic Deconstruction

5.3.5. Emerging Materials and Sustainable Manufacturing Processes

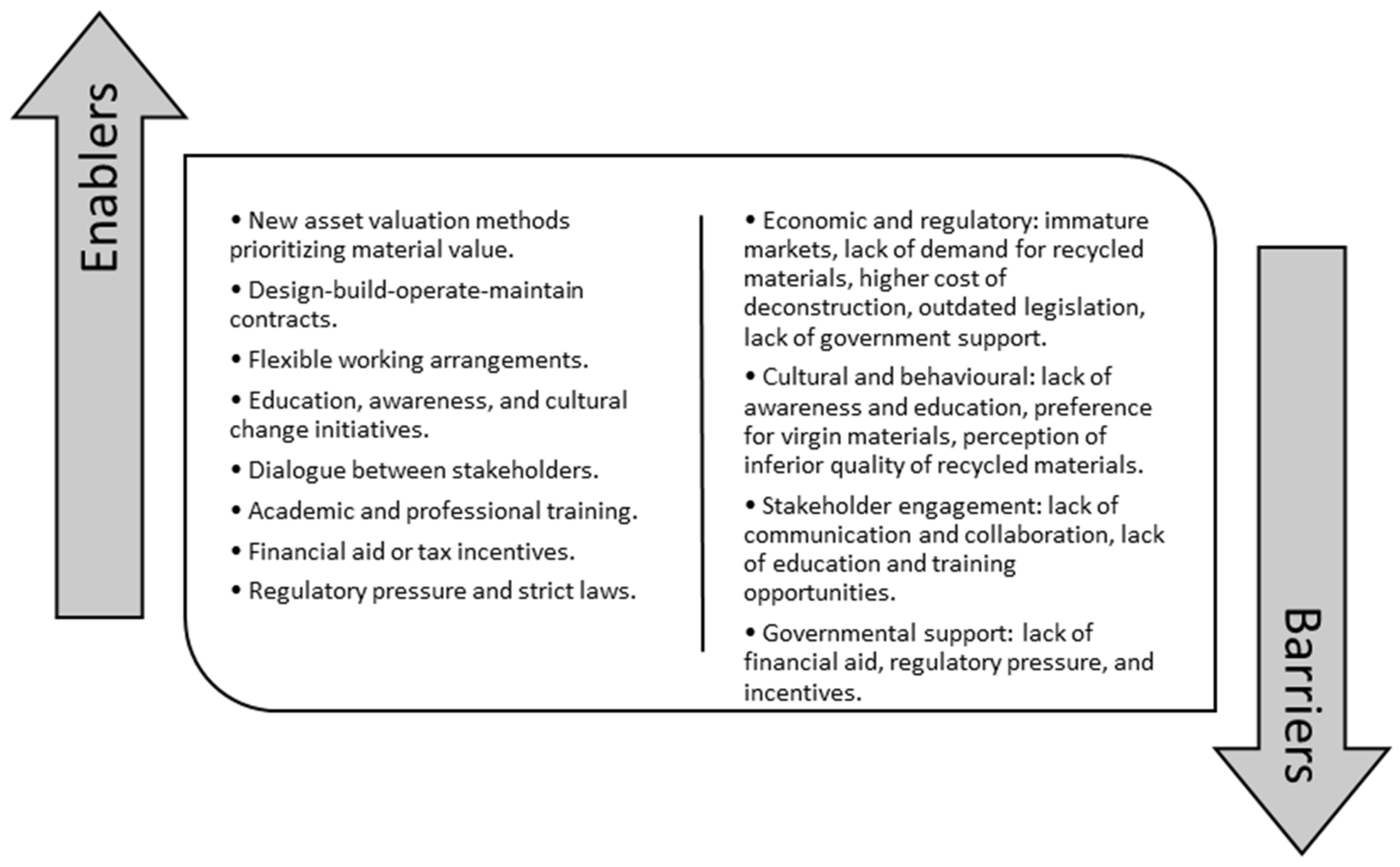

5.4. Barriers and Enablers of Circular Material Usage

5.4.1. Legislative and Economic Barriers

5.4.2. Cultural and Behavioral Challenges

5.4.3. Stakeholder Engagement and Awareness

5.4.4. Governmental Support and Incentives

6. Case Studies and Best Practices

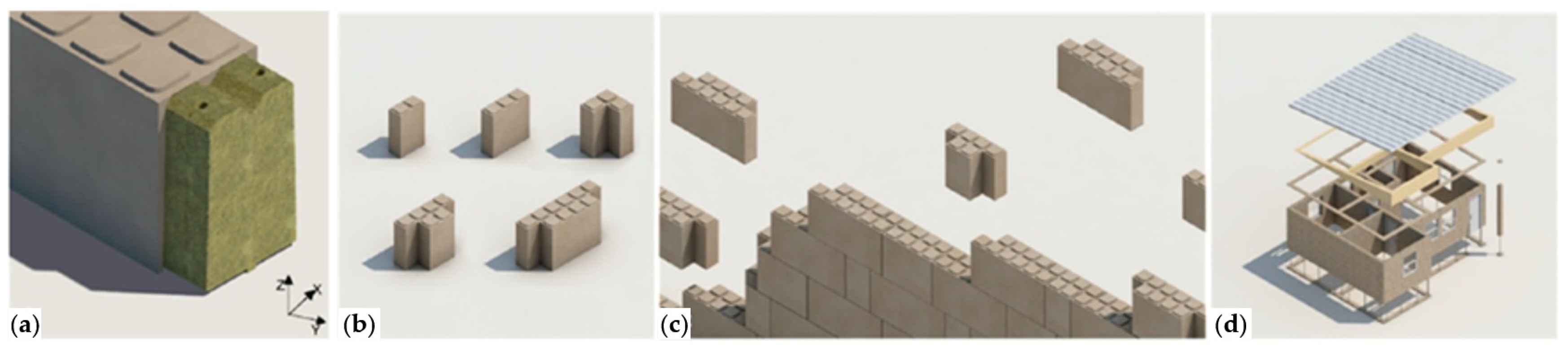

6.1. Polyblock System (Germany) [49]

6.2. Concrete Structure with Recycled Aggregates (Korbach, Germany) [152]

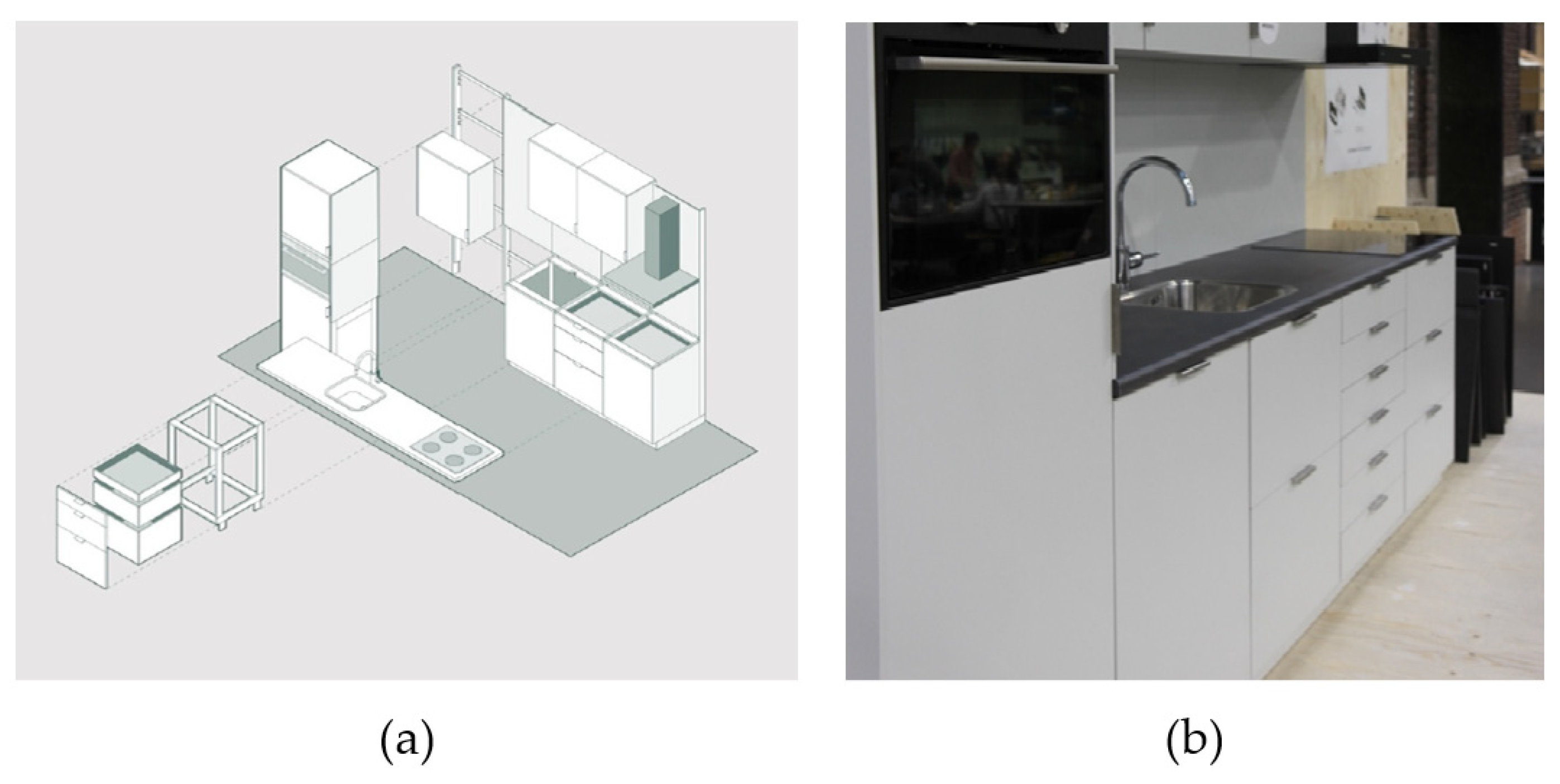

6.3. The Circular Kitchen (Delft, The Netherlands) [155]

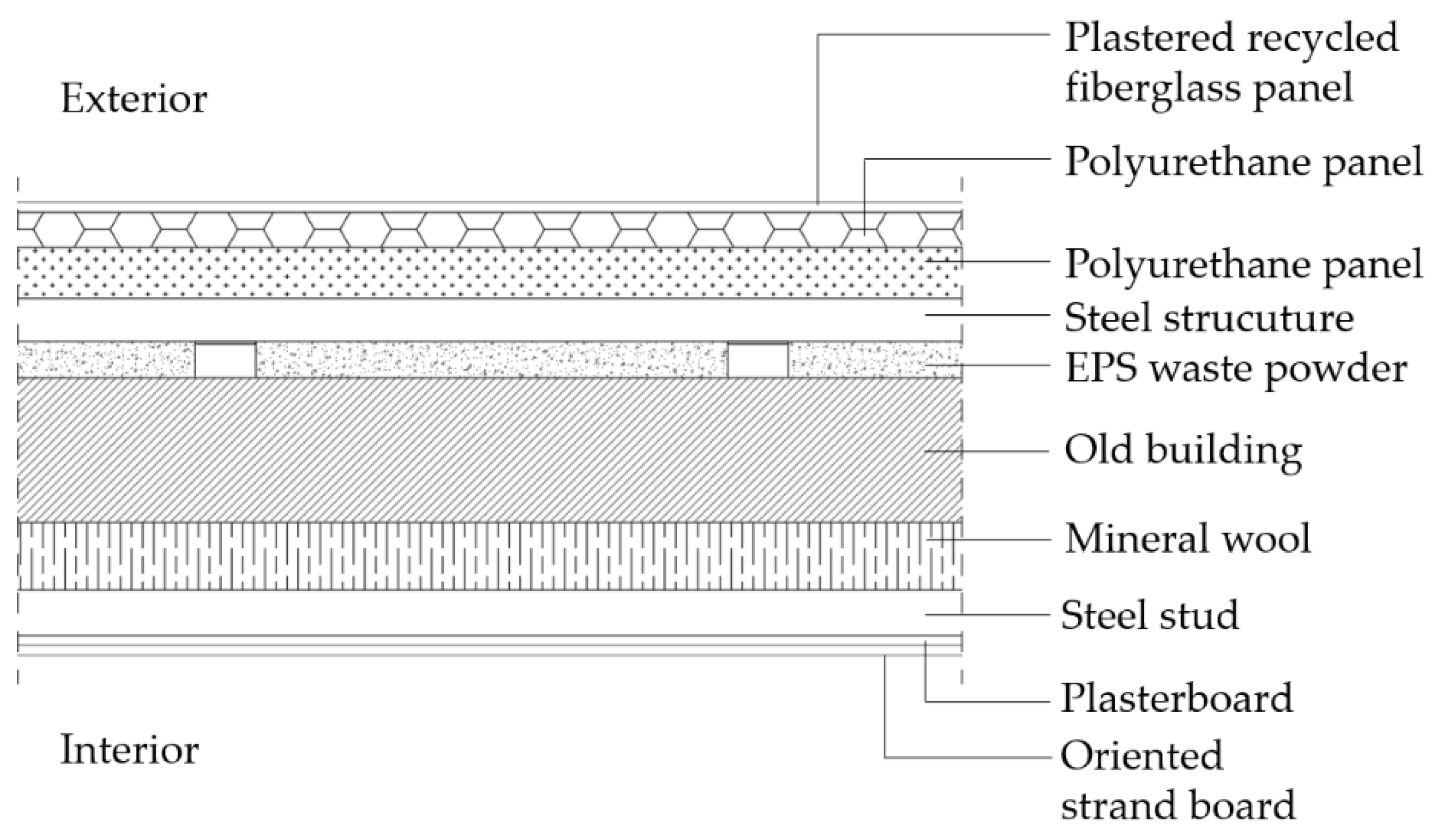

6.4. VELUXlab (Milano, Italy) [156]

7. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission COM. 640 Final, The European Green Deal 2019; European Commission: Brussels, Belgium, 2019.

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2022. [Google Scholar]

- European Commission COM. 98 Final, A New Circular Economy Action Plan for a Cleaner and More Competitive Europe 2020; European Commission: Brussels, Belgium, 2020.

- Bisht, A. Conceptualizing Sand Extractivism: Deconstructing an Emerging Resource Frontier. Extr. Ind. Soc. 2021, 8, 100904. [Google Scholar] [CrossRef]

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; zu Ermgassen, S.O.S.E.; Liu, J.; Jaeger, J.A.G.; Winter, M.; Lambin, E.F. Sustainability of the Global Sand System in the Anthropocene. One Earth 2021, 4, 639–650. [Google Scholar] [CrossRef]

- Gallagher, L.; Peduzzi, P. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Geneva, Switzerland, 2019. [Google Scholar]

- Zadeh, A.A.; Peng, Y.; Puffer, S.M.; Garvey, M.D. Sustainable Sand Substitutes in the Construction Industry in the United States and Canada: Assessing Stakeholder Awareness. Sustainability 2022, 14, 7674. [Google Scholar] [CrossRef]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; EU: Luxembourg, 2020. [Google Scholar]

- Baruya, P. Coking Coal—The Strategic Raw Material; Technical Report CCC/306; IEA Clean Coal Centre: London, UK, 2020. [Google Scholar]

