Abstract

In order to analyze the thixotropy of mastic asphalt concrete during the mixing process, the factors affecting the thixotropy of mastic asphalt binder and asphalt mastic are studied, and the measures to shorten the mixing time of mastic asphalt mixture are given. The dynamic viscosity of mastic asphalt binder and asphalt mastic with time and shear rate is obtained via the step frequency method, and the thixotropic constitutive models of mastic asphalt binder and asphalt mastic are constructed by structural dynamics model, exponential equation, and extended exponential equation respectvely. The improved time thixotropy index is used to analyze the effects of asphalt type, asphalt–aggregate ratio, filler type, heating temperature, and shear rate, and the laws of various factors affecting the thixotropy of mastic asphalt binder and asphalt mastic are obtained. The research shows that the extended exponential model can better characterize the thixotropy of mastic asphalt binder and asphalt mastic under different shear rates. When the amount of lake asphalt or cement is increased, the viscosity of the system and the mixing time to reach a steady viscosity increases; that is, the mixing time needs to be increased. Increasing shear temperature does not change the time parameter to reach steady viscosity; that is, it cannot shorten mixing time. When the shear rate is increased, the time for the system to reach the steady viscosity will be shortened; that is, the time for mixing the mixture can be shortened.

1. Introduction

Gussasphalt concrete is mainly used for steel bridge deck pavement, and it can be divided into two categories: gussasphalt and mastic asphalt. Gussasphalt has been widely used as a waterproofing material in building construction and for pavement engineering since 1917. In the United Kingdom, based on the material’s characteristics, gussasphalt concrete was improved and defined as mastic asphalt concrete. The mastic asphalt concrete production process is complex, requiring adding asphalt and aggregate in batches, then mixing for up to 6 h, and finally paving and forming with a special paver [1,2]. In the long-term mixing process, the viscosity of mastic asphalt concrete gradually decreases with the increase in mixing time. When the mixing stops, the viscosity recovers. This characteristic is collectively called “thixotropy” [3,4,5]. The biggest difference between a mastic asphalt mixture and an ordinary asphalt mixture is that it can be formed by gravity, so its fluidity cannot be too great but also not too small. The mastic asphalt mixture must be stirred for a long time to achieve the fluidity required by construction. Due to its long mixing time, it cannot be applied to large-scale production, making it difficult to popularize and apply. Relevant researchers began to study the methods of shortening the mixing time of mastic asphalt mixture to improve its production efficiency [6,7]. Due to the thixotropy of mastic asphalt mixture, the related research progress is slow. The viscosity change process in the mixing process of mastic asphalt mixture has been unable to be explored clearly, and the thixotropic constitutive model cannot be established accurately.

Thixotropy means that in the isothermal process, the material is subjected to certain shear action, and its viscosity changes with the increase of shear action time. Thixotropy can be divided into three types: positive thixotropy, negative thixotropy, and compound thixotropy [8,9,10]. Positive thixotropy means that under the action of shear external force, viscosity decreases with time and then recovers after quiescence, which was first discovered through studying hydrated iron oxide gel [11]. Negative thixotropy means that the viscosity increases with time under the action of shear external force and then recovers after quiescence, which was first discovered during the study of polyisobutylene tetralin solution [12]. Compound thixotropy refers to the positive and negative thixotropy of a specific system, which was found in the study of the Al-Mg-MMH-montmorillonite dispersion system [13]. Thixotropy is an important research content of the rheology of dispersion systems, which has important theoretical research significance and engineering application value [14,15,16,17,18].

The research on the thixotropy of asphalt has just begun. The existing research results have only proved and simply analyzed the thixotropy of asphalt but have not carried out systematic and in-depth research on its influencing factors. Perraton put forward that the failure rate of asphalt materials under cyclic loading can be divided into two parts: real failure rate and failure rate caused by thixotropy [19]. Kim pointed out that the viscoelastic master curve modulus of asphalt is very close. If thixotropy is introduced, it can only be by viscosity [20]. Soltani et al. established a new fatigue method for asphalt mixtures, stating that thixotropy can be separated from the fatigue of asphalt mixtures, but the applicability of this method to asphalt needs further study and confirmation [21]. Virginie et al. used cone-plate thixotropy test equipment to carry out the time scanning and stress scanning of asphalt, took composite modulus as the evaluation index of thixotropy, and studied the influence of test temperature, loading rate, and loading duration on thixotropy [22]. By analyzing the viscosity, stress, and hysteretic curve of asphalt mastic under cyclic shear load, Ma et al. found that adding fillers can significantly reduce the thixotropy, and different types of mineral fillers have little effect on the thixotropy [23]. Hassan et al. studied the thixotropy of two adhesives containing different fillers, and the thixotropy model of asphalt can be established by DSR [24]. Shan et al. applied various methods to test the thixotropy of four asphalt binders and established corresponding thixotropy models [25]. Hung et al. showed that the thixotropy of rubber-modified asphalt was the fastest, and the thixotropy of polymer-modified asphalt was the slowest [26]. Shanab et al. used DMA to study the mechanical properties of bio-modified asphalt binder and found that bio-modified asphalt showed thixo hardening with the increase of time [27]. Perez et al. found that the decrease of initial composite modulus was mainly caused by thixotropic effect by conducted time and strain scanning tests [28,29]. Researchers mainly pay attention to the influence of thixotropy of asphalt on the fatigue performance of asphalt concrete, but the influence of thixotropy is mainly the viscosity change during long-time mixing, but there is little research on mastic system which needs long-time mixing. The research on thixotropy of asphalt is relatively little, but the research on thixotropy in the field of polymer rheology is sufficient. Applying its research methods and achievements can provide valuable reference for the research on thixotropy of mastic asphalt binder and its mixture.

