Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid

Abstract

1. Introduction

2. Materials and Preparation

2.1. Raw Materials

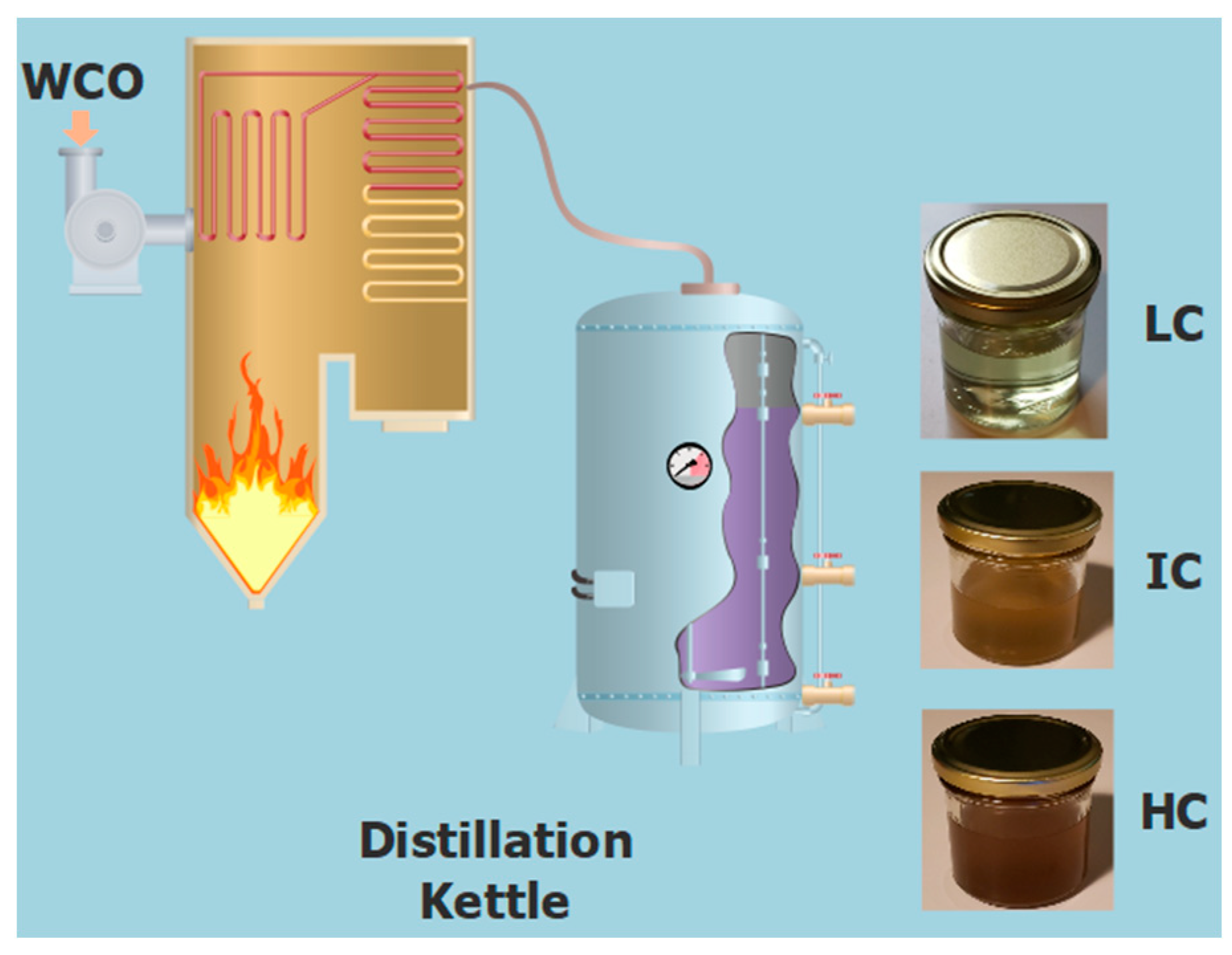

2.2. Preparation of Samples

3. Experimental Methods

3.1. LAS

3.2. Fatigue-Healing Test

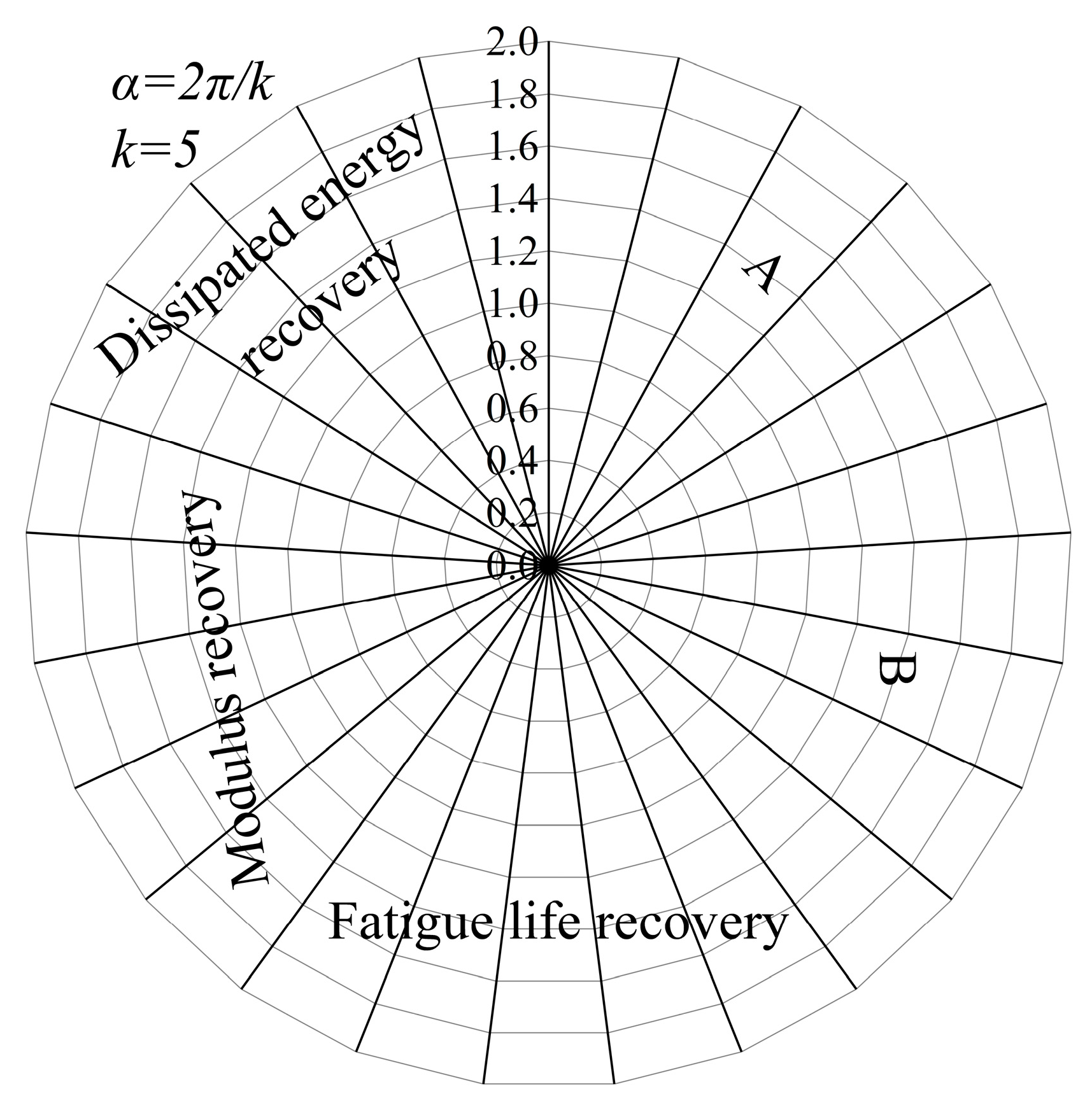

3.3. Radar Chart Method

3.4. SARA Fractionation

4. Results

4.1. Linear Amplitude Sweep Test

4.2. Self-Healing Property

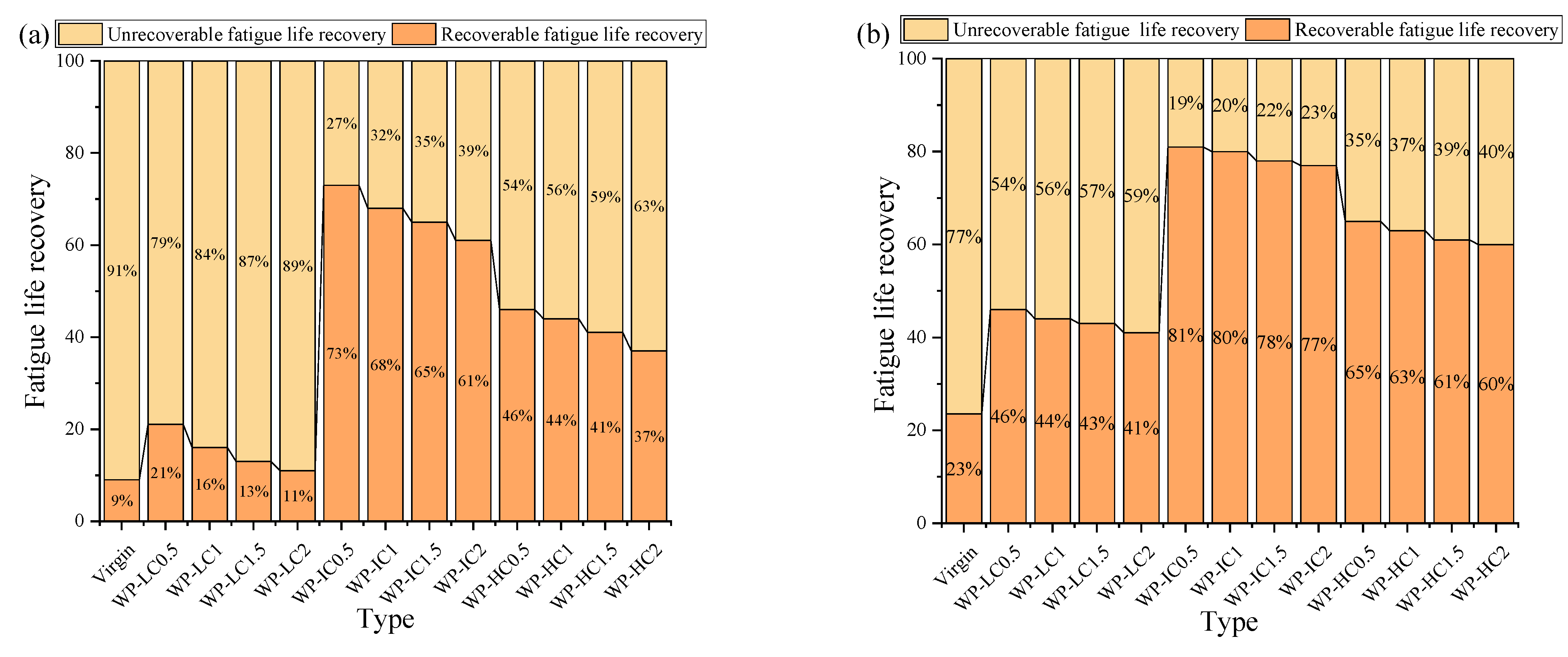

4.2.1. Fatigue Life Recovery

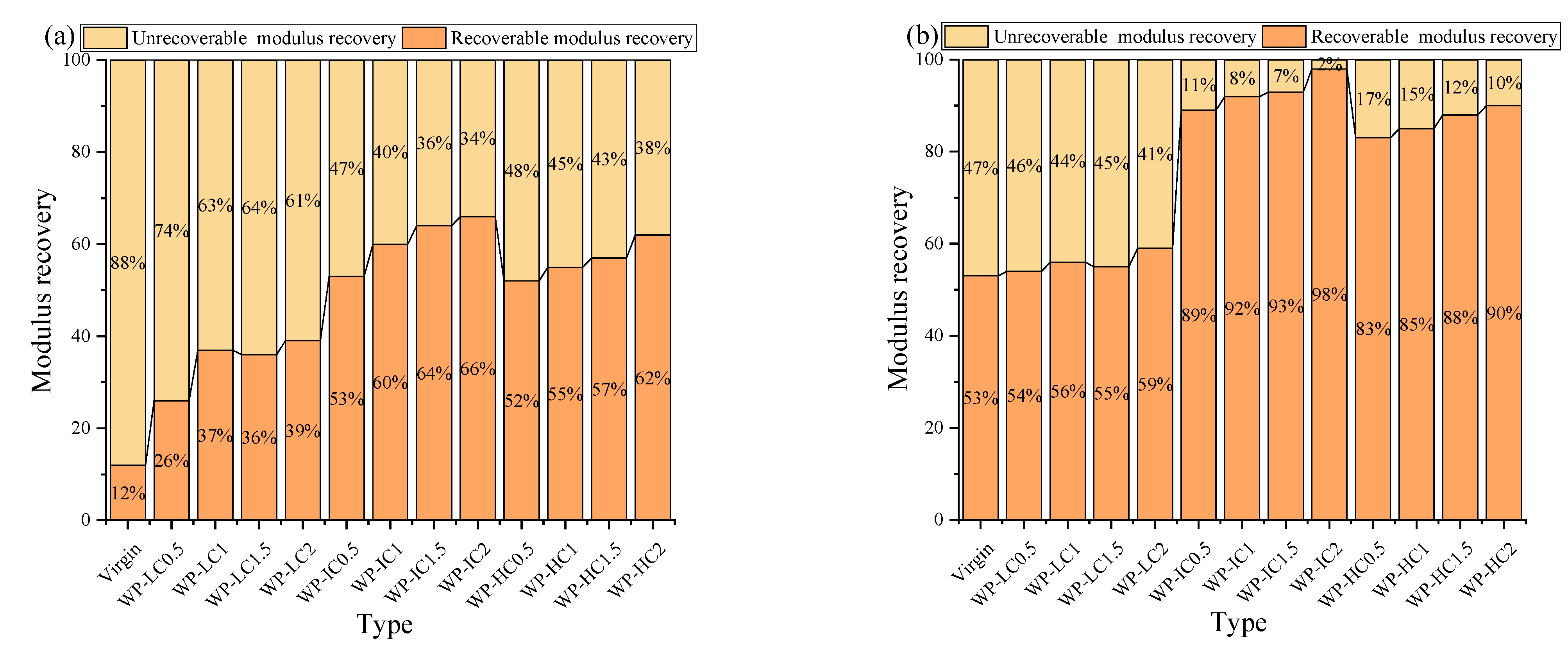

4.2.2. Modulus Recovery

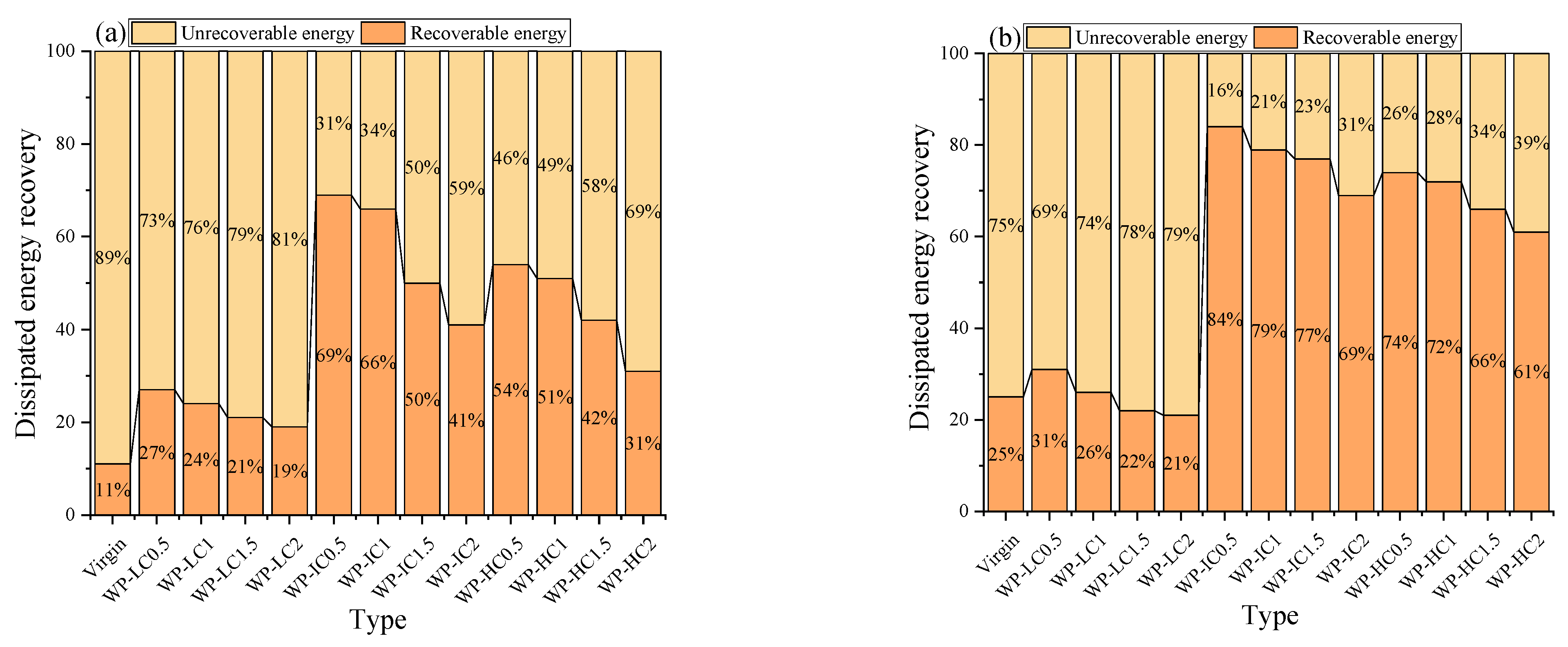

4.2.3. Dissipated Energy Recovery

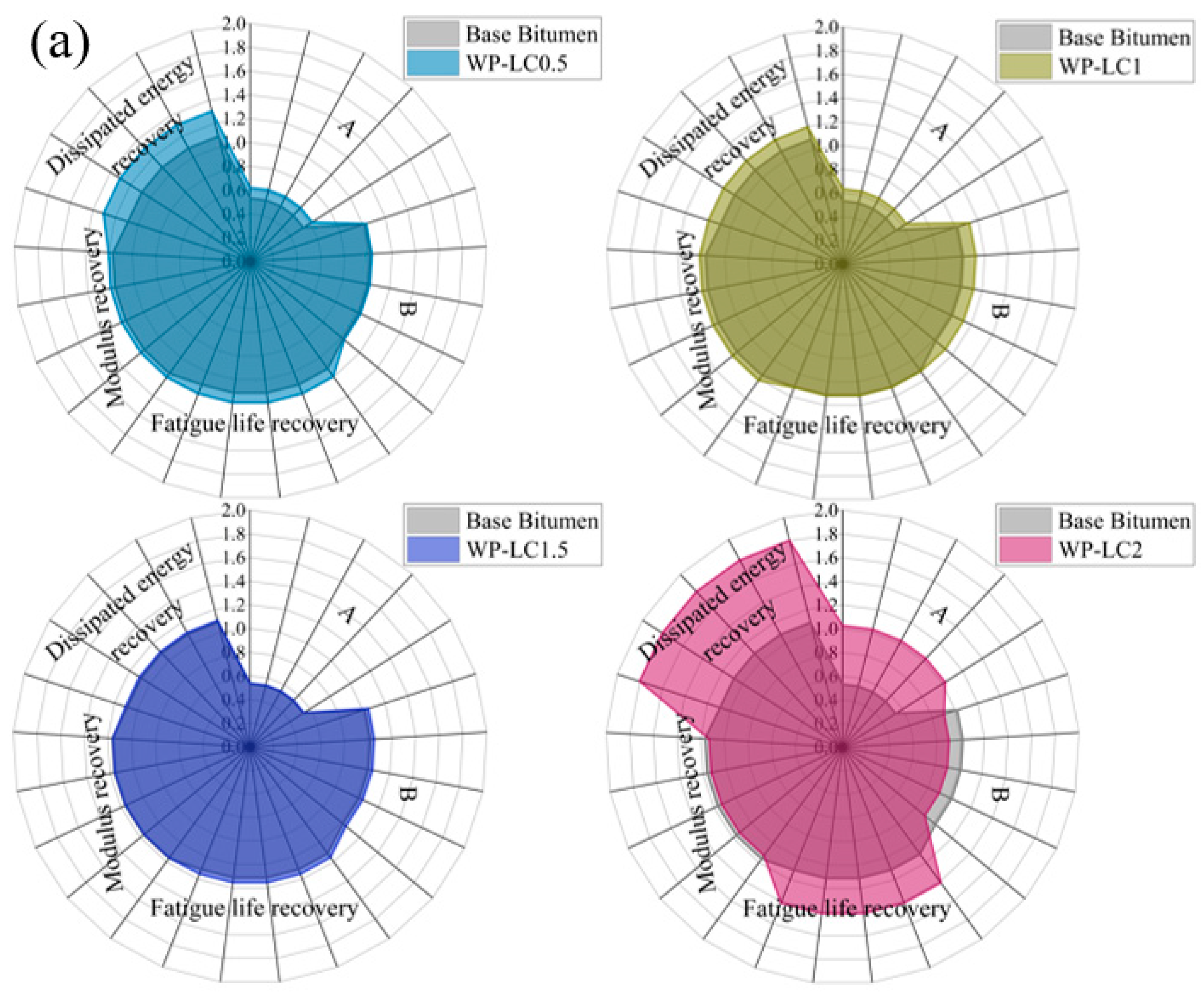

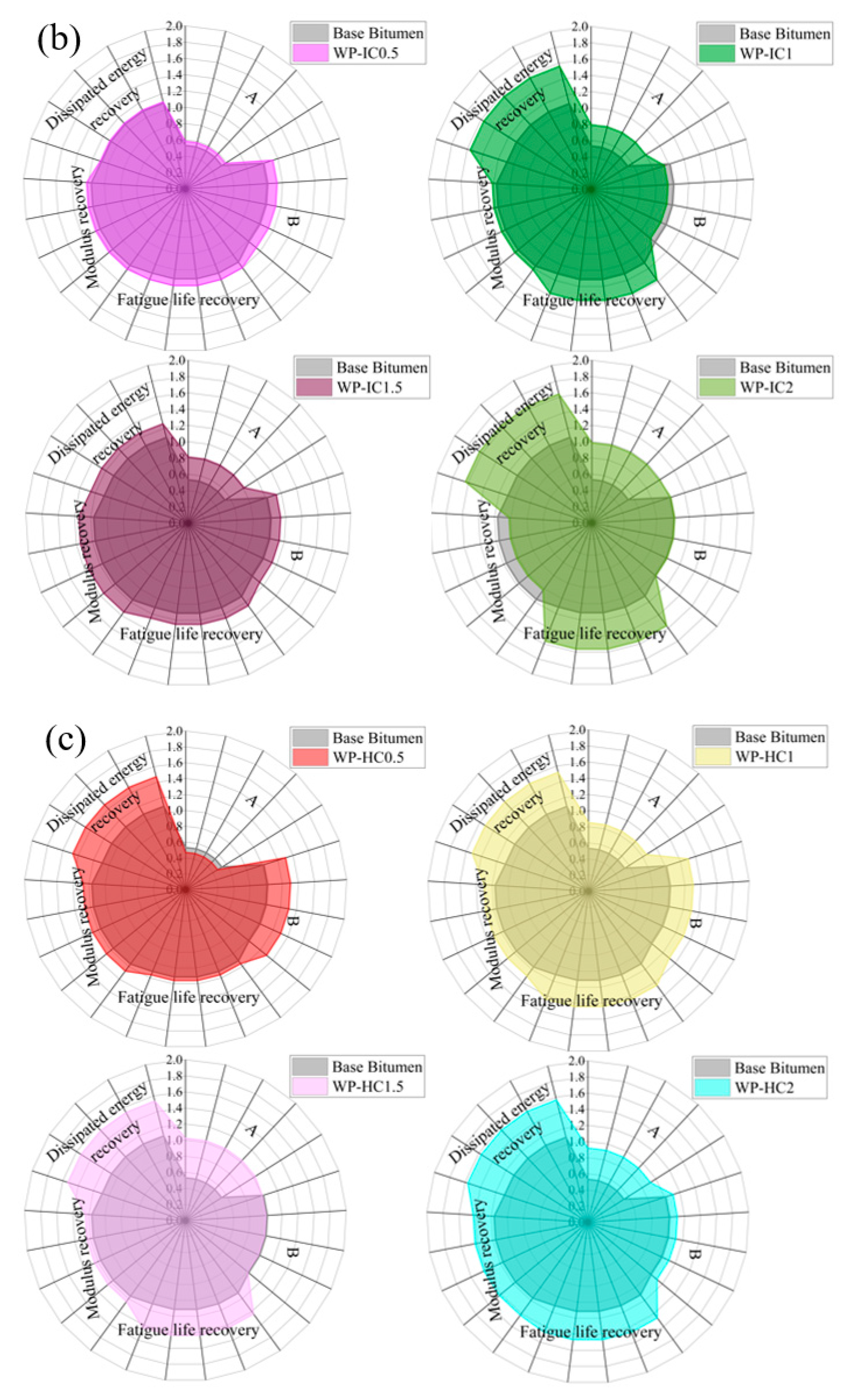

4.3. Optimum Proportion of WCO/PPA

