A Methodology for Designing an Automated System to Improve the Thermal Performance of a Large Building in Operation

Abstract

:1. Introduction

2. Materials and Methods

3. Building Assessment for Automation

3.1. Diagnosis

- (a)

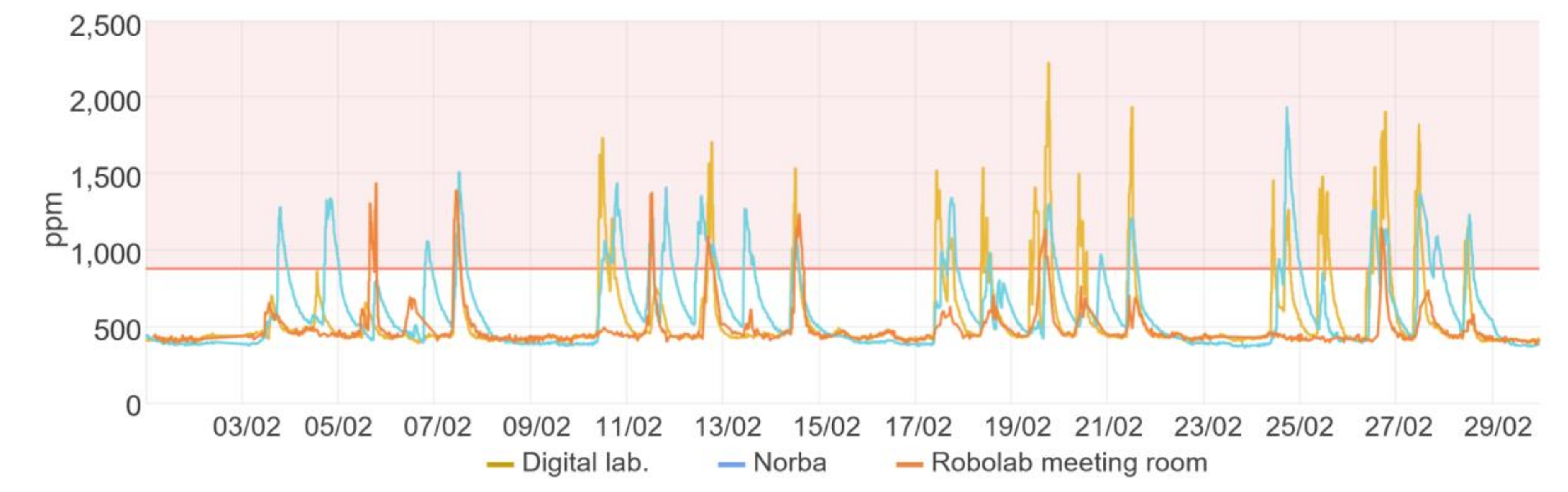

- Sensors installed in two classrooms and a meeting room measured high levels of CO2. According to the regulations [37], a good air quality level in classrooms corresponds to 880 ppm (500 ppm above the outdoor concentration, which is 380 ppm). However, during the school years analysed (from November 2016 to March 2020), an average of 9.6% of the occupied hours exceeded this value. Moreover, in February 2020, for example, peaks of up to 1964 ppm were reached in the digital lab classroom at 7 p.m. (Figure 3).

- (b)

