Measured Impact of Material Settlement in a Timber-Frame Wall with Loose Fill Insulation

Abstract

1. Introduction

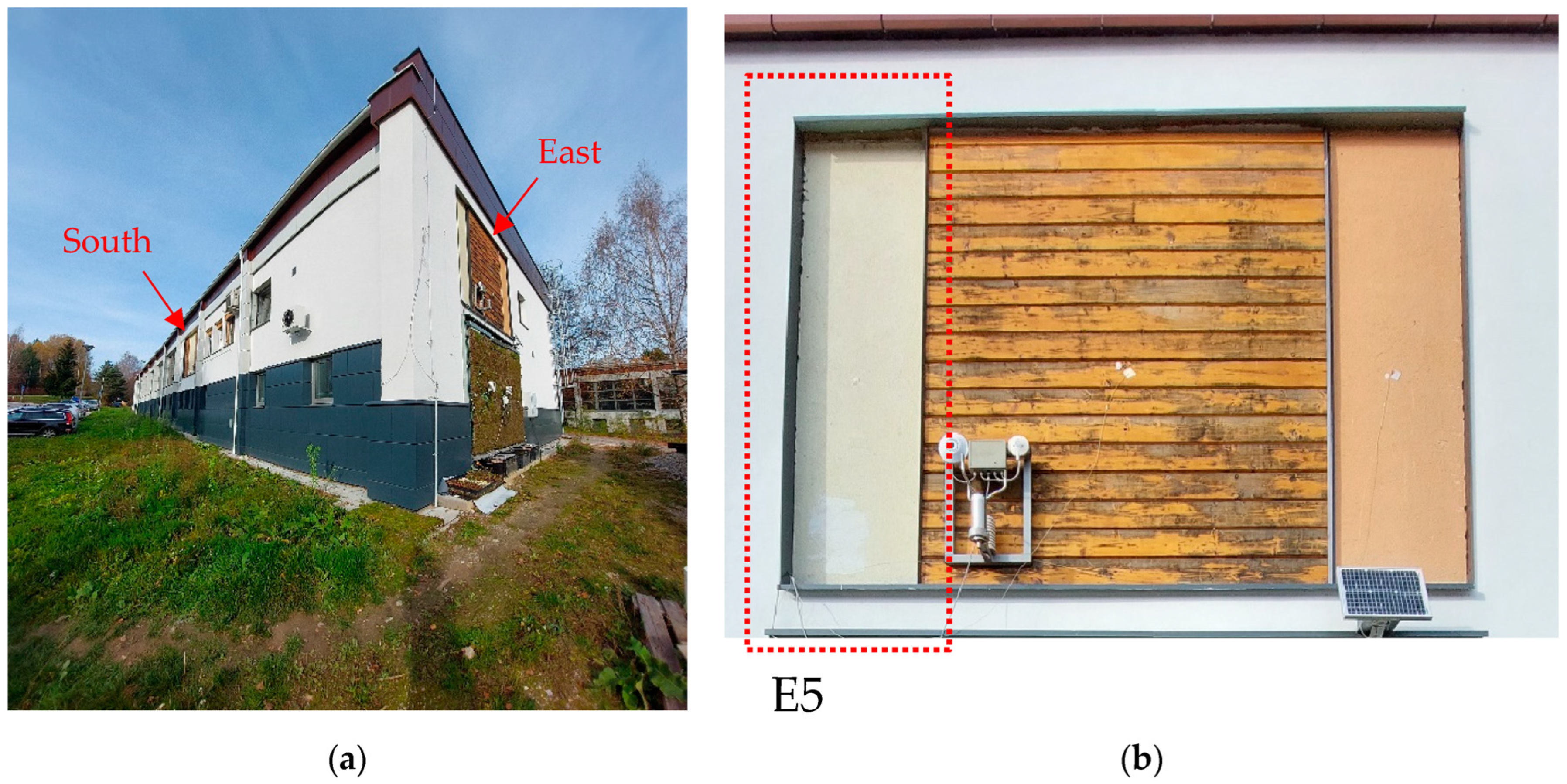

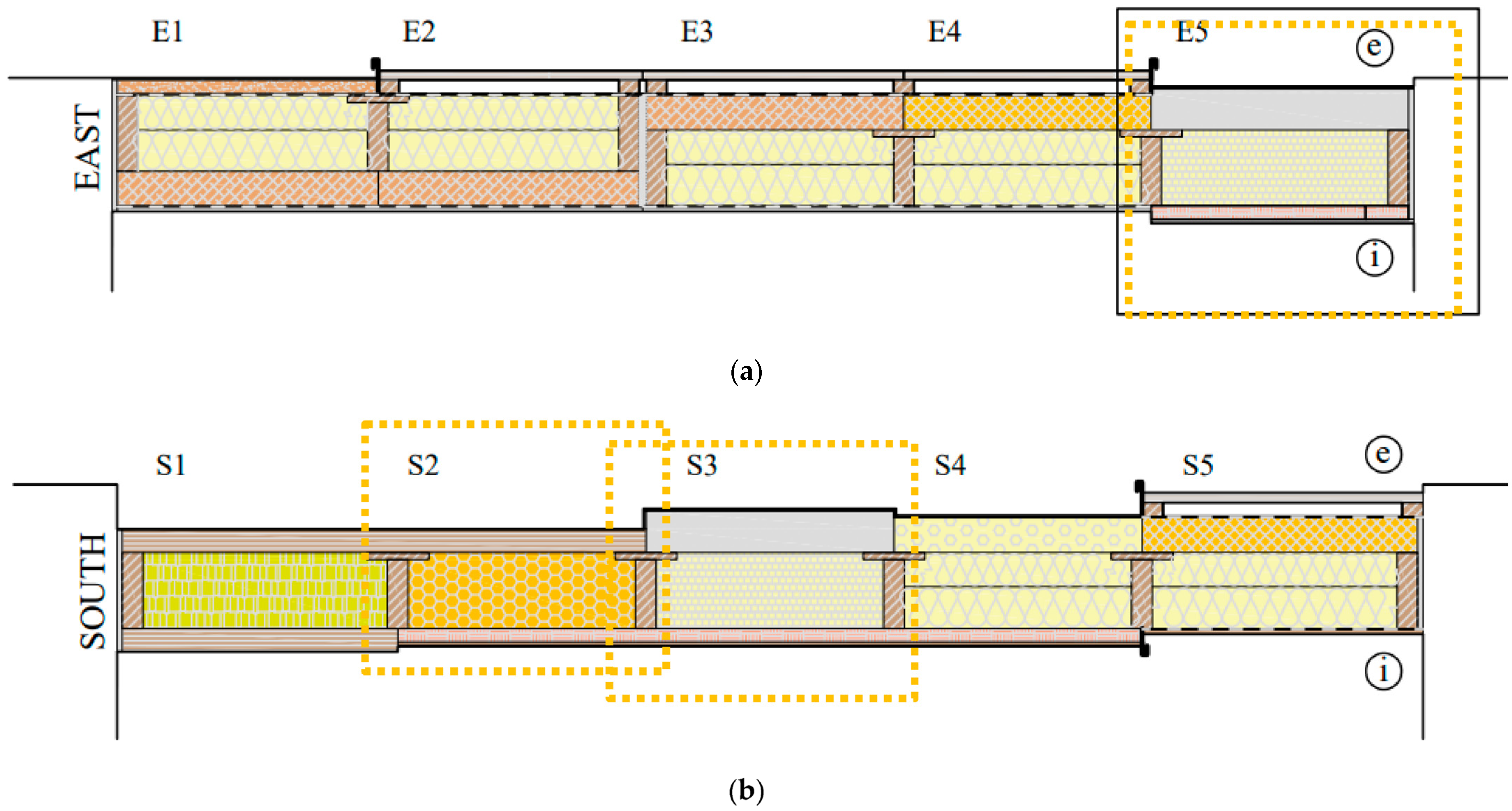

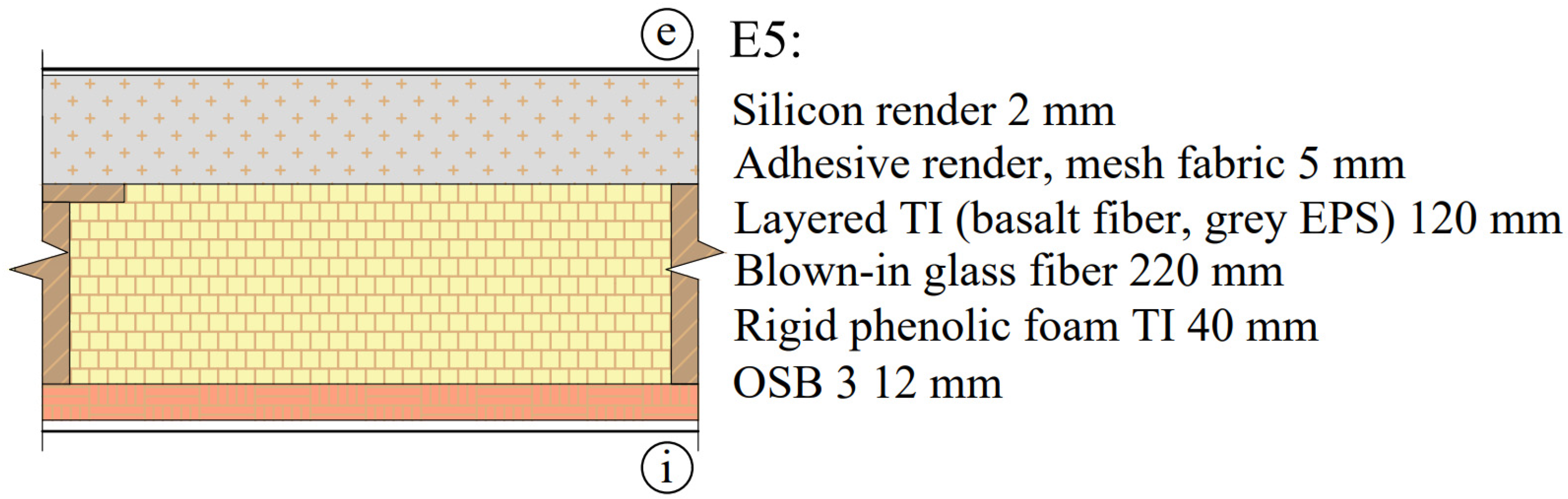

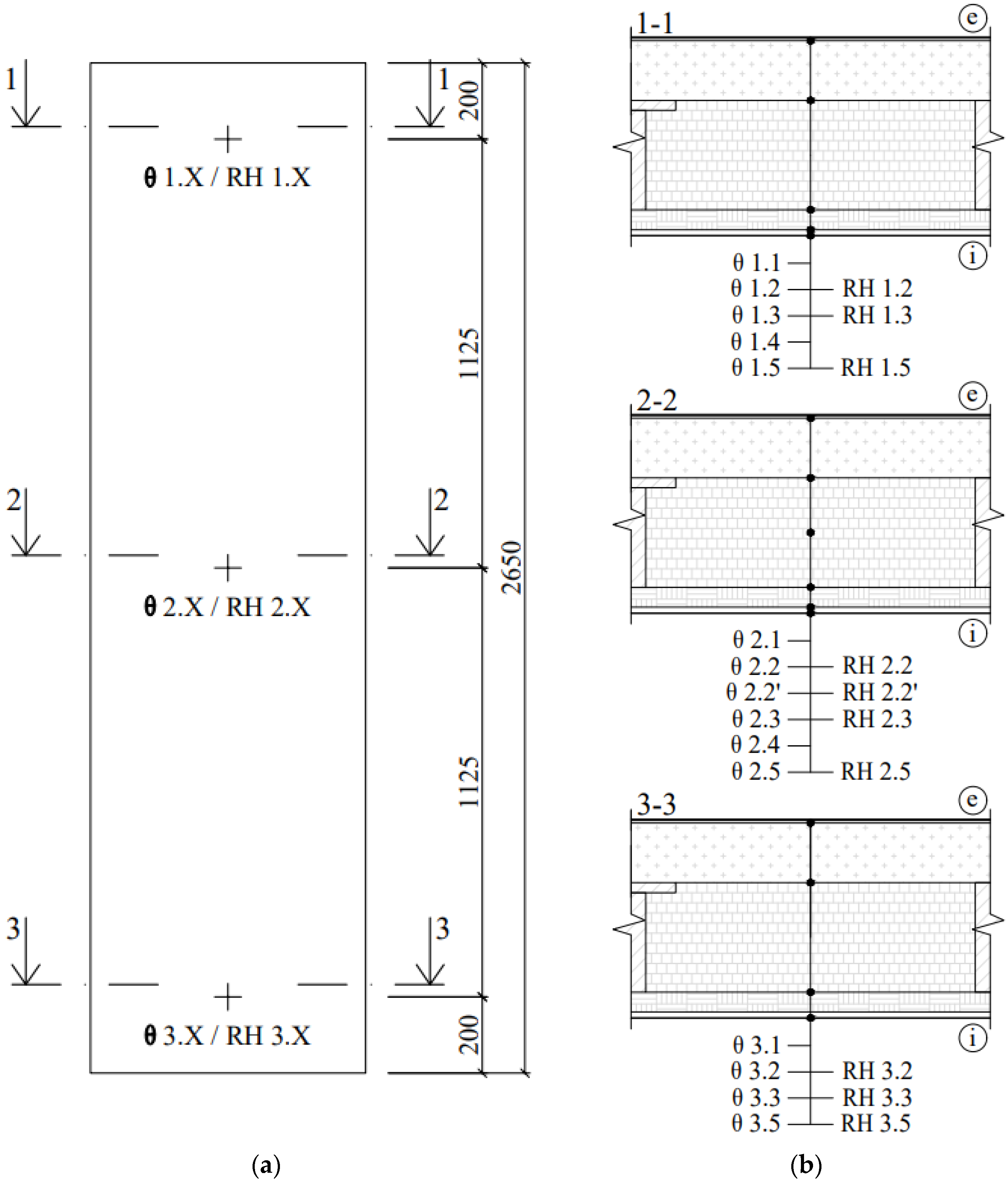

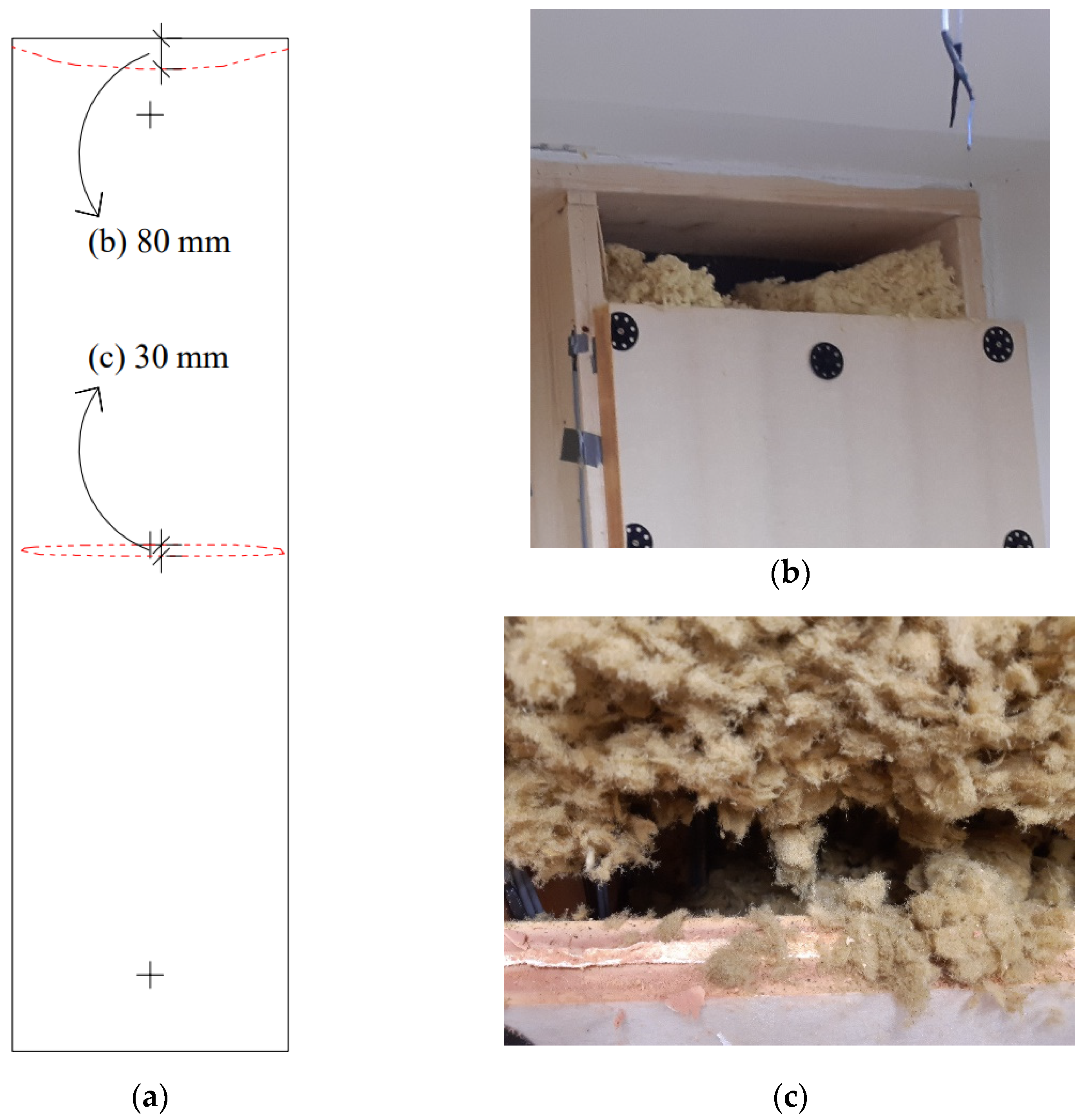

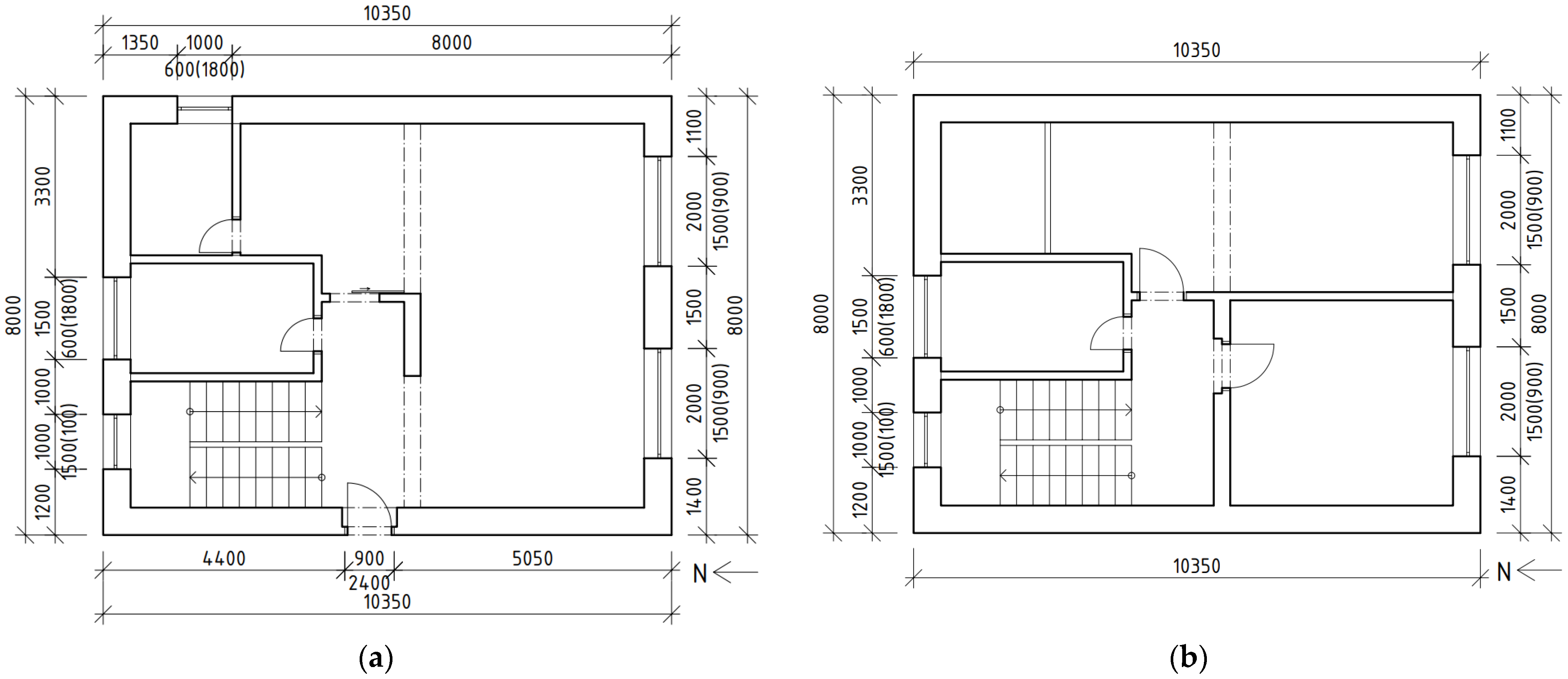

2. Materials and Methods

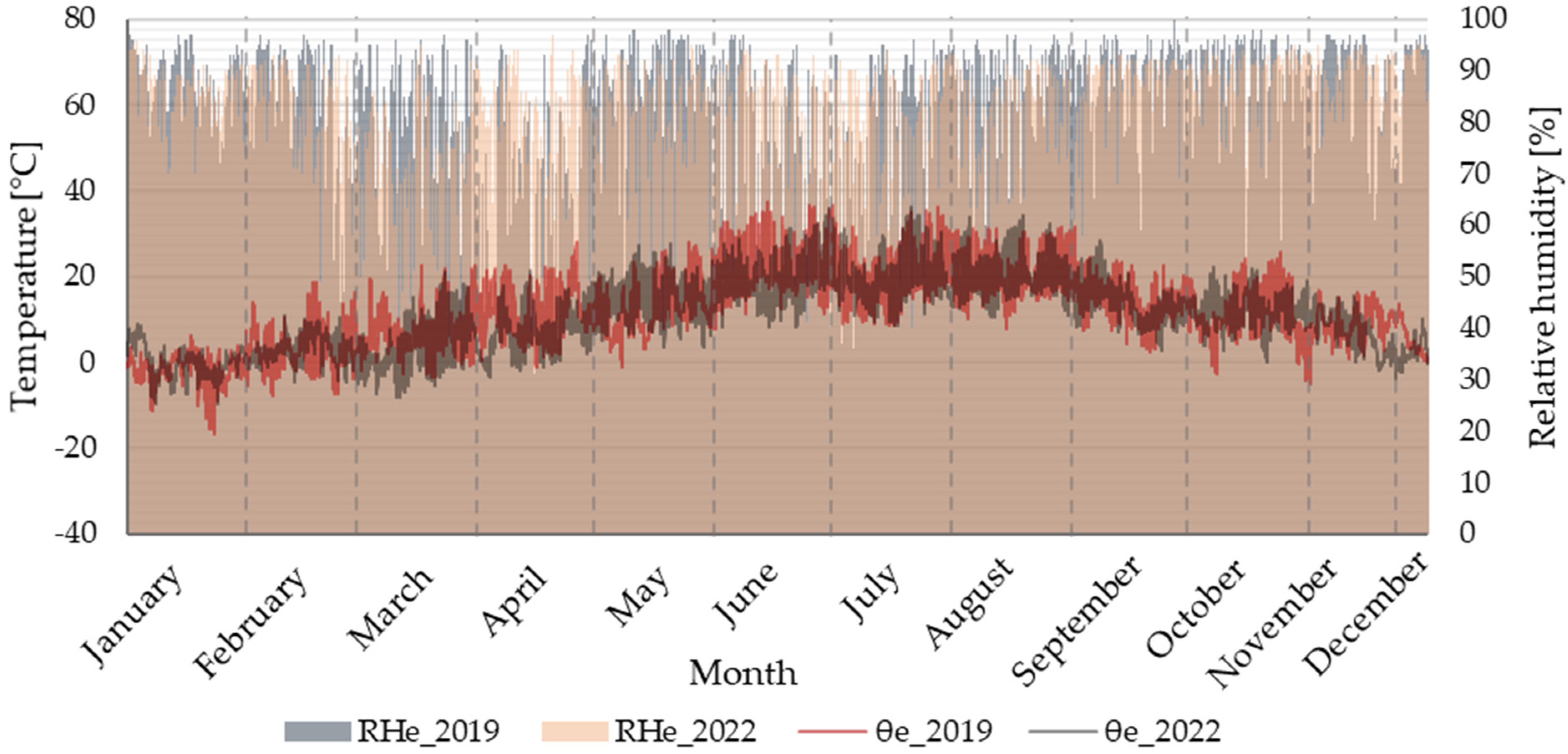

2.1. Temperature and Relative Humidity

2.2. Impact on Building Thermal Performance

3. Results

3.1. Temperature

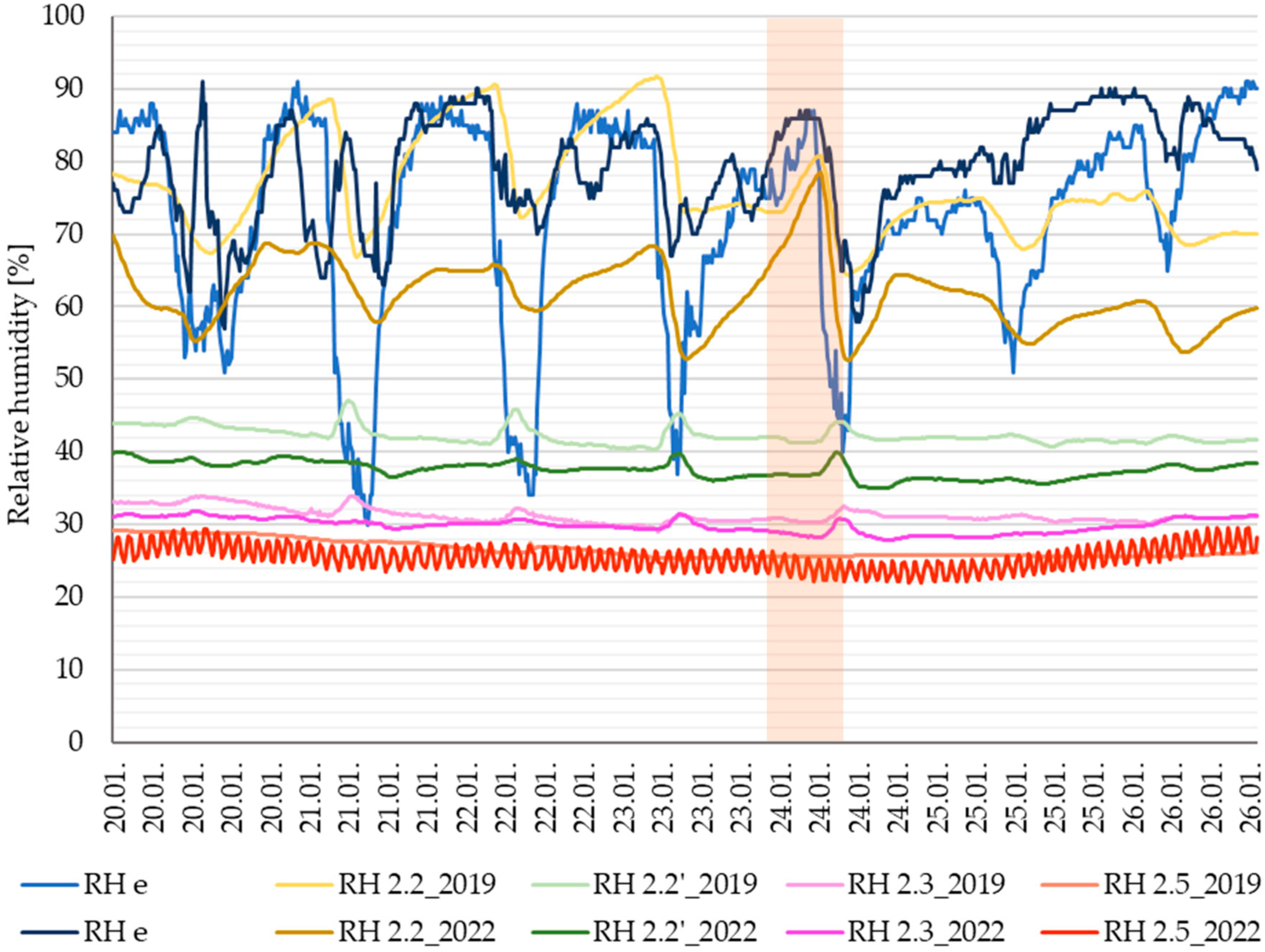

