Investigation of the Critical Factors Influencing Multi-Stakeholders’ Participation in Design Optimization of EPC Projects

Abstract

1. Introduction

2. Literature Review

2.1. Design Optimization of Engineering Projects

2.2. Factors Influencing Design Optimization of Engineering Projects

3. Research Methods

3.1. Establishment of the Influencing Factor System

3.2. DEMATEL–ISM Method

4. Result Analysis and Discussion

4.1. Data Collection

4.2. Relationship Analysis of Influencing Factors

4.2.1. Comprehensive Analysis of Influencing Factors

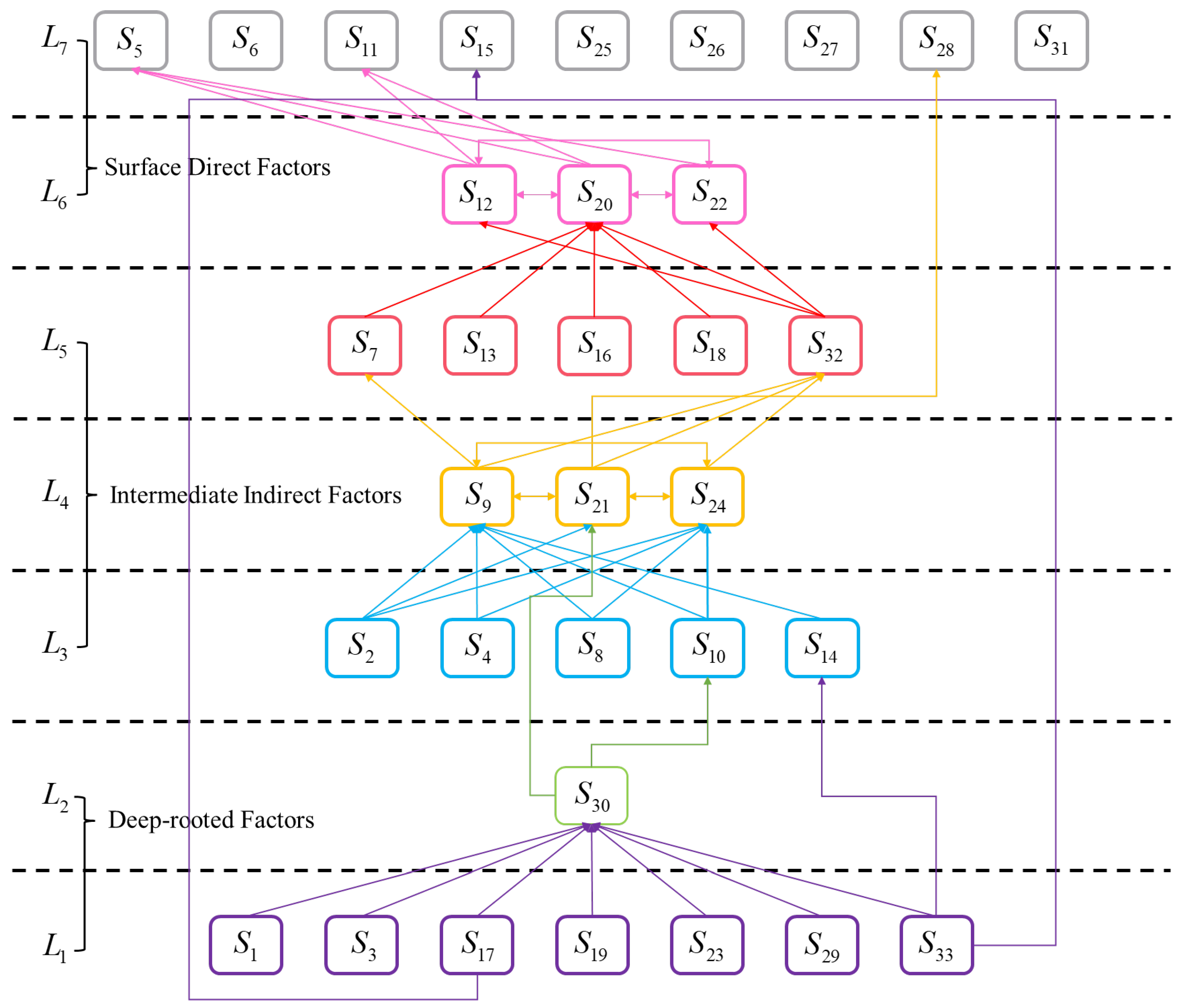

4.2.2. Development of a Hierarchical Structure Model

4.2.3. Analysis of the Causal Relationship between Influencing Factors

4.3. Recommendations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | |

| 1 | 0 | 2.6 | 2.4 | 0.6 | 3.4 | 2 | 2 | 2.6 | 2.4 | 2.5 | 2.4 | 3 | 0 | 2.6 | 0.1 | 0.1 | 0 | 0 | 0.4 | 2.4 | 2.4 | 2.5 | 0 | 2.2 | 0 | 0.2 | 2.4 | 2.8 | 0.1 | 2.8 | 0.6 | 2.2 | 0 |

