1. Introduction

In civil engineering practice, experts as well as the general public very often encounter the fact that while reconstructing an object or building attic structures, the construction technical surveys find construction elements affected by biotic agents.

These agents include:

Moulds,

Wood-decay fungi and

Wood-destroying insects, e.g., [

1,

2].

First, we need to focus on masonry drying itself.

The theoretical potential for the remedial treatment of building materials with the use of microwave radiation has been known for many years. Indeed, this technique is already used in practice by a number of implementation companies.

However, it is very difficult to obtain sufficiently precise information on suitable devices, procedures for their use (technology of use), benefits and drawbacks, or potential risks of using microwave radiation.

The implementation companies keep their findings as their know-how, which is understandable.

We are trying to eliminate this deficiency as part of the research our faculty has carried out in collaboration with an implementation company.

The goal is to make sufficient information gradually available on the potential and suitability of using microwave technology in practice. The information was obtained based on laboratory and long-term in situ measurements and experiments.

Last but not least, various construction materials using this progressive technology in civil engineering can be used [

1,

3].

Therefore, theCivil Engineering Faculty, BUT Brno, first focused on experiments related to heating and drying of aerated concrete masonry. This masonry has recently become the most frequently used construction material in construction practice. It is both for new building and for reconstructions of objects.

The obtained results from the below mentioned experiments and measurements will help investors to successfully deal with the following issues:

Effect of age of structures on non-functional hydro insulation,

Cracking of water piping,

Reconstruction of the so-called “wall base”,

Long-term leakage into structures, etc.

2. Microwave Radiation

Microwaves are part of electromagnetic radiation with a wavelength from 1 m to 1 mm, with frequency from 300 MHz to 300 GHz. A global frequency of 2.45 GHz with a corresponding wavelength of 12.2 cm is designated for industrial purposes [

4,

5].

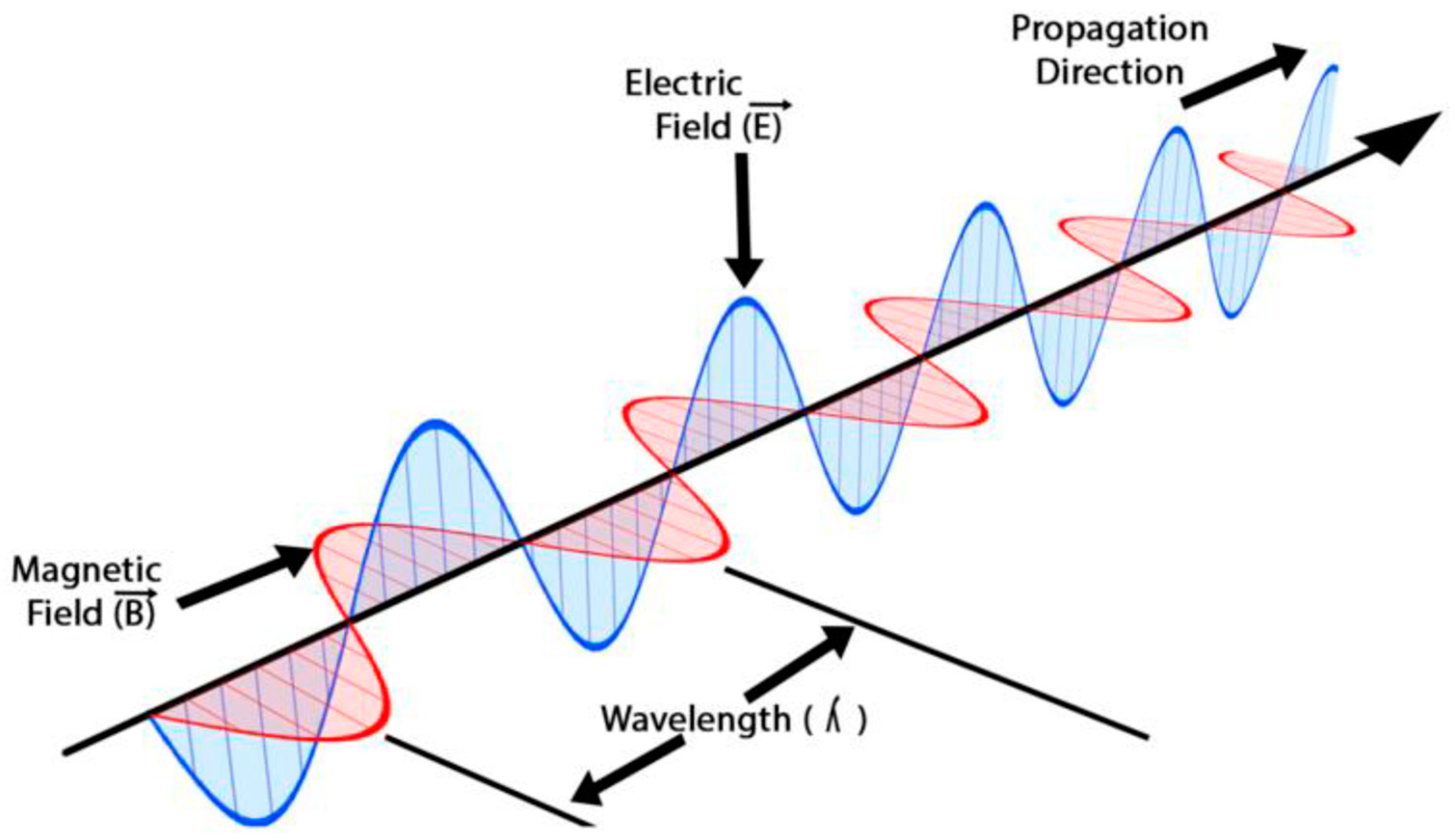

Water molecules are electrically neutral and have bipolar characteristics. Therefore, they are oriented in the electric field by polarity (positive part to negative pole and negative part to positive pole), in case the polarity alternates (

Figure 1). This is exactly the case of microwave radiation. The polarity of the electromagnetic field changes based on the frequency F even more than 10

9 times per second.

