1. Introduction

Addressing moisture in building structures is one of the most relevant topics in the construction industry. There is a range of methods for preventing moisture ingress into structures and for the actual removal of moisture from building materials. These methods can be today considered fairly effective, but it is necessary to develop them further and to come up with more economical and, in particular, more environmentally friendly solutions. Moisture problems in building materials are particularly serious because the water contained in them greatly affects their physical and mechanical properties. Currently, there are multiple methods that are used for removing moisture from building materials in the Czech Republic and Europe in general, which meet most of the requirements of today’s building practice.

The basic criteria for their use are the speed and efficiency of drying, the economic demands of the process, the cost of necessary equipment, and the overall environmental friendliness of the method. Commonly used methods for drying building materials are efficient, but the drying time can be rather long, and their applicability and suitability depend on the type of building material.

One approach to drying building materials is through the use of microwave radiation. This method has been known since about 1945, but in construction practice, it is currently still not widely used. This is due to the higher purchase cost of microwave generators and the lack of knowledge of the basic principles of microwave drying, which is also related to health concerns about exposure to this type of radiation. A combination of these reasons, together with low awareness about the method, results in limited interest in the use of microwave radiation in construction practice.

1.1. Literature Review

The origins of using microwave radiation date back to the first half of the 20th century, although its existence was predicted as early as 1865 by James Clerk Maxwell [

1]. August Žáček, a professor at the Faculty of Science of Charles University in Prague, was among the first to describe the principle of magnetron oscillation in 1924; in a foreign journal, his discovery was published in 1928, and since then, he has been considered the inventor of magnetron [

2]. It was not until the end of the war and afterward that the subject of microwave heating came up in earnest, and one of the most important people involved was Percy L. Spencer, who was interested in consumer and commercial microwave ovens. He filed his first patent on the microwave heating of food in October 1945. His associates describe the discovery as a gradual trial-and-error process, with experiments such as making corn pop or eggs explode. Percy Spencer worked for Raytheon, where the main focus was on the invention of the microwave oven, but other companies also researched microwave radiation by just concentrating more on industrial applications; for example, in 1947, a paper was published that addressed process acceleration through microwaves [

3]. Later, in the 1960s and 70s, the development of microwave technology advanced so much that the first household microwave ovens began to appear. Today almost every home has a microwave, and the principle of microwave heating is used in many other industries outside the food sector [

4]. It has been widely used, for example, in medicine [

5], the aforementioned food industry [

6], the military [

7], as well as within the construction industry [

8]. Within this industry, a number of studies have already been carried out confirming the potential use of microwaves for drying building materials [

9,

10,

11,

12].

1.1.1. Microwaves

Microwaves are a part of electromagnetic radiation with a frequency between 300 MHz and 300 GHz, corresponding to wavelengths between 1 m and 1 mm. For industrial purposes, more frequencies are permitted, but in construction, the globally used frequency was 2.45 GHz with a corresponding wavelength of 12.2 cm. Microwaves belong to a broad spectrum of electromagnetic waves, which also cover, for example, the visible light range. Their behavior is described by Maxwell’s equations. It holds that at any given point and any given instant, the vectors characterizing magnetic and electric fields are perpendicular to each other, and both are perpendicular to the direction of motion of the wave [

8,

13].

Microwave radiation causes heating, and the molecules become oriented according to their polarity in the electric field. When microwave radiation comes into contact with water molecules, the electromagnetic energy transforms, and heating occurs. This is followed by the heating of the construction materials [

8].

Microwaves fall in the range of electromagnetic waves with a lower frequency than solar radiation, so they do not leave any residual radiation that is harmful to health. The use of microwave devices is completely safe, and any damage to health can only occur from direct exposure from a few cm for at least several minutes, either made intentionally or by the improper handling of the device [

8].

Excessively strong microwave radiation poses the highest risk to human health. The use of microwave equipment with radiators emitting such electromagnetic radiation outside poses a serious hazard to people in the area of high microwave energy density. The permitted levels of electromagnetic field strength in the range of 2.45 GHz are established by EU regulations, including Directive 2004/40/EC and Recommendation 1999/510/EC, as well as by country-specific regulations. The regulations typically set the permissible electromagnetic field strength (from 7 V/m to 61 V/m) or watt density (from 0.1 W/m2 to 10 W/m2).