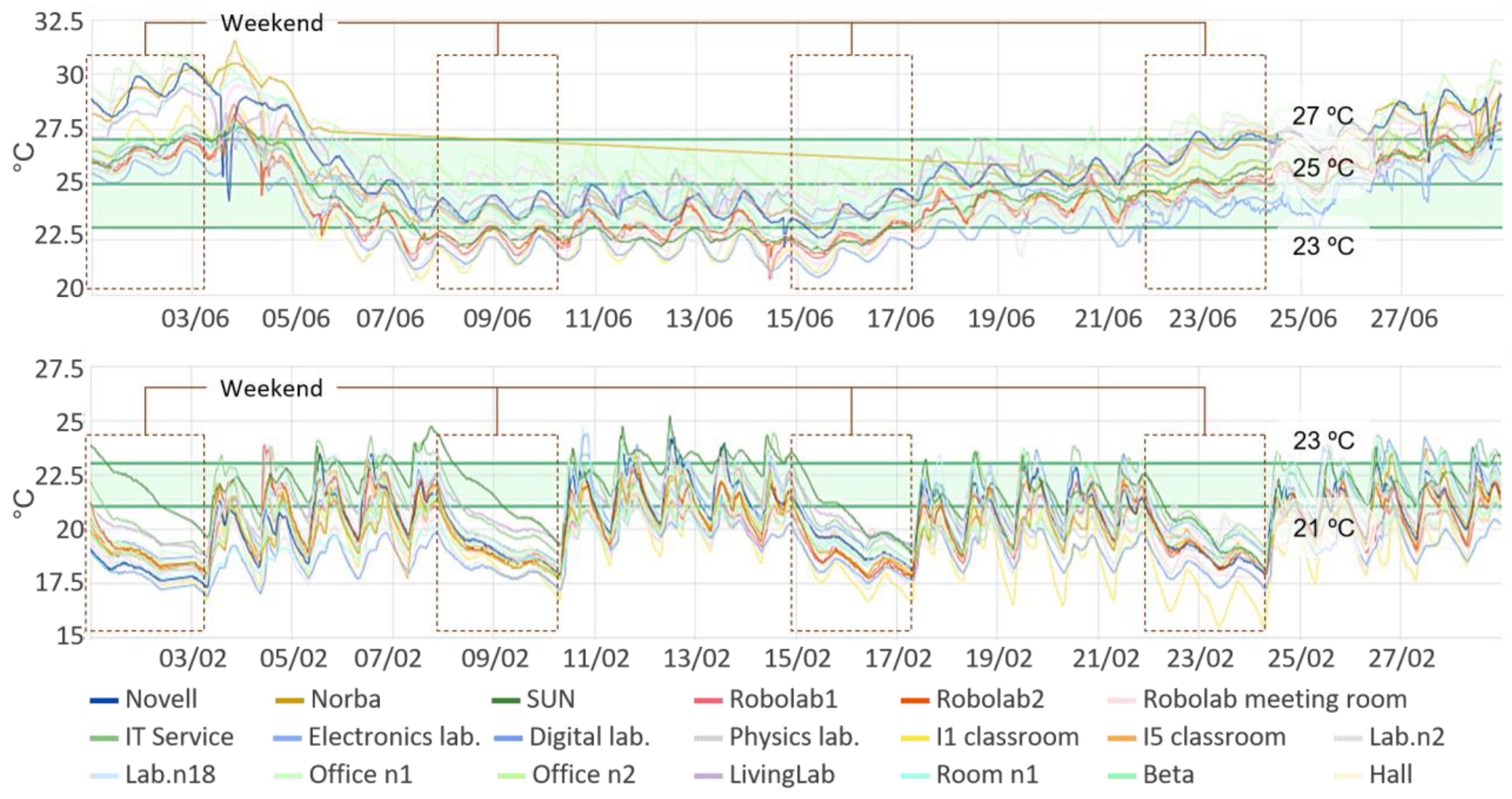

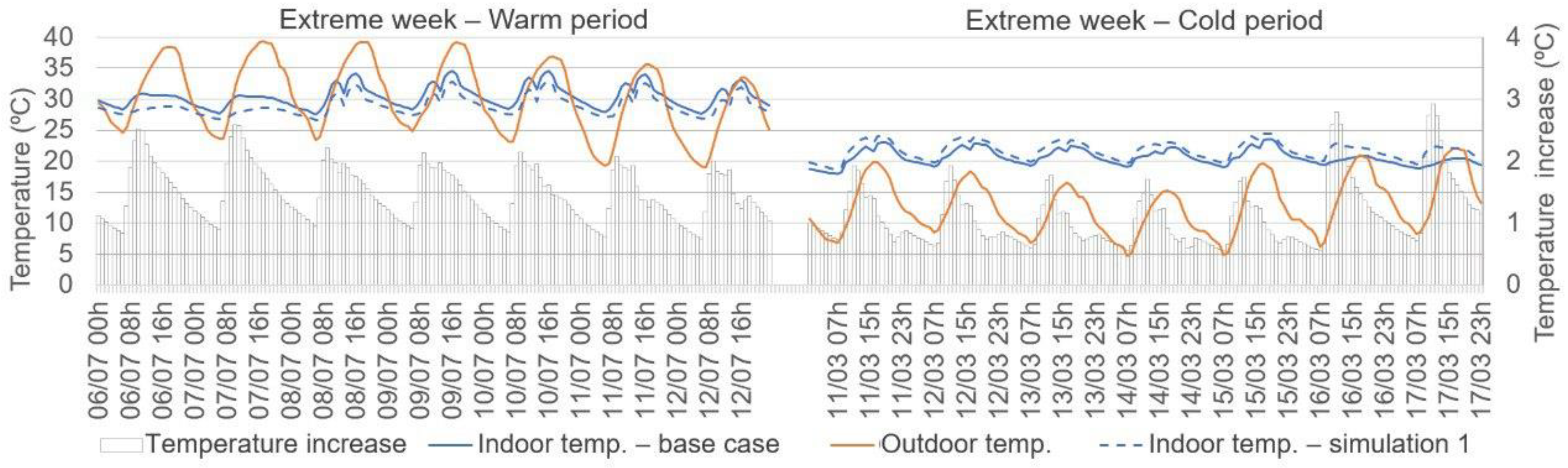

- It can be observed that rooms’ indoor temperature does not continuously reach the operative temperatures defined by the Spanish buildings regulations [37], nor the latest measures for energy savings (from 23 °C to 25 °C in the warm period, and from 21 °C to 23 °C in the cold period). In summer, indoor temperatures rise up to 30 °C. In winter, 20 °C is only reached in some rooms and at certain times around midday, even if the heating system has been on since November. The spaces with the highest occupancy (Norba, Novell, I.5. and n1 classrooms) have the highest temperatures (Figure 4).

- (c)

- Users do not perceive thermal comfort. This perception was analysed by means of surveys (according to ASHRAE 55-2017 [38]), where 247 responses received between 21/02/19 and 03/05/19 were compared with the comfort range defined by the regulations mentioned in the previous section. It was found that 53% of the respondents felt a neutral sensation, 20% felt slightly cold, and 13% felt slightly hot (Figure 5).

- (d)

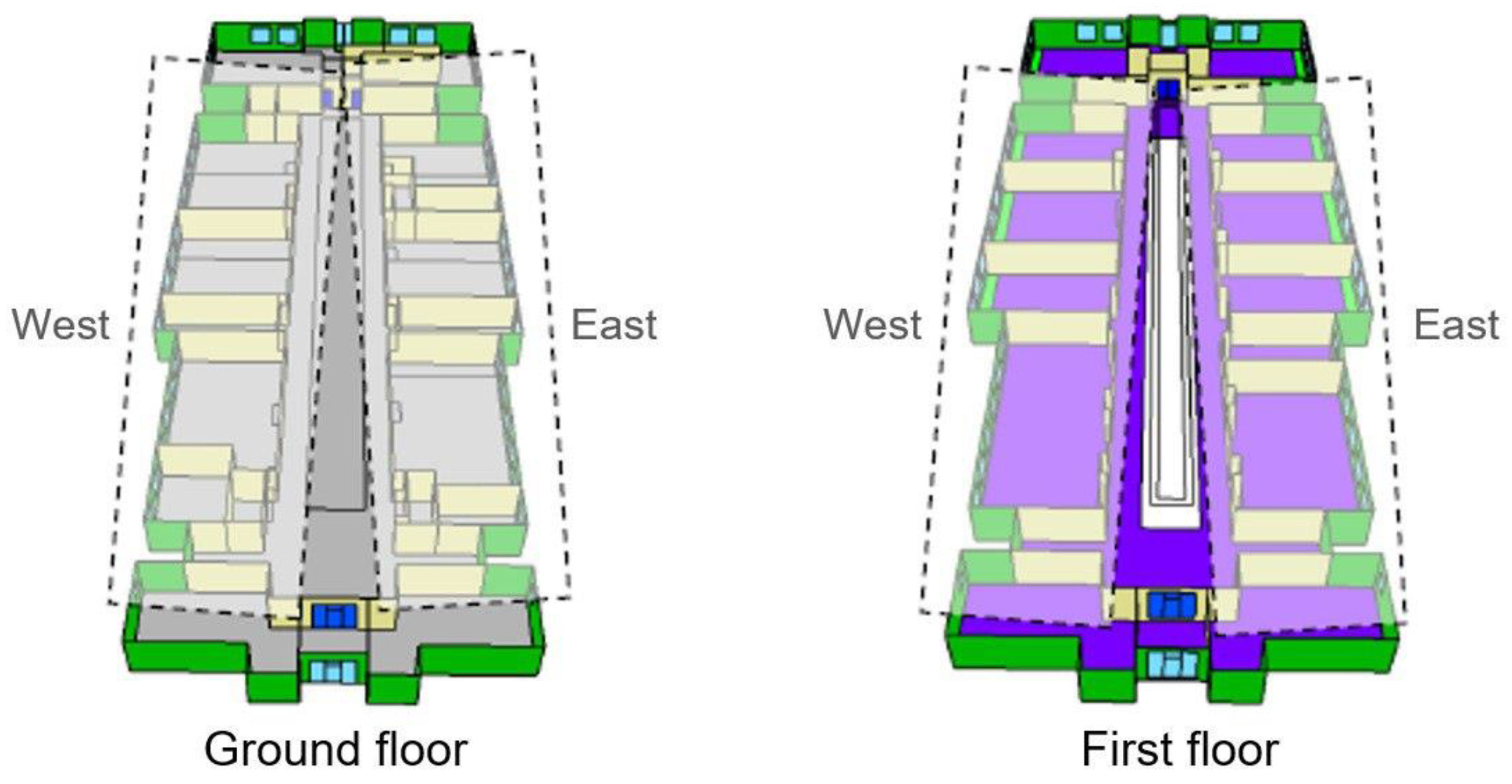

- There is no zoning allowing individual control of the heating system. There are two centralised natural gas boilers (main and backup) installed in the semi-basement of the building, which also serve three other buildings via independent underground branches. From these main branches, internal risers run above the suspending ceiling of the ground floor and parallel to the main façades. The connections to the risers for each radiator on the ground and first floors branch directly from these (Figure 6).

- (e)

