Evaluation of Safety Management of Smart Construction Sites from the Perspective of Resilience

Abstract

:1. Introduction

2. Literature Review

2.1. Smart Construction Site Safety Management

2.2. Feasibility of Safety Management Research Based on Perspective of Resilience

2.3. Research Gap

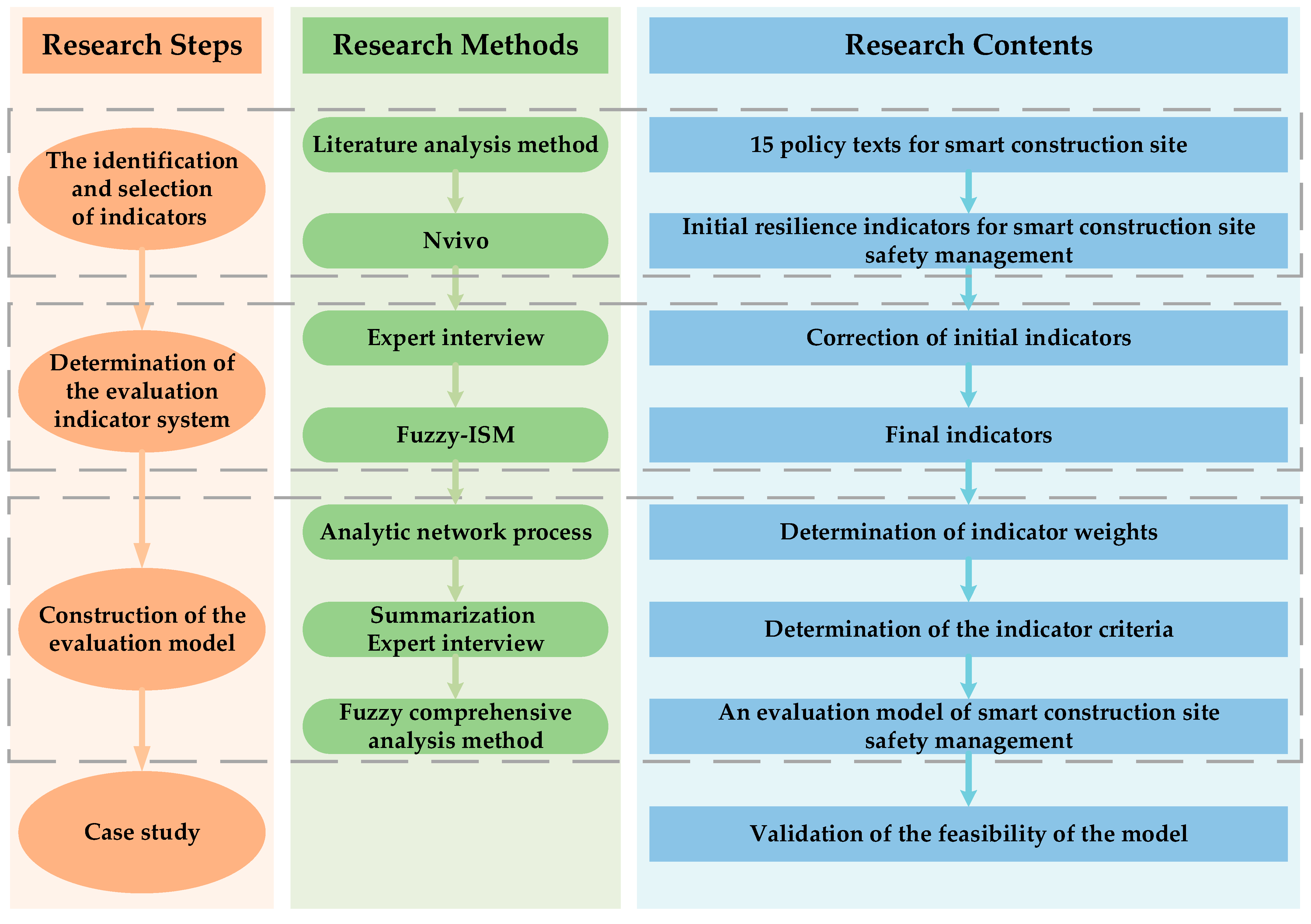

3. Methods

4. Model Development

4.1. Identification and Selection of Indicators

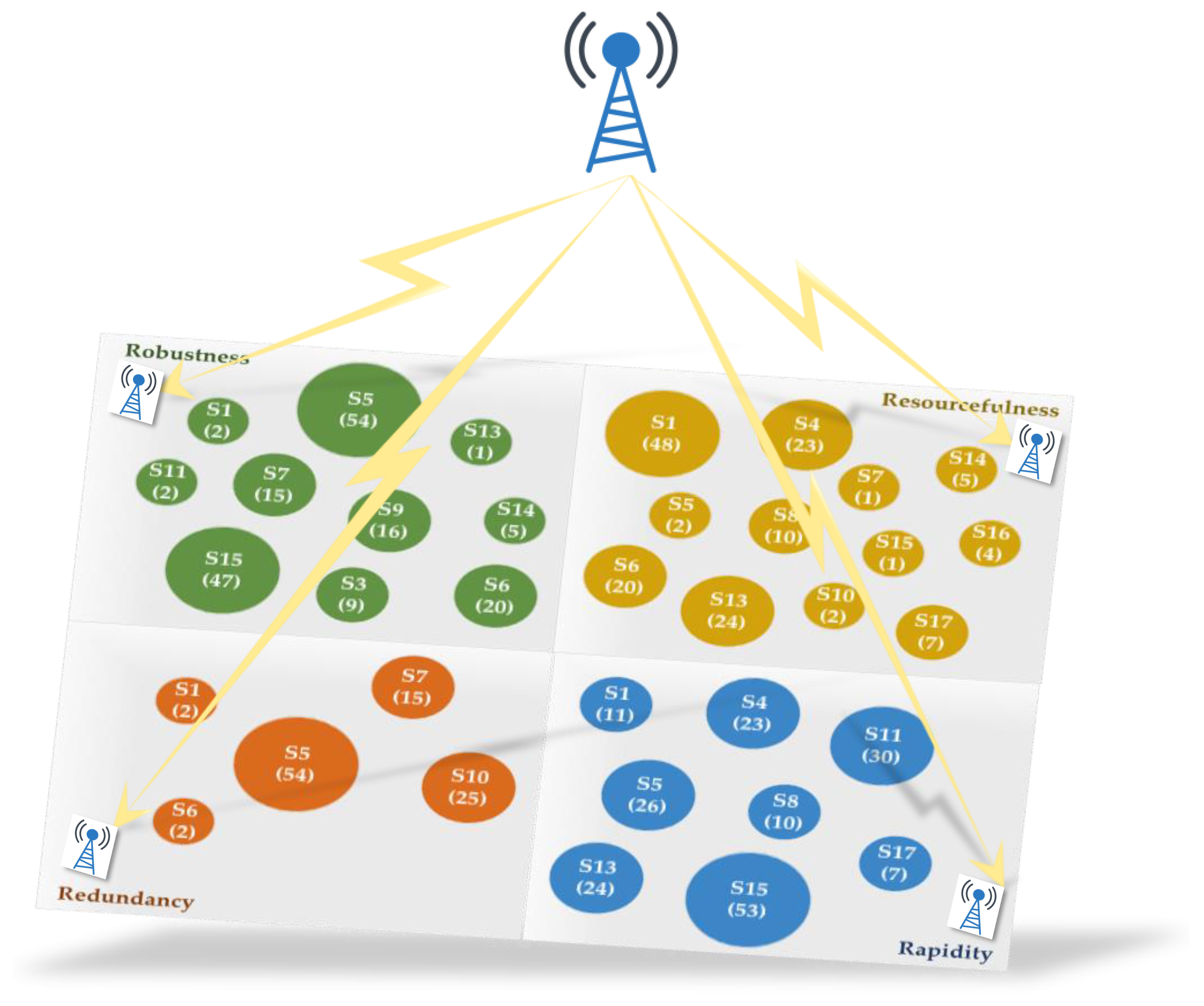

4.1.1. Based on the 4R Resilience Characteristics

4.1.2. Based on the 4M Theory

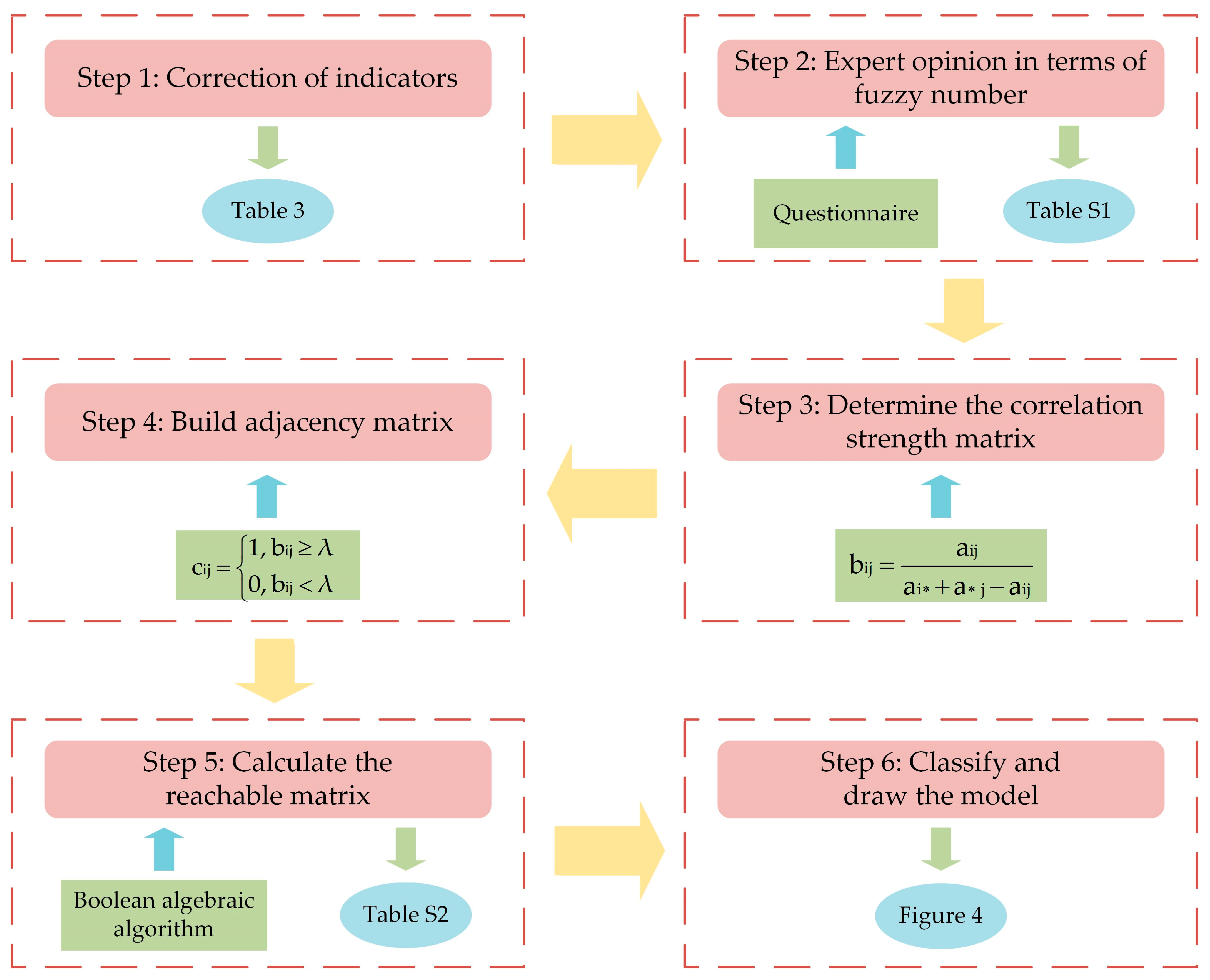

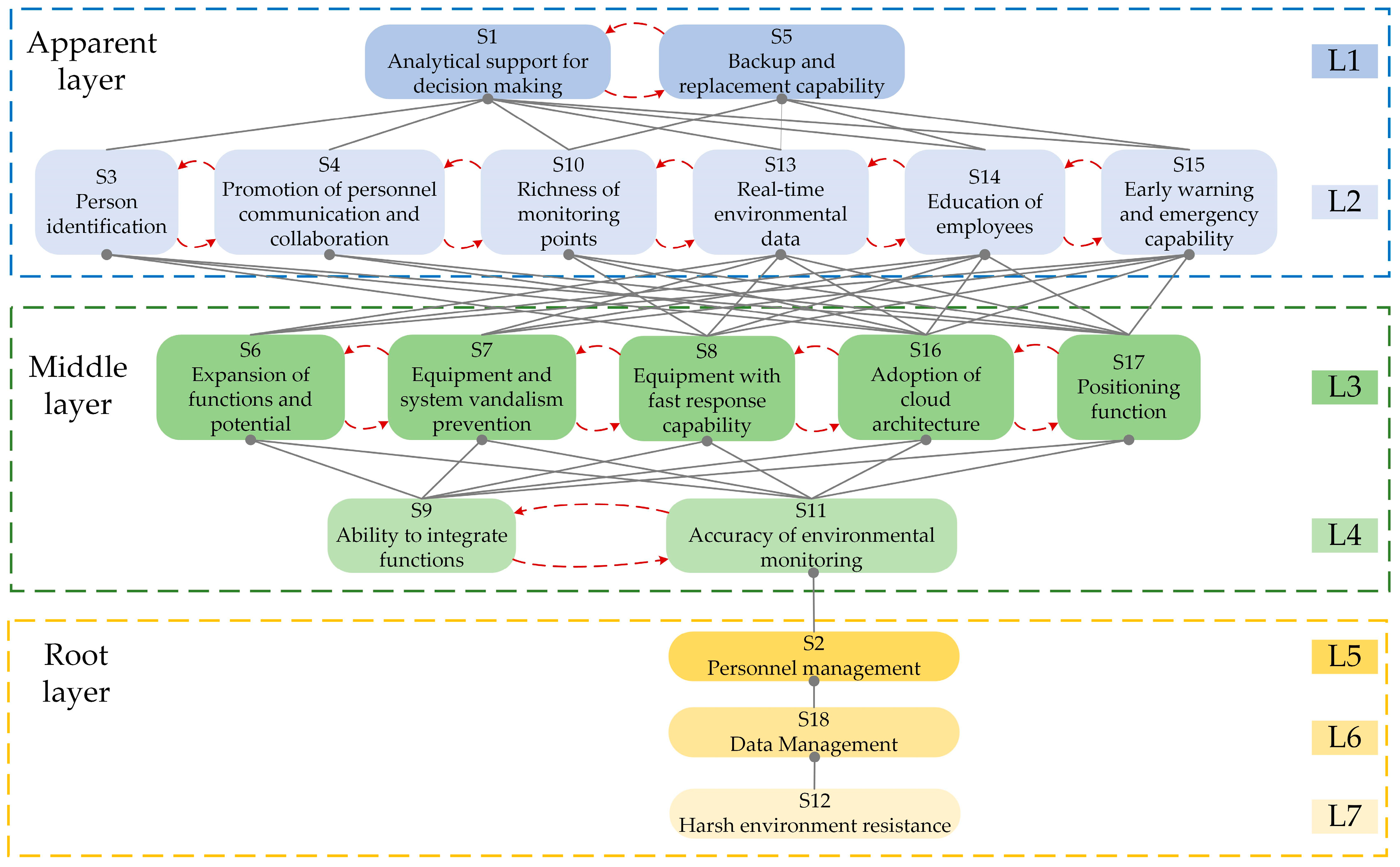

4.2. Construction of the Evaluation Indicator System

4.3. Construction of the Evaluation Model

4.3.1. Determination of Weights

4.3.2. Determination of the Evaluation Criteria

4.3.3. Model Construction

5. Case Study

5.1. Case Overview

5.1.1. Man

5.1.2. Machine

5.1.3. Media

5.1.4. Management

5.2. Evaluation Process

6. Discussion

6.1. Man

6.2. Machine

6.3. Media

6.4. Management