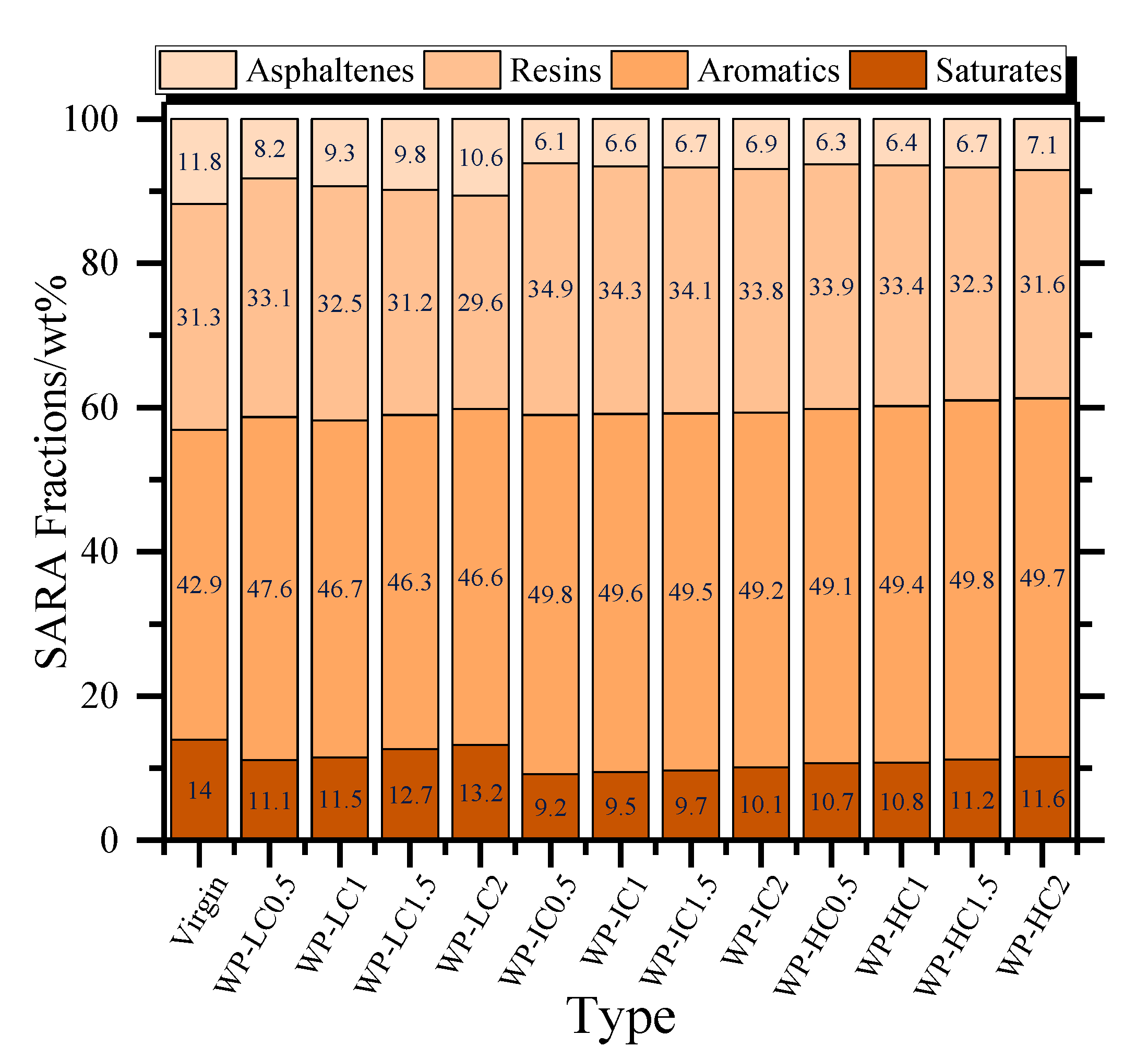

4.4. SARA

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Anupam, K.; Akinmade, D.; Kasbergen, C.; Erkens, S.; Adebiyi, F. A state-of-the-art review of Natural bitumen in pavement: Underlining challenges and the way forward. J. Clean. Prod. 2023, 382, 134957. [Google Scholar] [CrossRef]

- Praticò, F.G.; Giunta, M.; Mistretta, M.; Gulotta, T.M. Energy and environmental life cycle assessment of sustainable pavement materials and technologies for urban roads. Sustainability 2020, 12, 704. [Google Scholar] [CrossRef]

- Jiang, Q.; Chen, M.; Zhao, Y.; Wu, S.; Fan, Y.; Gan, Z.; Zhang, Y. Comprehensive assessment of the durability deterioration of asphalt pavement in salt environment: A literature review. Case Stud. Constr. Mater. 2022, 17, e01706. [Google Scholar] [CrossRef]