Test methods commonly used to evaluate the thixotropy of asphalt and other polymer materials include thixotropic ring, dynamic modulus, and stepped frequency [30,31,32]. The thixotropic ring method is the simplest. Its greatest defect is there are two variables, shear rate and action time, in the process of measuring thixotropy, which cannot distinguish the influence of these two factors [33]. The dynamic modulus method has obvious advantages in measuring the thixotropy of elastomers or viscoelastic substances, but it reflects thixotropy through dynamic modulus parameters and has a certain indirectness [34]. The stepped frequency method can not only reflect the internal structure changes of materials but can also be directly used to establish thixotropic models [35]. The thixotropic characteristics of mastic asphalt binder and asphalt mastic are explained by the stepped frequency method. Based on shear rheometer AR-2000, the curves of dynamic viscosity and other characteristic functions of asphalt mastic changing with time and shear rate are obtained by the stepping frequency method, the thixotropic constitutive equation of mastic asphalt binder and asphalt mastic is put forward, and the influencing factors of thixotropy are studied. It is of great help to master the rule of thixotropy of mastic asphalt concrete, reveal its rheological mechanism, and provide key theoretical support for engineering application.

2. Methods

Mastic asphalt binder and asphalt mastic are prepared in a laboratory. The viscosity index is discussed using the stepping frequency method. The thixotropy constitutive model of mastic asphalt binder and asphalt mastic is studied by the structural dynamics model and Mewis mathematical model, and the optimal constitutive model under different shear rates is established. The improved time thixotropy index method analyzes the effects of asphalt type, asphalt–aggregate ratio, filler type, heating temperature, and shear rate on thixotropy.

3. Experimental Plan

3.1. Test Equipment

An AR-2000 rheometer was used as the test instrument. It had three kinds of test heads for test fluid deformation, including concentric cylinder, cone and plate, and parallel plate. Because the test object was mastic asphalt binder and asphalt mastic, it belonged to the system filled with large particles at high temperatures, and its viscosity was high. Therefore, the parallel plate test head was selected in the test. The diameter of the parallel plates is 25 mm, and the spacing is 1 mm.

When using the stepped frequency method, it is necessary to select an appropriate shear rate. If the shear rate is too large, the samples between parallel plates overflow out of the plates with centrifugal force, resulting in distortion of test results. If the shear rate is too small, the equipment may not get accurate test results. The objective is to study the thixotropy of mastic asphalt mixture during mixing, so the shear rate of the test should be close to that of mastic asphalt mixture during mixing. The mixing speed of the cooker car, a professional preparation device for mastic asphalt mixture, is usually set to two gears, 3.5 r/min and 7 r/min. The relevant research shows that when the shear rate is 5 s−1, the blade speed of the horizontal cooker preparation device is equivalent to 3.5 r/min; When the shear rate is 10 s−1, the blade speed of the horizontal cooker preparation device is equivalent to 7 r/min [36]. In addition, the mixture shear rate caused by the blades is different, with different distances from the agitator axis to the blades. Besides the fixed shear rate in the axial direction, there is also a shear rate with a radial rate gradient in the radial direction of blades, and the shear rate at each point is different. To fully analyze the effect of shear rate on thixotropy, the range of shear rate is set wide enough to cover all possibilities during agitation. In summary, the shear rates of 0.01, 0.1, 1, 10, and 100 s−1 are selected. The test duration is 240 s.

3.2. Materials

Mastic asphalt binder is made of 30% base asphalt +70% lake asphalt. Shell 70# base asphalt is used as base asphalt, and Trinidad Lake asphalt is used as lake asphalt in South America. Technical indicators are shown in Table 1. As can be seen from Table 1, after the mixing of lake asphalt and base asphalt, the mastic asphalt binder has the anti-aging property and the anti-rutting property of lake asphalt, which effectively reduces the aging phenomenon in the production process of the mixture, and improves the anti-rutting ability of the mixture under the condition of high asphalt content. In the thixotropy study of castable asphalt mastic, the filler used is limestone powder, produced in the Xifu Mineral Powder Factory in Guangxi Province. The relevant technical indicators are shown in Table 2. The cement is Conch cement, and the technical indicators are shown in Table 3. Because the mastic asphalt mixture needs to realize the characteristics of self-leveling, it needs to use a lot of asphalt binder, which leads to very poor rutting resistance at high temperatures. Therefore, cement is added to the mastic asphalt mixture to improve the rutting resistance.

Table 1.

Technical index of asphalt.

Table 2.

Technical index of mineral powder.

Table 3.

Technical Indicators of Cement.

3.3. Preparation of Mastic Asphalt Binder and Asphalt Mastic

3.3.1. Preparation of Mastic Asphalt Binder Samples

The base asphalt and lake asphalt were placed in the oven, where the base asphalt heating temperature was 140 °C, the lake asphalt heating temperature was 180 °C, and the heating time was 4 h. The mixture was poured into a beaker according to the mass ratio of 3:7, and a miniature mixer was used for rapid mixing at a speed of 500 r/min for 3 min to ensure the uniform mixing of the two asphalts. The mixed asphalt was poured into a test mold with a diameter of 25 mm, and several mastic asphalt binder samples were prepared and molded.

3.3.2. Preparation of Asphalt Mastic Samples

Asphalt mastic is a mixture of mastic asphalt binder and filler. The mastic asphalt binder was heated to 180 °C by heating oven. The mineral fillers were heated to 195 °C and added into the mixture asphalt according to the mass ratio of 0.8, 1.2, 1.6, 2.0, 2.4. The mixture was quickly stirred by a mini-mixer at a speed of 500 r/min for 3 min, and the asphalt mastic samples were formed immediately after stirring for 3 min.

4. Thixotropic Constitutive Model of Mastic Asphalt Binder

4.1. Constitutive Model

Two commonly used thixotropic constitutive models are used to analyze the thixotropic behavior of mastic asphalt binder and asphalt mastic. The first is the structural dynamics model, which belongs to the rheological model [37,38]. The second is the mathematical model first adopted by Mewis et al. (Mewis mathematical model) [39,40,41]. For the structural dynamic model, the structural parameter (0 ≤ ≤ 1) is used to characterize the structural integrity of the instantaneous thixotropic body. When = 0, it means that the structure is completely destroyed; When = 1, it means that the structure has not been destroyed or completely restored. Equation (1) is the basic expression of the structural dynamic model. The basic expression of the structural dynamic model is complex, and another expression is the general expression of the structural parameter dynamic equation, as shown in Equation (2).

where: Residual viscosity (Pa·s) when the structure is completely destroyed; Contribution of structure to viscosity (Pa·s); yield stress (Pa); shear rate (s−1)

where: is structural parameters; are coefficients related to microstructure establishment; are coefficients related to microstructure failure; is the shear rate (s−1).

