Abstract

In current engineering practice, static calculation of windows for temperature loads is not performed. However, the existing experience in operating PVC windows in environmental conditions of Eastern and Northern Europe shows that the temperature deformation of such structures can reach values comparable to those of wind loads, which leads to a significant reduction in their technical and operational characteristics. Temperature deformations of windows can be assessed during laboratory tests. However, such tests are not representative. In this regard, it is necessary to develop an engineering method for calculating temperature deformations of windows. In this study, the authors present the results of the analysis of temperature deformations of PVC window profiles. The investigations were divided into several stages. First, the authors numerically analysed the character of temperature distribution over the cross section of PVC window profiles. Then, they theoretically substantiated the bending deformations of PVC window profiles disregarding the reinforcing steel core. Next, the authors considered the patterns of bending deformations of PVC window profiles, taking into account the presence of a reinforcing steel core in various schemes of their connection to each other. The authors also analysed the effect of the temperature dependence of the mechanical properties of PVC on the deformation of window profiles. The character of torsional temperature deformations of PVC window profiles was also studied. As a result of this investigation, the authors proposed a simplified analytical and numerical method for calculating the temperature deformations of PVC window profiles with a reinforcing steel core. The authors have used the proposed methods to calculate the temperature deformations of PVC window mullions (vertical bars that divide the window into parts). These theoretical calculations were compared with the experimental investigations data on PVC windows and showed a fine precision of results (the discrepancy was 10.6%).

1. Introduction

An important stage of window design is the selection of the static characteristics of their profile components. In current engineering practice, the static calculation of windows reduces only to separate calculations of their profile components and translucent filling. Static calculation of window profiles is performed only on deformations, and their strength calculation is not performed. Currently, the deformation calculation of window profiles is performed only for the wind loads [1,2] and the weight of translucent filling. Calculation of the temperature loads caused by the temperature difference between indoors and outdoors, as well as the impact of solar radiation, is not performed. This simplification is quite acceptable in certain cases. For example, wooden windows are practically not subject to temperature deformations, or in cases where windows are used in mild environmental conditions, such as those in Central Europe. However, this approach is not applicable to windows made of PVC profiles. Experience in operating PVC windows in the environmental conditions of Eastern and Northern Europe shows that especially in winter they are subjected to significant temperature deformations. Temperature deformations of window profiles in a PVC window are comparable in magnitude with deformations from wind loads [3]. A number of studies have shown that temperature deformations of PVC window profiles cause a significant decrease in several of their technical and operational characteristics, including resistance to heat transfer, air permeability, and sound insulation [4,5,6,7,8]. Temperature deformations of PVC window profiles also lead to difficulties with opening/closing window casements. A limited amount of scientific research currently describes a stress–strain state of windows [9,10,11,12]. At the same time, only qualitative dependencies describing the mechanism of temperature deformations of window profiles, which cannot be applied in engineering practice, have been obtained so far. An alternative way to estimate temperature deformations of window profiles is to conduct laboratory tests in climate chambers [6,13,14]. However, this method is not only time-consuming but also unrepresentative, because the results can be applied only to the windows, the construction of which is fully identical to the tested ones (overall dimensions, type of profile system, hardware kitting, etc.).

In this regard, it seems reasonable to develop a design model of PVC windows temperature deformations, which can be used in engineering practice. The key issue in its creation is to develop a method for calculating the temperature deformations of PVC window profiles, which will consider the key features of their design solution and operation mechanism. According to the standard [15] which is in force in the Russian Federation, it is necessary, in most cases, to install steel cores in the PVC windows profiles and fix them to the non-face side of PVC profiles with self-tapping screws (at least in two places) with a pitch of not more than 300–400 mm. Thus, the PVC window elements are heterogeneous in a mechanical and thermal sense (PVC profile outside, steel core inside), which makes the calculation of their mechanical work under the thermal load a non-trivial task that has not been considered until now. In this paper, the authors present the study of the stress–strain behaviour of a PVC profile reinforced with a steel core under a winter temperature load. The study was carried out at the research centre ‘Facade Systems’ of the National Research Moscow State University of Civil Engineering.

2. Materials and Methods

The article consists of several sections, reflecting the sequence of the authors’ research into the temperature deformations of PVC window profiles.

2.1. Pattern of Temperature Distribution in the PVC Window Profile

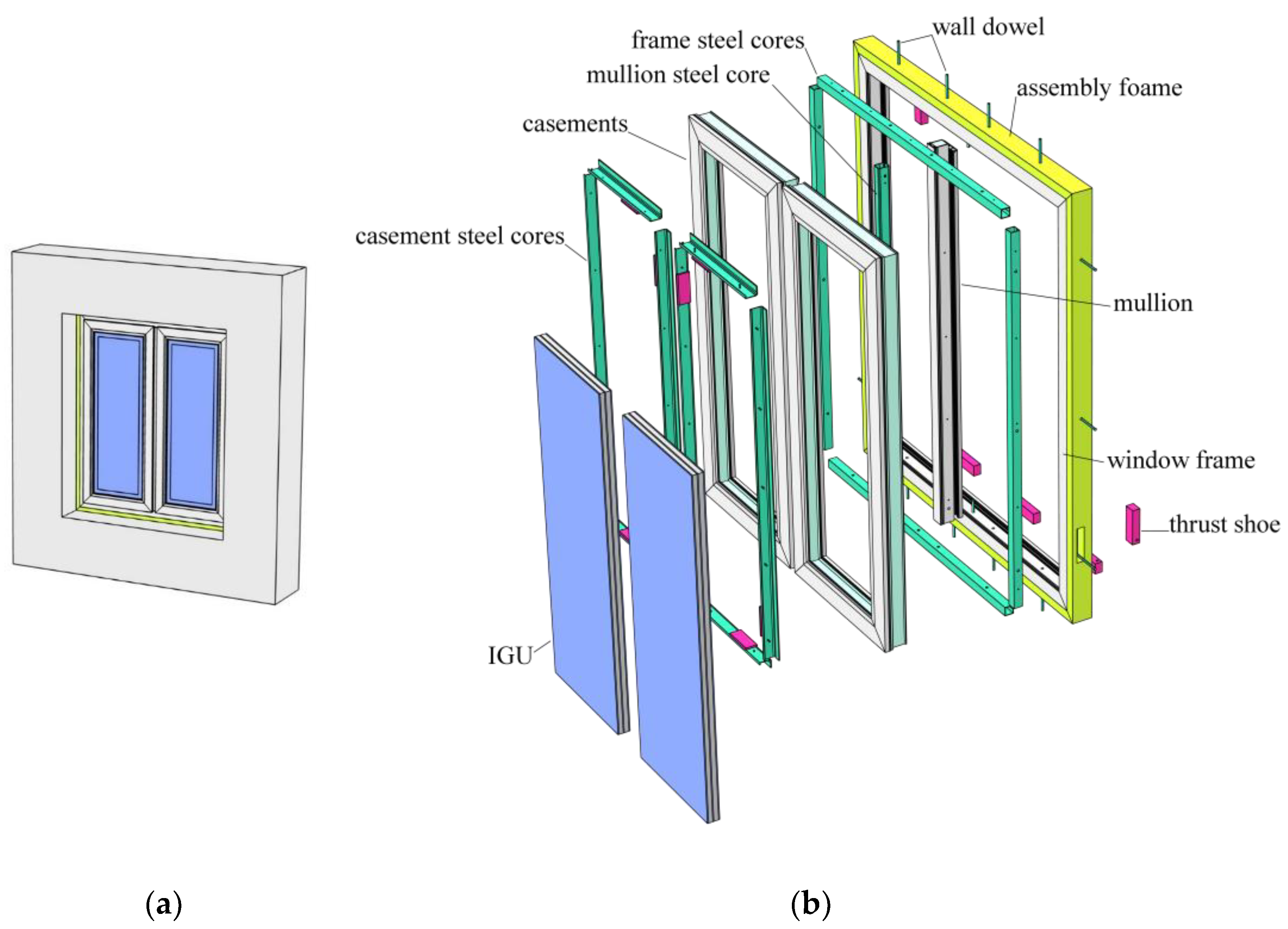

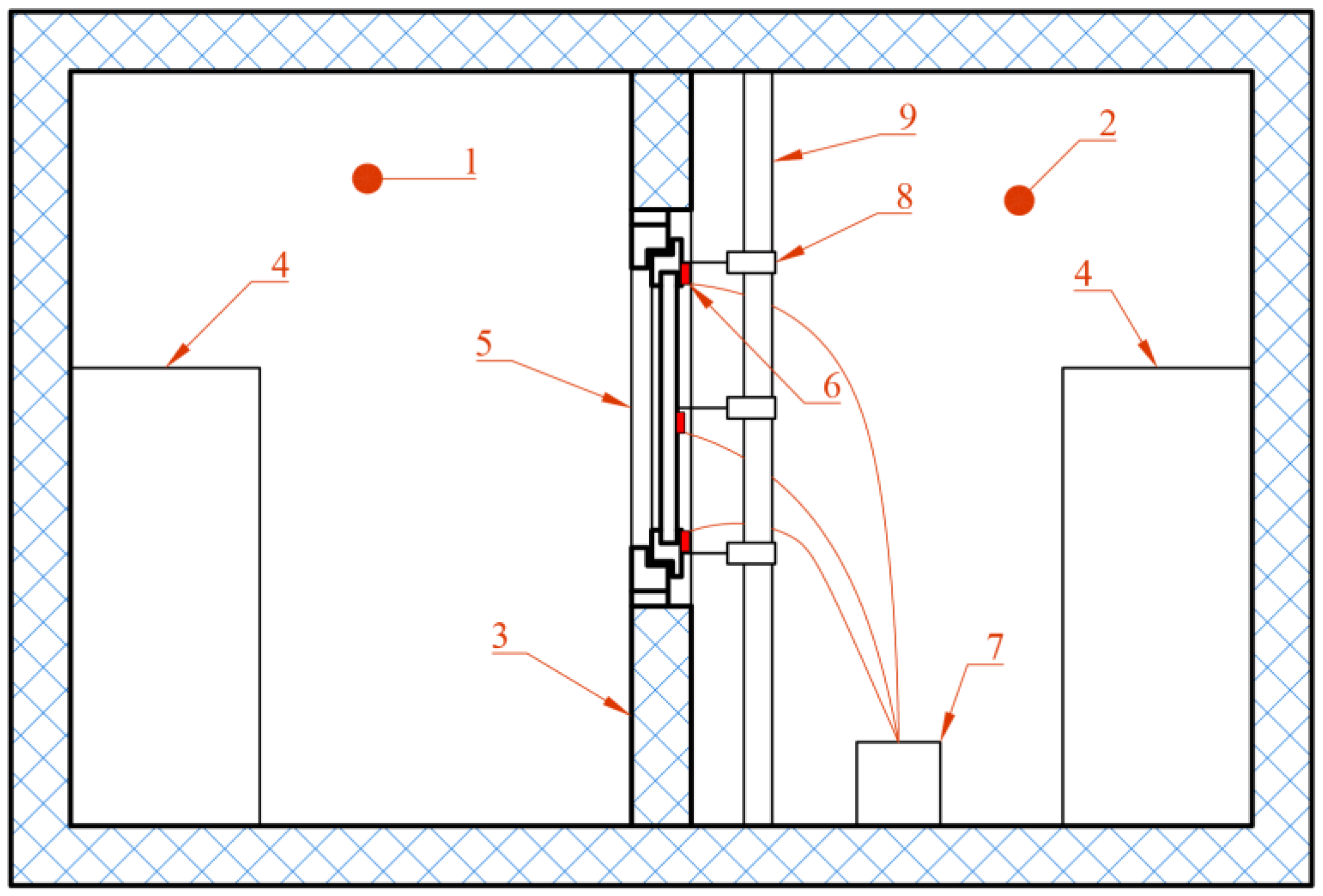

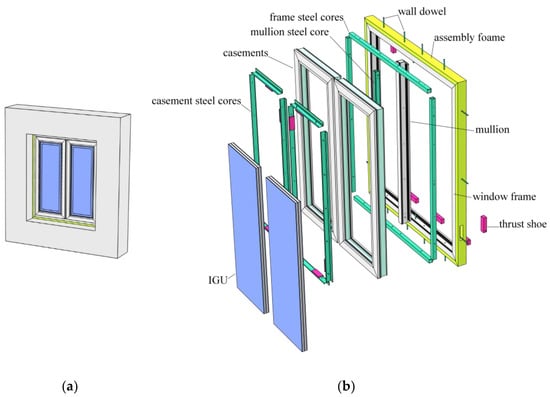

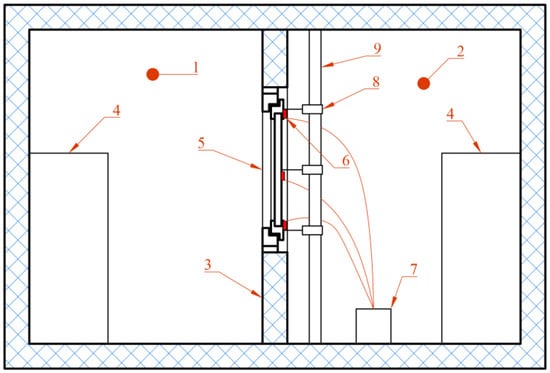

At the first stage, a design-basis justification of the nature of temperature distribution over the cross section of PVC profiles in winter was carried out. Therefore, a three-dimensional finite element model of the two-casement PVC window installed in the opening of the exterior wall made of autoclaved aerated concrete blocks was developed. The model included all major elements of PVC windows, except for hardware: PVC profiles, steel reinforcement, connecting elements (screws and anchors for mounting in the window opening), support and spacer pads, glazing and spacer frame, and seals (Figure 1). Window dimensions 1400 × 1200 mm, profile system—VEKA Softline 70 AD, double glazed window with 4-14-4-14-4I formula.

