Mechanical Properties of Post-Filling Coarse Aggregate Concrete under Biaxial Tension–Compression

Abstract

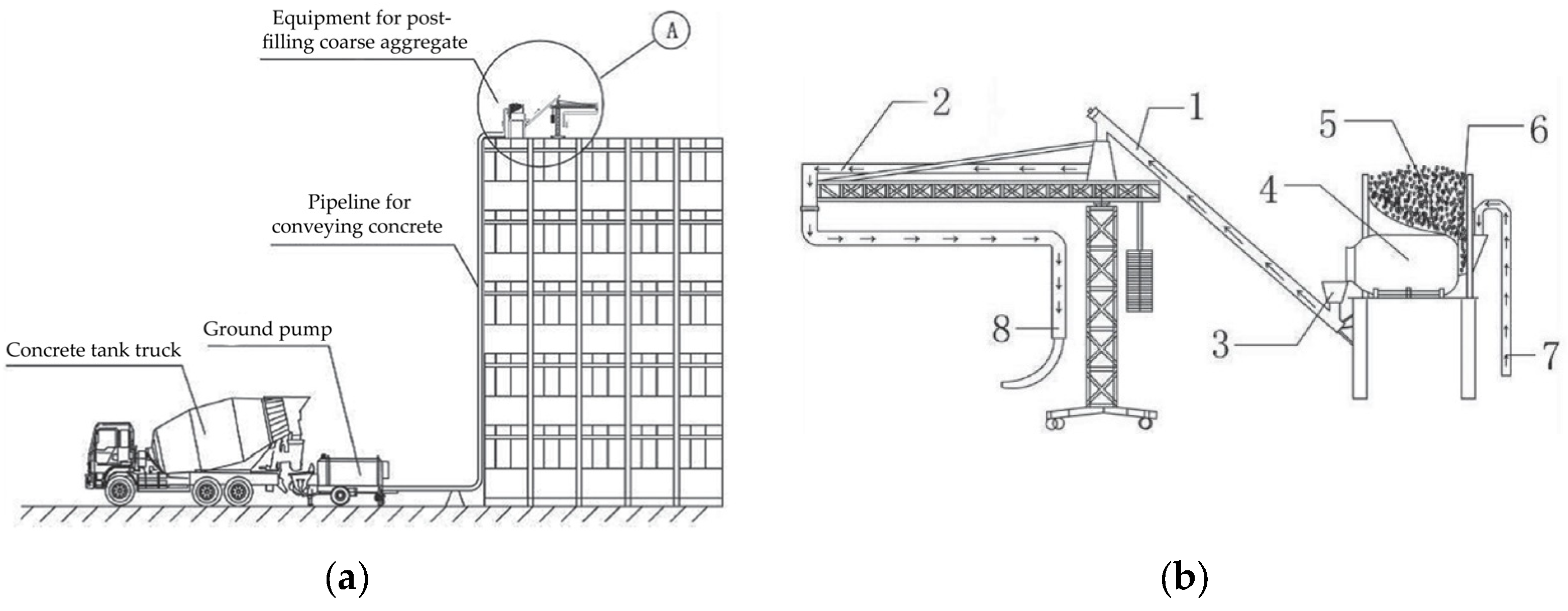

1. Introduction

2. Test Design

