Enhanced Ductility and Toughness of Desert Sand Engineered Cementitious Composites

Abstract

1. Introduction

2. Experimental Program

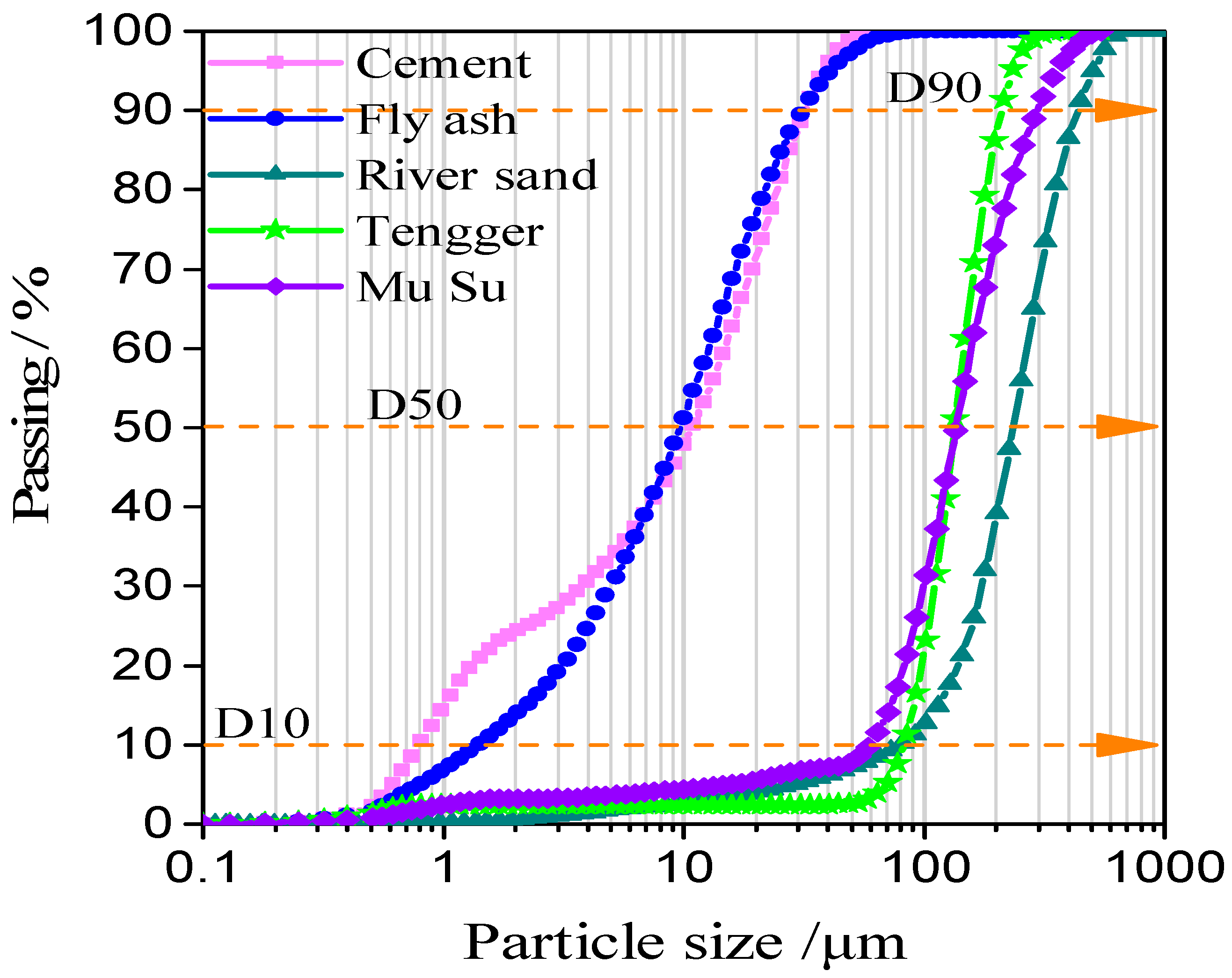

2.1. Materials

2.2. Mixing and Curing Procedure

2.3. Specimens and Test Procedures

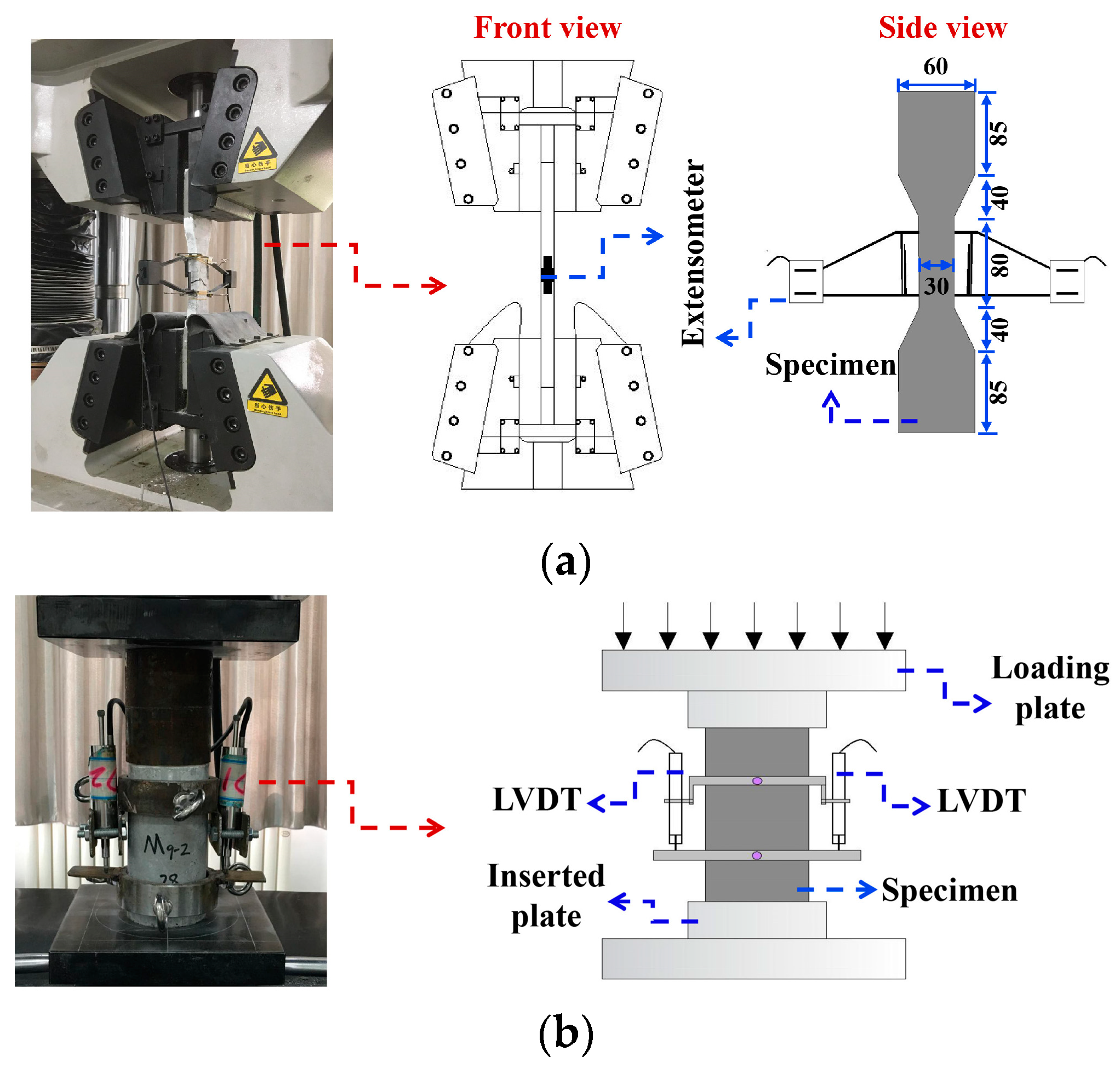

2.3.1. Uniaxial Tensile/Compression Test

