Abstract

A building faces several challenges across its lifecycle stages. Challenges such as production inefficiency and inadequate waste management hinder advancement in the construction industry. Furthermore, the sector has emerged as one of the largest producers of waste in the world, which can lead to detrimental impacts on the economy and the environment. Conventional approaches are insufficient to eradicate these concerns. Thus, practitioners have sought to implement novel methods to ameliorate the construction process. In this regard, design for manufacturing and assembly (DfMA) and design for deconstruction (DfD) have gained prominence, as studies have elucidated the methods’ unprecedented potential to wholly transform the construction process and mitigate the unwanted impacts brought about by the industry. This study identified the applications and benefits of DfMA and DfD in construction, as well as recent developments and research gaps, through a literature review, using Scopus as the primary database and MATLAB for conducting data text analytics. The current body of knowledge necessitates a further assessment of the following research gaps: (1) development of standard construction-oriented DfMA guidelines; (2) corroboration of the developed DfMA tools through practical application; (3) integration of these holistic design approaches with emerging technologies, such as additive manufacturing and digital fabrication; (4) comparison of structures constructed using DfMA and DfD with structures built with conventional approaches; (5) comprehensive application of DfD guidelines to structural systems; (6) integration of DfMA and DfD; (7) execution of sustainability assessment studies to evaluate the impact of DfMA and DfD; and (8) identification of solutions to the barriers to DfMA and DfD uptake in construction.

1. Introduction

Technological advancements and innovative ideas constantly arise in the changing world, heightening market competition. Industries must thrive by adapting to these changes. Design for X (DfX) approaches have attained significant prominence in the domains of research, innovation, and production in recent years. DfX is an approach for designing products and processes that aims to optimize costs and enhance quality throughout a product’s lifecycle [1]. In DfX, product design and its associated processes are integrated with specific aspects of product development to address a particular requirement [2]. Current DfX approaches include design for deconstruction (DfD), design for disassembly (DfDisa), design for reverse logistics (DfRL), design for assembly (DfA), design for change (DfCh), design for manufacturing and assembly (DfMA), design out waste (DoW), design for adaptability (DfAdapt), design for product service supportability (DfPSS) [3], and many others. DfAdapt is a product, system, and process design approach focusing on fabricating flexible products that can easily adapt to new situations or demands [4]. DfPSS refers to the process of designing products that are centered on customer needs while reducing production costs [5]. From these definitions, it can be discerned that DfX approaches aim to evaluate a particular facet of the production process, and their usage is widely dependent on several factors, such as product type and project objectives.

These methods can be classified based on virtue and lifecycle [6]. On one hand, DfX based on virtue addresses particular properties of a product, such as quality and durability. On the other hand, DfX based on lifecycle considers the various stages of a product’s service life, such as fabrication and demolition. This study focuses on the latter DfX classification. Each lifecycle stage has a corresponding effect on the overall output quality and production efficiency. Hence, addressing the processes encapsulated under these lifecycle phases is necessary. Among the DfX approaches, two notable lifecycle methods are DfMA and DfD.

DfMA is a methodology that enhances the design process by focusing on simplicity and reducing materials, labor, and manufacturing–related operations [7]. Utilizing this method enables efficiency and ensures excellent product quality. Hence, many industries, such as the automobile and aerospace industries, have implemented this approach in their processes [8]. The utilization of DfMA has been assessed in various studies focusing on diverse systems, such as the redesign of a ventilation unit [9], the prefabrication of non–structural building elements [7], the construction of a modular structure made of cross–laminated timber [10], the design of an Iranian–Islamic Muqarnas [11], and the development of a product data management system for selecting appropriate materials and welding processes [12]. Topics of DfMA–related studies range from the theoretical application of the design method in existing products through a case study [8,9,13] to its practical application in product development [10]. As a method, DfMA revolves around using guidelines, criteria, and principles. Several authors have presented different policies [8,14,15] allowing effective DfMA usage. Typical DfMA rules include minimization, standardization, and modularization of assembly parts [16].

Deconstruction, also known as “construction in reverse” [17], is the process of dismantling an item to reuse and recycle it. Traditional manufacturing practices utilize demolition and disposal when a product has reached the end of its service life. However, this method produces adverse environmental and economic effects. Continually implementing demolition practices results in the production of more waste and more raw materials being extracted from the Earth’s surface. Moreover, associated costs also escalate. Hence, it is imperative to replace this conventional practice by introducing deconstruction. While practitioners have taken measures to employ product recyclability, it would be substantially beneficial if deconstruction principles were incorporated in the initial design and planning stages. Thus, DfD has been developed to promulgate this practice. DfD is a methodology focusing on a product’s end-of-life and the procedures to disassemble the product into its original components for future reuse [17]. It follows the circular economy concept, wherein existing products must be reintroduced into the market to extend their service life. Utilizing DfD would aid in promoting circularity and would be conducive to enabling sustainable development.

Despite addressing different lifecycle stages, the methods have similar guidelines and presumed benefits. For instance, both methods implement guidelines that support easy process system execution, such as minimizing components, utilizing lightweight materials, and prefabrication [14,18,19]. These approaches are frequently used to reduce costs and improve quality. In addition, employing these methods has been considered a practical strategy for encouraging circularity in the asset lifecycle [3] and enhancing waste management [20]. These methods can be correlated because the assembly procedures directly impact product disassembly at the end-of-life stage. The plausibility of integrating the two approaches into one design method, known as design for manufacturing, assembly, and disassembly, has been showcased [21]. However, studies integrating DfMA and DfD in construction projects are scarce. As such, exploring these design methodologies’ guidelines and developments is needed to advance their use further. Currently, construction is one industry that has widely embraced these design methods.

The construction industry conventionally follows the approaches circumscribed by a linear economy. In this model, industrial production and resource consumption are exercised without considering raw materials’ physical limitations [22]. Due to the prevalence of this model, sustainability-related concerns continue to persist. About 40% of waste produced and resources consumed and 25% of global carbon emissions originate from building construction [23]. Most of the construction sector’s environmental impact is accounted for by the massive energy required for material production [24]. This continual use of new raw materials and energy also causes corresponding unfavorable effects on an economic level. With time, the need to address these concerns becomes more substantial as urbanization progresses and the population increases. Including DfMA and DfD in the design process is one step toward achieving radical changes and transformative evolution. In recent years, the construction industry has adopted these design methods, leading to substantial improvements in construction implementation and management.

The study of DfMA and DfD is essential because they address critical construction phases. The lifecycle stages of construction include planning, designing, construction, management, and demolition at the end-of-life phase [25]. In product design, DfMA focuses on optimizing the manufacturing stage, while DfD centers on the deconstruction processes involved in the end-of-life phase. As such, these methods address the planning, designing, construction, and demolition phases. Only the management phase is excluded, which is justifiable since it is the stage where the structure is utilized by its inhabitants.

Present review studies have yet to explore the current state of DfMA and DfD in the construction industry, despite the modern developments presented in case studies and experimental research. A recent study by Razak et al. [26] included a literature review on DfMA but with an emphasis on industrialized building systems and the Malaysian construction sector. In addition, a review article by Tuvayanond et al. [27] investigated DfMA in construction. However, it was limited to digital fabrication and additive manufacturing. For DfD, most literature reviews tackling DfD have discussed it as a subtopic of circular economy research [3,28,29,30], thus the need to elaborate it on the uptake of DfD in construction research. A paper by Kanters [31] addressed this gap by providing a literature review regarding the current state-of-the-art in DfD in the construction industry. However, the study only included ten articles from before June 2018. It did not consider the recent developments in DfD research. In addition, previous reviews have not discussed DfMA and DfD together, despite the existence of prominent DfX approaches that similarly focus on the product lifecycle. As such, the novelty of the current study is supported by the difference in its scope compared with previous review articles published. In this regard, the primary objective of this study was to analyze the challenges, research gaps, current developments, and impacts relating to DfMA and DfD in the construction industry through a literature review. It specifies the recent findings related to the methods, as well as barriers to their adoption and their advantages and effects on sustainable development. It also aimed to unravel whether or not DfMA and DfD have been integrated into construction-related studies. Guidelines were compiled for the use of industry practitioners. Furthermore, research areas that have not been extensively studied are provided. Section 2 of this paper presents the methodology used to conduct the literature review.

2. Methodology

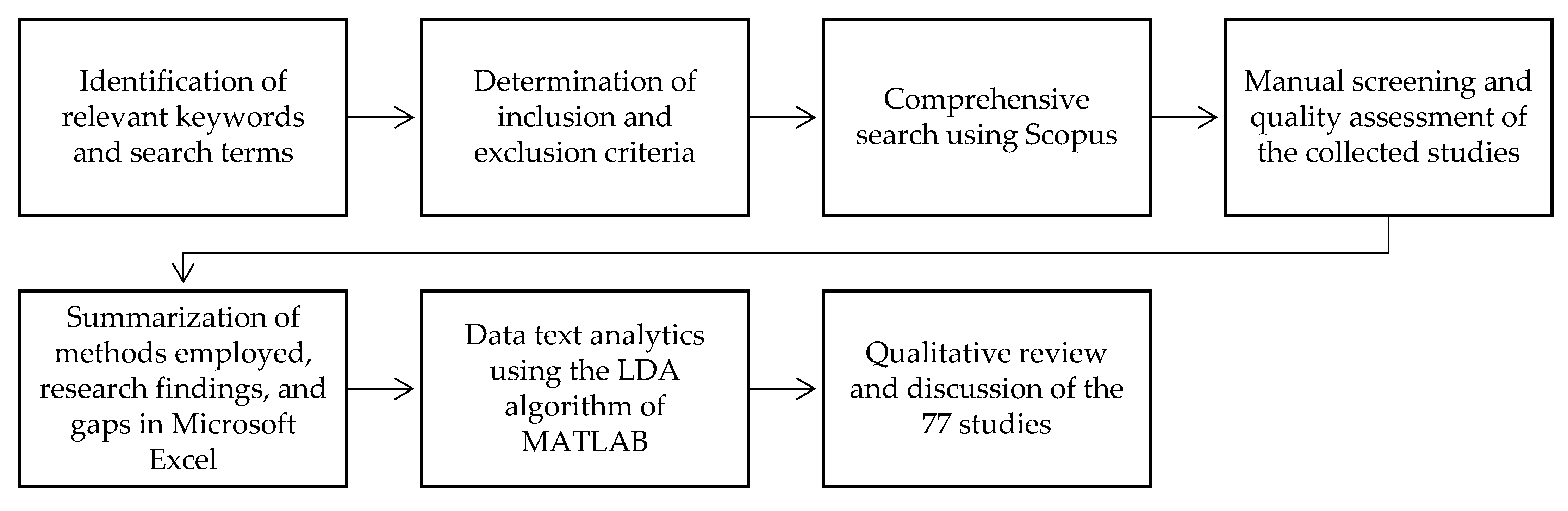

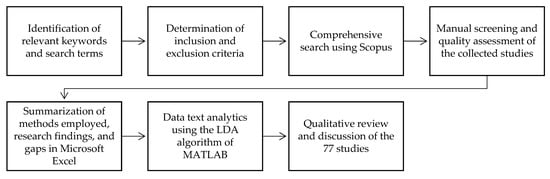

The primary purpose of a review of related literature is to provide a current and well-organized overview of existing literature regarding a particular subject that provides value to its readers [32]. This study collected and analyzed peer-reviewed publications discussing the application of DfMA and DfD in the construction industry. The steps indicated by Tranfield et al. [33] were used as a basis to execute the literature review. Figure 1 presents a summary of the methodology that was conducted. Since the research topic had already been identified, related literature was first obtained. Data acquisition was deemed critical for this research. Thus, it was ensured that references were reliable and peer-reviewed. Typical databases utilized in review articles include Google Scholar, Scopus, and Web of Science [34]. Upon inspecting these databases, Scopus and Web of Science resulted in more peer-reviewed journal articles, while Google Scholar had a more diversified collection of documents. Moreover, Scopus provides more journals than Web of Science [34]. In construction research, many review articles use Scopus as a principal source for gathering documents [35,36,37]. Thus, Scopus was selected as the primary database.