2.1. Concrete Mixtures and Specimen Preparation

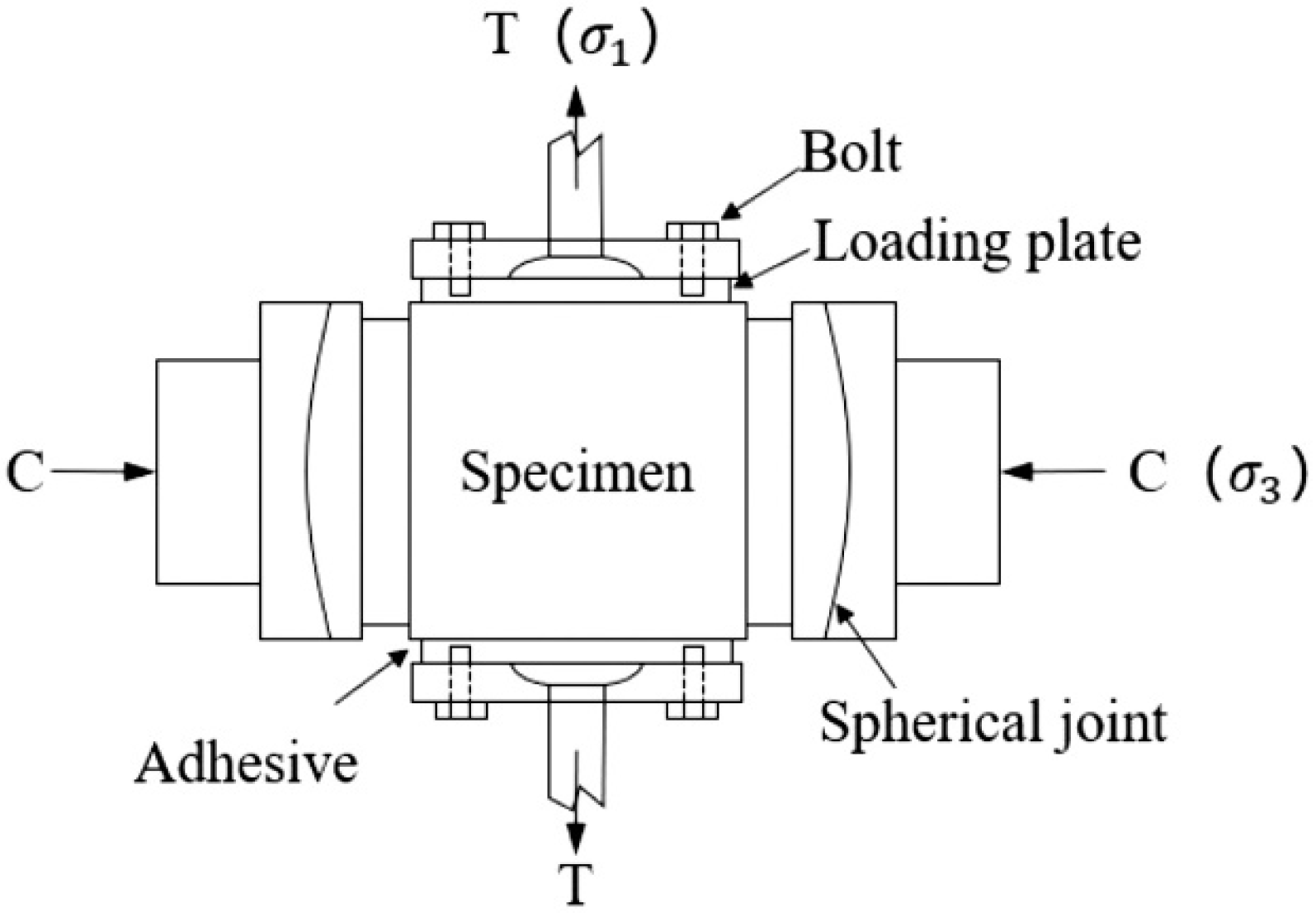

2.2. Loading Device and Test Process

3. Results and Discussion

3.1. Failure Mode

3.2. Peak Stress