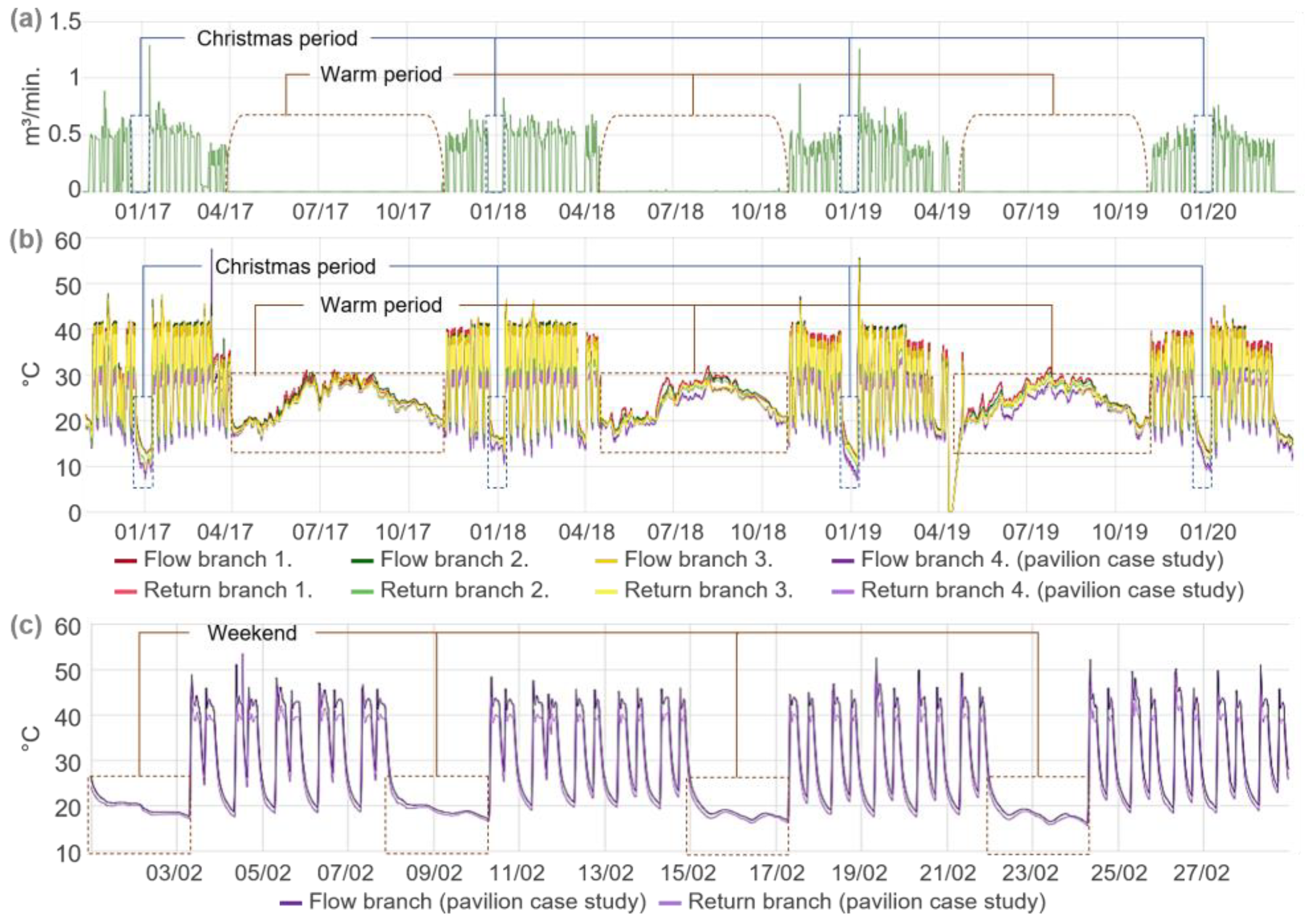

- It should be noted that the system is not automated, and that the heating is manually controlled by the centre’s concierge during cold periods. The switch-on/switch-off schedule varies according to the decisions and subjective thermal sensations of the centre´s administration and management between 6.30 a.m. and 9 p.m., from Monday to Friday. There is also a long closure at Christmas (Figure 7).

- (f)

- The system is monitored by means of fluid temperature sensors placed in the different branches of the buildings, which show that the main branch temperature usually oscillates between 50 °C and 70 °C, while the branches of each building oscillate between 37 °C and 50 °C, in both the supply and return circuits. The latter circuits are very close to their common collector, which produces a water mixture that makes it difficult to identify the heat losses produced during distribution. The same temperature difference between flow and return is also observed in the daily pattern of the branches of the case study. In addition, there are gas consumption sensors in the boiler, which make it possible to observe how maximum values of 0.5 m 3/min are reached on average (Figure 7).

- (g)

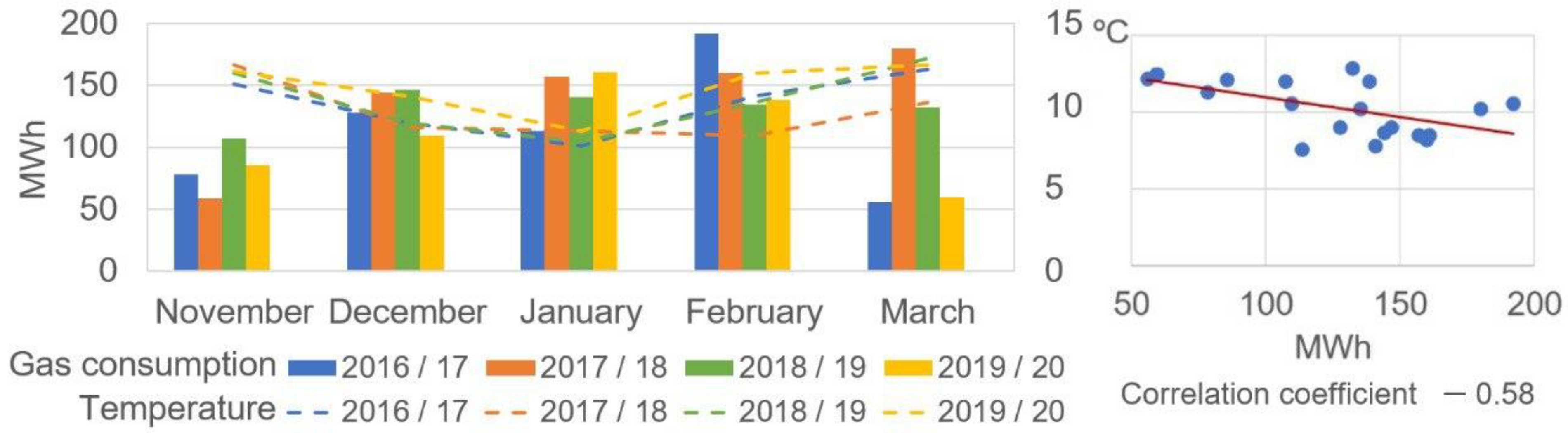

- It is not possible to establish a relationship between consumption and comfort or occupancy conditions, or to adapt the supply to the specific circumstances of the case study. Historical and habitual consumption is known. On the one hand, the gas consumption sensors in the boiler show peaks of 0.5 m3/min on average (Figure 4), but it is impossible to discern which part belongs to the building under study, as there are no flow meters for each branch. On the other hand, only general monthly invoices are available for the entire EPCC site. Furthermore, natural gas consumption shows an upward trend on the invoices up to January 2019, when it starts to decrease. The maximum monthly record was 17,086 m3 in February 2017. Higher consumption is observed in January and February, with consumption being zero from May to September (both included). In October and April there is only consumption for a few days. The monthly average from November to March is 10,899 m3, with a wide dispersion of results (Figure 8).

- (h)

- There is a moderate-to-low correlation between winter consumption and outdoor temperatures, with a coefficient of −0.58. This implies that both variables exhibit an inverse relationship, meaning that higher temperatures are associated with lower consumption, and vice versa. However, some exceptions should be mentioned: January 2020 was the warmest January in the series, but also the one with the highest consumption; January 2017 was the coldest, but also the one with the lowest consumption. The scheduling is currently based on a fixed timetable of working days, without taking into account outdoor temperature variations, forecasts, or actual indoor temperatures (Figure 9).

3.2. Identification of Strategies

3.2.1. Approach to Thermal Situation

3.2.2. Energy Simulation

- (a)

