Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting

Abstract

:1. Introduction

2. Methodology and Experimental Tests

2.1. Materials and Preparation of Specimens

2.2. MR Test

2.3. ITS Test

2.4. WTT

3. Results and Discussion

3.1. Results of Binder Test

3.2. Results of ITS Test

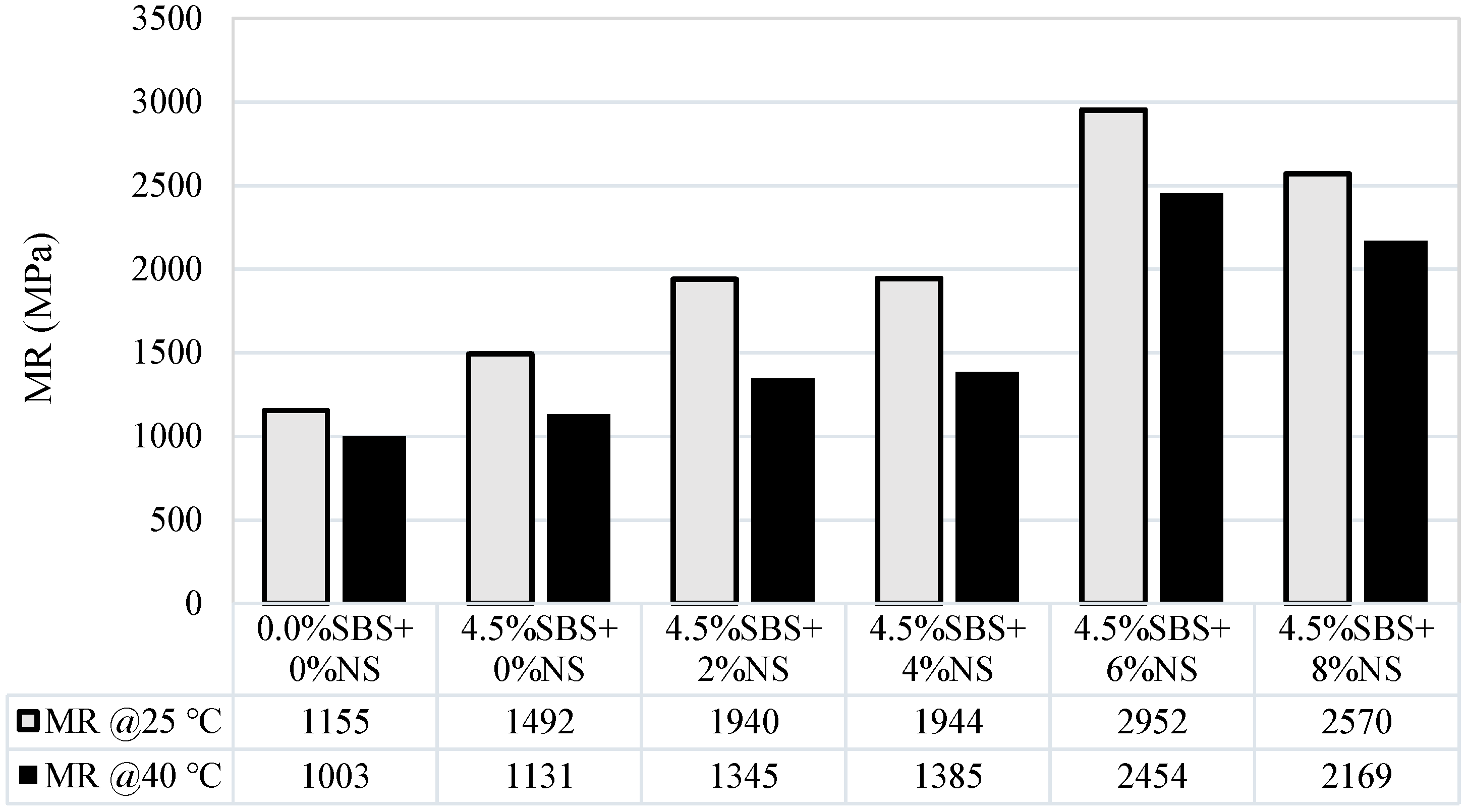

3.3. Results of MR Test

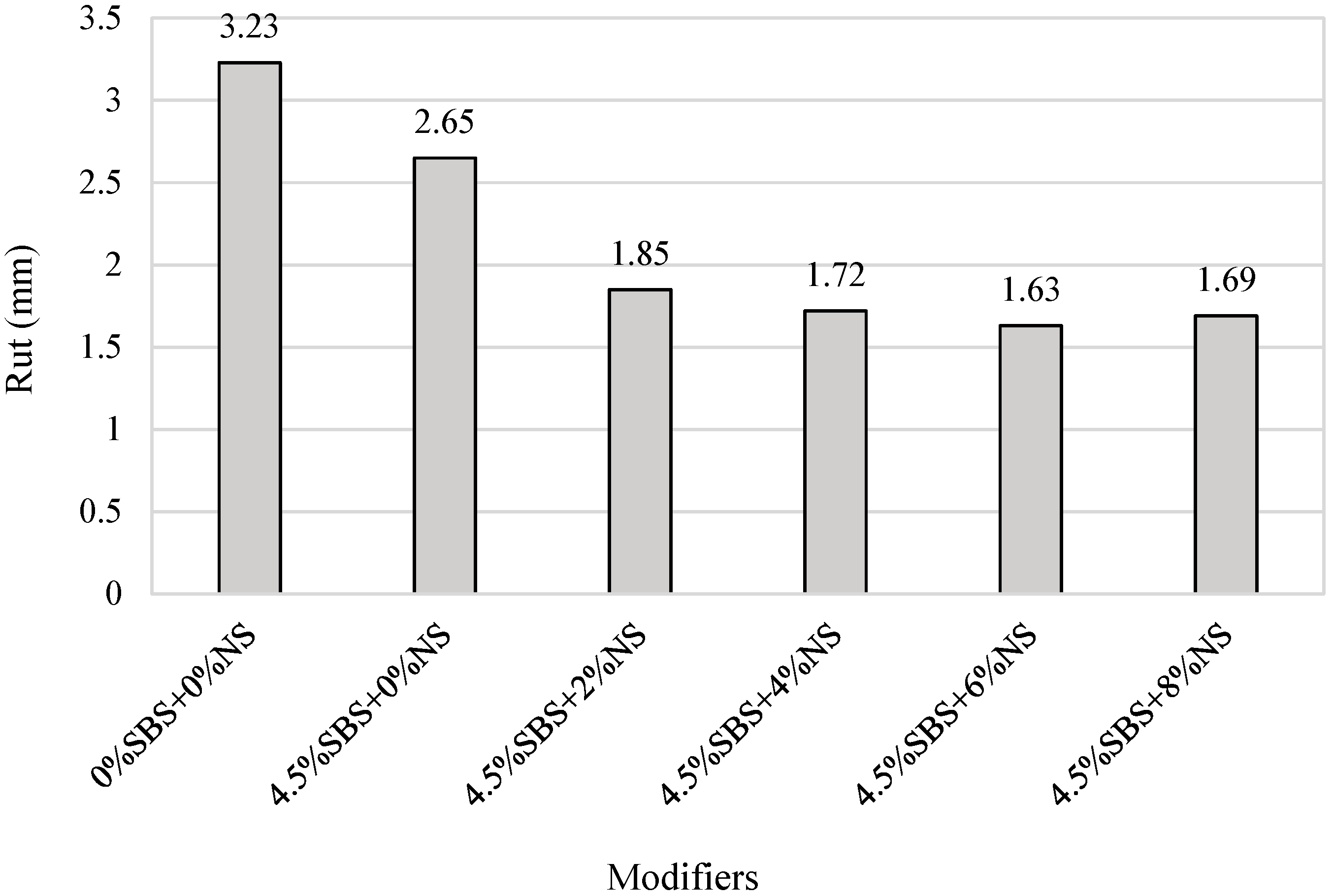

3.4. Results of WTT

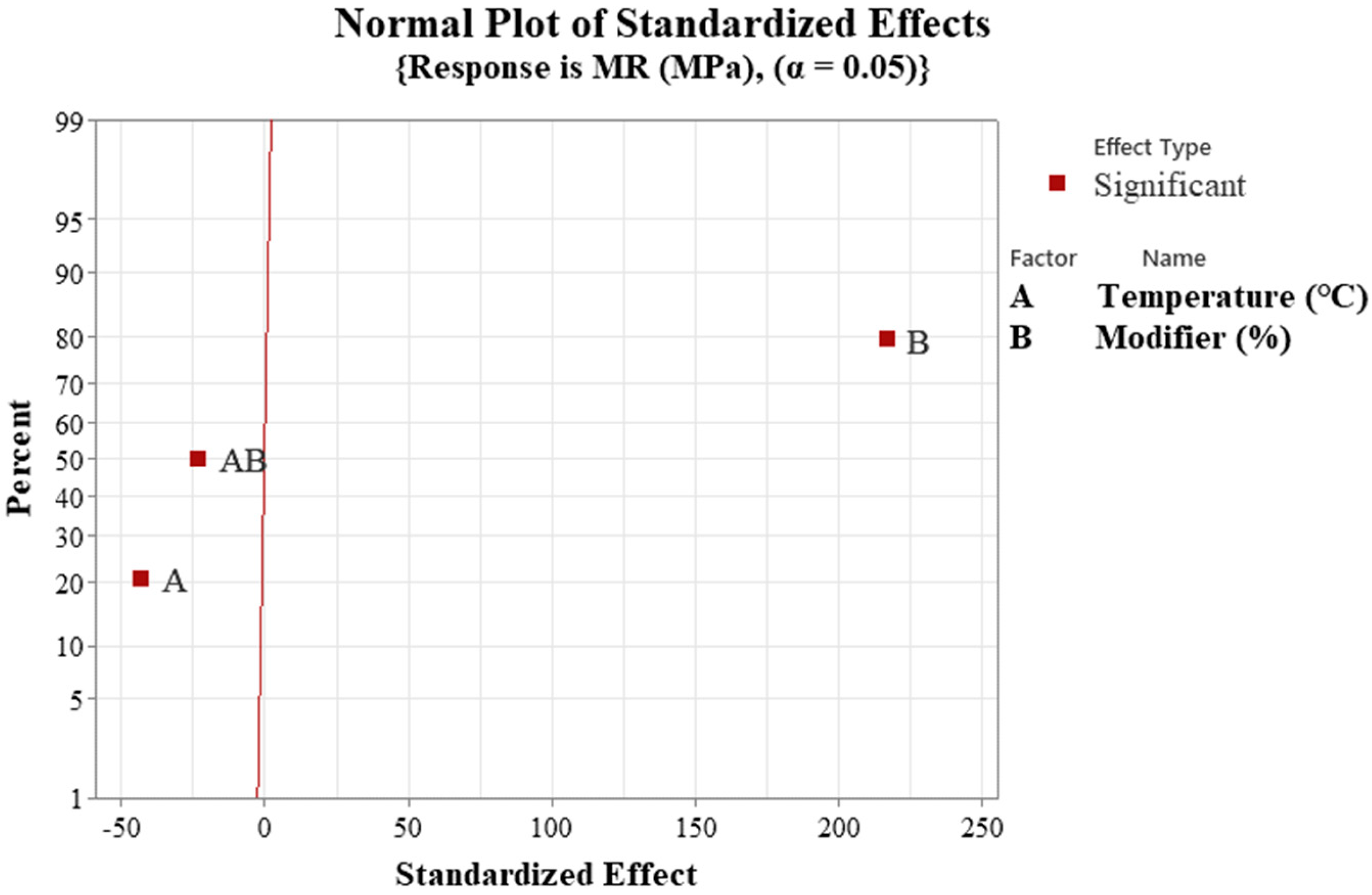

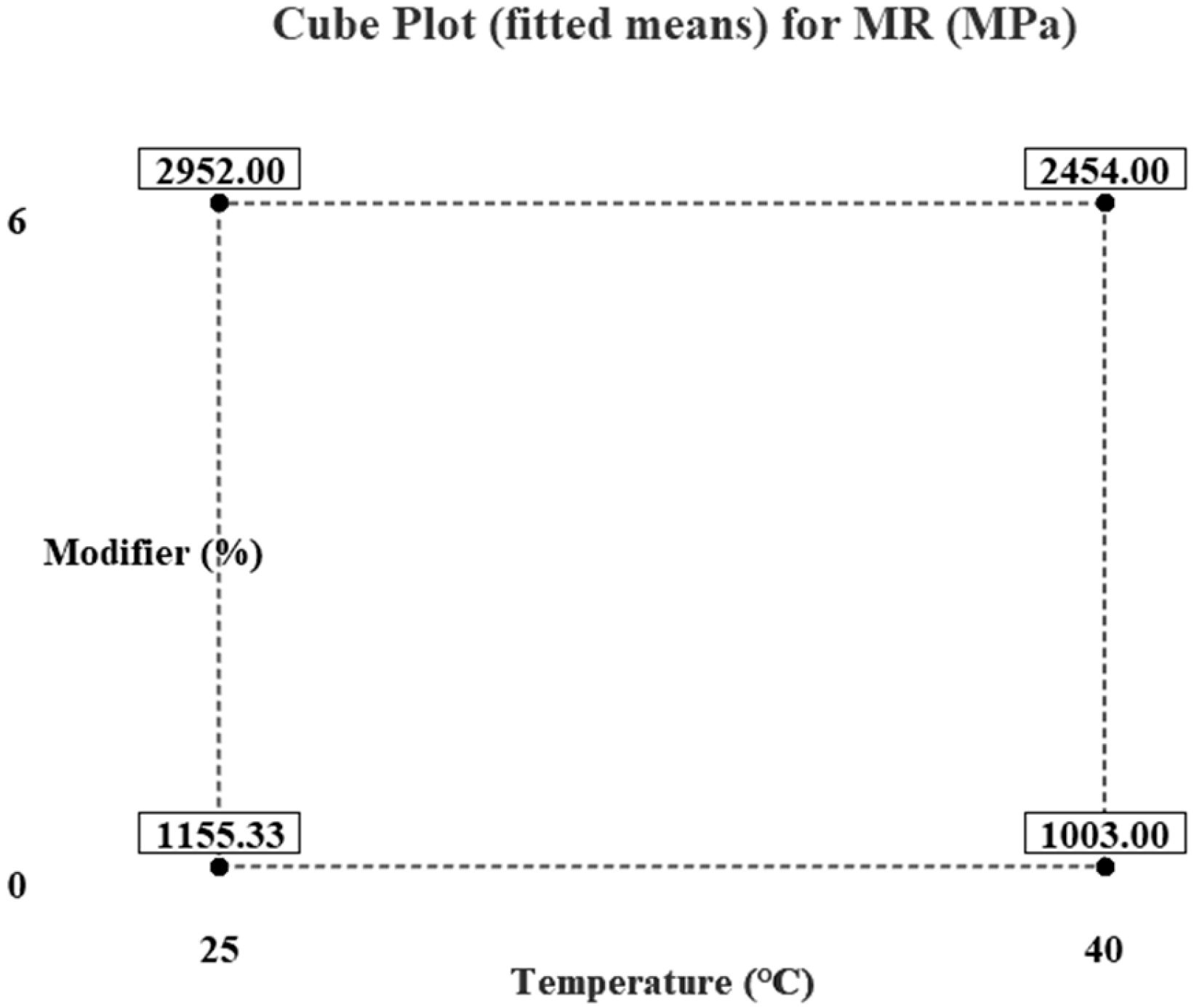

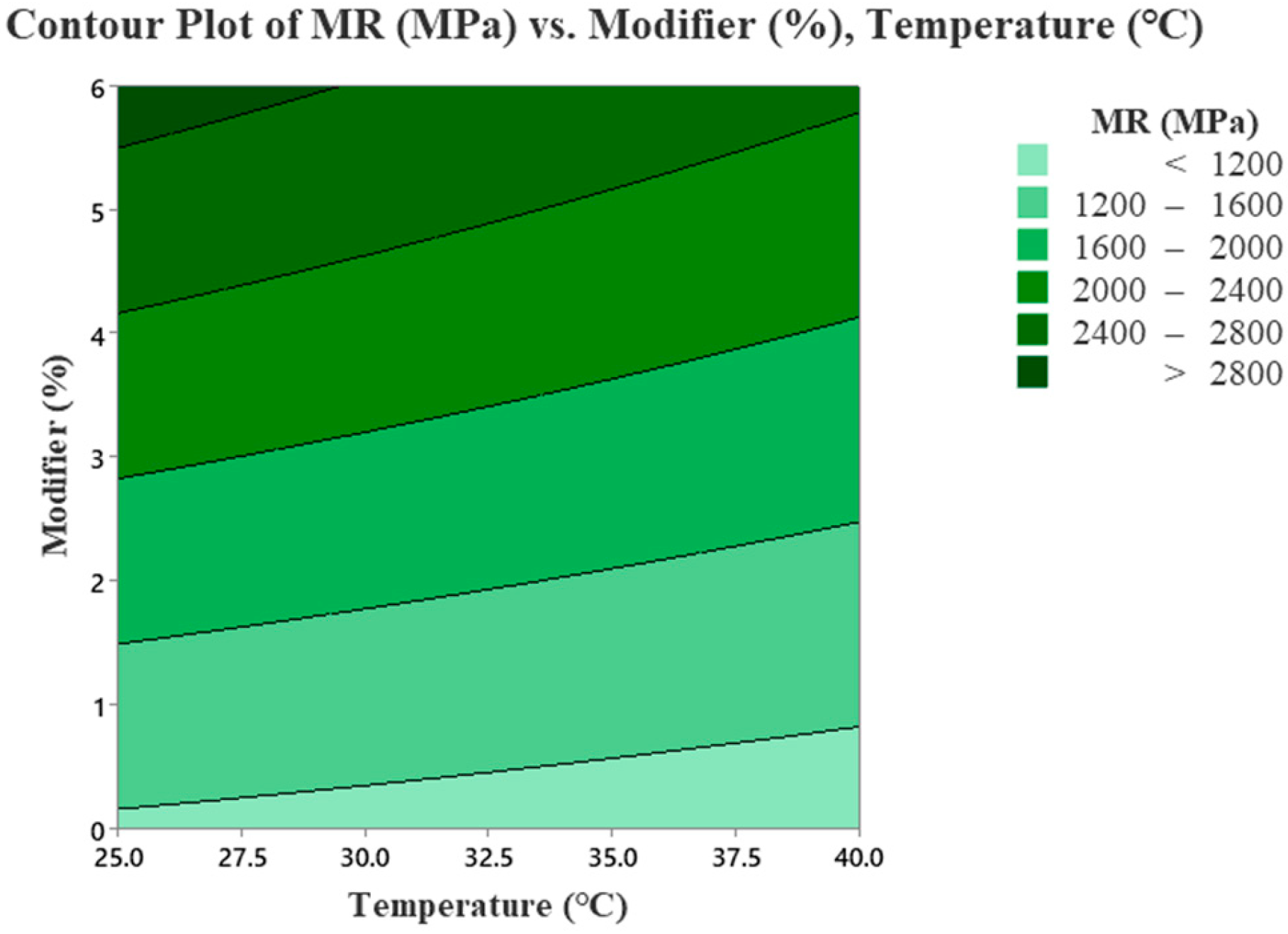

3.5. Experimental Design of MR