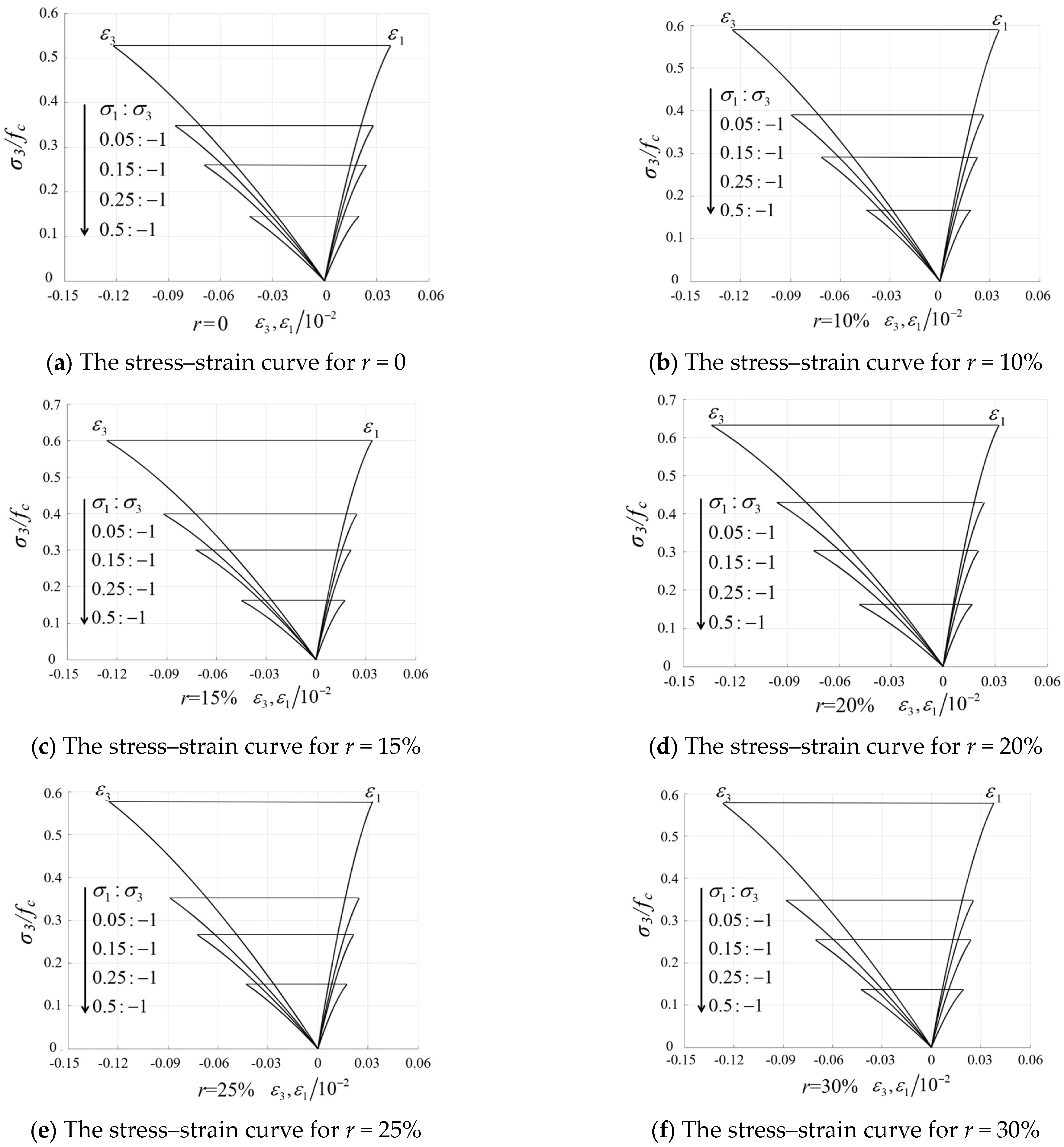

3.3. Stress–Strain Response

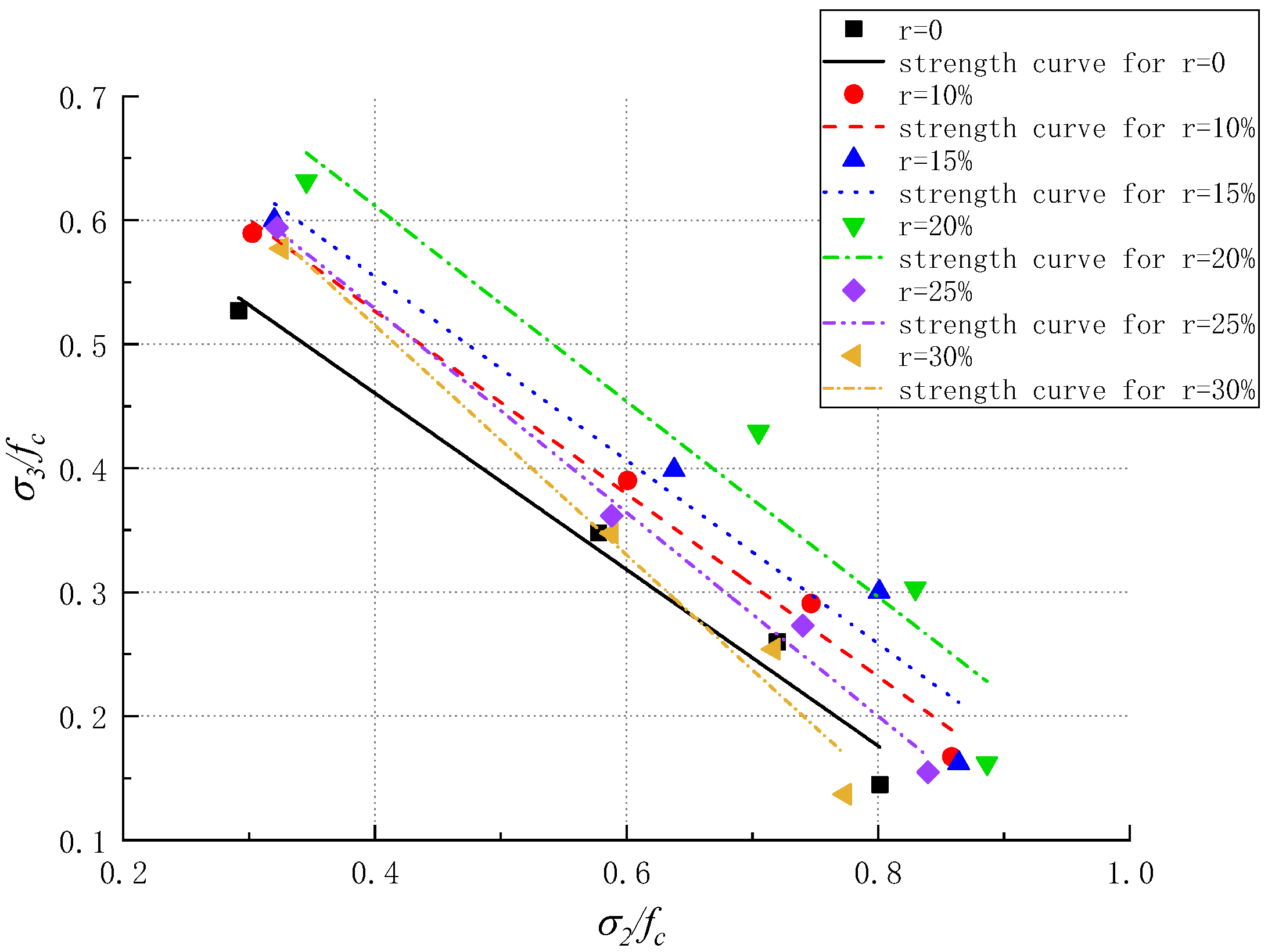

4. Failure Criterion

5. Conclusions

- The uniaxial tensile strength and the concrete strength under biaxial tension–compression both increase with increasing post-filling ratio, and then decrease, with the maximum value occurring at a PFR of 20%.