2.1. Expression of Microwave Technology (EMW) by Relationships

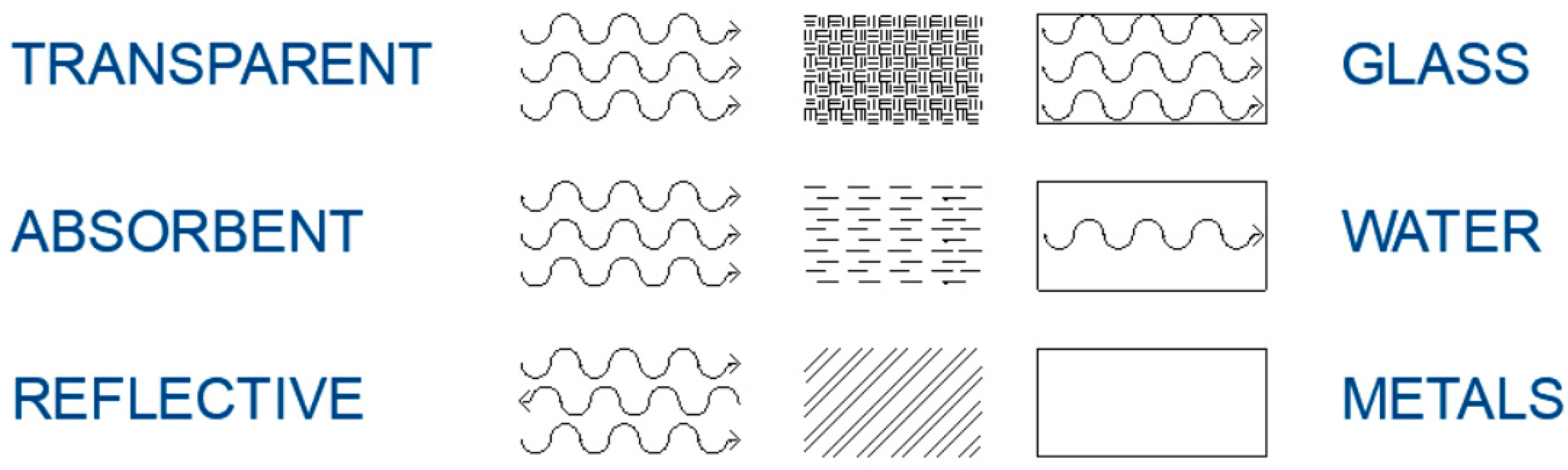

Microwave radiation belongs to a wide range of electromagnetic radiation including the area of visible light, which is based on Maxwell’s equations.

It applies that the vectors characterizing magnetic and electric fields are in each point and in each moment mutually perpendicular, and both are perpendicular to the wave movement direction (

Figure 2) [

1,

6,

7].

Figure 2.

Electromagnetic wave with length λ—electric (E) and wave magnetic (B) components [

8].

Figure 2.

Electromagnetic wave with length λ—electric (E) and wave magnetic (B) components [

8].

From a physical viewpoint, microwave radiation (EMW) can be simply defined in such a way that heat is produced by the effect of the radiation itself when water molecules start moving due to the effects of waves.

The mechanism of microwave energy transformation into heat is given by a relationship [

9]:

where P—energy absorbed in a unit of volume [W·m

−1],

π—Pi constant,

f—microwave field frequency [2450 MHz],

ε′—permittivity [F·m−1],

ε″—material dielectric loss factor,

E—electric field strength inside the material [V·m−1].

Wavelength can be characterized by a relationship [

9]:

where

λ—length of wave [m],

cλ—wave propagation speed [m·s−1],

f—microwave radiation fervency [Hz] (2450 MHz).