Mewis’s mathematical model adopts a replaceable method and does not use structural parameters. Viscosity is directly fitted by a mathematical model. The commonly used mathematical models are exponential equations and extended exponential equations, which are shown in Equations (3) and (4).

where: and are the initial viscosity and steady viscosity, respectively, and are time constants.

4.2. Establishment of Constitutive Model

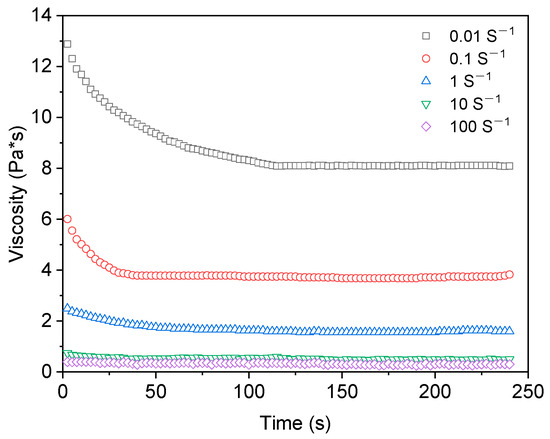

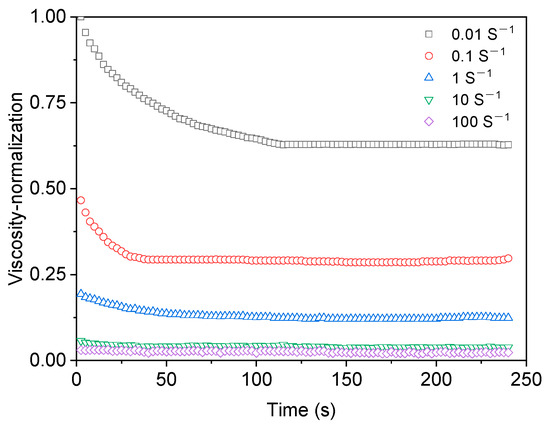

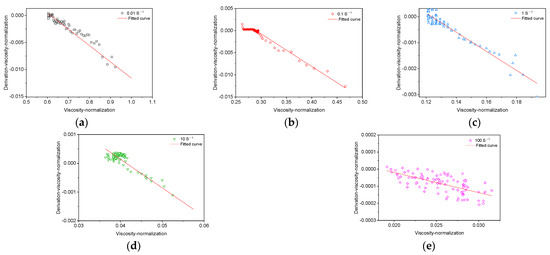

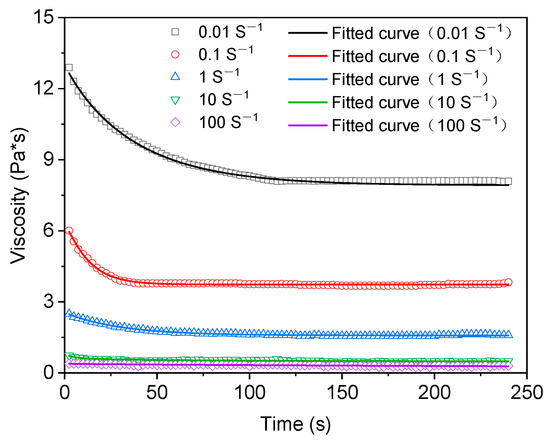

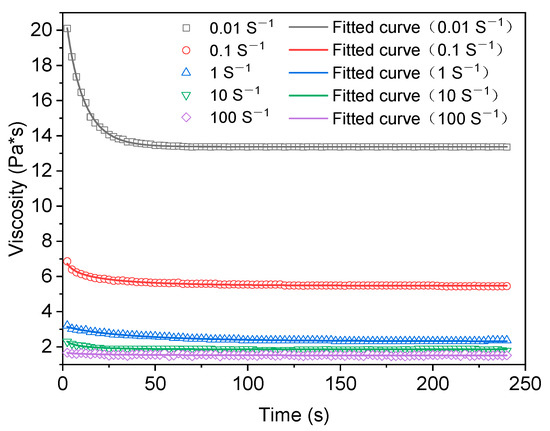

The viscosity index of the mastic asphalt binder under different shear rates is measured by an AR-2000 rheometer. The shear rate changes in the order of 0.01, 0.1, 1, 10, and 100 s−1. The test results are shown in Figure 1. The viscosity data are normalized, as shown in Figure 2. The normalized data is processed by the central difference method. As can be seen from Figure 2, the overall change trend remains consistent after normalization treatment. The fitting analysis is carried out by Equation (2). The results are shown in Figure 3 and Table 4.

Figure 1.

Viscosity test results of mastic asphalt binder.

Figure 2.

Normalization of test results.

Figure 3.

Fitting results of center differential differentiation of mastic asphalt binder. (a) Central differential fitting result (0.01 s−1); (b) Central differential fitting result (0.1 s−1); (c) Central differential fitting result (1 s−1); (d) Fitting results of central differential differentiation (10 s−1); (e) Fitting results of central differential differentiation (100 s−1).

Table 4.

Fitting results of a dynamic model of mastic asphalt binder structure.

