Seismic Performance of SFRC Shear Walls with Window Opening and the Substitution Effect for Steel Bars

Abstract

1. Introduction

2. Experimental Program

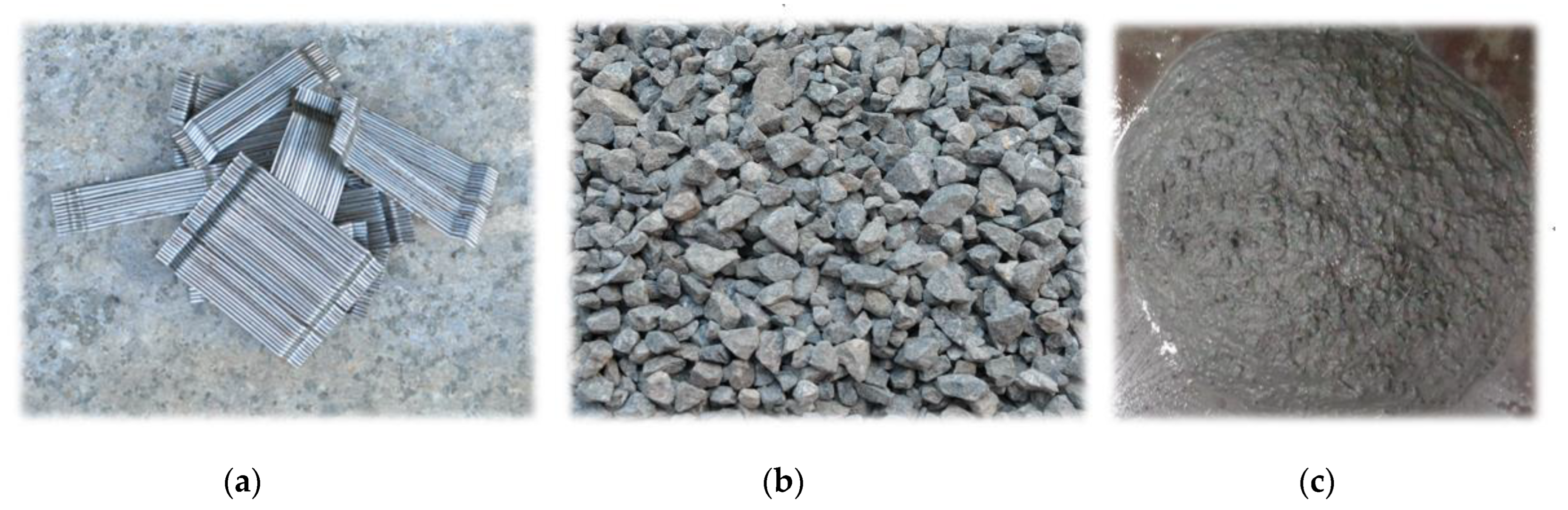

2.1. Materials

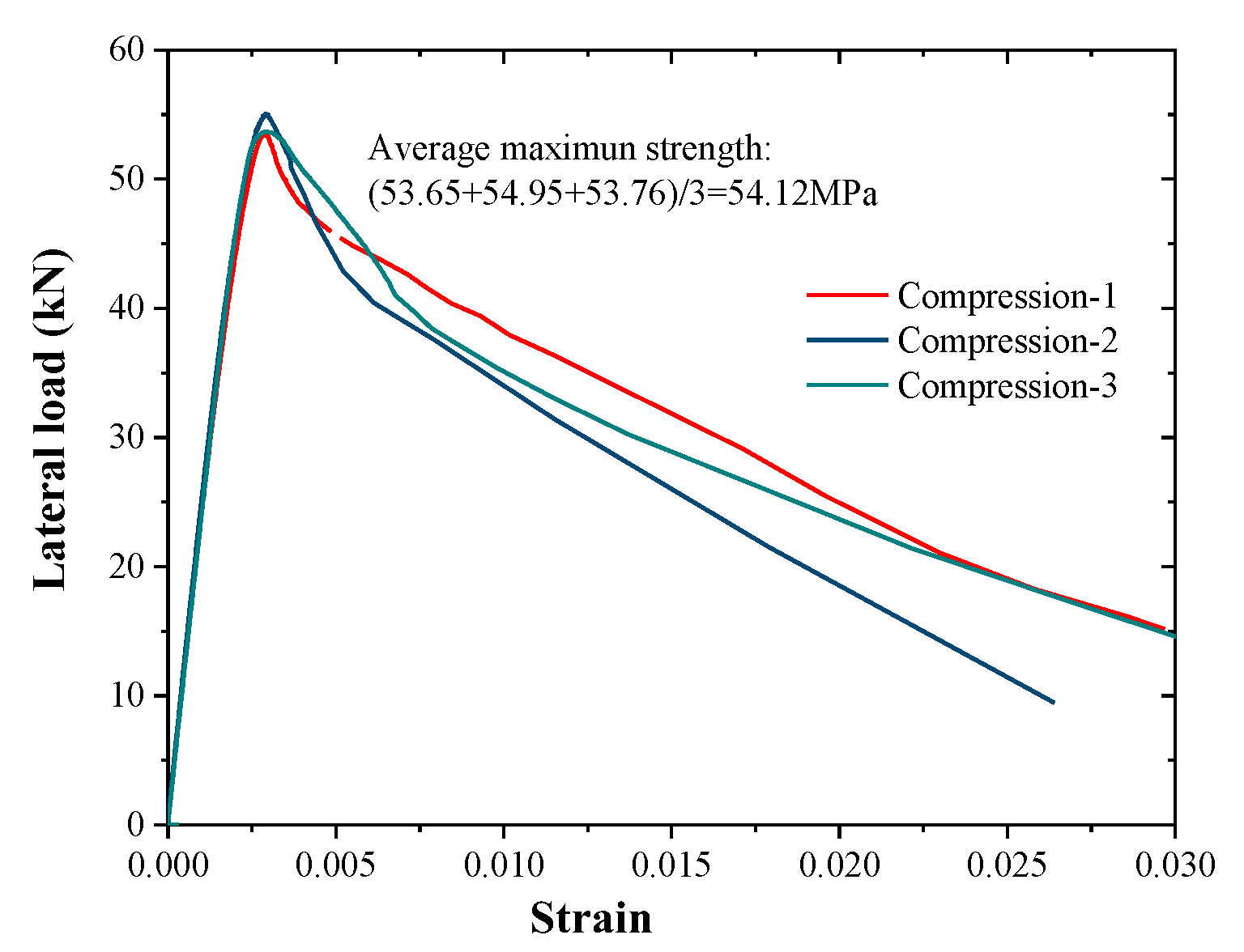

2.1.1. SFSC and Plain Concrete

2.1.2. Steel Material Properties

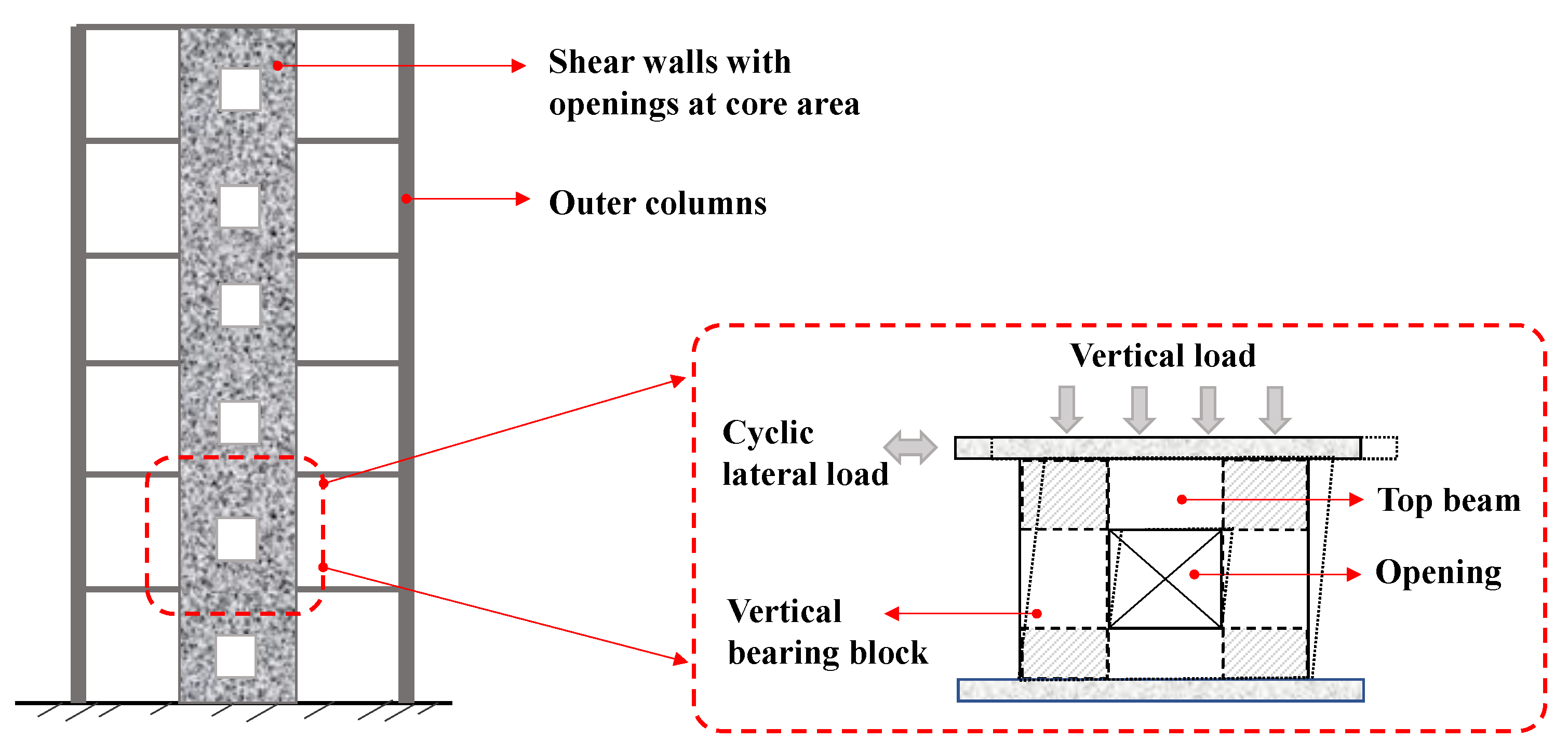

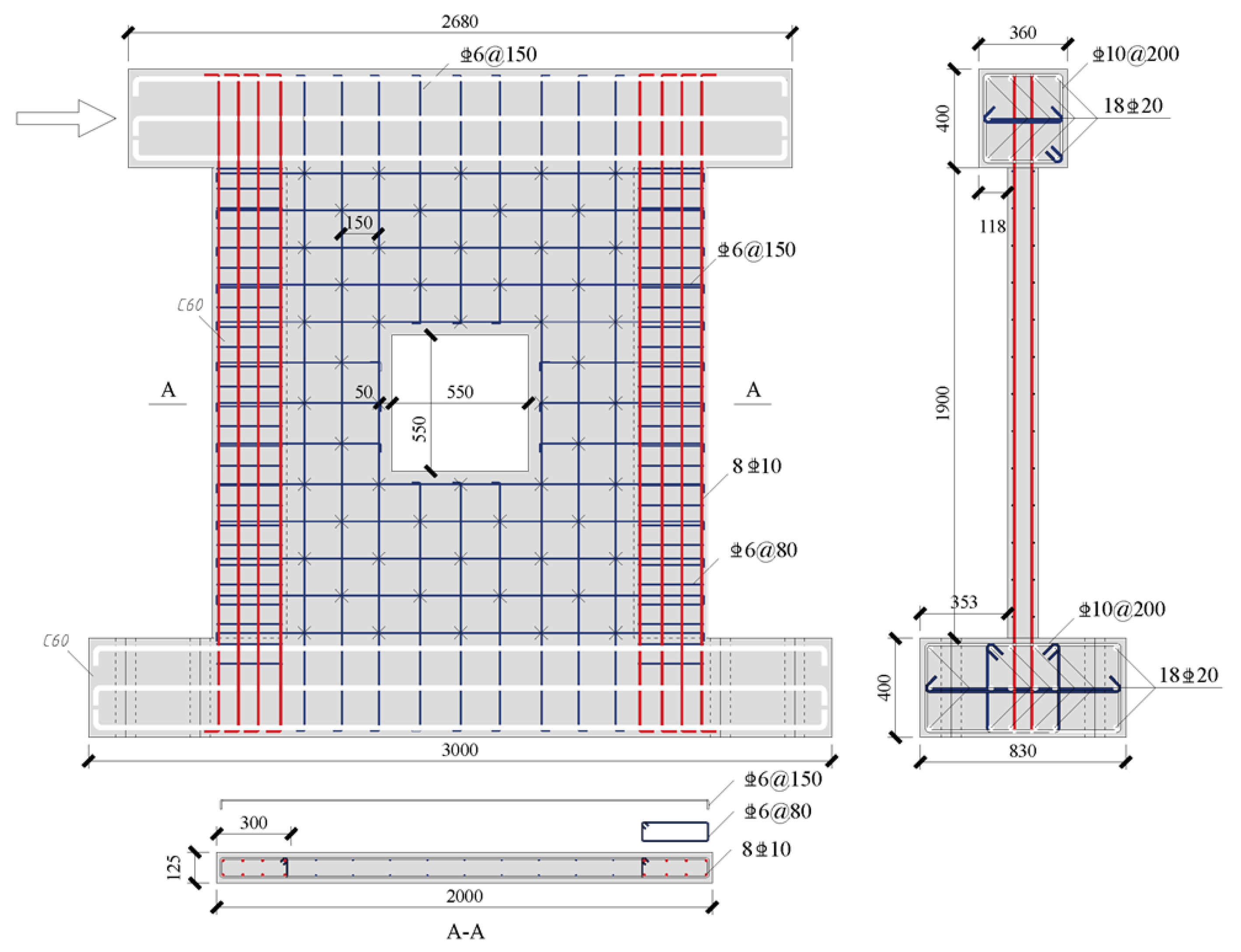

2.2. Shear Wall Specimen Design

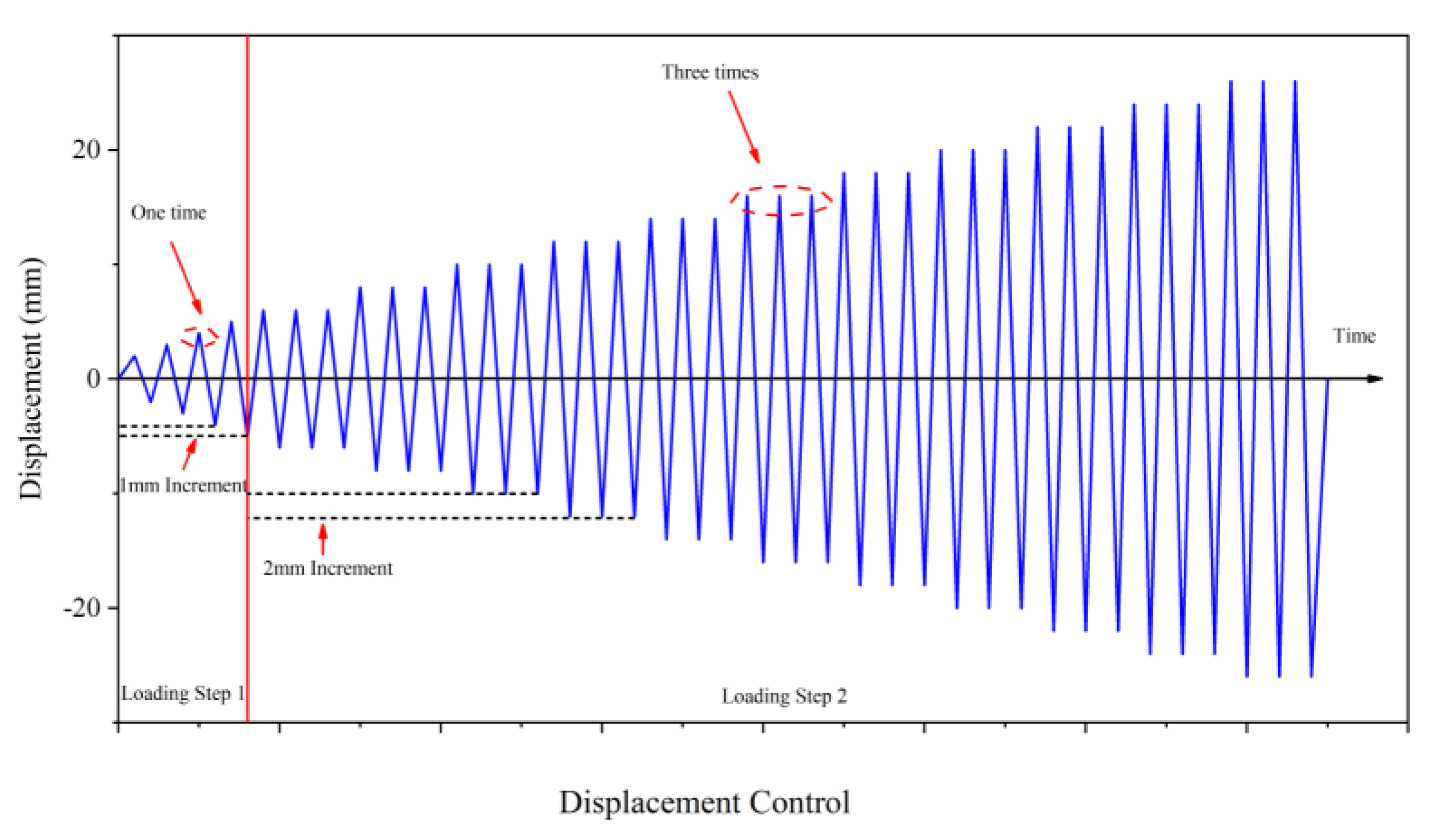

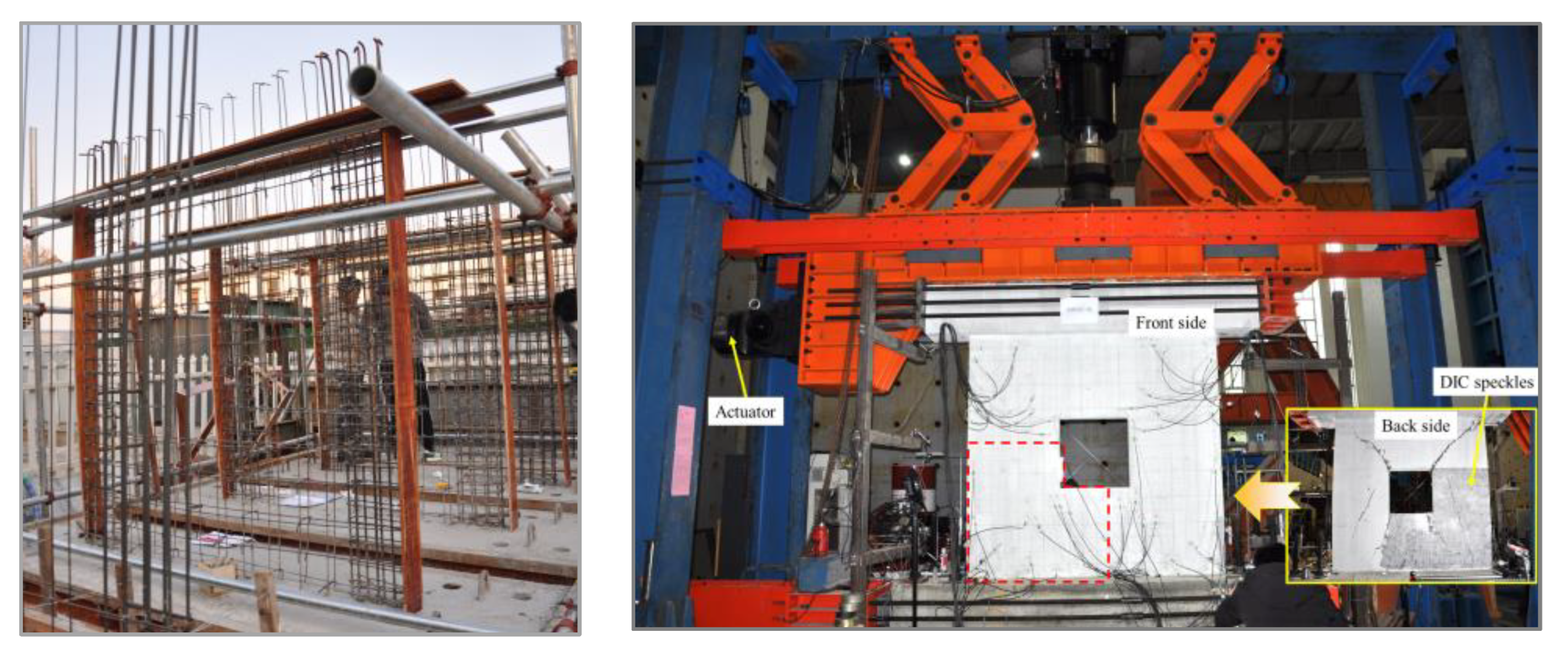

2.3. Test Setup and Loading Sequence

3. Test Results

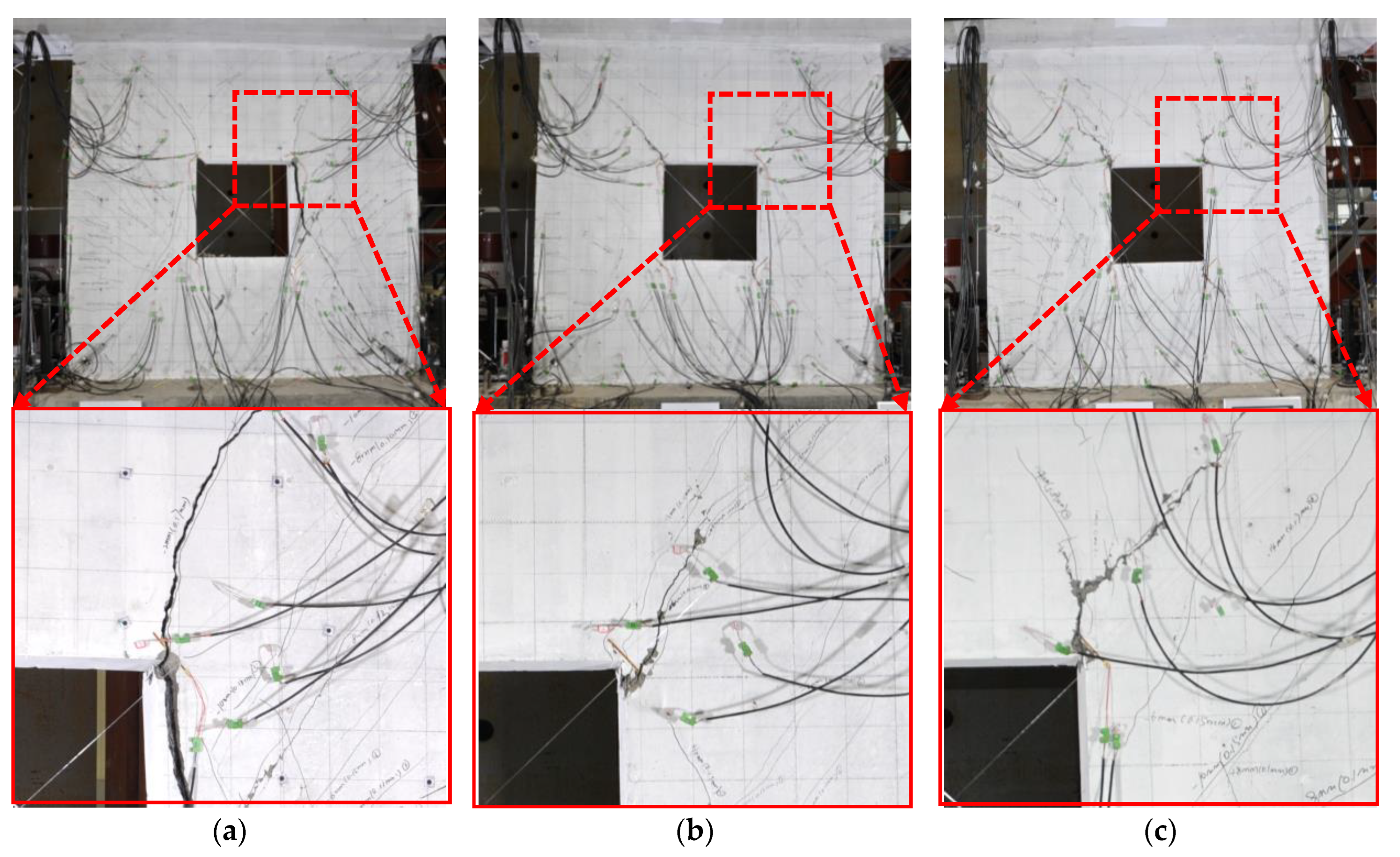

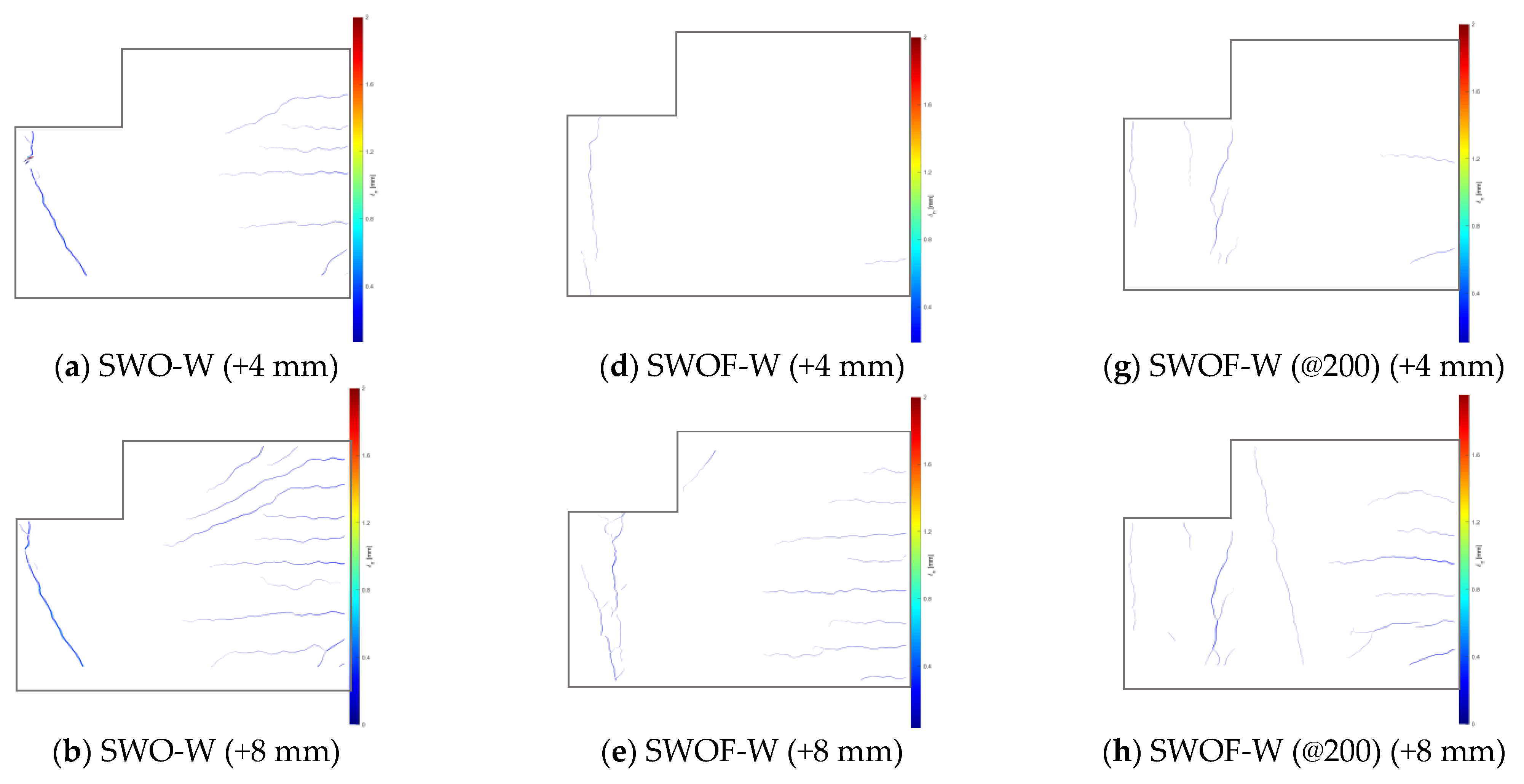

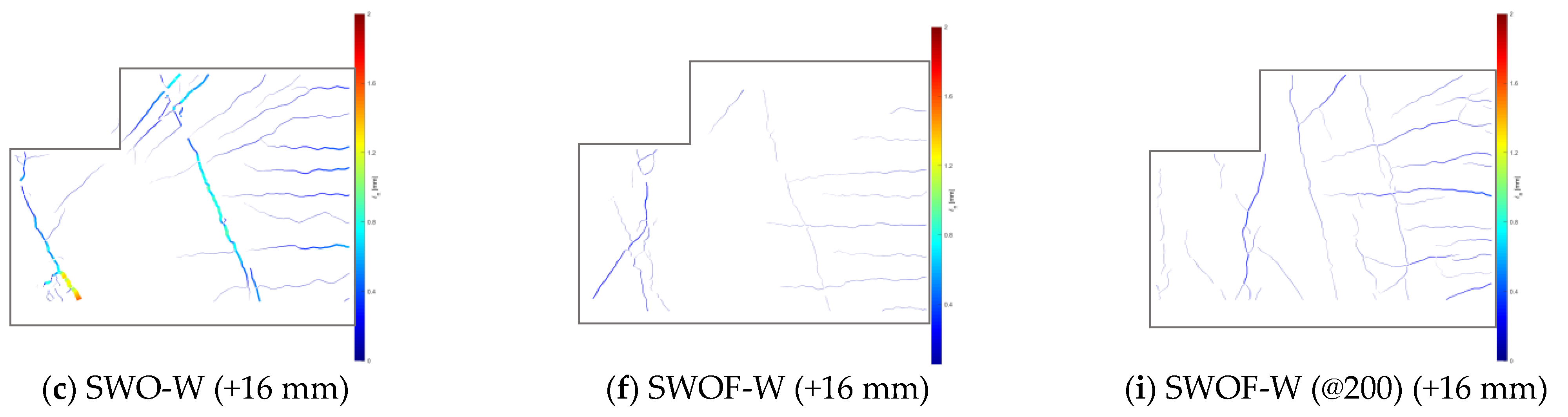

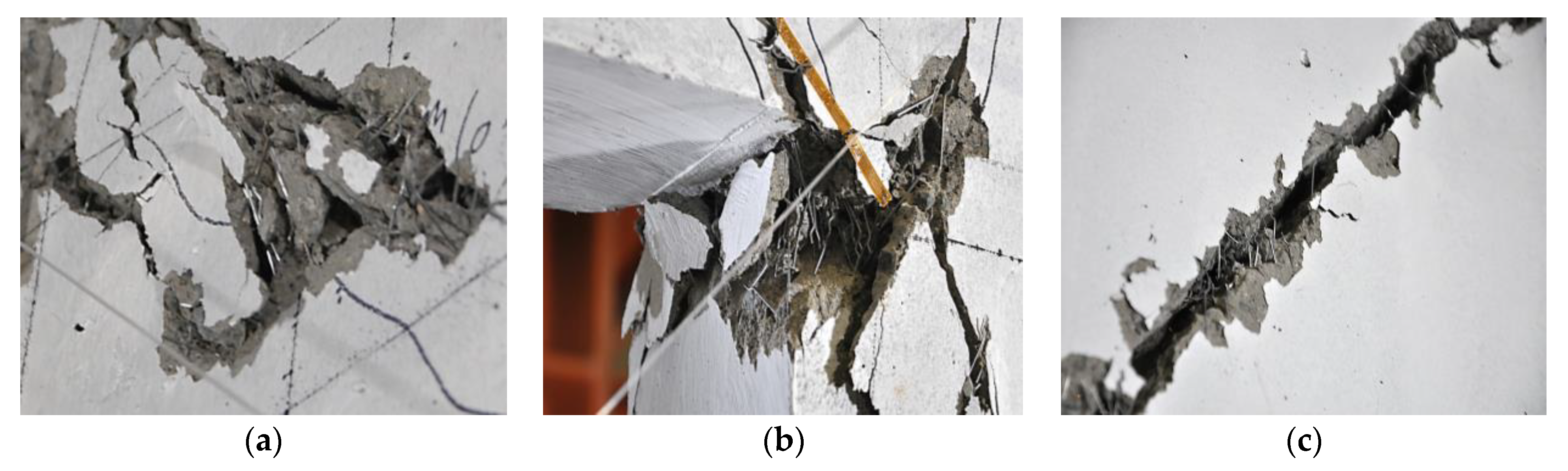

3.1. Damage and Crack Propagation