Figure 1.

Window model created to analyse the nature of temperature distribution in PVC window profiles: (a)—general view, (b)—exploded view drawing.

Temperature patterns modelling, as well as all subsequent numerical calculations, was performed in the COMSOL Multiphysics software solution (version 6.0).

Numerical calculation of the window model temperature patterns was performed with the following input data: Text = −20 °C; Tint = 20 °C; hext = 8.7 W/(m2·°C); hint = 23 W/(m2·°C). The values of the heat transfer coefficients hext, hint were defined according to the Russian Design Code. Heat transfer in the air chambers of PVC window profiles and glazing was calculated in a simplified manner, using the equivalent heat transfer resistance. Table 1 shows the basic material parameters adopted for the calculation.

Table 1.

Thermotechnical characteristics of materials in the numerical window model.

2.2. Temperature Deformations of a PVC Window Profile

At the second stage, we investigated the patterns of bending temperature deformations of PVC window profiles, taking into account the character of temperature distribution over the cross section of the PVC window profile obtained in the previous stage of the investigation.

First, the temperature bending deformation of the PVC window profile with no consideration of its interaction with the reinforcing steel core was considered, and their mathematical description was given. The equations derivation was based on the flat cross sections theorem and the use of the fundamentals of the solid mechanics.

Then, the temperature bending deformations of the PVC window profile were investigated with consideration of the reinforcing steel core. The assumption was made that the temperature pattern of the PVC window profile in the area of the reinforcing steel core can be considered homogeneous (due to the high thermal conductivity coefficient of steel). In this case, the reinforcing steel core experiences only longitudinal deformations and does not bend, while the PVC window profile experiences both longitudinal and bending deformations. To describe the nature of interaction between the PVC window profile and the reinforcing steel core, two design diagrams were proposed in which mechanical forces are transferred from the PVC window profile to the reinforcing steel core:

- -

- Only through the mounting with self-tapping screws;

- -

- Only through contact.

In both design diagrams, the steel reinforcing core was initially considered in relation to the PVC window profile as rigid body (due to the fact that the rigidity of the steel reinforcing core greatly exceeds the rigidity of the PVC window profile). Further, the bending stiffness of the reinforcing steel core was taken into account by introducing the transverse joint flexibility coefficient into the calculation.

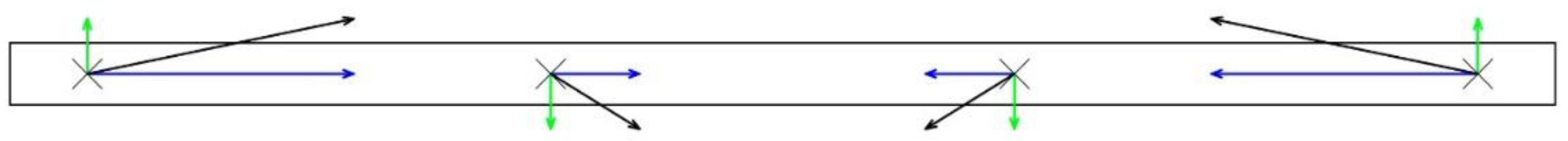

When describing the first design diagram, we ignored the fact that the self-tapping screws (as well as the forces arising in them) have an eccentricity with respect to the neutral axis of the reinforcing core and the PVC profile. Therefore, these forces were considered to be applied centrally. The forces acting between the PVC profile and the reinforcing core in the attachment points were decomposed into axial and transverse components (Figure 2). The axial components are caused by different temperature shrinkage of the PVC window profile and the reinforcing steel core. The transverse components are caused by the non-zero initial curvature of the PVC profile.

Figure 2.

Forces transmitted from the PVC window profile to the reinforcing steel core: green vectors—transverse force components, blue vectors—axial force components, black vectors—force vectors.

To find the magnitude of these forces, the superposition principle was used. It was assumed that due to the smallness of the window profile curvature, axial and transverse force components do not affect each other.

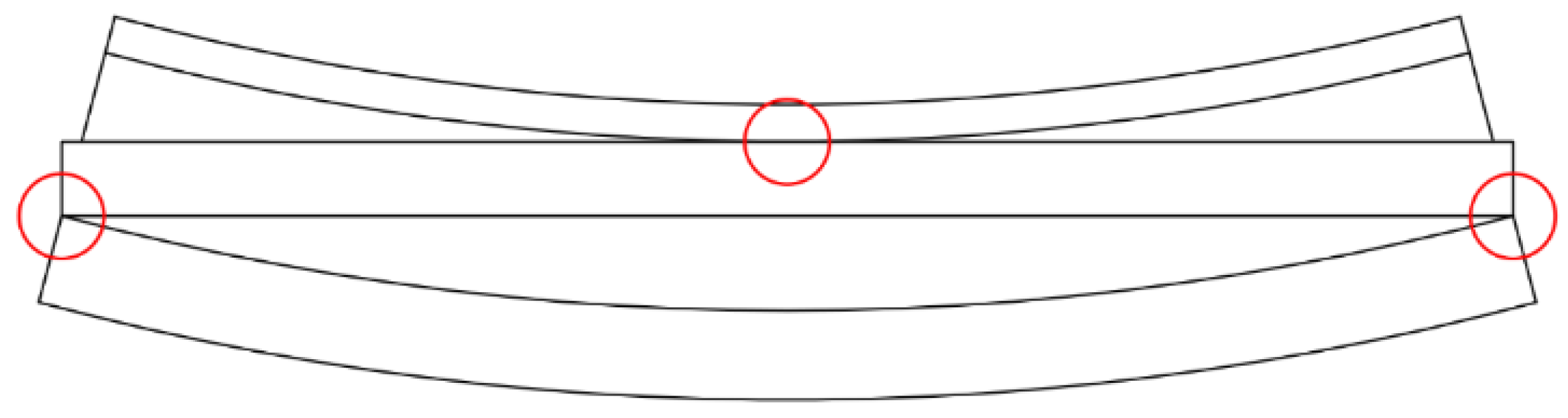

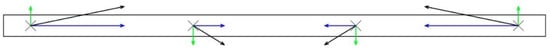

When describing the second design diagram, it was assumed that there will be three main contact points during bending: two extreme and one middle (Figure 3). If one ignores the fact that there may be a certain gap between the PVC window profile and the reinforcing steel core, which must be overcome to make contact, then the second design diagram becomes equivalent to the first with 3 connection points between the PVC window profile and the reinforcing steel core. The presence of the initial gap between them will increase the final deflection, because the PVC window profile at the moment of contact will already be in a bent state, but since the length of the PVC window profile is many times greater than the width of the gap, its impact on the final deflection can be considered by Equation (1).

where fg is the deflection with allowance for the gap and f is the deflection determined without allowance for the gap.

Figure 3.

Places of contact between PVC profile and core during bending.

Based on the investigations performed, the authors proposed a simplified analytical and numerical method for calculating the temperature deformations of PVC window profiles with a reinforcing steel core.

2.3. The Influence of the Polyvinyl Chloride Physical Nonlinearity on the Temperature Deformations of a Window Profile

The authors have evaluated the effect of the dependence of mechanical properties of PVC on temperature on the deformation of PVC window profiles. Therefore, a series of numerical calculations to determine the temperature deformations of PVC window profiles in a nonlinear formulation was performed. Four different formulations of the problem were considered:

- -

- Ignoring the physical nonlinearity of PVC;

- -

- Taking into account the dependence of the elastic modulus of PVC on temperature;

- -

- Taking into account the plastic properties of PVC and a constant yield strength;

- -

- Taking into account the dependence of the elastic modulus of PVC and its yield strength on temperature.

2.4. Assessment of Torsional Temperature Deformations of PVC Window Profiles

The nature and magnitude of torsional temperature deformations of PVC window profiles were studied. For this purpose, a series of numerical experiments were performed.

The data of numerical experiments confirmed that the effects considered in Section 2.3 and Section 2.4 can be ignored when carrying out engineering calculations of temperature deformations of PVC window profiles.

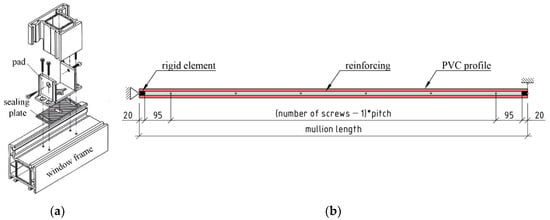

2.5. Assessment of Temperature Deformations of PVC Window Mullion with Different Mounting Schemes

The proposed methods for calculating the temperature deformations of PVC window profiles with a reinforcing steel core were used to calculate the temperature bending of a PVC window mullion. In this case, the varies parameters were the height of the window frame, which advises the mullion (from 900 to 2100 mm), the conditions for mounting the mullion (rigid/hinged), and the number of screws designed to connect the PVC profile and reinforcing steel core (from 3 to 7).