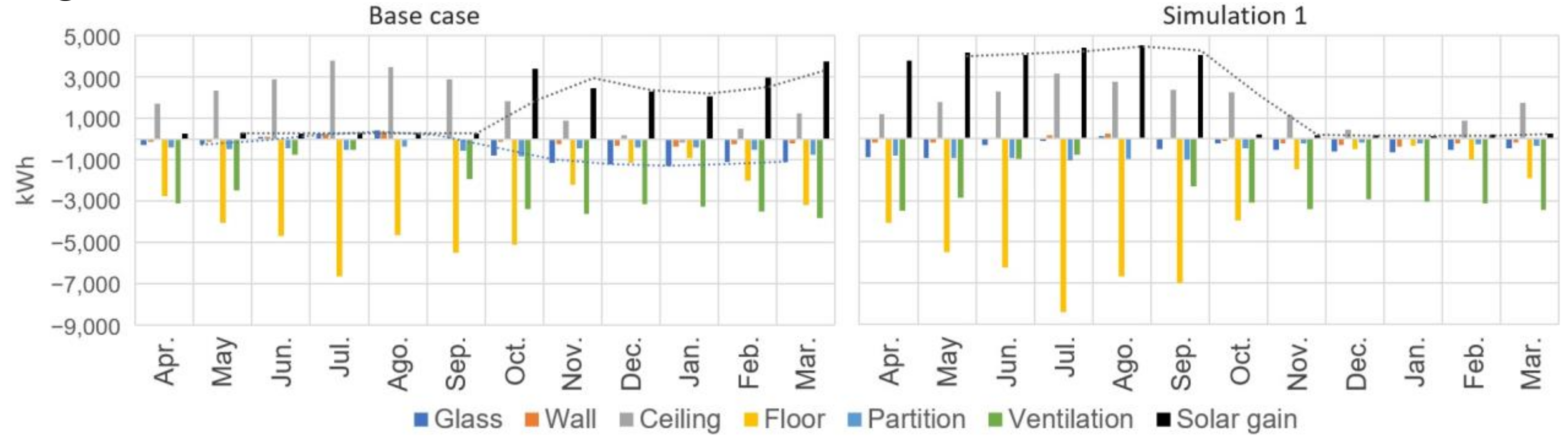

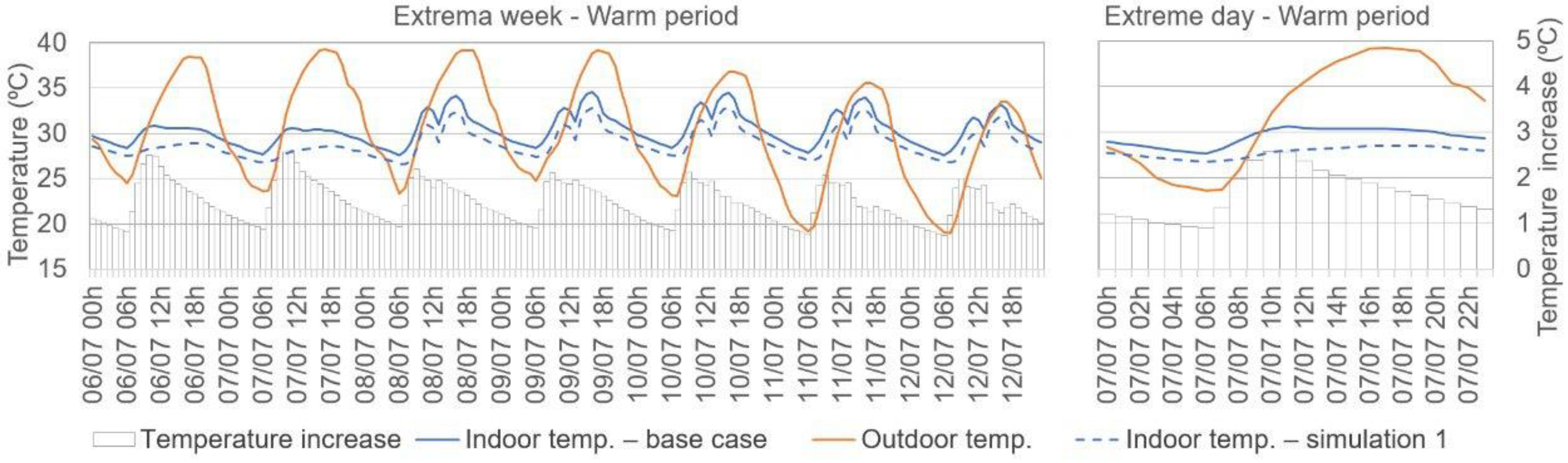

- Simulation n° 1: Solar shading in the openings during the cold period and solar gain during the warm period. These unfavourable situations occur very often when the blinds in the classrooms and offices are not raised (which also forces the lighting to be switched on when it is not necessary), or when the Sun´s rays overheat the spaces during the hottest season. The year was divided into two periods: cold, from 1 October to 31 March, and warm, from 1 April to 30 September. Simulation 1 thus removed the shading from the model in summer and introduced it in winter, and then it compared the new distribution of heat flow with the base case simulation. This shows that the gains from lighting, occupancy, and computers remain the same, and that there are quite similar annual exchanges (<±25% difference between the two flows and <3000 kWh): losses through floors, air infiltration, and external ventilation, and gains through ceilings. There is a greater difference (>±25% and <3000 kWh) through partitions (losses) and external walls (gains), which increases (>700% and <3000 kWh) through glazing, which is the weakest part of the enclosure (almost always losses). However, the most significant exchanges are those through solar gains (around 1000% more), which represent 23,386 kWh more thermal gains in summer and 15,854 kWh more losses in winter (2.948% and 5.012% of the total exchanges taking place in the building, respectively) (Figure 12).

- (b)

- Simulation n° 2: Activation of natural ventilation through windows at night during the warm period. This favourable situation does not usually occur in most public buildings, where there are no ventilation instructions when the buildings are closed (sometimes due to security concerns). In addition, it is common to open windows during the day, even though the outdoor temperature is much higher. For the simulation, windows’ natural ventilation was activated only at night, from 0 to 8 a.m., every day from June to September (when the outdoor temperature was lower than the indoor temperature, and the latter was above the comfort temperature), and the hourly air exchange rates were increased to the maximum (which means going from 12 ren/h in June to 25 ren/h in July, depending on the weather conditions). This compares the new distribution of heat flows with the base case simulation, showing that almost all exchanges remain similar (0%) in terms of lighting, solar, computer, and occupant gains (<±20% and <2000 kWh), and through walls, ceilings, floors, and partitions; (<−30% and <300 kWh) in glazing. However, the most significant difference in exchanges is through natural ventilation, which increases by 155%, representing an additional 4817 kWh of thermal reduction (Figure 14).

3.3. Action Proposal

- (a)

- Ventilation control that brings air into the building. The functions that can be implemented in this case are supply airflow control related to occupancy (VENT_RMFLOW_CTRL), room air temperature control by the ventilation system (VENT_RTEMP_CTRL), ventilation systems that allow the OA ratio or airflow to vary (VENT_OAFLOW_CTRL), and free mechanical cooling (VEN_FREECOOL_CTRL).

- (b)

- Blind control to prevent overheating (BLIND_CTRL). An automatically controlled motorised operating function was selected to allow solar gain at the required times.

- (c)

- Heating Control. The following function was selected: heating automatic control on emission units (HEAT_EMIS_CTRL_DEF), as this allows for free modification of the spaces and programming of control of rooms, sectors, floors, façades, halls, etc., covering all of the other possibilities and allowing each space to be adapted to its heating needs at a much lower cost. Functions that act on the distribution network are discarded, since they would require the installation of regulation keys in each branch or by means of new branches (by floor, by room, by sector, by the location of the radiators (windows/corridors)). The following were also discarded: those that act on the pumps, or with control on the general boiler panel.

4. Deployment of the Automation System

4.1. Devices

- -

- Compact, lightweight, low-cost, and easy to install.

- -

- Low consumption: Low-power batteries (<3.6 W) lasting between 1 and 10 years. Data transmission is achieved through a LoRa network (readings were configured to occur every 20 min to reduce battery consumption). In the case of camera data, the energy power is <4.5 W for wired networks and a maximum of 35 Wh and 310 Wh in air exchangers.

- -

- Accurate measurements: Temperature range varies from −40 or −20 to 60 or 80 °C, with a typical accuracy of ±0.3 to ±0.6 °C. Humidity range spans from 0 to 100%. The accuracy is ±3/±5%, respectively. CO2 concentration measurements range from 400 to 10,000 ppm, with an accuracy of ±3–10 ppm.

4.1.1. Input Devices

- (a)

- Indoor hygrothermal and CO2 concentration sensors (10 units) [45]: located in spaces with higher occupancy, affixed to vertical walls at an approximate height of 1.5 m and centrally located within each space.

- (b)

- Window open/closed status sensors (94 units) [46]: deployed on each window of the building. These units collect temperature and humidity data. The communication device is screwed to a vertical wall near the window, and the sensor itself, connected by a cable, is attached to the window frame at the same height.