1.1.2. Theory of Electromagnetic Field

The fundamental theory of the electromagnetic field was based on a number of physical laws drawn from experiments and findings linked to names such as Coulomb, Savart, Ampere, and Faraday. Faraday’s work, particularly the discovery of electromagnetic induction, and the work of Maxwell, who developed a model of the electromagnetic field following the discovery of the concept of a displacement current, were of major importance to the development of the theory [

14].

The general electromagnetic field, natural or man-made, is non-stationary (there is constant time variability). The variability of the field can often be considered marginal or slow. Following this simplification, the field can be classified into four types: (a) a static field, where all charges are considered to be at rest; (b) a stationary field generated by charges that form stationary currents; (c) a quasi-stationary field, which is a simplification of the general non-stationary field because the so-called displacement current against the free electron currents is disregarded here; and (d) a non-stationary field, i.e., a general electromagnetic field [

14].

1.1.3. Applications in the Construction Industry

There are multiple applications for microwave energy within the construction industry. It is used for drying building materials and structures [

15], accelerating the solidification of mixtures [

16], for the sterilization of biotic pests [

17], or even for moisture measurements [

18].

The material to be heated is subjected to a high-frequency electromagnetic field, causing the polarization of molecules, conduction, and magnetic processes. The internal energy of the molecules gradually increases, which causes the material to be heated. During perfect microwave heating, the distribution of the intensity of the microwave field is in the area completely even, and heat is generated uniformly across the entire volume of the material, but in a real situation, this is not the case. The presence of waves depends on the design of the equipment used and the type of material inside the heating chamber. The amount of energy absorbed varies with the size, shape, dielectric constant, and permittivity of the material. In addition to these properties of the heated object itself, particularly important are the frequency and intensity of the electromagnetic field. The heat generated in the objects spreads to the surroundings through heat transfer. If microwave energy is applied to the material for too long, it can lead to overheating and damage to the object [

16].

One of the advantages of microwave radiation is selective heating. Components were heated according to their ability to absorb electromagnetic energy; therefore, mainly, the most absorbent one was heated, which is usually loosely bound water. This component then heats the other material components, which results in a more in-depth heating of the object. Microwave energy can heat up the material more effectively compared to regular heating from the surface. It was used for the drying of various materials and the acceleration of the hardening of mixtures. Disadvantages to this method include higher energy consumption, possible changes in the mechanical properties of the object, and possible local overheating due to the inconsistency of the microwave field and the inhomogeneity of the heated material. Last but not least, there is also the requirement of proficiency while working with EMW radiation [

16,

19].

The microwave drying/hardening process can be divided into four stages. The first one is the actual heating of the water molecules in conjunction with the secondary heating of the material. The second stage consists of the evaporation of water contained in the surface layer of the material. During the third stage, the volume of water increases due to the heating of the water. This causes an increase in pressure, which spreads in all directions, including to the surface of the material, forcing the heated water to be expelled to the surface. A gradual cooling process is the last stage. The water on the surface of the material is continuously evaporated. The difference in moisture content at the surface and in the depth of the material results in a difference in the partial pressure, which enables the transport of moisture to the surface. The evaporation of moisture from the surface of the drying material requires a considerable amount of heat. Consequently, the surface of the material and the surrounding air are cooled [

16].

The following factors influence the rate of drying: temperature gradient, moisture content of the surface layer, relative humidity of the surroundings of the drying material, the ability of the material to distribute water from its core to the surface, the surface finish of the dried material, and thermal conductivity of the drying material [

16,

19].

2. Methods and Materials

The experimental determination of the basic characteristics of the studied material is presented in the following chapter. It should be noted that all the experiments herein presented were carried out on a ceramic construction material, namely solid burnt clay bricks. The purpose of this was to experimentally verify the influence of brick drying by microwave radiation on the mechanical properties of the brick.

Basic characteristics: brick dimensions were 290 × 140 × 65 mm; bricks were formed by pressing; there were 10 brick samples in the experiment; bulk density was 1718-kg∙m−3; compressive strength was 20 MPa as stated by the manufacturer.