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mocák, P.; Matlovičová, K.; Matlovic, R.; Pénzes, J.; Pachura, P.; Mishra, P.; Kostilníková, K.; Demková, M. 15-Minute City Concept as a Sustainable Urban Development Alternative: A Brief Outline of Conceptual Frameworks and Slovak Cities as a Case. Folia Geogr. 2022, 64, 69–89. [Google Scholar]

- Soltanmohammadlou, N.; Sadeghi, S.; Hon, C.K.H.; Mokhtarpour-Khanghah, F. Real-time locating systems and safety in construction sites: A literature review. Saf. Sci. 2019, 117, 229–242. [Google Scholar] [CrossRef]

- Li, X.; Liao, F.; Wang, C.; Alashwal, A. Managing Safety Hazards in Metro Subway Projects under Complex Environmental Conditions. J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2022, 8, 04021079. [Google Scholar] [CrossRef]

- Carter, G.; Smith, S.D. Safety hazard identification on construction projects. J. Constr. Eng. Manag. 2006, 132, 197–205. [Google Scholar] [CrossRef]

- Xiahou, X.; Wu, Y.; Duan, T.; Lin, P.; Li, F.; Qu, X.; Liu, L.; Li, Q.; Liu, J. Analyzing Critical Factors for the Smart Construction Site Development: A DEMATEL-ISM Based Approach. Buildings 2022, 12, 116. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Kameshwar, S.; Cox, D.T.; Barbosa, A.R.; Farokhnia, K.; Park, H.; Alam, M.S.; van de Lindt, J.W. Probabilistic decision-support framework for community resilience: Incorporating multi-hazards, infrastructure interdependencies, and resilience goals in a Bayesian network. Reliab. Eng. Syst. Saf. 2019, 191, 106568. [Google Scholar] [CrossRef]

- Brunetta, G.; Ceravolo, R.; Barbieri, C.A.; Borghini, A.; de Carlo, F.; Mela, A.; Beltramo, S.; Longhi, A.; De Lucia, G.; Ferraris, S.; et al. Territorial Resilience: Toward a Proactive Meaning for Spatial Planning. Sustainability 2019, 11, 2286. [Google Scholar] [CrossRef]

- Neumannová, M. Smart Districts: New Phenomenon in Sustainable Urban Development. Case Study of Špitálka in Brno, Czech Republic. Folia Geogr. 2022, 64, 27–48. [Google Scholar]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Delgado, J.M.D.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in construction industry: Use cases, benefits and challenges. Autom. Constr. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Štefanič, M.; Stankovski, V. A review of technologies and applications for smart construction. Proc. Inst. Civ. Eng. Civ. Eng. 2019, 172, 83–87. [Google Scholar] [CrossRef]

- Rey, R.O.; de Melo, R.R.S.; Costa, D.B. Design and implementation of a computerized safety inspection system for construction sites using UAS and digital checklists—Smart Inspecs. Saf. Sci. 2021, 143, 105430. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Yuen, K.V. Construction site information decentralized management using blockchain and smart contracts. Copmut. Aided Civ. Infrastruct. Eng. 2021, 37, 1450–1467. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, D.; Liu, X.; Liu, R.; Zhong, G. A Framework of on-site Construction Safety Management Using Computer Vision and Real-Time Location System. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC), Cambridge, UK, 8–10 July 2019; pp. 327–333. [Google Scholar]

- Liu, P. Research on Site Safety Management by BIM Technology Based on Fuzzy Intuition Set. Secur. Commun. Netw. 2022, 2022, 7289440. [Google Scholar] [CrossRef]