- Szczepański, M. Briefing: Critical Raw Materials for the EU—Enablers of the Green and Digital Recovery; European Parliamentary Research Service; European Union: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Establishing a Framework for Ensuring a Secure and Sustainable Supply of Critical Raw Materials and Amending Regulations (EU) 168/2013, (EU) 2018/858, 2018/1724 and (EU) 2019/1020; European Union: Belgium, Brussels, 2023. [Google Scholar]

- Moschen-Schimek, J.; Kasper, T.; Huber-Humer, M. Critical Review of the Recovery Rates of Construction and Demolition Waste in the European Union—An Analysis of Influencing Factors in Selected EU Countries. Waste Manag. 2023, 167, 150–164. [Google Scholar] [CrossRef] [PubMed]

- Acharya, D.; Boyd, R.; Finch, O. From Principles to Practices: First Steps towards a Circular Built Environment; ARUP, Ellen MacArthur Foundation: Isle of Wight, UK, 2018. [Google Scholar]

- European Commission. Construction and Demolition Waste. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 7 November 2023).

- Giorgi, S.; Lavagna, M.; Campioli, A. Guidelines for Effective and Sustainable Recycling of Construction and Demolition Waste. In Designing Sustainable Technologies, Products and Policies; Benetto, E., Gericke, K., Guiton, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-66980-9. [Google Scholar]

- European Parliament; Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Union: Brussels, Belgium, 2008. [Google Scholar]

- Mihai, F.-C. Construction and Demolition Waste in Romania: The Route from Illegal Dumping to Building Materials. Sustainability 2019, 11, 3179. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Reimagining Our Buildings and Spaces for a Circular Economy. Available online: https://ellenmacarthurfoundation.org/topics/built-environment/overview (accessed on 8 July 2023).

- Material Economics. Industrial Transformation 2050—Pathways to Net-Zero Emissions from EU Heavy Industry; University of Cambridge Institute for Sustainability Leadership (CISL): Cambridge, UK, 2019. [Google Scholar]

