Production of Large-Sized Ceramic Stones Based on Screenings from Waste Heap Processing Using the Technology of Stiff Extrusion for Molding Products

Abstract

1. Introduction

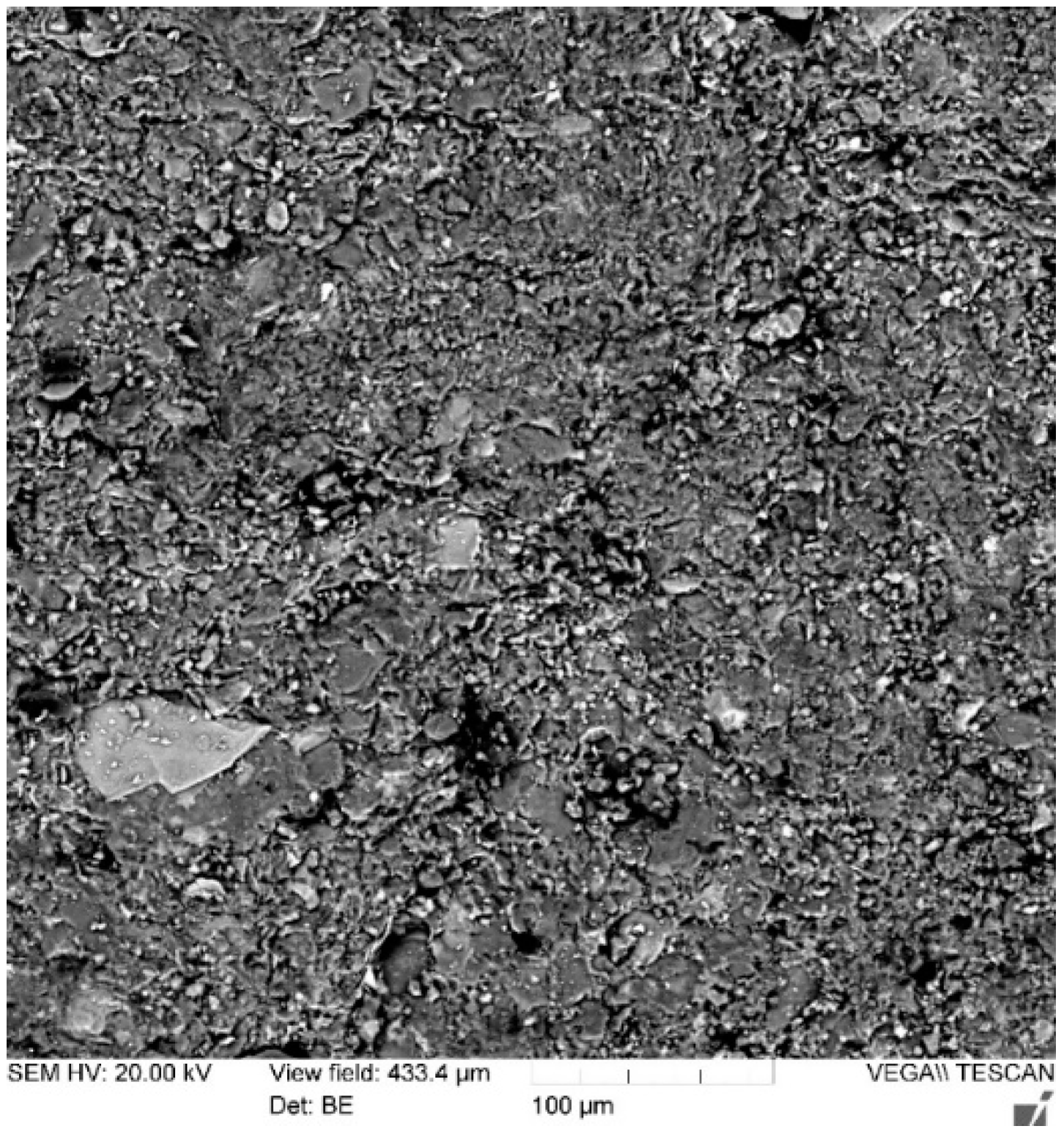

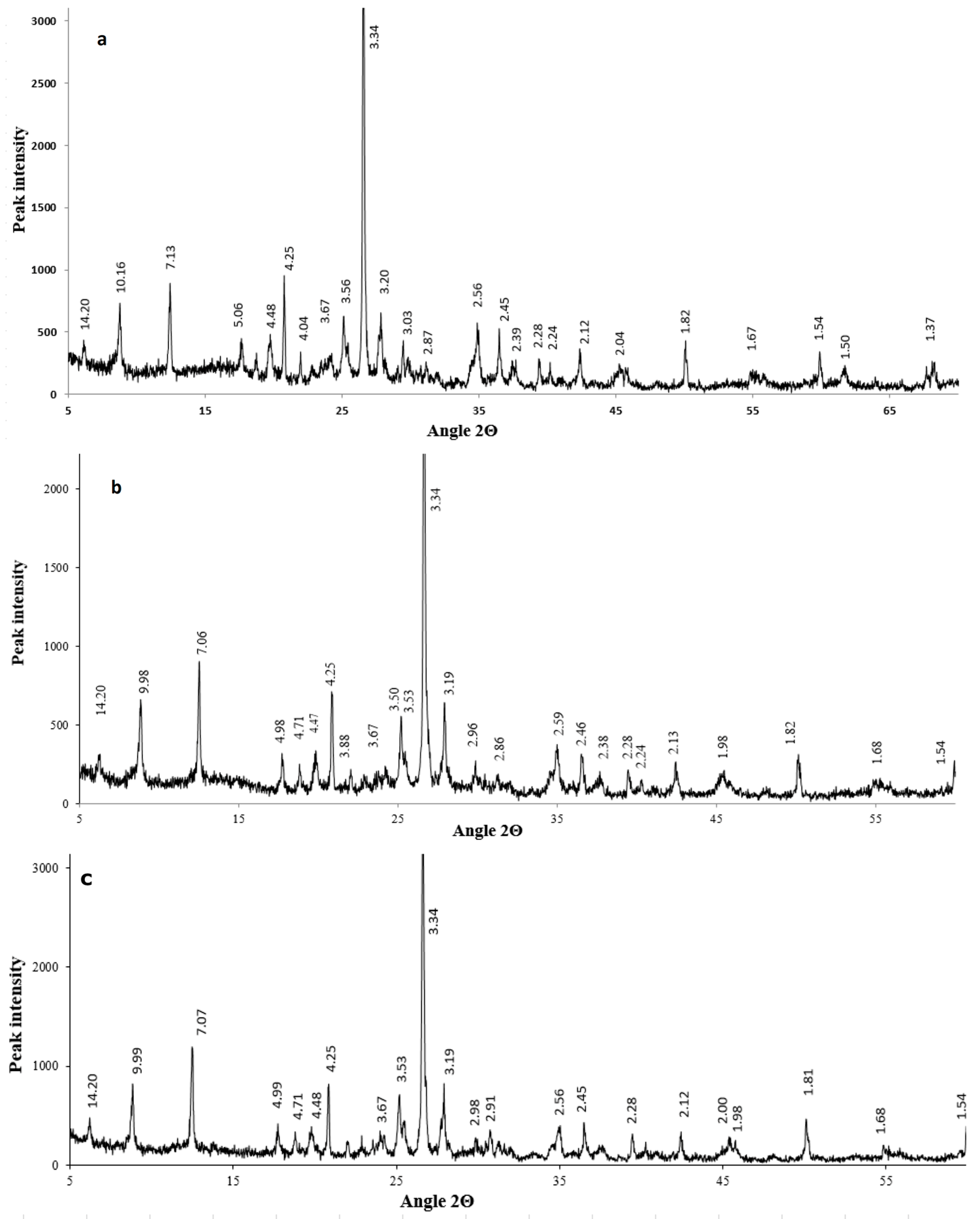

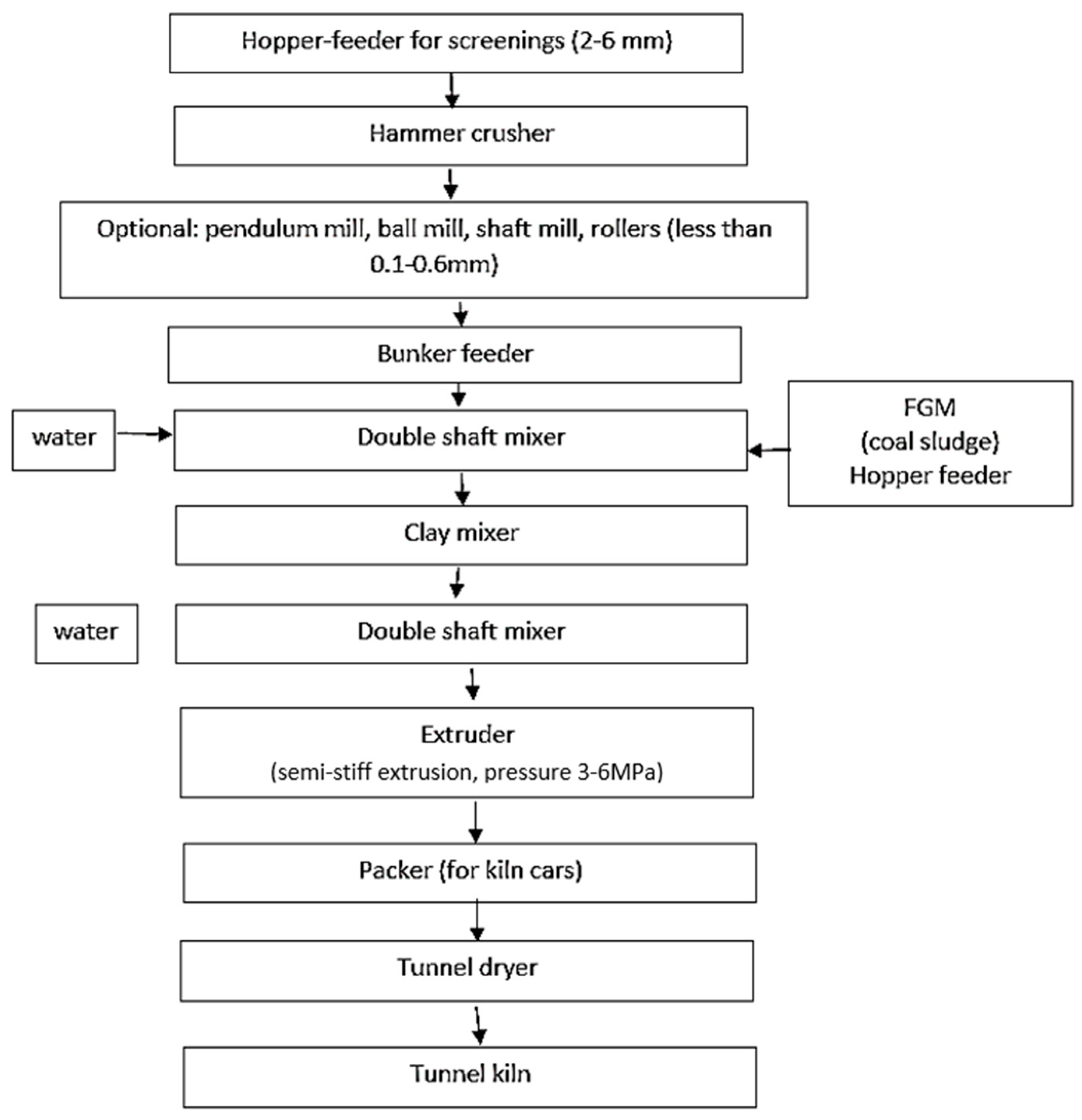

2. Materials and Methods

- Determination of structural features, chemical and mineralogical composition;

- Study of pre-fired ceramic properties using plastic and compression-molding methods in relation to plastic and low-plastic stone-like raw materials;

- Study of firing ceramic properties;

- Selection of raw materials with testing of laboratory samples;

- Characteristics of finished products, establishing relationships, determining the influence of various technological factors on them;

- Development of primary technological production schemes.

- Pore-forming, reducing the thermal conductivity and density of products;

- Plasticizing, known as “technological lubricant” because the external friction created during molding items is greatly reduced by finely dispersed coal particles;

- Fuel-like, leading to a significant reduction in the use of external fuel for firing (gas), or its complete reduction in use.