Figure 1.

Flowchart of the research methodology.

The researchers identified the appropriate keywords to be inputted in the search field. The search terms were carefully selected based on the research questions, key themes, and topics being addressed. These search terms were entered and combined with the applicable search strings and Boolean operators. The keywords were then typed as follows: (“DfMA” AND “Construction”) OR (“DfMA” AND “Prefabrication”) OR (“DfMA” AND “Off-site Construction”) OR (“DfMA” AND “Construction” AND “Sustainability”) OR (“DfMA” AND “Circular Economy”) OR (“Design for Manufacturing and Assembly” AND “Construction”) OR (“Design for Manufacturing and Assembly” AND “Prefabrication”) OR (“Design for Manufacturing and Assembly” AND “Off-site Construction”) OR (“Design for Manufacturing and Assembly” AND “Construction” AND “Sustainability”) OR (“Design for Manufacturing and Assembly” AND “Circular Economy” OR “Design for Deconstruction” AND “Construction”) OR (“Design for Deconstruction” AND “Sustainability”) OR (“Design for Deconstruction” AND “Circular Economy”). DfMA and DfD were expanded since they may stand for other words unrelated to the topic. Moreover, inclusion criteria were determined to identify which studies would be included in the literature review. The inclusion criteria included peer-reviewed publications, studies published between 2016 and 2022, studies written in English, and studies discussing the applicability of DfMA and DfD. There was no strict policy for the duration required for a review, as different studies adopted various timeframes [30,36,38]. Thus, only studies published from 2016 to 2022 were incorporated to corroborate the recentness of the review. However, some studies obtained pertinent information and figures from papers published before the established date range. In these cases, the original research is cited instead.

The initial search was executed in August 2022, which yielded 117 studies. Manual screening of these papers was conducted. The methods employed, research findings, and gaps were simultaneously identified and summarized in Microsoft Excel. The exclusion criteria used during this process included studies that merely mentioned DfMA and DfD, studies for which only the abstract was available and the provided information was lacking, and studies not connected to the topic of this review.

Some studies simply mentioned DfMA and DfD in the text but lacked any relevance to the topic. These studies were not included in the review. Additionally, only the abstract could be extracted from other studies. Some abstracts contained vital information, but others did not mention DfMA and DfD or essential details on them that could be added to the discussion in the present study. These studies were omitted. Moreover, unrelated studies in which DfMA and DfD appeared in the text but did not have any connection to the subject of the present study were excluded. Lastly, the quality of each study was evaluated to minimize possible errors and biases. Errors refer to studies with unreliable or inaccurate findings, such as mistakes in the results displayed, while biases refer to the incorporation of subjective decisions by the authors, such as publication bias, wherein unwanted findings are purposefully undisclosed to attain a particular conclusion [39]. After examining each study, 77 journals were deemed suitable for the review.

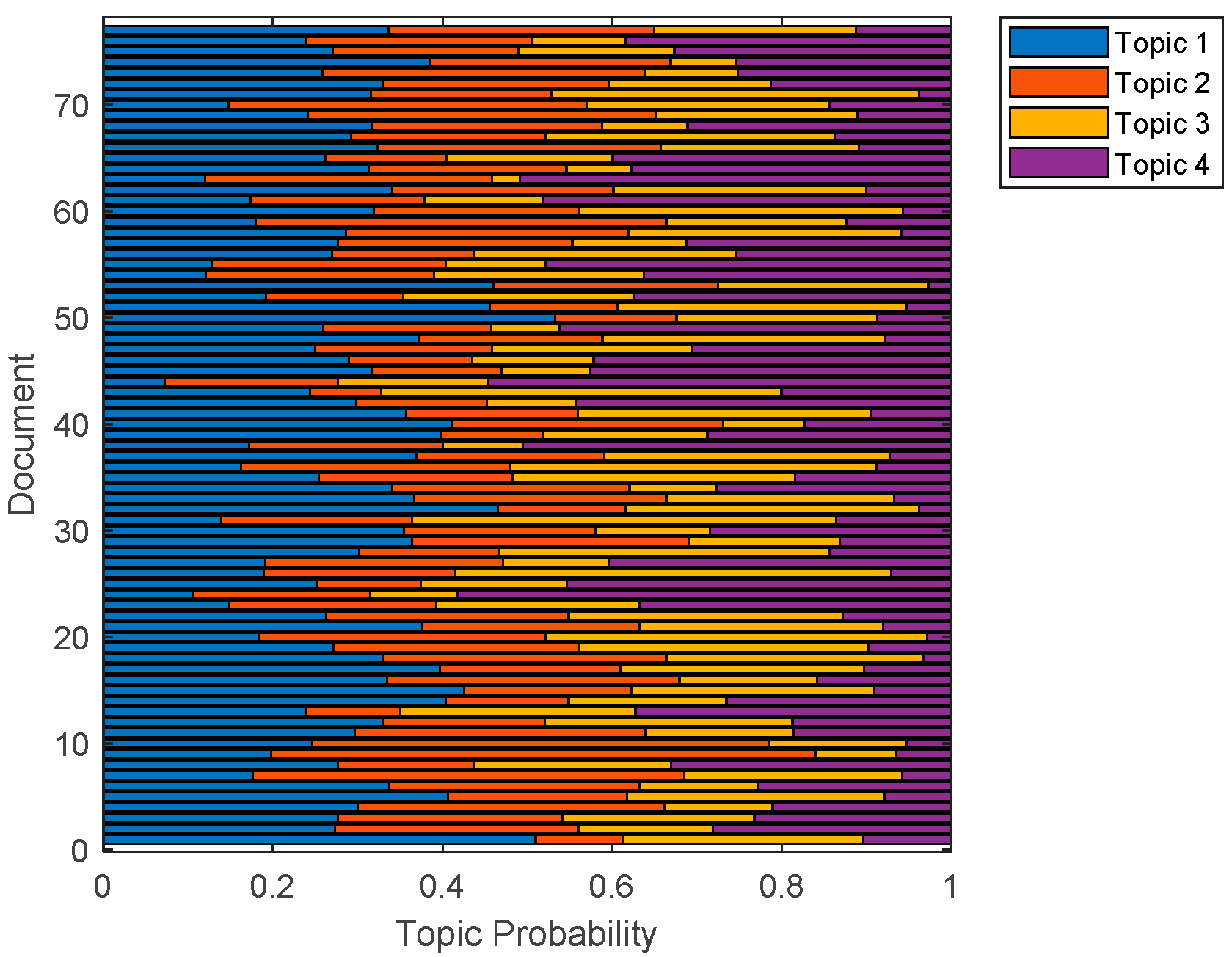

The MATLAB program was utilized for data extraction, where the collected studies were imported and processed. MATLAB uses the latent Dirichlet allocation (LDA) algorithm for data text analytics. LDA presents a generative probabilistic model of a distribution of words in a document belonging to a specific topic [40]. In the present study, MATLAB served as an assistive tool for analyzing the studies efficiently. It processed all the articles and identified similarities in the words and phrases used, which aided in highlighting the common themes among the papers. To begin this process, the titles and abstracts of the studies were exported using the CSV Excel feature in Scopus. This Microsoft Excel file was imported into MATLAB. The codes in MATLAB were then utilized.

The “Example” option under the “Help” menu in the MATLAB program was referred to for the codes used [41]. MATLAB provides several examples for conducting data text analytics. This study utilized the examples under the “Text Analytics Toolbox”. To generate a word cloud, “Visualize Text Data Using Word Clouds” was employed. To select the number of topics from a set of documents, “Choose Number of Topics for LDA Model” was used as a basis. For the generation of the topics, “Analyze Text Data Using Topic Models” was used. Lastly, to identify the proportions of the topics in each paper, the study employed the “Visualize LDA Topic Probabilities of Documents” example. Upon inputting the codes in these examples, the results were generated.