- European Parliament Circular Economy: Definition, Importance and Benefits. Available online: https://www.europarl.europa.eu/news/en/headlines/economy/20151201STO05603/circular-economy-definition-importance-and-benefits?&at_campaign=20234-Economy&at_medium=Google_Ads&at_platform=Search&at_creation=RSA&at_goal=TR_G&at_audience=importance of circula (accessed on 17 July 2023).

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular Economy in Construction: Current Awareness, Challenges and Enablers. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Ellen MacArthur Fundation. What Is Circular Economy? Available online: https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 17 July 2023).

- Akhimien, N.G.; Al Tawheed, A.A.; Latif, E.; Hou, S.S. Circular Economy in Buildings. In The Circular Economy—Recent Advances in Sustainable Waste Management; Zhang, T., Ed.; IntechOpen: London, UK, 2022. [Google Scholar]

- Çimen, Ö. Development of a Circular Building Lifecycle Framework: Inception to Circulation. Results Eng. 2023, 17, 100861. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and Built Environment in Circular Economy: A Comprehensive Literature Review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The Circular Economy: New or Refurbished as CE 3.0? — Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Mesa, J.A.; Esparragoza, I. Towards the Implementation of Circular Economy in Engineering Education: A Systematic Review. In Proceedings of the 2021 IEEE Frontiers in Education Conference (FIE), Lincoln, NE, USA, 13–16 October 2021. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrelland, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Garg, R. Here’s How to Creat a Circular Economy for Building Materials. In Proceedings of the United Nations Climate Change Conference COP27, World Economic Forum, Sharm el-Sheikh, Egypt, 6–18 November 2022; Volume 2. [Google Scholar]

- Ottenhaus, L.M. Butterfly Diagram of Circular Buildings. Figshare. Figure 2022. Available online: https://figshare.com/articles/figure/Butterfly_Diagram_of_Circular_Buildings/21249573/1 (accessed on 7 November 2023).