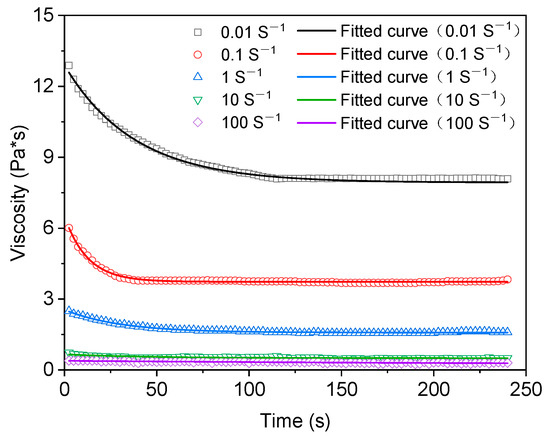

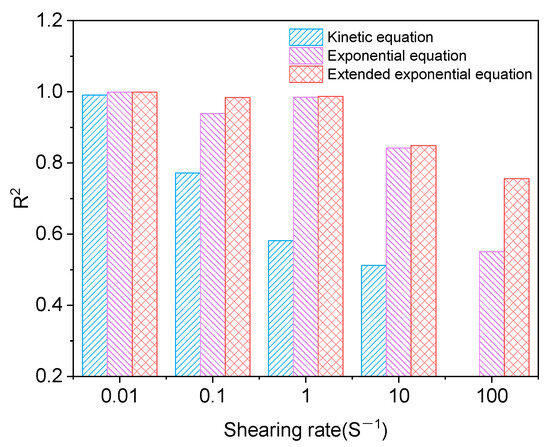

It can be seen from Table 4 that in the fitting of the structural dynamics model, the fitting effect of shear rates of 0.01, 0.1, and 1 s−1 is better, and R2 is above 0.9. The fitting results of shear rate 10 and 100 s−1 are average; R2 is 0.819 and 0.768, respectively. The main reason is that the data are too discrete to form a better fitting model. Mewis mathematical model is used to construct the thixotropic constitutive model of mastic asphalt binder, without normalization treatment and central difference differentiation treatment, and the exponential equation and extended exponential equation are directly used for fitting analysis. The fitting analysis results of the exponential equation are shown in Figure 4 and Table 5, and the fitting analysis results of the extended exponential equation are shown in Figure 5 and Table 5.

Figure 4.

Fitting results of the index equation of mastic asphalt binder.

Table 5.

Fitting results of Mewis mathematical model of mastic asphalt binder.

Figure 5.

Fitting results of expansion index equation of mastic asphalt binder.

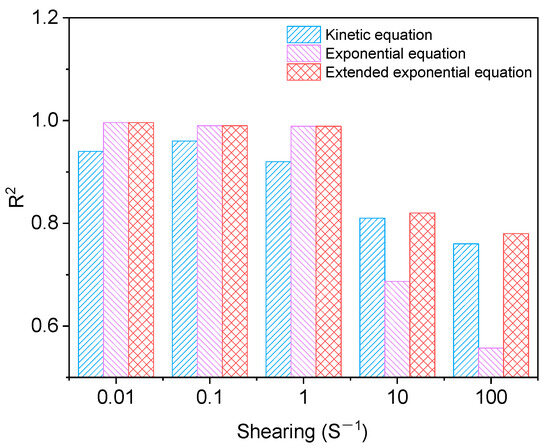

It can be seen from Table 5 that in the fitting analysis results of the Mewis mathematical model, the fitting effect of shear rates of 0.01, 0.1, and 1 s−1 is better, R2 is above 0.9, and the fitting effect of the exponential equation is consistent with that of the extended exponential equation. However, the fitting effect of the shear rate of 10 and 100 s−1 is average, and the extended exponential equation shows a better fitting effect. To further determine the thixotropic constitutive model of mastic asphalt binder, the fitting results of different models are analyzed, and the results are shown in Figure 6. It can be seen from Figure 6 that at shear rates of 0.01, 0.1, and 1 s−1, the fitting effect of the exponential equation is consistent with that of the extended exponential equation, and it is better than that of the kinetic equation. When the shear rates are 10 and 100 s−1, the extended exponential equation is the best, followed by the dynamic equation, and the exponential equation is the worst. To facilitate the analysis, the extended exponential equation is selected as the final constitutive model of the thixotropy of mastic asphalt binder.

Figure 6.

Fitting results of mastic asphalt binder.

5. Thixotropic Constitutive Model of Asphalt Mastic

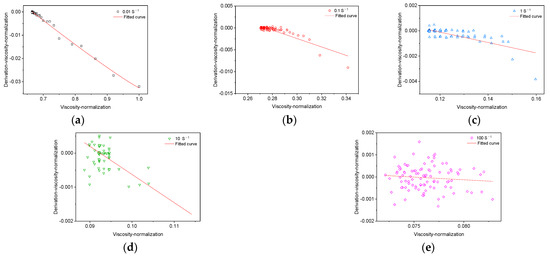

To further study the thixotropic constitutive model of asphalt mastic, the mineral powder was mixed into mastic asphalt binder to form asphalt mastic with an asphalt–aggregate ratio of 1.2. The stepped frequency method was used for the rheological test, and the structural dynamics model and Mewis mathematical model were used for fitting analysis. The structural dynamics fitting results are shown in Figure 7 and Table 6.

Figure 7.

Fitting results of center differential differentiation of asphalt mastic. (a) Central differential fitting result (0.01 s−1); (b) Central differential fitting result (0.1 s−1); (c) Central differential fitting result (1 s−1); (d) Fitting results of central differential differentiation (10 s−1); (e) Fitting results of central differential differentiation (100 s−1).

Table 6.

Fitting results of a structural dynamic model of asphalt mastic.

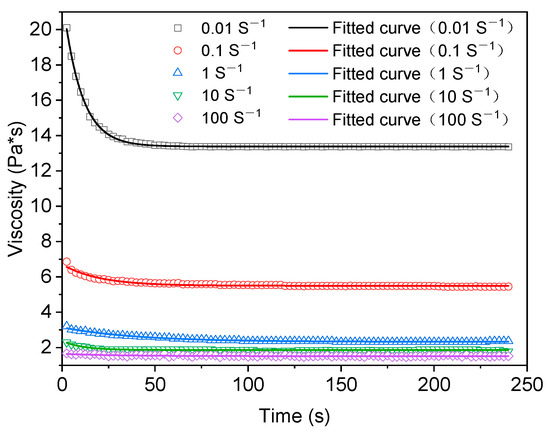

It can be seen from Figure 7 and Table 6 that in the fitting analysis results of the structural dynamics model, the fitting effect is better when the shear rate is 0.01 s−1 and R2 reaches 0.991. When the shear rates are 1, 10, and 100 s−1, the fitting results are average, and R2 is 0.772, 0.582, and 0.512. When the shear rate is 100 s−1, the fitting fails. The fitting results of the Mewis mathematical model are shown in Figure 8 and Figure 9 and Table 7, in which the fitting results of the exponential equation are shown in Figure 8, and the fitting results of the extended exponential equation are shown in Figure 9.

Figure 8.

Fitting results of the exponential equation of asphalt mastic.

Figure 9.

Fitting results of expansion index equation of asphalt mastic.

Table 7.