| 2 | 2.6 | 0 | 2.4 | 1 | 2.8 | 2.6 | 2 | 2.7 | 2 | 2.2 | 2.8 | 2.4 | 2.2 | 0.4 | 0.2 | 0.2 | 0 | 0 | 0.4 | 2.4 | 2.5 | 2.2 | 0.2 | 2.3 | 0 | 0.3 | 2.4 | 2.7 | 2.3 | 2.2 | 0.2 | 1.8 | 2.6 |

| 3 | 2.6 | 2.8 | 0 | 2.2 | 2.8 | 2.4 | 2.8 | 2.5 | 2.8 | 2.4 | 2.8 | 2.6 | 0.2 | 0.3 | 1.6 | 0.2 | 0 | 0 | 0.2 | 2.4 | 2.4 | 2.4 | 2 | 2.2 | 0.1 | 0.2 | 2.4 | 2.3 | 2.5 | 2.5 | 0.2 | 2.1 | 2.6 |

| 4 | 2.5 | 2.6 | 2.2 | 0 | 2.6 | 1 | 2.6 | 2.5 | 2.2 | 2.2 | 2.5 | 2.4 | 2.6 | 2.4 | 0.2 | 0 | 0 | 0 | 0.2 | 2.4 | 2.5 | 2.2 | 0.2 | 2.4 | 0.1 | 0.3 | 0.3 | 0.6 | 2.4 | 2.4 | 0.4 | 1.9 | 2.5 |

| 5 | 0.2 | 0.2 | 0.2 | 0.2 | 0 | 0.5 | 2.3 | 0.2 | 2.5 | 2 | 1.2 | 2.6 | 0 | 2.2 | 2.3 | 0.1 | 0 | 0 | 0.2 | 2.3 | 2 | 2.5 | 2.2 | 2.4 | 0.1 | 0.3 | 2.6 | 0.5 | 2.6 | 2.2 | 0.2 | 2.4 | 0.2 |

| 6 | 1.8 | 0.2 | 0.3 | 0.6 | 2.5 | 0 | 2.6 | 0 | 2.1 | 2 | 2.2 | 2.6 | 0 | 2.4 | 0.2 | 0.2 | 0 | 0 | 0.4 | 2.6 | 2 | 2.3 | 0.2 | 2.2 | 0 | 0.3 | 0.4 | 0.4 | 2.3 | 2 | 0.4 | 2 | 1.8 |

| 7 | 2.2 | 0.6 | 0.5 | 0.8 | 2.3 | 2.1 | 0 | 2.4 | 2.2 | 2.6 | 2.9 | 2.2 | 0 | 0.4 | 2.3 | 0.1 | 0 | 0 | 0.3 | 2.9 | 2 | 2.2 | 2.4 | 2.4 | 0 | 0.4 | 2.7 | 2.4 | 0 | 2.2 | 0.2 | 2.3 | 2.2 |

| 8 | 2.5 | 2.8 | 2 | 2.4 | 2.4 | 2.6 | 2.4 | 0 | 2.6 | 2.2 | 2.6 | 2.3 | 0 | 0 | 2 | 0 | 0.2 | 0 | 0.2 | 2.6 | 1.3 | 2.4 | 0.3 | 2.6 | 0.2 | 0.4 | 2.7 | 2 | 0.2 | 2.2 | 0.3 | 1.8 | 2.5 |

| 9 | 2.6 | 0.3 | 2.1 | 0.8 | 2.5 | 2.4 | 2.8 | 2.4 | 0 | 2.5 | 2.8 | 2.2 | 0 | 0.4 | 2.1 | 0.2 | 2.4 | 0 | 0 | 2.8 | 2.7 | 2 | 2.2 | 2.4 | 2.2 | 2 | 2.8 | 2.7 | 2.3 | 1 | 0.4 | 2 | 2.6 |

| 10 | 2.2 | 2.6 | 1.8 | 0.7 | 2.5 | 2.2 | 1.1 | 2.6 | 2.1 | 0 | 2.8 | 2.4 | 0 | 2.6 | 2 | 0 | 0.2 | 0 | 0 | 2.4 | 2 | 2.4 | 2 | 2.5 | 0.3 | 0.1 | 2.4 | 2.4 | 2.6 | 1.8 | 0.4 | 2 | 2.2 |