- Ellen MacArthur Foundation. Circular Economy Butterfly Diagram. Available online: https://ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 9 July 2023).

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; European Commission: Brussels, Belgium, 2018. [CrossRef]

- Niu, Y.; Rasi, K.; Hughes, M.; Halme, M.; Fink, G. Prolonging Life Cycles of Construction Materials and Combating Climate Change by Cascading: The Case of Reusing Timber in Finland. Resour. Conserv. Recycl. 2021, 170, 105555. [Google Scholar] [CrossRef]

- Ellen MacArthur Fundation. The Biological Cycle of the Butterfly Diagram. Available online: https://ellenmacarthurfoundation.org/articles/the-biological-cycle-of-the-butterfly-diagram (accessed on 9 July 2023).

- Jackson, A.; Brady, C.; Montano Owen, C. The Circular Built Environment Playbook; World Green Building Council: London, UK, 2023. [Google Scholar]

- Oberle, B.; Bringezu, S.; Hatfield-Dodds, S.; Hellweg, S.; Schandl, H.; Clement, J. Global Resources Outlook: 2019; International Resource Panel, United Nations Envio: Paris, France, 2019. [Google Scholar]

- Liu, F.; Lin, B.; Meng, K. Green Space Settlement Landscape Optimization Strategy under the Concept of Ecological Environment Restoration. J. King Saud Univ. Sci. 2023, 35, 102539. [Google Scholar] [CrossRef]

- Lu, J.; Jiao, S.; Han, Z.; Yin, J. Promoting Ecological Restoration of Deeply Urbanized Hilly Areas: A Multi-Scale Ecological Networks Approach. Ecol. Indic. 2023, 154, 110655. [Google Scholar] [CrossRef]

- Haines-Young, R. Land Use and Biodiversity Relationships. Land Use Policy 2009, 26, S178–S186. [Google Scholar] [CrossRef]

- Mouton, L.; Allacker, K.; Röck, M. Bio-Based Building Material Solutions for Environmental Benefits over Conventional Construction Products—Life Cycle Assessment of Regenerative Design Strategies (1/2). Energy Build. 2023, 282, 112767. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. A Review on Barriers, Drivers, and Stakeholders towards the Circular Economy: The Construction Sector Perspective. Clean. Responsible Consum. 2023, 8, 100107. [Google Scholar] [CrossRef]

- Wuni, I.Y. Mapping the Barriers to Circular Economy Adoption in the Construction Industry: A Systematic Review, Pareto Analysis, and Mitigation Strategy Map. Build. Environ. 2022, 223, 109453. [Google Scholar] [CrossRef]

- Sparandara, L.; Werner, M.; Kaminsky, A.; Finch, L.; Douglas, K. Accelerating the Circular Economy through Commercial Deconstruction and Reuse, 1st ed.; Ellen MacArthur Fundation & Google: Isle of Wight, UK, 2019. [Google Scholar]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Davila Delgado, J.M.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for Deconstruction Using a Circular Economy Approach: Barriers and Strategies for Improvement. Prod. Plan. Control 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Critical Consideration of Buildings’ Environmental Impact Assessment towards Adoption of Circular Economy: An Analytical Review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Cambier, C.; Galle, W.; De Temmerman, N. Research and Development Directions for Design Support Tools for Circular Building. Buildings 2020, 10, 142. [Google Scholar] [CrossRef]

- Brown, M.; Haselsteiner, E.; Apró, D.; Kopeva, D.; Luca, E.; Pulkkinen, K.-L.; Rizvanolli, B.V. (Eds.) Sustainability, Restorative to Regenerative: An Exploration in Progressing a Paradigm Shift in Built Environment Thinking, from Sustainability to Restorative Sustainability and on to Regenerative Sustainability; COST Action CA16114 RESTORE, Working Group One Report: Restorative Sustainability; COST Association: Belgium, Brussels, 2018; ISBN 978-3-9504607-0-4. [Google Scholar]

- Dumée, L.F. Circular Materials and Circular Design—Review on Challenges towards Sustainable Manufacturing and Recycling. Circ. Econ. Sustain. 2022, 2, 9–23. [Google Scholar] [CrossRef]

- Kouvara, A.; Priavolou, C.; Ott, D.; Scherer, P.; van Zyl-Bulitta, V.H. Circular, Local, Open: A Recipe for Sustainable Building Construction. Buildings 2023, 13, 2493. [Google Scholar] [CrossRef]

- del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Santa Cruz-Astorqui, J.; Castelluccio, R. A Review of the Research about Gypsum Mortars with Waste Aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of Proportion and Particle Size Gradation of Rubber from End-of-Life Tires on Mechanical, Thermal and Acoustic Properties of Plaster-Rubber Mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef]

- Cejuela, E.; Negro, V.; del Campo, J.M.; Martín-Antón, M.; Esteban, M.D.; López-Gutiérrez, J.S. Recent History, Types, and Future of Modern Caisson Technology: The Way to More Sustainable Practices. Sustainability 2018, 10, 3839. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Diaz-Velilla, J.P.; Zúñiga-Vicente, J.A. Manufacture and Characterisation of a New Lightweight Plaster for Application in Wet Rooms under Circular Economy Criteria. Case Stud. Constr. Mater. 2023, 19, e02380. [Google Scholar] [CrossRef]

- Ferrer, J.; Herrería, N.; Remón, A.; Armas, R.; Rivera, T.D.; Ramos, I.; Sartori, T.; Isla, M.; Morató, J.; Villanueva, B. Proyecto Economía Circular España—Acelerando La Transición En El Sector de Construcción. 2022. [Google Scholar]

- Morató, J.; Jiménez, L.M. Informe COTEC—Situación y Evolución de La Economía Circular En España; Fundación Cotec Para La Innovación: Madrid, Spain, 2021. [Google Scholar]

- Ellen Macarthur Foundation. Available online: https://ellenmacarthurfoundation.org/ (accessed on 8 July 2023).