- The tensile strength and compressive strength of concrete with different PFRs under biaxial tension–compression are lower than those under uniaxial tensile strength and uniaxial compressive strength at the same post-filling ratio. The variation of concrete strength with PFR is the same as that under uniaxial stress conditions.

- The rate of decline in the compressive strength of the specimens under biaxial tension–compression is simultaneously affected by the tension–compression ratio and the post-filling ratio. Tensile stress can increase the rate of decline in compressive strength. However, the increase in the post-filling ratio first slows down and then increases the rate of decline in tensile strength.

- From the stress–strain curves, it can be seen that tensile stress can significantly reduce the stiffness and ductility of PFCC under biaxial tension–compression. The stress–strain curve of PFCC subjected to biaxial tension–compression is approximately linear throughout the loading process.

- We established failure criteria for biaxial tension–compression under different post-filling ratios and derived a formula for PFCC failure criteria under biaxial tension–compression through regression analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Yue, Q.; Jin, H.; Fen, P. Research progress on carbon emission of steel structure buildings based on carbon peak and carbon neutral. Build. Struct. 2023, 53, 1–7+36. [Google Scholar]

- Gan, V.J.L.; Cheng, J.C.P.; Lo, I.M.C. A Systematic Approach for Low Carbon Concrete Mix Design and Production. In Proceedings of the 3rd International Conference on Civil Engineering, Architecture and Sustainable Infrastructure (ICCEASI), Hong Kong, China, 1–3 July 2015. [Google Scholar]

- Modarres, A.; Hosseini, Z. Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Mater. Des. 2014, 64, 227–236. [Google Scholar] [CrossRef]

- Najjar, M.F.; Soliman, A.M.; Nehdi, M.L. Critical overview of two-stage concrete: Properties and applications. Constr. Build. Mater. 2014, 62, 47–58. [Google Scholar] [CrossRef]

- An, X.; Wu, Q.; Jin, F.; Huang, M.; Zhou, H.; Chen, C.; Liu, C. Rock-filled concrete, the new norm of SCC in hydraulic engineering in China. Cem. Concr. Compos. 2014, 54, 89–99. [Google Scholar] [CrossRef]

- Wang, L.; Cao, M. Research on concrete aggregate frame model (AFM). In Proceedings of the 6th International Symposium on Cement and Concrete/Canmet-ACI International Symposium on Concrete Technology for Sustainable Development, Xi’an, China, 19–22 September 2006. [Google Scholar]

- Beshr, H.; Almusallam, A.A.; Maslehuddin, M. Effect of coarse aggregate quality on the mechanical properties of high strength concrete. Constr. Build. Mater. 2003, 17, 97–103. [Google Scholar] [CrossRef]

- Ozturan, T.; Cecen, C. Effect of coarse aggregate type on mechanical properties of concretes with different strengths. Cem. Concr. Res. 1997, 27, 165–170. [Google Scholar] [CrossRef]

- Stock, A.F.; Hannant, D.J.; Williams, R.I.T. Effect of Aggregate Concentration upon the Strength and Modulus of Elasticity of Concrete. Mag. Concr. Res. 1979, 31, 225–234. [Google Scholar] [CrossRef]

- Akçaoglu, T.; Tokyay, M.; Çelik, T. Effect of coarse aggregate size on interfacial cracking under uniaxial compression. Mater. Lett. 2002, 57, 828–833. [Google Scholar] [CrossRef]

- Shen, W.G.; Yang, Z.G.; Yang, Z.F.; Li, J.F.; Cao, L.; Zhang, C. Scattering-Filling Stone Concrete: Mechanism, Experiment and Utilization. Key Eng. Mater. 2014, 629–630, 522–527. [Google Scholar] [CrossRef]