Fitting results of Mewis mathematical model of asphalt mastic.

It can be seen from Table 7 that when the shear rates are 0.01, 0.1, 1, and 10 s−1, the exponential equation and the extended exponential equation can form better fitting results, and R2 is above 0.8. When the shear rate reaches 100 s−1, only the extended exponential equation forms a general fitting effect, and R2 is 0.756. To further determine the thixotropic constitutive model of asphalt mastic, the fitting effects of different models are analyzed, and the results are shown in Figure 10. As can be seen from Figure 10, the fitting effect of the extended exponential equation is the best. The extended exponential equation is selected as the final constitutive model of the thixotropy of asphalt mastic.

Figure 10.

Fitting results of asphalt mastic.

It can be seen from the above analysis that under constant shear rate and prolonging shear time, the thixotropic structure of mastic asphalt binder and asphalt mastic system is gradually destroyed, and the geometric entanglement density decreases, resulting in the viscosity of the system decreasing until it reaches the equilibrium viscosity. With the increase of shear rate, the thixotropic structure of mastic asphalt binder and asphalt mastic can be destroyed, and the system’s viscosity gradually decreases. Moreover, with the increase of shear rate, the time for the system to reach equilibrium viscosity shortens. For thixotropic bodies, the time effect is equivalent to the shear effect; that is, prolonging the shear time or increasing the shear rate can achieve the same state.

6. Influencing Factors of Thixotropy of Mastic Asphalt Binder

The characteristic of thixotropy is that the internal structure will change with time or shear rate, so the existing evaluation indexes of thixotropy are mainly established around this characteristic. The evaluation index of thixotropy can be divided into the following three methods: The first method is to analyze the effect of shear rate on viscosity. The second method is to analyze the effect of shear time on viscosity. The third method analyzes the effect of shear rate and shear time on viscosity. The improved time thixotropy index is used to analyze the influence of asphalt type, asphalt–aggregate ratio, filler type, heating temperature, and shear rate on thixotropy. The evaluation index is shown in Equation (5). The improved time thixotropy index indicates the influence of shear time on the viscosity of asphalt mastic under certain external conditions.

Firstly, the optimal constitutive equation of the thixotropic structure of mastic asphalt binder materials is obtained by fitting experimental data by using an extended exponential model to obtain initial shear viscosity and steady shear viscosity , and then the time corresponding to the reduction of initial shear viscosity to steady shear viscosity is obtained from experimental data. The initial shear viscosity is often considered as zero shear viscosity, so the corresponding time is zero, so the time required for viscosity change can be considered as , and the improved time thixotropic index analysis model can be modified to Equation (6). MTTI characterizes the thixotropy level of mastic asphalt binder under certain conditions. The higher the value of MTTI, the higher the thixotropy level, and the smaller the value, the weaker the thixotropy ability of the mastic asphalt binder.

6.1. Influence of Asphalt Types on Thixotropy

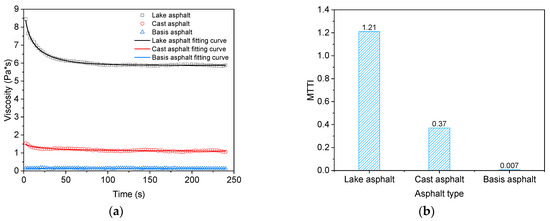

The stepper frequency test is carried out with lake asphalt, base asphalt, and mastic asphalt binder. The shear rate is 1.0 s−1, and the test temperature is 180 °C. The test results are fitted by an extended exponential equation to obtain MTTI calculation parameters, and the thixotropy of lake asphalt, base asphalt, and mastic asphalt binder is evaluated by calculation results. The results are shown in Figure 11.

Figure 11.

Influence of asphalt types on thixotropy. (a) Thixotropy fitting results of different asphalts; (b) MTTI calculation results of different asphalts.

As can be seen from Figure 11a, the viscosity of all asphalt decreases with the extension of shear time. Prolonging shear time leads to the increase of internal structure damage of the asphalt system and reduces the movement resistance of internal particles and molecular chains, showing the characteristics of reduced thixotropy of the system. The viscosity of lake asphalt is higher than that of mastic asphalt binder, while the viscosity of base asphalt is the smallest. Increasing the content of lake asphalt leads to an increase in the time to reach steady viscosity. As can be seen from Figure 11b, the thixotropic ability of different kinds of asphalt is in the order of lake asphalt > mastic asphalt binder > base asphalt. This shows that the thixotropy of asphalt materials is related to the properties and structural characteristics of asphalt materials themselves.

6.2. Effect of Asphalt–Aggregate Ratio on Thixotropy

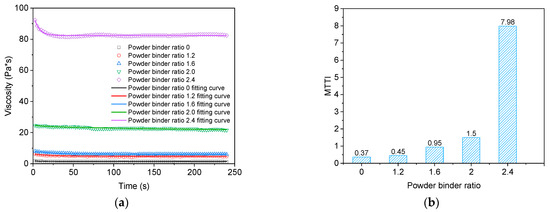

The mastic asphalt binder and asphalt mastic with asphalt–aggregate ratios of 1.2, 1.6, 2.0, and 2.4 are used for the stepping frequency test; the shear rate is 1.0 s−1, and the test temperature is 180 °C. The test results are fitted by an extended exponential equation to obtain MTTI calculation parameters, and the calculation results are used to evaluate the influence of different asphalt–aggregate ratios on the thixotropy of mastic asphalt binder and asphalt mastic. The results are shown in Figure 12.

Figure 12.

Effect of asphalt–aggregate ratio on thixotropy. (a) Thixotropy fitting results of different asphalt–aggregate ratios. (b) MTTI calculation results of different asphalt–aggregate ratios.

As shown in Figure 12a, the viscosity of all asphalt–aggregate ratios decreases continuously with the extension of shear time. Prolonging shear time leads to the increase of internal structure failure of the asphalt system and reduces the movement resistance of fine aggregate particles and molecular chains, showing the characteristics of reduced thixotropy of the asphalt system. The greater the asphalt–aggregate ratio, the greater its viscosity. This is due to the increase of fine particles, which fills the free volume between asphalt macromolecules, resulting in the irregular thermal movement of molecules slowing down, equivalent to the decrease of molecular spacing, resulting in the difficulty of asphalt molecular chains moving. As seen in Figure 12b, the thixotropic ability of mastic asphalt binder and asphalt mastic increases with the increase of the asphalt–aggregate ratio. The reason is that the volume concentration of fine aggregate particles increases due to the increase of the asphalt–aggregate ratio, thus increasing the viscosity of the system, resulting in the obstruction of particle movement and the increase of thixotropy.