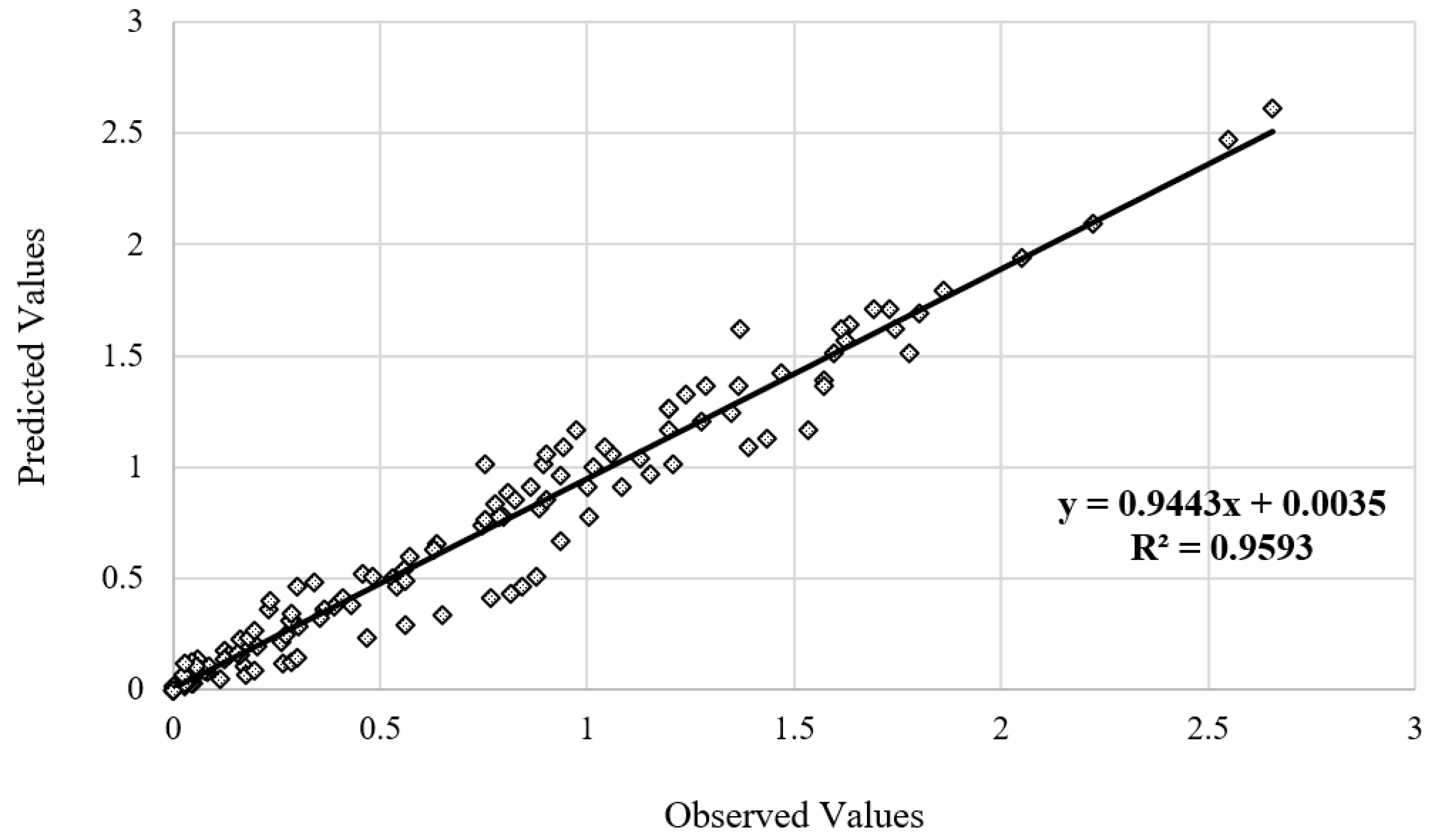

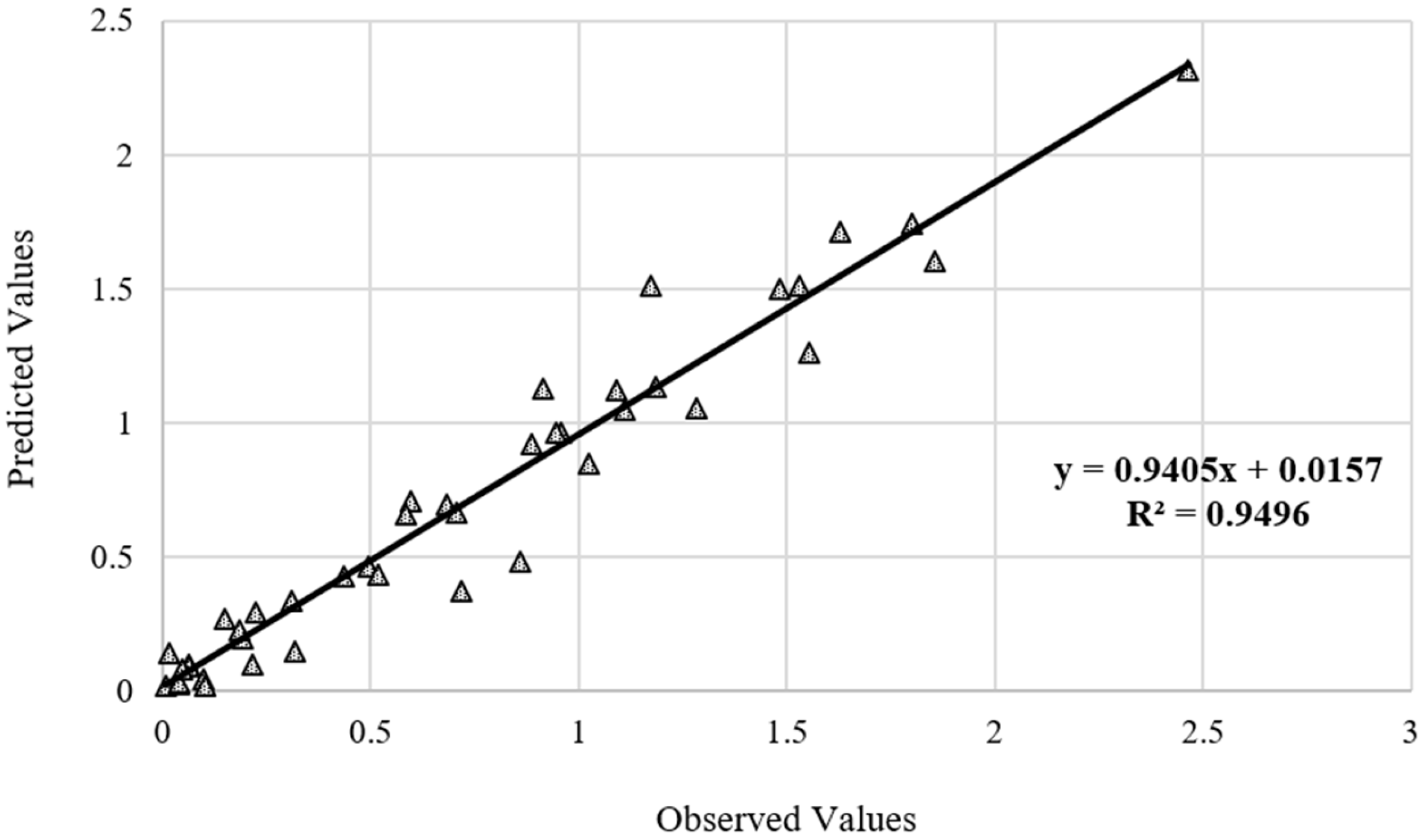

3.6. MEP

4. Conclusions

- The results showed that the SBS- and NS-modified specimens exhibited enhanced performance against the permanent deformation. The rut resistance was improved by 56% in the modified specimens as compared to the control specimen.

- The SBS- and NS-modified specimens had a higher rate of ITS compared to the control specimen. The results concluded that the use of NS along with SBS had significant effects on the moisture resistance, increasing it by 18%.

