Analysis Based on Ecotect Software of the Energy Consumption and Economic Viability of Solar Collector Pig Houses with Different Roof Forms and Translucent Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Pig Housing Model and Parameters

2.2. Experimental Method

2.2.1. Analysis Method for Evaluating Different Orientations of Pig Houses in Terms of Received Solar Radiation

2.2.2. Analysis Methods for Energy Consumption of Pig Houses with Different Translucent Materials

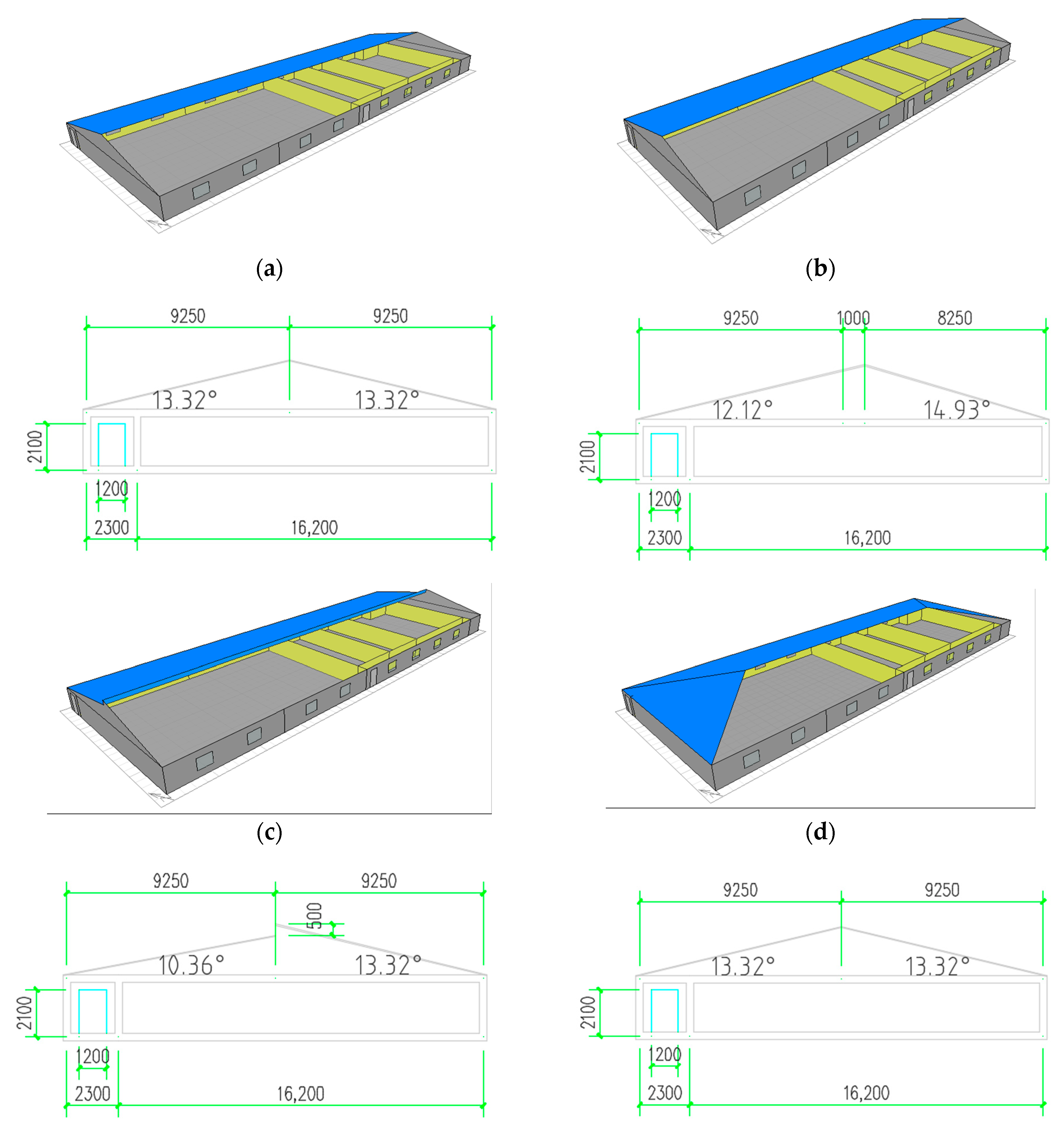

2.2.3. Analysis Methods for Energy Consumption of Pig Houses with Different Roof Forms

2.2.4. Economic Analysis Methods

3. Results and Discussion

3.1. Solar Irradiance Received by Pig Houses of Different Orientations

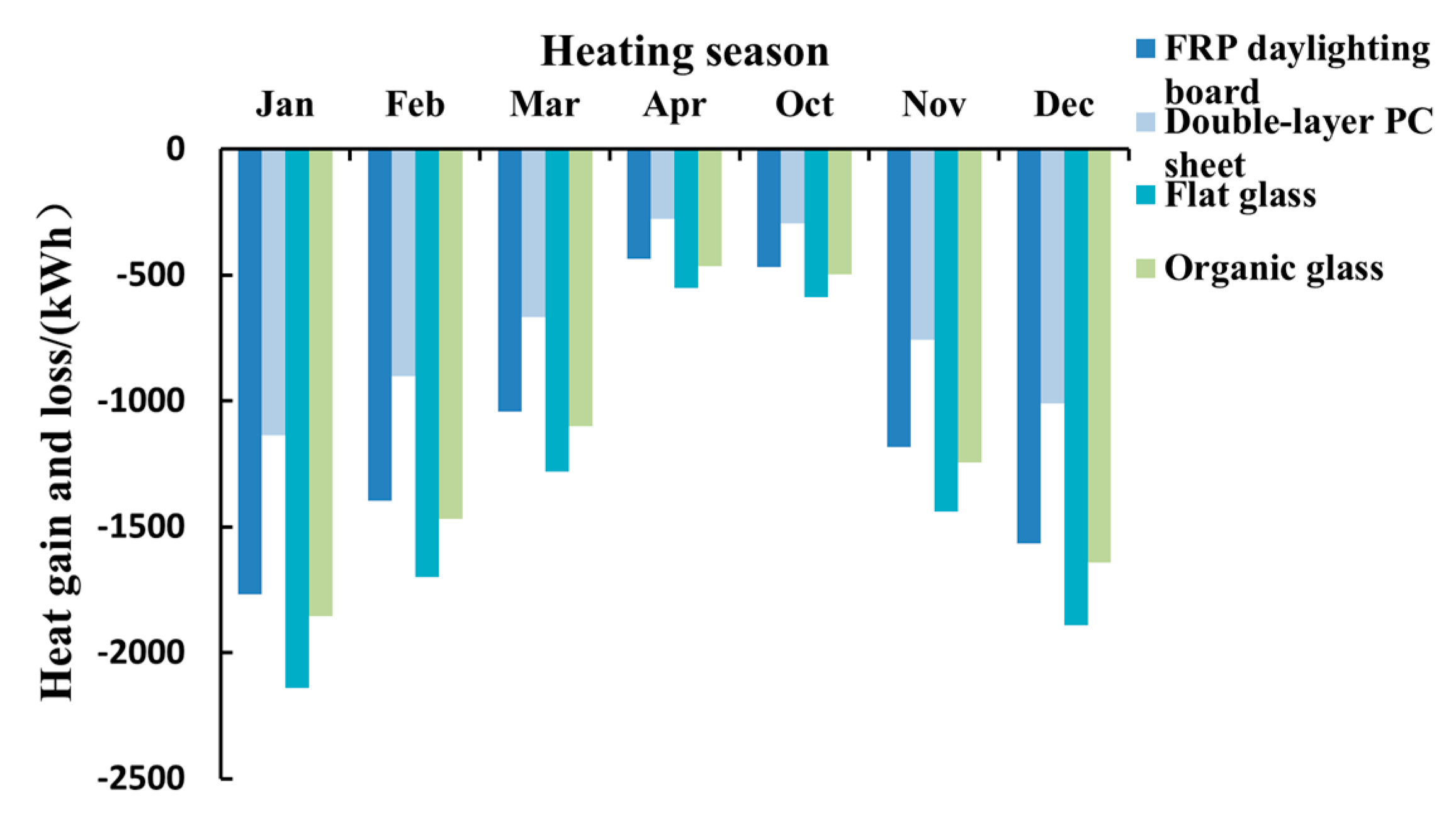

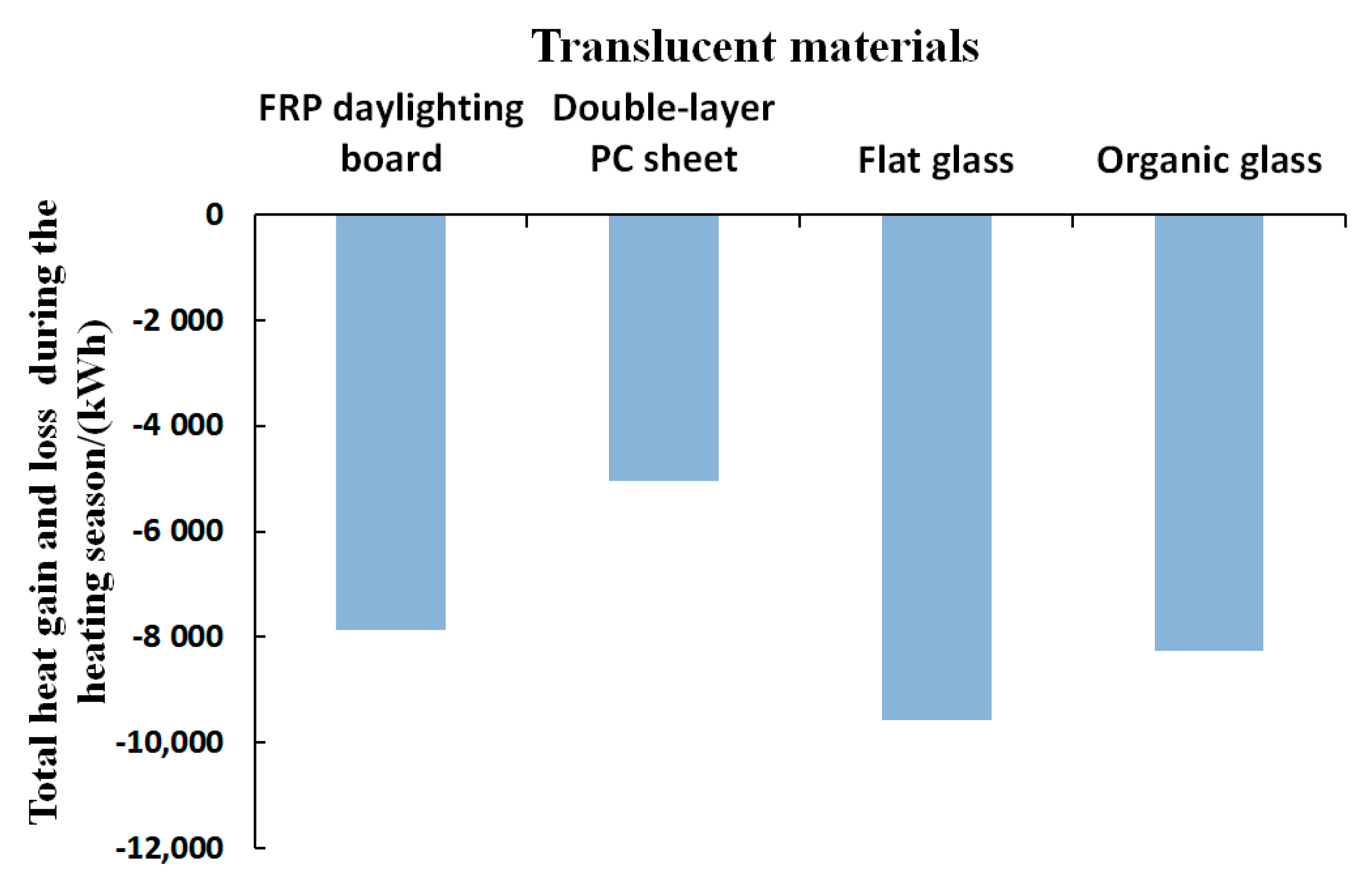

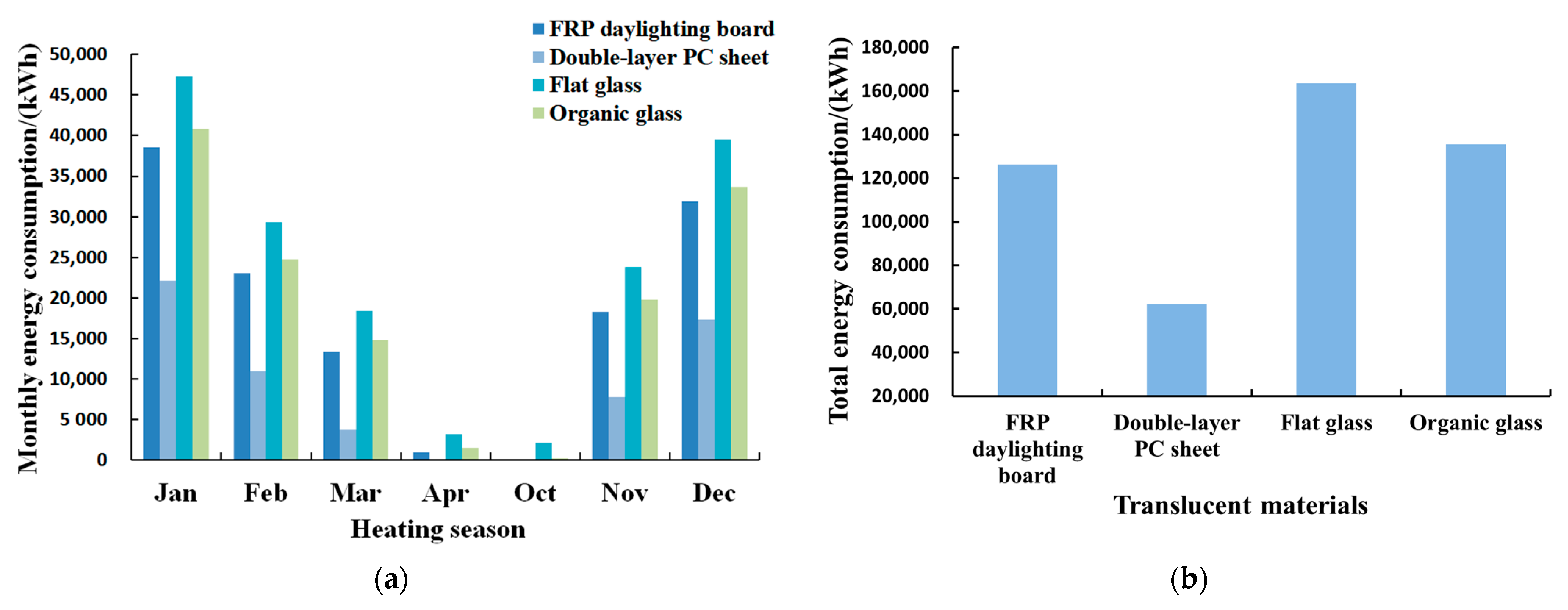

3.2. Energy Consumption Analysis of Pig Houses with Different Translucent Materials