2.3.2. Three-/Four-Point Bending Tests

2.3.3. Workability Test

3. Results and Discussion

3.1. Workability

3.2. Mechanical Properties of DS-ECCs

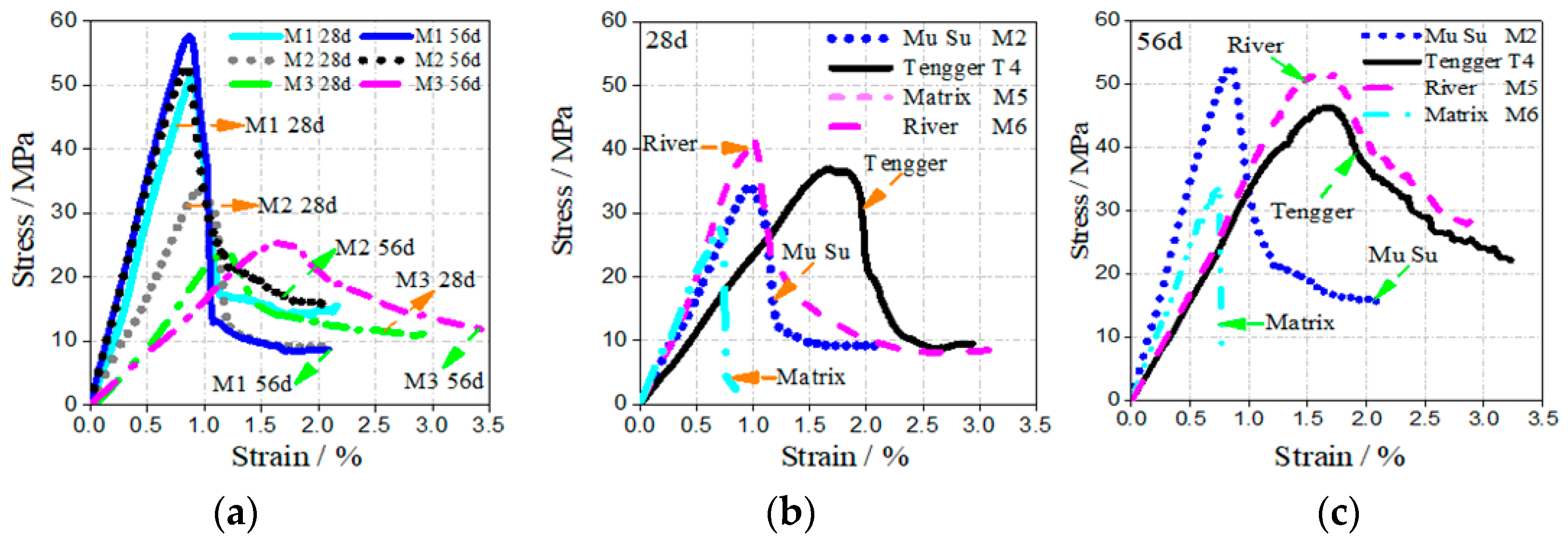

3.2.1. Uniaxial Tensile Properties

3.2.2. Uniaxial Compression Properties

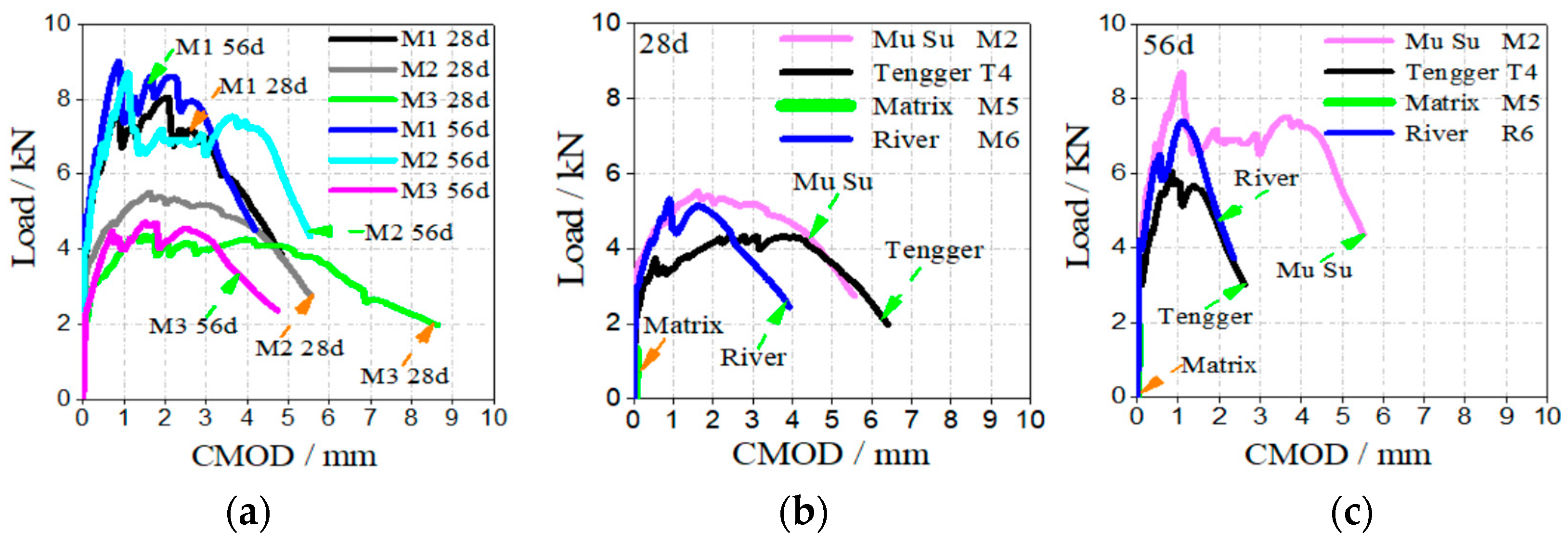

3.2.3. Fracture Properties under the Three-Point Bending Test