- Shen, W.; Dong, R.; Li, J.; Zhou, M.; Ma, W.; Zha, J. Experimental investigation on aggregate interlocking concrete prepared with scattering–filling coarse aggregate process. Constr. Build. Mater. 2010, 24, 2312–2316. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, T.; Zhou, M.; Cai, Z.; Hu, J.; Li, J. Investigation on the scattering-filling coarse aggregate self-consolidating concrete. Mater. Struct. 2010, 43, 1343–1350. [Google Scholar] [CrossRef]

- Jia, J.; Cao, Q.; Luan, L.; Wang, Z.; Zhang, L. Mechanical Properties of Large Slump Concrete Made by Post-Filling Coarse Aggregate Mixing Procedure. Materials 2020, 13, 2761. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Yu, Y.; Zhang, C.; Zhang, Y. Mesoscopic Fracture Model of Coarse Aggregate Interlocking Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 3453797. [Google Scholar] [CrossRef]

- Cao, Q.; Jia, J.; Zhang, L.; Ye, H. Steel reinforced post-filling coarse aggregate concrete columns under eccentric compression. Constr. Build. Mater. 2021, 270, 121420. [Google Scholar] [CrossRef]

- Jia, J.; Cao, Q.; Zhang, L.; Hu, Y.; Meng, Z. Shear Behavior of Reinforced Post-Filling Coarse Aggregate Concrete Beams Produced by Creative Construction Process. Buildings 2021, 11, 576. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Architecture and Building Press: Beijing, China, 2016.

- GB/T50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2003; 69p.

- Shang, H.; Yang, S.; Niu, X. Mechanical behavior of different types of concrete under multiaxial tension–compression. Constr. Build. Mater. 2014, 73, 764–770. [Google Scholar] [CrossRef]

- Shang, H.; Song, Y. Experimental study of strength and deformation of plain concrete under biaxial compression after freezing and thawing cycles. Cem. Concr. Res. 2006, 36, 1857–1864. [Google Scholar] [CrossRef]

- Cao, Q.; Lv, X.; Wu, Z.; Zhou, C.; Wang, X. Failure Criteria and Constitutive Model of Polypropylene Fiber-Reinforced Expansive Self-Consolidating Concrete under Biaxial Loading. J. Mater. Civ. Eng. 2021, 33, 04021371. [Google Scholar] [CrossRef]

- Kupfer, H.; Hilsdorf, H.K.; Rusch, H. Behavior of Concrete under Biaxial Stresses. ACI J. Proc. 1969, 66, 656–666. [Google Scholar] [CrossRef]

| Concrete Grade | PFR (%) | Mass per Unit Volume (kg/m3) | Slump (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Coarse Aggregate | Sand | Water Reducer | Water | Post-Filling Coarse Aggregate | |||