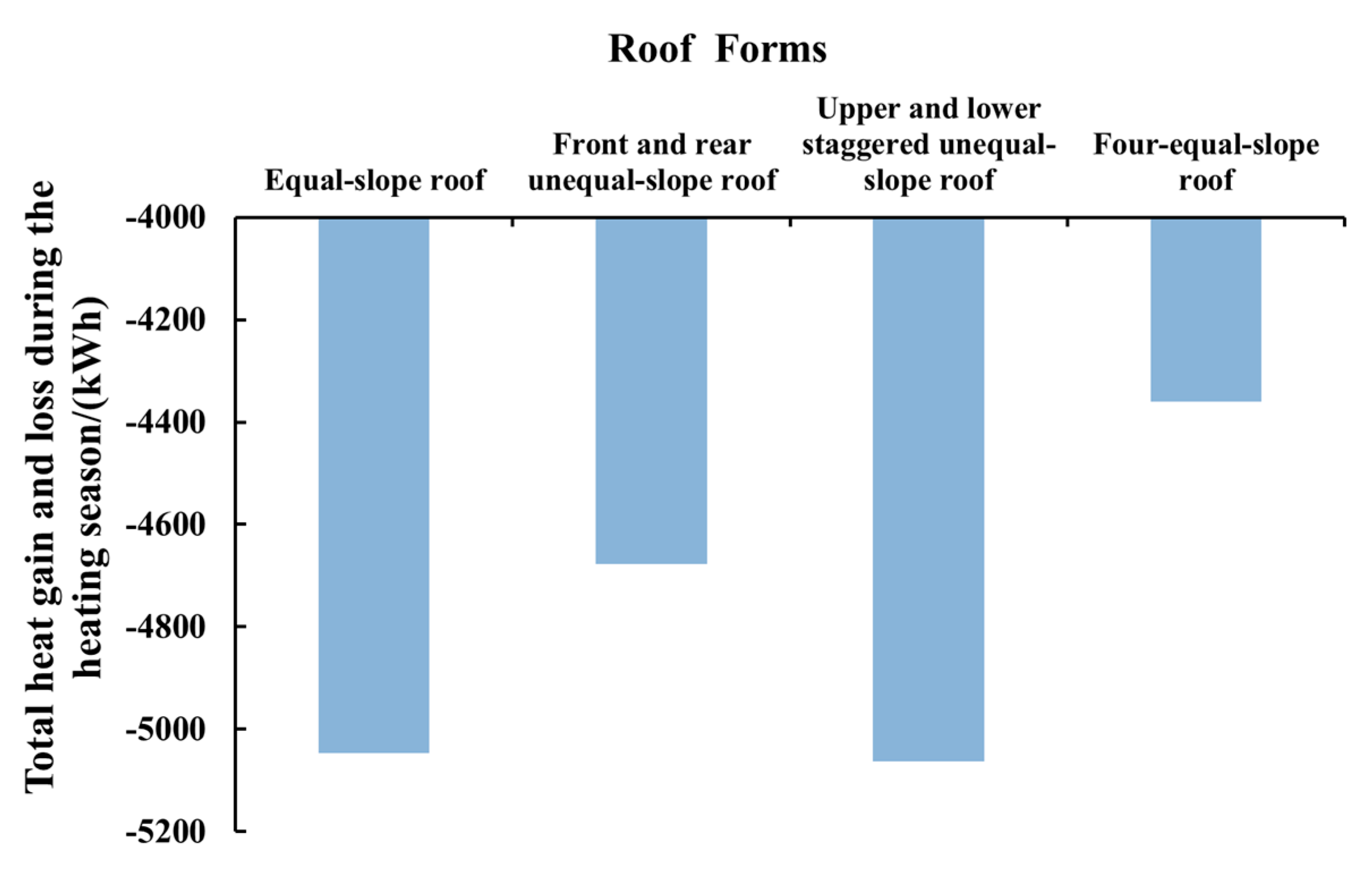

3.3. Energy Consumption Analysis of Pig Houses with Different Roof Forms

3.4. Economic Analysis

4. Conclusions

- (1)

- Through a comparative analysis of received solar irradiance of roofs at different orientations, it was determined that the optimal orientation for pig houses in the Songyuan area is 25° west of south. During construction, it is suggested that a range of orientation variations between 35° and 10° west of south be allowed.

- (2)

- Comparative analysis of energy consumption of pig houses with different translucent materials during the heating season. For pig houses with an equal-slope roof and different translucent materials, it was found that those with double-layer PC sheets consumed 103.15%, 163.46%, and 118.26% less energy than those with FRP daylighting boards, flat glass, and organic glass, respectively.

- (3)