2.6. Comparison of Calculation Data with Laboratory Test Results

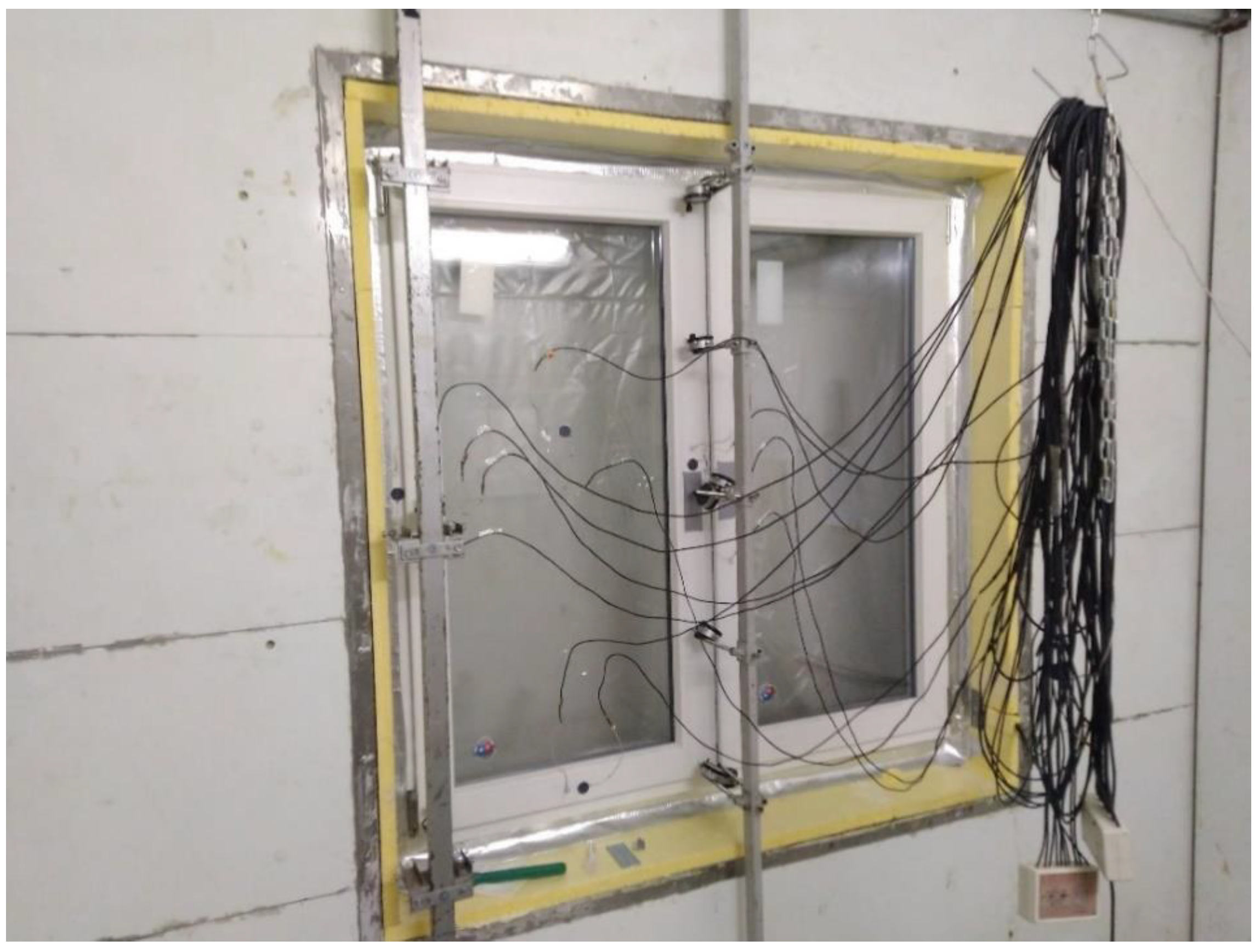

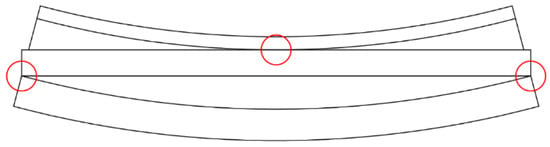

At the final stage of the study, the obtained data from the numerical experiments were compared with the results of laboratory tests (see Figure 4).

Figure 4.

PVC window installed in a climate chamber for temperature deformation tests.

Laboratory tests were carried out at the test centre ‘Facades SPK’ Federal State Budgetary Institution ‘Research Institute of Physics of Civil Engineering of the Russian Academy of Architecture and Construction Sciences’. The tests were carried out in a climate chamber (see Figure 5). In this case, the test conditions and the initial conditions of the numerical calculations performed at Section 2.5 were the same: Text = −33 °C, Tint = 20 °C. The calculations use the actual average values of the heat transfer coefficients of the outer and inner surfaces of the windows obtained during the tests hint = 5.52 W/(m2·°C); hext = 19.94 W/(m2·°C).

Figure 5.

Schematic diagram of a climate chamber for determining the temperature deformations of windows: 1—cold compartment; 2—warm compartment; 3—insulated partition; 4—climate system with air temperature regulation; 5—test specimen of a window; 6—temperature and heat flow sensors; 7—data collection device; 8—linear movement sensors; 9—support.

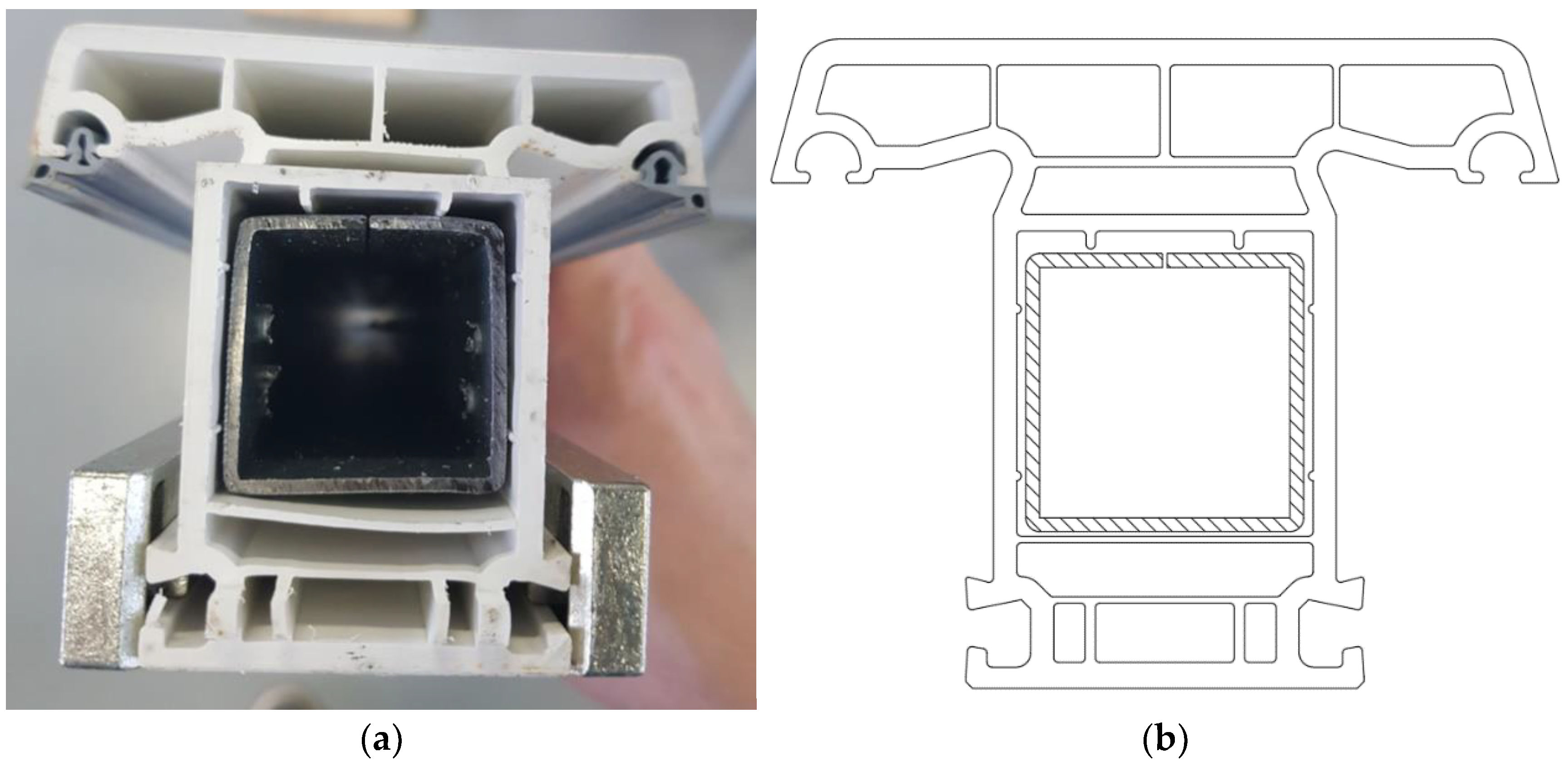

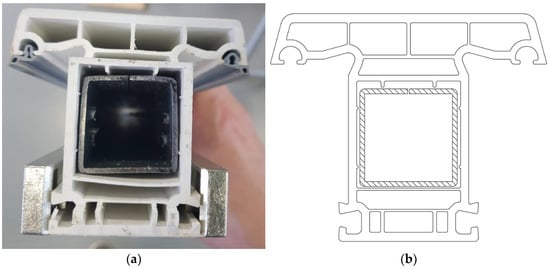

The cross section of the mullion (its geometric characteristics) adopted for the calculation at Section 2.5 also corresponded to the sample of the window structure used in the laboratory tests (Figure 6).

Figure 6.

Cross section of the PVC window impost: (a)—from the tested window unit, (b)—from the design model.