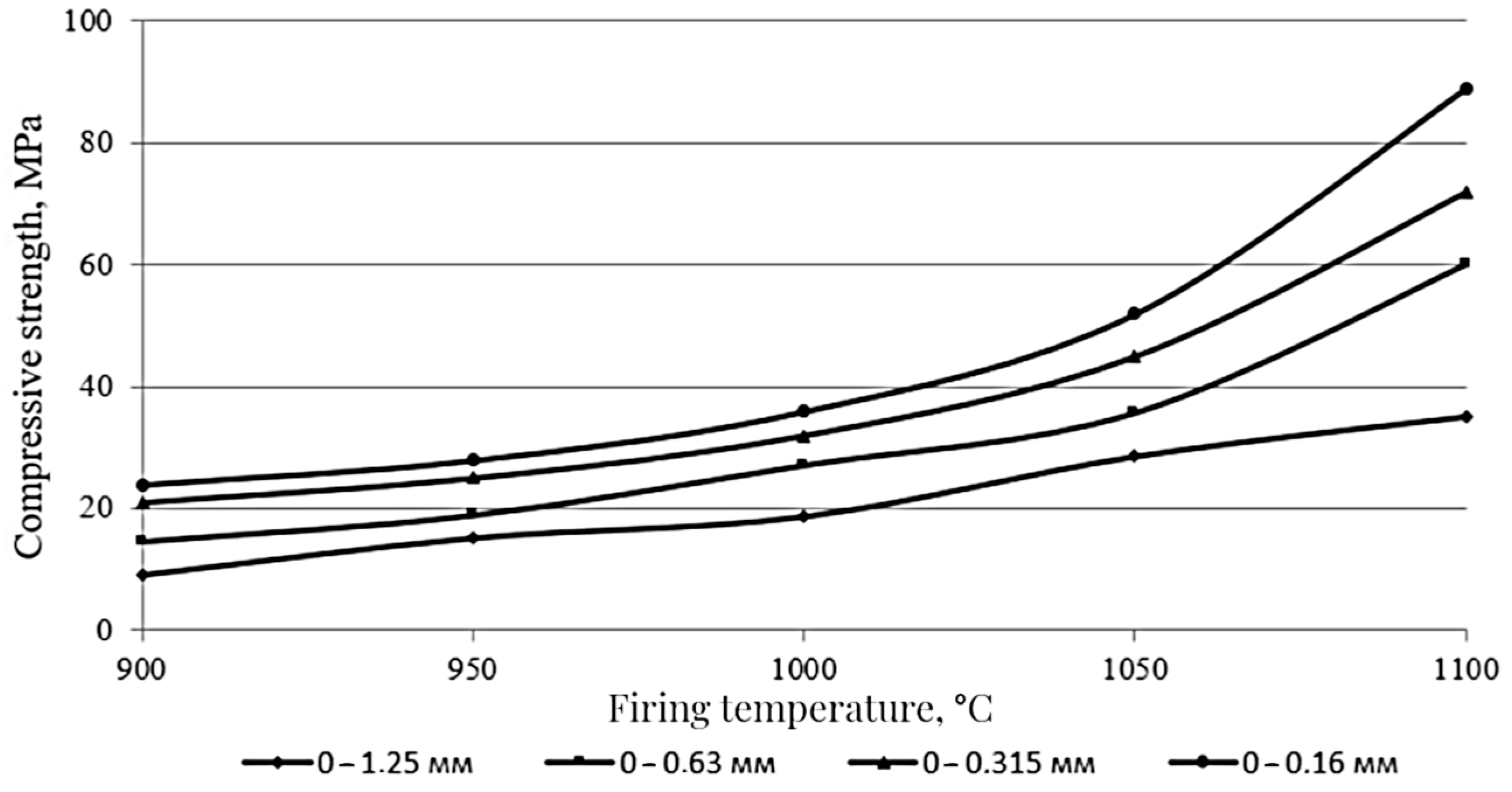

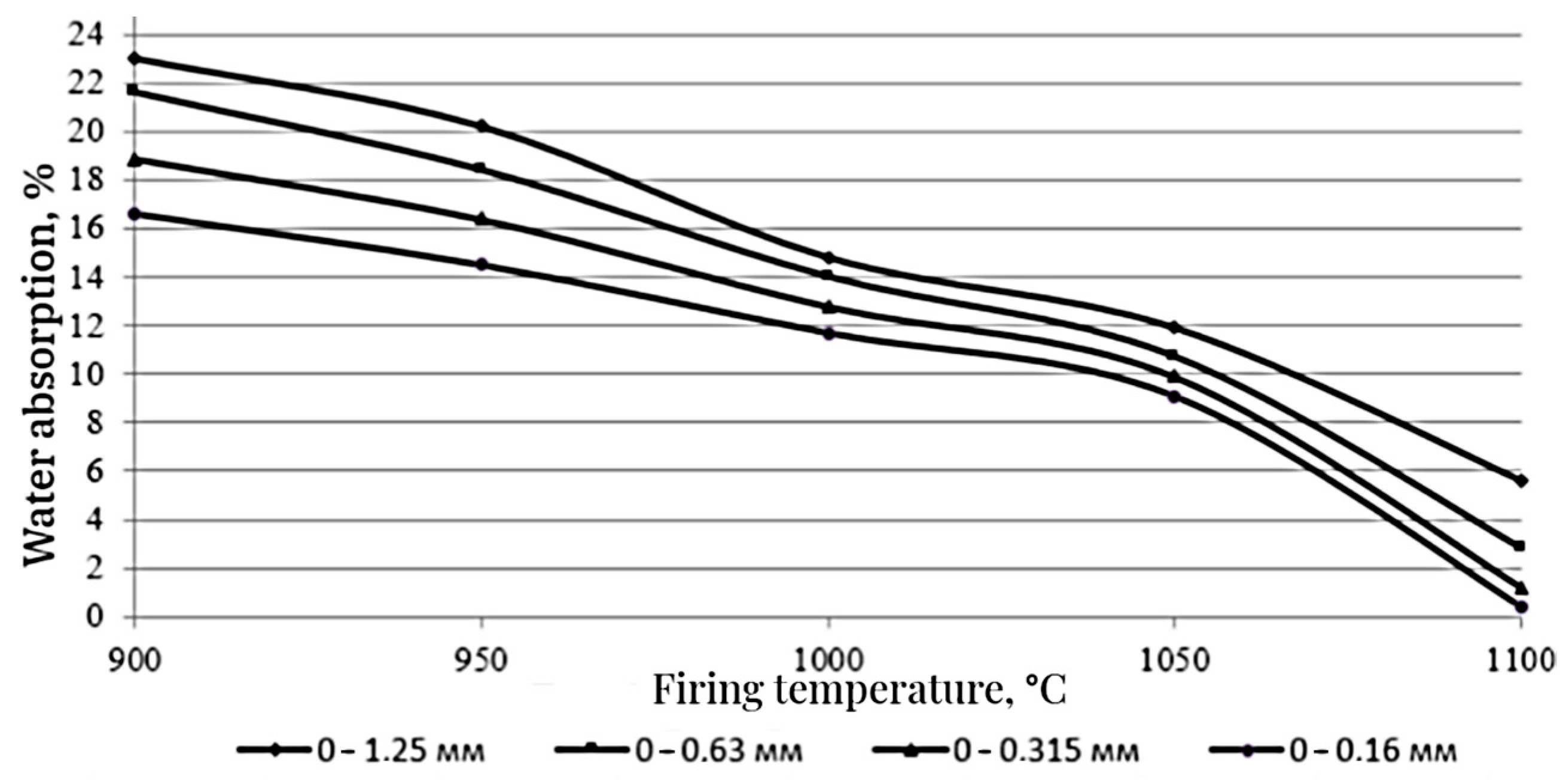

3. Results

4. Discussion

- Getting rid of free water. There is residual moisture in the products in the range of 2–4% after drying. It is removed in the temperature range up to 200 °C. Initially, the elimination of water occurs from larger pores, then from smaller ones, so this process occurs gradually;

- Oxidation (burnout) of organic impurities contained in screenings, which begins at temperatures of 250–350 °C. This process is completed at 700–800 °С;

- Clay dehydration begins at 400–600 °C—removal of chemically bound water;

- Isolation of iron oxides;

- At 650–700 °C anthracite ignites, heat is released, and the supply of external heat is interrupted;

- The formation of a liquid phase is accompanied by sintering from approximately 950 °C. The liquid phase is very important in the sintering of a shard as it helps separate mineral particles to stick together into a single one [37].

5. Conclusions

- Screenings of waste heap processing are raw materials for low-temperature sintering. Water absorption is less than 5% at firing temperatures up to 1100 °C;

- The grind size determines which group raw materials will be assigned to during firing;

- Screenings have a small sintering interval—no more than 50 °C, which is possible only when preparing screenings due to an increase in the content of fine fractions. Moreover, it is the degree of grinding of screenings that makes it possible to regulate the sintering process;

- In the manufacture of stones based on screenings and ordinary bricks, it is necessary to focus on temperatures of 1000—1050 °C;

- When choosing corrective additives for screenings, it is worth taking complex ones as a basis. They increase the plasticity and cohesion of the molding compositions and extend the sintering range. We decided to focus on siliceous clays and coal sludge in the form of such additives.