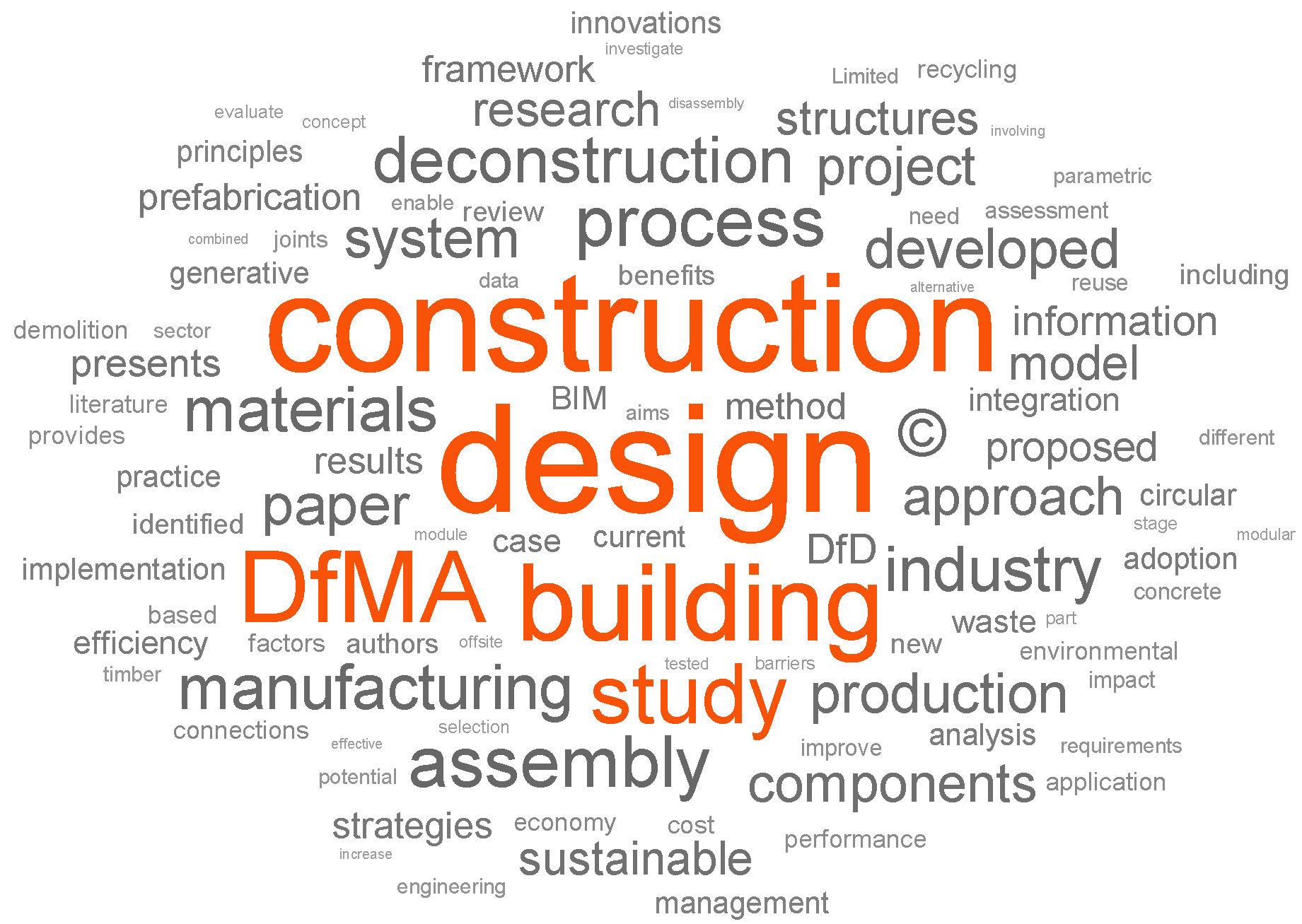

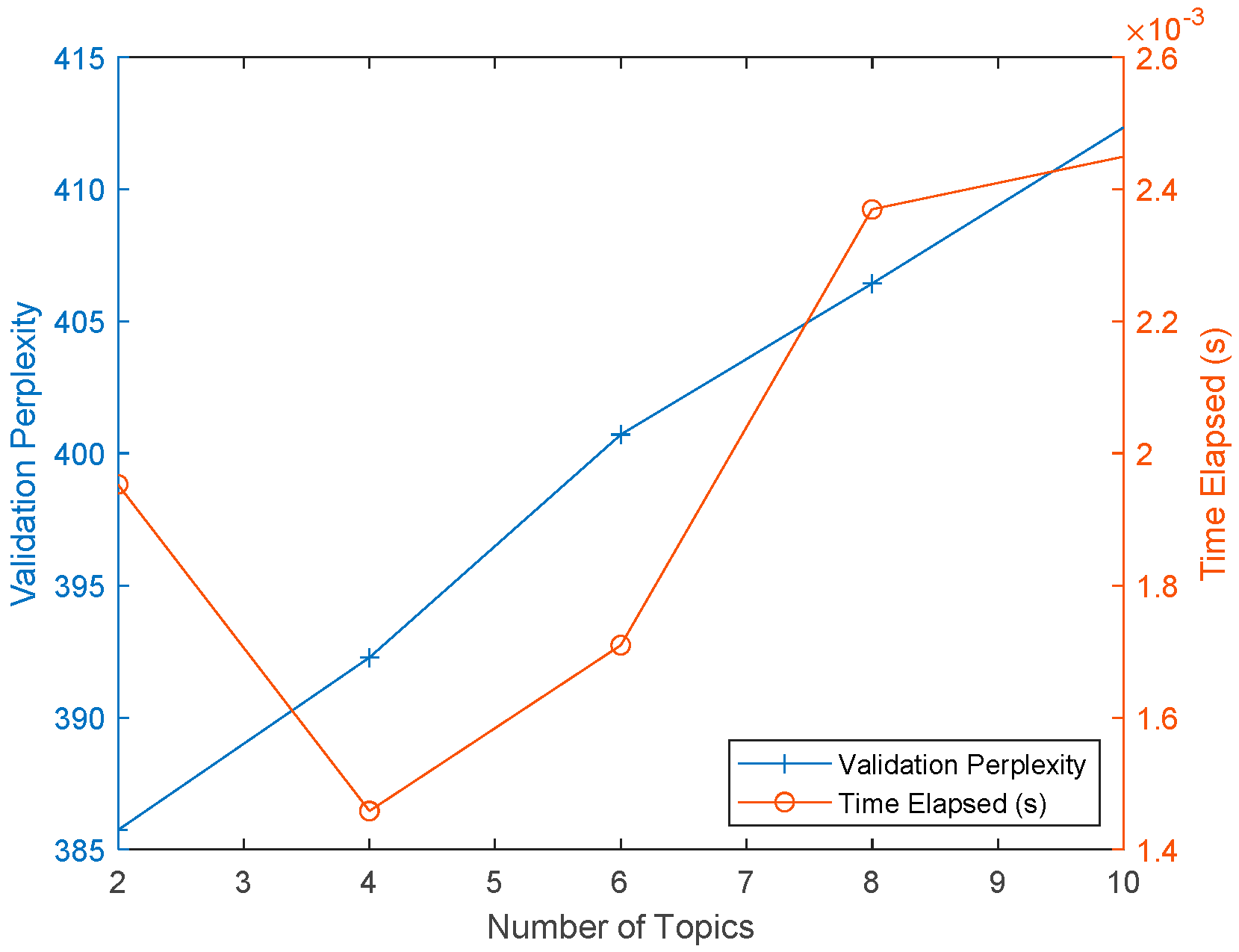

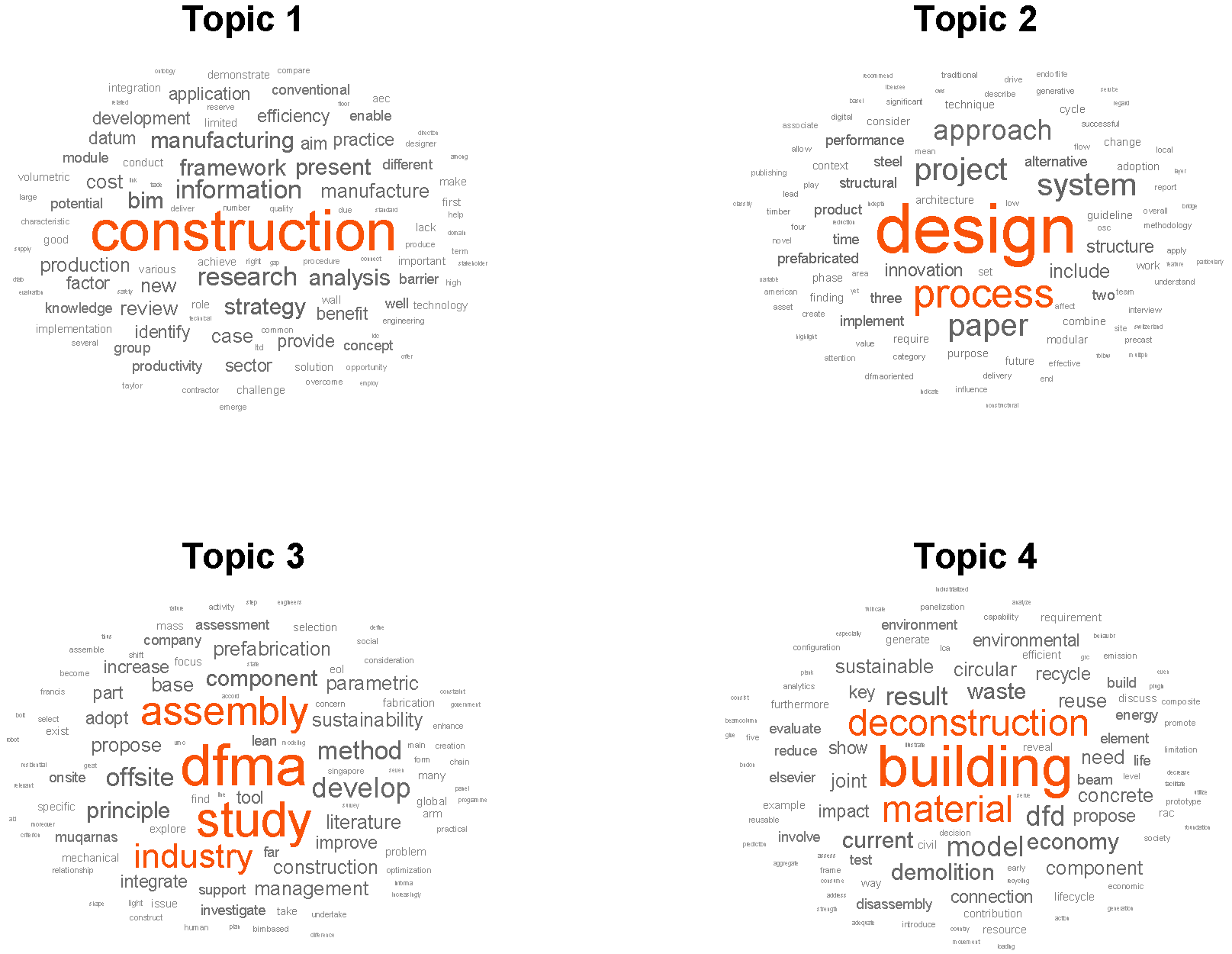

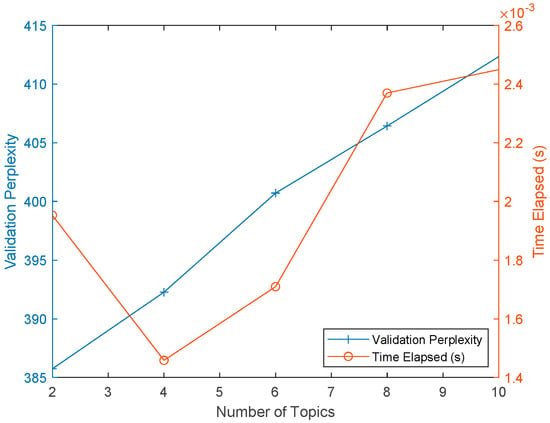

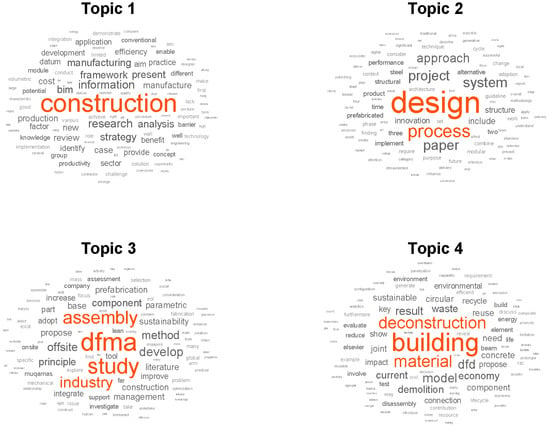

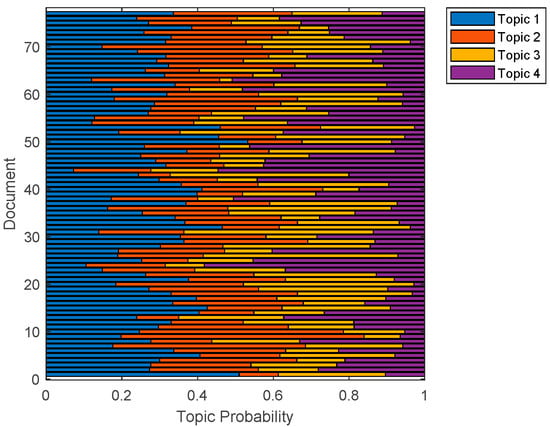

Figure 2 displays a word cloud containing the most frequently used words in the extracted documents. It provides an overview of the topics to be discussed. As can be seen, the most apparent words are “construction”, “design”, “DfMA”, “building”, and “study”, which verified the accuracy of the search terms used. Figure 3 provides the validation perplexity, which reveals how accurately a model explains a collection of documents [41]. The marks in the graph suggested that about four to eight topics would be suitable for the discussion. Hence, four topics were selected under which the studies’ subjects were categorized. Four topics were selected because this number was determined to be adequate for the review based on the themes and highlights of the studies identified. These specific topics are presented in Figure 4. Figure 5 displays the proportion of the topics in each document to help understand how these topics were generated. As can be seen, the topics were adequately distributed in all the documents. The corresponding interpretation of the developed topics is shown in Table 1. The first topic was interpreted to provide an overview of DfMA and DfD. This section introduces the development and background of DfMA and DfD. It also discusses the procedures implemented in employing these approaches. The two subsequent topics were easily comprehensible since “DfMA” and “deconstruction” were explicitly stated in the results. Hence, these topics were used to represent the principal discussion regarding the current state of DfMA and DfD in construction-related studies. Since the results generated can be given various interpretations, the last topic was chosen to emphasize the integration of DfMA and DfD in the construction industry. The selection of the studies under each document was based on the understanding and evaluation of the content of each article. After determining the topics, a qualitative review was undertaken as a basis for the discussion.