- Charef, R.; Lu, W.; Hall, D. The Transition to the Circular Economy of the Construction Industry: Insights into Sustainable Approaches to Improve the Understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Nußholz, J.; Çetin, S.; Eberhardt, L.; De Wolf, C.; Bocken, N. From Circular Strategies to Actions: 65 European Circular Building Cases and Their Decarbonisation Potential. Resour. Conserv. Recycl. Adv. 2023, 17, 200130. [Google Scholar] [CrossRef]

- Setaki, F.; van Timmeren, A. Disruptive Technologies for a Circular Building Industry. Build. Environ. 2022, 223, 109394. [Google Scholar] [CrossRef]

- Tavares, T.M.; Ganga, G.M.D.; Filho, M.G.; Rodrigues, V.P. The Benefits and Barriers of Additive Manufacturing for Circular Economy: A Framework Proposal. Sustain. Prod. Consum. 2023, 37, 369–388. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting Artificial Intelligence for Enhancing the Implementation of Systemic Circularity in the Construction Industry: A Critical Review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Marsh, A.T.M.; Velenturf, A.P.M.; Bernal, S.A. Circular Economy Strategies for Concrete: Implementation and Integration. J. Clean. Prod. 2022, 362, 132486. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Givry, P.; Canning, L.; Franklin-Johnson, E. Longevity and Circularity as Indicators of Eco-Efficient Resource Use in the Circular Economy. Ecol. Econ. 2018, 150, 297–306. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Mollaei, A.; Bachmann, C.; Haas, C. Estimating the Recoverable Value of In-Situ Building Materials. Sustain. Cities Soc. 2023, 91, 104455. [Google Scholar] [CrossRef]

- Zhuang, G.L.; Shih, S.G.; Wagiri, F. Circular Economy and Sustainable Development Goals: Exploring the Potentials of Reusable Modular Components in Circular Economy Business Model. J. Clean. Prod. 2023, 414, 137503. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-Healing Materials: A Pathway to Immortal Products or a Risk to Circular Economy Systems? J. Clean. Prod. 2021, 315, 128193. [Google Scholar] [CrossRef]

- Atta, N. Remanufacturing Towards Circularity in the Construction Sector: The Role of Digital Technologies. In Technological Imagination in the Green and Digital Transition; Springer International Publishing: Cham, Switzerland, 2023; pp. 493–503. ISBN 978-3-031-29515-7. [Google Scholar]

- van Stijn, A.; Gruis, V. Towards a Circular Built Environment: An Integral Design Tool for Circular Building Components. Smart Sustain. Built Environ. 2020, 9, 635–653. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Rameezdeen, R.; Chileshe, N.; Lehmann, S. Reverse Logistics in the Construction Industry. Waste Manag. Res. 2015, 33, 499–514. [Google Scholar] [CrossRef]

- Ding, L.; Wang, T.; Chan, P.W. Forward and Reverse Logistics for Circular Economy in Construction: A Systematic Literature Review. J. Clean. Prod. 2023, 388, 135981. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A Review of the Circularity Gap in the Construction Industry through Scientometric Analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and Drivers in a Circular Economy: The Case of the Built Environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Rebuydeal.Com. Available online: https://www.rebuydeal.com/en/buy-sell-second-hand/115/building-materials (accessed on 15 July 2023).

- Seconduse.Com. Available online: https://www.seconduse.com/inventory/categories/windows/ (accessed on 15 July 2023).

- Rotordc.Com. RotorDC—Deconstruction and Consulting, Photography by Pascal BROZE (2021162-20). 2022. Available online: https://rotordc.com/aboutus-1 (accessed on 7 November 2023).

- Oluleye, B.I.; Chan, D.W.M.; Saka, A.B.; Olawumi, T.O. Circular Economy Research on Building Construction and Demolition Waste: A Review of Current Trends and Future Research Directions. J. Clean. Prod. 2022, 357, 131927. [Google Scholar] [CrossRef]

- Ghobadi, M.; Sepasgozar, S.M.E. Circular Economy Strategies in Modern Timber Construction as a Potential Response to Climate Change. J. Build. Eng. 2023, 77, 107229. [Google Scholar] [CrossRef]

- Ahn, N.; Dodoo, A.; Riggio, M.; Muszynski, L.; Schimleck, L.; Puettmann, M. Circular Economy in Mass Timber Construction: State-of-the-Art, Gaps and Pressing Research Needs. J. Build. Eng. 2022, 53, 104562. [Google Scholar] [CrossRef]

- Llana, D.F.; González-Alegre, V.; Portela, M.; Íñiguez-González, G. Cross Laminated Timber (CLT) Manufactured with European Oak Recovered from Demolition: Structural Properties and Non-Destructive Evaluation. Constr. Build. Mater. 2022, 339, 127635. [Google Scholar] [CrossRef]

- Cobîrzan, N.; Balog, A.-A.; Thalmaier, G.; Nasui, M.; Munteanu, C.; Babota, F. Microscopical and Macroscopical Analysis of Recovered Bricks for Assessing Their Reusability in Masonry Buildings. Procedia Manuf. 2020, 46, 144–149. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.; Martinho, G.; Vasconcelos, L.; Ferreira, F. Local Scale Dynamics to Promote the Sustainable Management of Construction and Demolition Waste. Resour. Conserv. Recycl. Adv. 2023, 17, 200135. [Google Scholar] [CrossRef]

- Sahoo, P.; Dwivedi, A.; Tuppad, S.M.; Gupta, S. Sequestration and Utilization of Carbon Dioxide to Improve Engineering Properties of Cement-Based Construction Materials with Recycled Brick Powder: A Pathway for Cleaner Construction. Constr. Build. Mater. 2023, 395, 132268. [Google Scholar] [CrossRef]

- Bergonzoni, M.; Melloni, R.; Botti, L. Analysis of Sustainable Concrete Obtained from the By-Products of an Industrial Process and Recycled Aggregates from Construction and Demolition Waste. Procedia Comput. Sci. 2023, 217, 41–51. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Towards a More Sustainable Environmentally Production System for the Treatment of Recycled Aggregates in the Construction Industry: An Experimental Study. Heliyon 2023, 9, e16641. [Google Scholar] [CrossRef] [PubMed]