| 11 | 0.2 | 0.2 | 0.2 | 2 | 2.6 | 2.2 | 2.6 | 0.6 | 2.3 | 2.6 | 0 | 2.5 | 0 | 0.6 | 2.1 | 0.1 | 0 | 0 | 0 | 2.2 | 2.4 | 2.2 | 2.2 | 2.6 | 0.2 | 0 | 2.2 | 2.7 | 2.2 | 2.4 | 0.4 | 2.6 | 0.2 |

| 12 | 0.2 | 0.3 | 0.2 | 2.1 | 2.4 | 0.6 | 0.4 | 2.7 | 2.4 | 2.3 | 2.6 | 0 | 2.4 | 2.6 | 2.2 | 0.2 | 0.1 | 0 | 0 | 2.8 | 2.4 | 2.5 | 2.2 | 2.8 | 2 | 0 | 0.1 | 2.4 | 2.3 | 2.4 | 0.2 | 2 | 0.2 |

| 13 | 0.2 | 2 | 1.8 | 2.3 | 2.4 | 2.1 | 0.1 | 0.2 | 1 | 0.3 | 2.5 | 2.4 | 0 | 2.2 | 2.4 | 0.1 | 1.8 | 0 | 0 | 2.6 | 2.1 | 2.3 | 1.8 | 2.2 | 0.4 | 0 | 0.2 | 2.4 | 2.4 | 2 | 0.2 | 2.7 | 0.2 |

| 14 | 2.2 | 0.2 | 0.3 | 1.8 | 2.6 | 2.4 | 0.1 | 2.2 | 2.8 | 3 | 2.4 | 2.4 | 0.2 | 0 | 2.4 | 0 | 0.2 | 0 | 0 | 2.3 | 2.1 | 2.6 | 2 | 2.4 | 2.2 | 0 | 0 | 2.4 | 2.2 | 2.2 | 0.4 | 2.2 | 2.2 |

| 15 | 0.2 | 0.4 | 0.2 | 2.1 | 1.2 | 0.6 | 0.2 | 0.4 | 2.8 | 2.8 | 0.2 | 2.3 | 0.2 | 2.6 | 0 | 0.2 | 0 | 0 | 0 | 2.8 | 2.2 | 2.4 | 2 | 2.3 | 2.2 | 0 | 0 | 2.6 | 2.6 | 2.6 | 0.4 | 2 | 0.2 |

| 16 | 1.7 | 0.2 | 0.4 | 1.8 | 1.8 | 0.6 | 2 | 0.2 | 2.4 | 0.4 | 0.2 | 2.2 | 2.4 | 2.1 | 2.3 | 0 | 0 | 0 | 0 | 2.4 | 2.2 | 2.5 | 2.2 | 2.4 | 0.2 | 2.1 | 2.2 | 2.4 | 2.3 | 2 | 0.3 | 2.1 | 1.7 |

| 17 | 2.5 | 1.9 | 2.4 | 2.6 | 2.3 | 0.5 | 2.7 | 2.6 | 2.4 | 2.6 | 2.6 | 2.5 | 0 | 2.3 | 2.7 | 0.2 | 0 | 0.2 | 0 | 2.4 | 2.5 | 2.3 | 2.6 | 2.6 | 0.2 | 0.6 | 0.2 | 2.3 | 2.2 | 2.4 | 0.4 | 1.8 | 2.5 |

| 18 | 1.8 | 0.6 | 0.7 | 0.6 | 2.5 | 0.4 | 0.6 | 2.1 | 2.4 | 2.2 | 2.6 | 2.2 | 0.2 | 0.6 | 1.8 | 0 | 2.2 | 0 | 0 | 2.6 | 2.2 | 2.4 | 0.3 | 2.2 | 0.2 | 0.2 | 0.4 | 2.2 | 2.2 | 2.2 | 0.2 | 2.4 | 2.1 |

| 19 | 2.4 | 2.3 | 2.4 | 2.4 | 2.2 | 0.6 | 2.2 | 2.2 | 2.2 | 2 | 2.7 | 2.4 | 0 | 2.2 | 2 | 0.2 | 0.2 | 0 | 0 | 2.3 | 1.8 | 2.9 | 0.3 | 2.3 | 2.2 | 1.6 | 2.4 | 2.2 | 2.3 | 2.2 | 2.6 | 2.2 | 1.6 |

| 20 | 2.4 | 0.4 | 2 | 2 | 2.1 | 1.8 | 2.4 | 2.3 | 2.2 | 2.2 | 2.2 | 2.2 | 2.3 | 2.4 | 2.3 | 0.2 | 2 | 0 | 0 | 0 | 2 | 2.2 | 2.2 | 2.4 | 2.2 | 0.4 | 2 | 1.8 | 2.2 | 2.5 | 0.2 | 2.2 | 2 |