Figure 2.

Word cloud.

Figure 3.

Number of topics.

Figure 4.

LDA topics.

Figure 5.

Topic mixtures.

Table 1.

Topics for discussion.

3. Discussion

3.1. An Overview of DfMA and DfD

DfMA can be subdivided into two methods: design for manufacturing (DfM) and design for assembly (DfA) [7]. These methods focus on producing easy-to-assemble and cost-effective products without sacrificing output quality. The primary difference is that DfM focuses on fabricating individual components, while DfA emphasizes how these elements can be assembled [14]. The incorporation of manufacturing practices in the design stage can be dated back to the 1960s when several handbooks and guidelines were generated for assisting designers in adopting a manufacturing-centered approach [15]. One concern, however, was that these practices were only focused on the fabrication of components, and minimal emphasis was placed on the act of assembly. In this regard, the development of DfA was considered revolutionary because it reduced complexity, decreased the number of product components, and lowered costs [15]. However, despite the advantages provided by DfA, practitioners have asserted the importance of integrating it with another method that can be used to produce early component cost estimates and considers component fabrication challenges. Hence, DfA was combined with DfM to create a more comprehensive strategy.

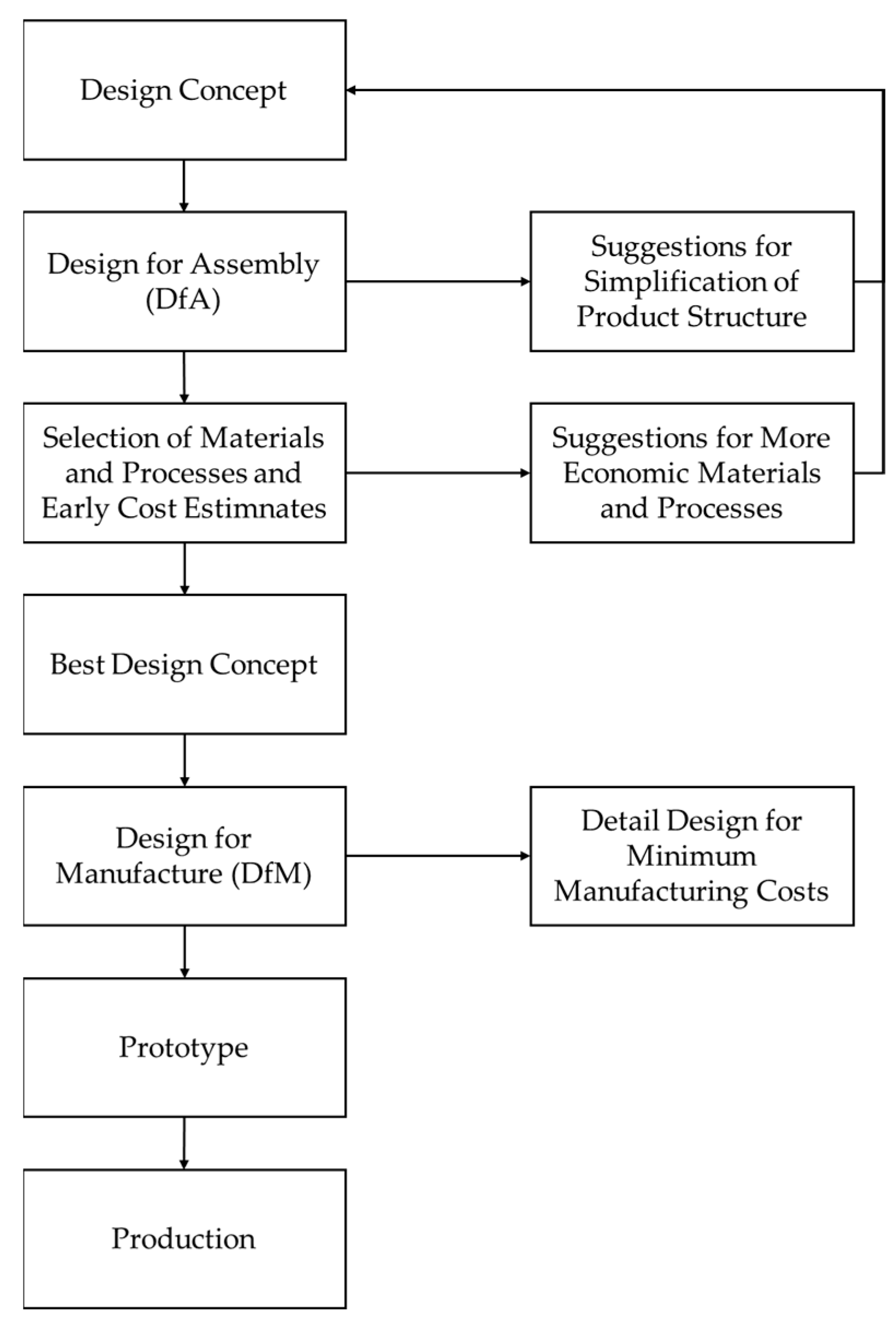

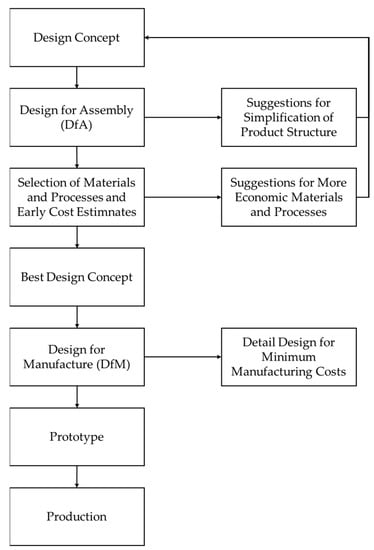

DfMA is a process, an evaluation method, and a technology [42]. It has been widely utilized since the 1980s to simplify product design and reduce manufacturing time and costs [43]. The primary procedures involved in DfMA are summarized in Figure 6 [15]. As can be seen, this method involves a collaborative decision-making process wherein all implementation-related activities are considered to simplify the product system and reduce possible expenses. The process commences by designing a product with the aim of easy assembly. In this stage, strategies are employed to reduce system complexity. The connections between parts are laid out, and installation procedures are planned. Afterward, the appropriate materials are selected, and the economic requirements are identified through cost estimation. This step is responsible for minimizing expenditures. Once the product’s structure has been simplified and optimized for cost efficiency, the optimal design can be determined, and the product components can be designed for manufacturing. Product fabrication commences after these steps and can be expected to demonstrate minimal issues because of the executed design approach.

Figure 6.

Typical DfMA procedure [15].

From the methodology stated, it can be inferred that employing the DfMA approach would prolong the design process because the designers and stakeholders would provide all necessary inputs during this step. However, incorporating this method can also optimize efficiency across all other procedures involved after the design phase, minimizing the overall production period. This effect has been observed in many studies. In a study involving a radiator and oil cooler design, the utilization of DfMA techniques resulted in a substantial reduction in the total number of components needed for the machinery and a significant enhancement in manufacturing productivity [44]. The study showcased the advantages of DfMA as the number of parts required was drastically reduced from 80 to 29. In a study conducted by Matthews et al. [45], DfMA was employed in the design of a paperboard tray press-forming prototype. The study’s findings revealed a 50% improvement in fabrication efficiency. Mitigating obstructed elements was also identified as an effective method to enhance productivity. Additionally, the benefits of DfMA for production efficiency were observed in the construction of a hybrid mass timber high-rise building in Canada [46,47]. Through a three-year case study, several process-based innovations, which included DfMA, were identified and incorporated into the structure’s construction. These process-based innovations enabled a more advanced structural system, enhancing efficiency and project delivery. It is evident from these studies that DfMA is an effective tool for facilitating production efficiency, supporting the efficacy of the provided workflow.

DfMA can be described as a multipurpose approach. It leverages the concepts of concurrent engineering and design-to-target value, which are common to lean management and digital fabrication, two contemporary methods for addressing existing industry problems [48]. In addition to fabrication efficiency, implementing DfMA provides a wide array of benefits. For instance, an integrated DfMA and lean manufacturing approach was proven to be highly effective in eliminating waste by-products while significantly reducing production time owing to the method’s capability to generate early cost estimates during the design phase [44]. An analysis regarding a prefabricated bamboo edifice revealed the applicability of DfMA in waste reduction and construction efficiency [13]. Moreover, an investigation on integrating pedestal fan fabrication with DfMA highlighted noticeable decreases in production time and costs and improved design efficiency [49]. These findings demonstrate the potential of DfMA in optimizing the fabrication process by reducing the accumulated waste and total costs. Moreover, it has helped to meet the demand for efficiently delivered, cost-effective, and high-quality products. Neve [50] described DfMA as a “potential medicine required to cure the symptoms of a deteriorating industry”. This statement was expressed in the construction industry context, wherein the sector was compared to a dying patient and DfMA was its medicine. The logic of this metaphorical connotation was attributed to the ability of DfMA to alleviate the concerns associated with conventional processes while enabling excellent production standards.