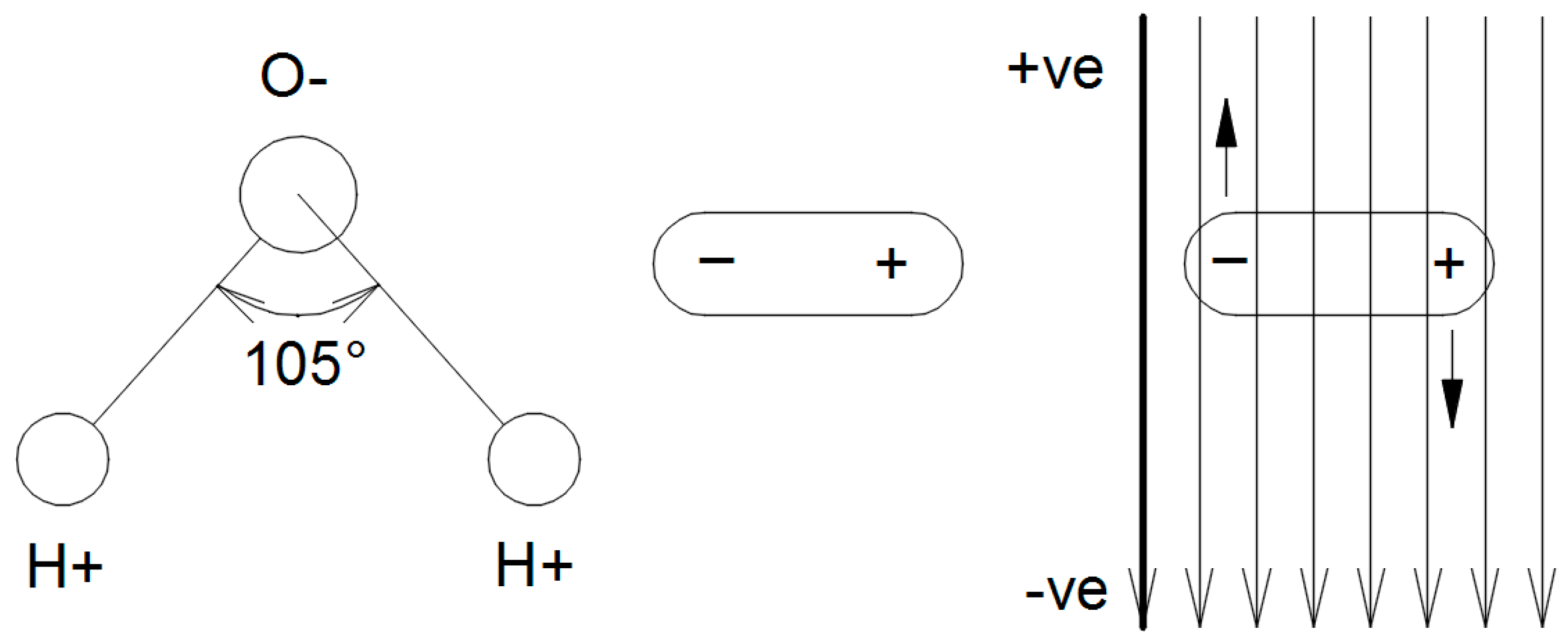

2.2. Effect of EMW Radiation on Construction Materials

Division of microwave radiation effects on construction materials (

Figure 3):

Radiation is reflected (e.g., majority of non-magnetic metals),

Radiation is transmitted (is transparent) (e.g., construction materials, such as wood, ceramics, glass, porcelain, most of plastics, etc.),

Energy is absorbed in the material and transformed into heat (water, magnetic materials (carbon steel), etc. [

10,

11,

12,

13]).

Figure 3.

Microwave radiation and its interactions with different types of materials, e.g., [

1,

14,

15].

Figure 3.

Microwave radiation and its interactions with different types of materials, e.g., [

1,

14,

15].

However, it is true that the majority of materials cannot be unambiguously placed in individual categories.

The first category, i.e., materials that are transmitted by MW, include, e.g., glass, ceramics, wood, and plastic. Nevertheless, the reality is a little different, e.g., [

11,

16,

17].

GLASS—may contain trace amounts of alloying elements, which lead to reflections of part of the microwave energy.

CERAMICS—may also contain trace amounts of metals, and unglazed ceramic products may contain water. In such cases, a part of the energy is reflected, a part is absorbed, and the rest of the energy is transmitted, e.g., [

18,

19,

20].

The second category particularly contains metals. The reflection coefficient varies significantly with different metals and their alloys. This property of the materials is used in radiolocation. A typical representative of this use is a radar.

They are bipolar materials in which individual molecules have the ability and possibility to change their polarity due to electromagnetic radiation. In this case, electromagnetic energy is transformed into kinetic energy and subsequently into thermal energy. A typical example is water. Basically, it makes no difference how the water molecules are stored or absorbed in an irradiated material. However, water usually contains various elements.

In some publications, the effects of MW radiation on absorption materials are described in such a way that the MW energy has an effect from the inside towards the surface. This is obviously not right and is against basic physical laws.

The gradual transformation of MW energy into thermal energy begins at the first contact with water.

This leads to a decrease in the intensity. The thickness and moisture of an irradiated material have an effect on whether and how much energy is transmitted through or whether it is absorbed completely.

This implies that everything that contains water is absorbed by these electromagnetic waves.

Actually, it makes no difference how the water molecules are located or absorbed in the irradiated material.

2.3. Used Devices and Equipment

We used the following microwave generators for individual laboratory experiments and field measurements:

Other meters or measuring technology was used for measuring the required data:

Hydro-thermometer Greisinger GFTH 200, (Greisinger, Regenstauf, Germany)

Infrared thermometer Ahlborn AmiR 7811, (Ahlborn, Germany)

Moisture meter Greisinger GMR 100, (Greisinger, Regenstauf, Germany)

Moisture meter MOIST 210 B, (hf sensor GMBH, Leipsig, Germany)

Thermovision camera FLIR i7 (Flir, Sweden) with resolution 140 × 140 px, thermal sensitivity 0.1 °C, e.g., [

3,

6].

2.4. Methods of Using EMW Radiation

2.4.1. Drying

One of the most common reasons is the drying of structures. In most cases, the main consequences of increasing moisture by weight in bearing structures are as follows:

Existing waterproofing degraded by age,

An unsuitably and improperly performed joint of waterproofing,

A building flooded by water from a flood wave,

Pipe failure of an indoor water system installation, drainage, central heating, and electrical installation,

Water leaking from the external environment.

After the causes disappear or are eliminated, a large amount of water stays in the masonry and needs to be removed (

Table 1). The area must be dried in the shortest possible time so that it can be fully used again.

The time needed to reach the required state, i.e., the speed of drying by, e.g., microwave radiation, depends on many factors. They are particularly concerned with the following:

Speed of water evaporation from the surface of a structure being dried,

Temperature and humidity of outside air,

Transport of water from the depth to the surface,

Speed of ambient air flow,

Barometric air pressure,

Bulk weight of dried material, etc., e.g., [

3,

6].

2.4.2. Biotic Pest Elimination

Biotic pests that are the most common ones are divided into the following:

Wood-Decay Fungi

We focused on the two most common species:

Serpula lacrymans,

Gloeophyllum trabeum.

Both species differ from each other in many aspects.

Some of the most common wood-decay fungi are Serpula lacrymans. This fungus is abundant both on masonry and on wooden elements.

An important aspect of eliminating this biotic pest species is to reach long-term excessive temperatures. However, this is rather uneconomical and often unrealistic.

It is not only necessary to remove the so-called sporocarp of the fungus, as we can see in the Figure below (

Figure 4), but the first aspect is to remove or eliminate moisture providing this fungus with nutrients.

Together with moisture removal from the structure, there is mechanical removal of the so-called root system (rhizomorph).

It is not always possible to maintain the principle in field conditions that all affected wood + part of unaffected wood (0.5–1.0 m) needs to be removed. In addition, the elimination of rhizomorphs that grow over or through adjacent masonry is problematic. Heating the affected materials to the required temperatures with the use of various hot air devices is lengthy, costly, and unfeasible in many cases. In contrast, when using microwave technology, everything that contains water is heated and the surrounding materials are heated from those, regardless of whether they are organic or inorganic materials. In most cases, rhizomorphs are much wetter than the surrounding materials. It is expected that part of the wood-decay fungi with a higher water content will be heated to a higher temperature, e.g., [

1,

5].