3.2. Relative Humidity

3.3. Thermal Performance

4. Discussion

5. Conclusions

- Due to the relatively low heat storage capacity of the studied structures, it is possible to compare measurements even in years where the minimum air temperature differs by 7.4 °C;

- The largest measured difference in temperature and relative humidity was at the upper location, where the most pronounced air cavity was previously discovered. This difference represented an 8 °C change in temperature and 45% relative humidity;

- The difference decreased rapidly as one progressed into the interior without affecting the internal surface temperature of the structure;

- The creation of this thermal bridge at the synchronous increase in relative humidity leads to an increased risk of mold formation and growth;

- An additional layer of thermal insulation on the interior side ensured constant conditions on the inner surface of the wall;

- The significant difference in temperature and relative humidity in the upper position did not affect the conditions in the lower two positions;

- The middle air cavity did not cause a difference in relative humidity. However, it did affect the temperature by 4 °C;

- The measured parameters in the lowest position were not affected by any of the upper defects;

- Despite the initial hypothesis, it turned out that these local thermal bridges did not have a significant impact on the specific heating demand during the winter season;

- In our case, the defects increased the risk of mold growth in the structure itself. In the case of using only blown-in thermal insulation, these defects could cause mold growth on the internal surface, as well as significantly increase the specific heat demand for heating and thus affect the energy balance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Nr. | GENERAL INFORMATION | ||||||||

| 1 | Building name: | Single-family house | |||||||

| 2 | Location: | Žilina, Slovakia | |||||||

| Calculation of heating demand | |||||||||

| INPUT DATA | |||||||||

| 3 | Building | Building category (single use) | Building for living | ||||||

| 4 | Year of approval | 2023 | |||||||

| 5 | Year of last thermal protection change | 2023 | |||||||

| 6 | Type, construction system, building system (apartment buildings) | Wood-frame | |||||||