| 21 | 0.6 | 2.2 | 1.7 | 2.2 | 2.4 | 1.8 | 2.5 | 2.2 | 2.8 | 0.3 | 2.1 | 2 | 2 | 2 | 2.7 | 0.2 | 0.2 | 0 | 0 | 2.6 | 0 | 2 | 2.8 | 2.3 | 0.2 | 2.6 | 2.6 | 2.2 | 2.2 | 2.4 | 0.3 | 2.4 | 2.1 |

| 22 | 1.8 | 2.2 | 1.8 | 2.1 | 2.6 | 0.6 | 0.4 | 2.4 | 2.1 | 2.2 | 0.2 | 2.4 | 2.1 | 2.6 | 1.9 | 0.1 | 1.8 | 0 | 0 | 2.2 | 2 | 0 | 2 | 2.3 | 2 | 0.2 | 2.2 | 2.4 | 2.2 | 2.3 | 0.2 | 1.6 | 2.1 |

| 23 | 0.5 | 1.6 | 1.8 | 2.4 | 1.8 | 1.8 | 2.4 | 0.2 | 3 | 1.6 | 2.4 | 2.4 | 2.7 | 2.3 | 2.3 | 0 | 0 | 0 | 0 | 2.6 | 2.4 | 2.2 | 0 | 2.4 | 2.4 | 2.4 | 2.3 | 2.1 | 2.2 | 2 | 0.2 | 2.2 | 1.9 |

| 24 | 1.7 | 2.3 | 2.3 | 1.9 | 2.2 | 2 | 2.6 | 2 | 2.2 | 1.8 | 2.8 | 2 | 2.2 | 2.2 | 2.2 | 0.2 | 0.1 | 0 | 0 | 2.2 | 2.6 | 2.2 | 0.4 | 0 | 2.2 | 2.4 | 2.6 | 2.2 | 0.3 | 2.6 | 0.3 | 2.2 | 1.8 |

| 25 | 1.7 | 1.6 | 2 | 2.1 | 2.2 | 1.4 | 0.6 | 1.9 | 0.5 | 1.6 | 2.4 | 2.2 | 0 | 2.4 | 1.6 | 0.2 | 0.1 | 0 | 0 | 2.2 | 2.2 | 2 | 0.2 | 0.4 | 0 | 0.4 | 0.2 | 2 | 2.1 | 2.1 | 0.2 | 1.5 | 1.8 |

| 26 | 1.6 | 1.8 | 2 | 0.8 | 1.8 | 2.2 | 1.2 | 2.2 | 1 | 2.2 | 2.7 | 2.3 | 0.2 | 1.4 | 1.7 | 0.1 | 0.2 | 0 | 0 | 2.2 | 1.2 | 2.2 | 0.4 | 0.2 | 2.4 | 0 | 1.3 | 2.4 | 0.7 | 2 | 0.4 | 1.7 | 2 |

| 27 | 1.9 | 0.4 | 2 | 0.3 | 2.4 | 1.1 | 2 | 0.9 | 2.4 | 2.2 | 2.8 | 2.5 | 0.2 | 1 | 1.4 | 0.2 | 0.2 | 0 | 0 | 2.2 | 1.2 | 2.2 | 0.6 | 0.6 | 0.4 | 0.4 | 0 | 2.6 | 0.8 | 2.4 | 0.2 | 2 | 1.8 |

| 28 | 1.8 | 0.2 | 0.5 | 0.2 | 1.8 | 2.2 | 2.4 | 0.6 | 2.3 | 1.8 | 2.8 | 2.4 | 0.2 | 1.6 | 2.4 | 0.1 | 0.2 | 0 | 0 | 2.4 | 2 | 2.4 | 2.2 | 2.2 | 0.4 | 0.5 | 2.6 | 0 | 0.8 | 2 | 0.2 | 2.1 | 2 |

| 29 | 2.2 | 0.4 | 0.6 | 2.7 | 2.5 | 0.8 | 2.2 | 0.8 | 2.2 | 2.3 | 2.4 | 2.7 | 2.1 | 2.2 | 2.2 | 0 | 0.2 | 0 | 0 | 2.5 | 2.4 | 2.5 | 2 | 2.6 | 0.6 | 0.4 | 2.4 | 2.4 | 0 | 2.4 | 0.3 | 2.2 | 1.8 |