- Analysis of energy consumption in pig houses with different roof forms during the heating season. Using double-layer PC sheets as the translucent material, it was found that pig houses with front and rear unequal-slope, upper and lower staggered unequal-slope, and four-equal-slope roofs required 9.65%, 3.46%, and 22.49% less heat supplementation, respectively, than those with an equal-slope roof.

- (4)

- The cost and expense analysis of pig houses with equal-slope roofs using different translucent materials and pig houses with double-layer PC sheets using different roof forms indicate that the combination of a four-equal-slope roof and double-layer PC sheets is the most economical option. The total life cycle cost is 49,828.74 USD, which represents a saving of 9521 USD compared with the experimental pig house.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, Q.F.; Chen, Q.; Liu, Z.Q.; Xiao, S.H. The present situation and challenges of pig industry in China. Guangdong J. Anim. Vet. Sci. 2017, 42, 5–8. [Google Scholar]

- Gao, H.; Yuan, X.K.; Jiang, L.L.; Wang, J.J.; Zang, J.J. Review of Environmental Parameters in Pig House. Sci. Agric. Sin. 2018, 51, 3226–3236. [Google Scholar]

- Hao, Z.Y.; Gao, F.X. Effects of Temperature on Growth Performance and Health for Growing Pigs. J. Domest. Anim. Ecol. 2019, 40, 6–9. [Google Scholar]

- Wang, M.; Yi, L.; Liu, J.; Yang, L.; Chen, Z.; Wu, Z. Study on heating effect of air source heat pump for floor heating of nursery pig house in Beijing. Trans. Chin. Soc. Agric. Eng. 2019, 35, 203–210. [Google Scholar]

- Blázquez, C.S.; Borge-Diez, D.; Nieto, I.M.; Maté-González, M.Á.; Martín, A.F.; González-Aguilera, D. Investigating the potential of the slurry technology for sustainable pig farm heating. Energy 2021, 234, 121258. [Google Scholar] [CrossRef]

- Shi, Z.F.; Ji, Z.Z.; Xi, L. Research Progress of Heating Process and Heating Equipment for Closed Livestock and Poultry Houses in China. Heilongjiang Anim. Sci. Vet. Med. 2017, 22, 56–58+293–294. [Google Scholar]

- Islam, M.M.; Mun, H.-S.; Bostami, A.B.M.R.; Park, K.-J.; Yang, C.-J. Combined active solar and geothermal heating: A renewable and environmentally friendly energy source in pig houses. Environ. Prog. Sustain. Energy 2016, 35, 1156–1165. [Google Scholar] [CrossRef]

- Yuan, Y.; Song, Y.; Xie, C.; Zhou, L. Analysis of light environment and thermal performance of piggery with different wall materials based on Ecotect. Trans. Chin. Soc. Agric. Eng. 2019, 35, 199–205. [Google Scholar]

- Mun, H.S.; Ahmed, S.T.; Islam, M.M.; Park, K.J.; Yang, C.J. Retrofitting of a pig nursery with solar heating system to evaluate its ability to save energy and reduce environmental pollution. Eng. Agric. Environ. Food 2015, 8, 235–240. [Google Scholar] [CrossRef]

- Vox, G.; Maneta, A.; Schettini, E. Evaluation of the radiometric properties of roofing materials for livestock buildings and their effect on the surface temperature. Biosyst. Eng. 2016, 144, 26–37. [Google Scholar] [CrossRef]