- The rise in the percentage of NS against SBS demonstrated a good increase in the stiffness modulus compared to the control specimen. MR had higher values at low temperatures while displaying lower values at higher temperatures. The maximum improvement in the modified HMA specimens was recorded at 1.55 times that of the control specimen.

- The importance of the modifier materials was examined via a two-way factorial design, which verified the experimental outcomes. The results uncovered the significance of the input variables, i.e., modifiers and variables, on the response variable (MR).

- To verify the performance of the MEP model for the rutting potential of the modified specimens, the projected values and experimental values were compared. After the regression analysis, the result revealed a good relation/connection with the experimental results. The optimum combination of SBS and NS was declared at 4.5% and 6%, respectively.

- This study can be applied to real-world road projects to improve the rut resistance of pavements and reduce the maintenance and rehabilitation of asphalt pavements, thus improving the life span of roads. Further improvement in this field can be achieved by carrying out the microstructure analysis of the NS- and SBS-modified asphalt specimens and their performance-based studies, especially at low temperatures. In addition, chemical and rheological testing are also recommended.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghanoon, S.A.; Tanzadeh, J.; Mirsepahi, M. Laboratory evaluation of the composition of nano-clay, nano-lime and SBS modifiers on rutting resistance of asphalt binder. Constr. Build. Mater. 2020, 238, 117592. [Google Scholar] [CrossRef]

- Ahmed, T.A.H. Investigating the Rutting and Moisture Sensitivity of Warm Mix Asphalt with Varying Contents of Recycled Asphalt Pavement. Ph.D. Thesis, The University of Iowa, Iowa City, IA, USA, 2014. [Google Scholar]

- Zhu, T.; Ma, T.; Huang, X.; Wang, S. Evaluating the rutting resistance of asphalt mixtures using a simplified triaxial repeated load test. Constr. Build. Mater. 2016, 116, 72–78. [Google Scholar] [CrossRef]

- Binder, L.; Wax, C.; Oil, C.; Ho, T.; Le, M. Feasibility and sustainable performance of RAP mixtures with low-viscosity binder and castor wax-corn oil rejuvenators. Buildings 2023, 13, 1578. [Google Scholar]