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Morón, C. New Lightened Plaster Material with Dissolved Recycled Expanded Polystyrene and End-of-Life Tyres Fibres for Building Prefabricated Industry. Case Stud. Constr. Mater. 2023, 18, e02178. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Morón, C. Recovery of End-of-Life Tyres and Mineral Wool Waste: A Case Study with Gypsum Composite Materials Applying Circular Economy Criteria. Materials 2023, 16, 243. [Google Scholar] [CrossRef]

- Sormunen, P.; Deviatkin, I.; Horttanainen, M.; Kärki, T. An Evaluation of Thermoplastic Composite Fillers Derived from Construction and Demolition Waste Based on Their Economic and Environmental Characteristics. J. Clean. Prod. 2021, 280, 125198. [Google Scholar] [CrossRef]

- Ahmed, N. Utilizing Plastic Waste in the Building and Construction Industry: A Pathway towards the Circular Economy. Constr. Build. Mater. 2023, 383, 131311. [Google Scholar] [CrossRef]

- Özçelikci, E.; Oskay, A.; Bayer, İ.R.; Şahmaran, M. Eco-Hybrid Cement-Based Building Insulation Materials as a Circular Economy Solution to Construction and Demolition Waste. Cem. Concr. Compos. 2023, 141, 105149. [Google Scholar] [CrossRef]

- Seco, A.; Omer, J.; Marcelino, S.; Espuelas, S.; Prieto, E. Sustainable Unfired Bricks Manufacturing from Construction and Demolition Wastes. Constr. Build. Mater. 2018, 167, 154–165. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Cazacliu, B.G.; Cothenet, A.; Poullain, P.; Wilhelm, M.; Sampaio, C.H.; Lima, E.C.; Ambros, W.; Torrenti, J.M. Fabrication, Microstructure, and Properties of Fired Clay Bricks Using Construction and Demolition Waste Sludge as the Main Additive. J. Clean. Prod. 2020, 258, 120733. [Google Scholar] [CrossRef]

- Islam, S.; Islam, J.; Robiul Hoque, N.M. Improvement of Consolidation Properties of Clay Soil Using Fine-Grained Construction and Demolition Waste. Heliyon 2022, 8, e11029. [Google Scholar] [CrossRef]

- Giannopoulou, I.; Robert, P.M.; Sakkas, K.M.; Petrou, M.F.; Nicolaides, D. High Temperature Performance of Geopolymers Based on Construction and Demolition Waste. J. Build. Eng. 2023, 72, 106575. [Google Scholar] [CrossRef]

- He, X.; Li, W.; Su, Y.; Zheng, Z.; Fu, J.; Zeng, J.; Tan, H.; Wu, Y.; Yang, J. Recycling of Plastic Waste Concrete to Prepare an Effective Additive for Early Strength and Late Permeability Improvement of Cement Paste. Constr. Build. Mater. 2022, 347, 128581. [Google Scholar] [CrossRef]

- Thwe Win, T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of Polypropylene Fibers Extracted from Recycled Surgical Face Masks in Cement Mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, M.; Santos, P.; Lopes, P.; Abrantes, D.; Ferrández, D. Performance Characterisation of a New Plaster Composite Lightened with End-of-Life Tyres’ Recycled Materials for False Ceiling Plates. Materials 2022, 15, 5660. [Google Scholar] [CrossRef] [PubMed]

- Santos, P.; Mateus, D. Experimental Assessment of Thermal Break Strips Performance in Load-Bearing and Non-Load-Bearing LSF Walls. J. Build. Eng. 2020, 32, 101693. [Google Scholar] [CrossRef]

- Santos, P.; Mateus, D.; Ferrandez, D.; Verdu, A. Numerical Simulation and Experimental Validation of Thermal Break Strips’ Improvement in Facade LSF Walls. Energies 2022, 15, 8169. [Google Scholar] [CrossRef]

- Paihte, P.L.; Lalngaihawma, A.C.; Saini, G. Recycled Aggregate Filled Waste Plastic Bottles as a Replacement of Bricks. Mater. Today Proc. 2019, 15, 663–668. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Dora, A.; Pontinha, R.; Santos, P.; Durães, L. Aerogel Composites Produced from Silica and Recycled Rubber Sols for Thermal Insulation. Materials 2022, 15, 7897. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues Pontinha, A.D.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping Construction Supply Chain Processes with Circular Economy Strategies: A Systematic Literature Review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Amir, S.; Salehi, N.; Roci, M.; Sweet, S.; Rashid, A. Towards Circular Economy: A Guiding Framework for Circular Supply Chain Implementation. Bus. Strategy Environ. 2023, 32, 2684–2701. [Google Scholar] [CrossRef]

- Yuan, F.; Shen, L.Y.; Li, Q.M. Emergy Analysis of the Recycling Options for Construction and Demolition Waste. Waste Manag. 2011, 31, 2503–2511. [Google Scholar] [CrossRef]

- Roci, M.; Salehi, N.; Amir, S.; Shoaib-ul-Hasan, S.; Asif, F.M.A.; Mihelič, A.; Rashid, A. Towards Circular Manufacturing Systems Implementation: A Complex Adaptive Systems Perspective Using Modelling and Simulation as a Quantitative Analysis Tool. Sustain. Prod. Consum. 2022, 31, 97–112. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply Chains in Circular Business Models: Processes and Performance Objectives. Resour. Conserv. Recycl. 2020, 162, 105046. [Google Scholar] [CrossRef]

- Ahmed, R.R.; Zhang, X. Multi-Stage Network-Based Two-Type Cost Minimization for the Reverse Logistics Management of Inert Construction Waste. Waste Manag. 2021, 120, 805–819. [Google Scholar] [CrossRef] [PubMed]

- Petrunya, Y.Y.; Pasichnyk, T.O. Impact of Modern Technologies on Logistics and Supply Chain Management. Mark. Manag. Innov. 2018, 9, 130–139. [Google Scholar] [CrossRef]

- Seroka-Stolka, O.; Ociepa-Kubicka, A. Green Logistics and Circular Economy. Transp. Res. Procedia 2019, 39, 471–479. [Google Scholar] [CrossRef]