| 30 | 1.7 | 2.5 | 2.1 | 2.8 | 1.9 | 0.9 | 2.4 | 2 | 2.6 | 2.2 | 2.8 | 2.6 | 2.2 | 2.2 | 2.2 | 0.2 | 1.8 | 0 | 0 | 2.3 | 2.9 | 2.1 | 1.9 | 2.4 | 0.2 | 2 | 2.2 | 2 | 2.4 | 0 | 0.2 | 2 | 2 |

| 31 | 0.5 | 0.8 | 0.8 | 0.6 | 2.6 | 2.1 | 2.2 | 2.4 | 1.9 | 0.4 | 0.2 | 1.2 | 2.2 | 0.8 | 0.6 | 0 | 0.4 | 0 | 0 | 1.4 | 2 | 2.4 | 1.9 | 2.4 | 0.2 | 1.7 | 2.4 | 2.4 | 2.8 | 2.2 | 0.2 | 2.4 | 1.7 |

| 32 | 0.8 | 2 | 2 | 2.2 | 2.8 | 2.2 | 2.4 | 0.4 | 2.5 | 0.6 | 2.4 | 2.5 | 2.2 | 2.4 | 1.8 | 0 | 0.2 | 0 | 0 | 2.5 | 1.9 | 2.6 | 0.9 | 2.5 | 0.5 | 2.2 | 2.7 | 1 | 0.5 | 1.2 | 0.2 | 0 | 2 |

| 33 | 2.2 | 1.8 | 2 | 2.6 | 2 | 2.5 | 2.2 | 2 | 2.3 | 2.1 | 2.4 | 2.2 | 2.6 | 2.2 | 2.5 | 2.4 | 2.5 | 0 | 0 | 2.7 | 2.1 | 2.4 | 2.1 | 2.6 | 2.2 | 2 | 2 | 2.4 | 1.1 | 2 | 0.2 | 2.6 | 0 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | |

| 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 2 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| 4 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 8 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 9 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 |

| 10 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 12 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 14 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 17 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| 18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 19 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| 20 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 |

| 21 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| 22 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 23 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 |

| 24 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 |

| 25 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 26 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 27 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 28 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 29 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| 30 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| 31 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 32 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| 33 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 |

References

- Oyetunji, A.A.; Anderson, S.D. Relative effectiveness of project delivery and contract strategies. J. Constr. Eng. Manag. 2006, 132, 3–13. [Google Scholar] [CrossRef]

- Liu, B.; Huo, T.; Meng, J.; Gong, J.; Shen, Q.; Sun, T. Identification of key contractor characteristic factors that affect project success under different project delivery systems: Empirical analysis based on a group of data from China. J. Manag. Eng. 2016, 32, 05015003. [Google Scholar] [CrossRef]

- Liu, B.; Xue, B.; Huo, T.; Shen, G.; Fu, M. Project external environmental factors affecting project delivery systems selection. J. Civ. Eng. Manag. 2019, 25, 276–286. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Liu, J.Y.; Li, B.G.; Lin, B.S. Project delivery system selection of construction projects in China. Expert. Syst. Appl. 2011, 38, 5456–5462. [Google Scholar] [CrossRef]

- Liu, B.; Huo, T.; Shen, Q.; Yang, Z.; Meng, J.; Xue, B. Which owner characteristics are key factors affecting project delivery system decision making? Empirical analysis based on the rough set theory. J. Manag. Eng. 2015, 31, 05014018. [Google Scholar] [CrossRef]

- Galloway, P. Design-build/EPC contractor’s heightened risk-Changes in a changing world. J. Leg. Aff. Dispute Resolut. Eng. Constr. 2009, 1, 7–15. [Google Scholar] [CrossRef]

- Hale, D.R.; Shrestha, P.P.; Gibson, G.E., Jr.; Migliaccio, G.C. Empirical comparison of design/build and design/bid/build project delivery methods. J. Constr. Eng. Manag. 2009, 135, 579–587. [Google Scholar] [CrossRef]

- Habibi, M.; Kermanshachi, S.; Rouhanizadeh, B. Identifying and measuring engineering, procurement, and construction (EPC) key performance indicators and management strategies. Infrastructures 2019, 4, 14. [Google Scholar] [CrossRef]

- Soibelman, L.; Liu, L.; Kirby, J.; East, E.; Caldas, C.; Lin, K. Design review checking system with corporate lessons learned. J. Constr. Eng. Manag. 2003, 129, 475–484. [Google Scholar] [CrossRef]

- Love, P.; Lopez, R.; Kim, J.T.; Kim, M.J. Influence of organizational and project practices on design errors costs. J. Perform. Constr. Fac. 2014, 28, 303–310. [Google Scholar] [CrossRef]