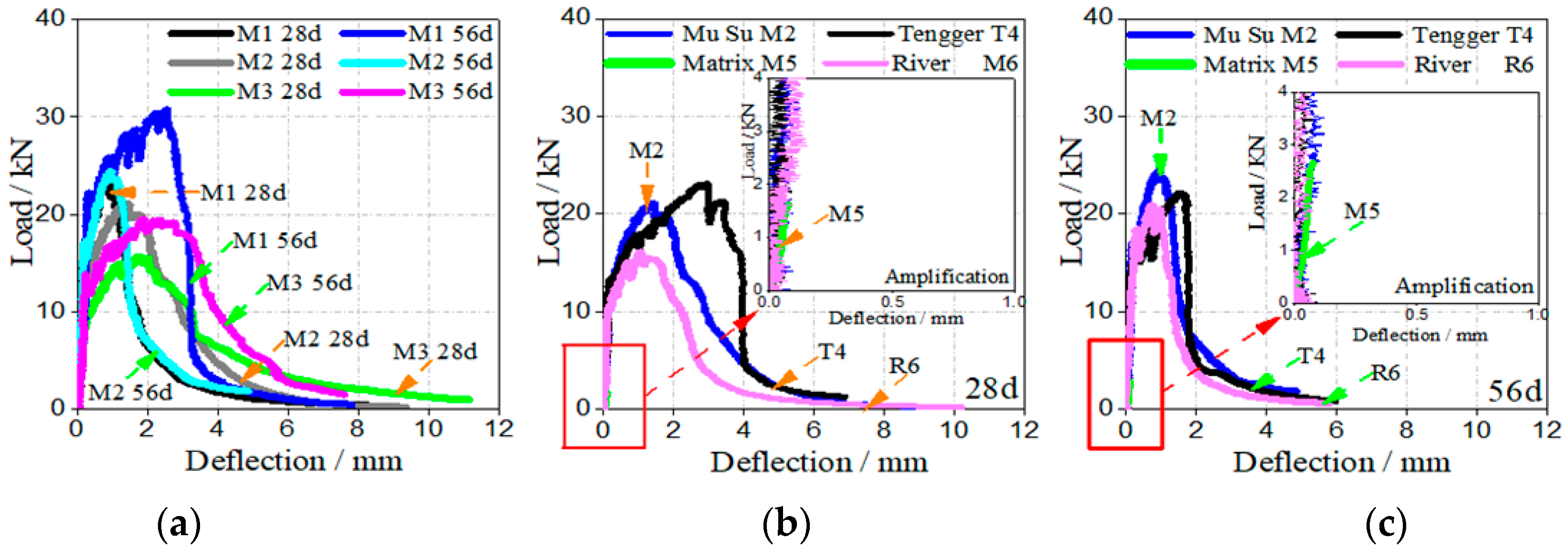

3.2.4. Bending Properties under the Four-Point Bending Test

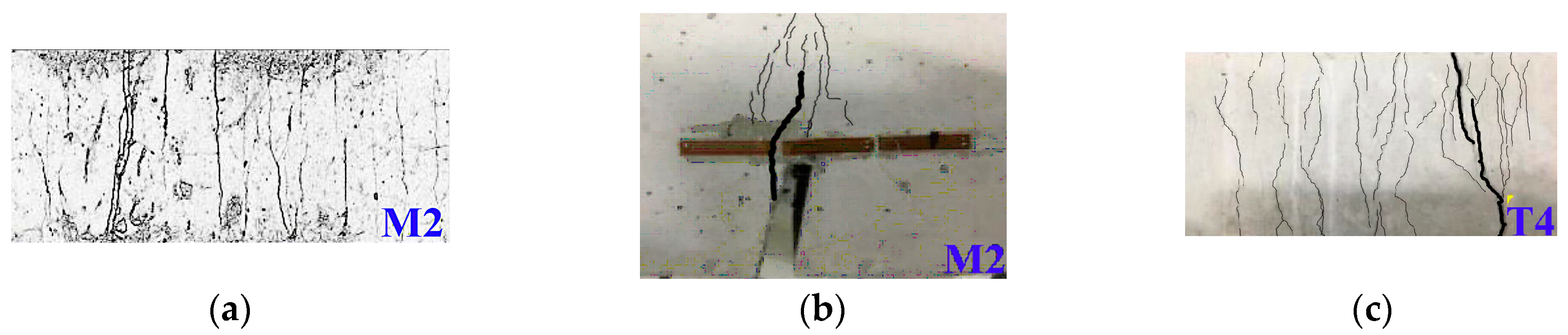

3.2.5. Failure Forms of DS-ECCs

4. Conclusions

- (1)

- Desert sands, as the favorable aggregate substitutes, satisfy the ingredient selection for ECCs due to their ultra-fine particle distribution, which can refine the microstructures of cement matrices containing different desert sands, affect the fiber-bridging capability for enhancing the matrices, and then tailor the mechanical behaviors of DS-ECCs. Both Mu Us DS-ECCs and Tengger DS-ECC possess excellent strength, ductility, and toughness using a reasonable mix ratio.