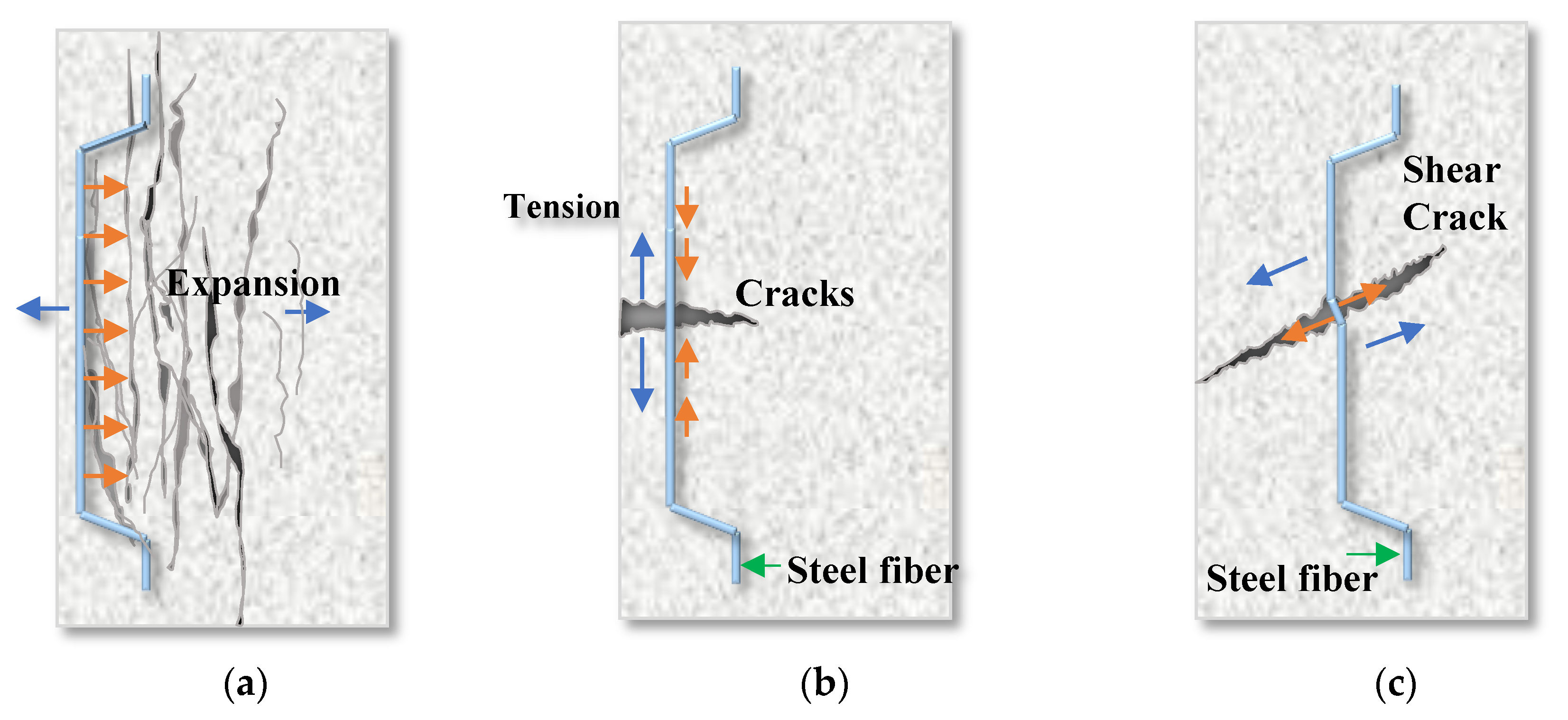

3.1.1. Improvement of SFSC

3.1.2. Substitution of Distribution Reinforcement by SFSC

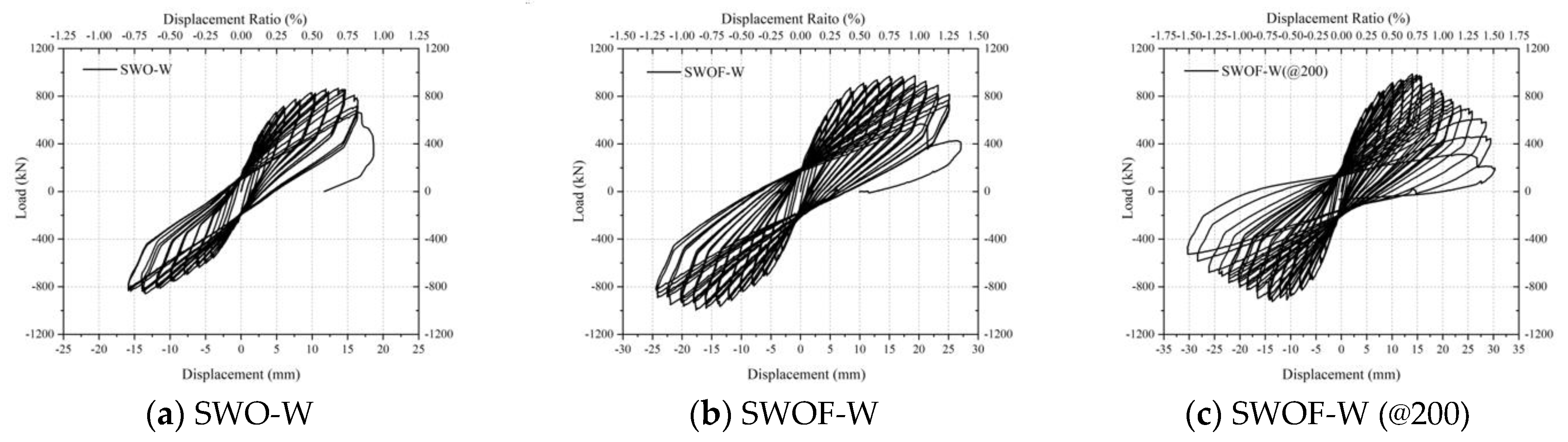

3.2. Hysteretic Behavior

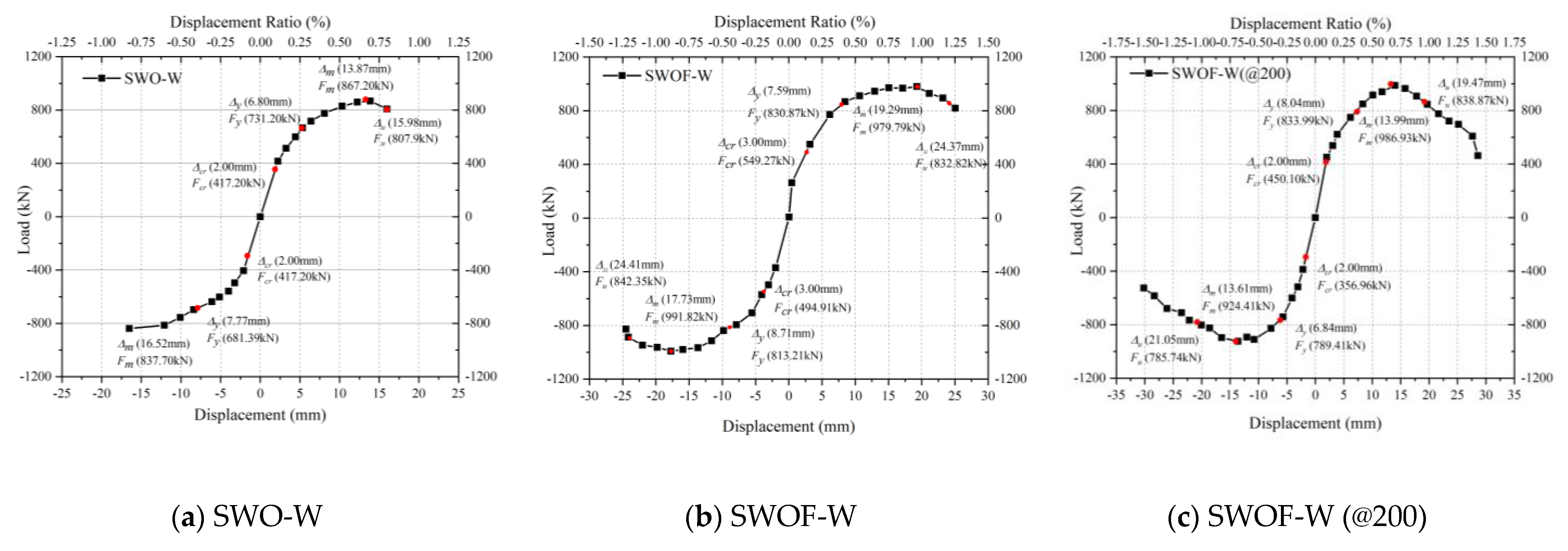

3.2.1. Hysteresis Curves

3.2.2. Skeleton Curves

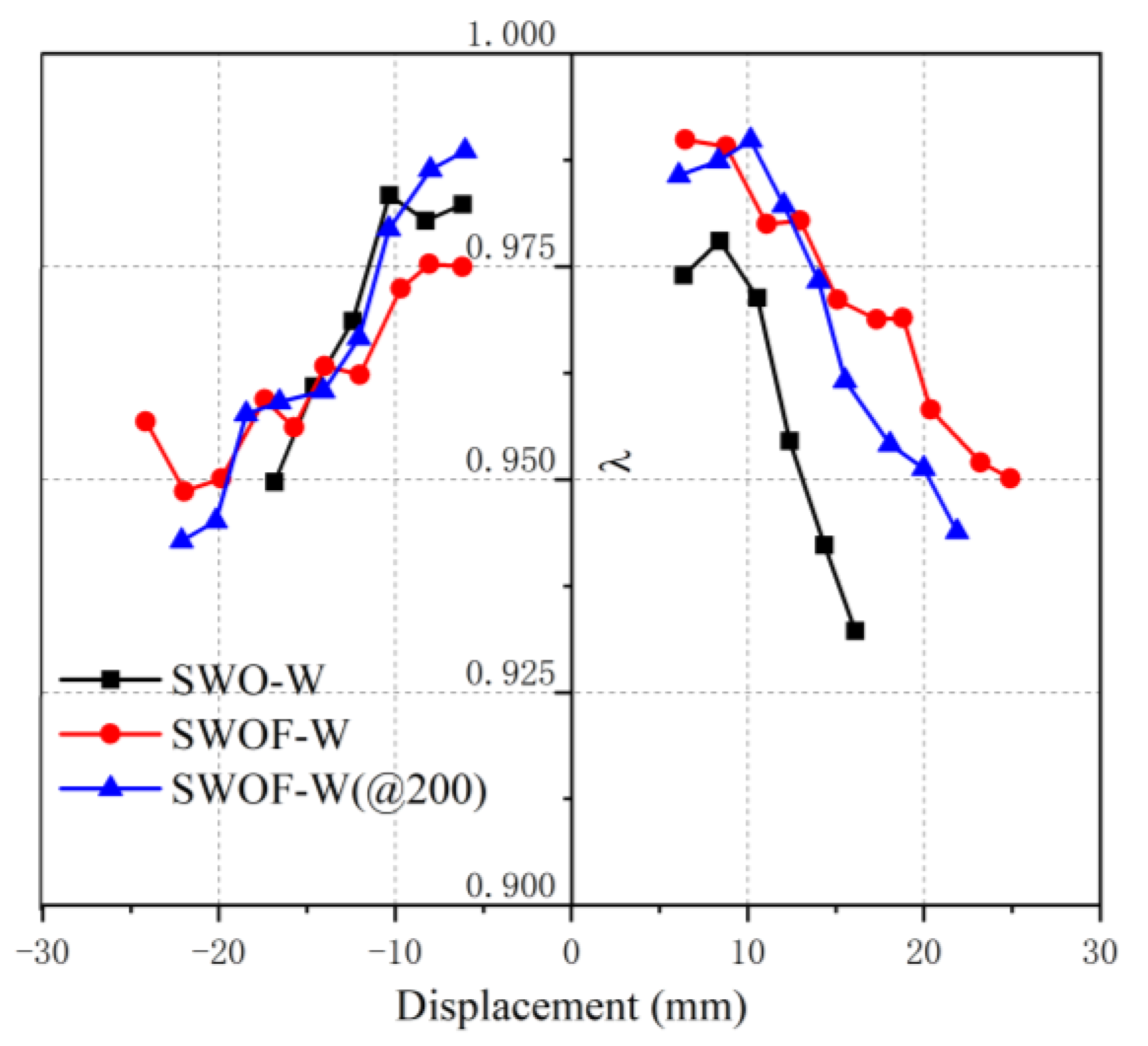

3.2.3. Load-Bearing Capacity Degradation

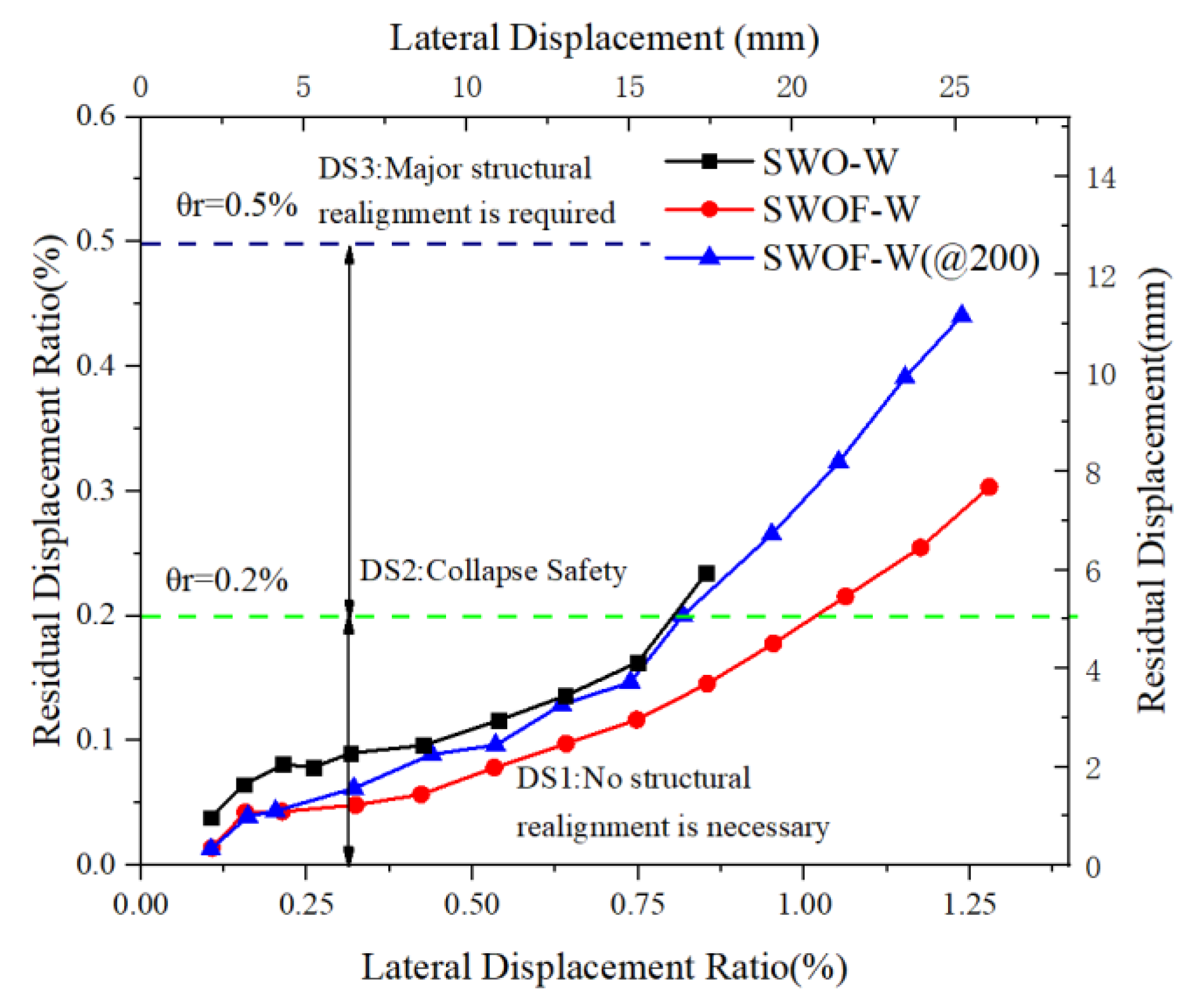

3.2.4. Residual Deformation

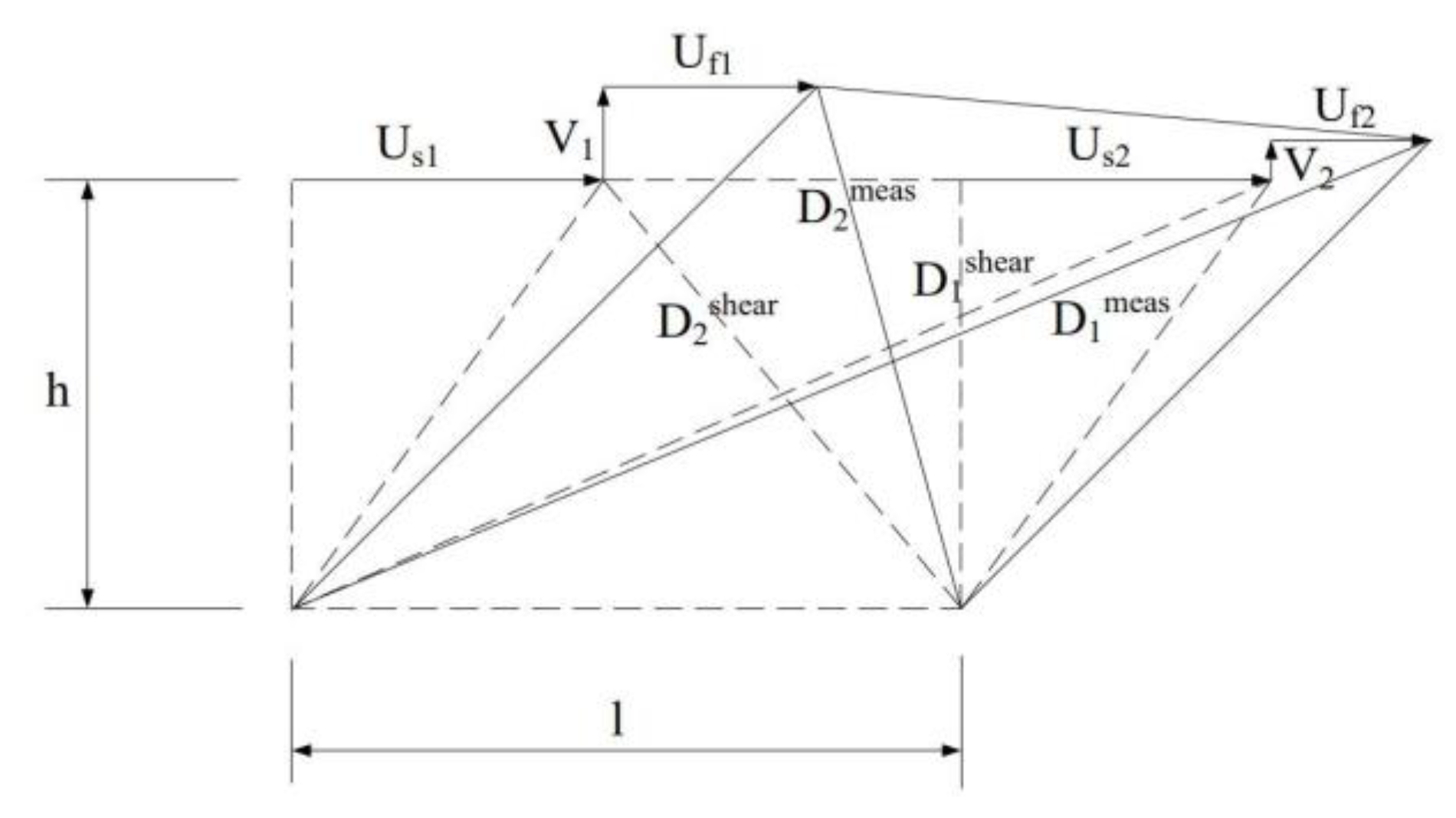

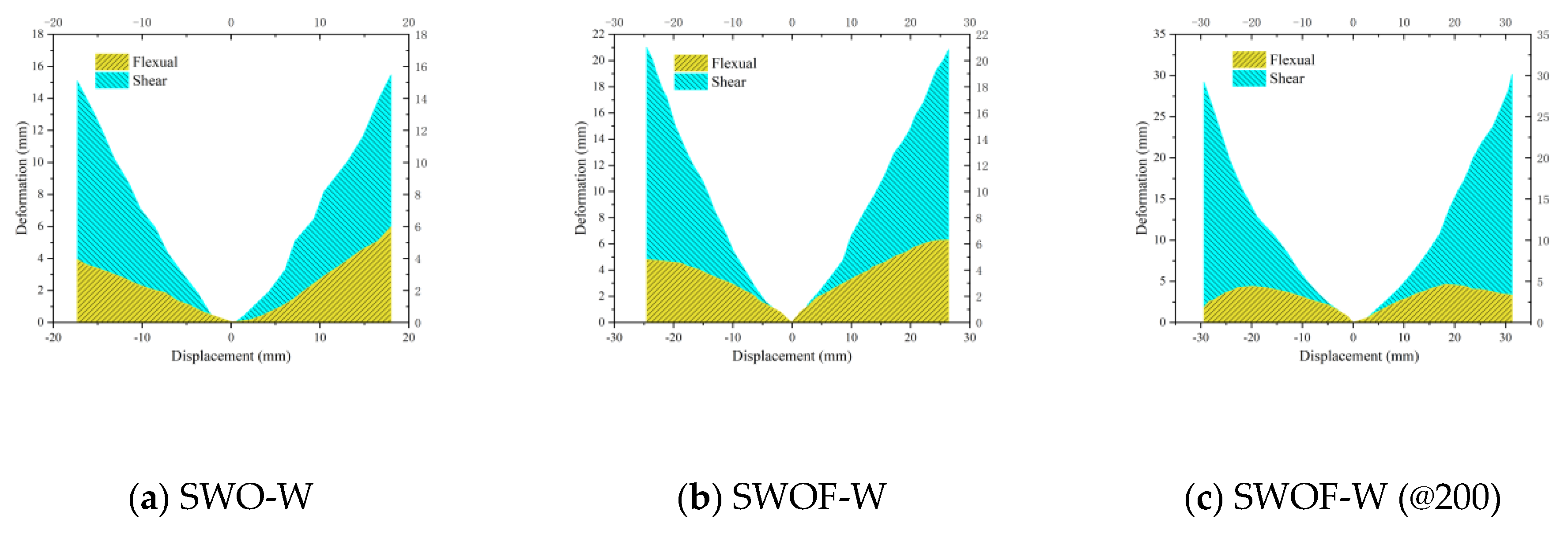

3.3. Bending and Shear Displacement

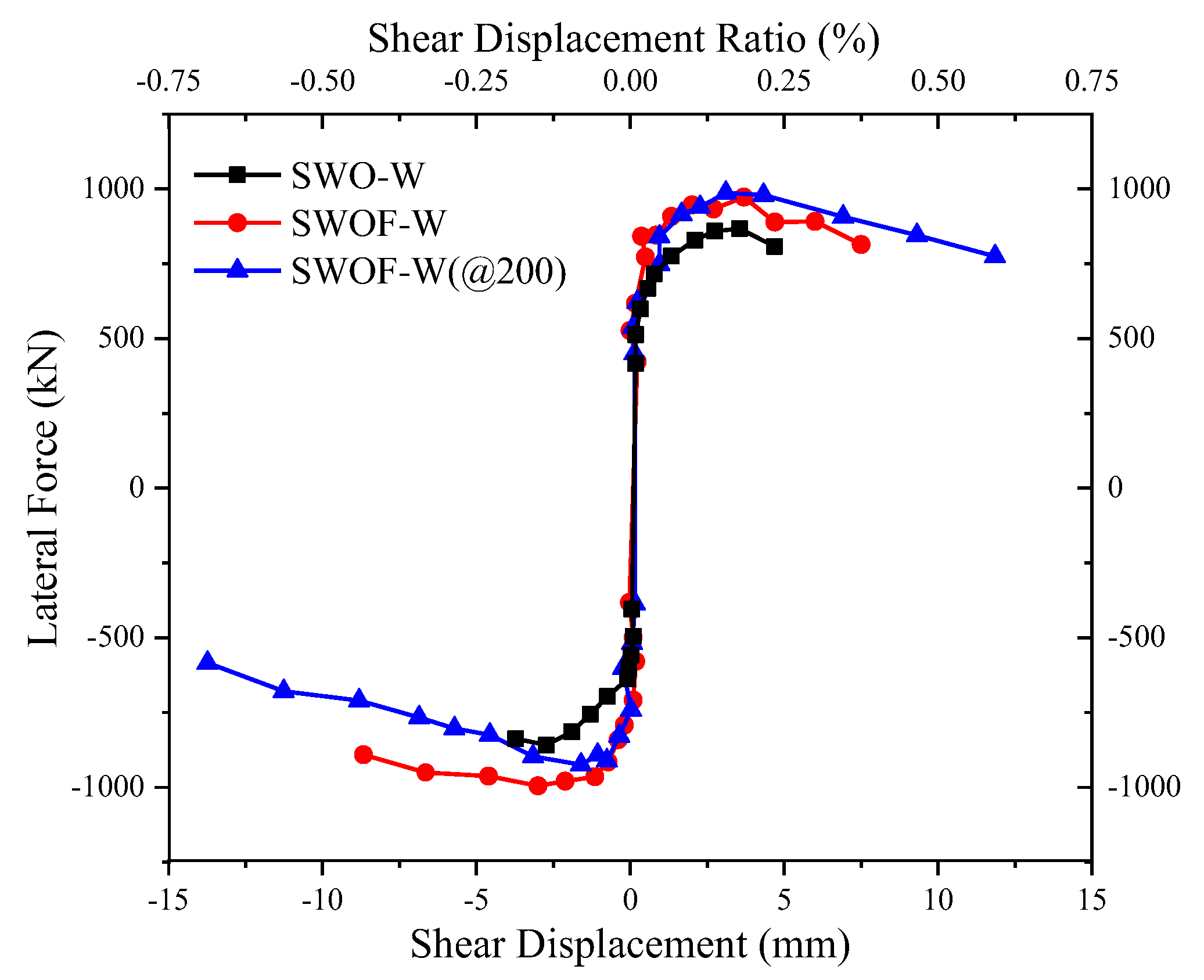

Shear Deformation Ductility

3.4. Seismic Damage Analysis

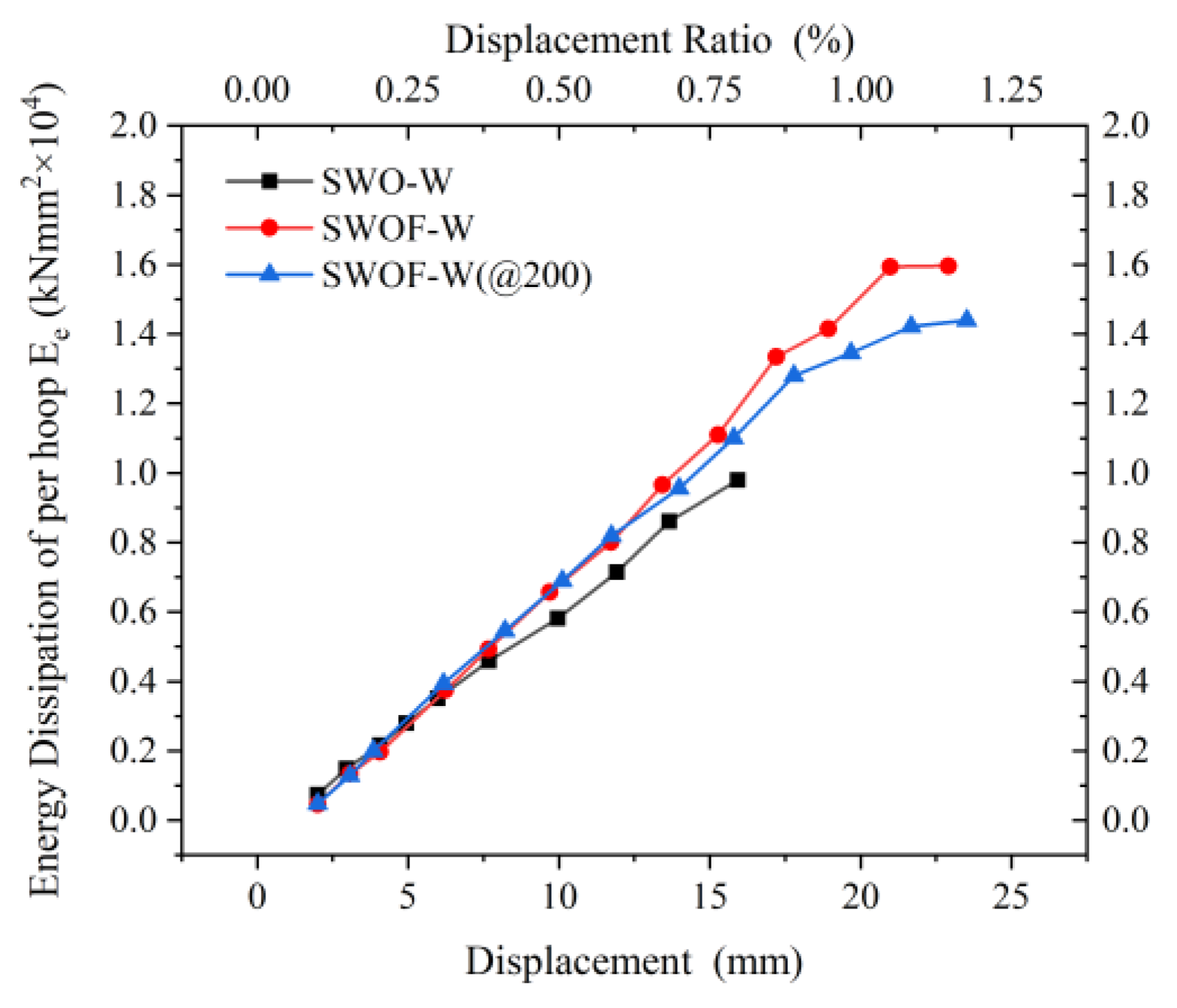

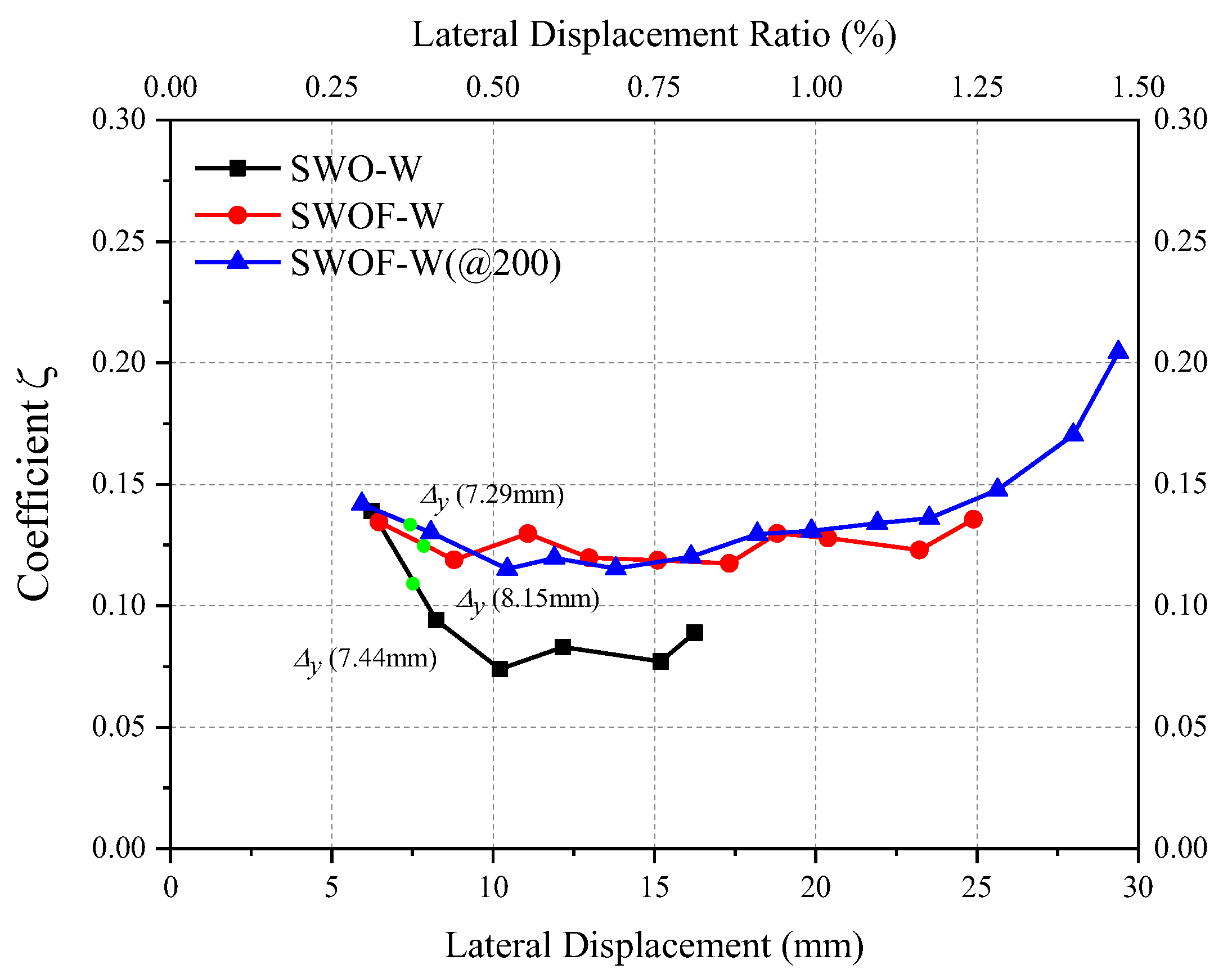