| 7 | Building width | 10.35 m | |||||||

| 8 | Building length | 8.0 m | |||||||

| 9 | Building height | 7.1 m | |||||||

| 10 | Number of floors | 2 | |||||||

| 11 | Building volume | 587.88 m3 | |||||||

| 12 | Total floor area | 130.9 m2 | |||||||

| 13 | Total heat exchange surface | 397.6 m2 | |||||||

| 14 | Average construction height | 3 | |||||||

| 15 | Form factor | 0.75 | |||||||

| 16 | Calc. | Calculation method | seasonal | ||||||

| 17 | Number of daily degrees | 3422 K.day | |||||||

| Heat loss | Description/name of the building envelope | Heat transfer coefficient of the structure Ui [W/m2K] | Heat exchange surface Ai [m2] | Temperature reduction factor b [−] | |||||

| Envelope structure: | |||||||||

| 18 | 1 | Exterior wall | 0.0959 | 220.28 | 1 | ||||

| Roof: | |||||||||

| 19 | 2 | Green roof | 0.1 | 80 | 1 | ||||

| Floor: | |||||||||

| 20 | 1 | Terrain floor | 0.096 | 80 | 1 | ||||

| Openings: | |||||||||

| 21 | 1 | Window 1000 × 1500, 2 pcs | 0.661 | 3 | 1 | ||||

| 22 | 2 | Window 2000 × 1500, 4 pcs | 0.62 | 12 | 1 | ||||

| 23 | 3 | Window 1500 × 600, 2 pcs | 0.721 | 1.8 | 1 | ||||

| 24 | 4 | Window 1000 × 600, 1 pcs | 0.74 | 0.6 | 1 | ||||

| 25 | 5 | Doors | 1.92 | 1 | |||||

| 26 | Average heat transfer coefficient Um | 0.121 | W/m2K | ||||||

| 27 | Thermal conductivity (transmittance) of the floor and walls in a heated basement | - | W/K | ||||||

| 28 | Impact of thermal bridges ∆U | 0.05 | W/m2K | ||||||

| 29 | Increase in heat loss due to thermal bridges ∆HTM | 19.88 | W/K | ||||||

| Heat loss | Description of the openings | Total length of joints of openings l [m] | Air permeability coefficient of window openings i.104 [m2/(s.Pa0.67)] | ||||||

| 30 | 1 | Window 1000 × 1500, 2 pcs | 8.88 | 0.00005 | |||||

| 31 | 2 | Window 2000 × 1500, 4 pcs | 25.76 | 0.00005 | |||||

| 32 | 3 | Window 1500 × 600, 2 pcs | 2.62 | 0.00005 | |||||

| 33 | 4 | Window 1000 × 600, 1 pcs | 5.28 | 0.00005 | |||||

| 34 | Building characteristic number B (if used for air change calculation) | - | Pa0.67 | ||||||

| 35 | Average air exchange rate calculated n | 0.091 | l/h | ||||||

| 36 | Measured airtightness n50 | - | l/h | ||||||

| 37 | Considered average air exchange rate n | 0.5 | l/h | ||||||

| 38 | Heat recovery unit | - | |||||||

| 39 | Efficiency of the heat recovery unit | - | % | ||||||

| 40 | Proportion of air passing through the unit | - | m3 | ||||||

| 41 | Heat gain | Thermal output of the indoor source q | 6 | W/m2 | |||||

| 42 | Internal heat gains Qi | 3927 | kWh/a | ||||||

| Orientation | Solar radiation intensity Isj [kWh/m2] | Solar transmittance g [−] | Shading factor [−] | Area of glazed opening structures A [m2] | Effective collection area, full sections A [m2] (cooling) | ||||

| 43 | 1 | North | 100 | - | - | 4.8 | 4.8 | ||

| 44 | 2 | South | 320 | - | - | 12 | 12 | ||

| 45 | 3 | East | 200 | - | - | 0.6 | 0.6 | ||

| 46 | Solar heat gains | 4440 | kWh/a | ||||||

| Heating demand | Seasonal method | ||||||||

| 47 | Specific heat loss through transition Ht | 67.85 | W/K | ||||||

| 48 | Specific heat loss through ventilation Hv | 82.303 | W/K | ||||||

| 49 | Heat gain recovery factor | 0.95 | |||||||

| 50 | Specific heating demand—seasonal method | 33.45 | kWh/(m2a) | ||||||

| Nr. | GENERAL INFORMATION | ||||||||

| 1 | Building name: | Single-family house | |||||||

| 2 | Location: | Žilina, Slovakia | |||||||

| Calculation of heating demand | |||||||||

| INPUT DATA | |||||||||

| 3 | Building | Building category (single use) | Building for living | ||||||

| 4 | Year of approval | 2023 | |||||||

| 5 | Year of last thermal protection change | 2023 | |||||||

| 6 | Type, construction system, building system (apartment buildings) | Wood-frame | |||||||

| 7 | Building width | 10.35 m | |||||||

| 8 | Building length | 8.0 m | |||||||

| 9 | Building height | 7.1 m | |||||||

| 10 | Number of floors | 2 | |||||||

| 11 | Building volume | 587.88 m3 | |||||||

| 12 | Total floor area | 130.9 m2 | |||||||

| 13 | Total heat exchange surface | 397.6 m2 | |||||||

| 14 | Average construction height | 3 | |||||||

| 15 | Form factor | 0.75 | |||||||

| 16 | Calc. | Calculation method | seasonal | ||||||

| 17 | Number of daily degrees | 3422 K.day | |||||||

| Heat loss | Description/name of the building envelope | Heat transfer coefficient of the structure Ui [W/m2K] | Heat exchange surface Ai [m2] | Temperature reduction factor b [−] | |||||

| Envelope structure: | |||||||||

| 18 | 1 | Exterior wall | 0.0940 | 220.28 | 1 | ||||

| Roof: | |||||||||

| 19 | 2 | Green roof | 0.1 | 80 | 1 | ||||

| Floor: | |||||||||

| 20 | 1 | Terrain floor | 0.096 | 80 | 1 | ||||

| Openings: | |||||||||

| 21 | 1 | Window 1000 × 1500, 2 pcs | 0.661 | 3 | 1 | ||||

| 22 | 2 | Window 2000 × 1500, 4 pcs | 0.62 | 12 | 1 | ||||

| 23 | 3 | Window 1500 × 600, 2 pcs | 0.721 | 1.8 | 1 | ||||

| 24 | 4 | Window 1000 × 600, 1 pcs | 0.74 | 0.6 | 1 | ||||

| 25 | 5 | Doors | 1.92 | 1 | |||||

| 26 | Average heat transfer coefficient Um | 0.121 | W/m2K | ||||||

| 27 | Thermal conductivity (transmittance) of the floor and walls in a heated basement | - | W/K | ||||||