Wood-Destroying Insects

At higher temperatures, irreversible changes in insect tissues and their subsequent death occur. How fast this condition is reached depends on the reached temperature.

In general, the time required to kill by heating through microwaves is shorter than using hot air.

Tissues in different insect development stages have different dielectric properties; therefore, they are heated at different speeds, so the effect of temperature also depends on the type of tissue.

Regarding temperatures over 50 °C, in all development stages of insects, irreversible changes of insect tissues and their subsequent death occur.

How fast this condition is reached depends on the reached temperature. The higher the temperature is, the faster the death.

Regarding the liquidation of wood-destroying insects, the suitable heating temperature is over 60 °C for a duration of several minutes (e.g., 10 min) (

Figure 5).

Most common wood-destroying insects:

The common feature of these selected representatives is their development. It is a complete metamorphosis, consisting of the following stages:

As a consequence of the fact that the water content in their bodies is significantly higher than that of the affected wood, they should become heated more rapidly than the surrounding material, e.g., [

6,

14,

21,

22].

2.4.3. Elimination of Moulds

Moulds are microscopic fungi that create fine fibrous coatings. If their life conditions are favourable, they may grow on all types of organic as well as inorganic materials. On wet walls, the occurrence of moulds is manifested by yellow, green, red, or black spots and a musty smell (

Figure 6). Moulds may be confused with efflorescence which is created from various salts and forms a crystalline coating that resembles moulds.

In general, moulds occur everywhere with higher moisture. There is a range of suitable conditions for their occurrence and growth. Leaking of rainwater from the exterior, capillary action, condensation of water vapours, etc.

Since moulds grow on the surface and their microscopic roots grow into the base material at a very shallow depth, in the majority of cases it is easier, faster, and more economical to disinfect it with chemical agents. There are a number of technological procedures:

The use of microwaves is reasonable at sites where the inactivation of mould would require the drying of base materials.

3. Demonstration of Real Measurement and Experiment—Heating of Aerated Concrete Blocks by Microwave Energy [15]

In this paper, we will first focus on the heating of construction materials, e.g., aerated concrete blocks. Surface temperature, weight loss, and moisture elimination will be examined. Microwave irradiation technology will be used in different time intervals of heating of the assembled blocks.

The Brno University of Technology (Faculty of Civil Engineering) began experimental measurements to determine the propagation of microwave radiation through aerated concrete elements. These were the so-called “heating aerated concrete blocks”.

The individual elements were immersed in a bath filled with water before assembling the blocks. In this way, mass moisture absorption was achieved in the assembled blocks.

Besides the heating itself, drying of the masonry elements was investigated. Since aerated concrete elements are becoming an increasingly popular material in construction practice, the findings are very important for further experiments, which we will further investigate and measure experimentally.

The measurement itself was divided into several different categories, such as the propagation of EMW radiation through an aerated concrete single-layer masonry. In another group, the given thickness of the masonry (blocks) was achieved by assembling several elements of the given masonry material. For that reason, we first focused specifically on the composition of masonry with aerated concrete blocks, as seen below in this article.

3.1. Experiment

3.1.1. Description of Experiment

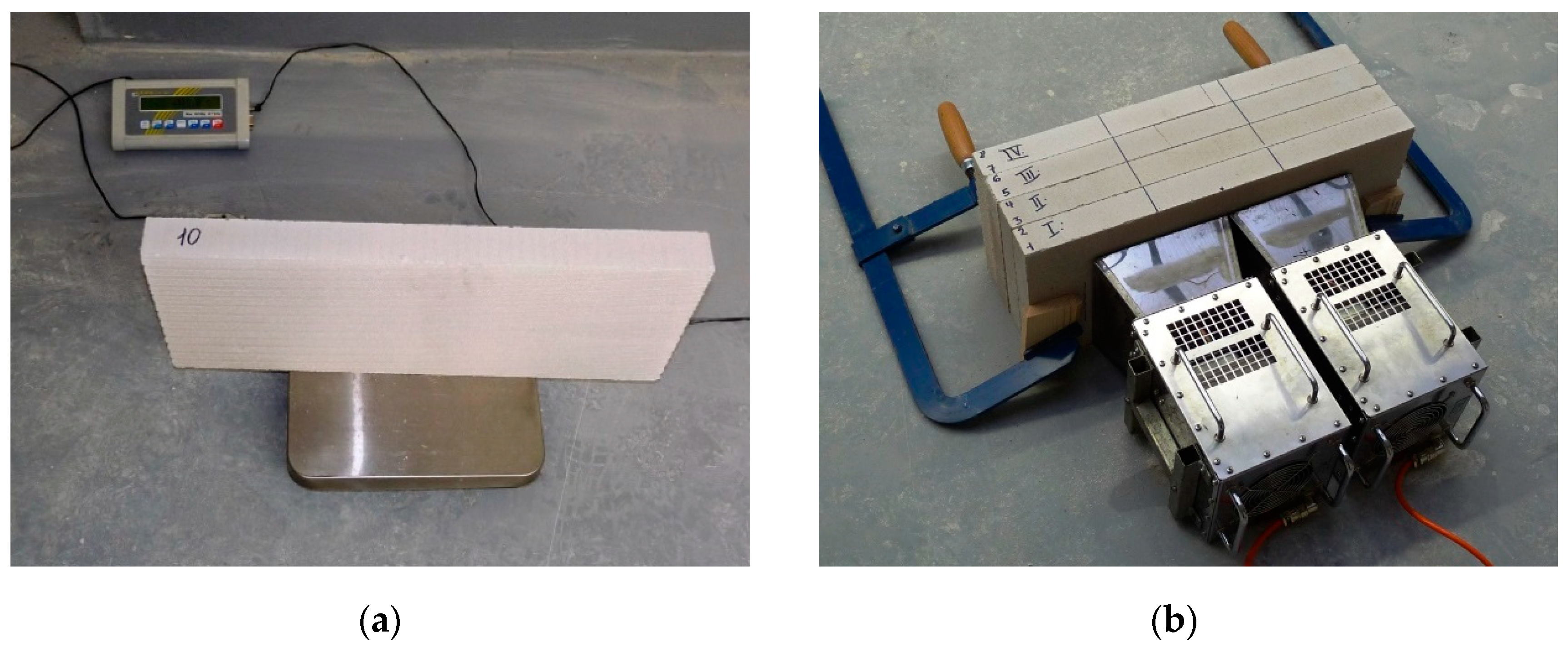

1 pcs of aerated concrete masonry units with dimensions of 600 × 50 × 250 mm were wetted and assembled into 3 blocks of 4 pcs of masonry units. The drying of each block was performed at different time intervals of a of cycle heating and cooling. However, the total heating time was identical for all blocks.