- Gransberg, D.D.; Windel, E. Communicating design quality requirements for public sector design/build projects. J. Manag. Eng. 2008, 24, 105–110. [Google Scholar] [CrossRef]

- Fredrickson, K. Design guidelines for design-build projects. J. Manag. Eng. 1998, 14, 77–80. [Google Scholar] [CrossRef]

- Zhang, S.B.; Liu, X.Y.; Gao, Y.; Ma, P. Effect of level of owner-provided design on contractor’s design quality in DB/EPC projects. J. Constr. Eng. Manag. 2019, 145, 04018121. [Google Scholar] [CrossRef]

- Grau, D.; Back, W.; Prince, J. Benefits of on-site design to project performance measures. J. Manag. Eng. 2012, 28, 232–242. [Google Scholar] [CrossRef]

- Wang, T.; Tang, W.; Qi, D. Enhancing Design Management by Partnering in Delivery of International EPC Projects: Evidence from Chinese Construction. J. Constr. Eng. Manag. 2015, 142, 04015099. [Google Scholar] [CrossRef]

- Li, M.K.; Lie, Y.H.; Wong, B.C.L.; Gan, V.J.L.; Cheng, J.C.P. Automated structural design optimization of steel reinforcement using graph neural network and exploratory genetic algorithms. Automat. Constr. 2023, 146, 104677. [Google Scholar] [CrossRef]

- Cai, H.W.; Aref, A.J. On the design and optimization of hybrid carbon fiber reinforced polymer-steel cable system for cable-stayed bridges. Compos. Part. B-Eng. 2015, 68, 146–152. [Google Scholar] [CrossRef]

- Baghdadi, A.; Heristchian, M.; Kloft, H. Design of prefabricated wall-floor building systems using meta-heuristic optimization algorithms. Automat. Constr. 2020, 114, 103156. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Mei, C.; Wang, H.; Lu, J.H. A multi-objective optimization model for synergistic effect analysis of integrated green-gray-blue drainage system in urban inundation control. J. Hydrol. 2022, 609, 127725. [Google Scholar] [CrossRef]

- Wang, Y.M.; Zhang, X.D.; Zhang, D.Z. The structure design of integrated urban drainage systems: A view of robust optimization. J. Environ. Manag. 2022, 322, 116050. [Google Scholar] [CrossRef]

- Berard, O.; Karlshoej, J. Information delivery manuals to integrate building product information into design. In Proceedings of the 28th International Conference of CIB W78, Sophia Antipolis, France, 26–28 October 2011. [Google Scholar]

- Zhang, Q.Z.; Tang, W.Z.; Liu, J. Improving Design Performance by Alliance between Contractors and Designers in International Hydropower EPC Projects from the Perspective of Chinese Construction Companies. Sustainability 2018, 10, 1171. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, W.Z.; Colin, F. Improving Design by Partnering in Engineering–Procurement–Construction (EPC) Hydropower Projects: A Case Study of a Large-Scale Hydropower Project in China. Water 2021, 13, 3410. [Google Scholar] [CrossRef]

- Gunduz, M.; Aly, A.A.; Mekkawy, T.E. Value Engineering Factors with an Impact on Design Management Performance of Construction Projects. J. Manag. Eng. 2022, 38, 04022012. [Google Scholar] [CrossRef]

- Walker, D.H.T.; Walker, B.L. Understanding early contractor involvement (ECI) procurement forms. In Proceedings of the 28th Annual ARCOM Conference, Edinburgh, UK, 3–5 September 2012; pp. 877–887. [Google Scholar]

- Wang, S.; Liu, X. Development of EPC model in Chinese public projects: Evolutionary game among stakeholders. J. Asian. Archit. Build. 2022, 21, 2095–2113. [Google Scholar] [CrossRef]

- FIDIC (International Federation of Consulting Engineers). Conditions of Contract for EPC/Turnkey Projects; FIDIC: Geneva, Switzerland, 2017. [Google Scholar]

- Mostafavi, A.; Karamouz, M. Selecting appropriate project delivery system: Fuzzy approach with risk analysis. J. Constr. Eng. M. 2010, 136, 923–930. [Google Scholar] [CrossRef]

- Li, L. The analysis on influencing factor of cost control of EPC project based on the DEMATEL-ISM. Civ. Eng. J. 2022, 31, 66–84. [Google Scholar] [CrossRef]

- Chua, D.K.H.; Kog, Y.C.; Loh, P.K. Critical success factors for different project objectives. J. Constr. Eng. M. 2016, 142, 142–150. [Google Scholar] [CrossRef]

- Fan, S.L.; Chong, H.Y.; Hung, T.W.; Wang, Y.C. Cost-based scheduling method using object-oriented approach. Automat. Constr. 2016, 65, 65–77. [Google Scholar] [CrossRef]