Before measurement, the samples were dried to a constant weight.

The actual experiment is based on the treatment of 10 fully water-soaked ceramic bricks with microwave radiation and varying exposure times for the bricks. The first interval of exposure to EMW radiation was 60 min, the second interval was 120 min, and the third interval was 240 min.

The individual experiments were carried out in two variants; in the first one, the EMW radiation was applied only for one cycle, and in the second variant for ten cycles.

Subsequently, an ultrasonic wave was used, and its transit time was measured. From these data, a calculated estimate of the compressive strength of each brick was determined.

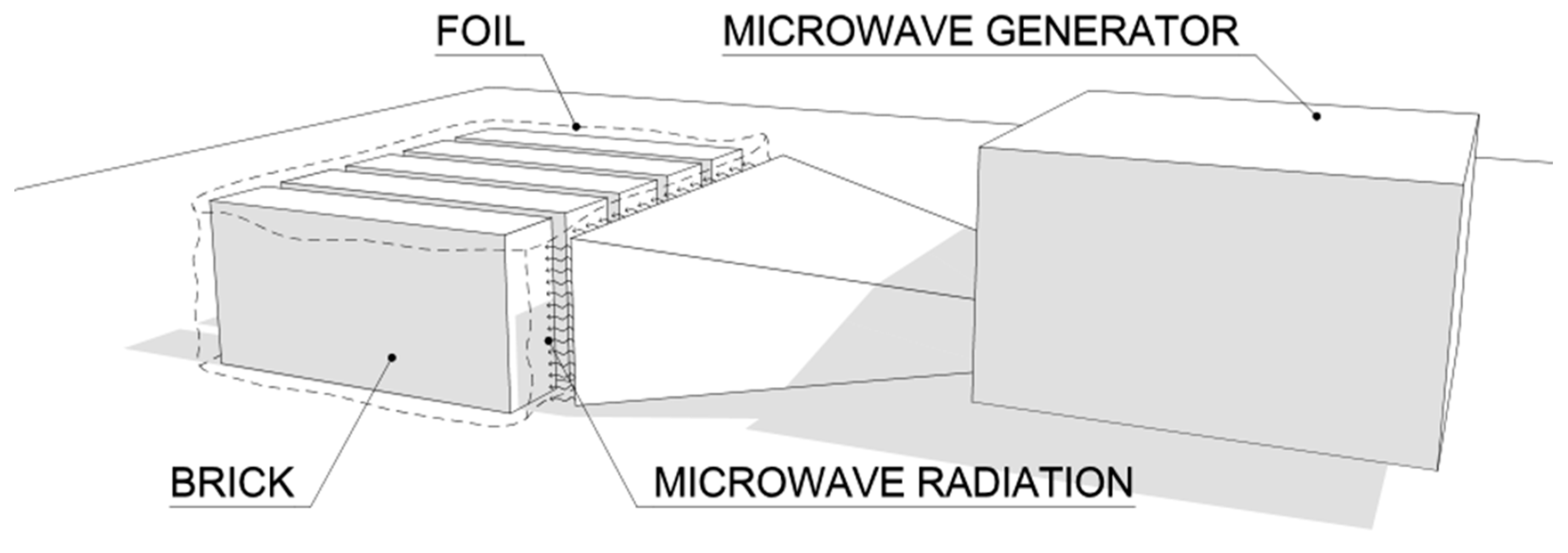

The measurements of the observed parameters were always taken before and after exposure to microwave radiation. In

Figure 1 we can see the layout of the brick samples and the EMW generator.

2.1. Material

Solid burnt clay bricks are suitable for standard load-bearing and infill plastered masonry. The ceramic material is rather porous, brittle, hard, water-insoluble, chemically resistant, and heat resistant. It is a poor thermal conductor and a good electrical insulator. It is produced by firing a natural clay-based raw material (oxide ceramics), which results in a very rigid material with good resistance to high temperatures. The physical properties of ceramic bricks were specified by technical standards. The required porosity was at least 10%, and the compressive strength value of the bricks was the key parameter for determining the load-bearing capacity of the masonry.