- Xu, N.; Wang, H.; Chen, Y.; Hossiney, N.; Ma, Z.; Wang, H. Insight into the effects of waste vegetable oil on self-healing behavior of bitumen binder. Constr. Build. Mater. 2023, 363, 129888. [Google Scholar] [CrossRef]

- Zhang, F.; Cao, Y.; Sha, A.; Wang, W.; Song, R.; Lou, B. Mechanism, rheology and self-healing properties of carbon nanotube modified asphalt. Constr. Build. Mater. 2022, 346, 128431. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Zhu, X.; Xiao, F. On the investigation of self-healing behavior of bitumen and its influencing factors. Mater. Des. 2017, 117, 7–17. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Chandrappa, A.K. A methodological review on self-healing asphalt pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Guo, X.-X.; Zhang, C.; Cui, B.-x.; Wang, D.; Tsai, J. Analysis of impact of transverse slope on hydroplaning risk level. Procedia-Soc. Behav. Sci. 2013, 96, 2310–2319. [Google Scholar] [CrossRef]

- Varma, R.; Balieu, R.; Kringos, N. A state-of-the-art review on self-healing in asphalt materials: Mechanical testing and analysis approaches. Constr. Build. Mater. 2021, 310, 125197. [Google Scholar] [CrossRef]

- Wan, P.; Wu, S.; Liu, Q.; Zou, Y.; Zhao, Z.; Chen, S. Recent advances in calcium alginate hydrogels encapsulating rejuvenator for asphalt self-healing. J. Road Eng. 2022, 2, 181–220. [Google Scholar] [CrossRef]