- (2)

- At the curing ages of 28 d and 56 d, all designed DS-ECCs exhibit superior mechanical properties compared to river sand-based ECC and DS-ECC with an ordinary matrix. The ultimate tensile strengths and strains of the DS-ECCs are about 10–14 MPa and 3–7%, respectively. The DS-ECCs have an ultimate compression strength of 30–50 MPa, which is comparable to that of the river sand-based ECC, while the former has excellent compression ductility of over 1%. Moreover, the DS-ECCs have desirable ultimate bending (fracture) strengths (4–9 kN and 21–30 kN) and toughness, outperforming the river sand-based ECC.

- (3)

- The DS-ECCs show apparent ductile damage, followed by fine multi-cracks under uniaxial tensile and pure-bending loads and olive-shaped multi-cracks under fracture loads. They behave differently from the river sand-based ECC, which shows only a main crack under the ultimate loads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| W/B | water-to-binder ratio | h′ | height of cylinder |

| S/B | sand-to-binder ratio | h | height of notched prismatic specimen |

| initial cracking length | knife-edged width of extensometer | ||

| critical cracking length | bending toughness index | ||

| notch depth | rising slope of load–CMOD curves | ||

| A | cross-sectional area of cylinder | initial fracture toughness | |

| critical areas corresponding to load–deflection curves | unstable fracture toughness | ||

| initial crack mouth displacement | maximum bending load | ||

| crack mouth displacement for | residual strength indexes | ||

| elastic modulus of DS-ECC | span of two supports of prismatic specimen | ||

| equivalent compression strength | t | notch-width of prismatic specimen | |

| ultimate compression strength | equivalent compression toughness index | ||

| F | ultimate compression strength | relatively effective elastic crack length | |

| geometric impact factor | ultimate tensile strength | ||

| peak fracture load | ultimate compression strength | ||

| ultimate fracture load | ultimate tensile strain | ||

| cracking load of prismatic specimen | ultimate compression strain | ||

| unstable critical load of prismatic specimen | integral area corresponding to n fu | ||

| tensile fracture energy | compression deformation |

References

- Li, V.C. Performance Driven Design of Fiber Reinforced Cementitious Composites. In Proceedings of 4th RILEM International Symposium on Fiber Reinforced Concrete; E&FN Spon: London, UK, 1992; pp. 12–30. ISBN 0419 18130 X. [Google Scholar]

- Li, V.C.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-hardening PVA-ECC. ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Ranade, R.; Li, V.C.; Stults, M.D.; Heard, W.F.; Rushing, T.S. Composite Properties of High-Strength, High-Ductility Concrete. ACI Mater. J. 2013, 110, 413–422. [Google Scholar]

- Ma, H.; Qian, S.Z.; Zhang, Z.G.; Lin, Z.; Li, V.C. Tailoring Engineered Cementitious Composites with local ingredients. Constr. Build. Mater. 2015, 101, 584–595. [Google Scholar] [CrossRef]

- Liu, W.; Xu, S.L.; Li, Q.H. Experimental study on fracture performance of ultra-high toughness cementitious composites with J-integral. Eng. Fract. Mech. 2012, 96, 656–666. [Google Scholar] [CrossRef]

- Chen, Y.X.; Yu, J.; Leung, C.K.Y. Use of high strength Strain-Hardening Cementitious Composites for flexural repair of concrete structures with significant steel corrosion. Constr. Build. Mater. 2018, 167, 325–337. [Google Scholar] [CrossRef]

- Jin, Q.X.; Li, V.C. Development of lightweight engineered cementitious composite for durability enhancement of tall concrete wind towers. Cem. Concr. Compos. 2019, 96, 87–94. [Google Scholar] [CrossRef]

- Niasar, A.N.; Alaee, F.J.; Zamani, S.M. Experimental investigation on the performance of unreinforced masonry wall, retrofitted using engineered cementitious composites. Constr. Build. Mater. 2020, 239, 117788. [Google Scholar] [CrossRef]

- Zhang, G.X.; Song, J.X.; Yang, J.S.; Liu, X.Y. Performance of mortar and concrete made with a fine aggregate of desert sand. Build. Environ. 2006, 41, 1478–1481. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, Y.Q.; Jiang, G.H. Orthogonal experiment on performance of mortar made with dune sand. Constr. Build. Mater. 2020, 264, 120254. [Google Scholar] [CrossRef]

- Abu Seif1, E.S.S.; Sonbul, A.R.; Hakami, B.A.H.; El-Sawy, E.K. Experimental study on the utilization of dune sands as a construction material in the area between Jeddah and Mecca, Western Saudi Arabia. Bull. Eng. Geol. Environ. 2016, 75, 1007–1022. [Google Scholar] [CrossRef]