3. Results

3.1. Pattern of Temperature Distribution in the PVC Window Profile

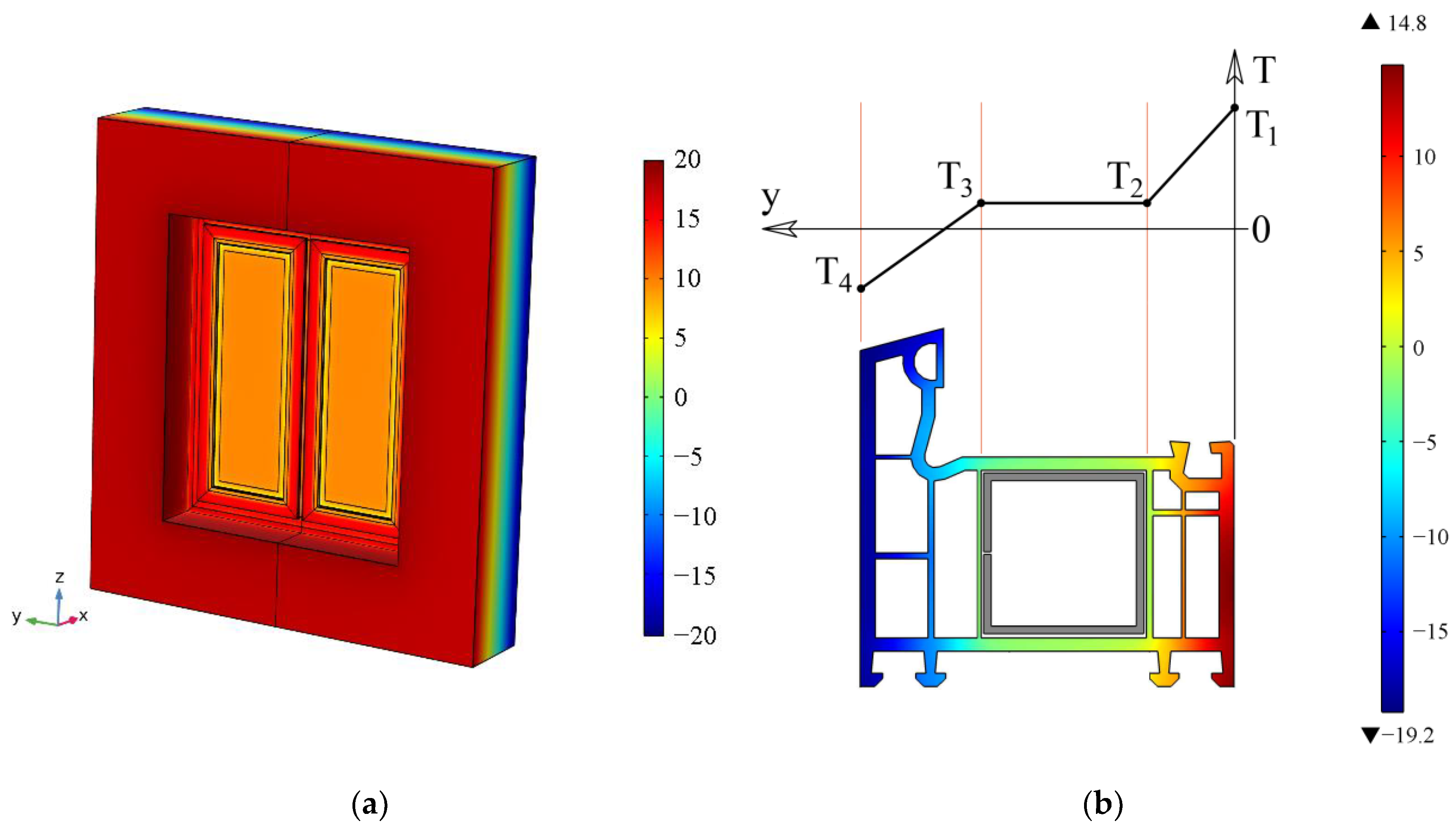

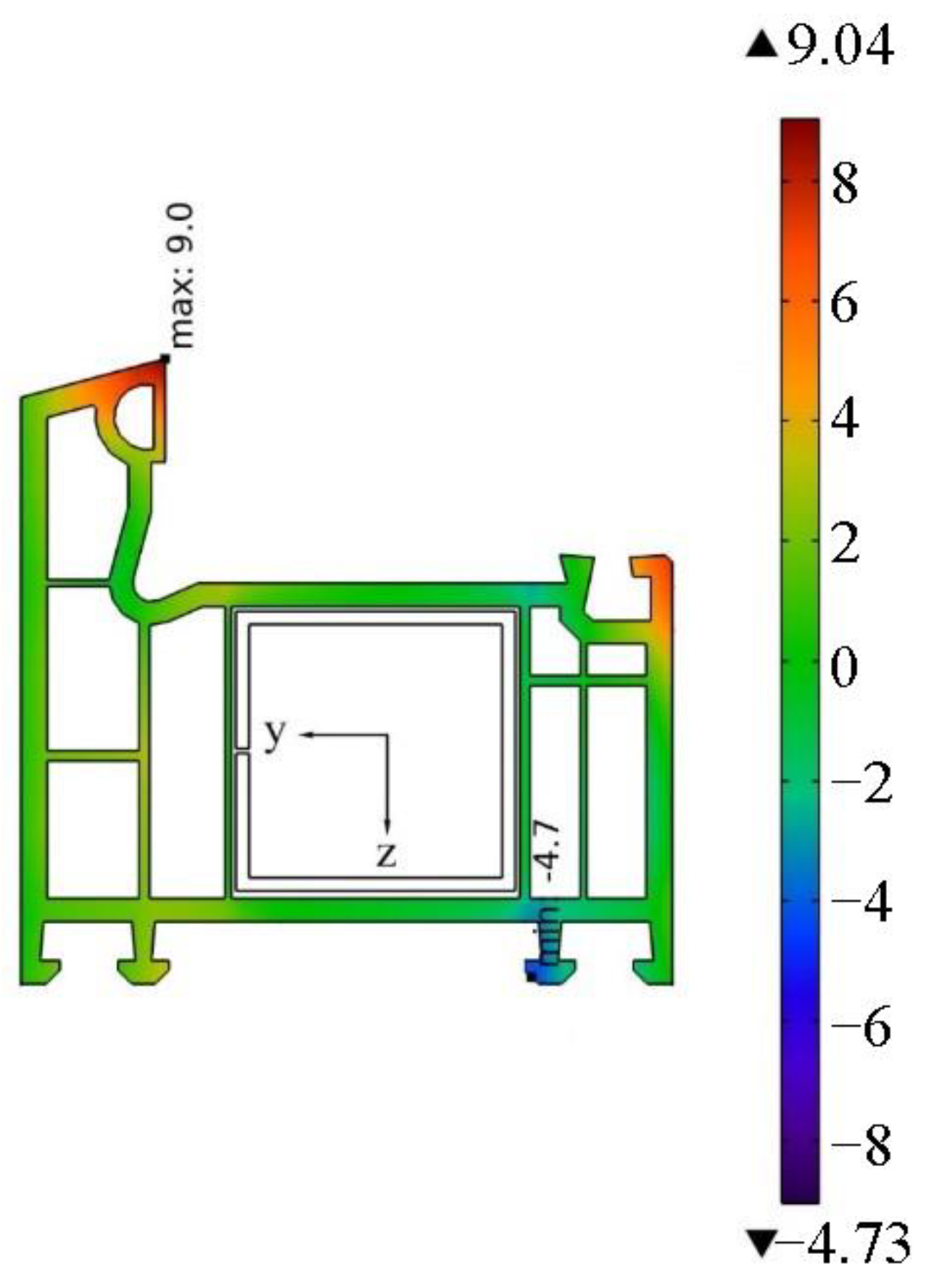

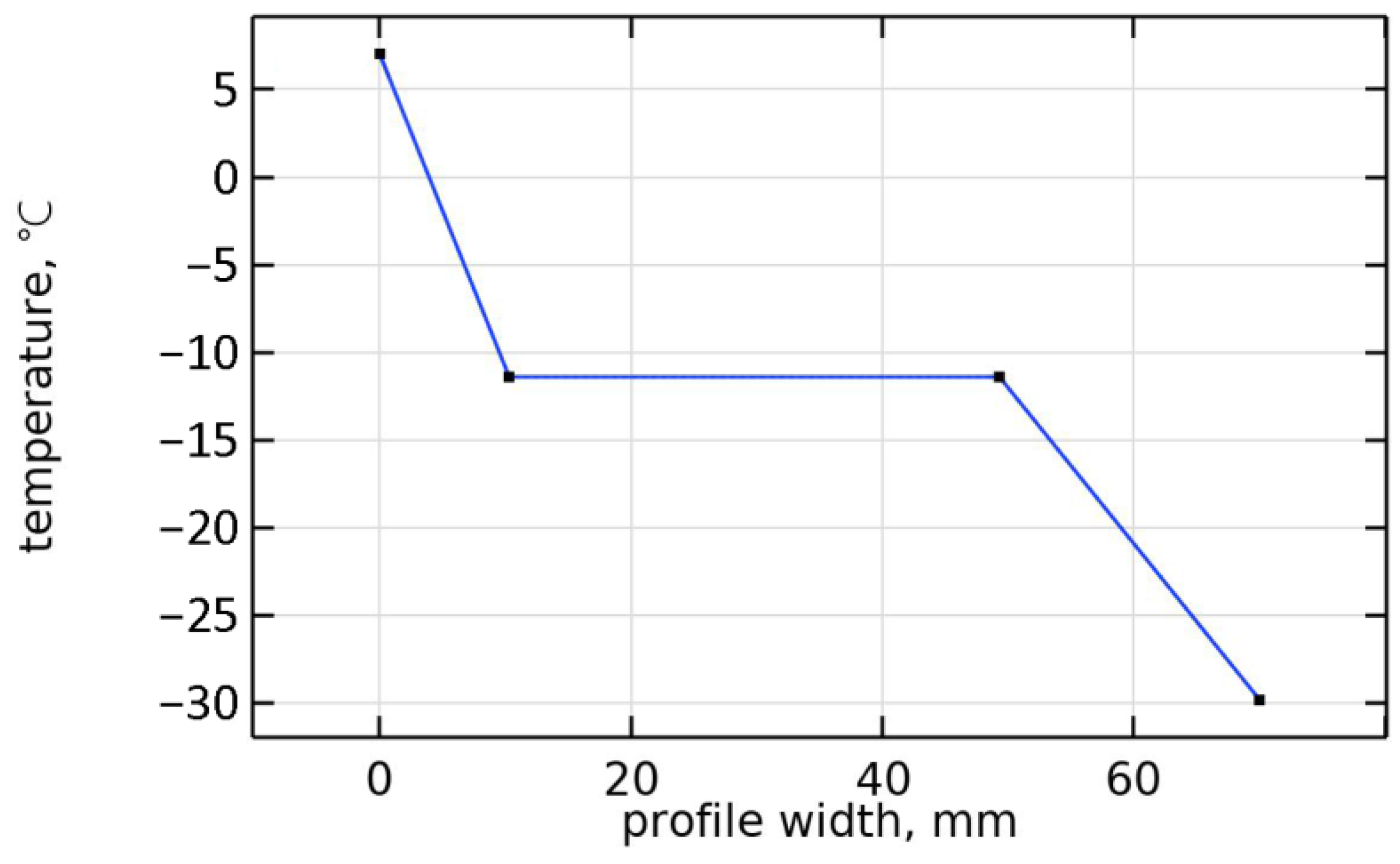

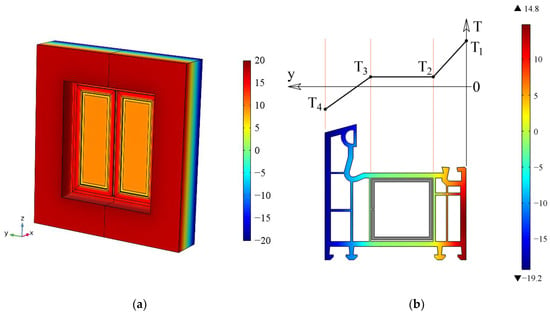

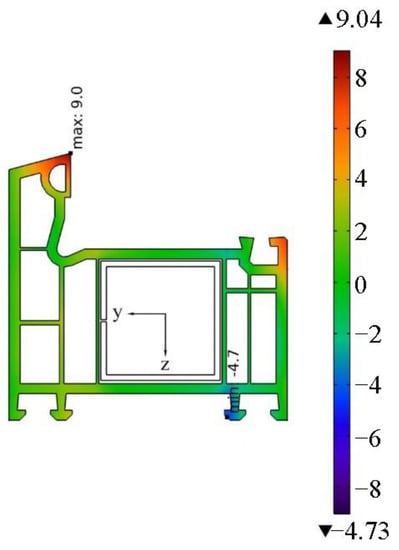

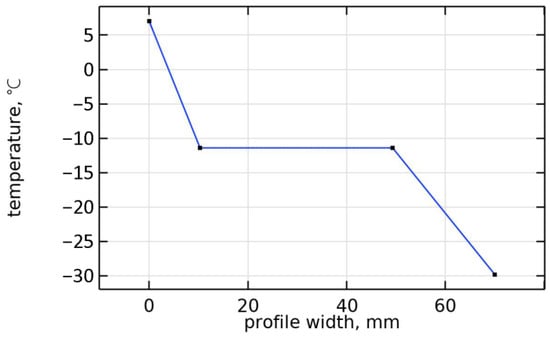

Analysis of the results of calculating the temperature pattern of the PVC window model (Figure 7) showed that the pattern of the temperature distribution in the cross section of its profile components can be simplified in the form of a graph shown in Figure 7b above the cross section of a frame profile of the model. In the centre of the PVC profile, there is a steel reinforcing core, which has almost zero thermal resistance, so in the area of the steel core the temperature pattern remains almost uniform. Therefore, the section of the PVC profile cross section directly adjacent to the steel reinforcing core acquires a constant temperature. This result is similar to those shown in other papers [16,17,18,19,20].

Figure 7.

Results of calculating the temperature pattern: (a)—general view of the model, (b)—pattern of temperature distribution in the cross section of the PVC frame profile, descriptive data in °C.

Considering the obtained character of temperature distribution over the cross section of PVC window profile with reinforcing steel core, it can be said that calculation of its temperature pattern can be conducted as for a three-layer enclosing structure. In this case, its cross section can be divided into three parts, within which the temperature field can be considered linear. Considering that the thermal resistance of the central part will be small, the total thermal resistance of the PVC window profile with a reinforcing steel core will be equal:

All theoretical and experimental research within the scope of this study were performed for PVC windows made on the basis of the VEKA Softline 70 profile system with a profile width of 70 mm which represents the most common type of PVC window systems used in the Russian Federation (with five chambers). Their design is distinguished by an almost symmetrical arrangement of the reinforcing steel core with respect to the PVC profile and an equal number of air chambers on both sides of the reinforcing steel core. Therefore, as a first approximation, it can assume that RI = RIII. Then:

The value of R0 can be determined by calculations or laboratory tests by standard methods and is usually stated by manufacturers of window profiles in their technical documentation. By carrying out additional research, the magnitude relation of RI and RIII can be found. At first approximation, it can be assumed that for an asymmetric profile, the ratio between the values RI and RII is equal to the ratio between the number of air chambers in the I and III parts of the PVC profile cross section (kR):

Then, knowing the values of the outside and inside air temperatures, as well as the heat transfer coefficients of the outer and inner surface of the PVC window profile, one can plot the graph of the temperature distribution over its cross section.