6.3. Effect of Filler Type on Thixotropy

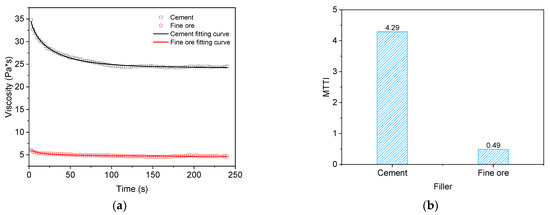

The mastic asphalt binder and asphalt mastic with calcium carbonate ore powder and cement as fillers (asphalt–aggregate ratio 1.2) are used for the stepping frequency test; the shear rate is 1.0 s−1, and the test temperature is 180 °C. The test results are fitted by an extended exponential equation to obtain MTTI calculation parameters, and the calculation results are used to evaluate the influence of different filler ratios on the thixotropy of mastic asphalt binder and asphalt mastic. The results are shown in Figure 13.

Figure 13.

Effect of filler type on thixotropy. (a) Thixotropy fitting results of different fillers; (b) MTTI calculation results of different fillers.

From Figure 13, it can be seen that the viscosity of asphalt mastic with cement as filler is greater than that with mineral powder as filler, and the thixotropy of asphalt mastic with cement filler is greater than that with mineral powder filler. The reason is that cement fineness is larger, which can be better mixed with mastic asphalt binder to form integrity. Cement is often added to mastic asphalt mixture to improve rutting resistance, which will lead to an increase in the time to reach steady viscosity; that is, prolonging the mixing time is required.

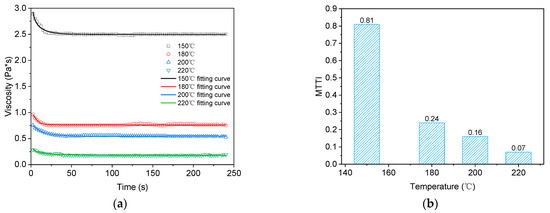

6.4. Effect of Temperature on Thixotropy

Step frequency tests at 150 °C, 180 °C, 200 °C, and 220 °C are carried out on mastic asphalt binder, and the shear rate is 10 s−1. The test results are fitted by an extended exponential equation to obtain MTTI calculation parameters, and the calculation results are used to evaluate the influence of different temperatures on the thixotropy of mastic asphalt binder. The results are shown in Figure 14.

Figure 14.

Effect of temperature on thixotropy. (a) Thixotropy fitting results at different temperatures; (b) MTTI calculation results at different temperatures.

As can be seen from Figure 14a, the viscosity of mastic asphalt binder decreases with the extension of shear time at different temperatures, and the higher the temperature, the smaller its viscosity. Increasing the shear temperature decreases the initial viscosity and steady viscosity, but it does not change the time parameter of reaching steady viscosity. As seen in Figure 14b, the thixotropy of mastic asphalt binder decreases with the increase in temperature. The analysis reason is that the molecular motion is intense, and the thixotropy becomes smaller due to the temperature increase.

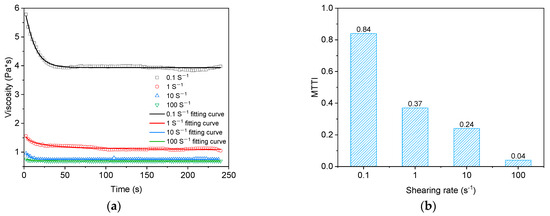

6.5. Effect of Shear Rate on Thixotropy

The mastic asphalt binder is tested with shear rates of 0.1 s, 1, 10, and 100 s−1 at 180 °C. The MTTI calculation parameters are obtained by fitting the extended exponential equation of the test results, and the influence of different shear rates on the thixotropy of mastic asphalt binder is evaluated by calculation results. The results are shown in Figure 15.

Figure 15.

Effect of shear rate on thixotropy. (a) Thixotropy fitting results at different shear rates; (b) MTTI calculation results at different shear rates.

As can be seen from Figure 15a, under different shear rates, the viscosity of mastic asphalt binder decreases with the extension of shear time, and the higher the shear rate, the smaller its viscosity. The main reason is that under the action of high-speed shearing, the original internal molecular chain or the inherent structure of filler particles are opened and cannot be restored before the next shearing, which makes the molecular chain and particles move along the flow direction, and finally makes the viscosity of the material decrease, which has important practical significance for the processing of mastic asphalt binder. The initial viscosity and steady-state viscosity of mastic asphalt binder and asphalt mastic decrease with the increase of shear rate, and the time for the system to reach steady-state viscosity shortens with the increase of shear rate. As seen in Figure 15b, the thixotropy of mastic asphalt binder decreases with the increase of shear rate. This shows that prolonging shear time and increasing shear rate can achieve the effect of reducing thixotropy, and they are equivalent.

7. Conclusions

The thixotropic structural dynamic model and Mewis mathematical model of mastic asphalt binder and asphalt mastic are obtained by stepping frequency test, and the following conclusions are formed:

- (1)

- The greater the amount of lake asphalt, the greater the thixotropy of mastic asphalt binder and asphalt mastic; The greater the asphalt–aggregate ratio, the greater the thixotropy of asphalt mastic; The thixotropy of asphalt mastic with cement as filler is much greater than that of asphalt mastic with mineral powder as filler; The higher the temperature and the higher the shear rate, the smaller the thixotropy of mastic asphalt binder, and they are equivalent;

- (2)

- The initial viscosity and steady-state viscosity of mastic asphalt binder and asphalt mastic decrease with the increase of shear rate, and the time for the system to reach steady-state viscosity shortens with the increase of shear rate. Therefore, when it is necessary to shorten the stirring time of mastic asphalt concrete, the shear rate can be increased;

- (3)

- Increasing the shear temperature does not change the time parameter of reaching steady-state viscosity obviously. When the mixing time is sufficient, the viscosity index of finished mastic asphalt concrete should be considered in the selection of mixing temperature;

- (4)

- When the amount of lake asphalt or cement in the asphalt mastic is increased, the viscosity of asphalt mastic and the mixing time to reach the steady viscosity increase; that is, the mixing time needs to be increased.