- Luo, F.J.; He, L.; Pan, Z.; Duan, W.H.; Zhao, X.L.; Collins, F. Collins, Effect of very fine particles on Workability and strength of concrete made with dune sand. Constr. Build. Mater. 2013, 47, 131–137. [Google Scholar] [CrossRef]

- Liu, H.F.; Ma, J.R.; Wang, Y.Y.; Ning, J.G. Influence of desert sand on the mechanical properties of concrete subjected to impact loading. Acta Mech. Solida Sin. 2017, 30, 583–595. [Google Scholar] [CrossRef]

- Zhang, M.H.; Liu, H.F.; Sun, J.X.; Chen, X.L.; Doh, S.I. Dynamic Mechanical Behaviors of Desert Sand Concrete (DSC) after Different Temperatures. Appl. Sci. 2019, 9, 4151. [Google Scholar] [CrossRef]

- Kaufmann, J. Evaluation of the combination of desert sand and calcium sulfoaluminate cement for the production of concrete. Constr. Build. Mater. 2020, 243, 118281. [Google Scholar] [CrossRef]

- Khan, M.I.; Fares, G.; Mourad, S. Optimized Fresh and Hardened Properties of Strain Hardening Cementitious Composites: Effect of Mineral Admixtures, Cementitious Composition, Size, and Type of Aggregates. J. Mater. Civ. Eng. 2017, 29, 1–16. [Google Scholar] [CrossRef]

- Meng, D.; Huang, T.; Zhang, Y.X.; Lee, C.K. Mechanical behaviour of a polyvinyl alcohol fiber reinforced engineered cementitious composite (PVA-ECC) using local ingredients. Constr. Build. Mater. 2017, 141, 259–270. [Google Scholar] [CrossRef]

- Che, J.L.; Li, Q.W.; Lee, M.G.; Dan, W. Experimental research on mechanical properties of desert sand steel-PVA fiber engineered cementitious composites. Funct. Mater. 2017, 24, 584–592. [Google Scholar]

- Han, G.S.; Che, J.L.; Li, Q.W.; Ma, C.X.; Liu, H.F. Experimental research on mechanical properties of desert sand PVA-ECC materials. Constr. Technol. 2018, 47, 27–31. (In Chinese) [Google Scholar]

- Che, J.L.; Wang, D.; Liu, H.F.; Zhang, Y.X. Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC). Appl. Sci. 2019, 9, 1857. [Google Scholar] [CrossRef]

- An, X.; Che, J.L.; Liu, H.F. Study on freeze-thaw resistance with NaCl of desert sand engineering cement composites. Phys. Chem. Earth Parts A/B/C 2020, 121, 102954. [Google Scholar] [CrossRef]

- Kan, L.L.; Zhang, Z.; Zhang, L.; Liu, W.D. Effect of low-cost PVA fibers on the mechanical properties of Engineered Cementitious Composites. Eng. Mech. 2019, 36, 121–129. (In Chinese) [Google Scholar]

- Li, X.; Grasley, Z.C.; Garboczi, E.J.; Bullard, J.W. Modeling the apparent and intrinsic viscoelastic relaxation of hydrating cement paste. Cem. Concr. Compos. 2015, 55, 322–330. [Google Scholar] [CrossRef]

- Slusarek, J.; Nowoswiat, A.; Olechowska, M. Logistic Model of Phase Transformation of Hardening Concrete. Materials 2022, 15, 4403. [Google Scholar] [CrossRef]

- Yu, J.; Lei, S.M.; Liang, X.W.; Liu, X.J.; Li, L. Design method for mixture proportioning of a new hybrid steel fiber self-compacting concrete. J. Build. Mater. 2017, 20, 611–615+629. (In Chinese) [Google Scholar]

- JSCE. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008. [Google Scholar]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2001.

- Deng, Z.C. High-Performance Synthetic Fiber Concrete; Science Press: Beijing, China, 2003; pp. 25–27. (In Chinese) [Google Scholar]

- Guettala, S.; Mezghiche, B. Compressive strength and hydration with age of cement pastes containing dune sand powder. Constr. Build. Mater. 2011, 25, 1263–1269. [Google Scholar] [CrossRef]

- Alhozaimy, A.; Jaafar, M.S.; Al-Negheimish, A.; Abdullah, A.; Taufiq-Yap, Y.H.; Noorzaei, J.; Alawad, O.A. Properties of high strength concrete using white and dune sands under normal and autoclaved curing. Constr. Build. Mater. 2012, 27, 218–222. [Google Scholar] [CrossRef]