- Sun, G.; Li, B.; Sun, D.; Zhang, J.; Wang, C.; Zhu, X. Roles of aging and bio-oil regeneration on self-healing evolution behavior of asphalts within wide temperature range. J. Clean. Prod. 2021, 329, 129712. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Li, H.B.; Zhang, M.M.; Temitope, A.A.; Guo, X.Y.; Sun, J.M.; Yombah, M.; Zou, X.L. Compound reutilization of waste cooking oil and waste engine oil as asphalt rejuvenator: Performance evaluation and application. Environ. Sci. Pollut. Res. 2022, 29, 90463–90478. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yu, M.; Cui, X.; Wang, W. Properties and components of recycled engine oil bottom rejuvenated asphalt and its grey relationship analysis. Adv. Mater. Sci. Eng. 2019, 2019, 2462487. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—Rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- de Barros, A.G.; Lucena, L.; Hernandez, A.G. Addition of Encapsulated Soybean Oil and Waste Cooking Oil in Asphalt Mixtures: Effects on Mechanical Properties and Self-Healing of Fatigue Damage. J. Mater. Civ. Eng. 2022, 34, 04022002. [Google Scholar] [CrossRef]

- Yamaç, Ö.E.; Yilmaz, M.; Yalçın, E.; Kök, B.V.; Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mastic using capsules containing waste oils. Constr. Build. Mater. 2021, 270, 121417. [Google Scholar] [CrossRef]

- Jiang, X.M.; Li, P.L.; Ding, Z.; Yang, L.D.; Zhao, J.K. Investigations on viscosity and flow behavior of polyphosphoric acid (PPA) modified asphalt at high temperatures. Constr. Build. Mater. 2019, 228, 116610. [Google Scholar] [CrossRef]

