Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand

Abstract

:1. Introduction

2. Samples and Methods

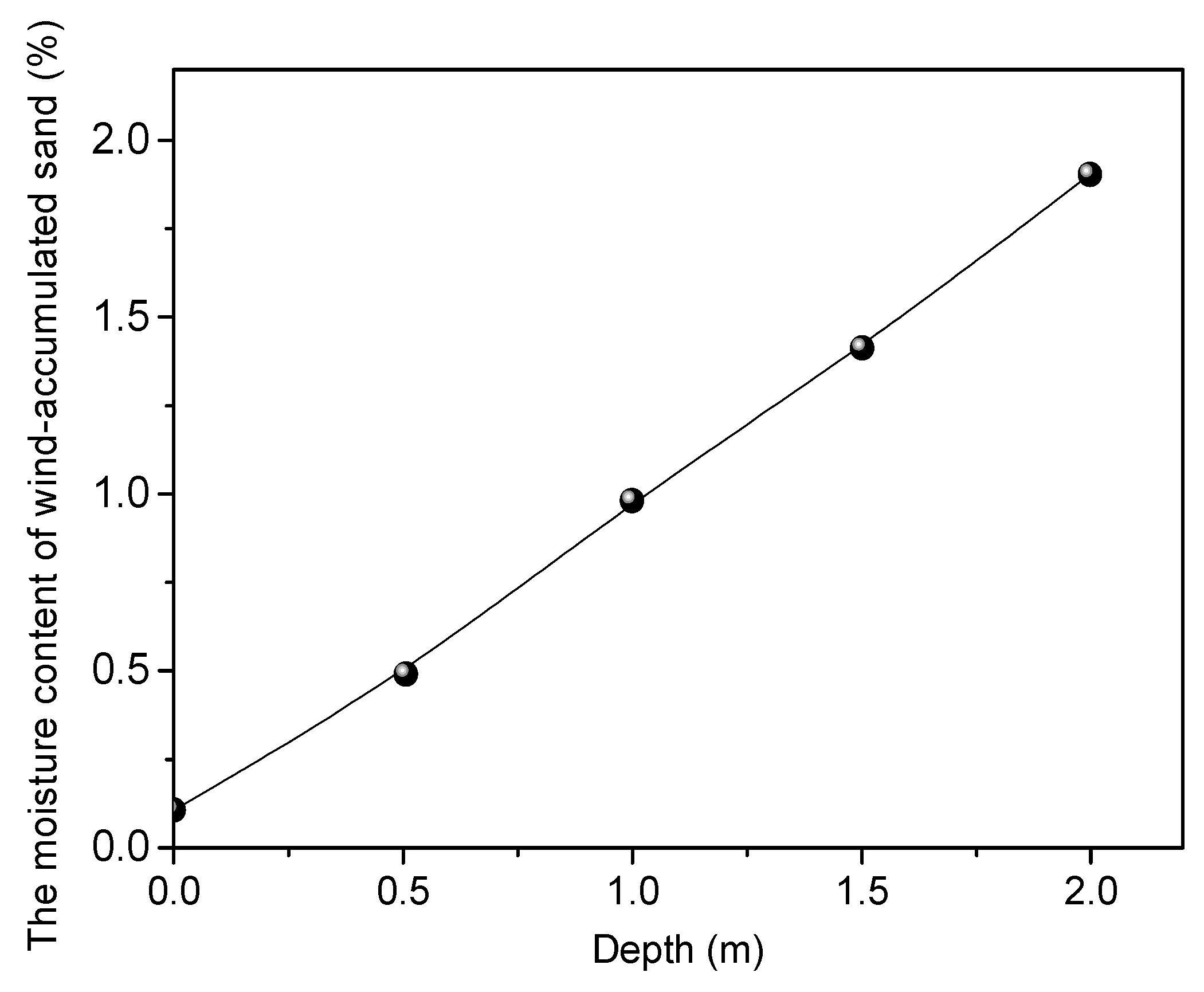

2.1. Sampling Site

2.2. Strength Test Preparation

- (1)

- A standard sieve with an aperture of 2 mm is used to sieve the aeolian sand to obtain fine particles.