- (c)

- Presence cameras (19 units) [47]: installed in the most frequently used classrooms, they record the occupancy fusing image analysis software developed for this purpose using deep convolutional neural networks. The cameras are installed on the ceiling or on the wall next to the teacher’s desk. The average time to capture, decode, and process each image is 2 s, so each instance of this program can process 30 cameras per minute given sufficient hardware resources.

- (d)

- Other data sources currently used include time schedules provided by the institutional room reservation software, and meteorological data acquired from the national climate service [41].

4.1.2. Output Devices

- (a)

- Thermostatic valves (185 units) [48]: Flow control at the emitters is required based on the operating conditions of the indoor and outdoor environment. Additionally, they monitor indoor temperature and humidity data, geographical position, battery level, and open window warning.

- (b)

- Air exchanger with heat recovery (4 units): The requirements of the system are to supply properly filtered outdoor air to the building and to extract indoor air, while exchanging heat as required. In addition, it facilitates nighttime operation in bypass mode. In calculating the equipment, the minimum ventilation flow rate for educational buildings of 12.5 dm3/s per person was used (indoor air quality level IDA 2, guaranteeing acceptable pollutant-free air by the extraction and discharge of stale air [37]), and an occupant density of 0.23 persons/m2 was determined (Section 3.2.2). The outdoor air quality is considered to be ODA 1, i.e., pure air, which may contain temporary solid particles such as pollen. The extract air is class AE 1, i.e., low pollution level, which requires a minimum extract airflow rate of 2 dm3/s per m2.

- (c)

- Automated motorised blinds (91 units): The requirements of the system are to prevent solar gain in hot weather and to provide protection in cold weather. It is installed on all existing manual roller shutters by replacing the drum shaft with a new one incorporating a tubular motor.

4.2. IoT Architecture

- -

- Open-source or software with a permissive licence software.

- -

- Multi-protocol, admitting any kind of IoT device to publish or take requests.

- -

- Scalable, easily extended and replicated in other facilities.

- -

- Modular, with containerised services and databases to facilitate maintenance and improvement.

- -

- Self-monitoring and self-diagnosing, with a parallel monitoring infrastructure that holds local models of each service and supervises their correct functioning.

- -

- User-friendly, to facilitate the controller’s development and tuning.

- -

- External access via microservices for connecting visualisation software and dashboards.

- -

- Flexible software development kit access for custom coded data analysis.

- -

- LoRA communication is supported by routers connected to the local Ethernet and configured to send all received packets to an instance of Chirpstack [51], which transforms them into JSON strings and publishes them via MQTT. Thermostatic valves, window open/close switches, and environmental sensors use LoRa.

- -

- Devices that support MQTT can publish their data directly. Motorised blind controllers connect to the local network using WiFi (with ESP32) and send and receive data using MQTT.

- -

- Environmental sensors send data using REST over a WiFi connection.

- -

- Several external sources are periodically queried to obtain meteorological data, air quality data, and other variables that may be of interest for future analysis of the building’s behaviour.

4.3. Control System Design

4.3.1. Adjustment of the Setpoint Temperatures

4.3.2. Logical Processes

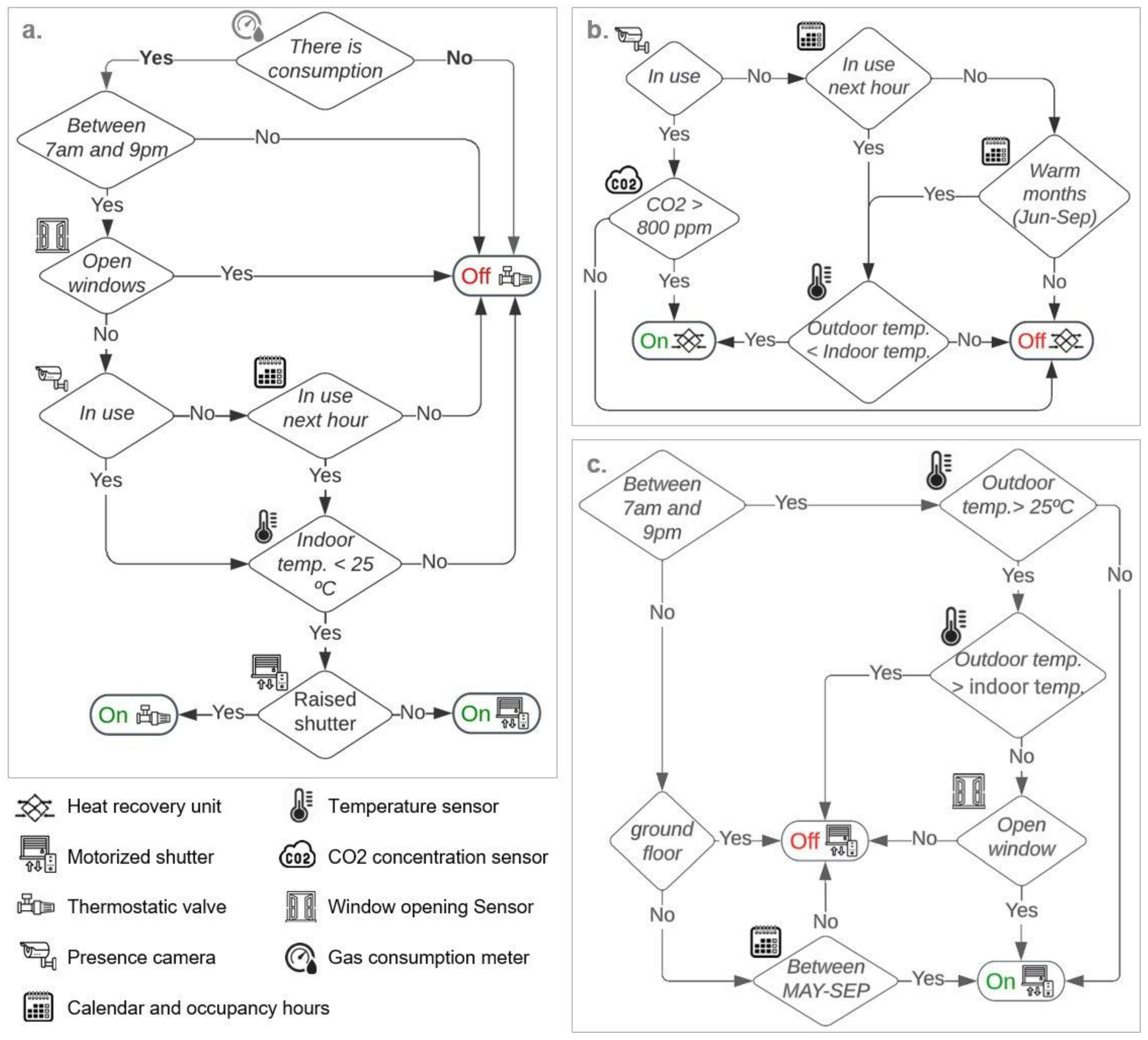

- (a)

- Heating control: The terminals—in this case, thermostatic valves—are activated according to decisions made on the basis of inputs such as time, window status, occupancy, schedule, indoor temperature, and shutter status. In addition, following the flow lines indicated in the diagram, the valves cut off the hot water supply to the terminals when they reach the setpoint temperatures defined for each space. Cutting off this supply means reducing the flow of hot water to the radiators and, in certain situations, reducing gas consumption. This also reduces the thermal gap that the boiler has to overcome, as the temperature of the return water flow drops less because it does not flow through the radiators.

- (b)

- Ventilation control: The system terminals are activated according to decisions based on the following inputs: occupancy, schedules, temperature, and CO2 concentration of each space. According to this programming, the recovery unit can operate in two different situations:

- -

- For cooling in the summer months, when the nighttime outdoor temperature is lower than the indoor temperature, the air exchanger is activated with its bypass function.

- -

- To improve the indoor air quality, when the rooms are occupied and the CO2 concentration level exceeds the limits, without the need to open the windows manually.