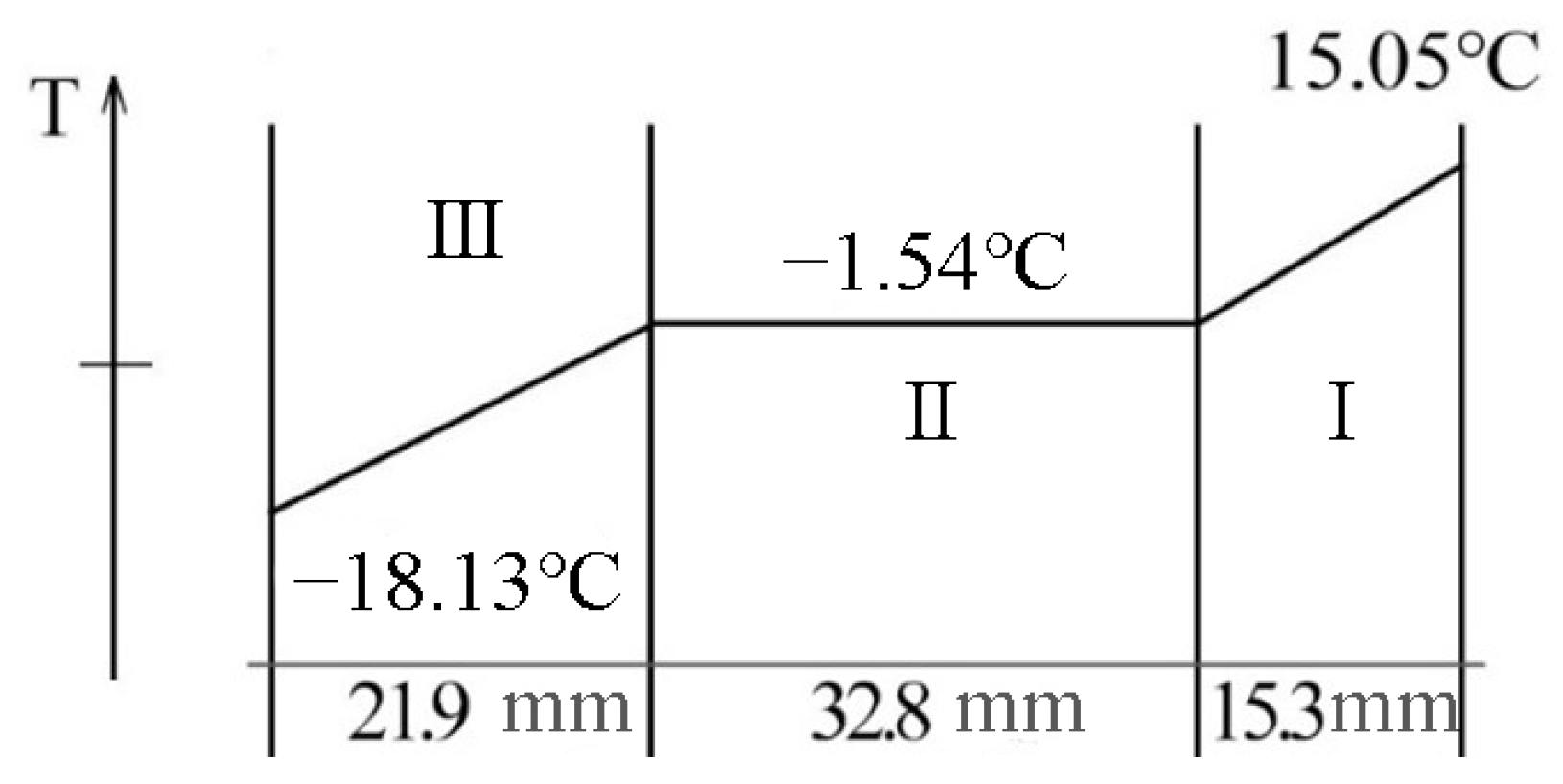

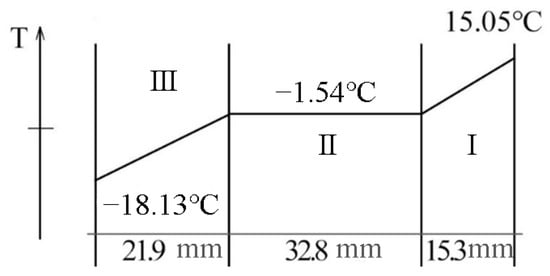

To test the proposed method of calculating the temperature field in a reinforced PVC profile, let us use it to calculate the parameters of the temperature field for the frame profile shown in Figure 7b. The calculation conditions (Text, Tint, hext, and hint) were assumed to be the same as for performing the simulation (see Section 2.1). The thermal resistance of the profile under consideration is R0 = 0.77 m2·°C/W (according to the manufacturer). Thus, RI = 0.385 m2·°C/W; RII = 0; RIII = 0.385 m2·°C/W. The temperature distribution graph (Figure 8) was obtained by the standard method of calculating the temperature field in multilayer homogeneous structures.

Figure 8.

Temperature distribution graph for Veka SL70 frame profile.

To compare the results obtained by analytical calculation and computer modelling, the difference between the temperature fields shown in Figure 7b and Figure 8 was found (Figure 9).

Figure 9.

The difference between the analytical calculation and the result of computer modelling, °C.

As can be seen, most of the profile section is in the green zone (where the difference is no more than 2 °C). Individual parts (two red and one blue), where the results of analytical calculation differ significantly from the results of modelling, have small dimensions. The observed discrepancies are explained by the fact that in reality the PVC profile is an inhomogeneous element (as a result of complex geometry, the presence of air chambers, and heat exchange with adjacent elements of the window structure), and an accurate calculation of its temperature field cannot be performed analytically. Meanwhile, the proposed method of analytical calculation, with its simplicity, gives an acceptable result.

3.2. Temperature Deformations of PVC Profiles Disregarding the Reinforcing Core

A detailed theoretical justification and mathematical description of the temperature deformations of the PVC profile disregarding the reinforcing core are considered by the authors of this article in the study [21].

According to the results of these investigations, it was found that the calculation of the curvature of the PVC window profile K (rad/m) with a general three-part step temperature distribution in its cross section can be performed using Equation (5).

where Mz—bending moment in the cross section of the PVC profile, N·m; E—elastic modulus of PVC, Pa; Ieq—equivalent moment of inertia of the PVC profile, m4, see Equation (7); K0—initial profile curvature, rad/m, see Equation (6).

where Szi, Izi—static moment, m3, and moment of inertia, m4, of the i-st part of the profile cross section with respect to the neutral axis; ai (dimentionless) and bi (m−1)—coefficients defined by Equation (11).

where ci (dimentionless) and di (m)—coefficients defined by Equation (11).

The axial stretch coefficient kax (dimentionless) is determined using Equation (8).

where Aeq is the equivalent cross-sectional area of the profile, m2, determined using Equation (9); N—internal axial force, N; kax0—initial longitudinal stretch coefficient of the profile axis, dimentionless, is determined using Equation (10).

where Ai—area of the i-st part of the profile cross section, m2.

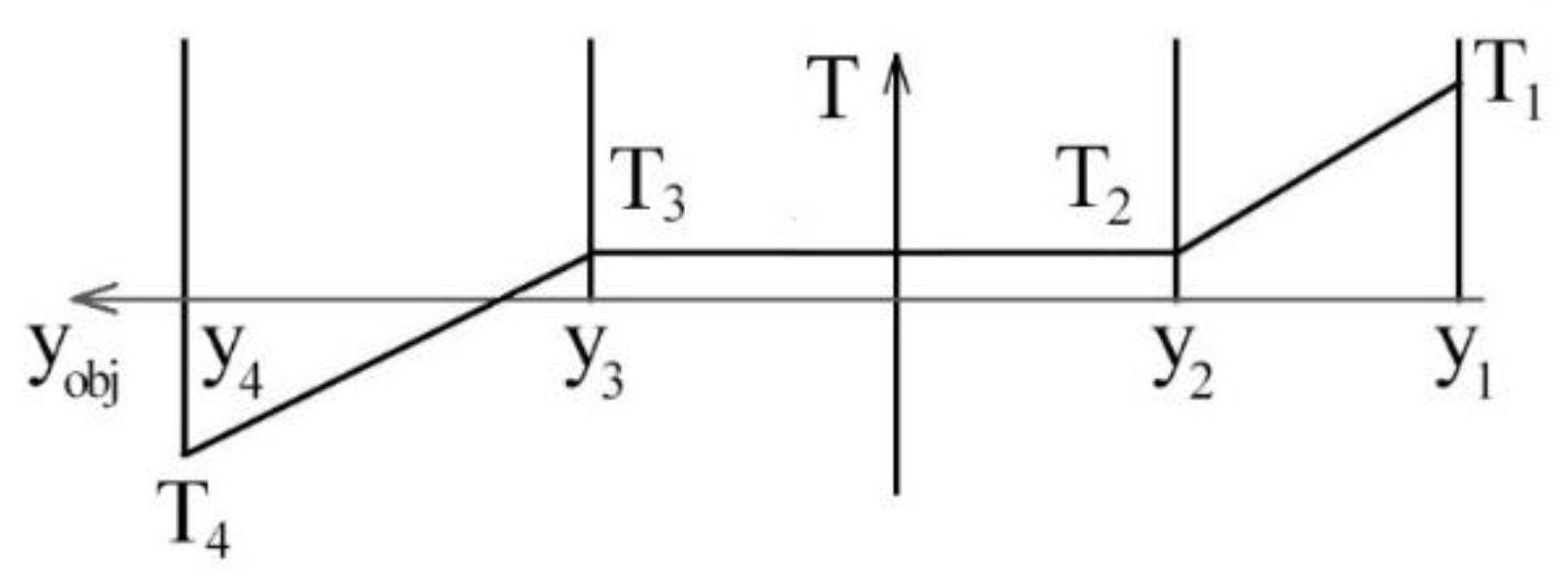

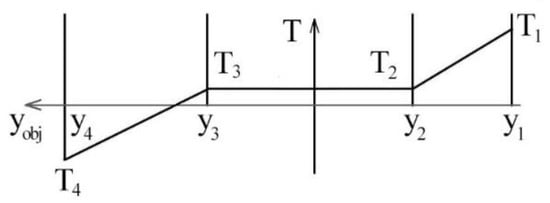

where yi—coordinates of the inflection point of the temperature function in the cross section of the PVC profile, m (see Figure 10); α—coefficient of linear thermal expansion of PVC, °C−1; Ti—temperature at the profile point with coordinate yi, °C; Tref—temperature in the PVC profile at the initial instant, °C, i.e., in the absence of temperature fluctuations. It can be assumed to be equal to the indoor air temperature Tint.

Figure 10.

Piecewise-defined temperature function.

Using the above formulas, it is possible to conduct a profile bending analysis at a general three-part step temperature distribution in the profile’s cross section.

3.3. Temperature Deformations of PVC Profiles Considering the Reinforcing Core

A detailed theoretical justification and mathematical description of the temperature deformations of the PVC profile considering the reinforcing core are considered by the authors of this article in the study [22].

Depending on its length PVC window profile can be connected to the reinforcing steel core with self-tapping screws in 2, 3, 4, or even more points. For the indicated mounting schemes, analytical dependences were obtained, which allow calculating the temperature bending of the PVC window profile.

The calculations must consider the flexibility of the connection ‘PVC window profile—reinforcing steel core’: axial ξx and transverse ξz. The axial flexibility coefficient ξx is due to deformations of the joint (local deformation of the profile wall, rotation of the self-tapping screw under the shear force). The calculations show that it can be adopted as 4.3·106 N/m. The transverse flexibility coefficient ξz describes the transverse stiffness of the reinforcing steel core itself.

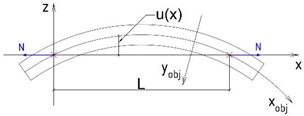

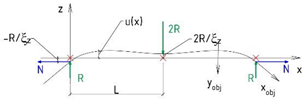

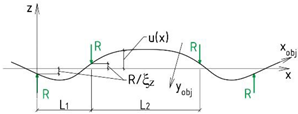

Table 2 shows analytical formulas and diagrams for calculating the bending of PVC window profile with the reinforcing steel core at different schemes of connection.

Table 2.

Calculation formulas and diagrams for determining the temperature deformations.

In Table 2: E—Young’s module of PVC, Pa; I—second moment of area of a PVC profile, m4; Es—Young’s module of steel, Pa; Is—second moment of area of a steel core, m4.

The formulas, shown in Table 2, are driven from the solution of the second-order differential equation:

With the number of attachment points more than four, the most heavily loaded are still the two extreme points, which create the main couple of forces that prevent the temperature bending of the PVC profile. There is practically no force at the middle attachment points. However, adding new attachment points disturbs the linear character of ξz. The forces coupling is also disturbed: the shear scalar force will be slightly greater (by 8%) at the second point from the end than at the first one. Nevertheless, if there are an arbitrarily large number of PVC profile attachment points to the reinforcing core, the calculation can be conducted as for four points, ignoring all the intermediate points.