| 28 | Impact of thermal bridges ∆U | 0.05 | W/m2K | ||||||

| 29 | Increase in heat loss due to thermal bridges ∆HTM | 19.88 | W/K | ||||||

| Heat loss | Description of the openings | Total length of joints of openings l [m] | Air permeability coefficient of window openings i.104 [m2/(s.Pa0.67)] | ||||||

| 30 | 1 | Window 1000 × 1500, 2 pcs | 8.88 | 0.00005 | |||||

| 31 | 2 | Window 2000 × 1500, 4 pcs | 25.76 | 0.00005 | |||||

| 32 | 3 | Window 1500 × 600, 2 pcs | 2.62 | 0.00005 | |||||

| 33 | 4 | Window 1000 × 600, 1 pcs | 5.28 | 0.00005 | |||||

| 34 | Building characteristic number B (if used for air change calculation) | - | Pa0.67 | ||||||

| 35 | Average air exchange rate calculated n | 0.091 | l/h | ||||||

| 36 | Measured airtightness n50 | - | l/h | ||||||

| 37 | Considered average air exchange rate n | 0.5 | l/h | ||||||

| 38 | Heat recovery unit | - | |||||||

| 39 | Efficiency of the heat recovery unit | - | % | ||||||

| 40 | Proportion of air passing through the unit | - | m3 | ||||||

| 41 | Heat gain | Thermal output of the indoor source q | 6 | W/m2 | |||||

| 42 | Internal heat gains Qi | 3927 | kWh/a | ||||||

| Orientation | Solar radiation intensity Isj [kWh/m2] | Solar transmittance g [−] | Shading factor [−] | Area of glazed opening structures A [m2] | Effective collection area, full sections A [m2] (cooling) | ||||

| 43 | 1 | North | 100 | - | - | 4.8 | 4.8 | ||

| 44 | 2 | South | 320 | - | - | 12 | 12 | ||

| 45 | 3 | East | 200 | - | - | 0.6 | 0.6 | ||

| 46 | Solar heat gains | 4440 | kWh/a | ||||||

| Heating demand | Seasonal method | ||||||||

| 47 | Specific heat loss through transition Ht | 67.531 | W/K | ||||||

| 48 | Specific heat loss through ventilation Hv | 82.303 | W/K | ||||||

| 49 | Heat gain recovery factor | 0.95 | |||||||

| 50 | Specific heating demand—seasonal method | 33.19 | kWh/(m2a) | ||||||

References

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the macro performance, mechanism, and durability of multiscale steel fiber reinforced low-carbon ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J. Hydration, reinforcing mechanism, and macro performance of multi-layer graphene-modified cement composites. J. Build. Eng. 2022, 57, 104880. [Google Scholar] [CrossRef]

- Lancashire, R. Achieving ‘thermal comfort’ in timber frame buildings. Struct. Eng. 2010, 88, 19–21. Available online: https://www.researchgate.net/publication/295295960_Achieving_’thermal_comfort’_in_timber_frame_buildings (accessed on 7 March 2023).

- Decree 625 MVaRRSR. Implementing Act No. 555/2005 Coll. on the Energy Performance of Buildings and on the Amendment of Certain Laws (in Slovak Original); Slovak Ministry of Justice: Bratislava, Slovakia, 2005. [Google Scholar]

- Švajlenka, J.; Kozlovská, M. Houses Based on Wood as an Ecological and Sustainable Housing Alternative—Case Study. Sustainability 2018, 10, 1502. [Google Scholar] [CrossRef]

- Zhen, M.; Zhang, B. Energy Performance of a Light Wood-Timber Structured House in the Severely Cold Region of China. Sustainability 2018, 10, 1501. [Google Scholar] [CrossRef]

- Steeman, M.; Himpe, E.; Vanroelen, M.; Roeck, M. Environmental impact of timber frame walls. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012141. [Google Scholar] [CrossRef]

- Hens, L.; Hugo, S. Timber-Framed Construction. In Performance Based Building Design 2: From Timber-Framed Construction to Partition Walls; Ernst & Sohn: Berlin, Germany, 2012; Volume 1, pp. 7–30. [Google Scholar]

- Rasmussen, T. Prediction of Density for Prevention of Settling of Hygroscopic and Nonhygroscopic Loose-fill Insulation in Walls. J. Build. Phys. 2005, 28, 245–267. [Google Scholar] [CrossRef]

- Bomberg, M. Blown Mineral Fiber Insulation; Special Publication NRC Canada: Ottawa, ON, Canada, 1980. [Google Scholar]

- Isover Insulfit. Available online: https://www.isover.sk/produkty/isover-insulfit (accessed on 28 December 2015).

- Nicolajsen, A. Thermal transmittance of a cellulose loose-fill insulation material. Build. Environ. 2005, 40, 907–914. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Duliasz, B. Moisture and wetting properties of thermal insulation materials based on hemp fiber, cellulose and mineral wool in a loose state. J. Nat. Fib. 2020, 17, 199–213. [Google Scholar] [CrossRef]

- Niziurska, M.; Wieczorek, M.; Borkowicz, K. Fire Safety of External Thermal Insulation Systems (ETICS) in the Aspect of Sustainable Use of Natural Resources. Sustainability 2022, 14, 1224. [Google Scholar] [CrossRef]

- Iringová, A. Design of envelopes for timber buildings in terms of sustainable development in the low-energy construction. IOP Conf. Ser. Mater. Sci. Eng. 2018, 415, 012010. [Google Scholar] [CrossRef]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of External Thermal Insulation Systems. Expanded Polystyrene vs. Mineral Wool: Case Study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Michálková, D.; Ďurica, P. Experimental Verification of Thermal Insulation in Timber Framed Walls. Materials 2022, 15, 2040. [Google Scholar] [CrossRef] [PubMed]

- Vasileva, I.L.; Nemova, D.V.; Vatin, N.I.; Fediuk, R.S.; Karelina, M.I. Climate-Adaptive Façades with an Air Chamber. Buildings 2022, 12, 366. [Google Scholar] [CrossRef]

- Ingebretsen, S.B.; Andenæs, E.; Kvande, T. Microclimate of Air Cavities in Ventilated Roof and Façade Systems in Nordic Climates. Buildings 2022, 12, 683. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed]

- STN EN ISO 6946; Building Components and Building Elements. Thermal Resistance and Thermal Transmittance. Calculation Methods (In Slovak Original). Slovak Office of Standards, Metrology, and Testing: Bratislava, Slovakia, 2001.