- Liberati, P.; Zappavigna, P. Evaluation of solar energy on the roofs of livestock houses. J. Agric. Eng. 2013, 43, e25. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Z.; Liu, J. Energy saving, emission reduction and economic feasibility evaluation of solar heating system in Beijing pig farms. J. Domest. Anim. Ecol. 2017, 38, 71–79. [Google Scholar]

- Wang, M.; Xue, X.; Liu, J.; Yi, L.; Chen, Z.; Wu, Z. Comparison of heating energy consumption and economy of pig house with different energy saving renovation measures. Trans. Chin. Soc. Agric. Eng. 2018, 34, 218–224. [Google Scholar]

- Liao, Y.Y. Effects of a sunshine pork feeding model on pig growth performance and the environment in the pig house. Anim. Sci. Abroad (Pigs Poult.) 2021, 41, 30–33. [Google Scholar]

- Liu, J.Y.; Zhang, C. Thermal design of solar insulated pig houses. J. Northeast. Agric. Univ. 2008, 4, 18–21. [Google Scholar]

- Yu, H.Y.; Wang, D.H.; Hao, J.F. Analysis of building design and energy saving of two-story round piglet houses in cold northeast China. Heilongjiang Anim. Sci. Vet. Med. 2017, 22, 53–55. [Google Scholar]

- Pan, L.N.; Zhang, B.L.; Fu, D.L. Solar insulated pig houses. Friends Farmers’ Wealth 2000, 12, 17–18. [Google Scholar]

- Feng, M.; Wang, Y.N.; Yu, B.; Xu, Y.R.; Zhang, T.; Guo, J.J.; Han, X.J.; Yang, Q.H. Survey on the breeding situation, architectural structures, and supporting facilities of pig houses in Chengde City in recent years. Heilongjiang Anim. Sci. Vet. Med. 2020, 24, 53–57. [Google Scholar]

- Han, G.X.; Xie, Q.J.; Xu, Y.D.; Wang, L. Advances in Environmental Monitoring Technology and Methods for Piggery. Chin. J. Anim. Sci. 2021, 57, 18–25. [Google Scholar]

- Gao, Y.; Wang, Y.; Lu, S.; Lei, M.; Luo, J.; Li, X. Thermal Comfort Evaluation of Pigsty and CFD Simulation of Wet Curtain in Summer. J. Agric. Sci. Technol. 2021, 23, 125–135. [Google Scholar]

- Cui, Z.; Guo, Z.M.; Zhang, J.P. Research on the application of energy saving design of green buildings based on Ecotect. Shanghai Real Estate 2021, 1, 41–44. [Google Scholar]

- Chen, H.F.; Wang, Y.J.; Cai, B.R.; Qiu, Y.; Yang, J. Optimization of Photovoltaic external shading structure based on Ecotect. Renew. Energy Resour. 2021, 39, 1166–1174. [Google Scholar]

- Nima, A. Building energy conservation in atrium spaces based on ECOTECT simulation software in hot summer and cold winter zone in Iran. Int. J. Energy Sect. Manag. 2018, 12, 298–313. [Google Scholar]

- Peng, H.; Yun, H.X. Simulation Analysis of Different Enclosure Materials for Pig Welfare Breeding. J. Shanxi Agric. Sci. 2019, 47, 268–271. [Google Scholar]

- Luo, M.Y.; Wu, X.; Liu, K.; Xu, H.J. Study on the change rule of solar radiation in solar greenhouse group based on Ecotect. Agric. Eng. Technol. 2022, 42, 12–18+34. [Google Scholar]

- Wang, B.; Chen, J.L.; Ying, J.Y. Analysis of luminous environment of photovoltaic greenhouse using Ecotect models. Jiangsu Agric. Sci. 2018, 46, 221–224. [Google Scholar]

- Miao, X.; He, J.; Li, G.Z.; Yang, H.M.; Che, Q.M.; Guan, H.M.; Wang, X.N.; Wei, R. The effect of the construction status of large-scale pig farms on the health of swine. China Swine Ind. 2019, 14, 102–108. [Google Scholar]

- Cai, W.G.; Wei, H.F.; Wang, X.; Li, X.H. Building energy consumption measurement data differences and causes. Heat. Vent. Air Cond. 2017, 47, 35–39. [Google Scholar]

- Vandenbogaerde, L.; Verbeke, S.; Audenaert, A. Optimizing building energy consumption in office buildings: A review of building automation and control systems and factors influencing energy savings. J. Build. Eng. 2023, 76, 107233. [Google Scholar] [CrossRef]