- (c)

- Blind control: The terminals are shutter motors that operate according to decisions made on the basis of the following inputs: date and time, indoor and outdoor temperature, window status, and room location within the building. The terminals can be used for solar shading in winter and protection in summer. The actuators have manual switches that allow the blinds to be raised or lowered as required while the command remains on the system. In this way, glare can be avoided, or situations of total darkness can be achieved when the use requires it.

5. Conclusions

- -

- Without investment in the envelope and systems, large buildings in operation can improve thermal performance.

- -

- Prior knowledge plays a crucial role in identifying key issues (such as timetables or facilities, operations, actual occupancy of spaces, comfort and consumption deficiencies, climate adaptations, etc.) and designing proper strategies before initiating the automation design process.

- -

- Energy simulations facilitate decision-making by effectively targeting actions.

- -

- Standards provide a useful framework for focusing action, although their slow updating makes it difficult to track progress in implementation.

- -

- Different variables such as occupancy, air quality, or building states should be taken into account to optimise energy efficiency and user comfort during the building’s operation.

- -

- Mandatory features for competitive automation systems in building savings include real-time monitoring, low cost, low consumption, open-source compatibility, and scalability.

- -

- Given the complexity of the processes involved in this type of development, incorporating self-monitoring capability is appropriate. The proposed system has low cost and low power consumption but, like any automation system, it requires preventive and corrective maintenance and continuous inspection.

- -

- Strategic placement of certain sensors during the initial stages of implementation is vital to enable an accurate initial diagnosis.

- -

- Certain variables in buildings may remain uncontrollable or pose challenges in measurement, necessitating the design of control architectures that are capable of effectively coping with and compensating for disturbances.

- -

- The real-time data collection and analysis carried out initially prove satisfactory for the current methodology. However, repetition of these processes in the future will confirm or disconfirm any concerns. Consequently, continuous review is essential, given that buildings continually adapt to their dynamic needs and circumstances.

- -

- Research focusing on predicting personal thermal comfort assessment models holds crucial significance for informed decision-making in designing and controlling buildings to achieve optimal HVAC. While this article employs operating temperatures defined by Spanish regulations for the automation system’s operation, future research could consider integrating temperatures related to other setpoints, closer to individual thermal comfort preferences, within the system flow.

- -

- The proposed methodology for building automation to enhance thermal performance could be extended to control other functionalities. First and foremost, a specific assessment of each functionality should be conducted, followed by the design of appropriate strategies and functions. EN ISO 52120-1 provides a list of other control, building automation, and technical building management functions contributing to the energy performance of buildings, such as domestic hot water supply, cooling, and lighting. Additionally, emergency and security control services may be incorporated. The selection of suitable devices is imperative to ultimately design an efficient control system.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Specific abbreviations used: | |

| BAC | Building automation and control |

| BACS | Building automation and control system |

| EMS | Energy management system |

| EPB | Energy performance of buildings |

| EPCC | School of Technology of Cáceres |

| HBES | Home and building electronic systems |

| HVAC | Heating, ventilation, and air conditioning |

| IAQ | Indoor air quality |

| IEQ | Indoor environmental quality |

| PPD | Percentage of persons dissatisfied |

| TBM | Technical building management |

References

- United Nations Environment Programme, Global Alliance for Buildings and Construction. 2022. Available online: https://globalabc.org/ (accessed on 18 June 2023).

- International Energy Agency, Buildings. Sectorial Overview. 2022. Available online: https://www.iea.org/reports/buildings (accessed on 5 November 2022).

- The European Parliament and the Council, Directive 2002/91/CE, Relative to the Energy Efficience in Buildings. 2002. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32002L0091 (accessed on 18 June 2023).

- European Climate Infrastructure and Environment Executive Agency, Digitalization in Urban Energy Systems Outlook 2025, 2030 and 2040. 2022. Available online: https://cinea.ec.europa.eu/publications/digitalization-urban-energy-systems_en (accessed on 29 July 2023).

- International Energy Agency. Energy Efficiency and Digitalisation. Available online: https://www.iea.org/areas-of-work/promoting-energy-efficiency/energy-efficiency-and-digitalisation (accessed on 9 January 2023).

- EN 50090; Home and Building Electronic Systems HBES. European Standardization Committee: Bruxelles, Belgium, 2020.

- Rao, A.S.; Radanovic, M.; Liu, Y.; Hu, S.; Fang, Y.; Khoshelham, K.; Palaniswami, M.; Ngo, T. Real-time monitoring of construction sites: Sensors, methods, and applications. Autom. Constr. 2022, 136, 104099. [Google Scholar] [CrossRef]

- Al Dakheel, J.; Del Pero, C.; Aste, N.; Leonforte, F. Smart buildings features and key performance indicators: A review. Sustain. Cities Soc. 2020, 61, 102328. [Google Scholar] [CrossRef]

- Hajdukiewicz, M.; Byrne, D.; Keane, M.M.; Goggins, J. Real-time monitoring framework to investigate the environmental and structural performance of buildings. Build. Environ. 2015, 86, 1–16. [Google Scholar] [CrossRef]

- Tekler, Z.D.; Low, R.; Zhou, Y.; Yuen, C.; Blessing, L.; Spanos, C. Near-real-time plug load identification using low-frequency power data in office spaces: Experiments and applications. Appl. Energy 2020, 275, 115391. [Google Scholar] [CrossRef]

- Morkunaite, L.; Pupeikis, D.; Jurelionis, A.; Fokaides, P.A.; Papadopoulos, A. An Analytical Model for the Impact of Building Control and Automation Upgrade on Space Heating Energy Efficiency. Buildings 2022, 12, 1074. [Google Scholar] [CrossRef]

- Grassi, B.; Piana, E.A.; Lezzi, A.M.; Pilotelli, M. A Review of Recent Literature on Systems and Methods for the Control of Thermal Comfort in Buildings. Appl. Sci. 2022, 12, 5473. [Google Scholar] [CrossRef]

- Baqer, N.S.; Mohammed, H.A.; Albahri, A.; Zaidan, A.; Al-Qaysi, Z. Development of the Internet of Things sensory technology for ensuring proper indoor air quality in hospital facilities: Taxonomy analysis, challenges, motivations, open issues and recommended solution. Measurement 2022, 192, 110920. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Wang, S. An event-driven multi-agent based distributed optimal control strategy for HVAC systems in IoT-enabled smart buildings. Autom. Constr. 2021, 132, 103919. [Google Scholar] [CrossRef]

- Taheri, S.; Hosseini, P.; Razban, A. Model predictive control of heating, ventilation, and air conditioning (HVAC) systems: A state-of-the-art review. J. Build. Eng. 2022, 60, 105067. [Google Scholar] [CrossRef]

- Zou, H.; Zhou, Y.; Jiang, H.; Chien, S.-C.; Xie, L.; Spanos, C.J. WinLight: A WiFi-based occupancy-driven lighting control system for smart building. Energy Build. 2018, 158, 924–938. [Google Scholar] [CrossRef]

- Tekler, Z.D.; Low, R.; Yuen, C.; Blessing, L. Plug-Mate: An IoT-based occupancy-driven plug load management system in smart buildings. Build. Environ. 2022, 223, 109472. [Google Scholar] [CrossRef]

- Zhuang, D.; Gan, V.J.; Tekler, Z.D.; Chong, A.; Tian, S.; Shi, X. Data-driven predictive control for smart HVAC system in IoT-integrated buildings with time-series forecasting and reinforcement learning. Appl. Energy 2023, 338, 120936. [Google Scholar] [CrossRef]

- Merabet, G.H.; Essaaidi, M.; Ben Haddou, M.; Qolomany, B.; Qadir, J.; Anan, M.; Al-Fuqaha, A.; Abid, M.R.; Benhaddou, D. Intelligent building control systems for thermal comfort and energy-efficiency: A systematic review of artificial intelligence-assisted techniques. Renew. Sustain. Energy Rev. 2021, 144, 110969. [Google Scholar] [CrossRef]

- Liu, X.; Ren, M.; Yang, Z.; Yan, G.; Guo, Y.; Cheng, L.; Wu, C. A multi-step predictive deep reinforcement learning algorithm for HVAC control systems in smart buildings. Energy 2022, 259, 124857. [Google Scholar] [CrossRef]