- (2)

- According to the water content and cement contents shown in Table 1, a certain amount of water and Portland cement were added to the air-dried aeolian sand. Then we stirred the aeolian sand evenly and sealed it with plastic wrap for one day.

- (3)

- We sprayed some water on the inner wall of the triaxial sample maker and attached the plastic wrap to the inner wall of the sample maker.

- (4)

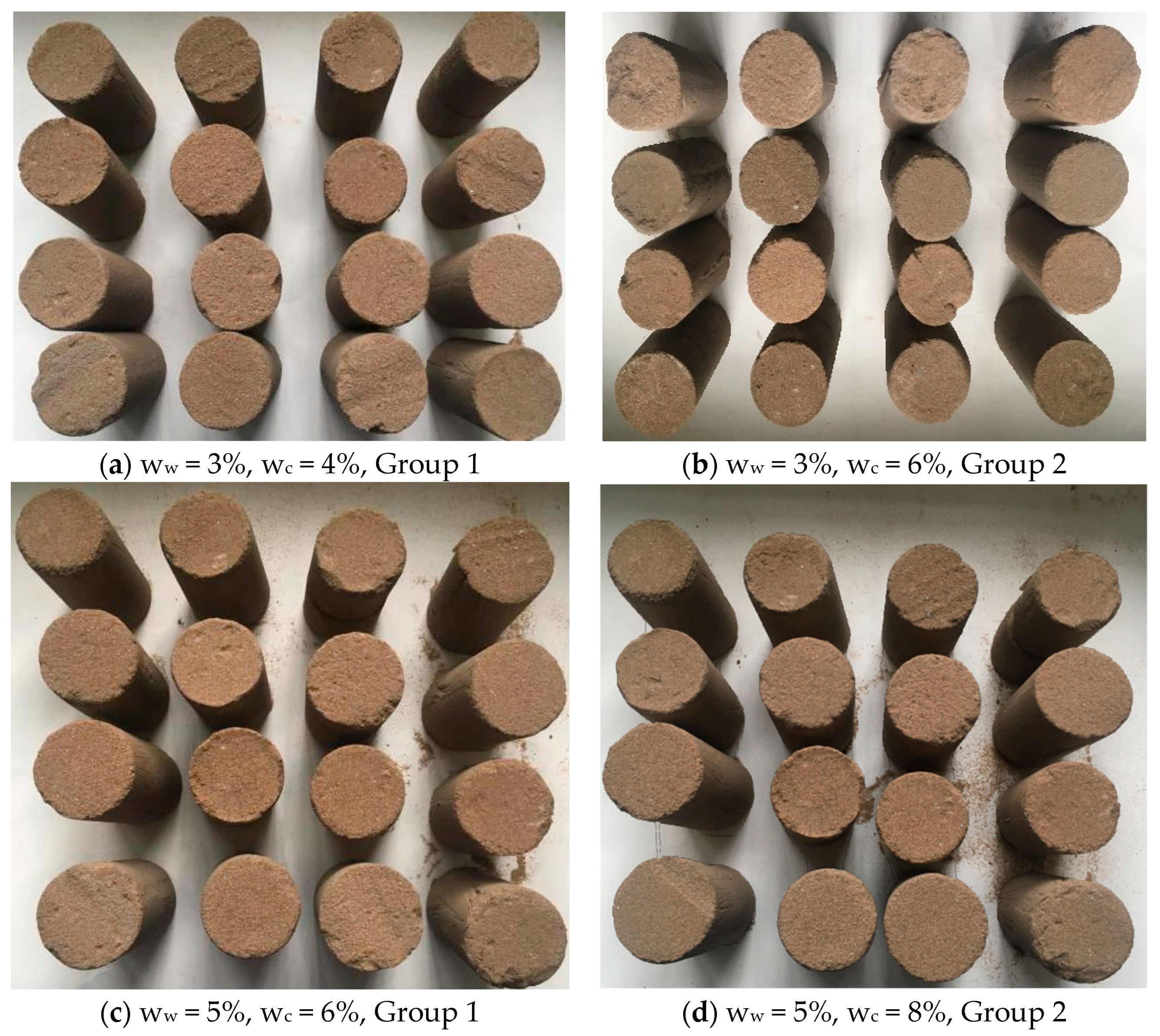

- The sample was compacted in 3 layers according to the sample height. During the compaction process, all layers of soil had equal quality. After each layer was compacted to the required height, we shaved the surface and then added another layer of soil. This process continued until the last layer was compacted. Subsequently, both ends of the sample were flattened. These samples were taken out after one day of natural hardening in the compaction equipment. These specimens were placed in the laboratory for 14 days prior to the triaxial compressive tests. The formed triaxial test sample has a diameter of 31.9 cm and a height of 8 cm, as shown in Figure 4.