3.5. The Equivalent Viscous Damping Coefficient

4. Summary

4.1. Improving Effect of SFRC on Seismic Performance

4.2. The Substitution Effect of Steel Fiber Concrete for Steel Bar

5. Conclusions

- 1.

- The failure evolution comparison indicates that the presence of SFRC can delay the appearance of horizontal cracks; the oblique crack can be significantly lightened for the bridging effect of the steel fibers;

- 2.

- Compared with the ordinary plain concrete shear wall specimen, the SFRC shear wall exhibits significantly improved seismic performance and the damage of the opening corner was significantly relived;

- 3.

- The SFRC wall with 30% reduced distribution rebar still shows improved seismic capacity comparing to the plain concrete wall which indicate the participate of the SFRC can substitute part of the shear rebar.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, B.; Qian, K.; Wu, H. Flange effects on seismic performance of reinforced concrete squat walls with irregular or regular openings. Eng. Struct. 2016, 110, 127–144. [Google Scholar] [CrossRef]

- Guo, Z.X.; Lu, X.L. Experimental study on the hysteretic model of RC columns with high axial compressive ratio. China Civ. Eng. J. 2004, 37, 32–38. [Google Scholar]

- Zhang, Y.; Wang, Z. Seismic behavior of reinforced concrete shear walls subjected to high axial loading. ACI Struct. J. 2000, 97, 739–750. [Google Scholar]

- Massone, L.M.; Muñoz, G.; Rojas, F. Experimental and numerical cyclic response of RC walls with openings. Eng. Struct. 2019, 178, 318–330. [Google Scholar] [CrossRef]