- Hao, P.; Zhai, R.; Zhang, Z.; Cao, X. Investigation on performance of polyphosphoric acid (PPA)/SBR compound-modified asphalt mixture at high and low temperatures. Road Mater. Pavement Des. 2019, 20, 1376–1390. [Google Scholar] [CrossRef]

- Liu, H.Y.; Chen, Z.J.; Wang, Y.D.; Zhang, Z.X.; Hao, P.W. Effect of poly phosphoric acid (PPA) on creep response of base and polymer modified asphalt binders/mixtures at intermediate-low temperature. Constr. Build. Mater. 2018, 159, 329–337. [Google Scholar] [CrossRef]

- Cao, W.D.; Liu, S.T.; Mao, H.L. Experimental Study on Polyphosphoric Acid (PPA) Modified Asphalt Binders. In Proceedings of the International Conference on Advances in Materials and Manufacturing Processes, Shenzhen, China, 6–8 November 2010; pp. 288–294. [Google Scholar]

- Yuechao, Z.; Meizhu, C.; Shaopeng, W.; Qi, J. Rheological properties and microscopic characteristics of rejuvenated asphalt using different components from waste cooking oil. J. Clean. Prod. 2022, 370, 133556. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Zhang, X.; Wu, S.; Zhou, X.; Jiang, Q. Effect of chemical component characteristics of waste cooking oil on physicochemical properties of aging asphalt. Constr. Build. Mater. 2022, 344, 128236. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Wang, Y. Waste engine oil and polyphosphoric acid enhanced the sustainable self-healing of asphalt binder and its fatigue behavior. J. Clean. Prod. 2022, 339, 130767. [Google Scholar] [CrossRef]

- Feng, L.; Liu, J.; Hu, L. Rheological behavior of asphalt binder and performances of asphalt mixtures modified by waste soybean oil and lignin. Constr. Build. Mater. 2023, 362, 129735. [Google Scholar] [CrossRef]

- Hintz, C.; Bahia, H. Simplification of linear amplitude sweep test and specification parameter. Transp. Res. Rec. 2013, 2370, 10–16. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y. Laboratory research on asphalt mastic modified with activated carbon powder: Rheology, micro-structure, and adhesion. Road Mater. Pavement Des. 2021, 22, 1424–1441. [Google Scholar] [CrossRef]

- Saboo, N. New damage parameter for fatigue analysis of asphalt binders in linear amplitude sweep test. J. Mater. Civ. Eng. 2020, 32, 04020126. [Google Scholar] [CrossRef]

- Liu, Z.; Luo, S.; Wang, Y.; Chen, H. Induction heating and fatigue-damage induction healing of steel fiber–reinforced asphalt mixture. J. Mater. Civ. Eng. 2019, 31, 04019180. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Meng, Y.; Han, Z.; Jin, T. Comprehensive performance evaluation of steel fiber-reinforced asphalt mixture for induction heating. Int. J. Pavement Eng. 2022, 23, 3838–3849. [Google Scholar] [CrossRef]

- Uchoa, A.F.; Rocha, W.S.; Feitosa, J.P.; Brito, D.H.; Gondim, L.M.; Ricardo, N.M.; Soares, J.B.; Soares, S.A. Exploiting epoxidized cashew nut shell liquid as a potential bio-additive to improve asphalt binder performance. J. Clean. Prod. 2021, 314, 128061. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.; Peng, A. Evaluation of polyphosphoric acid on the performance of polymer modified asphalt binders. J. Appl. Polym. Sci. 2020, 137, 48984. [Google Scholar] [CrossRef]

- Hung, A.M.; Mousavi, M.; Fini, E.H. Implication of wax on hindering self-healing processes in bitumen. Appl. Surf. Sci. 2020, 523, 146449. [Google Scholar] [CrossRef]

- Chen, H.; He, J.; Chen, Y.; Hua, H. Performance of a common rail diesel engine using biodiesel of waste cooking oil and gasoline blend. J. Energy Inst. 2018, 91, 856–866. [Google Scholar] [CrossRef]

- Dai, J.; Ma, F.; Fu, Z.; Li, C.; Jia, M.; Shi, K.; Wen, Y.; Wang, W. Applicability assessment of stearic acid/palmitic acid binary eutectic phase change material in cooling pavement. Renew. Energy 2021, 175, 748–759. [Google Scholar] [CrossRef]

- Zhang, C.C.; Xu, T.; Shi, H.Q.; Wang, L.L. Physicochemical and pyrolysis properties of SARA fractions separated from asphalt binder. J. Therm. Anal. Calorim. 2015, 122, 241–249. [Google Scholar] [CrossRef]

- Wang, W.; Li, J.; Wang, D.; Liu, P.; Li, X. The Synergistic Effect of Polyphosphates Acid and Different Compounds of Waste Cooking Oil on Conventional and Rheological Properties of Modified Bitumen. Materials 2022, 15, 8681. [Google Scholar] [CrossRef]

- Jia, M.; Sha, A.; Jiang, W.; Li, X.; Jiao, W. Developing a solid–solid phase change heat storage asphalt pavement material and its application as functional filler for cooling asphalt pavement. Energy Build. 2023, 285, 112935. [Google Scholar] [CrossRef]

- Xintao, Z.; Meizhu, C.; Yuechao, Z.; Shaopeng, W.; Dongyu, C.; Yuanhang, S. Influence of macromolecular substances in waste cooking oil on rejuvenation properties of asphalt with different aging degrees. Constr. Build. Mater. 2022, 361, 129522. [Google Scholar] [CrossRef]

- Cai, J.; Wen, Y.; Wang, D.; Li, R.; Zhang, J.; Pei, J.; Xie, J. Investigation on the cohesion and adhesion behavior of high-viscosity asphalt binders by bonding tensile testing apparatus. Constr. Build. Mater. 2020, 261, 120011. [Google Scholar] [CrossRef]