- Alanne, K. A novel performance indicator for the assessment of the learning ability of smart buildings. Sustain. Cities Soc. 2021, 72, 103054. [Google Scholar] [CrossRef]

- Benavente-Peces, C.; Ibadah, N. Buildings Energy Efficiency Analysis and Classification Using Various Machine Learning Technique Classifiers. Energies 2020, 13, 3497. [Google Scholar] [CrossRef]

- Qin, H.; Wang, X. A multi-discipline predictive intelligent control method for maintaining the thermal comfort on indoor environment. Appl. Soft Comput. 2022, 116, 108299. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Guo, D.; Zhang, X.; Lai, Y.; Luo, D. Intelligent Distributed Temperature and Humidity Control Mechanism for Uniformity and Precision in the Indoor Environment. IEEE Internet Things J. 2022, 9, 19101–19115. Available online: https://ieeexplore.ieee.org/document/9745524 (accessed on 18 June 2023). [CrossRef]

- Felius, L.C.; Hamdy, M.; Hrynyszyn, B.D.; Dessen, F. The impact of building automation control systems as retrofitting measures on the energy efficiency of a typical Norwegian single-family house. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012054. [Google Scholar] [CrossRef]

- Ceballos-Fuentealba, I.; Álvarez-Miranda, E.; Torres-Fuchslocher, C.; del Campo-Hitschfeld, M.L.; Díaz-Guerrero, J. A simulation and optimisation methodology for choosing energy efficiency measures in non-residential buildings. Appl. Energy 2019, 256, 113953. [Google Scholar] [CrossRef]

- Ferrari, S.; Beccali, M.; Caputo, P.; Zizzo, G. Electricity Consumption Analysis of Tertiary Buildings: An Empirical Approach for Two University Campuses. J. Arch. Eng. 2020, 26, 05020005. [Google Scholar] [CrossRef]

- EN ISO 52120-1:2022; Energy Performance of Buildings—Contribution of Building Automation, Controls and Building Management—Part 1: General Framework and Procedures. European Standardization Committee: Bruxelles, Belgium, 2022.

- EN 15232-1; Energy Performance of Buildings. Impact of Building Automation, Controls and Building Management. European Standardization Committee: Bruxelles, Belgium, 2018.

- Ożadowicz, A. A New Concept of Active Demand Side Management for Energy Efficient Prosumer Microgrids with Smart Building Technologies. Energies 2017, 10, 1771. [Google Scholar] [CrossRef]

- Engelsgaard, S.; Alexandersen, E.K.; Dallaire, J.; Jradi, M. IBACSA: An interactive tool for building automation and control systems auditing and smartness evaluation. Build. Environ. 2020, 184, 107240. [Google Scholar] [CrossRef]

- Bonomolo, M.; Zizzo, G.; Ferrari, S.; Beccali, M.; Guarino, S. Empirical BAC factors method application to two real case studies in South Italy. Energy 2021, 236, 121498. [Google Scholar] [CrossRef]

- Van Thillo, L.; Verbeke, S.; Audenaert, A. The potential of building automation and control systems to lower the energy demand in residential buildings: A review of their performance and influencing parameters. Renew. Sustain. Energy Rev. 2022, 158, 112099. [Google Scholar] [CrossRef]

- INNOINVEST Project. Promotion of Business Investment in Innovation of Energy Products for Buildings. 2022. Available online: http://innoinvestproject.eu/ (accessed on 17 December 2022).

- Pozas, B.M.; Holgado, B.M.; Bonilla, M.L.; Ramírez, S.B.; de Castro, P.B.G. Iterative Optimization of a Social Inmotics-Based Method in Order to Make Buildings Smart and Resilient. Sustain. Cities Soc. 2022, 82, 103876. [Google Scholar] [CrossRef]

- Pozas, B.M.; de Castro, P.B.G.; García, M.B.; Domínguez, A.S.; Rodríguez, P.G.; Del Río Pérez, M. Improving energy efficiency in public buildings through social inmotics. In Construction Pathology, Rehabilitation Technology and Heritage Management; Rehabend 18; University of Cantabria: Cáceres, Spain, 2018. [Google Scholar]

- Reglamento Instalaciones Térmicas en los Edificios, RITE, BOE-A-2007-15820. 2022. Available online: https://www.boe.es/eli/es/rd/2007/07/20/1027 (accessed on 18 June 2023).

- ANSI/ASHRAE Standard 55-2020; Thermal Environmental Conditions for Human Occupancy. American National Standards Institute: Washington, DC, USA, 2020.

- Agencia Estatal de Meteorología. Weather Data. Available online: https://www.aemet.es/es/serviciosclimaticos/datosclimatologicos/valoresclimatologicos?l=3469A&k=undefined (accessed on 15 January 2023).

- Givoni, B. Comfort, climate analysis and building design guidelines. Energy Build. 1992, 18, 11–23. [Google Scholar] [CrossRef]

- Ministry of Ecological Transition and Demographic Challenge, Agencia Estatal de Meteorología. 2022. Available online: https://www.aemet.es/es/portada (accessed on 18 November 2022).

- DesignBuilder Software Ltd. DESIGN BUILDER. 2022. Available online: https://designbuilder.co.uk/ (accessed on 18 November 2022).

- Montalbán-Pozas, B.; Serrano-Candela, F. Simulating specific bioclimatic strategies to recover valuable designs in vernacular architecture. Case study: Thermal inertia in El Valle, Simulación de estrategias bioclimáticas concretas con el objetivo de poner en valor los diseños de la arquitectura t. Inf. Constr. 2022, 74, e443. [Google Scholar] [CrossRef]

- Ministerio de Transporte Movilidad y Agenda Urbana, DB SI, Minist. Transp. Movil. y Agenda Urbana. 2019. Available online: https://www.codigotecnico.org/pdf/Documentos/SI/DBSI.pdf (accessed on 20 December 2019).

- Ray Ingenieria Electronica. Wireless STHR Sensors. 2015. Available online: http://www.ray-ie.com/ (accessed on 2 January 2020).

- Milesight/IoT. Magnetic Contact Switch. Available online: https://www.milesight-iot.com/lorawan/sensor/em300-mcs/ (accessed on 1 December 2022).

- Foscam. DIY Security, Foscam D2EP. Available online: https://foscam.es/es/camaras-ip-exterior/d2ep.html (accessed on 3 December 2022).

- Climate, M. Vicky LoRaWAN. Available online: https://mclimate.eu/products/vicki-lorawan (accessed on 3 December 2022).

- Recuperators Prana. Prana 200c ErP. Available online: https://es.prana-smart.com/recuperador-prana-200c-erp/ (accessed on 8 December 2022).

- Recuperators Prana. Prana 340s. Available online: https://es.prana-smart.com/recuperador-prana-340s-ventilacao/ (accessed on 28 November 2022).