- Taylor, C.; Cote, P.; Wallace, J.W. Design of slender reinforced concrete walls with openings. ACI Struct. J. 1998, 95, 420–433. [Google Scholar]

- Wang, J.Y.; Sakashita, M.; Kono, S.; Tanaka, H. Shear behavior of reinforced concrete structural walls with eccentric openings under cyclic loading: Experimental study. Struct. Des. Tall Spec. Build. 2012, 21, 669–681. [Google Scholar] [CrossRef]

- Song, X.B.; Cai, Q.; Xiao, X.W.; Cao, Z.W.; Li, C.; Zhang, S.Q. Study on mechanical behavior of monolithic assembled concrete shear wall with non-connected vertical distribution reinforcement and window opening. Build. Struct. 2023, 53, 30–35. [Google Scholar]

- Hosseini, S.A.; Kheyroddin, A.; Mastali, M. An experimental investigation into the impacts of eccentric openings on the in-plane behavior of squat RC shear walls. Eng. Struct. 2019, 197, 109410. [Google Scholar] [CrossRef]

- Bhanu, K.C.; Ganesan, N.; Indira, P.V. Behavior of High-Performance Concrete Shear Walls with Openings under Reversed Cyclic Loading. ACI Struct. J. 2022, 119, 227–241. [Google Scholar]

- Mosoarca, M. Failure analysis of RC shear walls with staggered openings under seismic loads. Eng. Fail. Anal. 2014, 41, 48–64. [Google Scholar] [CrossRef]

- Yu, H.J.; Kang, S.M.; Park, H.G.; Chung, L. Cyclic Loading Test of Structural Walls with Small Openings. Int. J. Concr. Struct. Mater. 2019, 13, 40. [Google Scholar] [CrossRef]

- Ali, A.; Reinforced Wight, J. Concrete Structural Walls with Staggered Opening Configurations under Reverse Cyclic Loading; Report No. UMCE 90–05; Department of Civil Engineering, University of Michigan: Ann Arbor, MI, USA, 1990. [Google Scholar]

- Ou, Y.C.; Hoang, L.; Roh, H. Cyclic behavior of squat reinforced concrete walls with openings typical of exterior walls of row houses in Taiwan. Eng. Struct. 2019, 195, 231–242. [Google Scholar] [CrossRef]

- ACI (American Concrete Institute). ACI 318-08: Building Code Requirements for Reinforced Concrete; ACI: Farmington Hills, MI, USA, 2008. [Google Scholar]

- GB 50010-2010; Industry Standard of the People’s Republic of China. Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- NZS 3101; SNZ (Standards New Zealand). Code of Practice for the Design of Concrete Structures, Parts 1 and 2. Standards New Zealand: Wellington, New Zealand, 1995.