2.3. Microscopic Test Methods

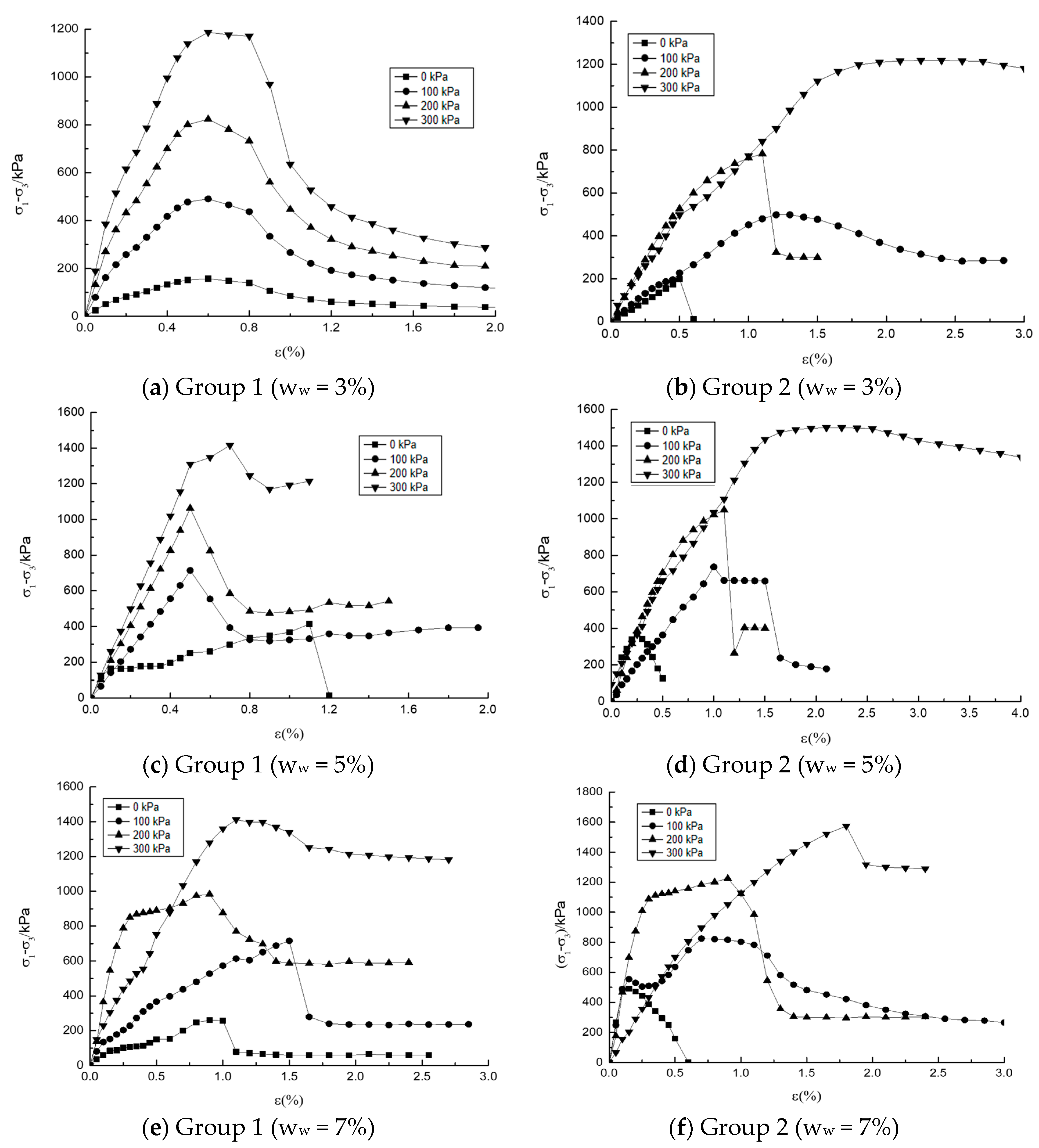