- Hanna, A.S.; Camlic, R.; Peterson, P.A.; Lee, M.J. Cumulative Effect of Project Changes for Electrical and Mechanical Construction. J. Constr. Eng. Manag. 2004, 130, 762–771. [Google Scholar] [CrossRef]

- Song, X.Y.; Pena-Mora, F.; Menassa, C.C.; Arboleda, C.A. Insurance as a risk management Tool for ADR implementation in construction disputes. J. Constr. Eng. M. 2012, 138, 14–21. [Google Scholar] [CrossRef]

- Zolfagharian, S.; Irizarry, J. Constructability assessment model for commercial building designs in the United States. J. Constr. Eng. Manag. 2017, 143, 04017031. [Google Scholar] [CrossRef]

- Yin, Y.L.; Qiao, L. Research on constructability of EPC mode in design phase. In Proceedings of the International Conference on Engineering and Business Management (EBM2010), ChengDu, China, 25–27 March 2010; pp. 1705–1709. [Google Scholar]

- Zhu, J.W.; Zhou, L.N.; Li, L.; Ali, W. Decision simulation of construction project delivery system under the sustainable construction project management. Sustainability 2022, 12, 12062202. [Google Scholar] [CrossRef]

- Wang, T.F.; Tang, W.Z.; Du, L.; Duffield, C.F.; Wei, Y.P. Relationships among Risk Management, Partnering and Contractor Capability in International EPC Project Delivery. J. Manag. Eng. 2016, 32, 04016017. [Google Scholar] [CrossRef]

- Cheng, E.W.L.; Li, H. Construction partnering process and associated critical success factors: Quantitative investigation. J. Manag. Eng. 2002, 18, 194–202. [Google Scholar] [CrossRef]

- Shi, Z.Y. Discussion on design optimization of EPC general contract project. Water Resour. Hydropower Eng. 2013, 44, 87–88. [Google Scholar]

- Ling, Y.Y.; Lau, B. A case study on the management of the development of a large-scale power plant project in East Asia based on design-build arrangement. Int. J. Proj. Manag. 2002, 20, 413–423. [Google Scholar] [CrossRef]

- Whang, S.W.; Flanagan, R.; Kim, S.; Kim, S. Contractor-Led Critical Design Management Factors in High-Rise Building Projects Involving Multinational Design Teams. J. Constr. Eng. Manag. 2017, 143, 06016009. [Google Scholar] [CrossRef]

- Demetracopoulou, V.; O’Brien, W.J.; Khwaja, N. 2020 Lessons learned from selection of project delivery methods in highway projects: The Texas experience. J. Leg. Aff. Dispute Resolut. Eng. Constr. 2020, 12, 4519040. [Google Scholar] [CrossRef]

- You, J.Y.; Chen, Y.Q.; Wang, W.Q.; Shi, C.X. Uncertainty, opportunistic behavior, and governance in construction projects: The efficacy of contracts. Int. J. Proj. Manag. 2018, 36, 795–807. [Google Scholar] [CrossRef]

- Si, S.L.; You, X.Y.; Liu, H.C.; Zhang, P. DEMATEL Technique: A systematic review of the state-of-the-art literature on methodologies and applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Shen, J.; Li, F.; Shi, D.; Li, H.; Yu, X. Factors affecting the economics of distributed natural gas-combined cooling, heating and power systems in China: A systematic analysis based on the integrated decision making trial and evaluation laboratory-interpretative structural modeling (DEMATEL-ISM) Technique. Energies 2018, 11, 2318. [Google Scholar]

- Chen, P.; Cai, B.; Wu, M.; Zhao, Y. Obstacle analysis of application of blockchain technology in power data trading based on improved DEMATEL–ISM method under fuzzy environment. Energy Rep. 2022, 8, 4589–4607. [Google Scholar] [CrossRef]

- He, Y.; Kang, J.; Pei, Y.; Ran, B.; Song, Y. Research on influencing factors of fuel consumption on superhighway based on DEMATEL-ISM model. Energy Policy 2021, 158, 112545. [Google Scholar] [CrossRef]