- Lin, Z.; Zhang, H.; Monti, G.; Castoro, C. Effects of Openings and Axial Load Ratio on the Lateral Capacity of Steel-Fiber-Reinforced Concrete Shear Walls. Buildings 2022, 12, 2032. [Google Scholar] [CrossRef]

- Hwang, S.J.; Lee, H.J. Analytical model for predicting shear strengths of interior reinforced concrete beam column joints for seismic resistance. ACI Struct. J. 2000, 97, 35–44. [Google Scholar]

- Liao, W.C. Crack opening evaluation of highly flowable strain hardening fiber-reinforced concrete (HF-SHFRC) under tensile and shear forces. Am. Soc. Civ. Eng. 2014, 253, 9–16. [Google Scholar]

- Liao, W.C.; Su, W.R. Implementation of highly-flowable strain hardening fiber reinforced concrete in new RC beam-column joints. MATEC Web Conf. 2018, 147, 01003. [Google Scholar] [CrossRef]

- Boita, I.E.; Dan, D.; Stoian, V. Seismic behavior of composite steel fiber reinforced concrete shear walls. IOP Conf. Ser. -Mater. Sci. Eng. 2017, 245, 022006. [Google Scholar] [CrossRef]

- Lu, X.L.; Zhang, Y.; Zhang, H.M.; Zhang, H.; Xiao, R. Experimental study on seismic performance of steel fiber reinforced high strength concrete composite shear walls with different steel fiber volume fractions. Eng. Struct. 2018, 171, 247–259. [Google Scholar] [CrossRef]

- Zhang, H.M.; Zhang, Y.; Lu, X.L. Influence of Axial Load Ratio on the Seismic Behavior of Steel Fiber Reinforced Concrete Composite Shear Walls. J. Struct. Eng. 2019, 146, 04019171. [Google Scholar] [CrossRef]

- Zhao, J.; Qiu, J.H.; Gao, D.Y. Experimental Study of Steel Fiber Partially Reinforced Concrete Shear Wall. J. Appl. Basic Eng. Sci. 2010, 18, 10. [Google Scholar]

- Carrillo, J.; Alcocer, S.M.; Pincheira, J.A. Behavior of low-rise, steel fiber-reinforced concrete thin walls under shake table excitations. Eng. Struct. 2017, 138, 146–158. [Google Scholar] [CrossRef]

- Tseng, C.-C.; Chen, L.-P.; Hwang, S.-J. Experimental Study of Non-ductile Frame Infilled with RC Shear Wall with Openings. Struct. Eng. 2018, 33, 68–83. [Google Scholar]

- JGJ/T 101-2015; Industry Standard of the People’s Republic of China. Specification of Testing Method for Earthquake Resistant Building. China Architecture & Building Press: Beijing, China, 2015.

- GB 50011-2019; Industry Standard of the People’s Republic of China. Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2019.

- Hiraishi, H. Evaluation of shear and flexural deformation of flexural type shear walls. Bull. N. Z. Soc. Earthq. Eng. 1984, 17, 135–144. [Google Scholar] [CrossRef]

- Massone, L.M.; Wallace, J.W. Load-Deformation Responses of Slender Reinforced Concrete Walls. ACI Struct. J. 2004, 101, 103–113. [Google Scholar]

- Park, Y.J.; Ang AH, S. Mechanistic seismic damage model for reinforced concrete. J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Peruš, I.; Fajfar, P.; Grabec, I. Prediction of the seismic capacity of RC structural walls by non-parametric multidimensional regression. Earthq. Eng. Struct. Dyn. 1994, 23, 1139–1155. [Google Scholar] [CrossRef]

- Gan, J.F.; Chen, X.L.; Zhang, Y.B.; Fu, J.P. Shear failure test and seismic damage analysis of shear walls. Civ. Constr. Environ. Eng. 2018, 40, 142–150. [Google Scholar]

| Items | Cement | Fly Ash | Coarse Aggregate | Fine Aggregate | Water | Additive | Steel Fiber |

|---|---|---|---|---|---|---|---|

| Plain concrete (C60) | 644 | 136 | 412 | 963 | 250 | 4.5 | 0 |

| SFSC | 644 | 136 | 412 | 963 | 250 | 5 | 156 |

| Items | Cubic Strength (MPa) | Prism Strength (MPa) | Tensile Strength (MPa) | Limit Strain (%) | ||||

|---|---|---|---|---|---|---|---|---|

| SFSC | Plain Concrete | SFSC | Plain Concrete | SFSC | Plain Concrete | SFSC | Plain Concrete | |

| Strength | 60.74 61.42 61.88 | 61.25 62.33 60.57 | 53.65 54.95 53.76 | 56.05 56.21 57.19 | 3.88 4.01 4.38 | - | 0.68 0.62 0.71 | - |

| Average | 61.35 | 61.38 | 54.12 | 56.48 | 4.09 | - | 0.67 | - |

| Items | Yielding Strength (MPa) | Maximum Strength (MPa) | Young’s Module (105 MPa) | Elongation |

|---|---|---|---|---|

| HRB400 C 6 | 524.67 | 545.00 | 2.06 | 5.3% |

| HRB400 C 10 | 454.00 | 617.00 | 2.00 | 26.2% |

| Specimen No. | Concrete Type | Distribution Bars | Edge Longitudinal Bars | Aspect Ratio | Design Compression Axial Ratio |

|---|---|---|---|---|---|

| SWO-W | Plain concrete | HRB400, C 6@150 | HRB400, 8 C 10 | 0.95 | 0.2 |

| SWOF-W | SFSC | HRB400, C 6@150 | 0.95 | 0.2 | |

| SWOF-W (@200) | SFSC | HRB400, C 6@200 | 0.95 | 0.2 |

| Specimen No. | Loading Direction | Yielding | Peak | Failure | |||

|---|---|---|---|---|---|---|---|

| Δy (mm) | Fy (kN) | Δm(mm) | Fm (kN) | Δu (mm) | Fu (kN) | ||

| SWO-W | Push | 6.80 | 731.20 | 13.87 | 867.2 | 15.98 | 807.9 |

| Pull | 7.77 | 681.39 | 16.52 | 837.7 | - | - | |

| Average | 7.29 | 706.30 | 15.20 | 852.45 | 15.98 | 807.9 | |

| SWOF-W | Push | 7.59 | 830.87 | 19.29 | 979.79 | 24.37 | 832.82 |

| Pull | 8.71 | 813.21 | 17.73 | 991.81 | 24.41 | 842.45 | |

| Average | 8.15 | 822.04 | 18.51 | 985.8 | 24.39 | 837.635 | |

| SWOF-W (@200) | Push | 8.04 | 833.99 | 13.99 | 986.9 | 19.47 | 838.87 |

| Pull | 6.84 | 789.41 | 13.61 | 924.41 | 21.05 | 785.74 | |

| Average | 7.44 | 811.7 | 13.8 | 955.655 | 20.26 | 812.305 | |

| Specimen | Loading Direction | Yielding | Peak | Failure | Ductility Coefficient | |||

|---|---|---|---|---|---|---|---|---|

| Δy (mm) | Fy (kN) | Δm (mm) | Fy (kN) | Δu (mm) | Fu (kN) | μ | ||

| SWO-W | Push | 0.680 | 692.70 | 3.552 | 867.2 | 4.690 | 807.9 | 6.897 |

| SWOF-W | Push | 0.635 | 842.94 | 3.691 | 979.79 | 7.266 | 832.82 | 13.581 |

| SWOF-W (@200) | Push | 1.204 | 867.02 | 3.107 | 986.9 | 9.543 | 838.87 | 7.926 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Tang, Z.; Duan, Y.; Chen, Z. Seismic Performance of SFRC Shear Walls with Window Opening and the Substitution Effect for Steel Bars. Buildings 2023, 13, 1550. https://doi.org/10.3390/buildings13061550

Zhang H, Tang Z, Duan Y, Chen Z. Seismic Performance of SFRC Shear Walls with Window Opening and the Substitution Effect for Steel Bars. Buildings. 2023; 13(6):1550. https://doi.org/10.3390/buildings13061550

Chicago/Turabian StyleZhang, Hongmei, Zizhao Tang, Yuanfeng Duan, and Zhiyuan Chen. 2023. "Seismic Performance of SFRC Shear Walls with Window Opening and the Substitution Effect for Steel Bars" Buildings 13, no. 6: 1550. https://doi.org/10.3390/buildings13061550

APA StyleZhang, H., Tang, Z., Duan, Y., & Chen, Z. (2023). Seismic Performance of SFRC Shear Walls with Window Opening and the Substitution Effect for Steel Bars. Buildings, 13(6), 1550. https://doi.org/10.3390/buildings13061550