Immediately after the end of the heating phase, the block was always dismantled, the surface temperature was measured for each masonry unit at the front and back sides, and then the masonry units were weighed and assembled again [

23].

3.1.2. Procedure of the Experiment

The course of experiment:

Weighing and description of individual samples;

Immersion of masonry units in a water bath for 60 min;

Taking out of water, 30 min balancing of absorbed moisture, and wrapping in a PVC foil for 22 h;

Weighing of individual masonry units;

Drying of the assembled block (each block was dried in a different time cycle);

The blocks were disassembled and individual masonry units were weighed 120 min after the last heating

Figure 7a shows an aerated concrete masonry unit from which aerated concrete blocks were assembled, as shown in

Figure 7b.

Figure 7b shows microwave generators MG electronic MB with an input power of approx. 1500 W and power of approx. 800 W.

3.1.3. Heating and Cooling Intervals

Time intervals of heating and cooling of the assembled blocks:

Block No. 1: 4 × 15 min of heating, breaks between individual heating sessions of 15 min;

Block No. 2: 3 × 20 min of heating, breaks between individual heating sessions of 20 min;

Block No. 3: 2 × 30 min of heating, break between heating sessions of 30 min.

The mass of individual aerated concrete masonry units was weighed before their drying and then again 18 h after the drying ended.

The blocks were disassembled after each individual stage, surface temperatures were measured on the front and back sides of individual boards, and immediately afterwards, the blocks were assembled into a single unit again.

The whole experiment was focused on the following:

Measuring temperatures reached at different depths of the wet block;

Assessment of moisture loss in individual layers;

Based on the measured surface temperatures of boards and assessment of the propagation of microwave radiation through the whole irradiated block.

3.1.4. Measured Block Temperature Values

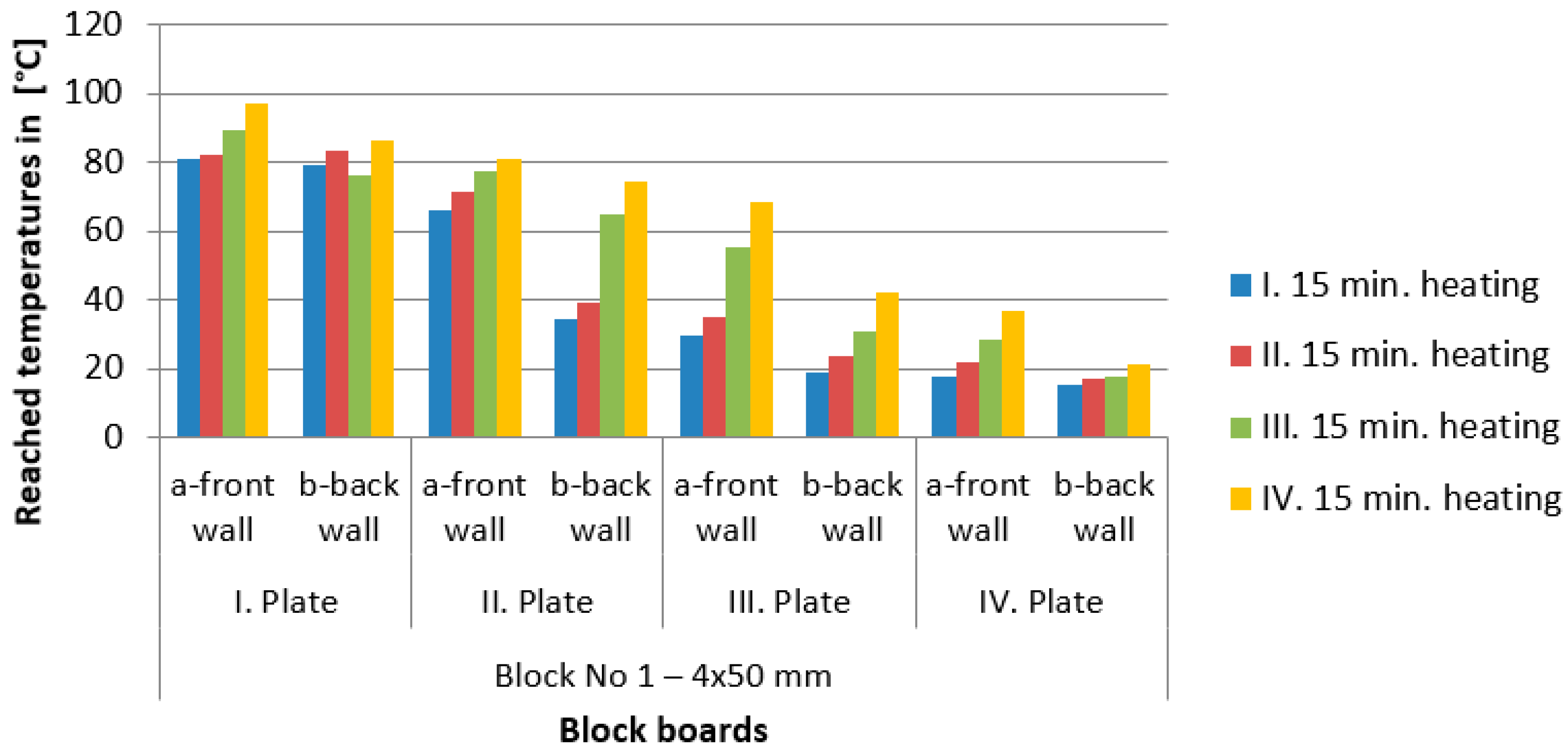

Block No. 1

The values specified in

Table 2 indicate the heating of the aerated concrete masonry units of a fixed assembled block. In addition, the values at the front and back board sides are shown for the individual phases. After the end of the heating phase, the sample was disassembled for easier measurement of temperature values at the front and back sides. After the end of the temperature measurements of the individual board sides of the block, all masonry units were firmly fixed together for another subsequent heating interval. In total, there were 4 heating intervals in 15 min cycles (

Figure 8).