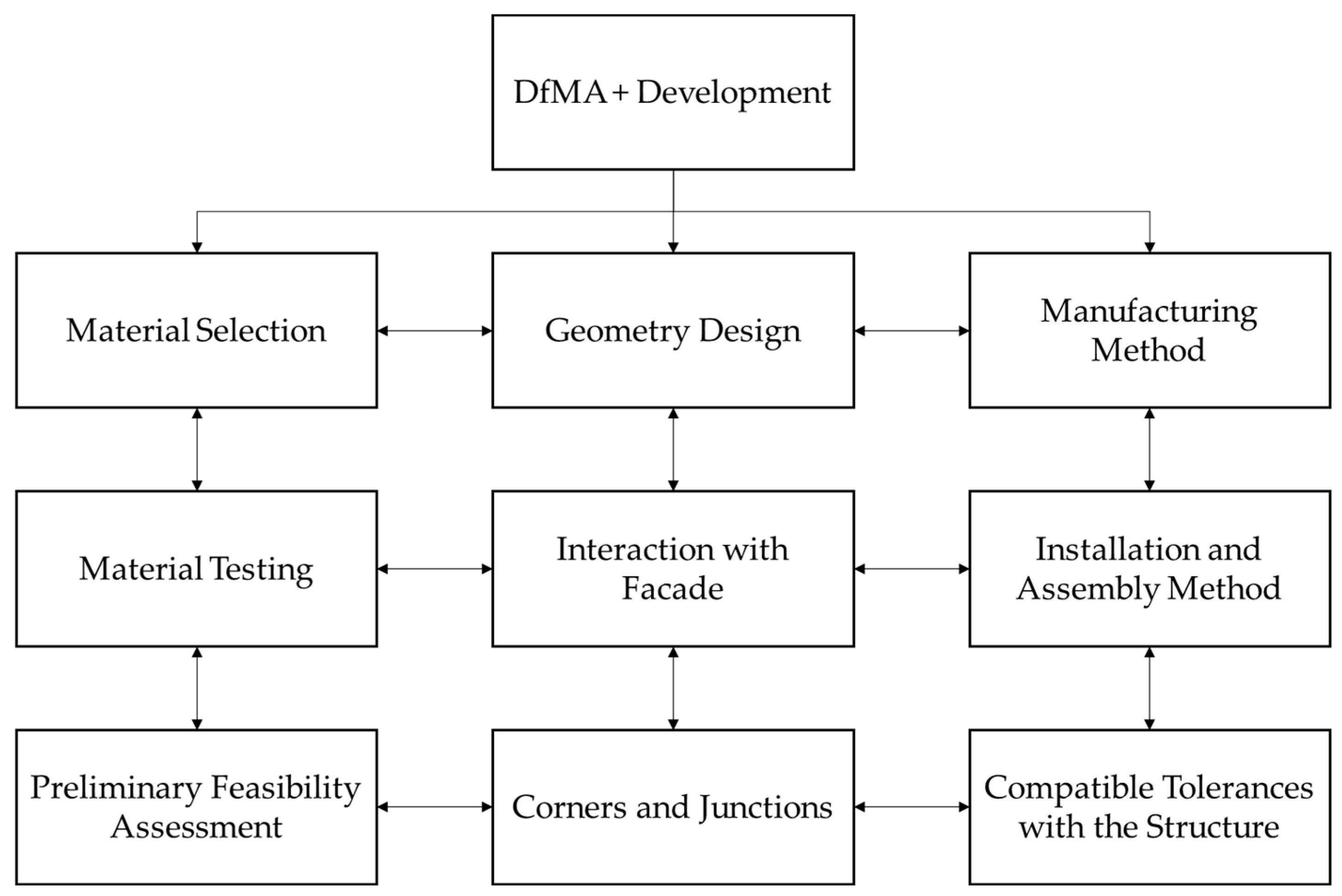

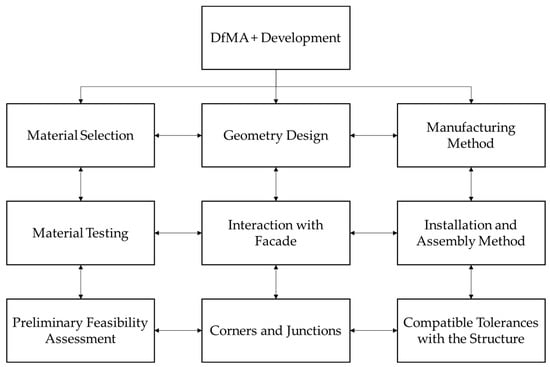

There are various methods through which DfMA can be employed in product fabrication. Some studies utilized DfMA techniques throughout the production process, while others merely followed a few of its concepts. The latter was evident in a study discussing the successful manufacturing of a robotic arm [51]. Although DfMA was not implemented extensively, the approach was explicitly applied and considered vital to the process. Notably, manual installation was avoided in the production of the robotic arm because the parts needed to be larger for handling. This practice was underlain by the DfMA criterion of ensuring easy assembly. This decision led to an adequate approach that improved the flow of installation. As mentioned above, some studies also utilized DfMA across the entire manufacturing process. A study by Orlowski et al. [52] employed numerous DfMA techniques for constructing weatherproof seals. The study focused on the weatherproofing of prefabricated elements, including panels and modules, to address the gaps in conventional methods. A flowchart was created to implement DfMA effectively, as seen in Figure 7. Although this framework was developed to be unique to weatherproof seals, it follows the methodology provided by Boothroyd [15]. As shown, the procedure focuses on the type of material to be used, technical product specifications, methods to be implemented, connections between components, and evaluation of the developed system. These steps all align and help to select the ideal product design concept. Furthermore, this framework addresses the typically encountered technical limitations and difficulties, resulting in optimized production execution.

Figure 7.

Developed DfMA flowchart [52].

Like DfMA, DfD is a design method that has gained a relative degree of prominence in engineering research. Its adoption is attributed to its connection with the circular economy concept. In recent years, there has been increasing interest in adopting circular economy practices. The approaches encapsulated in a linear economy, where raw materials are extracted to be transformed into market products and demolished at the end-of-life stage [23], remain dominant in the present world. This method significantly contributes to the increasing volume of waste found in landfills, leading to adverse environmental impacts. In contrast, a circular economy is a model wherein existing products are reused or recycled as raw materials to manufacture new products, prolonging these materials’ service lives [53]. Promoting this type of economy can eradicate the growing concerns in the present economy by focusing on material longevity and waste mitigation [54]. Hence, the adoption of this model is highly encouraged.

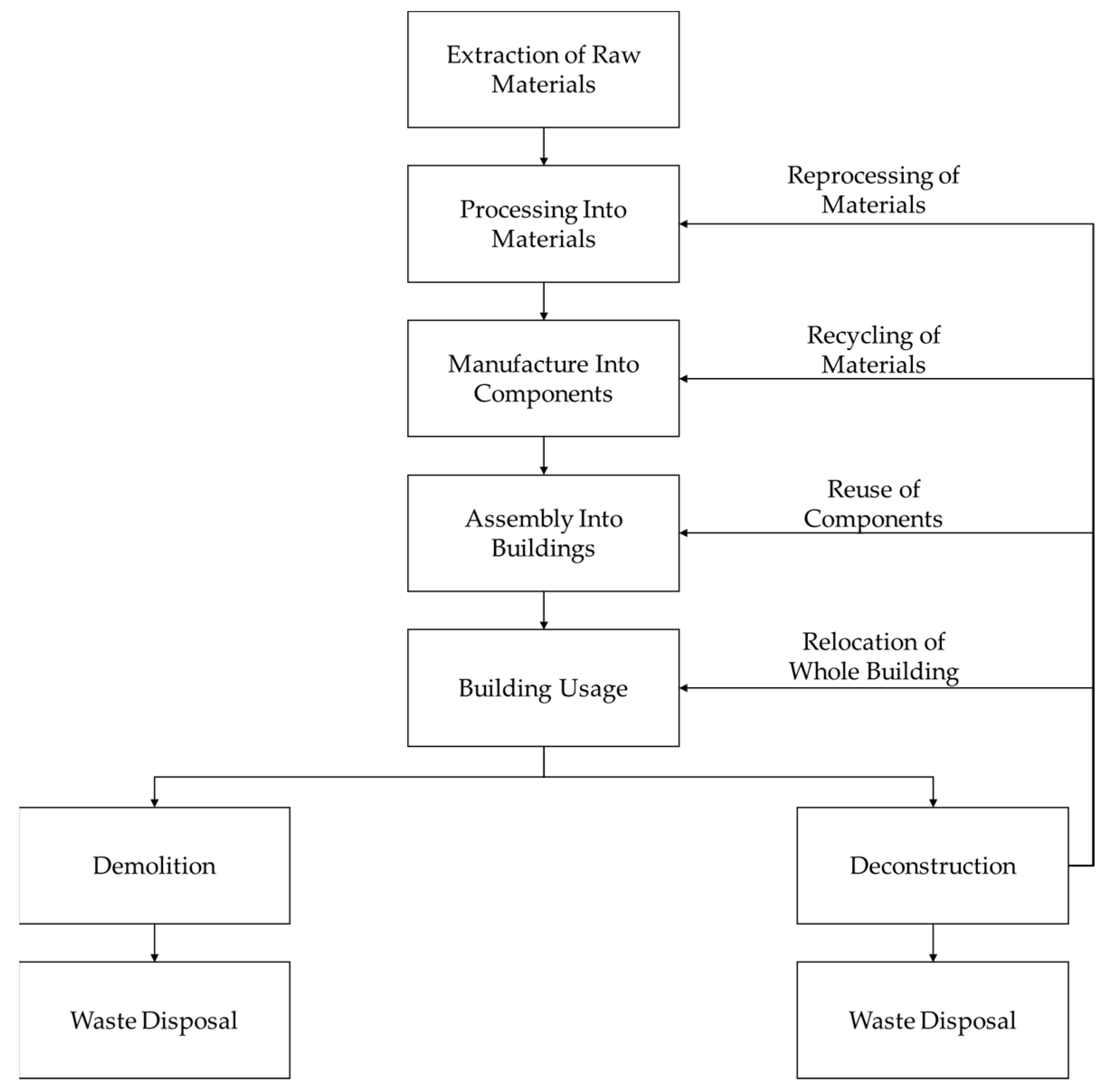

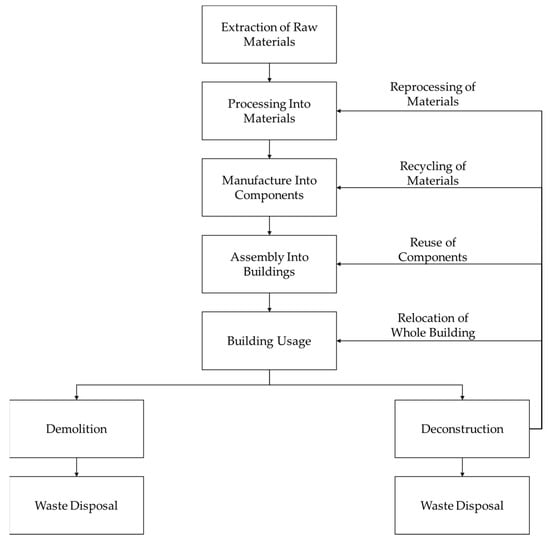

DfD was developed in terms of the circular economy philosophy as it provides a sustainable approach for future product disassembly [55] and, in the process, promotes reusability and recyclability as opposed to conventional demolition [56]. This continuous utilization of product elements after the initial usage would significantly contribute to preserving raw materials on the Earth’s surface. Figure 8 shows the difference between an end-of-life approach that uses demolition and one that utilizes disassembly. This flowchart was developed specifically for building construction. As observed, utilizing demolition only produces a single destination for the materials used; namely, waste disposal. Conversely, deconstruction introduces four additional alternatives, including reprocessing the materials, recycling the dismantled components for other structures, reusing the parts, and relocating the entire building for the same or a different purpose. These options encourage a sustainable built environment because they eradicate the need to restart the process every time a new facility is constructed, supporting the rationale of consuming less natural resources and reducing discarded waste by employing DfD.

Figure 8.

Building demolition and deconstruction end-of-life strategies [57].

3.2. DfMA in the Construction Industry

As established, DfMA is a method that considers manufacturing and assembly processes in the initial planning and designing stages to eradicate possible challenges and complexities that may be encountered during production, optimizing quality, time, and total costs [58]. It is similar to the concept of manufacturability analysis, in which the ability to manufacture a product effectively is measured and assessed [59]. This approach originated in the manufacturing industry [15] and has expanded to other sectors. In construction, several studies have examined the applicability of DfMA in different research areas. These studies encompass a vast range of subjects, such as the design of a prefabricated building through an integrated BIM and DfMA approach [60], the analysis of DfMA as a method for promoting construction standardization practices [61], and the construction of a prefabricated bamboo building [13]. To apply DfMA in the design stage, most studies stated the necessity of adhering to guidelines to ensure the method is adequately employed.

Many DfMA guidelines have been generated in past publications and used as a basis for succeeding studies. Prominent DfMA guidelines were developed and provided by Boothroyd [15]. Several construction-related studies [62] have used and referred to these guidelines for implementing DfMA techniques. Vaz-Serra et al. [8] presented a systematic and concise example of how these guidelines can be applied to design a prefabricated bathroom wet wall panel. The criteria employed include minimizing the number of components, designing for ease of handling, designing for ease of insertion, standardization of parts, designing for current process capabilities, and maintaining awareness of alternative process capabilities. DfMA was applied in the wall panel framing and hydraulic components by identifying the appropriate action for each criterion. For instance, for minimizing the number of parts criterion, the structural framing components that could be combined or eliminated were identified and the modifications were implemented in the construction phase. Building the prefabricated bathroom wet wall panel resulted in reduced construction time, incurred costs, and generated waste, thereby highlighting the effectiveness of the implemented guidelines.