Raw materials for the production of bricks consist of particles of weathered rocks, especially granite, gneiss, and porphyry. The products of rock weathering are the clay, silt, sand, and various impurities. The most important component is clay, specifically clay minerals such as illite, montmorillonite, and kaolinite. In terms of chemistry, these are hydrated aluminum silicates with a characteristic layered structure.

2.2. Equipment

In construction practice, there are several types of EMW radiation currently used to dry damp building structures. Many devices dry the masonry only by attaching an EMW generator with a magnetron but using EMW antennas makes drying more efficient. The basic drying methods in construction practice use a rod-shaped or funnel-shaped EMW antenna [

15]. In this experiment, only the funnel-shaped antenna was used.

In the drying process, a device equipped with a funnel-shaped antenna was attached to the masonry at a distance of 0 to 50 mm and left to operate for a certain period of time at any given location. The drying of the whole area was achieved by the successive cyclical repositioning of the antenna. It is important to dry the locations more than once, as otherwise, the formation of subsurface pockets during rapid drying can result in only the surface of the masonry being dried and moisture remaining in the depth of the material. Cyclic drying prevents the formation of pockets and ensures heating in the depth of the material.

This experiment used a portable microwave generator Romill, G1/2011, to irradiate the bricks. The used voltage was 230 V, 50 Hz, the power input was 1.5 kW, the microwave frequency was 2450 MHz, and the maximum microwave power was 1 kW.

2.3. Experimental Drying of the Bricks

A total of 10 samples were prepared for the experimental measurements. The samples were stored in laboratory conditions where the indoor air temperature was controlled and ranged from 19.9 °C to 22.3 °C.

The procedure for conducting the test can be summarized in a sequence of laboratory activities. First, the samples were dried in a drying chamber to their constant weight at a temperature of 100 °C. Afterward, they were weighed, and their basic mechanical and physical properties were determined and compared with the manufacturer’s declared values. Next, the samples were soaked in a water tank for 24 h. Then, they were weighed again, and their values of water absorption and apparent porosity were calculated. In the next step, the samples were dried using microwave radiation in two sets (five samples were exposed to microwave radiation only once, and the other five samples were exposed to it for 10 cycles). In both cases, 1 sample was irradiated for 1 h, 2 samples for 2 h, and the last 2 samples for 4 h. A metal-shielded chamber called a Faraday cage was created around the samples to limit the spread of microwave radiation to the surrounding area. After exposure, the samples were weighed and then dried in the drying chamber to their constant weight at the temperature of 100 °C. Subsequently, the propagation speed of the ultrasonic pulse was measured, and the calculated compressive strength of the brick was determined. The measurements results can be seen in

Table 1.

2.4. Physical and Mechanical Properties of Bricks

The bulk density of the bricks was determined according to standard ČSN 72 2603 [

20], as the samples were geometrically regular. The monitored property of the brick samples was evaluated in a so-called air-dry state in the laboratory environment [

21].

The moisture absorption was determined according to the national standard ČSN 72 2603 [

20]. In conjunction with the determination of bulk density, the moisture absorption and the apparent porosity of the samples were determined [

21].

The correlation between the velocity of ultrasonic wave propagation and the velocity of sound propagation in the material was used to quantify the compressive strength of the bricks.

2.5. Ultrasonic Pulse Velocity Method

The experiment was performed by measuring the wave passage through the samples, and it was carried out by the direct sounding of the samples. The following procedure was used to measure the time of passage of the ultrasonic pulse: along the length of the brick was the measurement performed in three measuring points, which were evenly distributed over the measured area. The actual frequency of the probes was chosen as 54 kHz in order to satisfy the condition a ≥ 1.25λ (where a is the minimum dimension of the sample at the measurement point and λ is the wavelength), and the bonding agent was Sonogel, commonly used in the medical industry. At each measuring point, three measurements of the ultrasonic pulse passage time were taken.

Ultrasound is defined as the mechanical vibration of environmental particles at frequencies greater than 20 kHz. For testing building materials, probes with a frequency ranging from 40 kHz to 150 kHz are typically used. When an ultrasonic wave propagates through a medium, its particles vibrate in different directions relative to the direction of the wave’s propagation. Accordingly, ultrasonic waves can be distinguished into four types: longitudinal (particles of the medium vibrate parallel to the direction of the wave’s propagation), transverse (particles of the medium vibrate perpendicular to the direction of propagation of the wave), surface (they travel along the surface of thick solids and do not influence the bulk of the medium below), and plate waves (these waves are produced in thin metal, whose thickness is similar to the wavelength) [

22].