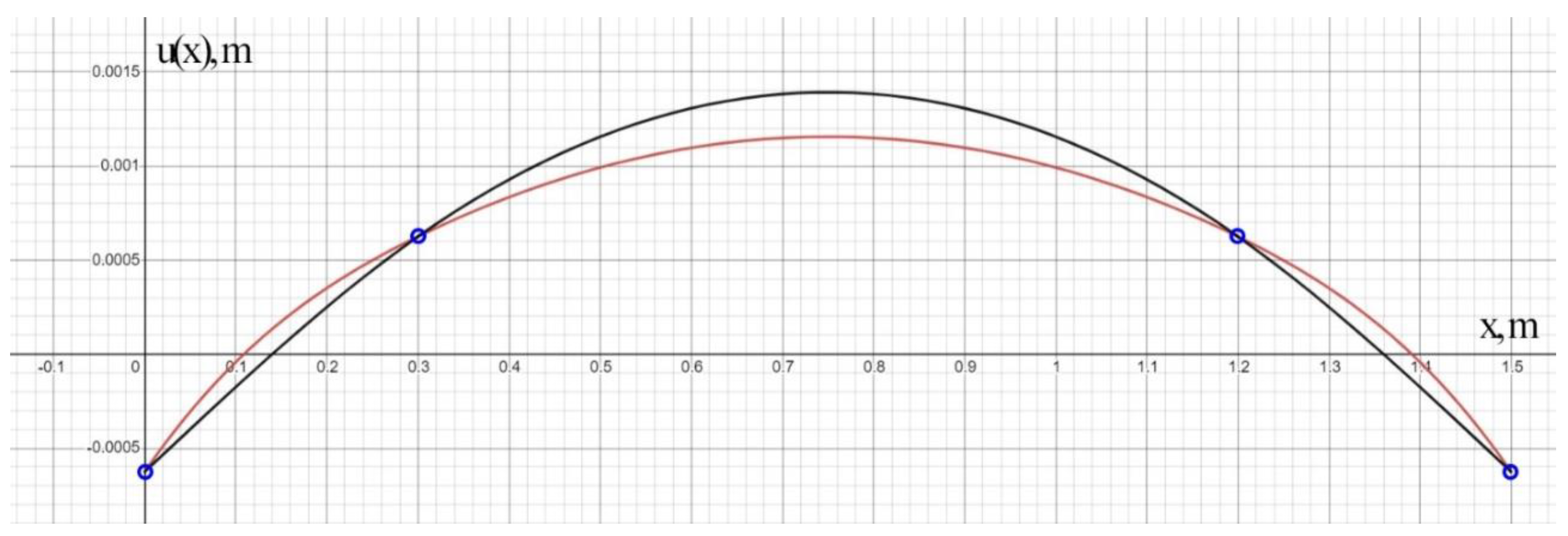

A simplified numerical solution can more accurately determine the transverse force components for the case of an arbitrarily large number of attachment points. The following physical model can be used: two parallel beams with different transverse stiffnesses are connected by hinges. In this case, one of the beams has non-zero initial curvature (due to the temperature load) and bends the second beam, impacting it through the hinges (Figure 11).

Figure 11.

Physical model, considering the joint work of PVC profile (red line) and reinforcing core (black line) during temperature bending.

3.4. The Influence of the Polyvinyl Chloride Physical Nonlinearity on the Temperature Deformations of a Window Profile

Evaluation of the material nonlinearity of the PVC mechanical properties in terms of the value of temperature deformations of PVC window profiles with a reinforcing steel core was performed by the authors. The problem was solved in four different formulations:

- -

- The PVC modulus of elasticity was assumed constant (equal to 2700 MPa) and independent of temperature, PVC material was considered to be perfectly elastic.

- -

- The dependence of the PVC elastic modulus on temperature was used [23]. The PVC material was considered to be perfectly elastic.

- -

- The PVC elastic modulus was assumed constant (equal to 2700 MPa) and independent of temperature. PVC material was considered perfectly elastoplastic with yield point independent of temperature (equal to 47 MPa).

- -

- The dependence of the PVC elastic modulus on temperature was used [23]. PVC material was considered to be perfectly elastoplastic with yield point determined by interpolation as a function of temperature.

Calculations were performed on a PVC profile model with a length of 1060 mm, which has four points of attachment to the reinforcing steel core (in increments of 300 mm). The cross section of the PVC window profile and the reinforcing steel core corresponds to Figure 6b. The profile was fixed at both ends using the ‘Rigid Connector’ bounding condition in a flexible formulation. At one end, movements along the x-, y-, and z-axes as well as rotation around the x and y axes were restrained, and at the other end, movements along the y and z axes and rotation around the x and y axes were restrained. Such attachment is more reflective of the real working conditions of the profile in the window system than full hinge support, because in the corners of the window frame elements of the profile are rigidly connected by welding [9,24]. The temperature pattern corresponding to the approximation function in Figure 8 was established in the profile.

The controlled parameters, on the basis of which the results were compared, were

- -

- Maximum movements in the PVC profile and in the reinforcing core;

- -

- Reaction forces in the restraint on the ends of the PVC profile.

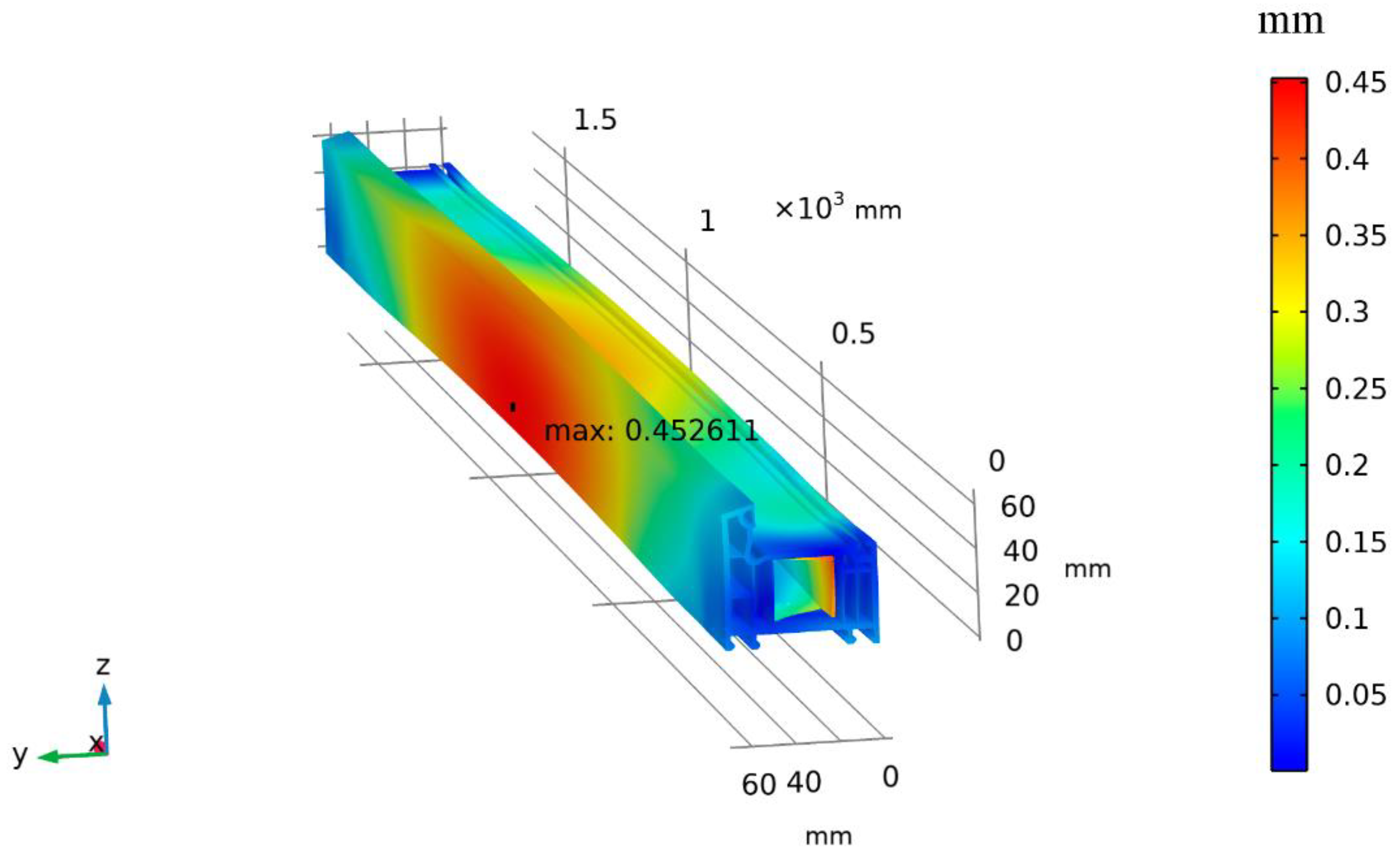

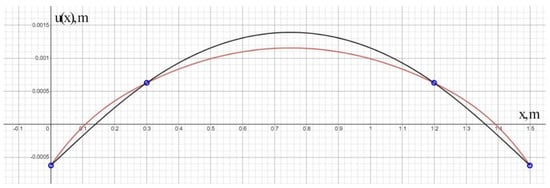

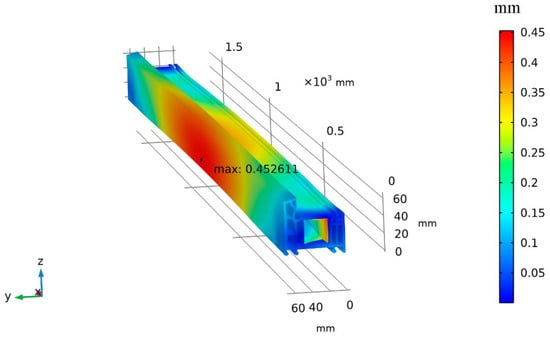

The general view of the deformation diagram (by the example of the 4th formulation) based on the calculation results is shown in Figure 12.

Figure 12.

Deformation diagram of the profile (movements in mm).

It was found that the physical nonlinearity of PVC has almost no effect on the bending of the PVC window profile with a reinforcing steel core. The relative difference in bending between the 1st formulation (where the physical nonlinearity of the material was not taken into account) and the 4th formulation (where it was taken into account to the greatest extent) is 4.8%. In this case, the results for the 1st and 3rd formulation, as well as for the 2nd and 4th, coincided in pairs (with an accuracy up to rounding). This suggests that the observed difference of 4.8% is due to the dependence of the PVC elastic modulus on temperature, rather than its plastic properties. The PVC modulus of elasticity increases as the temperature decreases, and the profile thus acquires greater bending stiffness. The PVC window profile bends the reinforcing steel core with more force. The PVC plastic properties lead to a slight decrease in the torsional moment My. The profile bends around the y-axis (bending occurs downward) because in the hinges connecting the PVC profile and the reinforcing core there are forces (due to the different temperature ‘shrinkage’ of the profile and core’) directed along the x-axis from the centre of the profile. These forces are eccentric with respect to the neutral axis of the PVC profile which causes bending. As a result of the PVC plastic properties, stress relaxation occurs at the attachment points; the value of axial forces decreases, and the bending moment decreases. Considering the dependence of the PVC elastic modulus and yield strength on temperature, on the contrary, increases the torsional moment My, because cooling increases the profile stiffness and reduces the effect of stress relaxation (yield strength increases as the temperature decreases). The results also show that the profile experiences almost no torsion.

Thus, it was found that ignoring the physical nonlinearity of PVC does not lead to significant errors in the calculation of temperature deformations of components of PVC window profiles based on winter operating conditions.