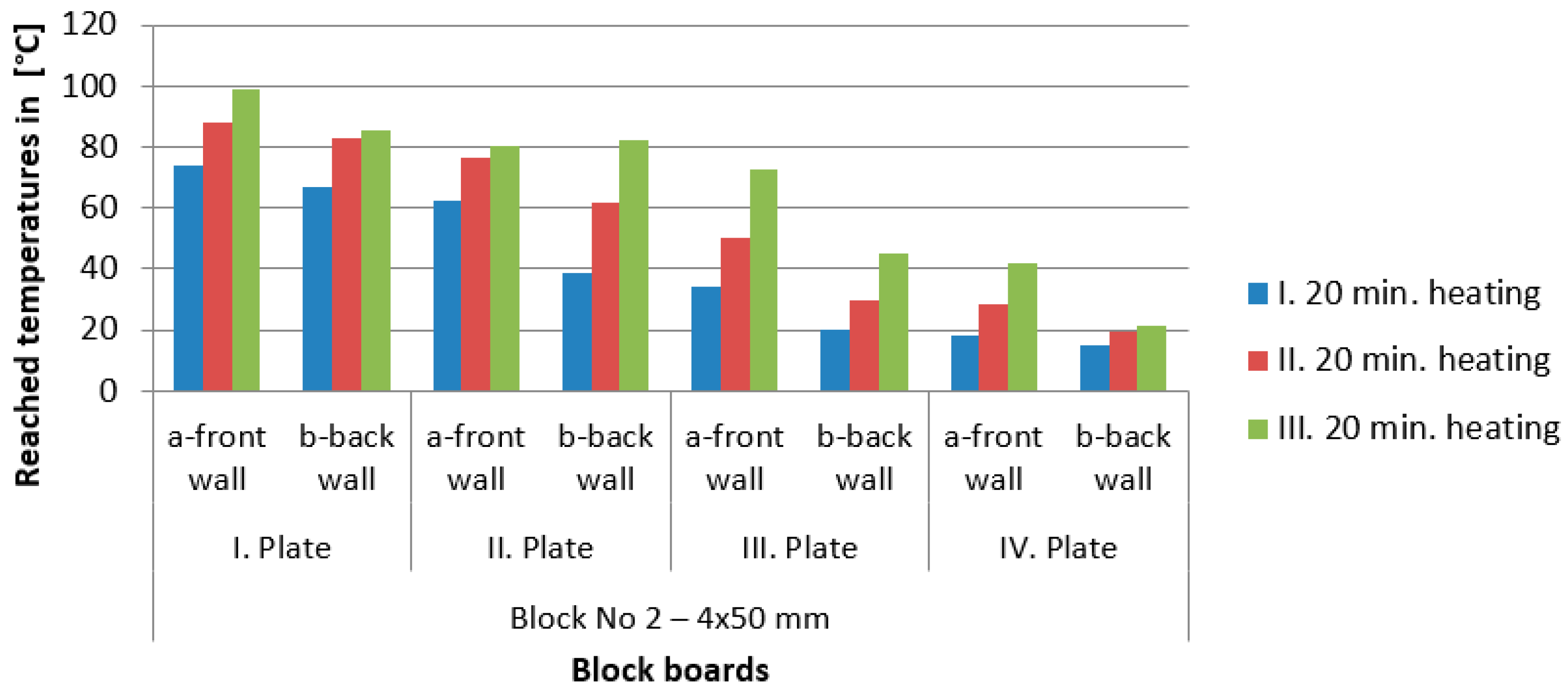

Block No. 2

The values specified in

Table 3 indicate the heating of the aerated concrete masonry units of a fixed assembled block. In addition, the values at the front and back board sides are shown for the individual phases. After the end of the heating phase, the sample was disassembled for easier measurement of temperature values at the front and back sides. After the end of the temperature measurements of the individual board sides of the block, all masonry units were firmly fixed together for another subsequent heating interval. In total there were 3 heating intervals in 20 min cycles (

Figure 9).