- Sáez, P.V.; Porras-Amores, C.; Del Río Merino, M. New Quantification Proposal for Construction Waste Generation in New Residential Constructions. J. Clean. Prod. 2015, 102, 58–65. [Google Scholar] [CrossRef]

- Pallewatta, S.; Weerasooriyagedara, M.; Bordoloi, S.; Sarmah, A.K.; Vithanage, M. Reprocessed Construction and Demolition Waste as an Adsorbent: An Appraisal. Sci. Total Environ. 2023, 882, 163340. [Google Scholar] [CrossRef]

- Ruvald, R.; Bertoni, A.; Askling, C.J. A Role for Physical Prototyping in Product-Service System Design: Case Study in Construction Equipment. Procedia CIRP 2019, 83, 358–362. [Google Scholar] [CrossRef]

- Guerra, B.C.; Shahi, S.; Molleai, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular Economy Applications in the Construction Industry: A Global Scan of Trends and Opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lin, S.; Chen, C.C.; Calahorrano Sarmiento, L.S.; Tan, C.L. A Causal Sustainable Product-Service System Using Hierarchical Structure with Linguistic Preferences in the Ecuadorian Construction Industry. J. Clean. Prod. 2019, 230, 477–487. [Google Scholar] [CrossRef]

- Cook, M.; Gottberg, A.; Angus, A.; Longhurst, P. Receptivity to the Production of Product Service Systems in the UK Construction and Manufacturing Sectors: A Comparative Analysis. J. Clean. Prod. 2012, 32, 61–70. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, D.; Xu, Y.; Zhang, H. A Framework for Design Knowledge Management and Reuse for Product-Service Systems in Construction Machinery Industry. Comput. Ind. 2012, 63, 328–337. [Google Scholar] [CrossRef]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A Blockchain- and IoT-Based Smart Product-Service System for the Sustainability of Prefabricated Housing Construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Ness, D.; Xing, K.; Kim, K.; Jenkins, A. An ICT-Enabled Product Service System for Reuse of Building Components. IFAC-PapersOnLine 2019, 52, 761–766. [Google Scholar] [CrossRef]

- Räisänen, J.; Ojala, A.; Tuovinen, T. Building Trust in the Sharing Economy: Current Approaches and Future Considerations. J. Clean. Prod. 2021, 279, 123724. [Google Scholar] [CrossRef]

- Fraccascia, L.; Yazan, D.M. The Role of Online Information-Sharing Platforms on the Performance of Industrial Symbiosis Networks. Resour. Conserv. Recycl. 2018, 136, 473–485. [Google Scholar] [CrossRef]

- Thierer, A.; Koopman, C.; Hobson, A.; Kuiper, C. How the Internet, the Sharing Economy, and Reputational How the Internet, the Sharing Economy, and Reputational Feedback Mechanisms Solve the “Lemons Problem” Feedback Mechanisms; University of Miami School of Law Institutional Repository: Miami, FL, USA, 2016; Volume 70. [Google Scholar]

- Lindhqvist, T. Extended Producer Responsibility in Cleaner Production: Policy Principle to Promote Environmental Improvements of Product Systems; Lund University: Lund, Sweden, 2000. [Google Scholar]

- Kasuga, A. Evolution of Fib Model Codes: Mastering Challenges and Encountering New Ones. Struct. Concr. 2023, 24, 4336–4340. [Google Scholar] [CrossRef]

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Moora, H.; Klöga, M.; Voronova, V. An Overview of the Problems Posed by Plastic Products and the Role of Extended Producer Responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Jang, Y.C. Waste Electrical and Electronic Equipment (WEEE) Management in Korea: Generation, Collection, and Recycling Systems. J. Mater. Cycles Waste Manag. 2010, 12, 283–294. [Google Scholar] [CrossRef]

- Xu, J.; Ye, M.; Lu, W.; Bao, Z.; Webster, C. A Four-Quadrant Conceptual Framework for Analyzing Extended Producer Responsibility in Offshore Prefabrication Construction. J. Clean. Prod. 2021, 282, 124540. [Google Scholar] [CrossRef] [PubMed]

- Campbell-Johnston, K.; Calisto Friant, M.; Thapa, K.; Lakerveld, D.; Vermeulen, W.J.V. How Circular Is Your Tyre: Experiences with Extended Producer Responsibility from a Circular Economy Perspective. J. Clean. Prod. 2020, 270, 122042. [Google Scholar] [CrossRef]

- Ferrão, P.; Ribeiro, P.; Silva, P. A Management System for End-of-Life Tyres: A Portuguese Case Study. Waste Manag. 2008, 28, 604–614. [Google Scholar] [CrossRef] [PubMed]

- Deutz, P. Producer Responsibility in a Sustainable Development Context: Ecological Modernisation or Industrial Ecology? Geogr. J. 2009, 175, 274–285. [Google Scholar] [CrossRef]

- Zhang, X.; Yousaf, H.M.A.U. Green Supply Chain Coordination Considering Government Intervention, Green Investment, and Customer Green Preferences in the Petroleum Industry. J. Clean. Prod. 2020, 246, 118984. [Google Scholar] [CrossRef]

- Xie, Y.; Zhao, Y.Q.; Chen, Y.H.; Allen, C. Green Construction Supply Chain Management: Integrating Governmental Intervention and Public–Private Partnerships through Ecological Modernisation. J. Clean. Prod. 2022, 331, 129986. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W.; Chi, B.; Yuan, H.; Hao, J. Procurement Innovation for a Circular Economy of Construction and Demolition Waste: Lessons Learnt from Suzhou, China. Waste Manag. 2019, 99, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Munoz-Jofre, J.; Hinojosa, S.; Mascle-Allemand, A.L.; Temprano, J. A Selectivity Index for Public-Private Partnership Projects in the Urban Water and Sanitation Sector in Latin America and the Caribbean. J. Environ. Manag. 2023, 335, 117564. [Google Scholar] [CrossRef]

- Tang, L.Y.; Shen, Q.; Cheng, E.W.L. A Review of Studies on Public-Private Partnership Projects in the Construction Industry. Int. J. Proj. Manag. 2010, 28, 683–694. [Google Scholar] [CrossRef]

- Azarian, M.; Shiferaw, A.T.; Laedre, O.; Wondimu, P.A.; Stevik, T.K. Project Ownership in Public-Private Partnership (PPP) Projects of Norway. Procedia Comput. Sci. 2023, 219, 1838–1846. [Google Scholar] [CrossRef]

- Ampratwum, G.; Osei-Kyei, R.; Tam, V.W.Y. Exploring the Concept of Public-Private Partnership in Building Critical Infrastructure Resilience against Unexpected Events: A Systematic Review. Int. J. Crit. Infrastruct. Prot. 2022, 39, 100556. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; Briefing No. 14/2019; European Environment Agency (EEA): Copenhagen, Denmark, 2019.