- Stone format, dimensions, porosity;

- Special rack shape;

- Type of firing unit;

- Firing mode;

- Firing environment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Komarov, A.K.; Filonenko, E.A. Influence of the type of wall material on the technical and economic indicators of the construction of a low-rise building. Bull. ISTU 2015, 8, 103. [Google Scholar]

- Tilinin, Y.I.; Uvarov, G.D.; Bravy, A.Y. Improving the technology of building walls in low-rise housing construction. Colloq. J. 2019, 24, 48. [Google Scholar]

- Tolegenov, D.T.; Yelubai, M.A.; Tolegenova, D.J.; Kulumbaev, N.K.; Tylyubaev, R.A. Use of Man-Made Energy and Metallurgical Waste in Building Ceramics; Vestnik Toraigyrov University: Pavlodar, Republic of Kazakhstan, 2022; Volume 2, pp. 310–321. [Google Scholar] [CrossRef]

- Gadaev, R.S.; Esetova, A.M. Improvement of pricing methods in construction. Reg. Probl. Econ. Transform. 2022, 3, 33–41. [Google Scholar] [CrossRef]

- Bozhko, Y.A.; Lazareva, Y.V.; Gaishun, E.S. Phase transformations of siliceous clays during the firing of ceramics. In Proceedings of the 63rd International Scientific Conference of the Astrakhan State Technical University, Dedicated to the 25th Anniversary of the Astrakhan State Technical University, Astrakhan, Russia, 15–19 April 2019. [Google Scholar]

- Yavruyan, K.S.; Gaishun, E.S.; Teryokhina, Y.V.; Kotlyar, V.D. The research on the sifting from Donbass refuse heap for manufacturing wall ceramic goods. In MATEC Web of Conferences 2018; EDP Sciences: Les Ulis, France, 2018; pp. 4–55. [Google Scholar]

- Yavruyan, K.S.; Gaishun, E.S.; Kotlyar, V.D.; Lotoshnikova, E.O. Raw Materials in East Donbass Based on Waste Piles Processing Screenings for the Large-Sized Ceramic Stones’ Production. In Materials and Technologies in Construction and Architecture III, 1st ed.; Yazyev, B., Litvinov, S., Lapina, A., Kotesova, A., Akay, O., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2020; pp. 116–122. [Google Scholar]

- Yavruyan, K.S.; Gaishun, E.S.; Kotlyar, V.D.; Serebryanaya, I.А.; Filippova, A.А.; Gaishun, A.S. Selection of compositions of ceramic masses based on industrial wastes using mathematical planning methods. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 164. [Google Scholar]

- Ashmarin, G.D.; Kurnosov, V.V.; Lastochkin, V.G. Energy and resource-saving technology of ceramic wall materials. Build. Mater. 2010, 4, 24–27. [Google Scholar]

- Ashmarin, G.D.; Livada, A.N. Expansion of the raw material base is an important factor in the development of ceramic wall materials industry. Build. Mater. 2008, 4, 22–23. [Google Scholar]

- Ilyicheva, S.I.; Yaskevich, T.G. Production of Bricks with the Use of Waste Coal; Express Information. Series 19, Issue 10; VNIIESM: Moscow, Russia, 1986; pp. 10–11. [Google Scholar]

- Loseva, G.I. Production of Bricks from Coal Waste; Express Information. Series 19, Issue 16; VNIIESM: Moscow, Russia, 1986; pp. 12–13. [Google Scholar]

- Kotlyar, V.D.; Yavruyan, K.S.; Gaishun, E.S.; Terekhina, Y.V. Comprehensive Approach to the Processing of East Donbass Spoil Tip. In Proceedings of the 2018 IEEE International Conference “Management of Municipal Waste as an Important Factor of Sustainable Urban Development” (WASTE), St. Petersburg, Russia, 4–6 October 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA; pp. 39–41. [Google Scholar]

- Fomina, O.A.; Stolboushkin, A.Y. Approbation of the Method for Studying the Core-Shell Transition Layer of Ceramic Matrix Composites on the Example of Coal Waste; International participation, Novokuznetsk, 8–10 October 2019; Stolboushkina, A.Y., Aleshina, E.A., Matekhina, O.V., Blaginykh, E.A., Eds.; Siberian State Industrial University: Novokuznetsk, Russia, 2019; pp. 123–126. Available online: https://www.elibrary.ru/item.asp?id=41863738 (accessed on 19 March 2023).