- Alawad, O.A.; Alhozaimy, A.; Jaafar, M.S.; Aziz, F.N.A.; Al-Negheimish, A. Effect of Autoclave Curing on the Microstructure of Blended Cement Mixture Incorporating Ground Dune Sand and Ground Granulated Blast Furnace Slag. Int. J. Concr. Struct. Mater. 2015, 9, 381–390. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Mihashi, H. Strain hardening behavior of lightweight hybrid polyvinyl alcohol (PVA) fiber reinforced cement composites. Mater. Struct. 2010, 44, 1179–1191. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yücel, H.E.; Demirhan, S.; Arık, M.T.; Li, V.C. Combined effect of aggregate and mineral admixtures on tensile ductility of engineered cementitious composites. ACI Mater. J. 2012, 109, 627. [Google Scholar]

- Deng, M.K.; Han, J.; Liu, H.B.; Qin, M.; Liang, X.W. Analysis of Compressive Toughness and Deformability of High Ductile Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 384902. [Google Scholar] [CrossRef]

- Xu, S.L.; Lyu, Y.; Xu, S.J.; Li, Q.H. Enhancing the initial cracking fracture toughness of steel-polyvinyl alcohol hybrid fibers ultra high toughness cementitious composites by incorporating multi-walled carbon nanotubes. Constr. Build. Mater. 2019, 195, 269–282. [Google Scholar] [CrossRef]

- ASTM C 1018-98; Standard Test Method for Flexural Toughness and First Crack Strength of Fiber Reinforced Concrete. Book of ASTM Standard, Part 04.02. ASTM: West Conshohocken, PA, USA, 1991; pp. 507–513.

| Component | Al2O3 | Na2O | CaO | SiO2 | P2O5 | SO3 | Fe2O3 | K2O | TiO2 | Cl | MgO |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 5.05 | 0.73 | 60.24 | 21.22 | / | 2.67 | 3.26 | 0.50 | / | / | 0.97 |

| Fly ash | 23.6 | 13.2 | 6.12 | 38.5 | 1.06 | 2.13 | 7.49 | 1.84 | / | 0.26 | 3.66 |

| River sand | 11.8 | 16.0 | 6.87 | 45.2 | 1.01 | 0.58 | 6.33 | 4.65 | 0.86 | 0.33 | / |

| Mu Us desert sand | 12.3 | / | 4.83 | 74.2 | 0.80 | 0.50 | 3.69 | 2.62 | 0.49 | 0.41 | / |

| Tengger desert sand | 13.10 | / | 3.57 | 70.80 | 1.72 | 1.03 | 4.62 | 3.63 | 0.62 | / | / |

| Fiber | Length (mm) | Diameter (μm) | Density (kg/m3) | Ultimate Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| PVA | 12 | 39 | 1300 | 1600 | 40 |

| Mix. NO | W/B | S/B | W/(C + FA) | S/(C + FA) | FA Ratio | SP Ratio | PVA Ratio | Flow Diameter | ||

|---|---|---|---|---|---|---|---|---|---|---|

| by Weight | by Volume | mm | ||||||||

| Basic groups | M1 | 0.29 | 0.46 | 0.29 | DS | 0.46 | 50% | 0.1% | 2% | 61 |

| M2 | 0.35 | 0.35 | 50% | 2% | 65 | |||||

| M3 | 0.35 | 0.35 | 70% | 2% | 67 | |||||

| T4 | 0.35 | 0.35 | 50% | 2% | 65 | |||||

| Control groups | M5 | 0.35 | 0.35 | 50% | 0 | 72 | ||||

| R6 | 0.35 | 0.35 | RS | 50% | 2% | 65 | ||||

| Mix. No. | (MPa) | (%) | (N/mm) | (MPa) | (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 28 d | 10.18 | 3.23 | 16.76 | 51.34 | 0.92 | 27.52 | 28.90 | 0.026 | 0.029 |

| 56 d | 9.71 | 3.19 | 16.00 | 57.66 | 0.88 | 32.34 | 32.15 | 0.030 | 0.034 | |

| M2 | 28 d | 14.84 | 4.06 | 24.60 | 34.31 | 0.97 | 18.93 | 19.2 | 0.021 | 0.022 |

| 56 d | 10.67 | 4.82 | 29.09 | 52.98 | 0.84 | 29.93 | 30.74 | 0.028 | 0.033 | |

| M3 | 28 d | 12.17 | 5.38 | 15.48 | 23.85 | 1.19 | 12.74 | 13.26 | 0.017 | 0.031 |

| 56 d | 11.07 | 6.68 | 17.10 | 25.77 | 1.67 | 13.44 | 14.48 | 0.03 | 0.048 | |

| T4 | 28 d | 10.03 | 3.76 | 22.74 | 36.50 | 1.74 | 21.75 | 21.75 | 0.043 | 0.046 |

| 56 d | 9.55 | 2.74 | 24.84 | 46.27 | 1.68 | 28.37 | 28.76 | 0.054 | 0.090 | |

| M5 | 28 d | 1.27 | 0.10 | 0.0042 | 28.01 | 0.73 | 0.003 | 0.004 | 0.001 | 0.001 |