The thixotropic behavior of mastic asphalt binder and asphalt mastic is studied, which provides important basic data for objectively and comprehensively analyzing its mechanical response, exploring the best process window period, and subsequent research. The above-mentioned experimental studies are all based on small-scale indoor experiments, and aggregate gradation and other factors must be considered for the mastic asphalt mixture. Therefore, follow-up research should focus on the thixotropy of mastic asphalt mixtures and further reveal the thixotropy behavior of the mastic asphalt mixture.

Author Contributions

Conceptualization, S.Z. and C.L.; methodology, S.Z.; software, J.L.; validation, S.Z., C.L. and J.L.; formal analysis, Z.H.; investigation, Z.H.; resources, Z.H.; data curation, J.L.; writing—original draft preparation, S.Z.; writing—review and editing, S.Z.; visualization, S.Z.; supervision, C.L.; project administration, C.L.; funding acquisition, C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Fund of Guangdong Province, grant number 2019A1515011965, and the Natural Science Foundation of China, grant number 51808228.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Natural Science Fund of Guangdong Province, grant number 2019A1515011965, and the Natural Science Foundation of China, grant number 51808228.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bieliatynskyi, A.; Yang, S.; Pershakov, V.; Shao, M.; Ta, M. Investigation of the properties of cast asphalt concrete mixture with the addition of fiber from the fly ash of thermal power plnts. Mater. Sci. 2022, 40, 125–146. [Google Scholar] [CrossRef]

- Vorontsov, S.V.; Maidanova, N.V.; Syroezhko, A.M.; Ivanov, S.N. Choice of Polymer-Bitumen Binders for Cast Asphalt Concrete Mixes. Russ. J. Appl. Chem. 2012, 85, 309–316. [Google Scholar] [CrossRef]

- Dai, X.; Hou, W.; Duan, H. Effect of Electrolytes and Polymers on the Thixotropy of Mg-AI-Layered Double Hydroxides/Kaolinite Dispersions. Chin. J. Chem. 2011, 29, 2027–2033. [Google Scholar] [CrossRef]

- Li, S.P.; Hou, W.G.; Sun, D.J.; Zhang, C.G. Studies on the thixotropy of ferric aluminum magnesium hydroxide/montmorillonite suspension. Chem. J. Chin. Univ.-Chin. 2001, 22, 1173–1176. [Google Scholar]

- Hou, W.-G.; Sun, D.-J.; Han, S.-H.; Zhang, C.-G.; Wang, G.-T. Study on the thixotropy of aluminum magnesium hydroxide Na-montmorillonite suspension. Colloid Polym. Sci. 1998, 276, 274–277. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Yang, W.; Ding, S.; Hao, M.; Zhao, X.; Liu, J. Electrode Layout Optimization and Numerical Simulation of Cast Conductive Asphalt Concrete Steel Bridge Deck Pavement. Materials 2022, 15, 7033. [Google Scholar] [CrossRef]

- Zhang, S.; Sha, A.; Lu, X.; Nie, W.; Li, W.; Yan, J. Nonlinear Constitutive Model of High-Temperature Viscoelastic Deformation of Gussasphalt Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 8316014. [Google Scholar] [CrossRef]

- Dai, X.N.; Hou, W.G.; Li, S.P.; Liu, S.Y. Influence of pH on the thixotropy of magnesium aluminum hydroxide-kaolinite suspension. Sci. China Ser. B-Chem. 2001, 44, 641–649. [Google Scholar] [CrossRef]

- Dai, X.N.; Hou, W.G.; Li, S.P.; Wang, X.F. Studies on the thixotropy of magnesium aluminum hydroxide-Kaolinite suspension. Chem. J. Chin. Univ.-Chin. 2001, 22, 1578–1580. [Google Scholar]

- Tang, B.; Zhou, B.; Xie, L.; Yin, J. Evaluation Method for Thixotropy of Clay Subjected to Unconfined Compressive Test. Front. Earth Sci. 2021, 9, 683454. [Google Scholar] [CrossRef]

- Li, S.P.; Hou, W.G.; Dai, X.N.; Hu, J.F.; Li, D.Q. The influence of pH on the thixotropy of ferric aluminum magnesium hydroxide/montmorillonite suspension. Chem. J. Chin. Univ.-Chin. 2002, 23, 1763–1766. [Google Scholar]

- Li, S.-P.; Hou, W.-G.; Zhao, W.-A.; Duan, H.-D. The influence of shear rate and rest time on the thixotropy of the complex thixotropic suspension of Fe-Al-Mg-MMH/montmorillonite. J. Indian Chem. Soc. 2003, 80, 160–162. [Google Scholar]

- Hou, W.G.; Su, Y.L.; Sun, D.J.; Zhang, C.G. Study on the thixotropy of magnesium ferric hydroxide—Montmorillonite suspension. Acta Chim. Sin. 2000, 58, 722–726. [Google Scholar]

- Abdou, M.I.; Ahmed, H.E.-S. A Study on the Thixotropy of Egyptian Bentonite Suspensions. Pet. Sci. Technol. 2013, 31, 1980–1991. [Google Scholar] [CrossRef]

- Cheng, D.C.H. Characterisation of thixotropy revisited. Rheol. Acta 2003, 42, 372–382. [Google Scholar] [CrossRef]

- Li, L.; Wang, L.; Wang, J.; Wang, D. Influence of Mg-Fe-HTlc on Xanthan Gum Rheological Properties. Acta Chim. Sin. 2011, 69, 1760–1764. [Google Scholar]

- Wang, Y.; Ewoldt, R.H. Distinguishing thixotropy, anti-thixotropy, and viscoelasticity using hysteresis. arXiv 2022, arXiv:2212.07572. [Google Scholar]

- Wang, Y.; Ewoldt, R.H. New insights on carbon black suspension rheology—Anisotropic thixotropy and anti-thixotropy. arXiv 2022, arXiv:2202.05772. [Google Scholar]