The concept of the method consists of transmitting repeated ultrasonic pulses into the material by the transmittance transducer and then detecting the pulses passed through the examined material by the receiving transducer, i.e., measuring the time interval that elapses during the pulse passage through the measuring base. Measurements can be made by direct, indirect, and semi-direct sounding. Measurements made by the ultrasonic pulse velocity method are influenced by several factors, namely, moisture, defects in the structure of the tested material, the dimensions and shape of the sample, the natural frequency of the probes, as well as the means of acoustic coupling between the probes and the tested material. It is necessary to take these factors into account when developing a measurement methodology for specific materials [

22,

23].

A correlation exists for predicting the compressive strength of bricks from parameters measured by the ultrasonic pulse velocity method. Based on the results of the experimental measurements, an estimate of the compressive strength of the bricks was determined according to the formula [

22]:

where

fc is the compressive strength of the brick in mPa,

V is the ultrasonic pulse propagation velocity in m·s−1,

r is the correlation coefficient.

3. Results

Physical Properties of Bricks

Prior to actual exposure to microwave radiation, the basic physical properties of the tested samples were determined; in particular, this included the bulk density, moisture absorption, apparent porosity, and compressive strength of the individual bricks. These values were compared with the information declared by the manufacturer. The values can be seen in

Table 2.