| 56 d | 1.21 | 0.09 | 0.0064 | 31.08 | 0.51 | 0.004 | 0.004 | 0.002 | 0.002 | |

| R6 | 28 d | 12.27 | 2.64 | 12.66 | 41.32 | 1.01 | 21.92 | 22.43 | 0.023 | 0.028 |

| 56 d | 11.44 | 4.58 | 20.91 | 51.94 | 1.63 | 31.51 | 0.032 | 0.061 | 0.096 | |

| [17] | W/B (0.29) | 1.18 | 2.59 | - | ||||||

| W/B (0.35) | 2.72 | 2.59 | - | |||||||

| [18] | W/B (0.30) | 0.56 | 0.58 | - | ||||||

| Mix. No. | |||||||

|---|---|---|---|---|---|---|---|

| M1 | 28 d | 6.13 | 8.25 | 0.22 | 4.22 | 23.88 | 0.86 |

| 56 d | 6.63 | 9.03 | 0.16 | 4.77 | 30.72 | 2.58 | |

| M2 | 28 d | 3.64 | 5.57 | 0.63 | 3.87 | 21.10 | 1.47 |

| 56 d | 6.78 | 8.70 | 0.20 | 5.52 | 24.40 | 0.93 | |

| M3 | 28 d | 2.71 | 4.35 | 0.33 | 4.14 | 15.45 | 2.07 |

| 56 d | 2.35 | 4.75 | 0.5 | 3.28 | 19.18 | 2.75 | |

| T4 | 28 d | 2.56 | 4.37 | 0.74 | 3.8 | 23.03 | 3.03 |

| 56 d | 3.66 | 6.05 | 0.32 | 3.02 | 27.63 | 1.57 | |

| M5 | 28 d | 1.42 | 1.42 | 0.12 | 0.39 | 1.61 | 0.08 |

| 56 d | 1.94 | 1.94 | 0.17 | 0.17 | 2.67 | 0.08 | |

| R6 | 28 d | 3.08 | 5.34 | 0.54 | 1.04 | 15.53 | 1.45 |

| 56 d | 4.21 | 7.45 | 0.37 | 3.34 | 20.84 | 1.02 | |

| Mix Ratio | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 28 d | 5.80 | — | — | — | — | 6.11 | — | — | — | — | — |

| 56 d | 8.1 | 16.2 | — | — | — | 35.1 | 203.8 | — | — | — | 236.3 | |

| M2 | 28 d | 5.9 | 12.0 | — | — | — | 15.8 | 153.3 | — | — | — | 190 |

| 56 d | 8.3 | 17.3 | — | — | — | 19.7 | 224.8 | — | — | — | 120 | |

| M3 | 28 d | 7.3 | 15 | 39.3 | 66.8 | 96.1 | 100.3 | 193.3 | 242.7 | 275 | 293.5 | 209 |

| 56 d | 6.3 | 12.6 | 30.9 | — | — | 36.4 | 159.5 | 182.4 | — | — | 137.5 | |

| T4 | 28 d | 7.6 | 15.2 | 37.0 | 61.9 | 89.4 | 90.5 | 190.3 | 217.9 | 248.5 | 275.6 | / |

| 56 d | 5.3 | 9.8 | 22.8 | — | — | 24.2 | 112.8 | 130.2 | — | — | 68.5 | |

| M5 | 28 d | — | — | — | — | — | 1 | — | — | — | — | — |

| 56 d | — | — | — | — | — | 1 | — | — | — | — | — | |

| R6 | 28 d | 9.9 | 21.2 | 53.9 | — | — | 75.4 | 280 | 327.6 | — | — | 358.0 |

| 56 d | 7.5 | 15.5 | — | — | — | 19.5 | 200.3 | — | — | — | 199.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Che, J.; Liu, H.; Chin, S.C. Enhanced Ductility and Toughness of Desert Sand Engineered Cementitious Composites. Buildings 2023, 13, 1538. https://doi.org/10.3390/buildings13061538

Wang D, Che J, Liu H, Chin SC. Enhanced Ductility and Toughness of Desert Sand Engineered Cementitious Composites. Buildings. 2023; 13(6):1538. https://doi.org/10.3390/buildings13061538

Chicago/Turabian StyleWang, Dan, Jialing Che, Haifeng Liu, and Siew Choo Chin. 2023. "Enhanced Ductility and Toughness of Desert Sand Engineered Cementitious Composites" Buildings 13, no. 6: 1538. https://doi.org/10.3390/buildings13061538

APA StyleWang, D., Che, J., Liu, H., & Chin, S. C. (2023). Enhanced Ductility and Toughness of Desert Sand Engineered Cementitious Composites. Buildings, 13(6), 1538. https://doi.org/10.3390/buildings13061538