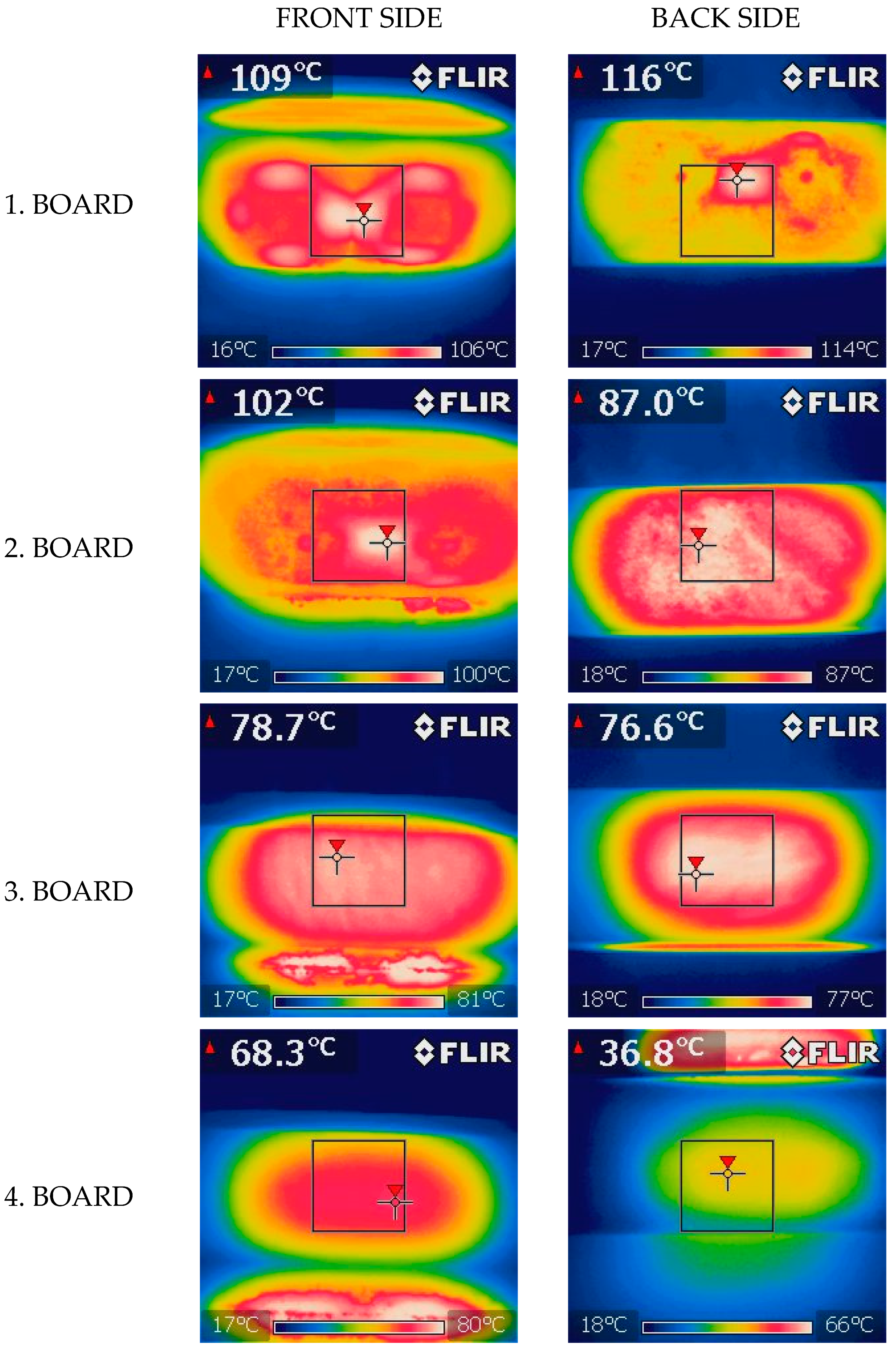

Block No. 3

The values specified in

Table 4 indicate the heating of the aerated concrete masonry units of a fixed assembled block. In addition, the values at the front and back board sides are shown for the individual phases. After the end of the heating phase, the sample was disassembled for easier measurement of temperature values at the front and back sides. After the end of the temperature measurements of the individual board sides of the block, all masonry units were firmly fixed together for another subsequent heating interval. In total, there were 2 heating intervals in 30 min cycles.

Chart No. 3 in

Figure 10 shows the highest temperature values reached in radiation cycles in comparison with two previous assembled blocks.