- Uetsuji, Y.; Yasuda, Y.; Yamauchi, S.; Matsushima, E.; Adachi, M.; Fuji, M.; Ito, H. Multiscale study on thermal insulating effect of a hollow silica-coated polycarbonate window for residential buildings. Renew. Sustain. Energy Rev. 2021, 152, 111718. [Google Scholar] [CrossRef]

- Shi, H.Y.; Zhao, S.N. Study on Thermal Performance of Typical Rural Roof in Chifeng Area. Sci. Technol. Innov. 2022, 19, 136–139. [Google Scholar]

| Title | Authors | Main Findings | Citation Numbers |

|---|---|---|---|

| Research Progress of Heating Process and Heating Equipment for Closed Livestock and Poultry Houses in China. | Shi Z.F.; Ji Z.Z.; Xi L. | Using solar energy to heat livestock and poultry houses saved energy and reduced pollution. | [6] |

| Combined active solar and geothermal heating: A renewable and environmentally friendly energy source in pig houses. | Islam M.M.; Mun H.; Bostami R.M.B.A.; et al. | Compared with the traditional heating system, the solar and geothermal combined heating system significantly reduced electricity consumption, CO2 emissions and costs. | [7] |

| Analysis of light environment and thermal performance of piggery with different wall materials based on Ecotect. | Yuan Y.M.; Song Y.; Xie C.H.; et al. | Measured values were compared with simulated values using Ecotect software, with a relative error range of 0.74% to 8.62%. | [8] |

| Retrofitting of a pig nursery with solar heating system to evaluate its ability to save energy and reduce environmental pollution. | Mun H.S.; Ahmed S.T.; Islam M.M.; et al. | The solar-powered pig house reduced electricity usage by 15% (261 kWh) compared with the conventional house, resulting in a 15% decrease in CO2 emissions (128 kg). | [9] |

| Evaluation of the radiometric properties of roofing materials for livestock buildings and their effect on the surface temperature. | Vox G.; Maneta A.; Schettini E. | Roofing materials with a solar reflectivity coefficient higher than 22% and an emissivity coefficient higher than 90% can greatly reduce surface temperatures in livestock buildings, especially during the warmest periods. | [10] |

| Evaluation of solar energy on the roofs of livestock houses. | Liberati P.; Zappavigna P. | The annual energy absorption of a shed roof was 2.5% higher than that of a gabled roof. | [11] |

| Research on the application of energy saving design of green buildings based on Ecotect. | Cui Z.; Guo Z.M.; Zhang J.P. | Ecotect software enables simulation and analysis of lighting, acoustics, thermal conditions, visibility, and other aspects of architectural designs. | [21] |

| Optimization of Photovoltaic external shading structure based on Ecotect. | Chen H.F.; Wang Y.J.; Cai B.R.; et al. | The Ecotect software can be utilized to study the daylighting and power generation performance of external photovoltaic panels. | [22] |

| Building energy conservation in atrium spaces based on Ecotect simulation software in hot summer and cold winter zone in Iran | Nima A. | The Ecotect software can effectively assist in energy-saving design research for buildings. | [23] |

| Simulation Analysis of Different Enclosure Materials for Pig Welfare Breeding | Peng H.; Yun H.X. | The Ecotect software analysis suggested that adding insulation materials and architectural coatings to the enclosure structure of pig housing improves animal welfare in farming. | [24] |

| Study on the change rule of solar radiation in solar greenhouse group based on Ecotect. | Luo M.Y.; Wu X.; Liu K.; et al. | Ecotect software accurately simulated daylighting conditions, with a relative error range of −0.54% to 7.92%. | [25] |

| Analysis of luminous environment of photovoltaic greenhouse using Ecotect models. | Wang B.; Chen J.L.; Ying J.Y. | Comparing the simulated values of Ecotect software with the measured values, the average difference in solar radiation at each testing point was within 10%. | [26] |

| Components | Heat Transfer Coefficient | Access Coefficient | Solar Absorptivity/% | Attenuation Coefficient | Delay Time/h | Solar Transmittance/% | |

|---|---|---|---|---|---|---|---|

| Wall | 10 mm plastic flame-retardant plywood + 20 mm polyethylene foam layer + 290 mm foam concrete wall panel + 20 mm cement mortar layer. | 0.56 | 3.12 | 50.00 | 0.30 | 11.36 | - |

| North side roof | 25 mm wooden board + 2 mm asphalt felt layer + 10 mm polystyrene foam board + 0.5 mm blue color steel tile. | 0.50 | 2.42 | 80.00 | 0.80 | 3.12 | - |

| South side roof | Double-layer PC sheets (Various polycarbonate fillers adopted from Ecotect material library). | 3.00 | 6.00 | - | - | - | 78.00 |