- Cristescu, N.D.; Craciun, E.; Soós, E.; Crc, H. Mechanics of Elastic Composite; Chapman & Hall/CRC: Boca Raton, FL, USA, 2003. [Google Scholar]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Rajabi, M. The fatigue behavior of SBS/nanosilica composite modified asphalt binder and mixture. Constr. Build. Mater. 2019, 229, 116796. [Google Scholar] [CrossRef]

- Izzi, N.; Abozed, A.; Breem, S.; Alattug, H.N.M.; Hamim, A.; Ahmad, J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- Sohel, S.; Singh, S.K.; Ransinchung, G.D.R.N.; Ravindranath, S.S. Effect of property deterioration in SBS modified binders during storage on the performance of asphalt mix. Constr. Build. Mater. 2020, 272, 121644. [Google Scholar] [CrossRef]

- Bala, N.; Napiah, M.; Kamaruddin, I. Effect of nanosilica particles on polypropylene polymer modified asphalt mixture performance. Case Stud. Constr. Mater. 2018, 8, 447–454. [Google Scholar] [CrossRef]

- Xia, T.; Chen, X.; Xu, J.; Li, Y.; Zhang, A. Influence of hydrophilic nanosilica premixing method on the property of isocyanate-based polymer modified bitumen. Constr. Build. Mater. 2021, 275, 122174. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. Use of nanomaterial for asphalt binder and mixtures: A comprehensive review on development, prospect, and challenges. Road Mater. Pavement Des. 2021, 22, 492–538. [Google Scholar] [CrossRef]

- Izzi, N.; Ibrahim, D.; Nazrul, A.; Ibrahim, H.; Atmaja, S.; Rosyidi, P.; Abdul, N. Engineering characteristics of nanosilica/polymer-modified bitumen and predicting their rheological properties using multilayer perceptron neural network model. Constr. Build. Mater. 2019, 204, 781–799. [Google Scholar] [CrossRef]

- Zarei, M.; Salehikalam, A.; Tabasi, E.; Naseri, A.; Worya, M. Pure mode I fracture resistance of hot mix asphalt (HMA) containing nano-SiO2 under freeze—thaw damage (FTD). Constr. Build. Mater. 2022, 351, 128757. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Performance of PET and nano-silica modified stone mastic asphalt mixtures. Case Stud. Constr. Mater. 2022, 16, e01044. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A. Characteristics of asphalt binder and mixture containing nanosilica. Int. J. Pavement Res. Technol. 2017, 10, 148–157. [Google Scholar] [CrossRef]

- Miguel, J.; Crucho, L.; Manuel, J.; Dias, S. Mechanical performance of asphalt concrete modified with nanoparticles: Nanosilica, zero-valent iron and nanoclay. Constr. Build. Mater. 2018, 181, 309–318. [Google Scholar] [CrossRef]

- ASTM D2726/D2726M-17; Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt Mixtures 1. ASTM International: West Conshohocken, PA, USA, 2021; pp. 7–10.

- Saltan, M.; Terzi, S.; Karahancer, S. Examination of hot mix asphalt and binder performance modified with nano silica. Constr. Build. Mater. 2017, 156, 976–984. [Google Scholar] [CrossRef]

- Yang, J.; Tighe, S. A review of advances of nanotechnology in asphalt mixtures. Procedia-Soc. Behav. Sci. 2013, 96, 1269–1276. [Google Scholar] [CrossRef]

- AS 2891; Methods of Sampling and Testing Asphalt—Methods 13.1: Determination of Resilient Modulus of Asphalt—Indirect Tensile Method. Standards Australia: Sydny, Autralia, 1995.

- D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- Drews, A. D5-95; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 1998; pp. 47–49.

- D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2009.

- Taherkhani, H.; Afroozi, S. The properties of nanosilica-modified asphalt cement. Pet. Sci. Technol. 2018, 34, 1381–1386. [Google Scholar] [CrossRef]

- D6926; Practice for Preparation of Bituminous Specimens Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 2010.

- Nguyen, H.P.; Cheng, P.; Nguyen, T.T. Properties of stone matrix asphalt modified with polyvinyl chloride and nano silica. Polymers 2021, 13, 2358. [Google Scholar] [CrossRef]

- Obaid, H.A. Characteristics of warm mixed asphalt modified by waste polymer and nano-silica. Int. J. Pavement Res. Technol. 2021, 14, 397–401. [Google Scholar] [CrossRef]

- Szydlo, A.; Mackiewicz, P. Asphalt mixes deformation sensitivity to change in rheological parameters. J. Mater. Civ. Eng. 2005, 17, 1–9. [Google Scholar] [CrossRef]

- Szydlo, A.; Mackiewicz, P. Verification of bituminous mixtures’ rheological parameters through rutting test. Road Mater. Pavement Des. 2002, 4, 423–438. [Google Scholar] [CrossRef]