- Yang, J.; Luo, B.; Zhao, C.; Zhang, H. Artificial intelligence healthcare service resources adoption by medical institutions based on TOE framework. Digit. Health 2022, 8, 20552076221126034. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.; Kumaraswamy, M. Relational contracting and teambuilding: Assessing potential contractual and noncontractual incentives. J. Manag. Eng. 2008, 24, 48–63. [Google Scholar] [CrossRef]

| Subsystem | Influencing Factor |

|---|---|

| Designer | Subcontractor’s participation during design () |

| Design capacity () | |

| Design management level () | |

| Cost control awareness () | |

| Rationality of design schemes () | |

| Appropriate initial design quantities () | |

| Information communication () | |

| Level of detail in design drawings () | |

| Information coordination between multi-stakeholders () | |

| Subcontractor | Designer’s participation during construction () |

| Design schedule control () | |

| Frequency of changes () | |

| Engineering insurance () | |

| Constructability assessment () | |

| Personal initiative () | |

| Engineering market () | |

| Designer and subcontractor | Performance evaluation mechanism () |

| Policies and regulations () | |

| Technological development () | |

| Risk management ability of EPC contractor () | |

| EPC contractor | Trust of the owner () |

| Innovation awareness () | |

| Owners’ attitude towards disputes () | |

| Degree of involvement in design management () | |

| Project document reviews () | |

| Errors of materials provided by the owner () | |

| Approval efficiency of design documents () | |

| Owner | Project schedule () |

| Sensitivity to project cost growth () | |

| Selection of EPC contractor () | |

| Level of expertise () | |

| EPC contractor and owner | Contract formulation () |

| Uncertainty brought by external environments () |

| Influencing Factor | ||||

|---|---|---|---|---|

| Subcontractor’s participation during design () | 3.74 | 3.67 | 7.41 | 0.07 |

| 3.82 | 3.06 | 6.88 | 0.76 | |

| 4.15 | 3.29 | 7.44 | 0.86 | |

| 3.74 | 3.77 | 7.51 | −0.03 | |

| 3.05 | 5.37 | 8.42 | −2.32 | |

| 2.89 | 3.84 | 6.73 | −0.95 | |

| 3.50 | 4.36 | 7.86 | −0.86 | |

| 3.62 | 3.80 | 7.42 | −0.18 | |

| 4.17 | 5.25 | 9.42 | −1.08 | |

| 3.85 | 4.63 | 8.48 | −0.78 | |

| 3.44 | 5.20 | 8.64 | −1.76 | |

| 3.63 | 5.43 | 9.06 | −1.8 | |

| 3.45 | 2.58 | 6.03 | 0.87 | |

| 3.64 | 4.19 | 7.83 | −0.55 | |

| 3.18 | 4.34 | 7.52 | −1.16 | |

| 3.49 | 0.48 | 3.97 | 3.01 | |

| 4.22 | 1.30 | 5.52 | 2.92 | |

| 3.35 | 0.01 | 3.36 | 3.34 | |

| 4.29 | 0.17 | 4.46 | 4.12 | |

| 4.18 | 5.60 | 9.78 | −1.42 | |

| 4.08 | 4.96 | 9.04 | −0.88 | |

| 3.87 | 5.29 | 9.16 | −1.42 | |

| Owners’ attitude towards disputes ( | 4.06 | 3.63 | 7.69 | 0.43 |

| 4.06 | 5.17 | 9.23 | −1.11 | |

| 3.05 | 2.22 | 5.27 | 0.83 | |

| 3.20 | 1.91 | 5.11 | 1.29 | |

| 3.02 | 4.26 | 7.28 | −1.24 | |

| 3.29 | 4.83 | 8.12 | −1.54 | |

| 3.85 | 4.08 | 7.93 | −0.23 | |

| 4.34 | 4.99 | 9.33 | −0.65 | |

| 3.31 | 0.72 | 4.03 | 2.59 | |

| 3.61 | 4.86 | 8.47 | −1.25 | |

| 4.66 | 4.51 | 9.17 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ren, Z.; Hu, B.; Zheng, H. Investigation of the Critical Factors Influencing Multi-Stakeholders’ Participation in Design Optimization of EPC Projects. Buildings 2023, 13, 1654. https://doi.org/10.3390/buildings13071654

Chen Y, Ren Z, Hu B, Zheng H. Investigation of the Critical Factors Influencing Multi-Stakeholders’ Participation in Design Optimization of EPC Projects. Buildings. 2023; 13(7):1654. https://doi.org/10.3390/buildings13071654

Chicago/Turabian StyleChen, Yuan, Zichen Ren, Bingyue Hu, and Hemin Zheng. 2023. "Investigation of the Critical Factors Influencing Multi-Stakeholders’ Participation in Design Optimization of EPC Projects" Buildings 13, no. 7: 1654. https://doi.org/10.3390/buildings13071654

APA StyleChen, Y., Ren, Z., Hu, B., & Zheng, H. (2023). Investigation of the Critical Factors Influencing Multi-Stakeholders’ Participation in Design Optimization of EPC Projects. Buildings, 13(7), 1654. https://doi.org/10.3390/buildings13071654