| Glass | Fully enclosed double-layer insulated glass windows (Using Ecotect prototype double-layer aluminum alloy glass mode). | 2.70 | 2.80 | - | - | - | 63.00 |

| Roofing Translucent Materials | FRP Daylighting Board | Double-Layer PC Sheet | Flat Glass | Organic Glass |

|---|---|---|---|---|

| Thickness (mm) | 8.00 | 8.00 | 8.00 | 8.00 |

| Density (kg/m3) | 1400.00 | 1200.00 | 2500.00 | 1190.00 |

| Specific heat capacity (J/kg·K) | 840.00 | 1172.00 | 800.00 | 1164.00 |

| Thermal conductivity (W/m·K) | 0.16 | 0.17 | 0.76 | 0.19 |

| U-value (W/m2·K) | 4.37 | 4.42 | 5.30 | 4.54 |

| Access coefficient (W/m2·K) | 4.34 | 4.39 | 5.26 | 4.51 |

| Solar absorptivity (%) | 24.00 | 22.00 | 10.00 | 18.00 |

| Visible light transmission rate (%) | 76.00 | 78.00 | 90.00 | 82.00 |

| Pig Houses | Color Steel Plate Price (USD/m2) | Color Steel Plate Area (m2) | Translucent Materials Price (USD/m2) | Translucent Materials Area (m2) | Roofing Cost (USD) | Supplementary Heat Supply in the Heating Season (kWh) | Electricity Cost (USD) | TLLC (USD) |

|---|---|---|---|---|---|---|---|---|

| FRP daylighting board | 18.62 | 481.00 | 6.15 | 481.00 | 11,914.37 | 126,172.00 | 9394.96 | 105,863.97 |

| Double-layer PC sheet | 18.62 | 481.00 | 8.62 | 481.00 | 13,102.44 | 62,109.00 | 4624.73 | 59,349.74 |

| Flat glass | 18.62 | 481.00 | 6.92 | 481.00 | 12,284.74 | 163,630.00 | 12,184.14 | 134,126.14 |

| Organic glass | 18.62 | 481.00 | 17.85 | 481.00 | 17,542.07 | 135,559.00 | 10,093.93 | 118,481.37 |

| Pig Houses | Color Steel Plate Price (USD/m2) | Color Steel Plate Area (m2) | Translucent Materials Price (USD/m2) | Translucent Materials Area (m2) | Roofing Cost (USD) | Supplementary Heat Supply in the Heating Season (kWh) | Electricity (USD) | TLLC (USD) |

|---|---|---|---|---|---|---|---|---|

| Equal-slope roof | 18.62 | 481.00 | 8.62 | 481.00 | 13,102.44 | 62,109.00 | 4624.73 | 59,349.74 |

| Front and rear Unequal-slope roof | 18.62 | 530.30 | 8.62 | 431.90 | 13,597.16 | 56,116.00 | 4178.48 | 55,381.96 |

| Upper and lower staggered unequal-slope roof | 18.62 | 501.10 | 8.62 | 481.00 | 13,476.70 | 59,961.00 | 4464.79 | 58,124.60 |

| Four-equal-slope roof | 18.62 | 569.20 | 8.62 | 392.80 | 13,984.44 | 48,138.00 | 3584.43 | 49,828.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Zhou, L.; Guo, X.; Wu, H.; Li, J.; Zhu, F.; Chen, L. Analysis Based on Ecotect Software of the Energy Consumption and Economic Viability of Solar Collector Pig Houses with Different Roof Forms and Translucent Materials. Buildings 2024, 14, 22. https://doi.org/10.3390/buildings14010022

Zhou L, Zhou L, Guo X, Wu H, Li J, Zhu F, Chen L. Analysis Based on Ecotect Software of the Energy Consumption and Economic Viability of Solar Collector Pig Houses with Different Roof Forms and Translucent Materials. Buildings. 2024; 14(1):22. https://doi.org/10.3390/buildings14010022

Chicago/Turabian StyleZhou, Lina, Leijinyu Zhou, Xinhe Guo, Hongbo Wu, Jinsheng Li, Fengwu Zhu, and Limei Chen. 2024. "Analysis Based on Ecotect Software of the Energy Consumption and Economic Viability of Solar Collector Pig Houses with Different Roof Forms and Translucent Materials" Buildings 14, no. 1: 22. https://doi.org/10.3390/buildings14010022

APA StyleZhou, L., Zhou, L., Guo, X., Wu, H., Li, J., Zhu, F., & Chen, L. (2024). Analysis Based on Ecotect Software of the Energy Consumption and Economic Viability of Solar Collector Pig Houses with Different Roof Forms and Translucent Materials. Buildings, 14(1), 22. https://doi.org/10.3390/buildings14010022