| C30 | 0 | 326 | 82 | 950 | 842 | 5.30 | 200 | 0 | 220 |

| 10 | 293 | 74 | 855 | 758 | 4.77 | 180 | 260 | 180 | |

| 15 | 277 | 70 | 808 | 716 | 4.51 | 170 | 390 | 165 | |

| 20 | 261 | 66 | 760 | 674 | 4.24 | 160 | 520 | 140 | |

| 25 | 245 | 62 | 713 | 632 | 3.98 | 150 | 650 | 120 | |

| 30 | 228 | 57 | 665 | 589 | 3.71 | 140 | 780 | 100 | |

| Post-Filling Ratio/ | Stress Ratio | /MPa | /MPa | ||

|---|---|---|---|---|---|

| 0 | 0:−1 | 0 | −31.060 | - | −0.245 |

| 0.05:−1 | 0.819 | −16.372 | 0.038 | −0.122 | |

| 0.15:−1 | 1.621 | −10.803 | 0.028 | −0.086 | |

| 0.25:−1 | 2.019 | −8.076 | 0.024 | −0.069 | |

| 0.50:−1 | 2.248 | −4.495 | 0.020 | −0.043 | |

| 1:0 | 2.805 | 0.000 | 0.015 | - | |

| 10% | 0:−1 | 0.000 | −34.250 | - | −0.231 |

| 0.05:−1 | 1.009 | −20.186 | 0.036 | −0.125 | |

| 0.15:−1 | 2.004 | −13.357 | 0.026 | −0.090 | |

| 0.25:−1 | 2.490 | −9.961 | 0.023 | −0.071 | |

| 0.50:−1 | 2.863 | −5.726 | 0.019 | −0.044 | |

| 1:0 | 3.135 | 0.000 | 0.015 | - | |

| 15% | 0:−1 | 0.000 | −35.810 | - | −0.216 |

| 0.05:−1 | 1.075 | −21.492 | 0.034 | −0.126 | |

| 0.15:−1 | 2.141 | −14.272 | 0.025 | −0.092 | |

| 0.25:−1 | 2.688 | −10.751 | 0.021 | −0.072 | |

| 0.50:−1 | 2.900 | −5.800 | 0.018 | −0.045 | |

| 1:0 | 3.356 | 0.000 | 0.014 | - | |

| 20% | 0:−1 | 0.000 | −37.290 | - | −0.209 |

| 0.05:−1 | 1.178 | −23.556 | 0.032 | −0.133 | |

| 0.15:−1 | 2.402 | −16.014 | 0.024 | −0.096 | |

| 0.25:−1 | 2.827 | −11.309 | 0.020 | −0.075 | |

| 0.50:−1 | 3.021 | −6.042 | 0.017 | −0.048 | |

| 1:0 | 3.408 | 0.000 | 0.014 | - | |

| 25% | 0:−1 | 0.000 | −34.530 | - | −0.217 |

| 0.05:−1 | 0.996 | −19.921 | 0.033 | −0.125 | |

| 0.15:−1 | 1.818 | −12.122 | 0.025 | −0.089 | |

| 0.25:−1 | 2.288 | −9.150 | 0.021 | −0.072 | |

| 0.50:−1 | 2.595 | −5.191 | 0.017 | −0.043 | |

| 1:0 | 3.091 | 0.000 | 0.014 | - | |

| 30% | 0:−1 | 0.000 | −32.470 | - | −0.245 |

| 0.05:−1 | 0.937 | −18.744 | 0.038 | −0.127 | |

| 0.15:−1 | 1.693 | −11.285 | 0.026 | −0.088 | |

| 0.25:−1 | 2.063 | −8.250 | 0.024 | −0.070 | |

| 0.50:−1 | 2.226 | −4.451 | 0.020 | −0.043 | |

| 1:0 | 2.877 | 0.000 | 0.014 | - |

| 0 | 10% | 15% | 20% | 25% | 30% | |

|---|---|---|---|---|---|---|

| 0.745 | 0.821 | 0.850 | 0.927 | 0.857 | 0.886 | |

| −0.711 | −0.737 | −0.740 | −0.789 | −0.822 | −0.926 | |

| 0.975 | 0.989 | 0.953 | 0.923 | 0.992 | 0.979 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, J.; Li, L.; Liu, W. Mechanical Properties of Post-Filling Coarse Aggregate Concrete under Biaxial Tension–Compression. Buildings 2024, 14, 203. https://doi.org/10.3390/buildings14010203

Jia J, Li L, Liu W. Mechanical Properties of Post-Filling Coarse Aggregate Concrete under Biaxial Tension–Compression. Buildings. 2024; 14(1):203. https://doi.org/10.3390/buildings14010203

Chicago/Turabian StyleJia, Jinqing, Lu Li, and Wei Liu. 2024. "Mechanical Properties of Post-Filling Coarse Aggregate Concrete under Biaxial Tension–Compression" Buildings 14, no. 1: 203. https://doi.org/10.3390/buildings14010203

APA StyleJia, J., Li, L., & Liu, W. (2024). Mechanical Properties of Post-Filling Coarse Aggregate Concrete under Biaxial Tension–Compression. Buildings, 14(1), 203. https://doi.org/10.3390/buildings14010203