- Sun, L.; Xin, X.; Ren, J. Asphalt modification using nano-materials and polymers composite considering high and low temperature performance. Constr. Build. Mater. 2017, 133, 358–366. [Google Scholar] [CrossRef]

- Montgomery, D.C. Experimental design for product and process design and development. J. R. Stat. Soc. Ser. D Stat. 1999, 48, 159–177. [Google Scholar] [CrossRef]

- Mee, R. A Comprehensive Guide to Factorial Two-Level Experimentation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Broota, K.D. Experimental Design in Behavioural Research; New Age International: Dhaka, Bangladesh, 1989. [Google Scholar]

- Zahid, A.; Ahmed, S.; Irfan, M. Experimental investigation of nano materials applicability in Hot Mix Asphalt (HMA). Constr. Build. Mater. 2022, 350, 128882. [Google Scholar] [CrossRef]

| Test Description | Result | Specification | Standard |

|---|---|---|---|

| Penetration test @ 25 °C (mm) | 66 | 60–70 | ASTM 5 |

| Flash point test (°C) | 254 | 232 (Min) | ASTM D 92 |

| Fire point test (°C) | 300 | 270 (Min) | ASTM D 92 |

| Specific gravity test | 1.03 | 1.01–1.06 | ASTM D 70 |

| Softening point test (°C) | 50.4 | 49–56 | ASTM D 36-06 |

| Ductility test (cm) | 107 | 100 (Min) | ASTM D113-99 |

| Sieve Size | 19 | 12.5 | 9.5 | 4.75 | 2.38 | 1.18 | 0.075 | Pan |

|---|---|---|---|---|---|---|---|---|

| NHA-B specification | 100 | 75–90 | 60–80 | 40–60 | 20–40 | 5–15 | 3–8 | - |

| Our selection | 100 | 82.5 | 70 | 50 | 30 | 10 | 5.5 | - |

| Type of Test | Results (%) | Specification | Standard | |

|---|---|---|---|---|

| Fractured particles | 99 | 90% (Min) | ASTM D-5821 | |

| Los Angeles abrasion | 20.3 | 30% (Max) | ASTM C-131 | |

| Flakiness of aggregates | 4.8 | 10% (Max) | ASTM D-4791 | |

| Elongation index of aggregates | 4.7 | 10% (Max) | ASTM D-4791 | |

| Impact value of aggregates | 16.23 | 30% (Max) | BS-812 | |

| Crushing value of aggregates | 18.52 | 30% (Max) | BS-812 | |

| Water absorption | Fine aggregates | 2.53 | 3% (Max) | ASTM C-128 |

| Coarse aggregates | 0.80 | 3% (Max) | ASTM C-127 | |

| Specific gravity | Fine aggregates | 2.626 | - | ASTM C-128 |

| Coarse aggregates | 2.633 | - | ASTM C-127 | |

| Clay percentage | Coarse aggregates | 0.565 | - | ASTM C-142 |

| Fine aggregates | 2.815 | - | ASTM C-142 | |

| Description | Property |

|---|---|

| SBS type | SBS YH-791H |

| Structure | Linear |

| Purity | >95% |

| Appearance | White granules |

| Brand name | TY |

| Viscosity of 5% styrene solution at 25 °C | 2.24 Pa·s |

| S/B | 30%/70% |

| Tensile strength | 20 MPa |

| Hardness | ~76 A |

| Name | Unit | Result |

|---|---|---|

| Chemical formula | - | SiO2 |

| Microstructure shape | - | Spherical |

| SiO2 (dry basis) | % | >98 |

| Specific surface area | m2/gm | 580 |

| Average pore diameter | nm | 7 |

| Original particle size | nm | 14–36 |

| Grain size distribution | nm | <120 |

| Bulk density | gm/cm3 | 0.1–0.15 |

| Tamping density | gm/cm3 | 0.2–0.30 |

| Temperature resistance | °C | 1350 |

| pH | - | 6–7 |

| MEP Hyperparameter | Modified HMA |

|---|---|

| Number of subpopulations | 10 |

| Subpopulation size | 100 |

| Code length | 50 |

| Crossover probability | 0.9 |

| Mutation probability | 0.01 |

| Crossover type | Uniform |

| Number of generations | 1000 |

| Total runs | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, I.; Khattak, A.W.; Bahrami, A.; Khattak, S.; Ejaz, A. Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting. Buildings 2023, 13, 2352. https://doi.org/10.3390/buildings13092352

Khan I, Khattak AW, Bahrami A, Khattak S, Ejaz A. Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting. Buildings. 2023; 13(9):2352. https://doi.org/10.3390/buildings13092352

Chicago/Turabian StyleKhan, Inamullah, Abdul Wahab Khattak, Alireza Bahrami, Shahab Khattak, and Ali Ejaz. 2023. "Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting" Buildings 13, no. 9: 2352. https://doi.org/10.3390/buildings13092352

APA StyleKhan, I., Khattak, A. W., Bahrami, A., Khattak, S., & Ejaz, A. (2023). Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting. Buildings, 13(9), 2352. https://doi.org/10.3390/buildings13092352