- Perraton, D.; Baaj, H.; Di Benedetto, H.; Paradis, M. Evaluation of the fatigue strength of bituminous asphalts based on the evolution of material damage during a test—Fundamental aspects and application to stone matrix asphalts. Can. J. Civ. Eng. 2003, 30, 902–913. [Google Scholar] [CrossRef]

- Kim, Y.S.; Sigwarth, T.; Buechner, J.; Wistuba, M.P. Accelerated Dynamic Shear Rheometer Fatigue Test for investigating asphalt mastic. Road Mater. Pavement 2021, 22, S383–S396. [Google Scholar] [CrossRef]

- Soltani, A.; Anderson, D.A. New test protocol to measure fatigue damage in asphalt mixtures. Road Mater. Pavement 2005, 6, 485–514. [Google Scholar] [CrossRef]

- Mouillet, V.; De la Roche, C.; Chailleux, E.; Coussot, P. Thixotropic Behavior of Paving-Grade Bitumens under Dynamic Shear. J. Mater. Civ. Eng. 2012, 24, 23–31. [Google Scholar] [CrossRef]

- Ma, X.; Wang, Y.; Hou, J.; Sheng, Y.; Zheng, W.; Wu, S. Study on Thixotropic Properties of Asphalt Mastics Based on Energy Viewpoint. Coatings 2023, 13, 650. [Google Scholar] [CrossRef]

- Hassan, M.M. Thixotropic Properties of Mastics Incorporates Secondary Filler. In Airfield and Highway Pavement 2013: Sustainable and Efficient Pavements, Proceedings of the 2013 Airfield and Highway Pavement Conference, Los Angeles, CA, USA, 9–12 June 2013; Al-Qadi, I.L., Murrell, S., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 913–920. [Google Scholar]

- Shan, L.; Tan, Y.; Underwood, B.S.; Kim, Y.R. Thixotropic Characteristics of Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1681–1686. [Google Scholar] [CrossRef]

- Hung, S.; Elkashef, M.; Harvey, J.; Wu, R.; Jones, D. Effect of Different Loading Conditions on the Fatigue Response and Recovery of Neat and Modified Asphalt Binders. J. Test. Eval. 2022, 50, 1364–1376. [Google Scholar] [CrossRef]

- Abo-Shanab, Z.L.; Ragab, A.A.; Naguib, H.M. Improved dynamic mechanical properties of sustainable bio-modified asphalt using agriculture waste. Int. J. Pavement Eng. 2021, 22, 905–911. [Google Scholar] [CrossRef]

- Perez-Jimenez, F.E.; Botella, R.; Miro, R. Differentiating between damage and thixotropy in asphalt binder’s fatigue tests. Constr. Build. Mater. 2012, 31, 212–219. [Google Scholar] [CrossRef]

- Perez-Jimenez, F.E.; Botella, R.; Miro, R.; Martinez, A.H. Analysis of the thixotropic behavior and the deterioration process of bitumen in fatigue tests. Constr. Build. Mater. 2015, 101, 277–286. [Google Scholar] [CrossRef]

- Dullaert, K.; Mewis, J. A model system for thixotropy studies. Rheol. Acta 2005, 45, 23–32. [Google Scholar] [CrossRef]

- Huang, F.Y.; Lv, J.S.; Li, H.; Xu, S.Y. Regulation rule of cellulose nanocrystals on thixotropy of hydrogel for water shutoff in horizontal wells. Colloids Surf. A-Physicochem. Eng. Asp. 2022, 643, 128735. [Google Scholar] [CrossRef]

- Shakeel, A.; Zander, F.; de Klerk, J.W.; Kirichek, A.; Gebert, J.; Chassagne, C. Effect of organic matter degradation in cohesive sediment: A detailed rheological analysis. J. Soils Sediments 2022, 22, 2883–2892. [Google Scholar] [CrossRef]

- Yilmaz, M.T.; Vatansever, C. Three interval thixotropy test to determine structural regeneration of a glucomannan based hydrocolloid film at air/water interface: Interfacial, molecular, thermal and surface characterization. Food Hydrocoll. 2016, 61, 458–468. [Google Scholar] [CrossRef]

- Maestro, A.; Gonzalez, C.; Gutierrez, J.M. Shear thinning and thixotropy of HMHEC and HEC water solutions. J. Rheol. 2002, 46, 1445–1457. [Google Scholar] [CrossRef]

- Baldewa, B.; Joshi, Y.M. Thixotropy and Physical Aging in Acrylic Emulsion Paint. Polym. Eng. Sci. 2011, 51, 2085–2092. [Google Scholar] [CrossRef]

- Chen, J.-H.; Zou, G.-L.; Zhang, X.-N.; Zhang, S.-X.; Nie, W.; Wan, T.-T. Study on the Thixotropic Properties of Mastic Asphalt. In Proceedings of the International Conference on Materials, Transportation and Environmental Engineering (CMTEE 2013), Taichung, Taiwan, 21–23 August 2013; pp. 356–362. [Google Scholar]

- Labanda, J.; Llorens, J. A structural model for thixotropy of colloidal dispersions. Rheol. Acta 2006, 45, 305–314. [Google Scholar] [CrossRef]

- Quemada, D. Rheological modelling of complex fluids: IV: Thixotropic and “thixoelastic” behaviour. Start-up and stress relaxation, creep tests and hysteresis cycles. Eur. Phys. J.-Appl. Phys. 1999, 5, 191–207. [Google Scholar] [CrossRef]

- Dullaert, K.; Mewis, J. A structural kinetics model for thixotropy. J. Non-Newton. Fluid Mech. 2006, 139, 21–30. [Google Scholar] [CrossRef]

- Huang, S.X.; Lu, C.J.; Qin, N.; Huang, X. Descriptions on the thixotropy-loop tests by the simplified Mewis-Denn model. In Proceedings of the 15th International Congress on Rheology/80th Annual Meeting of the Society-of-Rheology, Monterey, CA, USA, 3–8 August 2008; pp. 464–466. [Google Scholar]

- Zyla, G.; Witek, A.; Gizowska, M. Rheological profile of boron nitride-ethylene glycol nanofluids. J. Appl. Phys. 2015, 117, 014302. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).