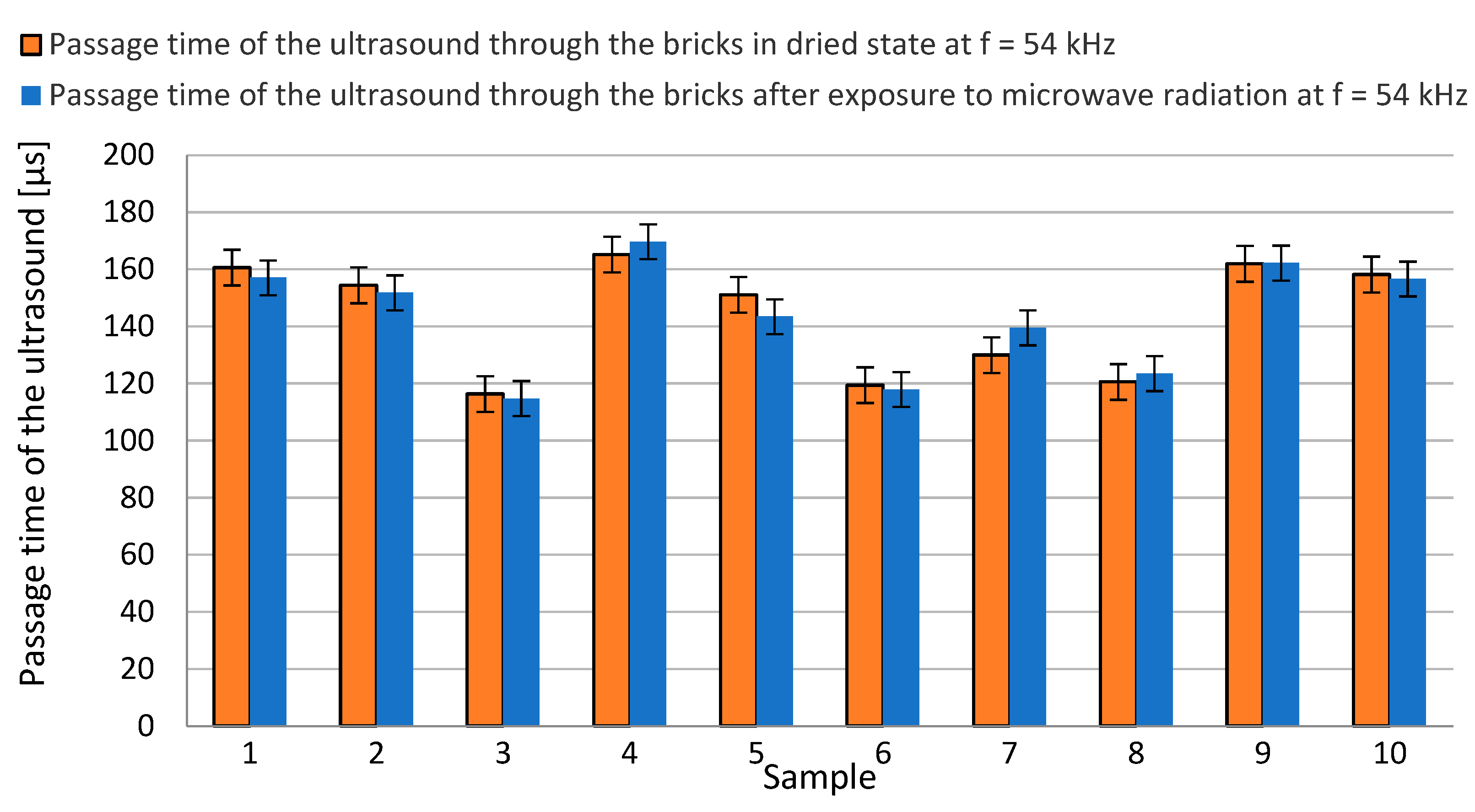

4. Discussion of Results

The analysis of the obtained results provided insights into the suitability of using microwave radiation for drying brick components. The experiments performed confirmed the insignificant effect of microwave drying on the compressive strength of the porous ceramic material. The experimental results can be observed in

Table 3 and

Table 4 and the resulting ultrasonic wave propagation times are shown in

Table 5. Graphical representation of the results can be seen in

Figure 2 and

Figure 3.

The compressive strength data of the tested ceramic bricks were calculated estimates based on the ultrasonic pulse method, which is directly affected by the homogeneity of the material on the transmission path between the transmitter and the receiver, particularly in the material structure. It was also recognized that the moisture content of materials affects the propagation speed of the ultrasonic pulse [

24,

25]. The presence of material moisture, which appears as a liquid phase of water in the porous structure of the materials and fills the free pore space, increases the velocity of the ultrasound propagation in the material (the ultrasound velocity in water is about 3.5 times higher than in air) [

22]. Therefore, it is necessary to determine the moisture state of the samples during the measurements to ensure the reproducibility of the measurement results. To eliminate the influence of moisture on the results, the ceramic bricks were dried to their constant weight before the experiment.

As already mentioned, the results derived from the ultrasonic pulse velocity method are influenced by the shape and dimension of the brick units, the mineralogical components of the bricks, their porosity, and any defects in their structure. These factors are also reflected, to varying degrees, in the calibration equations developed for determining compressive strength from the results of non-destructive tests. The evaluation of calibration equations was based on the value of the correlation coefficient, which assessed the strength of the relationship between the measurement results and the actual compressive strength values. Calibration equations with a correlation coefficient of

r ≥ 0.85 were considered to be reasonably usable, although calibration equations with

r ≥ 0.9 were more appropriate [

22]. The relationship that was used for the computational estimation of the compressive strength of ceramic bricks was

r = 0.85.

For burnt clay bricks, in general, a minor crack in the brick is not a defect unless it adversely affects the declared compressive strength. In terms of the assessment of the compressive strength of solid burnt bricks by the ultrasonic method, the influence of disorderly defects in the microstructure of the brick samples is very pronounced, and therefore, the observed data are more of an estimate. It was technically not possible to carry out objectively conclusive destructive compressive strength tests on the bricks examined, and therefore, a calculated estimate of compressive strength was used—as seen in the results above. This estimation has its limitations in the form of statistical error. Despite the above, this compressive strength estimation procedure can be recommended for further research [

22].

5. Conclusions

Based on the experiments carried out and their subsequent evaluation, it was possible to confirm the effect of drying by microwave radiation on the compressive strength of porous ceramic material. The data prove that microwave radiation can be a suitable method for drying solid burnt bricks as it does not affect the compressive strength of the bricks. The experiment was conducted in two sets, where the solid burnt bricks were dried by microwave radiation for different periods of time, and even after ten cycles of exposure, there were no changes in the measured strength values. The porosity of ceramics is usually 15–25%, so it is understood that there was internal pore space available for the removal of water vapor into the surrounding environment.