3. Results and Discussion

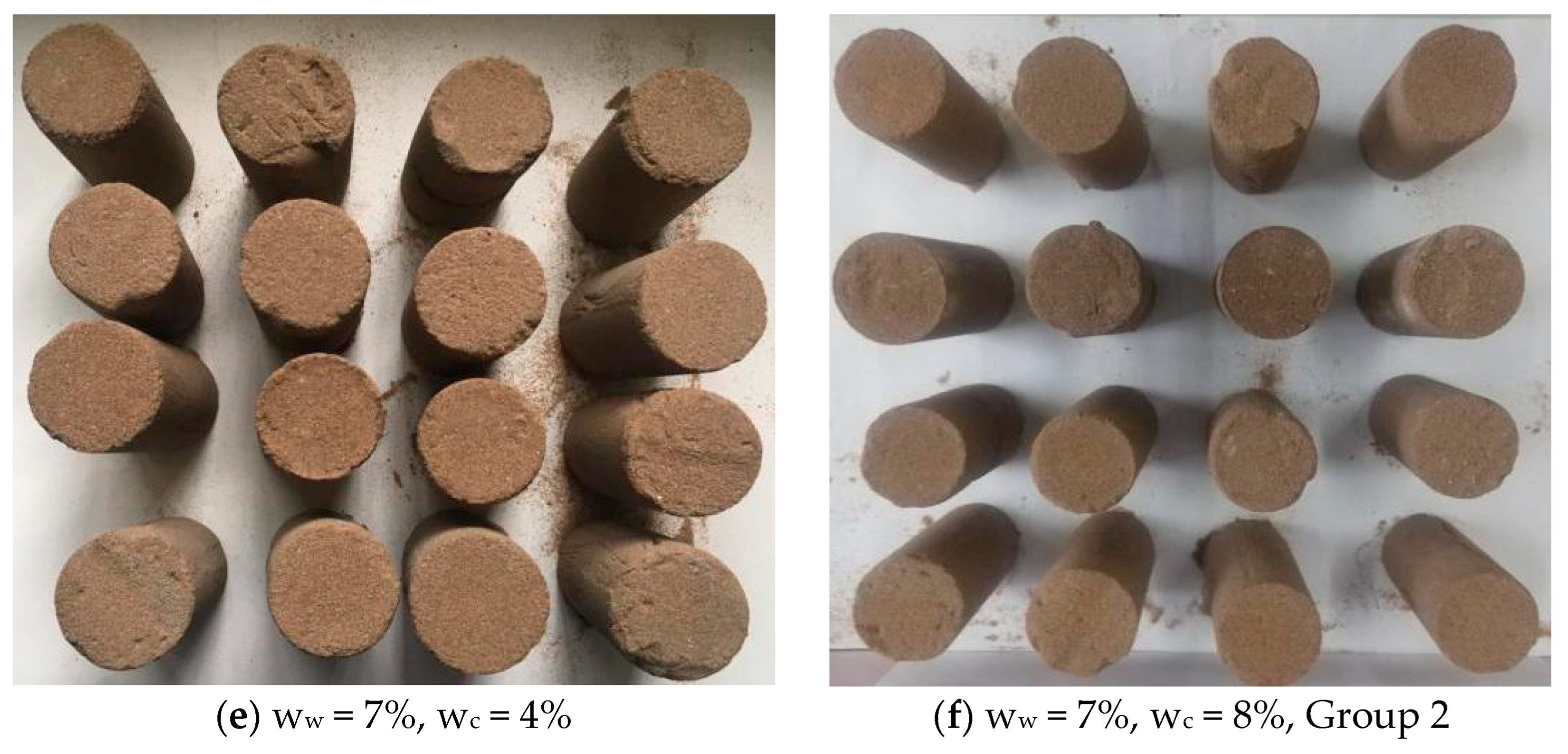