- Eliche-Quesada, D.; Martínez-García, C.; Martínez-Cartas, M.L.; Cotes Palomino, M.T.; P’erez-Villarejo, L.; Cruz-P’erez, N.; Corpas-Iglesias, F.A. The use of different forms of waste in the manufacture of ceramic bricks. Appl. Clay Sci. 2011, 52, 270–276. [Google Scholar] [CrossRef]

- Stolboushkin, A.Y. Perspective direction of development of building ceramic materials from low-quality raw materials. Stroit. Mater. 2018, 4, 24–28. [Google Scholar]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [PubMed]

- Gaishun, E.S.; Gaishun, A.S.; Yavruyan, K.S. Technogenic raw materials of the coal series for the production of coarse building ceramics. Actual problems of science and technology. In Proceedings of the National Scientific and Practical Conference, Rostov-on-Don, Russia, 26–28 March 2019; Don State Technical University: Rostov-on-Don, Russia, 2019; pp. 762–763. Available online: https://www.elibrary.ru/item.asp?id=39453330 (accessed on 19 March 2023).

- Kotlyar, V.D.; Yavruyan, K.S. Wall ceramic products based on finely dispersed waste heap processing products. Build. Mater. 2017, 4, 38–41. [Google Scholar]

- Yavruyan, K.S.; Kotlyar, V.D.; Gaishun, E.S. Medium-fraction materials for processing of coal-thread waste drains for the production of wall ceramics. Mater. Sci. Forum 2018, 931, 532–536. [Google Scholar] [CrossRef]

- Yavruyan, K.S.; Gaishun, E.S.; Kotlyar, V.D.; Okhotnaya, A.S. Features of phase and mineralogical of conversions when burning wall ceramics on the basis of secondary materials for processing coal deposits of Eastern Donbass. In Materials and Technologies in Construction and Architecture II. Materials Science Forum—CATPID 2019; Trans Tech Publications Ltd.: Bäch, Switzerland, 2019; Volume 974, pp. 67–74. [Google Scholar] [CrossRef]

- Guzman, I.Y. Workshop on Ceramics Technology; LLC RIF Stroymaterialy: Moscow, Russia, 2005; p. 336. [Google Scholar]

- Padmalosan, P.; Vanitha, S.; Sampath Kumar, V.; Anish, M.; Rajesh, T.; Dhapekar, N.K.; Yadav, A.S. An investigation on the use of waste materials from industrial processes in clay brick production. Mater. Proc. 2023. [Google Scholar] [CrossRef]

- Kotlyar, V.D.; Terekhina, Y.V.; Kotlyar, A.V. Method of testing stone-likeraw materials for the production of wall products of compression molding. Stroit. Mater. 2014, 4, 24–27. [Google Scholar]

- Hoppe Filho, J.; Pires, C.A.O.; Leite, O.D.; Garcez, M.R.; Medeiros, M.H.F. Red ceramic waste as supplementary cementitious material: Microstructure and mechanical properties. Constr. Build. Mater. 2021, 296, 123653. [Google Scholar] [CrossRef]

- Fiala, L.; Konrád, P.; Fořt, J.; Keppert, M.; Černý, R. Application of ceramic waste in brick blocks with enhanced acoustic properties. J. Clean. Prod. 2020, 261, 121185. [Google Scholar] [CrossRef]

- Kotlyar, V.D.; Ustinov, A.V.; Terekhina, Y.V.; Kotlyar, A.V. Features of the coal firing process for the production of wall ceramics. Tech. Technol. Silic. 2014, 21, 8–15. [Google Scholar]

- Eterigho-Ikelegbe, O.; Trammell, R.; Bada, S. Preparation and characterization of ceramic composites from South Africa coal discard. Constr. Build. Mater. 2021, 302, 124164. [Google Scholar] [CrossRef]

- Stolboushkin, A.Y.; Storozhenko, G.I. Coal waste as a raw material and energy base for factories that produce ceramic wall materials. Build. Mater. 2011, 4, 43–46. [Google Scholar]

- Sun, J.; Zhou, H.; Jiang, H.; Zhang, W.; Mao, L. Recycling municipal solid waste incineration fly ash in fired bricks: An evaluation of physical-mechanical and environmental properties. Constr. Build. Mater. 2021, 294, 123476. [Google Scholar] [CrossRef]

- Kotlyar, A.V.; Talpa, B.V.; Lazareva, Y.A.V. Features of the chemical composition of argillite-like and clays and argillites. Stroymaterialy 2016, 4, 10–13. [Google Scholar]