Recently, studies have developed these criteria to produce more industry-specific guidelines. Table 2 presents the guidelines provided by Bogue [14] and their respective benefits. These benefits encourage practitioners to integrate DfMA in construction operations. These guidelines emanate from the guidelines provided by Boothroyd [15]. For instance, reductions in the number of fasteners and connections and their standardization can fall under the minimization of the number of components and the standardization of parts criteria. Specifying these additional guidelines prevents the designer from excluding other necessary methods that may be disregarded if not otherwise stated. However, despite the increasing uptake of DfMA and the continuous development of its respective guidelines, it is essential to note that most guidelines are intended for the manufacturing industry and lack a focus on implementation in construction projects, which may have resulted to a potential challenge because of the apparent differences between the manufacturing and construction sectors [63]. A study by Tan et al. [19] generated construction-oriented DfMA guidelines, including “context-based design, technology-rationalized design, logistics-optimized design, component-integrated design, and material-lightened design”. Context-based design refers to the environment where the structure will be erected. It considers the physical condition of the site and the culture of the community surrounding it. Technology-rationalized design highlights the prefabrication and craftsmanship that can be employed during construction. Logistics-optimized design tackles the enhancement of logistics processes during production. Component-integrated design comprises the effective selection and combination of building parts. Finally, material-lightened design encompasses the need for suitable material specifications and an efficient structural system to minimize the structure’s weight and achieve an optimal stiffness-to-weight ratio. These guidelines were created to cater to construction projects. However, these guidelines seemed to be more representative of themes than guidelines. Their application to construction projects need further examination by providing concrete instructions for employing DfMA practices. Nonetheless, these guidelines serve as foundation for solidifying standard DfMA criteria in future research works.

Table 2.

DfMA guidelines.

While there is a lack of construction-oriented DfMA guidelines, several studies have successfully applied DfMA, as exhibited in their findings. Table 3 outlines several sets of DfMA guidelines, their corresponding advantages, and the structures for which they were used in construction-related research. A study by Wasim et al. [7] used the DfMA guidelines presented by Boothroyd [15] to design a timber frame wall and plumbing drainage system. This study devised a MATLAB tool to estimate the theoretical assembly time and design efficiency when constructing each component through a DfMA-based approach. Through a comparison of cases in which the elements were built on-site and off-site, it was revealed that DfMA enabled the construction method to be three times more efficient than conventional approaches.

Table 3.

DfMA guidelines and benefits in construction-related studies.

A limitation of this research is the lack of practical application of DfMA, which is essential to verify the results from the calculations. While a theoretical study is suitable given that the correct formulas and parameters are used, the study could have benefitted from addressing how these computed values reflect a real-world context. Another observation is the method used to determine the theoretical minimum number of parts, as no criteria were provided to identify what constitutes the minimum requirement. The findings would be more comprehensive if other configurations were incorporated. Finally, critical parameters impacting the assembly and manufacturing times would have been also considered. While data were gathered from a local manufacturing company, it is essential to incorporate the effect of plausible delays to represent a more practical scenario. The innovative tool developed in this study can be further enhanced through a comparison with actual construction work in future studies. Other researchers should employ the same codes used in the MATLAB program for a fair comparison.

In contrast to the previous study, Chen et al. [64] adopted a more practical approach by incorporating DfMA into the design and construction of a curtain wall system. This curtain wall system was built on-site using DfMA. The design process, however, utilized slightly different guidelines from the work of Wasim et al. [7]. The DfMA procedures were modified to meet the project’s target objectives and the multidisciplinary team’s expert recommendations. Hence, the guidelines and approaches used were more unique to the project rather than based on what was previously developed. A significant discovery from the results was the substantial improvement in the correctness of execution. The usage of DfMA considerably reduced implementation errors, leading to decreased waste production and improved productivity. Furthermore, the typical 15 min installation of one curtain wall system unit was reduced to 8 min with DfMA. However, it must be pointed out that this improvement relied heavily on the expert opinion of the interviewed professional. The 7 min improvement in construction time was not tested. The study would have been more significant if it had introduced another curtain wall system unit that was constructed conventionally. In this case, the authors could have incorporated a more adequate evaluation by including a controlled setup. Nonetheless, the current study does not disregard the interviewee’s response and acknowledges the value of the professional judgment that was provided.

Extending the practical approach of the earlier study, Banks et al. [65] investigated a 40 story mixed-use development encompassing DfMA in the structure’s entirety. This study showcased the usage of DfMA through its application in actual construction. However, the principal difference was that the structure was erected before the study commenced. Hence, a case study approach was employed. The article stated that 72% of the structure’s frames and facades were prefabricated, and DfMA was comprehensively applied to the building project. By utilizing DfMA, benefits, including improved efficiency, reduced expenses, reduced waste by-products, and optimized safety, quality, and reliability, were observed across all aspects of the building facility, corroborating the previous studies’ findings. This construction project is an outstanding example of the application of DfMA in building structures. Similar to the earlier studies, while DfMA principles were adopted, standard guidelines were not utilized. In particular, the guidelines employed included reducing site activities, immediately identifying structural capacity, incorporating prefabrication practices, and standardization. These principles comply with some of the established DfMA practices, but it was mostly the project’s specific needs that were considered. There seems to be a trend among DfMA studies that integrate initially established DfMA principles with other guidelines relevant to the constructed structure. This trend may be justified by the dynamic nature of construction, wherein each project is unique. Hence, a “one size fits all” concept may not entirely apply to the development of DfMA guidelines. In this regard, a more suitable approach would be the generation of general construction-oriented DfMA guidelines based on the underlying themes of the construction process. Through this method, practitioners are given the option to incorporate specific guidelines they perceive to be relevant to a particular project from the general guidelines developed.

In addition to building members, another study by Kim et al. [66] discussed the suitability of precast bridge components for compliance with DfMA criteria. Unlike the previously discussed studies, this research did not utilize DfMA as a process. Instead, it affirmed the initially established definition of DfMA as an evaluation method. Through an interview with a senior engineer, precast components were selected in order to identify which would be adequate for bridge construction and applied in a case study. The sufficiency of these precast parts was based on the requirements of general DfMA criteria. In particular, the study explored their adequacy for connection specifications, components’ standardization, and manufacturing suitability. The case study revealed that the precast elements were feasible for constructing a bridge. However, as with the case of Chen et al. [64], only a single interviewee was involved. Despite the interviewee’s professional background, potential biases could have been reduced by conferring with other construction practitioners to substantiate the findings. Nevertheless, the study displayed the efficacy of DfMA as an assessment tool. This research area can be developed by extending the applicability of DfMA as an evaluation method for comprehensively assessing structures.

From the studies discussed, the advantages of DfMA are evident. However, the adoption of DfMA in construction is still in its infancy [63]. Techniques must be employed to promulgate DfMA uptake in construction. As such, two principal themes were identified in the collected studies: highlighting DfMA’s impact on productivity for practitioners and integrating it with modern technologies.

Emphasizing efficiency can be utilized to promulgate the adoption of DfMA. A frequent problem in building construction is the presence of constant delays, which substantially contribute to the accumulation of expenses and client dissatisfaction. Through a novel design assessment system, Gbadamosi et al. [67] revealed that construction professionals indicated the speed of on-site assembly as the most critical consideration among the examined assessment factors. In addition, a study by Shang et al. [68] suggested improved productivity as a possible way to maximize the adoption of prefinished volumetric construction, a form of DfMA. Accordingly, several studies have demonstrated the feasibility of using DfMA for improving the efficiency of construction processes [7,8,13,64]. For instance, a study by Wasim et al. [69] showed that incorporating DfMA in the production of a glass fiber concrete floor resulted in the construction time being 33.33% faster than for its traditionally manufactured counterpart. The positive impact of DfMA on productivity is apparent. Furthermore, none of the reviewed studies revealed a negative outcome of DfMA usage concerning construction efficiency. Hence, underlining enhanced efficiency would compel companies to espouse DfMA practices.

Other authors have integrated DfMA with emerging technologies to expand its usage. These technologies include modular integrated construction (MiC), virtual design and construction (VDC), the Internet of Things (IoT), building information modeling (BIM), prefabrication, smart construction [63], volumetric modular construction [70,71], additive manufacturing, and digital fabrication [27]. The integration of DfMA with these tools and technologies has been explored in various studies. Most investigated the applicability of BIM for enhancing DfMA. A study by Tan et al. [72] revealed that BIM could have three functions when integrated with DfMA: enabling the DfMA process, serving as a tool for employing DfMA techniques, and producing an information model for DfMA.

The first two functions of BIM have been discussed in several studies. For example, Alfieri et al. [73] verified the effectiveness of a combined BIM and DfMA approach by devising a six-level framework through an extant review of related literature to guide designers and planners. This framework was composed of the following stages: “Project Brief, Concept Design, Detailed Design, Pre-Construction, Construction, and Post-Completion” [73]. A case study applying this framework in an Italian kindergarten building revealed the successful implementation of DfMA with BIM. In this study, BIM was utilized as a tool to connect the downstream and upstream activities and achieve enhanced coordination among the stakeholders involved.

As an information model, research by Abrishami et al. [74] integrated the methods of DfMA, BIM, and prefabrication to generate a BIM component-based library to mitigate concerns in on-site construction, such as regarding inefficiency and inadequate quality. This library contained components for usage in construction. A two-bedroom house was successfully designed using this technology, and it can also be utilized for future disassembly of the structure. In this case, BIM enhanced DfMA usage by helping in developing and managing prefabricated components, thereby decreasing the time, costs, and effort associated with on-site construction. Therefore, BIM served as a support to accomplish the DfMA objective of enhanced efficiency.

In the two studies discussed, however, it can be observed that justifications were unclear to support successful execution. In particular, a control variable was not introduced to determine how the structures designed using the BIM and DfMA integrated technologies performed in comparison to conventional approaches. The definition of success in this context was limited to the ability to utilize the developed technologies. Such expositions do not disclose how efficient their performances are with regard to improving total expenditures, construction efficiency, and building quality. These studies demonstrated the feasibility of employing the technologies developed but not the effectiveness. The findings can be made more conclusive if compared with structures designed without the developed technology.

Moreover, there is a lack of integration between DfMA and other emerging technologies. For instance, additive manufacturing and digital fabrication are two innovative technologies that have gained relative traction among practitioners in recent years. Additive manufacturing is a method that transforms three-dimensional model designs into physically printed elements or parts [75]. It is typically interchanged with rapid prototyping and 3D printing [27]. Moreover, it has been investigated in several research studies. A study by Li et al. [76] indicated that the structural qualities of 3D printed walls, such as the microstructure composition and surface shape, might impact heat and moisture transfer and local heat-moisture risk. Research by Lim et al. [77] determined the possibility of concrete printing using additive manufacturing, which assisted in achieving design flexibility, accurate manufacturing, and minimization of complex labor work. Reducing manual labor can drastically reduce the time required and costs incurred. Hence, integrating DfMA with additive manufacturing could substantially enhance the fabrication process and further optimize current construction practices.