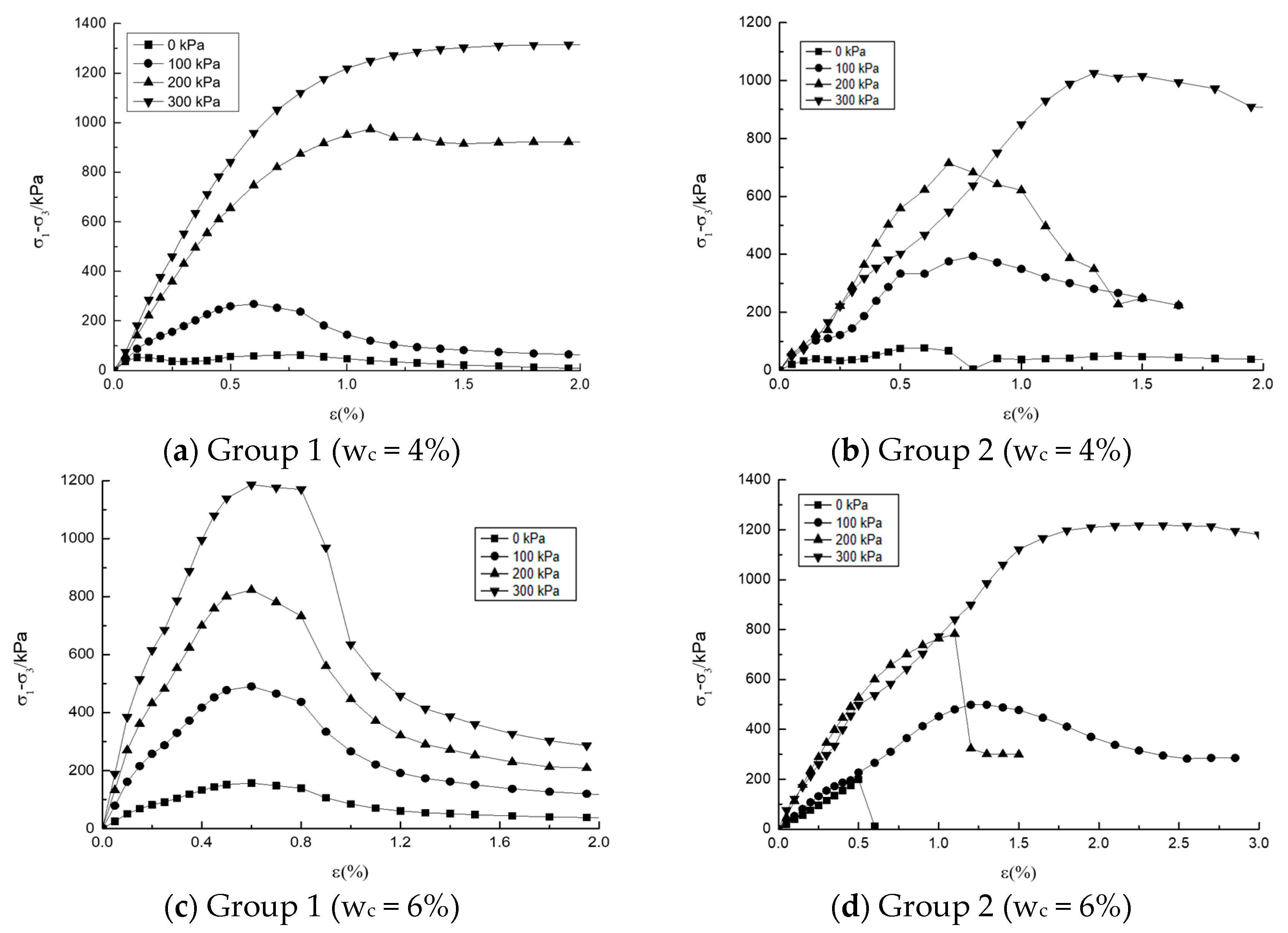