- Bowo, L.P.; Prilana, R.E.; Furusho, M. A Modified HEART—4M Method with TOPSIS for Analyzing Indonesia Collision Accidents. TransNav 2020, 14, 751–759. [Google Scholar] [CrossRef]

- Sulistiyono, A.B.; Mutmainnah, W.; Furusho, M. 4M Study to Support Indonesia’s Maritime Tourism Development. TransNav 2017, 11, 723–728. [Google Scholar] [CrossRef]

- Huang, G.; Sun, S.; Zhang, D. Safety Evaluation of Construction Based on the Improved AHP-Grey Model. Wireless Pers. Commun. 2018, 103, 209–219. [Google Scholar] [CrossRef]

- Hollnagel, E. Is safety a subject for science? Saf. Sci. 2014, 67, 21–24. [Google Scholar] [CrossRef]

- Patterson, M.; Deutsch, E.S. Safety-I, Safety-II and resilience engineering. Curr. Probl. Pediatr. Adolesc. Health Care 2015, 45, 382–389. [Google Scholar] [CrossRef]

- Pecillo, M. The concept of resilience in OSH management: A review of approaches. Int. J. Occup. Saf. Ergon. 2016, 22, 291–300. [Google Scholar] [CrossRef]

- Sapeciay, Z.; Wilkinson, S.; Costello, S.B. Building organisational resilience for the construction industry: New Zealand practitioners’ perspective. Int. J. Disaster Resil. 2017, 8, 98–108. [Google Scholar] [CrossRef]

- Gilmore, B.; Ndejjo, R.; Tchetchia, A.; de Claro, V.; Mago, E.; Diallo, A.A.; Lopes, C.; Bhattacharyya, S. Community engagement for COVID-19 prevention and control: A rapid evidence synthesis. BMJ Glob Health 2020, 5, e003188. [Google Scholar] [CrossRef]

- du Plessis, E.M.; Vandeskog, B. Other stories of resilient safety management in the Norwegian offshore sector: Resilience engineering, bullshit and the de-politicization of danger. Scand. J. Manag. 2020, 36, 101096. [Google Scholar] [CrossRef]

- Bergström, J.; Van Winsen, R.; Henriqson, E. On the rationale of resilience in the domain of safety: A literature review. Reliab. Eng. Syst. Saf. 2015, 141, 131–141. [Google Scholar] [CrossRef]

- Santos de Melo, R.R.; Costa, D.B. Integrating resilience engineering and UAS technology into construction safety planning and control. Eng. Constr. Archit. Manag. 2019, 26, 2705–2722. [Google Scholar] [CrossRef]

- Fox-Lent, C.; Bates, M.E.; Linkov, I. A matrix approach to community resilience assessment: An illustrative case at Rockaway Peninsula. Environ. Syst. Decis. 2015, 35, 209–218. [Google Scholar] [CrossRef]

- Xiahou, X.; Chen, J.; Zhao, B.; Yan, Z.; Cui, P.; Li, Q.; Yu, Z. Research on Safety Resilience Evaluation Model of Data Center Physical Infrastructure: An ANP-Based Approach. Buildings 2022, 12, 1911. [Google Scholar] [CrossRef]

- Xu, W.; Xiang, L.; Proverbs, D.; Xiong, S. The Influence of COVID-19 on Community Disaster Resilience. Int. J. Environ. Res. Public Health 2020, 18, 88. [Google Scholar] [CrossRef]

- Zhu, Z.; Yuan, J.; Shao, Q.; Zhang, L.; Wang, G.; Li, X. Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective. Int. J. Environ. Res. Public Health 2020, 17, 6167. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, J.; Dun, Z.; Cheng, J.; Li, H.; Dun, Z. Resilience Evaluation of High-Speed Railway Subgrade Construction Systems in Goaf Sites. Sustainability 2022, 14, 7806. [Google Scholar] [CrossRef]

- Zhang, C.; Oh, J.; Park, K. Evaluation of sewer network resilience index under the perspective of ground collapse prevention. Water Sci. Technol. 2022, 85, 188–205. [Google Scholar] [CrossRef] [PubMed]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M.; Shinozuka, M.; Tierney, K.; Wallace, W.A.; von Winterfeldt, D. A framework to quantitatively assess and enhance the seismic resilience of communities. Earthq. Spectra 2003, 19, 733–752. [Google Scholar] [CrossRef]

- Ranasinghe, U.; Jefferies, M.; Davis, P.; Pillay, M. Resilience Engineering Indicators and Safety Management: A Systematic Review. Saf. Health Work-Kr. 2020, 11, 127–135. [Google Scholar] [CrossRef]

- Siccama, C.J.; Penna, S. Enhancing Validity of a Qualitative Dissertation Research Study by Using NVIVO. Qual. Res. J. 2008, 8, 91–103. [Google Scholar] [CrossRef]

- Corbin, J.M.; Strauss, A. Grounded theory research: Procedures, canons, and evaluative criteria. Qual. Sociol. 1990, 13, 3–21. [Google Scholar] [CrossRef]

- Dube, A.S.; Pati, N.; Gawande, R.S. Analysis of green supply chain barriers using integrated ISM-fuzzy MICMAC approach. Benchmarking 2016, 23, 1558–1578. [Google Scholar] [CrossRef]