In addition to the earlier findings, other studies produced innovations by consolidating BIM and DfMA. Bakhshi et al. [78] developed a novel BIM-based DfMA framework that considers customer participation in the design process. The BIM-based algorithm incorporates the clients in tailoring the structural members’ designs according to their preferences without requiring engineering expertise. This approach ensures that client satisfaction is achieved at the conceptualization stage. Research by Liu et al. [79] produced a BIM-enabled framework for building panelization wherein an automated panel system was developed. The system allowed the immediate selection of panel designs and evaluated these alternatives to determine the ideal option. This method substantially improved design efficiency as time consumed during decision making was dramatically reduced. Gbadamosi et al. [67] developed a design optimization system that used the principles of DfMA for evaluating construction materials and was integrated with BIM. This system compared building envelope materials, including precast concrete, brick, prefabricated exterior insulation and finish systems, and concrete blockwork. The design optimization system revealed that the prefabricated exterior insulation and finish system demonstrated the best ease of assembly and installation speed. Similarly, Tan et al. [80] generated a BIM-enabled multi-criteria decision making (MCDM) method to conduct a sustainability assessment of parametric facades. This tool allows stakeholders to efficiently select the most sustainable facade option during construction, which could help promulgate widespread off-site customization. Furthermore, Kalemi et al. [81] devised an ifcOWL-DfMA ontology, an application that implements a manufacturing costing strategy to categorize cost data while capturing the application’s production process. This application was applied to a wall panel system. This program gives decision makers more detailed information that promotes taking corrective measures to mitigate costs, thereby reducing mistakes during construction. Overall, these cases support the potential of BIM-based DfMA approaches to provide access to new routes toward an optimal building design methodology. They have introduced new methods that were previously unseen in construction. For instance, customer involvement in the design stage is a pioneering practice that could revolutionize the sector.

While the studies mentioned offered valuable inputs regarding the integration of BIM and DfMA, it is essential to point out that they have some limitations. For instance, some studies focused solely on a specific parameter, such as material selection and sustainability assessment, instead of a more comprehensive approach. Furthermore, the studies heavily relied on simulations rather than the actual construction. It is unclear if complexities and challenges typically encountered in practical situations were captured. Nevertheless, these studies revealed the potential of adopting an integrated BIM and DfMA approach to improve utilization, productivity, and sustainability. More studies and construction projects are required to fully acknowledge the problems in a real-world environment.

On the question of recent developments in terms of construction type, DfMA usage is particularly prevalent in off-site construction (OSC). OSC is a modern construction approach that shifts the building process from the actual construction site into a regulated factory setting [82]. Moreover, it adheres to the principles of DfMA [61]. In fact, a study by Cooper [83] interchanged the concept of DfMA with prefabrication.

Several authors have expounded on the application of DfMA in off-site construction. Hyun et al. [84] developed a DfMA-based design methodology, which was corroborated through a case study in which more than half of the reinforced concrete members of a structure were replaced with precast concrete. Considerations were determined based on the structural and architectural designs. Results revealed decreases in construction time and execution mistakes. However, the study did not take into account the design’s mechanical, electrical, and plumbing (MEP) aspects. Although only the structural design primarily required the OSC technology employed, incorporating the MEP design may have significantly affected the study results, as it is a primary requirement for most construction projects.

In a study by Tan et al. [13], DfMA was employed to design a prefabricated bamboo building. A designer-led DfMA approach was executed that followed several guidelines, such as the selection of the appropriate materials and components, reduction of waste, and maximizing productive activities. As expected, efficiency, quality, and waste mitigation were optimized. The project’s contractor mentioned that the construction process would have taken two weeks more without DfMA. However, similarly to the previously referenced studies, the claim for enhanced productivity relied on a single professional’s assessment. No comparisons were made with other structure prototypes constructed without DfMA. Furthermore, in contrast, the study by Banks et al. [65] mentioned earlier employed a contractor-led DfMA approach. While these two studies showcased positive findings, a DfMA approach involving a complete multidisciplinary team may provide better results, as this method would enable improved collaboration among different stakeholders.

Similarly, in an article by Yuan et al. [60], the design of prefabricated buildings was explored using a DfMA-based parametric design approach instead. As opposed to the conventional parametric design process, the DfMA-oriented parametric design process incorporates split design analysis and DfMA analysis, takes into account the needs of the manufacturing and assembly stages, creates a standard parametric precast component library using the re-development and family template from BIM, and improves the BIM functions required by precast component assembly using re-development technology. The prefabricated building was successfully designed, but the authors recommended further improvements to the approach. Similar to the previous studies, this technology requires practical applications to gauge its efficacy in an actual construction project.

3.3. DfD in the Construction Industry

DfD is a method that incorporates the deconstruction and disassembly approaches in the design phase. It is a prominent strategy for fostering a circular economy [3]. In recent years, the accumulation of waste in landfills has presented itself as a growing concern that must be addressed. A substantial portion of global waste originates from the construction industry. According to Tafesse et al. [85], the five most significant impacts of construction waste, in order, are increased costs, worsened pollution, decreased profits for and possible failure of construction companies, unnecessary extraction of natural resources, and dangers to public health and safety. In addition, 75.71% of construction companies lack a waste management professional [85]. Despite these concerns, the construction industry must remain active because countries’ economic growth substantially relies on construction projects [85]. Thus, studies have recommended changing focus from conventional demolition practices to deconstruction as a more sustainable alternative [86].

Xu and Lu [20] argued that waste management should not be addressed after beginning construction. Instead, construction waste must be handled immediately at the design stage. Osaily et al. [87] supported this statement by mentioning that a demolition contractor must coordinate with the designers before constructing a building. This sustainable practice can be incorporated into modern construction by implementing DfD. To promote DfD usage, guidelines that construction practitioners can adhere to are critical. Table 4 shows construction-oriented guidelines collated from different sources. To properly employ DfD, a building system should be simplified, appropriate materials should be used, and relevant deconstruction information should be readily available. These principles would enable fair DfD usage in construction. Through the integration of the planning stages with DfD, the unimpeded production of construction and demolition waste can be eradicated [88]. Moreover, as seen in Table 4, many of the collated guidelines can apply to DfMA, particularly the criteria for the simplifying building systems and materials and connection themes.

Table 4.

DfD guidelines.

Drawing from these deconstruction principles, specific DfD guidelines have also been generated. A study by Broniewicz et al. [91] emphasized the effectiveness of steel as a material that can be deconstructed because of its sustainable characteristics, such as the minimal waste produced, its reusability, and of its applicability for dry construction. In this regard, Lu [90] provided several DfD guidelines for application in cold-formed steel structures and listed their consequent effects as ease of disassembly, increased reusability, and optimized safety. These guidelines include the following:

- Design of reversible connections;

- Utilization of demountable fasteners and elimination of adhesives;

- Ease of access to connections using tools at the disassembly stage;

- Simplification and standardization of shapes and connection details;

- Reduction in the number of connection elements;

- Reduction in the variety of member sizes.

These guidelines, however, are intended for cold-formed steel structures. No policies have been generated for hot-rolled steel structures and other construction materials. Nevertheless, the provided guidelines are general enough to be implemented for buildings made of conventional steel. These guidelines could be further explored in construction-oriented studies examining DfD for structural and non-structural steel elements.

There have been several developments in DfD research. Table 5 presents the studies that have explored the application of DfD in different structures and elements. These studies primarily focused on designing building materials and connections that can be readily disassembled at their end-of-life stage. A study by Ding et al. [92] furnished a novel concrete beam-column joint design with DfD connections. To evaluate its behavior against seismic loads, seven full-scale joint samples were subjected to two-series cyclic loading tests. Results showed that the designed joints performed reasonably under seismic conditions and exhibited ductile behavior. Furthermore, it was evinced that the developed joints could be easily deconstructed. Xiao et al. [93] extended this research by identifying the impact of recycled coarse aggregates on beam-column joint design. Minimal adverse effects were revealed at the final loading application when these aggregates were added to the joint, and its performance was considered allowable, showing adequate durability. Wang et al. [94] conducted an experimental study that revealed the feasibility of applying DfD on a composite beam design built with precast concrete planks and clamping connectors. The composite beams exhibited ductile behavior with minimal post-peak strength degradation. Minimal yielding was detected when the beams were subjected to full-service loading. Nevertheless, minor adjustments to the beams through straightening were expected at the deconstruction stage. Similarly, Cai et al. [95] conducted an experimental study to test the performance of DfD bolts in three concrete blocks under cyclic conditions subjected to compressive forces. The findings raised numerous issues, including failure modes, the negligible structural benefit of staggered bolts, and bolt slippage and rotation. The design could be improved by utilizing high-strength bolts, tightening bolts during assembly, and adequately placing reinforcements to allow stirrups to assist bolts in supporting the loads. These studies showcased the plausibility of designing building components for deconstruction. They also help to promote proper construction waste management using recycled materials, such as coarse aggregates. Hence, developing these materials would also promulgate the use of sustainable practices while being demountable. However, evaluations of these connections are limited to the structural element being examined. For instance, in the study by Ding et al. [89], the developed connection only applied to beams and columns and was not tested for the slab. These connections could be studied further by building panels and structures. Another observation is that none of these elements were directly incorporated into comprehensive structural systems. A relatively small body of knowledge addresses the actual usage of DfD in construction. The scope of these studies was more focused on the development of components rather than the construction process. As established earlier, DfD is intended to address the end-of-life stage of construction. While the properties and behavior of these components were observed, the findings were limited because of the lack of application in the construction of structures.

Table 5.

Summary of DfD studies.

A study by Leso et al. [96] attempted to address this gap by examining the applicability of DfD in a barn built for dairy cows. This study implemented several DfD techniques, such as using dry construction by reducing concrete usage, simplifying the building system, using locally sourced timber with steel connections, and including recyclable materials for the housing architecture. After several years, the designers revisited the barn and no substantial deterioration was noticed, indicating the effectiveness of the employed DfD approaches. Even so, the guidelines utilized in this study were non-exhaustive as they seemed to be explicitly developed only for this project. Furthermore, the study’s interpretation regarding the successful application of DfD overlooked the necessity of determining whether or not the structure could be deconstructed. While it was not directly mentioned, a plausible reason for this was that the barn was still operational during the visit. Hence, the authors could not disassemble it into its individual components. This issue serves as a challenge to DfD researchers due to the long life span of buildings. Typically, the service life of a building is 60 years [97]. However, waiting for such a long time may lead to inefficient progress in DfD research. In this regard, future studies should develop methods to observe whether a building can be deconstructed at its end-of-life. For instance, studies could look into the utilization of recycled materials from previous structures to build novel prototypes to observe their behavior when they are disassembled. Furthermore, utilizing simulations and virtual models would be an excellent method to predict the demountability of a structure. This method was exemplified in a study by Basta et al. [98]. In this research, BIM was employed using Autodesk Revit to develop a deconstructability assessment scoring system. This technology enabled the authors to assess if a steel structure could be deconstructed without waiting until its end-of-life phase. Studies can leverage modern tools to evaluate whether or not a structure can be disassembled.

Other authors have explored other applications for DfD. A study by Zoghi et al. [86] generated an effective way of selecting the most suitable construction material among a given set of alternatives based on DfD factors. The questionnaire results assessed through the integrated fuzzy-AHP and TOPSIS method revealed precast gypsum board to be the best-performing material among the presented options. This study provides a material selection framework for the construction industry considering deconstruction at the end-of-life stage. DfD can also be integrated with emerging technologies. Akanbi et al. [56] devised a system incorporating deconstruction processes in BIM to optimize material reuse and recycling and waste management and enable efficient use of natural resources. Likewise, Marzouk et al. [99] produced a BIM plug-in tool to input deconstruction practices into building design. For architectural design, Iuorio et al. [100] designed a tessellated shell that employs DfD, resulting in a structure that can be quickly assembled and disassembled.