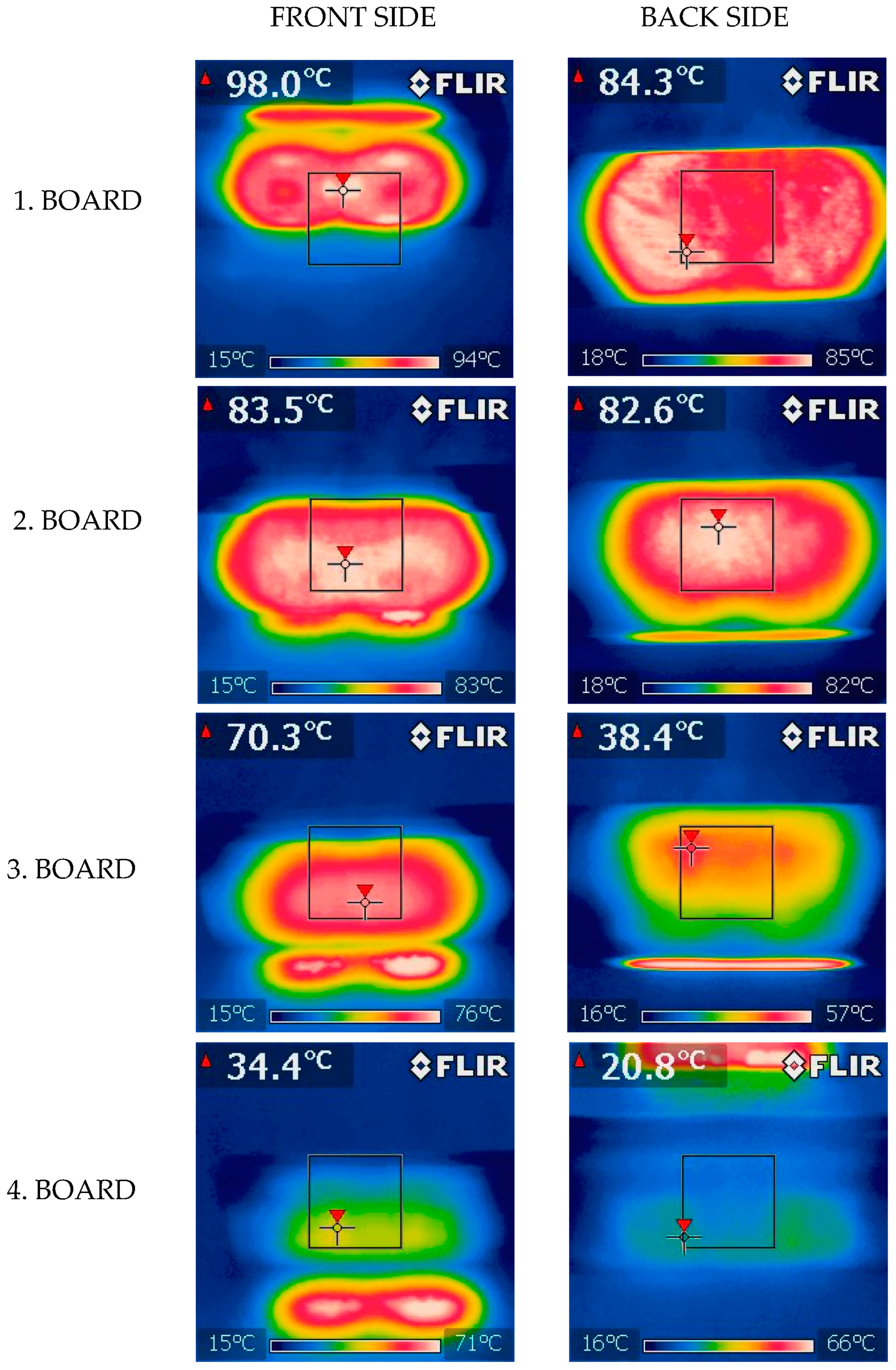

Figure 11 and

Figure 12 show the temperature images of the assembled block measured with a thermal camera. All images show an aerated concrete board and its measured temperatures from the irradiated and back side.

- I

Heating—30 min + 30 min of cooling, moisture evaporation.

- II

Heating—30 min + 30 min of cooling, moisture evaporation.

The Comparison of initial and final masses after moisture evaporation is shown in

Table 5,

Table 6 and

Table 7, where the total loss values of assembled blocks of a given number of masonry units are shown. It is interesting to notice that the lowest initial mass was for Block No. 2, so this block absorbed the lowest amount of water. However, Block No. 2 had the highest mass loss after moisture evaporation.

3.1.5. Evaluation of Experiment

The aim of the experiment was to determine the propagation of the microwave energy and the related heating in the cross-section of a wet block at different heating and cooling cycle lengths.

The total irradiation time was equal in all cases.

The crucial criterion was the measurement of temperatures at the front and back sides of each masonry unit, performed immediately after the ends of the individual heating phases.

The moisture loss that occurred during drying was given by the difference between the initial mass and the mass measured after the last cooling phase.

Although the preparation of all 12 pieces of masonry units before drying was completely identical, their masses were different. This means that they contained different amounts of water, which probably influenced the amount of absorbed microwave energy in individual layers, the propagation of microwaves, and thus the temperature reached in the block cross-section.

The reason was most likely the quality of the individual masonry units and their water absorption.

4. Discussion of Results

It is necessary to point out that a different irradiation frequency was set for each individual assembled block.

The irradiation time was 4 × 15 min for Block No. 1, 2 × 30 min for Block No. 2, and 2 × 30 min for Block No. 3. The sum of the irradiation times was always identical, as shown in the text.

Temperature values on the front and back sides of the boards were measured after individual irradiation phases.

The moisture loss that occurred during drying was given by the difference between the initial weight and the weight measured after the last cooling phase. Weight loss for blocks from concrete masonry reached 7.3–7.90% (for Block No. 1—7.30%; for Block No. 2—7.90%; for Block No. 3—7.51%).

The evaluations of measurements of assembled blocks of aerated concrete masonry found and the values confirmed that the method of microwave irradiation and moisture elimination were the most effective for block No. 2. A heating interval of 3 × 20 min was set for this assembled block. However, it is necessary to point out and emphasize that this block had the highest loss of moisture, while at the same time, it had the lowest value of absorbed water from the water bath in which the shapes were immersed and removed after a given time interval of 60 min.

Another important finding of our research was the fact that all aerated concrete blocks (12 blocks 50 mm wide) were produced, delivered to the testing room, and packed on a single pallet.

Assumingly, such different results were measured due to unsuitably mixed material during the production of blocks.

Another important finding was the fact that the assembled block No. 2 showed the highest weight loss, although its initial weight was the lowest, and the measurements of surface temperatures after the individual heating phases showed that the temperature of block No. 2 was not the highest.

It is necessary to emphasise that the aim was to find the propagation of microwave energy and the related heating in the cross-section of a wet block at different heating and cooling cycle lengths.

The total irradiation time was in all cases identical, as shown above.

The crucial criterion was measuring temperatures on the front and back sides off each block, performed immediately after the end of individual heating phases.

The loss of moisture which occurred during drying was given by the difference between the initial weight and the weight measured after the last cooling phase.

Despite the fact that the preparation of all 12 blocks before drying was identical, their weights were different in many cases. This means that they contained different amounts of water. This probably affected the amount of absorbed microwave energy in individual layers, propagation of microwaves, and the temperature reached in the cross-section of individual parts.

The reason was most likely the quality of the individual used blocks and their water absorption rate.

5. Conclusions

The aim of the experiment was to determine the propagation of microwave energy and related heating in the cross-section of wet blocks at different heating and cooling cycle lengths.

The results of the performed experiments showed that the elimination of moisture through applied microwave radiation is very effective and successful.

Therefore, using this method in real construction will be very effective, particularly from time and economic viewpoints.

Based on extensive experimental activities in the field of moisture elimination by EMW, the following conclusions were made:

Moisture elimination is highly effective,

Electromagnetic radiation technology allows the treatment of structures directly on the spot without the need to disassemble the structure and is relatively fast.

Based on the results of the experimental measurements, further experimental activities can be envisaged:

Setting the duration of EMW (microwave) irradiation,

Setting the power of EMW radiation for effective moisture elimination from irradiated construction material,

Setting EMW radiation intensity.

Regarding mobile microwave radiation generators, it is necessary to take into account that the irradiated area is not heated evenly. This fact is even more complicated for real structures from the viewpoint of free space, e.g., in smaller-sized rooms. It always depends on the size and shape of the antenna which regulates the EMW radiation.

In conclusion, the use of microwave energy can be evaluated for aerated concrete masonry as follows:

Highly optional, depending on emitted and absorbed energy,

Very fast effectiveness to achieve EMW energy for aerated concrete masonry,

Very strong effect of repeated process of “irradiation and exhalation”,

Reduction of high mass moisture in irradiated materials,

Last but not least, the economic viewpoint.

To conclude, this progressive method is recommended for further measurements and scientific research and can be used for other construction materials.