- Balaji, M.; Dinesh, S.N.; Vikram Vetrivel, S.; Manoj Kumar, P.; Subbiah, R. Augmenting agility in production flow through ANP. Mater. Today Proc. 2021, 47, 5308–5312. [Google Scholar] [CrossRef]

- Ml, Z.; Wp, Y. Fuzzy Comprehensive Evaluation Method Applied in the Real Estate Investment Risks Research. Phys. Procedia 2012, 24, 1815–1821. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, S.; Yan, B.; Miao, S. Environmental safety evaluation of geopark based on CPTED concept and fuzzy comprehensive analysis. PLoS ONE 2021, 16, e0260316. [Google Scholar] [CrossRef] [PubMed]

- Ylikoski, P.; Zahle, J. Case study research in the social sciences. Stud. Hist. Phil. Sci. 2019, 78, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, X.; Wang, J.a. A Way to Sustainability: Perspective of Resilience and Adaptation to Disaster. Sustainability 2016, 8, 737. [Google Scholar] [CrossRef]

- Peng, J.; Song, Y.; Yuan, P.; Xiao, S.; Han, L. An novel identification method of the environmental risk sources for surface water pollution accidents in chemical industrial parks. J. Environ. Sci. 2013, 25, 1441–1449. [Google Scholar] [CrossRef] [PubMed]

- Sindhu, S.; Nehra, V.; Luthra, S. Identification and analysis of barriers in implementation of solar energy in Indian rural sector using integrated ISM and fuzzy MICMAC approach. Renew. Sust. Energ. Rev. 2016, 62, 70–88. [Google Scholar] [CrossRef]

- Okoli, C.; Pawlowski, S.D. The Delphi method as a research tool: An example, design considerations and applications. Inform. Manag. Amster. 2004, 42, 15–29. [Google Scholar] [CrossRef]

- Sonar, H.; Khanzode, V.; Akarte, M. Investigating additive manufacturing implementation factors using integrated ISM-MICMAC approach. Rapid Prototyp. J. 2020, 26, 1837–1851. [Google Scholar] [CrossRef]

- Saaty, T.L. Some Mathematical Concepts of the Analytic Hierarchy Process. Behaviormetrika 1991, 18, 1–9. [Google Scholar] [CrossRef]

- JGJ/T 434-2018; Technical Standard for Information Systems of Construction Site Supervision And Management. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2018.

- DB32/T 4175-2021; Technical Standard for Intelligent Safety Supervision of Building Construction. Jiangsu Province Market Supervision Administration: Nanjing, China, 2021.

- DB13(J)/T 8312-2019; Technical Standard of Implementing Smart Construction Sites. Hebei Provincial Department of Housing and Urban-Rural Development: Shijiazhuang, China, 2019.

- DB64/T 1684-2020; Technical Standard for Smart Construction Sites. Department of Housing and Urban-Rural Development of Ningxia Hui Autonomous Region and Department of Market Supervision and Administration of Ningxia Hui Autonomous Region: Yinchuan, China, 2020.

- DB11/T 1710-2019; Technical Specification for Smart Construction Sites. Beijing Municipal Commission of Housing and Urban-Rural Development, Beijing Municipal Administration of Market Supervision: Beijing, China, 2019.

- Yang, J.; Shen, L.; Jin, X.; Hou, L.; Shang, S.; Zhang, Y. Evaluating the quality of simulation teaching in Fundamental Nursing Curriculum: AHP-Fuzzy comprehensive evaluation. Nurse Educ. Today 2019, 77, 77–82. [Google Scholar] [CrossRef]

- Okasha, N.M.; Frangopol, D.M. Redundancy of structural systems with and without maintenance: An approach based on lifetime functions. Reliab. Eng. Syst. Saf. 2010, 95, 520–533. [Google Scholar] [CrossRef]

- Yu, H.; Liu, F.; Wang, Y. Construction and Evaluation of Construction Safety Management System Based on BIM and Internet of Things. Secur. Commun. Netw. 2022, 2022, 9757049. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Cyber physical system for safety management in smart construction site. Eng. Constr. Archit. Ma. 2020, 28, 788–808. [Google Scholar] [CrossRef]

- Pan, Y.; Zuo, L.; Ahmadian, M. A half-wave electromagnetic energy-harvesting tie towards safe and intelligent rail transportation. Appl. Energy 2022, 313, 118844. [Google Scholar] [CrossRef]

- Wan, J.; Xiong, N.; Zhang, W.; Zhang, Q.; Wan, Z. Prioritized degree distribution in wireless sensor networks with a network coded data collection method. Sensors 2012, 12, 17128–17154. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Chang, J.; Xiao, F.; Hu, Y.; Xiong, N.N. Design and Analysis of a Persistent, Efficient, and Self-Contained WSN Data Collection System. IEEE Access 2018, 7, 1068–1083. [Google Scholar] [CrossRef]