- Brocaar. ChirpStack. Available online: https://www.chirpstack.io/ (accessed on 13 February 2023).

| BAC and TBM Functions, EN 15232-1 | Actions | |

|---|---|---|

| Ventilation Control | ||

| VENT_RMFLOW_CTRL | Type 1. Time control: the system runs according to a given time schedule | Installation of air exchangers with heat recovery dependent on time schedule, occupancy, air quality, air temperature, heating/cooling loads, number of people or indoor air parameters, and nighttime air temperature |

| Type 2. Occupancy detection: the system runs dependent on the occupancy | ||

| Type 3. The system runs dependent on the air quality demand (CO2 measurement) | ||

| VENT_RTEMP_CTRL | Type 1. Continuous control: either airflow rate or supply air temperature at the room level can be varied continuously; room temperature setpoints are set individually | |

| Type 2. Optimised control: minimum energy demand by optimised control. Both airflow rate and supply air temperature at the room level are controlled dependent on heating/cooling load | ||

| VENT_OAFLOW_CTRL | Type 2. Stage (low/high) OA ratio/OA flow: depending on a given time schedule | |

| Type 3. Variable control: the system is controlled by sensors that detect the number of people or indoor air parameters or adapted criteria. The used parameters are adapted to the kind of activity in the space | ||

| VEN_FREECOOL_CTRL | Type 1. Nighttime cooling: the amount of outside air is set to its maximum during the unoccupied period provided: (1) the room temperature is above the setpoint for the comfort period; (2) the difference between the room temperature and the outside temperature is above a given limit; if free nighttime cooling is achieved by automatically opening windows, there is no airflow control. | |

| Blind Control (Solar Protection) | ||

| BLIND_CTRL | Type 2. Motorised operation with automatic control: automatic controlled dimming to reduce cooling energy | Installation of automated motorised blinds |

| Heating Control | ||

| HEAT_EMIS_CTRL_DEF | Type 2. Individual room control: by thermostatic valves or electronic controller | Installation of thermostatic valves |

| Technical Home and Building Management (TBM) | ||

| BMS_SP | Type 4. Adaptation from a central room (e.g., work station, web operation; room operating units are excluded) with frequent setback of user inputs | Automation and control system |

| BMS_RT | Type 2. Individual setting following a predefined schedule; adaptation from a central room (e.g., work station, web operation; room operating units are excluded); variable preconditioning phases | |

| BMS_FD | Type 1. With central indication of detected faults and alarms | |

| BMS_RPR | Type 2. Analysis, performance evaluation, benchmarking of indoor environment and energy | |

| Inputs | Output Devices (Actions) | ||||

|---|---|---|---|---|---|

| Parameters | Devices | Automated Motorised Blinds | Thermostatic Valves | Air Exchanger with Heat Recovery | |

| Environmental conditions | CO₂ concentration | CO₂ sensor | x | ||

| Indoor humidity and temperature | Thermostatic valve | x | x | x | |

| Indoor sensor | |||||

| Air exchanger with heat recovery | |||||

| Outdoor humidity and temperature | Outdoor sensor | x | x | ||

| AEMET data | |||||

| Occupant- related variables | Number | Presence of cameras | x | x | x |

| Time | Timetable | x | x | ||

| Date | x | x | |||

| Building components | Windows state | Window open/closed status | x | x | |

| Thermostatic valve | |||||

| Blinds state | Automated motorised blinds | - | x | ||

| Building systems | Heating (On/Off) | Boiler sensor | - | ||

| Thermostatic valve | |||||

| Ventilation (On/Off) | Air exchanger with heat recovery | - | |||

| Intelligent thermostatic valves -Vicki LoRaWan -MClimate  | Environmental sensor LoRaTH—RAY | Window open/close status EM300-MCS  –Milesight | Presence camera FOSCAM D2EP | ||

| Size (mm) | 54 × 84 × 54 | 84 × 84 × 36 | 88 × 87 × 27 | 112 × 112 × 88 | |

| Weight (g) | 107 | 150 | 218 | 480 | |

| Output type | Analog | Analog | Digital | Analog | |

| Power supply (duration) | 2xAA batteries (10 years) | 2xAA batteries (1 year) | ER18505 4000 mAh Li-SOCl2 batteries (5/10 years) | Data network | |

| Energy power (w) | 2.7–3.6 | 0.39 | - | Medium/average < 4.5 | |

| Communication | LoRaWAN | LoRaWAN | LoRaWAN and NFC | 10/100 Mbits, POE 802.3af connection and WPS | |

| IP protection | IP40 | IP67 | IK10 vandal resistant | ||

| Memory | Flash: 32 K and RAM: 2 Kb | External SD card slot. Internal 128 GB. Micro SD class 10 min. | |||

| Operating Range | |||||

| Temperature (°C) | −20 to 60 | −40 to 80 | −40 to 70 | from −20 to 60 | |

| Humidity (%) | 0 to 80 | 0 to 100 | 0 to 85 | from 20 to 85 | |

| Measurement Range | Image Sensing | ||||

| Temperature (°C) | - | −40 to 80 | −30 to 70 | Type | 1/4” CMOS 1.0 Mpx |

| Humidity (%) | - | 0 to 100 | 0 to 100 | Resolution (Mpx) | 2.0 (1920 × 1080) |

| CO2 concentration (ppm) | - | 400 to 10,000 | - | Illumination (lux) | Minimum 0 |

| Typical Accuracy | Lens | ||||

| Temperature (°C) | ±0.5 | ±0.3/±0.6 | Lens and zoom | f:2.8, night vision 6× digital zoom | |

| Humidity (%) | ±3 | ±3/± 5 | Vision angle (°) | 130 diagonal and 110 horizontal | |

| CO₂ concentration (ppm) | - | ±3–10 | - | Audio | With input/output |

| Resolution | Software | ||||

| Temperature (°C) | 0.18 | 0.1 | −0.1 | Video | H.264, MJPEG |

| Humidity (%) | 0.39 | 1 | 0.5 | OS-compatible | Windows, MAC, Android… |

| CO₂ concentration (ppm) | - | 1 | - | Multi-stream | Dual-stream |

| Domestic heat recovery unit PRANA 200C ErP  | Industrial heat recovery unit PRANA 340-S  | ||

| Energy class | A+ | A | |

| Volume of air exchanges in recovery (m3/h) | Simultaneous discharge/extraction | 185/177 | 1100/1020 |

| Minimum mode/off mode | 21/10 | 110/from 15 to 30 | |

| Operating temperature range (°C) | Indoor | From −30 to +50 | From 0 to +35 °C |

| Outdoor | From −20 to +45 °C | ||

| Energy consumption (Wh) efficiency (%) | From 4 to 35/93 | From 80 to 310/78 | |

| Power supply (V) | 230 ± 10% | 230 ± 10% | |

| Insulation class/weather protection level | II/IP 24 | ||

| Acoustic pressure (dB(A)) | From 15 to 54 | 52 | |

| Working module length/diameter/with thermal insulation (mm) | 500/200/210 | From 890 to 1030/340/350 | |

| Mounting hole diameter (mm) | 215 | ≥350 | |

| Activity 1 | Activity 2 | |||||

|---|---|---|---|---|---|---|

| Metabolic Speed (W/m2) | Type of Job | With the hands | 15 | With both arms | 65 | |

| Position | Sitting | 10 | Standing | 25 | ||

| Movement | Motionless | 0 | Walking | 110 | ||

| Activity correction | By basal metabolism (W/m2) | 42.5 | ||||

| Subtotal (W/m2) | 67.5 | 242.5 | ||||

| Total (partial by body surface) (W) (body surface 1.80 m2) | 121.5 | 436.5 | ||||

| Base metabolic activity/metabolic activity value (met) | 1.22/1.49 | 1.25/4.37 | ||||

| Degrees of correction (°C) | −0.03 | −3.12 | ||||

| Operative temperature (°C) | Occupied in working period | 21–25 | 18–22 | |||

| Non-working period | Off/Off | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montalbán Pozas, B.; Lucas Bonilla, M.; Serrano Candela, F.; Bustos García de Castro, P. A Methodology for Designing an Automated System to Improve the Thermal Performance of a Large Building in Operation. Buildings 2023, 13, 1938. https://doi.org/10.3390/buildings13081938

Montalbán Pozas B, Lucas Bonilla M, Serrano Candela F, Bustos García de Castro P. A Methodology for Designing an Automated System to Improve the Thermal Performance of a Large Building in Operation. Buildings. 2023; 13(8):1938. https://doi.org/10.3390/buildings13081938

Chicago/Turabian StyleMontalbán Pozas, Beatriz, Marta Lucas Bonilla, Francisco Serrano Candela, and Pablo Bustos García de Castro. 2023. "A Methodology for Designing an Automated System to Improve the Thermal Performance of a Large Building in Operation" Buildings 13, no. 8: 1938. https://doi.org/10.3390/buildings13081938

APA StyleMontalbán Pozas, B., Lucas Bonilla, M., Serrano Candela, F., & Bustos García de Castro, P. (2023). A Methodology for Designing an Automated System to Improve the Thermal Performance of a Large Building in Operation. Buildings, 13(8), 1938. https://doi.org/10.3390/buildings13081938