3.5. Assessment of Torsional Temperature Deformations of PVC Window Profiles

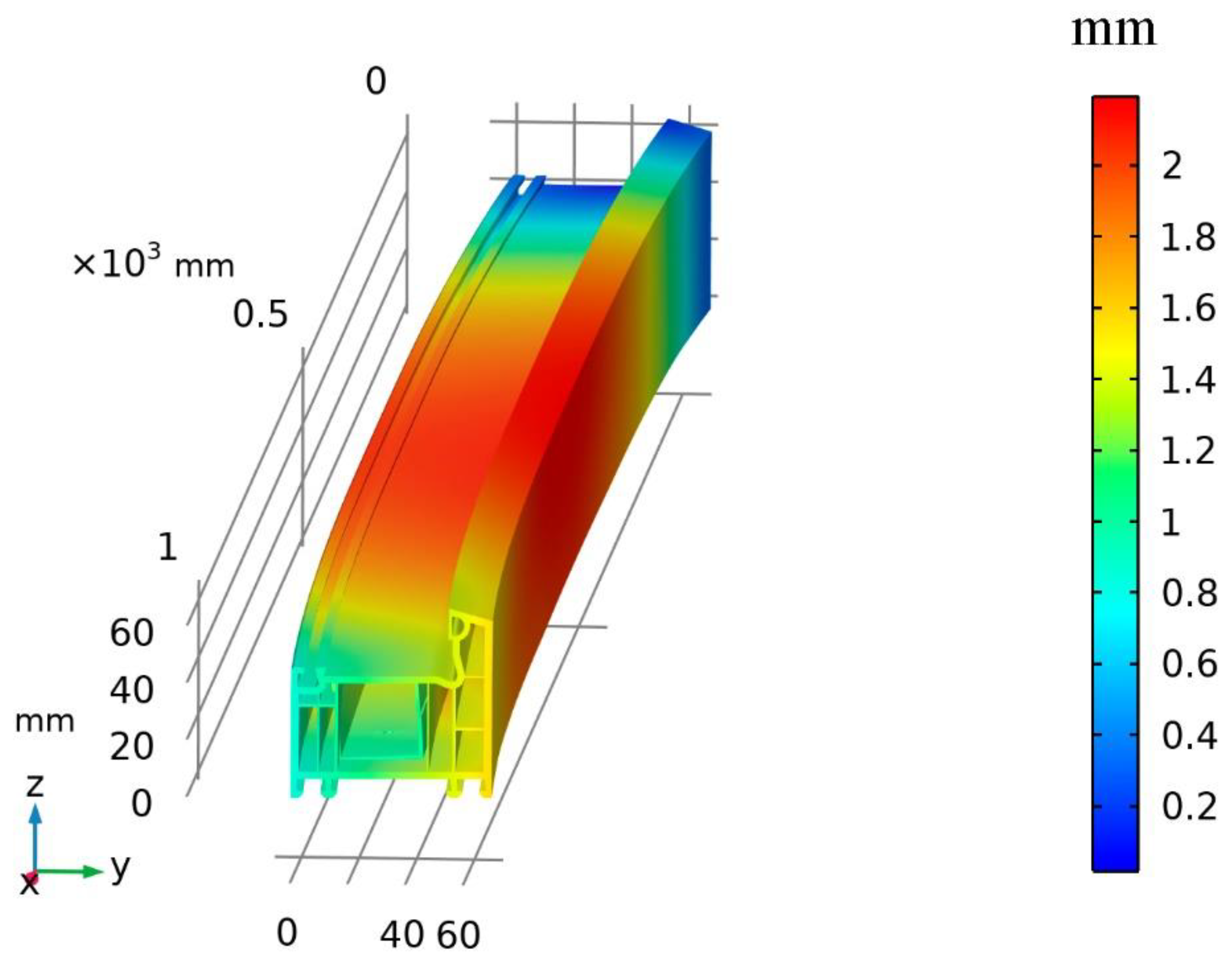

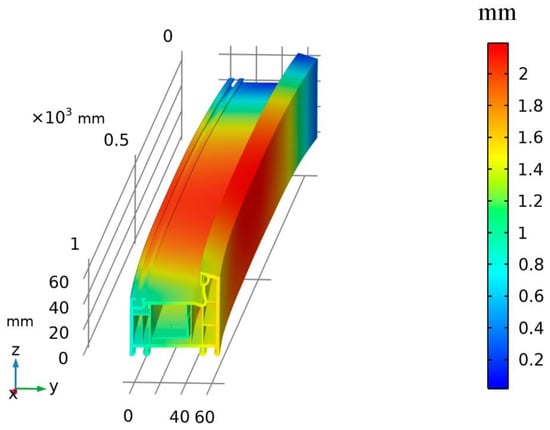

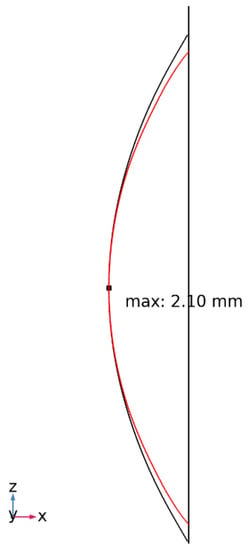

If the assumptions made earlier (see Section 2.2) about the central application of forces are ignored, both the PVC window profile and the reinforcing steel core will undergo torsional deformations under temperature loads. The relative magnitude of the torsional moment compared to the bending moment can be estimated by calculating the reinforced PVC profile bending from the impact of the temperature pattern when its edges are rigidly fixed (Figure 13).

Figure 13.

Deflections of reinforced PVC profile under temperature load with rigidly fixed end faces (descriptive data in mm).

A test numerical calculation of a 1.5 m-long rigidly fixed PVC window profile model with a reinforcing steel core showed that the bending moment around the z-axis was 55.8 N·m, and the torque moment was 0.003 N·m. On this basis, one can say that almost no torsion occurs at the level of individual profile components of the PVC window under temperature loads.

Torsion can occur with the mechanical interaction of window components with each other. Due to the symmetry of the considered type of window structures, the mullion cannot be subject to torsional deformation. The experimental study [25] found that the mullion of a two-casement window and the casement elements adjacent to it deform jointly under the temperature load. Their relative movements are small (0.2 mm with a total deflection of about 3.5 mm). Therefore, one can conclude that there is no force transfer between these elements through the trunnions of the closing mechanisms, so not only the mullion but also the casement elements adjacent to it will not experience torsional deformation.

Horizontal profile components of the casement (located at the top and bottom) have a short length and usually no locking mechanisms located there, and therefore, these elements do not take concentrated transverse loads applied with eccentricity.

The most likely place of torsional deformation in the window is at the junction of the window frame and vertical casement profile. Support mechanisms are placed here, and the deformation of the frame is much less than the deformation of the casement, because the frame is rigidly fixed in the opening (with anchors, mounting foam, and support pads in the installation joint, installed in the distance), so in this case the trunnions of the locking devices will transfer forces applied with eccentricity (both for the frame and the sash). Nevertheless, the rigidly fixed frame element prevents its cross section from rotating due to the transverse load, and the cross section of the sash element cannot rotate freely due to the glazing installed in the sash.

Thus, one can conclude that the torsional deformations can be neglected when considering the static operation of the PVC window structure.

3.6. Assessment of Temperature Deformations of PVC Window Mullion with Different Mounting Schemes

The window mullion of the Veka Softline 70 profile system was chosen as a model for the calculations, (see Figure 6b).

The temperature pattern in the cross section of the mullion was calculated according to the methodology and environment conditions of Section 3.1 (see Figure 14). The mullion bending from the temperature load was calculated according to the model of deformation of reinforced PVC profiles in the form of rod elements proposed in Section 3.2. At the same time, the hinge mounts had a flexibility (along the rod axis) equal to 4.3·106 N/m. All other parameters required for the calculation were obtained in the standard way (Table 3).

Figure 14.

The result of calculating the temperature pattern in the cross section of the mullion.

Table 3.

Parameters for calculating the mullion.

The model was calculated in the COMSOL Multiphysics software solution.

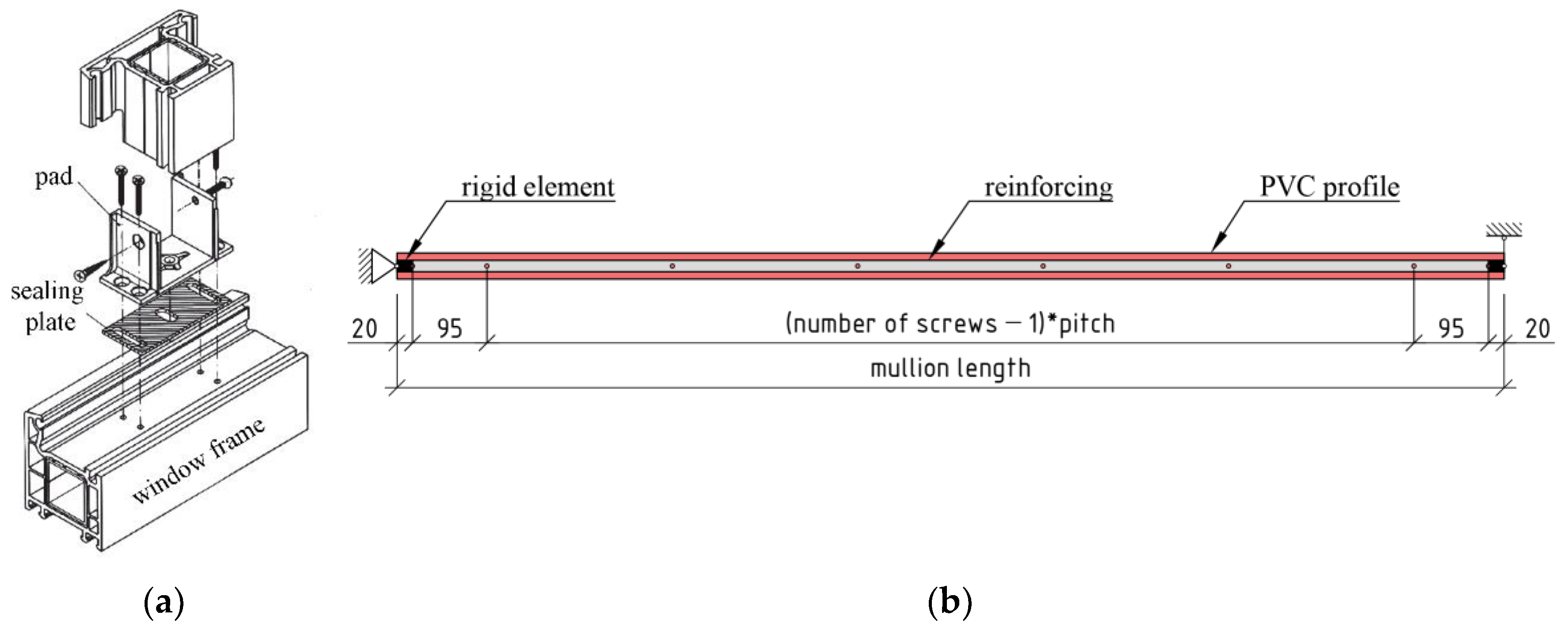

Veka Softline 70 profile system has the mullion attached to the frame mechanically via a block (see Figure 15a). Such a connection should be regarded as close to a hinged connection. Thus, in this instance, the design diagram shown in Figure 15b was chosen.

Figure 15.

Impost-frame mounting diagram (a), and the design diagram of the impost (b).

In addition, the second mullion-frame mounting diagram (in the form of anchoring) was considered. It was similar to the one shown in Figure 15b with the exception that rigid inserts are not hinged but rigidly attached (below—rigid attachment, above—slip connection along the longitudinal axis of the profiles).

Thus, the calculation was carried out with the following variable parameters:

- -

- Impost attachment at the end points: hinged/rigid;

- -

- Number of intermediate PVC attachment points to the core: 3–7;

- -

- Height of the window unit to which the mullion corresponds: from 900 to 2100 mm in increments of 300 m.

The calculation results for hinged attachment of the mullion to the frame and seven intermediate attachment points of the PVC profile to the reinforcing steel core are shown in Table 4.

Table 4.

Calculation results of mullion temperature bending depending on window height.

The calculations show that:

- -

- When there are more than four attachment points of the PVC window profile to the reinforcing steel core, the outermost two points are always the most stressed. They are the ones that create the main rotation moment on the ends of the PVC profile, which suppresses the bending temperature deformations.

As a consequence, the mullion deflection is almost unchanged when the number of attachment points is increased. Thus, with three intermediate attachment points (in the case of hinge supports) the deflection of the 2100 mm high window impost was 3.8 mm, and with seven attachment points—3.78 mm.

- -

- Changing the hinged fixing to rigid significantly reduces the deflection of the impost (by about 16 times) and increases the transverse force components at the PVC attachment points to the core (by about 45%), while the axial force components remain the same (they depend only on the temperature shrinkage of the PVC).

3.7. Comparison of Calculation Data with Laboratory Test Results

To verify the proposed simplified methods for calculating the temperature deformations of PVC window profiles with a reinforcing steel core, the following work was carried out:

- -

- The temperature deformations of the PVC window mullion under laboratory conditions were determined.

- -

- Calculations of the temperature deformations of the mullion using a simplified analytical method (since the number of points of the reinforcing steel impost exceeds 4) and numerical method were performed.