- Alateeq, M.M.; Fathimathul Rajeena, P.P.; Ali, M.A.S. Construction Site Hazards Identification Using Deep Learning and Computer Vision. Sustainability 2023, 15, 2358. [Google Scholar] [CrossRef]

- Su, Y.; Mao, C.; Jiang, R.; Liu, G.; Wang, J. Data-Driven Fire Safety Management at Building Construction Sites: Leveraging CNN. J. Manag. Eng. 2021, 37, 04020108. [Google Scholar] [CrossRef]

- Park, J.; Cai, H.; Dunston, P.S.; Ghasemkhani, H. Database-Supported and Web-Based Visualization for Daily 4D BIM. J. Constr. Eng. Manag. 2017, 143, 04017078. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S.; Abu Samra, S.; Gaterell, M.; Hosseini, M.R.; Wise, R. Cash flow system development framework within integrated project delivery (IPD) using BIM tools. Int. J. Constr. Manag. 2019, 21, 555–570. [Google Scholar] [CrossRef]

- Liu, T.; Hou, J.; Xiong, G.; Nyberg, T.R.; Li, X. Smart Cloud-based Platform for Construction Sites. In Proceedings of the 2016 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Beijing, China, 10–12 July 2016; pp. 168–173. [Google Scholar]

- Yi, W.; Chan, A.P.C.; Wang, X.; Wang, J. Development of an early-warning system for site work in hot and humid environments: A case study. Autom. Constr. 2016, 62, 101–113. [Google Scholar] [CrossRef]

| Main Category | Subcategories | R1 | R2 | R3 | R4 |

|---|---|---|---|---|---|

| Auxiliary personnel management | Personnel hierarchical authorization | √ | √ | ||

| Person identification | √ | ||||

| Personnel information management | √ | ||||

| Analytical support for decision making | Assistance to personnel in decision making | √ | √ | ||

| Visual aid analysis | √ | ||||

| Promotion of personnel communication and collaboration | Communication skills | √ | √ | ||

| Collaboration skills | √ | √ | |||

| Equipment failure resilience | Partial function substitutability of equipment | √ | √ | ||

| Equipment and system vandalism prevention | √ | √ | |||

| Equipment with fast response capability | √ | √ | |||

| Backup and expansion capability | Backup capability | √ | √ | √ | |

| Expansion of functions and potential | √ | √ | |||

| Early warning and emergency capability | Emergency response capability | √ | |||

| Early warning capability | √ | √ | |||

| Data analysis and processing capability | Adoption of cloud architecture | √ | |||

| Positioning function | √ | √ | |||

| Data acquisition and transmission | √ | ||||

| Data processing and management | √ | ||||

| Data hierarchical storage and processing | √ | ||||

| Education of employees | Employee safety education | √ | √ | ||

| Employee skills training | √ | √ | |||

| Ability to integrate functions | Integration of environmental monitoring | √ | |||

| Real-time environmental data | Real-time acquisition | √ | √ | ||

| Real-time processing | √ | √ | |||

| Harsh environment resistance | Large operating temperature range | √ | √ | ||

| Inconsistent ability of equipment to resist harsh environments | √ | √ | |||

| Accuracy of environmental monitoring | High environmental monitoring accuracy and fast response | √ | |||