- Hugener, M.; Wang, D.; Cannone Falchetto, A.; Porot, L.; Kara De Maeijer, P.; Orešković, M.; Sa-da-Costa, M.; Tabatabaee, H.; Bocci, E.; Kawakami, A. Recommendation of RILEM TC 264 RAP on the evaluation of asphalt recycling agents for hot mix asphalt. Mater. Struct. 2022, 55, 31. [Google Scholar] [CrossRef]

- Büchler, S.; Cannone Falchetto, A.C.; Walther, A.; Riccardi, C.; Wang, D.; Wistuba, M.P. Wearing course mixtures prepared with high reclaimed asphalt pavement content modified by rejuvenators. Transp. Res. Rec. 2018, 2672, 96–106. [Google Scholar] [CrossRef]

| Technical Indexes | Measured Results | Test Method |

|---|---|---|

| Ductility (15 °C, cm) | 93.1 | T0604 |

| Penetration (25 °C, 0.1 mm) | >150 | T0605 |

| Softening Point (°C) | 46.2 | T0604 |

| Index | Unit | Test Results |

|---|---|---|

| Density (25 °C) | g/cm3 | 2.15 |

| Viscosity (85 °C) | mPa.s | 562 |

| Surface tension | N·cm−1 | 7.5 × 10−4 |

| Index | Test Results | ||

|---|---|---|---|

| LC | IC | HC | |

| Viscosity (50 °C, cP) | 66 | 85 | 219 |

| Flash point (°C) | 197 | 219 | 242 |

| Fire point (°C) | 216 | 233 | 264 |

| Density (g/cm3) | 0.89 | 0.92 | 0.97 |

| Mechanical impurity (%) | 0.425 | 0.002 | 0 |

| Types | A | B | Fatigue Life Recovery | Modulus Recovery | Dissipated Energy Recovery |

|---|---|---|---|---|---|

| Virgin bitumen | 0.5315 | 1.0185 | 1.1128 | 1.1637 | 1.0866 |

| WP-LC0.5 | 0.6214 | 1.032 | 1.1956 | 1.2031 | 1.3066 |

| WP-LC1 | 0.6347 | 1.1263 | 1.1196 | 1.2138 | 1.1945 |

| WP-LC1.5 | 0.5388 | 1.0506 | 1.1542 | 1.1599 | 1.1043 |

| WP-LC2 | 1.028 | 0.9025 | 1.4133 | 1.1285 | 1.8021 |

| WP-IC0.5 | 0.5832 | 1.1344 | 1.1966 | 1.2201 | 1.1023 |

| WP-IC1 | 0.7936 | 0.9458 | 1.3724 | 1.2166 | 1.563 |

| WP-IC1.5 | 0.8125 | 1.1369 | 1.2524 | 1.3488 | 1.2595 |

| WP-IC2 | 0.9853 | 1.021 | 1.5634 | 1.0224 | 1.637 |

| WP-HC0.5 | 0.4695 | 1.3025 | 1.1589 | 1.2733 | 1.4692 |

| WP-HC1 | 0.8516 | 1.3024 | 1.4428 | 1.3016 | 1.5201 |

| WP-HC1.5 | 1.0238 | 1.002 | 1.4369 | 1.2456 | 1.5348 |

| WP-HC2 | 0.9213 | 1.1148 | 1.4698 | 1.4261 | 1.5674 |

| Si | Wi | |

|---|---|---|

| s11, s12 | 0.4322, 0.6971 | 0.5488 |

| s21, s22 | 0.5193, 0.7408 | 0.6202 |

| s31, s32 | 0.6251, 0.7852 | 0.7006 |

| s41, s42 | 0.6785, 0.7932 | 0.7336 |

| s51, s52 | 0.7341, 0.8793 | 0.8034 |

| s61, s62 | 0.6371, 0.8489 | 0.7354 |

| s71, s72 | 0.6856, 0.9037 | 0.7871 |

| s81, s82 | 0.7595, 0.9579 | 0.8526 |

| s91, s92 | 0.9227, 0.9566 | 0.9394 |

| s101, s102 | 0.6476, 0.8038 | 0.7215 |

| s111, s112 | 0.7155, 0.8643 | 0.7864 |

| s121, s122 | 0.7596, 0.8961 | 0.8251 |

| s131, s132 | 0.7668, 0.9543 | 0.8554 |

| Value | Virgin | WP-LC0.5 | WP-LC1 | WP-LC1.5 | WP-LC2 | WP-IC0.5 | WP-IC1 | WP-IC1.5 | WP-IC2 | WP-HC0.5 | WP-HC1 | WP-HC1.5 | WP-HC2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2.88 | 4.18 | 3.81 | 3.44 | 3.2 | 5.54 | 5.21 | 5.09 | 4.88 | 4.87 | 4.81 | 4.59 | 5.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Guo, D.; Liu, C.; Falchetto, A.C.; Li, X.; Wang, T. Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid. Buildings 2023, 13, 1188. https://doi.org/10.3390/buildings13051188

Wang W, Guo D, Liu C, Falchetto AC, Li X, Wang T. Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid. Buildings. 2023; 13(5):1188. https://doi.org/10.3390/buildings13051188

Chicago/Turabian StyleWang, Wentong, Dedong Guo, Congcong Liu, Augusto Cannone Falchetto, Xinzhou Li, and Teng Wang. 2023. "Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid" Buildings 13, no. 5: 1188. https://doi.org/10.3390/buildings13051188

APA StyleWang, W., Guo, D., Liu, C., Falchetto, A. C., Li, X., & Wang, T. (2023). Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid. Buildings, 13(5), 1188. https://doi.org/10.3390/buildings13051188