The resulting compressive strengths of the tested bricks were calculated from the ultrasonic wave propagation velocity, though only an estimate of the strength can be derived using this procedure, resulting in higher measurement uncertainty. The differences in the ultrasonic pulse wave propagation velocity between the dried samples and the samples after exposure to microwave radiation were proved to be negligible. This conclusion was confirmed, despite the possible inhomogeneity of the microwave radiation, the production variance in the properties of the ceramic bricks, and/or the effect of any uneven residual moisture from incomplete drying (the resulting compressive strength estimations can be observed in

Table 6 and the corresponding graphical representation in

Figure 3).

Nevertheless, this experiment was very limited, and the paper is mainly intended to serve as a trigger for further research to determine the effect of EMW radiation on different types of bricks with different porosity and, thus, obtain more conclusive results. This area is very promising because a major advantage of microwave heating is that the heating and evaporation of the moisture contained in the porous system of the ceramic brick occurs directly in the material through the absorption of microwave radiation by water. Other drying methods conduct necessary heat from the surface of the dried material, and the process of moisture removal is slower and usually more energy-consuming.

Author Contributions

Conceptualization, D.P. and K.S.; methodology, D.P., K.Š., S.Š. and T.Ž.; formal analysis, D.P.; data curation, D.P. and T.Ž.; writing—original draft preparation, D.P., S.Š., K.S., K.H. and T.Ž.; writing—review and editing, K.Š. and V.V.; supervision, K.Š., V.V. and S.Š.; project administration, K.S.; funding acquisition, D.P. and K.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Brno University of Technology, Faculty of Civil Engineering, Internal grant agency, grant number FAST-J-21-7238.

Data Availability Statement

The raw data supporting the conclusions of this article are available from the authors on reasonable request.

Acknowledgments

This research acknowledges the support received from the Brno University of Technology, Faculty of Civil Engineering and UiT, The Arctic University of Norway, Faculty of Engineering Sciences & Technology, providing basic infrastructure and laboratory spaces.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Maxwell, J.C. A dynamical theory of the electromagnetic field. Philos. Trans. R. Soc. Lond. 1865, 155, 459–512. [Google Scholar]

- The 70th birthday of Prof. Dr. August Žáček. Czech J. Phys. 1956, 6, 204–205. [CrossRef]

- Kinn, T.P.; Marcum, J. Possible Uses of Microwaves for Industrial Heating. Prod. Eng. 1947, 18, 137–140. [Google Scholar]

- Osepchuk, J.M. A History of Microwave Heating Applications. IEEE Trans. Microw. Theory Tech. 1984, 32, 1200–1224. [Google Scholar] [CrossRef]

- Gartshore, A.; Kidd, M.; Joshi, L.T. Applications of Microwave Energy in Medicine. Biosensors 2021, 11, 96. [Google Scholar] [CrossRef] [PubMed]

- Guzik, P.; Kulawik, P.; Zając, M.; Migdał, W. Microwave applications in the food industry: An overview of recent developments. Crit. Rev. Food Sci. Nutr. 2022, 62, 7989–8008. [Google Scholar] [CrossRef] [PubMed]

- Hoehn, J.R. Defense Primer: Military Use of the Electromagnetic Spectrum. Library of Congress. Congressional Research Service 2022, Report IF11155, Version 15. Available online: https://crsreports.congress.gov/product/details?prodcode=IF11155 (accessed on 24 March 2023).

- Procházka, M.; Sobotka, J.; Šuhajda, K.; Novotný, M. Microwave radiation and its application on construction materials. Eng. Struct Tech. 2016, 8, 150–156. [Google Scholar] [CrossRef]

- Makul, N. Effect of low-pressure microwave-accelerated curing on the drying shrinkage and water permeability of Portland cement pastes. Elsevier 2020, 13, e00358. [Google Scholar] [CrossRef]

- Kvapilova, V. Evaluation of microwave drying effects on historical brickwork and modern building materials. IOP Conf. Ser. Mater. Sci. Eng. 2020, 867, 012026. [Google Scholar] [CrossRef]