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Debnath, B.; Siraj, M.T.; Rashid, K.H.O.; Mainul Bari, A.B.M.; Karmaker, C.L.; Al Aziz, R. Analyzing the Critical Success Factors to Implement Green Supply Chain Management in the Apparel Manufacturing Industry: Implications for Sustainable Development Goals in the Emerging Economies. Sustain. Manuf. Serv. Econ. 2023, 2, 100013. [Google Scholar] [CrossRef]

- Leder, S.; Menges, A. Architectural Design in Collective Robotic Construction. Autom. Constr. 2023, 156, 105082. [Google Scholar] [CrossRef]

- Lee, S.; Pan, W.; Linner, T.; Bock, T. A Framework for Robot Assisted Deconstruction: Process, Sub-Systems and Modelling. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining: Connected to the Future, Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Charef, R.; Morel, J.C.; Rakhshan, K. Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W. Barriers and Enablers of Circular Economy in Construction: A Multi-System Perspective towards the Development of a Practical Framework. Constr. Manag. Econ. 2023, 41, 3–21. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Chileshe, N.; Rameezdeen, R.; Lehmann, S. Reverse Logistics for the Construction Industry: Lessons from the Manufacturing Context. Int. J. Constr. Eng. Manag. 2014, 3, 75–90. [Google Scholar] [CrossRef]

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Tleuken, A.; Tokazhanov, G.; Jemal, K.M.; Shaimakhanov, R.; Sovetbek, M.; Karaca, F. Legislative, Institutional, Industrial and Governmental Involvement in Circular Economy in Central Asia: A Systematic Review. Sustainability 2022, 14, 8064. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Borucki, C.; Karaca, F. Performance Assessment of Construction Companies for the Circular Economy: A Balanced Scorecard Approach. Sustain. Prod. Consum. 2022, 33, 991–1004. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current State and Barriers to the Circular Economy in the Building Sector: Towards a Mitigation Framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Mostert, C.; Sameer, H.; Glanz, D.; Bringezu, S. Climate and Resource Footprint Assessment and Visualization of Recycled Concrete for Circular Economy. Resour. Conserv. Recycl. 2021, 174, 105767. [Google Scholar] [CrossRef]

- GewAbfV Verordnung Über Die Bewirtschaftung von Gewerblichen Siedlungsabfällen Und von Bestimmten Bau- Und Abbruchabfallen. Bundesrepublik Deutschland 2017. Available online: https://www.gesetze-im-internet.de/gewabfv_2017/ (accessed on 7 November 2023).

- European Parliament and Council. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste; European Union: Brussels, Belgium, 2018. [Google Scholar]

- Wouterszoon Jansen, B.; van Stijn, A.; Gruis, V.; van Bortel, G. Cooking Up a Circular Kitchen: A Longitudinal Study of Stakeholder Choices in the Development of a Circular Building Component. Sustainability 2022, 14, 15761. [Google Scholar] [CrossRef]

- Brambilla, A.; Salvalai, G.; Imperadori, M.; Sesana, M.M. Nearly Zero Energy Building Renovation: From Energy Efficiency to Environmental Efficiency, a Pilot Case Study. Energy Build. 2018, 166, 271–283. [Google Scholar] [CrossRef]

| Categories | Challenge |

|---|---|

| Economic | Cost of upfront investment |

| Lack of financial aid, incentives, or short-term benefits | |

| Low value of circular materials | |

| Lack of grants or unclear financial case | |

| Informational | Lack of awareness, interest, and knowledge |

| Lack of research, education, and information | |

| Lack of best practice case studies and leadership | |

| Institutional/Structural | Fragmented supply chains |

| Lack of strategic vision and collaborative platforms | |

| Lack of market mechanisms for recovery | |

| Political/Governmental | Lack of regulatory instruments or pressure |

| Lack of tax actions | |

| Lack of circular vision | |

| Technological | Lack of integrated processes, tools, and practices |

| Lack of an information management system | |

| Complexity of buildings | |

| Technology and infrastructure readiness |

| Lifecycle Stage | CE Strategies/Principles |

|---|---|

| Design stage | - Reduction of material usage through design and specification |

| - Design for increased longevity | |

| In-service | - Maintenance |

| - Repair | |

| - Refurbishing | |

| End-of-use | - Reuse |

| - Remanufacturing | |

| - Recycling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, P.; Cervantes, G.C.; Zaragoza-Benzal, A.; Byrne, A.; Karaca, F.; Ferrández, D.; Salles, A.; Bragança, L. Circular Material Usage Strategies and Principles in Buildings: A Review. Buildings 2024, 14, 281. https://doi.org/10.3390/buildings14010281

Santos P, Cervantes GC, Zaragoza-Benzal A, Byrne A, Karaca F, Ferrández D, Salles A, Bragança L. Circular Material Usage Strategies and Principles in Buildings: A Review. Buildings. 2024; 14(1):281. https://doi.org/10.3390/buildings14010281

Chicago/Turabian StyleSantos, Paulo, Génesis Camila Cervantes, Alicia Zaragoza-Benzal, Aimee Byrne, Ferhat Karaca, Daniel Ferrández, Adriana Salles, and Luís Bragança. 2024. "Circular Material Usage Strategies and Principles in Buildings: A Review" Buildings 14, no. 1: 281. https://doi.org/10.3390/buildings14010281

APA StyleSantos, P., Cervantes, G. C., Zaragoza-Benzal, A., Byrne, A., Karaca, F., Ferrández, D., Salles, A., & Bragança, L. (2024). Circular Material Usage Strategies and Principles in Buildings: A Review. Buildings, 14(1), 281. https://doi.org/10.3390/buildings14010281