| Richness of monitoring points | Monitoring with redundancy | √ | |||

| Multiple environmental monitoring points | √ | ||||

| Total (number of nodes) | 204 | 204 | 94 | 179 | |

| Robustness | Resourcefulness | Redundancy | Rapidity | |

|---|---|---|---|---|

| Man | 12.31% | 57.64% | 0.35% | 29.70% |

| Machine | 32.93% | 17.13% | 30.08% | 16.22% |

| Media | 32.67% | 10.17% | 19.60% | 37.57% |

| Management | 29.24% | 41.28% | 0% | 29.48% |

| Category | Code | Indicators |

|---|---|---|

| Man | S1 | Analytical support for decision making |

| S2 | Personnel management | |

| S3 | Person identification | |

| S4 | Promotion of personnel communication and collaboration | |

| Machine | S5 | Backup and replacement capability |

| S6 | Expansion of functions and potential | |

| S7 | Equipment and system vandalism prevention | |

| S8 | Equipment with fast response capability | |

| Media | S9 | Ability to integrate function |

| S10 | Richness of monitoring points | |

| S11 | Accuracy of environmental monitoring | |

| S12 | Harsh environment resistance | |

| S13 | Real-time environmental data | |

| Management | S14 | Education of employees |

| S15 | Early warning and emergency capability | |

| S16 | Adoption of cloud architecture | |

| S17 | Positioning function | |

| S18 | Data management |

| Category | Weight | Indicator | Weight |

|---|---|---|---|

| Man | 0.247672 | S1 Analytical support for decision making | 0.005057 |

| S3 Person identification | 0.210437 | ||

| S4 Promotion of personnel communication and collaboration | 0.032178 | ||

| Machine | 0.128442 | S5 Backup and replacement capability | 0.009634 |

| S6 Expansion of functions and potential | 0.024269 | ||

| S7 Equipment and system vandalism prevention | 0.019844 | ||

| S8 Equipment with fast response capability | 0.074695 | ||

| Media | 0.295949 | S9 Ability to integrate functions | 0.109917 |

| S10 Richness of monitoring points | 0.028938 | ||

| S11 Accuracy of environmental monitoring | 0.112172 | ||

| S13 Real-time environmental data | 0.044922 | ||

| Management | 0.327938 | S14 Education of employees | 0.051581 |

| S15 Early warning and emergency capability | 0.052841 | ||

| S16 Adoption of cloud architecture | 0.133831 | ||

| S17 Positioning function | 0.089685 |

| Category | Indicator | Evaluation Criteria |

|---|---|---|

| Man | S1 Analytical support for decision making | The number of areas covered with the ability to perform statistical analysis of information data |

| S3 Person identification | The number of smart and biometric modules offered, and the number of scenes in which they are used | |

| S4 Promotion of personnel communication and collaboration | The number of participants involved in the multi-collaborative management of engineering construction | |

| Machine | S5 Backup and replacement capability | The number of modules with automatic data backup, video history replay, and video download functions |

| S6 Expansion of functions and potential | Whether it is possible to realize the expansion of system functions by adding business modules according to actual needs | |

| S7 Equipment and system vandalism prevention | Whether the designed software has encryption, whether the hardware has waterproof and drop-proof functions | |

| S8 Equipment with fast response capability | Responsiveness of the platform and critical equipment in terms of page response, backup/restore time of logs | |

| Media | S9 Ability to integrate functions | The number of interface support tools for various types of IoT monitoring equipment at construction sites |

| S10 Richness of monitoring points | The number of types that reflect the amount of redundancy in product design | |

| S11 Accuracy of environmental monitoring | Technical parameters related to the efficiency of key equipment used on sites (cameras, various sensors) | |

| S13 Real-time environmental data | The number of devices that can automatically monitor, display in real time, and synchronize the transmission of environmental data on sites | |

| Management | S14 Education of employees | Whether to provide employee education-related online training, course exam management, and richness of content |

| S15 Early warning and emergency capability | The number of types of warnings provided by the sites | |

| S16 Adoption of cloud architecture | The number of types of users involved in the platform | |

| S17 Positioning function | The number of types of positioning technology |

| Indicator | i-Value | Indicator | i-Value |

|---|---|---|---|

| S1 | 9 | S3 | 3 |

| S4 | 7 | S5 | 8 |

| S9 | 10 | S10 | 12 |

| S13 | 9 | S15 | 7 |

| S16 | 6 | S17 | 7 |

| Indicator | Evaluation Value | ||||

|---|---|---|---|---|---|

| 0.8–1 | 0.6–0.8 | 0.4–0.6 | 0.2–0.4 | 0–0.2 | |

| S6 | high | relatively high | average | relatively low | low |

| S7 | high | relatively high | average | relatively low | low |

| S8 | high | relatively high | average | relatively low | low |

| S11 | high | relatively high | average | relatively low | low |

| S14 | high | relatively high | average | relatively low | low |

| Affiliation Value | [0.8, 1] | [0.6, 0.8) | [0.4, 0.6) | [0.2, 0.4) | [0, 0.2) |

| Evaluation Level | excellent | good | average | poor | very poor |

| Category | Indicator | Actual Value | Evaluation Value |

|---|---|---|---|

| Man | S1 | 7 | 0.7778 |

| S3 | 2 | 0.6667 | |

| S4 | 7 | 1.0000 | |

| Machine | S5 | 5 | 0.6250 |

| S6 | / | 0.3150 | |

| S7 | / | 0.4900 | |

| S8 | / | 0.7250 | |

| Media | S9 | 6 | 0.6000 |

| S10 | 10 | 0.8333 | |

| S11 | / | 0.5050 | |

| S13 | 5 | 0.5556 | |

| Management | S14 | / | 0.7050 |

| S15 | 3 | 0.4286 | |

| S16 | 4 | 0.6667 | |

| S17 | 2 | 0.2857 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, Y.; Liu, H.; Mao, P.; Zheng, X. Evaluation of Safety Management of Smart Construction Sites from the Perspective of Resilience. Buildings 2023, 13, 2205. https://doi.org/10.3390/buildings13092205

Qian Y, Liu H, Mao P, Zheng X. Evaluation of Safety Management of Smart Construction Sites from the Perspective of Resilience. Buildings. 2023; 13(9):2205. https://doi.org/10.3390/buildings13092205

Chicago/Turabian StyleQian, Yutong, Hui Liu, Peng Mao, and Xiaodan Zheng. 2023. "Evaluation of Safety Management of Smart Construction Sites from the Perspective of Resilience" Buildings 13, no. 9: 2205. https://doi.org/10.3390/buildings13092205

APA StyleQian, Y., Liu, H., Mao, P., & Zheng, X. (2023). Evaluation of Safety Management of Smart Construction Sites from the Perspective of Resilience. Buildings, 13(9), 2205. https://doi.org/10.3390/buildings13092205