- Kotlyar, V.D.; Ustinov, A.V.; Terekhina, Y.V.; Kotlyar, A.V. Peculiarities of the firing process of coal sludge in the production of wall ceramics. Tekhnika Tekhnol. Silik. 2014, 4, 8–15. [Google Scholar]

- Fomina, O.A.; Stolboushkin, A.Y. Development of a novel mold design for manufacturing of hollow ceramic products from coal wastes. Mater. Today Proc. 2019, 11, 348–353. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Chu, P.K. An eco-friendly and cleaner process for preparing architectural ceramics from coal fly ash: Pre-activation of coal fly ash by a mechanochemical method. J. Clean. Prod. 2019, 214, 419–428. [Google Scholar] [CrossRef]

- Terekhina, Y.V.; Talpa, B.V.; Kotlyar, A.V. Mineralogical and technological features of lithified clayey rocks and prospects for their use as a raw material for the production of building ceramics. Stroit. Mater. 2017, 4, 8–10. [Google Scholar]

- Babisk, M.P.; Amaral, L.F.; da Silva Ribeiro, L.; Vieira, C.M.F.; do Prado, U.S.; Gadioli, M.C.B.; Oliveira, M.S.; da Luz, F.S.; Monteiro, S.N.; da Costa Garcia Filho, F. Evaluation and application of sintered red mud and its incorporated clay ceramics as materials for building construction. J. Mater. Res. Technol. 2020, 9, 2186–2195. [Google Scholar] [CrossRef]

- Muñoz Velasco, P.; Morales Ortíz, M.P.; Medívil Giró, M.A.; Muñoz Velasco, L. Fired clay bricks manufactured by adding wastes as sustainable construction material—A review. Constr. Build. Mater. 2014, 63, 97–107. [Google Scholar] [CrossRef]

- Storozhenko, G.I.; Stolboushkin, A.Y.; Ivanov, A.I. Processing of carbonaceous argillites for obtaining ceramic raw materials and technological fuel. Build. Mater. 2015, 8, 50–59. [Google Scholar]

- Stolboushkin, A.Y.; Ivanov, A.I.; Fomina, O.A. A study on structure and phase composition of cellular ceramic materials from dispersed silicarich rocks. In Solid State Phenomena; Trans Tech Publications Ltd.: Bäch, Switzerland, 2018. [Google Scholar]

- Kotlyar, A.V.; Talpa, B.V. Stone-like clayey rocks of the Eastern Donbass are a promising raw material for the production of wall ceramics. In Proceedings of the Scientific Conference of Students and Young Scientists with International Participation “Actual Problems of the Earth Sciences”; SFU Publishing House: Rostov-on-Don, Russia, 2015; pp. 49–51. [Google Scholar]

- Stolboushkin, A.Y.; Akst, D.V.; Fomina, O.A.; Ivanov, A.I.; Syromyasov, V.A. Analysis of waste coal from the enterprises of Kemerovo region as raw materials for production of ceramic materials. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

| Loss on Ignition | SiO2 | AI2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 3.2–6.3 | 56.5–64.8 | 17.0–22.2 | 3.1–6.3 | 1.1–3.3 | 0.5–2.1 | 0.4–1.0 | 2.1–4.6 | 0.8–2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yavruyan, K.; Gaishun, E. Production of Large-Sized Ceramic Stones Based on Screenings from Waste Heap Processing Using the Technology of Stiff Extrusion for Molding Products. Buildings 2023, 13, 845. https://doi.org/10.3390/buildings13040845

Yavruyan K, Gaishun E. Production of Large-Sized Ceramic Stones Based on Screenings from Waste Heap Processing Using the Technology of Stiff Extrusion for Molding Products. Buildings. 2023; 13(4):845. https://doi.org/10.3390/buildings13040845

Chicago/Turabian StyleYavruyan, Khungianos, and Evgeniy Gaishun. 2023. "Production of Large-Sized Ceramic Stones Based on Screenings from Waste Heap Processing Using the Technology of Stiff Extrusion for Molding Products" Buildings 13, no. 4: 845. https://doi.org/10.3390/buildings13040845

APA StyleYavruyan, K., & Gaishun, E. (2023). Production of Large-Sized Ceramic Stones Based on Screenings from Waste Heap Processing Using the Technology of Stiff Extrusion for Molding Products. Buildings, 13(4), 845. https://doi.org/10.3390/buildings13040845