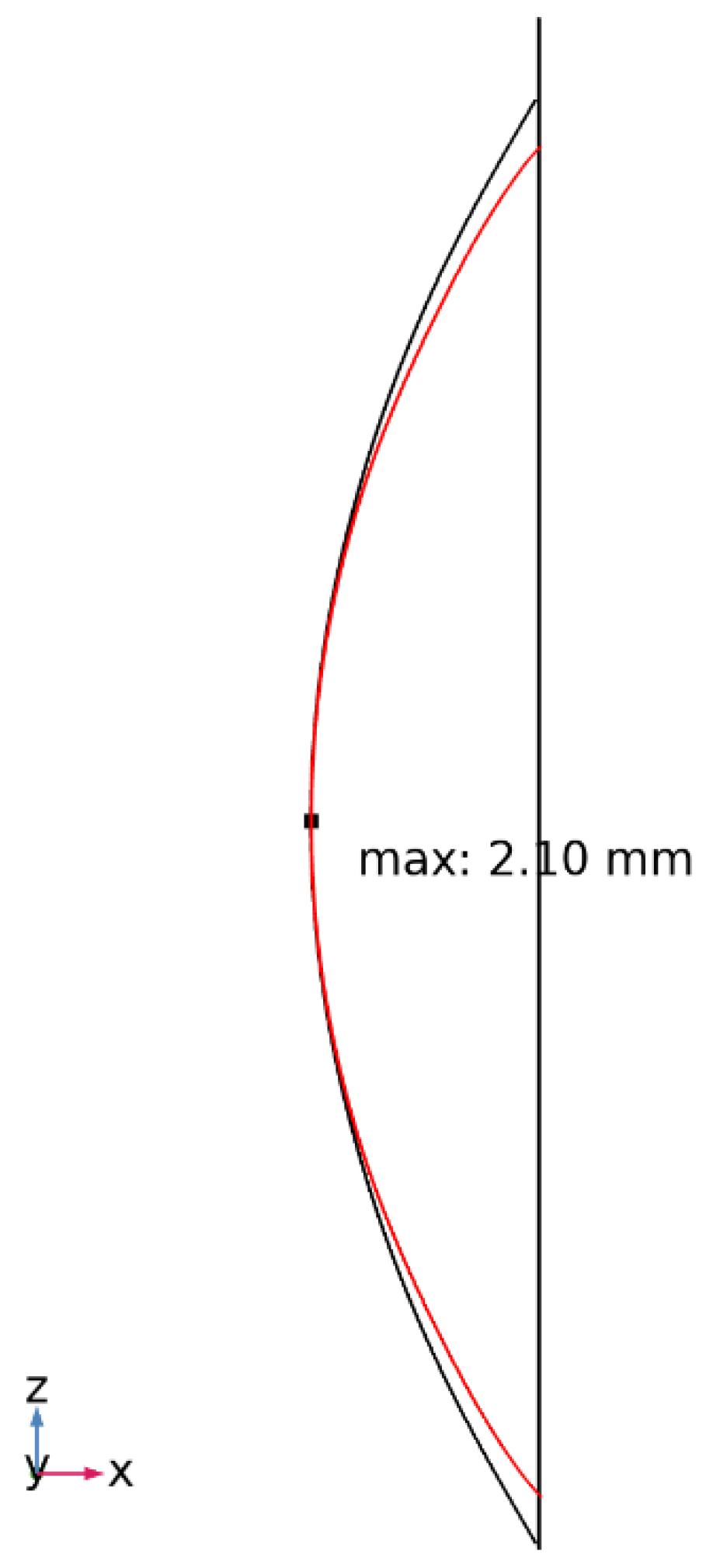

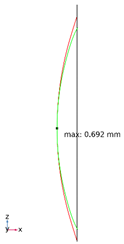

A detailed description of the methodology and the results of laboratory tests are presented in study [25]. Figure 16 shows the numerically determined deformation diagram of the PVC window mullion.

Figure 16.

Deformation diagram of the mullion (enlarged 100 times).

According to the experimental data, the mullion deflection under the experimental condition (Text = −33 °C, Tint = 20 °C) was 2.35 mm. The simplified analytical calculation obtained a deflection of 1.97 mm, while the numerical calculation was 2.1 mm. The difference between the experiment and calculations was 16.2% and 10.6% accordingly.

4. Discussion

The authors consider the presented method of calculating the temperature deformations of PVC window profiles as one of the stages of development of both the analytical model of PVC window temperature deformations in general and analytical methods for calculating the technical and operational characteristics of windows under temperature loads (air permeability, sound insulation, and heat transfer resistance). The experimental research conducted by the authors [25] has shown that the tightness of the windows is affected primarily by the relative deformation of individual window components (frame, sashes, and impost). To maintain the tightness of windows, it is necessary that the relative deformation of window components must not exceed the range of effective operation of the window seal.

The proposed methods of analytical and numerical calculation of PVC window profiles with a reinforcing steel core can be refined in terms of detailed accounting for the profiles mounting conditions (for example, mullion to a frame). In this case, it is necessary to consider not only the conditions of fixing the mullion to the frame but also the frame to the window opening.

The authors of the study have considered only temperature deformations of PVC window profiles typical for winter operating conditions. At the same time, the approaches presented in this study can also be used to calculate the temperature deformation of PVC window profiles for summer operating conditions (i.e., considering the impact of solar radiation). Obviously, in this case, it is necessary to consider the changes in the PVC mechanical properties upon heating [14].

The approaches proposed in this work can be applied not only to PVC window profiles with reinforcing steel core but also to other types of windows, including aluminium profiles with thermal break, combined wooden profiles, etc.

The developed analytical and numerical methods for evaluating the temperature deformations of PVC window profiles with a reinforcing steel core can be used by profile systems manufacturers as well as by window manufacturers for:

- -

- Justified assignment of the PVC window profile to the reinforcing steel core attachment diagram;

- -

- Development of new types of connections between profiles.

5. Conclusions

- The theoretical and experimental research carried out by the authors made it possible to develop simplified methods for calculating the temperature deformations of PVC window profiles with a reinforcing steel core.

- The analytical solution for determining the temperature deformations of PVC window profiles with two, three, and four attachment points to the reinforcing steel core is proposed.

- The simplified numerical solution is proposed for PVC window profiles with five or more attachment points to the reinforcing steel core. It consists of using a design model in the form of two parallel beams with different transverse stiffness, which are connected to each over by hinges.

- The proposed simplified methods for calculating the temperature deformations of PVC window profiles with a reinforcing steel core were verified with the laboratory test data. The difference between the calculated and actual bending was 10.6%.

- It has been found that ignoring the physical nonlinearity of PVC does not lead to significant errors in the calculation of temperature deformations of components of PVC window profiles based on winter operating conditions.

- It has been proven that torsional deformations do not significantly manifest themselves in PVC windows under temperature loading.

- It has been found that in PVC window profiles deformed by temperature load, the most stressed are the outermost points of their attachment to the reinforcing steel core. The location and characteristics (load-bearing capacity or flexibility) of the extreme points of attachment of the PVC window profile to the reinforcing steel core are a key factor determining the temperature deformations.

Author Contributions

Conceptualization, A.P.K.; methodology, A.P.K. and I.S.A.; software, I.S.A.; validation, A.P.K. and I.S.A.; formal analysis, I.S.A.; investigation, A.P.K. and I.S.A.; resources, I.S.A.; data curation I.S.A.; writing—original draft preparation, I.S.A.; writing—review and editing A.P.K.; visualization, I.S.A.; supervision, A.P.K.; project administration, A.P.K.; funding acquisition, A.P.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors express their profound gratitude to A.A. Verkhovsky, head of the test centre ‘Facades of SPK’ Federal State Budgetary Institution ‘Research Institute of Physics of Civil Engineering of the Russian Academy of Architecture and Construction Sciences’ for his help in organizing and conducting laboratory research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Saadatian, S.; Freire, F.; Simões, N. Embodied impacts of window systems: A comparative assessment of framing and glazing alternatives. J. Build. Eng. 2021, 35, 102042. [Google Scholar] [CrossRef]

- Feng, F.; Kunwar, N.; Cetin, K.; O’Neill, Z. A critical review of fenestration/window system design methods for high performance buildings. Energy Build 2021, 248, 111184. [Google Scholar] [CrossRef]

- Konstantinov, A.; Verkhovsky, A. Assessment of the Wind and Temperature Loads Influence on the PVC Windows Deformation. IOP Conf. Ser. Mater. Sci. Eng. 2020, 753, 032022. [Google Scholar] [CrossRef]

- Fleury, G.; Thomas, M. Variations to window air permeability according to outside temperature. Cahiers Du Centre Scientifique et Technique Du Batiment 1972, 132. [Google Scholar]

- Henry, R.; Patenaude, A. Measurements of window air leakage at cold temperatures and impact on annual energy performance of a house. ASHRAE Trans. 1998, 104 Pt 1B, 1254–1260. [Google Scholar]

- Kehrli, D. Window air leakage performance as a function of differential temperatures and accelerated environmental aging. In Thermal Performance of Exterior Envelopes of Building III; Amer Society of Heating: Atlanta, GA, USA, 1985; pp. 872–890. Available online: https://web.ornl.gov/sci/buildings/conf-archive/1985 B3 papers/066.pdf (accessed on 12 March 2023).

- Elmahdy, A.H. Air leakage characteristics of windows subjected to simultaneous temperature and pressure differentials. In Window Innovations; NRC Institute for Research in Construction: Toronto, ON, Canada, 1995; pp. 146–163. [Google Scholar]

- NRCan. Air Infiltration Rate of Windows under Temperature and Pressure Differentials, CANMET Report; Canada Centre for Mineral and Energy Technology: Ottawa, ON, Canada, 1995. [Google Scholar]

- Postawa, P.; Stachowiak, T.; Gnatowski, A. Strength analysis of welded corners of PVC window profiles. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2017; Volume 225. [Google Scholar] [CrossRef]

- Rejman, E.; Bałon, P.; Kiełbasa, B.; Smusz, R. Influence of the shape of reinforcing window profiles on the strength and torsional stiffness of windows. Mechanik 2022, 95, 46–51. [Google Scholar] [CrossRef]

- Iliev, V.; Samichkov, V.; Yavorov, N.; Ivanov, R.; Geshkova, Z. Constitutive Model of Unplasticized Polyvinyl Chloride for Numerical Stress-Strain Analysis. Sci. Eng. Education. 2020, 5, 3–8. Available online: https://www.researchgate.net/publication/347257058 (accessed on 12 March 2023).

- Memo TBV.01; Deformation by Temperature and Humidity in the Production of Windows, Doors and Facades; Union of Window and Facade Manufacturers (VFF): New York, NY, USA, 2017.

- ASTM E1424; Standard Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure and Temperature Differences Across the Specimen. ASTM International: West Conshohocken, PA, USA, 2022.

- Verkhovskiy, A.; Umnyakova, N.; Savich, A. Especially The Use Of Windows And Curtain Wall In Climatic Conditions Of Russia. IOP Conf. Ser. Mater. Sci. Eng. 2018, 463, 032033. [Google Scholar] [CrossRef]

- GOST 30674-99; Windows of polyvinylchloride profiles. Specifications. Gosstroj Rossii, GUP CzPP: Moscow, Russia, 2000.

- Koper, P.; Jankowska, M. Additional insulation materials in a window frame: Experimental and CFD analyses. Archit. Civ. Eng. Environ. 2019, 12, 149–157. [Google Scholar] [CrossRef]

- Smusz, R.; Bałon, P.; Kiełbasa, B.; Rejman, E.; Bembenek, M.; Kowalski, Ł. Experimental and Numerical Characterizataion of Thermal Bridges in Windows. Adv. Sci. Technol. Res. J. 2023, 17, 315–331. [Google Scholar] [CrossRef]

- Moumtzakis, A.; Zoras, S.; Evagelopoulos, V.; Dimoudi, A. Experimental Investigation of Thermal Bridges and Heat Transfer through Window Frame Elements at Achieving Energy Saving. Energies 2022, 15, 5055. [Google Scholar] [CrossRef]

- Lechowska, A.A.; Schnotale, J.A.; Baldinelli, G. Window frame thermal transmittance improvements without frame geometry variations: An experimentally validated CFD analysis. Energy Build 2017, 145, 188–199. [Google Scholar] [CrossRef]

- Lacki, P.; Różycka, J.; Rogoziński, M. Analysis of heat transfer through PVC window profile reinforced with Ti6Al4V alloy. In Key Engineering Materials; Trans Tech Publications Ltd.: Basel, Switzerland, 2016; Volume 687, pp. 236–242. [Google Scholar] [CrossRef]

- Aksenov, I.S.; Konstantinov, A.P. An analytical method for calculating the stress-strain state of PVC window profiles under thermal loading. Vestn. MGSU 2021, 16, 1437–1451. [Google Scholar] [CrossRef]

- Aksenov, I.; Konstantinov, A. Temperature deformations of pvc window profiles with reinforcement. Int. J. Comput. Civ. Struct. Eng. 2022, 18, 98–111. [Google Scholar] [CrossRef]

- Rostam, S.; Ali, A.K.; Abdalmuhammad, F.H. Experimental Investigation of Mechanical Properties of PVC Polymer under Different Heating and Cooling Conditions. J. Eng. 2016, 2016, 3791417. [Google Scholar] [CrossRef]

- Wygoda, M.; Paprocki, M.; Adamczyk, W. Influence of the Welding Process on the Quality of PVC Frames. Manuf. Technol. 2022, 22, 356–366. [Google Scholar] [CrossRef]

- Aksenov, I.S.; Konstantinov, A.P.; Verkhovsky, A.A. Numerical analytic method for calculation of pvc window profiles temperature deformation. Build. Reconstr. 2022, 102, 3–14. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).