- Decree No. 364/2012 Coll; Decree of the Ministry of Transport, Construction and Regional Development of the Slovak Republic implementing Act No. 555/2005 Coll. on the Energy Performance of Buildings and on Amendments and Additions to Certain Acts, as amended (in Slovak Original). Slovak Ministry of Justice: Bratislava, Slovakia, 2012.

- STN EN 73 0540-2+Z1+Z2; Thermal Protection of Buildings. Thermal Performance of Buildings and Components. Part 2: Functional Requirements (In Slovak Original). Slovak Office of Standards, Metrology, and Testing: Bratislava, Slovakia, 2019.

- Gas Prices from the Slovak Gas Industry. Available online: https://www.spp.sk/domacnosti/plyn/tarify-a-cenniky-plynu/ (accessed on 15 April 2013).

- Price List for Electricity Supply to Households from Central Slovak Power Plants. Available online: https://www.sse.sk/domacnosti/elektrina/sadzby?page_id=5521 (accessed on 1 January 2023).

- Slee, B.; Hyde, R. Using Thermal Mass in Timber-framed Buildings: Effective use of thermal mass for increased comfort and energy efficiency. Wood Solut. 2015. Available online: https://www.researchgate.net/publication/281348414_Using_Thermal_Mass_in_Timber-framed_Buildings_Effective_use_of_thermal_mass_for_increased_comfort_and_energy_efficiency (accessed on 7 March 2023).

- Rasmussen, T. Modelling Settling of Loose-Fill Insulation in Walls. Part I. J. Build. Phys. 2001, 25, 129–141. [Google Scholar] [CrossRef]

- Yarbrough, D.; Wright, J.H.; McElroy, D.L.; Scanlan, T.F. Settling of loose-fill insulations due to vibration. In Thermal Insulation, Materials, and Systems for Energy Conservation in the ’80s; American Society for Testing: Conshohocken, PA, USA, 1983. [Google Scholar]

- Svennerstedt, B. A Model for the Settling of Attic Loose-Fill Insulations. In Proceedings of the Insulation Materials: Testing and Applications, Quebec City, QC, Canada, 15–17 May 1997; Volume 3, pp. 259–269. [Google Scholar]

| Material | ρ 1 [kg/m3] | λ 2 [W/(m2.K)] | μ 3 [−] | c 4 [J/(kg.K)] |

|---|---|---|---|---|

| Silicon render | 1600 | 0.860 | 130 | 920 |

| Adhesive render with mesh fabric | 1660 | 0.900 | 20 | 900 |

| Layered TI—30 mm basalt fiber and 90 mm grey polystyrene | 25 | 0.033 | 30 | 1100 |

| Blown-in glass fiber TI | 35 | 0.043 | 1 | 940 |

| TI—rigid phenolic foam | 35 | 0.021 | 35 | 1400 |

| OSB 3 | 650 | 0.130 | 50 | 1700 |

| Measurement Position | Year | Probe Position 1 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| θ e | θ x.1 | θ x.2 | θ x.2′ | θ x.3 | θ x.4 | θ x.5 | θ i | ||

| Top | 2019 | −9.80 | −15.79 | 0.07 | - | 13.71 | 19.54 | 19.21 | 19.34 |

| 2022 | −9.80 | −15.05 | 7.99 | - | 16.71 | 19.15 | 18.90 | 19.04 | |

| Middle | 2019 | −9.80 | −16.58 | −2.40 | 9.35 | 5.59 | 14.3 | 18.81 | 19.34 |

| 2022 | −9.80 | −16.33 | −1.43 | 11.12 | 9.54 | 14.8 | 18.86 | 19.04 | |

| Bottom | 2019 | −9.80 | −16.46 | −3.64 | - | 11.45 | - | 18.74 | 19.34 |

| 2022 | −9.80 | −16.21 | −2.23 | - | 12.98 | - | 18.5 | 19.04 | |

| Measurement Position | Year | Probe Position 1 | |||||

|---|---|---|---|---|---|---|---|

| RH e | RH x.2 | RH x.2′ | RH x.3 | RH x.5 | RH i | ||

| Top | 2019 | 88 | 90 | - | 36 | 32 | 30 |

| 2022 | 86 | 45 | - | 27 | 25 | 23 | |

| Middle | 2019 | 88 | 83 | 43 | 32 | 28 | 30 |

| 2022 | 86 | 76 | 37 | 28 | 25 | 23 | |

| Bottom | 2019 | 88 | 75 | - | 31 | 29 | 30 |

| 2022 | 86 | 74 | - | 31 | 25 | 23 | |

| Variant | |||

|---|---|---|---|

| 1—Old | 2—New | ||

| Specific heating demand [kWh/(m2.a)] | 33.45 | 33.19 | |

| Total floor area A [m2] | 130.9 | 130.9 | |

| Annual demand [kWh/a] | 4378.605 | 4344.571 | |

| Regional pricing [€/kWh] | Gas | 0.042 | 0.042 |

| Electricity | 0.0998 | 0.0998 | |

| Financial costs [€] | Gas | 183.90 | 182.472 |

| Electricity | 436.98 | 433.59 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michálková, D.; Ďurica, P. Measured Impact of Material Settlement in a Timber-Frame Wall with Loose Fill Insulation. Buildings 2023, 13, 1622. https://doi.org/10.3390/buildings13071622

Michálková D, Ďurica P. Measured Impact of Material Settlement in a Timber-Frame Wall with Loose Fill Insulation. Buildings. 2023; 13(7):1622. https://doi.org/10.3390/buildings13071622

Chicago/Turabian StyleMichálková, Daniela, and Pavol Ďurica. 2023. "Measured Impact of Material Settlement in a Timber-Frame Wall with Loose Fill Insulation" Buildings 13, no. 7: 1622. https://doi.org/10.3390/buildings13071622

APA StyleMichálková, D., & Ďurica, P. (2023). Measured Impact of Material Settlement in a Timber-Frame Wall with Loose Fill Insulation. Buildings, 13(7), 1622. https://doi.org/10.3390/buildings13071622