- Kvapilova, V.; Suhajda, K. Possibility of Using Microwave Radiation for Rehabilitation of Historical Masonry Constructions. Key Eng. Mat. 2020, 868, 119–126. [Google Scholar] [CrossRef]

- Tauhiduzzaman, M.; Hafez, I.; Bousfield, D.; Tajvidi, M. Modeling Microwave Heating and Drying of Lignocellulosic Foams through Coupled Electromagnetic and Heat Transfer Analysis. Processes 2021, 9, 2001. [Google Scholar] [CrossRef]

- Sobotka, J.; Šuhajda, K.; Jiroušek, Z. Microwave Theory in Construction Practice. TZB-Info 2017. Available online: https://stavba.tzb-info.cz/izolace-strechy-fasady/15568-mikrovlnna-teorie-ve-stavebni-praxi (accessed on 20 September 2022). (In Czech).

- Novotný, M.; Šuhajda, K.; Sobotka, J.; Gintar, J.; Dová, E.S.; Mádl, M.; Jiroušek, Z. Use of microwave radiation in building industry through application of wood element drying. Wood Res. 2014, 59, 389–400. [Google Scholar]

- Šuhajda, K. Analysis of Interaction of Microwave Radiation with Moisture in Porous Building Materials. Habilitation Thesis, Brno University of Technology, Brno, Czech Republic, 2016. (In Czech). [Google Scholar]

- Průša, D.; Šťastník, S.; Šuhajda, K. The possibilities of using microwave radiation to accelerate the solidification of mixtures consisting of a polymer matrix binder and a waste thermal insulation filler. AIP Conf. Proc. 2022, 2488, 020023. [Google Scholar] [CrossRef]

- Novotný, M.; Škramlik, J.; Šuhajda, K.; Tichomirov, V. Sterilization of Biotic Pests by Microwave Radiation. Procedia Eng. 2013, 57, 1094–1099. [Google Scholar] [CrossRef]

- Kääriäinen, H.; Rudolph, M.; Schaurich, D.; Tulla, K.; Wiggenhauser, H. Moisture measurements in building materials with microwaves. NDT E Int. 2001, 34, 389–394. [Google Scholar] [CrossRef]

- Sobotka, J. Disposal of Biotic Pests by EMW Radiation. Ph.D. Thesis, Brno University of Technology, Brno, Czech Republic, 2015. (In Czech). [Google Scholar]

- ČSN 72 2603; Skúšanie Tehliarskych Výrobkov. Stanovenie Hmotnosti, Objemovej Hmotnosti a Nasiakavosti. ÚNMZ: Praha, Czech Republic, 1979. (In Czech)

- Khestl, F. Ceramics. Testing of Building Materials and Products. Technical University of Ostrava: Ostrava, Czech Republic, 2010. Available online: https://homel.vsb.cz/~khe0007/opory/opory.php?stranka=cihly_zkouseni (accessed on 15 September 2022). (In Czech).

- Brožovský, J. Use of the ultrasonic pulse method for detecting the compressive strength of different types of bricks (Využití ultrazvukové impulsové metody pro zjišťování pevnosti v tlaku různých druhů cihel). TZB-Info 2018. Available online: https://stavba.tzb-info.cz/cihly-bloky-tvarnice/17190-vyuziti-ultrazvukove-impulsove-metody-pro-zjistovani-pevnosti-v-tlaku-ruznych-druhu-cihel (accessed on 20 September 2022). (In Czech).

- Silva, F.A.N.; Delgado, J.M.P.Q.; Cavalcanti, R.S.; Azevedo, A.C.; Guimarães, A.S.; Lima, A.G.B. Use of Nondestructive Testing of Ultrasound and Artificial Neural Networks to Estimate Compressive Strength of Concrete. Buildings 2021, 11, 44. [Google Scholar] [CrossRef]

- Schuller, M.P. Nondestructive testing and damage assessment of masonry structures. Prog. Struct. Eng. Mat. 2003, 5, 239–251. [Google Scholar] [CrossRef]

- Lencis, U.; Udris, A.; Korjakins, A. Moisture Effect on the Ultrasonic Pulse Velocity in Concrete Cured under Normal Conditions and at Elevated Temperature. Constr. Sci. 2013, 14, 71–78. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).