Despite the justifiable arguments in favor of implementing DfD, it remains underutilized among construction practitioners, and buildings designed for dismantling are scarce [31]. Relevant studies by Tleuken et al. [101] and Akinade et al. [88] identified the barriers to the adoption of DfD in the context of Central Asia and the United Kingdom (UK), respectively. Even though these studies do not comprehensively reflect the global market, they provided critical highlights for advancing the use of DfD techniques in building construction.

From the perspective of Central Asia, the study by Tleuken et al. [101] found that the economic aspect highly influences DfD uptake since applying deconstruction may increase initial building expenditures. As such, the study recommended that stakeholders view costs across the entire building lifecycle to obtain a more sensible understanding of the benefits of DfD from a financial standpoint.

In the UK context, Akinade et al. [88] identified five significant factors affecting DfD adoption: “stringent legislation and policy, design process and competency for deconstruction, design for material recovery, design for material reuse, and design for flexibility”. This study concluded that the development of policies, such as including DfD in sustainability guidelines, is also a key parameter to promulgate DfD uptake, and it is equally essential as the design aspect. Hence, legal and design requirements were deemed the most critical aspects of DfD acceptance. However, this study also agreed with the financial aspect’s importance in promoting DfD usage. Hence, despite the studies by Tleuken et al. [101] and Akinade et al. [88] being carried out in the context of different regions, they arrived at the same conclusions regarding the necessity of addressing the economic aspect of DfD, which may present global implications. Further studies taking this variable into account are necessary.

In addition, Akinade et al. [88] pointed out the importance of allowing demolition engineers to participate in the design phase for considerations of the end-of-life phase in the decision-making process. Along the same lines, Casini [102] subsequently argued that the differences between decisions made at the design and end-of-life stages in building construction are a major hindrance to DfD adoption because of the significant gap between the two phases. Hence, the involvement of demolition engineers would allow stakeholders to amalgamate these differences by anticipating plausible decisions to be made during the disassembly phase. These findings indicate that widespread DfD uptake is a multifaceted subject that cannot be wholly achieved by merely presenting its advantages to industry practitioners. Currently, there is a need to promulgate DfD approaches in the global market and identify how this objective could be accomplished based on the identified barriers.

3.4. Integration of DfMA and DfD in the Construction Industry

Sustainability is defined as “meeting the needs of the present without compromising the ability of the future generations to meet their own needs” [103]. The circular economy was proposed to support sustainable development. Charef et al. [3] indicated that the adoption of sustainable approaches is a critical method to promulgate the circular economy. These sustainable approaches include the DfX methods. Among the primary DfX methods, DfMA and DfD are lifecycle approaches that could provide holistic perspectives on the circular economy [104]. Hence, in addition to addressing critical lifecycle stages, these methods similarly enable circularity in the built environment.

A key factor related to using DfMA and DfD to enable the circular economy is the preservation of material conditions. The lifespan of structural elements is typically longer than the service life of the whole structure [105]. Utilizing DfMA and DfD has the potential to extend material service life. DfMA enables the components of a structure to maintain excellent quality throughout its lifecycle stages. DfD ensures that these elements are suitable for disassembly at the end-of-life stage. Concerning these approaches, Boothroyd et al. [106] introduced the idea of integrating DfA with DfD as early as 1992, when DfA had not yet been combined with DfM, to propagate an economy centered on recycling. In this context, it is essential to note that the author who proposed this idea is the same one who developed DfMA. However, while extensive research has been carried out on the individual applications of DfMA and DfD, there are limited studies which attempted to integrate these design methods for fabricating products. Studies appear to support the plausibility of integrating these methods but do not execute the aforementioned integration. For instance, it has been argued in several studies that a primary motivation for investigating the modularity of mass timber structures in current studies is due to the possibility of incorporating it with an integrated DfMA and DfD approach [21]. However, little to no studies have been undertaken to execute this idea. This finding is somewhat unexpected given that several studies have indicated the similar potential of these methods for tackling sustainability concerns [3,74].

For instance, several studies support the capability of DfMA and DfD to promote environmental sustainability. DfMA research centers on waste eradication. In industrialized building systems [26] and volumetric modular construction [70], DfMA enabled construction waste reduction and dematerialization. In a study by Bakhshi et al. [78], a BIM-based DfMA tool was developed that reduced the total amount of waste generated. With the DfMA tool, fewer design revisions were needed since clients directly participated in the initial decision-making process. A study by Yazdi et al. [107] developed an original mathematical model based on a genetic algorithm to promulgate the mass customization of structural walls made of cross-laminated timber. The developed system followed the principles of DfMA, and the eradication of material waste was identified as one of its guidelines. Through the framework, the waste produced was substantially reduced compared to a production approach without the DfMA-based tool. A study by Fatima et al. [62] improved the design of an angle grinder using DfMA. The DfMA approach resulted in component reduction and design simplification, which correspondingly reduced the amount of accumulated waste. In another study, DfMA was included in the design phase before constructing a wall panel, substantially reducing accumulated waste [8]. Although DfMA is mainly intended for efficiency improvements, these studies show that researchers have adapted it to more sustainable approaches by employing waste management as one of its primary purposes.

DfD research also emphasizes the environmental dimension. In a study involving the lifecycle assessment of concrete structures, utilizing DfD resulted in an environmental benefit 1.8 to 2.8 times greater than a structure without DfD [108]. A study by Ortlepp et al. [109] examined the effect of DfD in relation to the removal of chemical bonds in building connections. Through this dry construction technique, material recyclability was enhanced. Eckelman et al. [110] evaluated a novel DfD flooring system. The results revealed that the DfD flooring system appeared to be a more environmentally beneficial alternative than conventional flooring systems when the components were reused. If components are subjected to three reuses, the adverse environmental impact of traditional flooring systems would be mitigated by around 60% to 70%. Cai et al. [111] and Jayasinghe et al. [112] developed material and component banks through BIM for storing deconstruction information. In addition to efficiently collecting disassembly knowledge, material and component banks can transform non-DfD structures into DfD structures by redesigning the parts and connections of the former, thereby highlighting a solution for waste management for conventionally built structures.

These design methods’ similar function of enhancing waste management is also a key highlight, especially for regions that suffer from poor construction waste management. For instance, although the Philippines had a policy for proper waste management under the Solid Waste Management Act in 2000 [113], the country lacked adequate governance to implement the established waste management guidelines [114]. Hence, incorporating these methods can aid in enhancing local waste management.

The studies suggest that DfMA and DfD are effective methods for promoting sustainability. While there is a growing body of knowledge that supports the usage of DfMA and DfD for addressing sustainability concerns in construction, there is a lack of research evaluating the sustainability of structures built using DfMA and DfD. Hence, a natural progression of this work would be the uptake of sustainability assessment methods for analyzing structures designed using DfMA and DfD. Together with the similarities in the objectives, guidelines, and findings from the earlier studies, DfMA and DfD can be promulgated in construction by highlighting their impact on sustainability and their benefits for a building’s lifecycle stages. Currently, very little can be found in the literature on this subject. Therefore, it is necessary to explore the integration of DfMA and DfD as a novel approach in the construction sector for enabling sustainable development.

4. Research Gaps and Challenges

In reviewing the literature, it was found that there is an escalating interest in the adoption of DfMA and DfD in the construction industry. However, several challenges remain unresolved. The identified research gaps are as follows: (1) development of standard construction-oriented DfMA guidelines, (2) corroboration of the developed DfMA tools through practical application, (3) integration of these holistic design approaches with emerging technologies, (4) comparison of structures constructed using DfMA and DfD with structures built with conventional approaches, (5) comprehensive application of DfD guidelines on structural systems, (6) integration of DfMA and DfD, (7) execution of sustainability assessment studies to evaluate the impact of DfMA and DfD, and (8) identification of solutions to the barriers to DfMA and DfD uptake in construction.

4.1. Standard Construction-Oriented DfMA Guidelines

This study found a lack of standard DfMA guidelines intended for construction projects. Present guidelines [14,15] come from the manufacturing industry. However, the differences between the construction and manufacturing industries can result in the inadequate implementation of these guidelines [63]. Construction-oriented DfMA guidelines presented in current research [19] can still be made exhaustive. In addition, the specific methods for employing these guidelines are vague [115]. Furthermore, it was also observed that DfMA studies in construction [7,8,64,66] utilized different criteria depending on the element being designed, although similar principles were adhered to. For instance, Chen et al. [64] included waste reduction as a DfMA criterion, while Vaz-Serra et al. [8] did not. Hence, a “one size fits all” notion may not be adequate for developing standard guidelines. As such, standard construction-oriented DfMA guidelines do not need to be very specific. They should be suitable enough to address the underlying themes in the construction process while providing practitioners with the liberty of generating the particular guidelines needed for each unique project.

4.2. DfMA Tools in Previous Studies

Prior studies developed modern tools for improving and evaluating the applicability of DfMA. Despite the promising results of these studies, the interpretations of the findings suffer from a lack of consideration of practical scenarios. The challenges encountered in actual construction projects are not considered in some studies. Hence, these tools could be utilized in future research and verified compared to real-world execution.

4.3. Integration with Emerging Technologies

The present study discovered that DfMA has been integrated with emerging technologies. However, all the studies reviewed focused on using BIM as a tool for supporting DfMA and as an information model. While BIM has been proven to be an effective tool for the general application of DfMA, current research does not take into account other existing technologies, such as digital fabrication and additive manufacturing. A focus on other contemporary technologies could produce interesting findings that account for more innovative practices in the construction sector.

4.4. Comparison of DfMA and DfD with Conventional Methods

The current study found many studies examining the efficacy of employing DfMA and DfD approaches to enhance the construction process. However, a significant drawback of these studies was the lack of comparison with conventional methods. While studies have demonstrated the possibility of using DfMA and DfD to design or construct a structure, these findings do not fully explain the effectiveness of DfMA and DfD without a control variable to compare their performance with. For instance, although an integrated BIM and DfMA approach was proved to be helpful in successfully constructing an Italian kindergarten [73], this conclusion must be interpreted with caution since its construction was not compared to another scenario in which BIM and DfMA were excluded.

4.5. Application of DfD for Structures

In DfD research, several guidelines specific to the construction industry [18,57,85,86] have been developed. However, similar to DfMA studies, different criteria are utilized for each unique structure. Additionally, minimal studies encompass the extensive application of these guidelines to comprehensive structural systems. Current research can be extended by tackling the use of the guidelines stated in this study to construct buildings and other structures.

4.6. Integration of DfMA and DfD

The present study identified that DfMA and DfD similarly address critical construction project lifecycle stages. Whereas DfMA deals with the construction process, DfD tackles the end-of-life phase. Studies regarding sustainability and the circular economy propose integrating these approaches since both address the critical concern regarding waste produced by the construction sector. There are several possible explanations for this challenge. A potential argument is that different stakeholders are involved in the construction and demolition stages. In addition, as mentioned, a building typically has a long lifespan [94]. Thus, the designers and contractors involved in the construction phase may not be present at the end-of-life stage when decisions regarding deconstruction are relevant. Furthermore, although DfMA and DfD integration was proposed a long time ago [106], the development of DfD is still relatively new and under research [111]. Hence, it will take some time to integrate it with other design methodologies.

4.7. Sustainability Assessment of DfMA and DfD Structures

Another finding was that DfMA and DfD are often described as sustainability approaches because of their respective benefits with regard to waste mitigation, a critical concern in the construction industry. However, most of the research regarding DfMA and DfD do not evaluate the sustainability of structures utilizing these design approaches. It is imperative to evaluate these structures to fortify the rationale of DfMA and DfD as sustainability methods and to promote these methods’ integration further.

4.8. Barriers to Adoption of DfMA and DfD