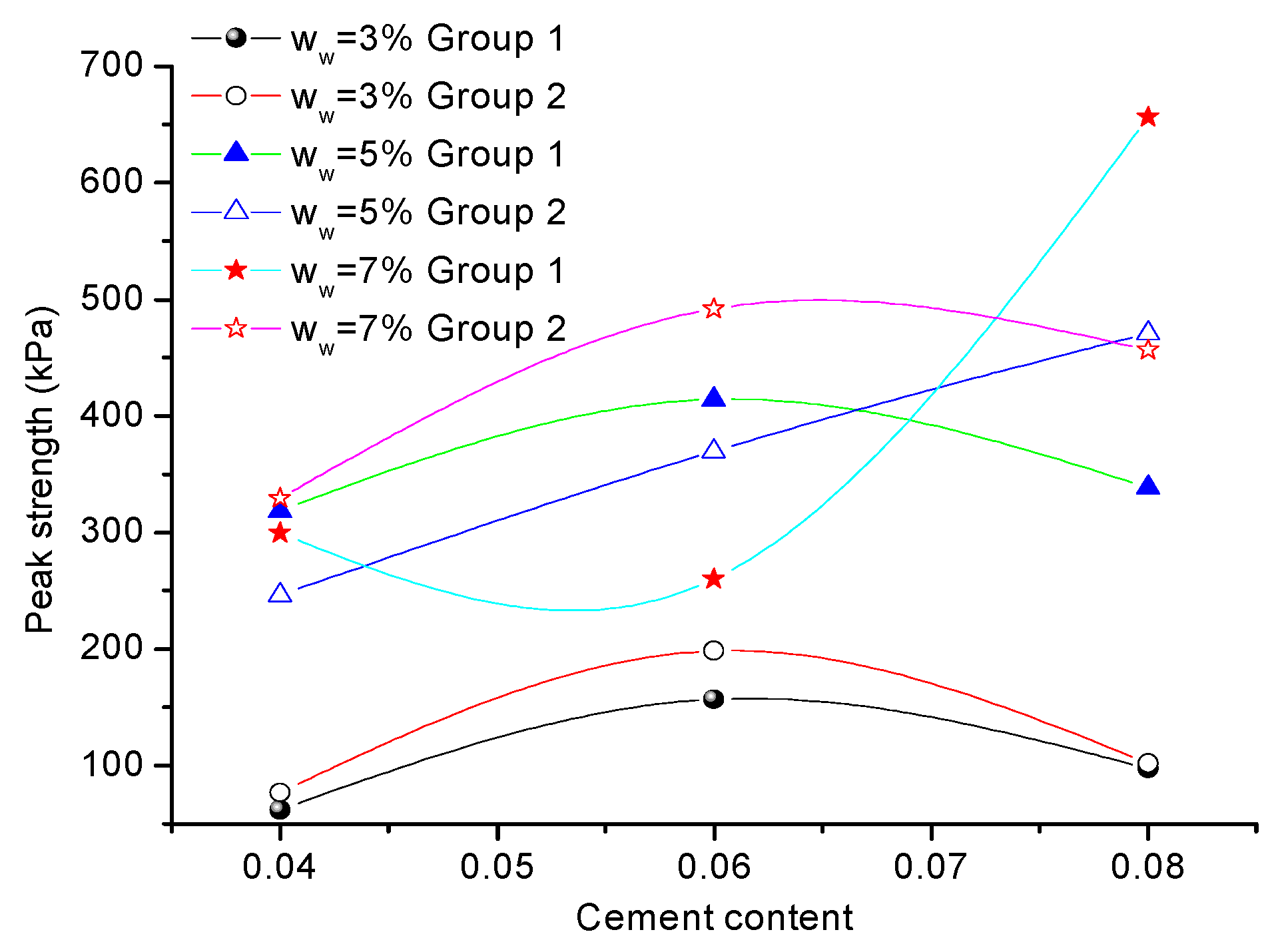

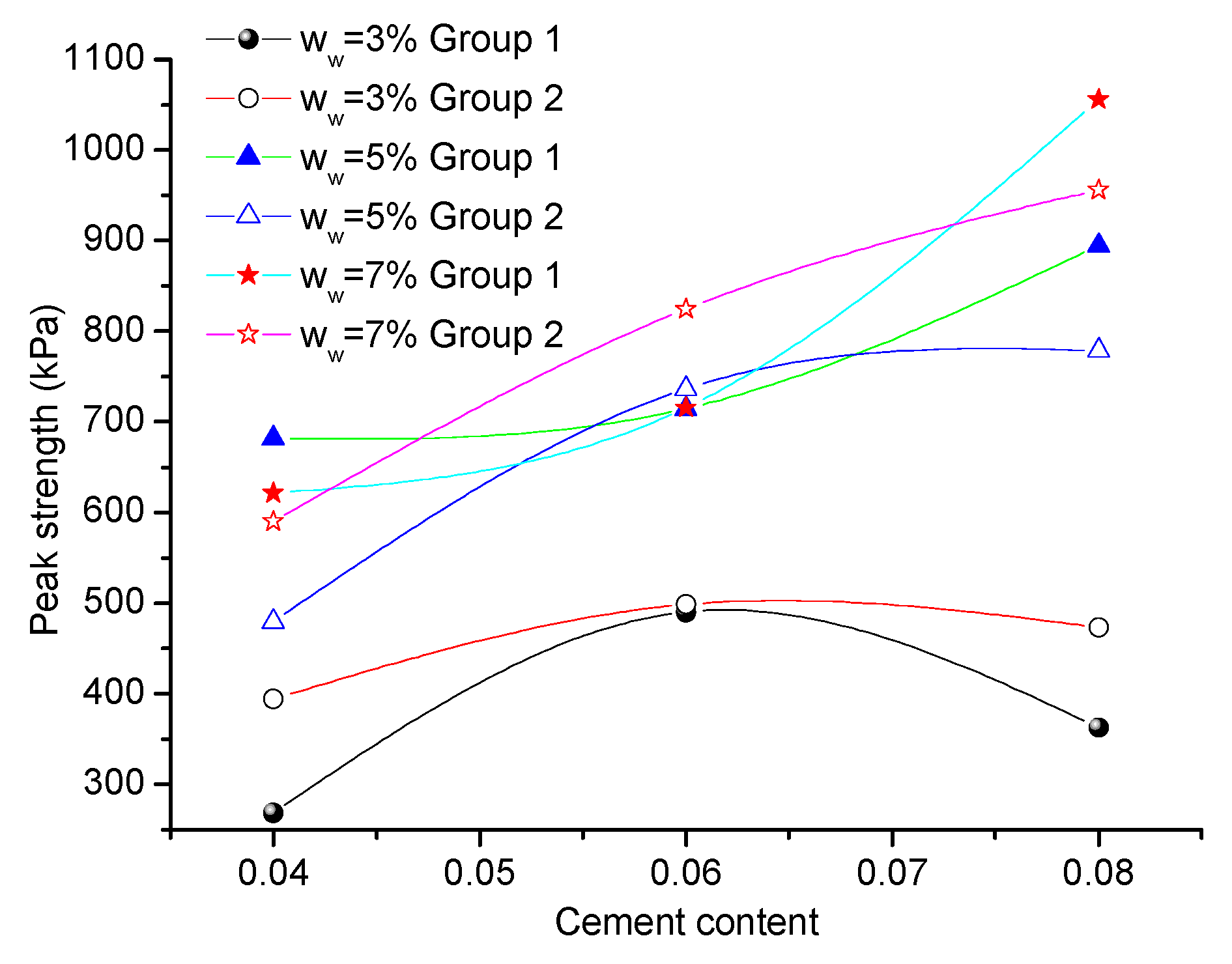

3.1. Influence of Cement Contents on the Compressive Strength

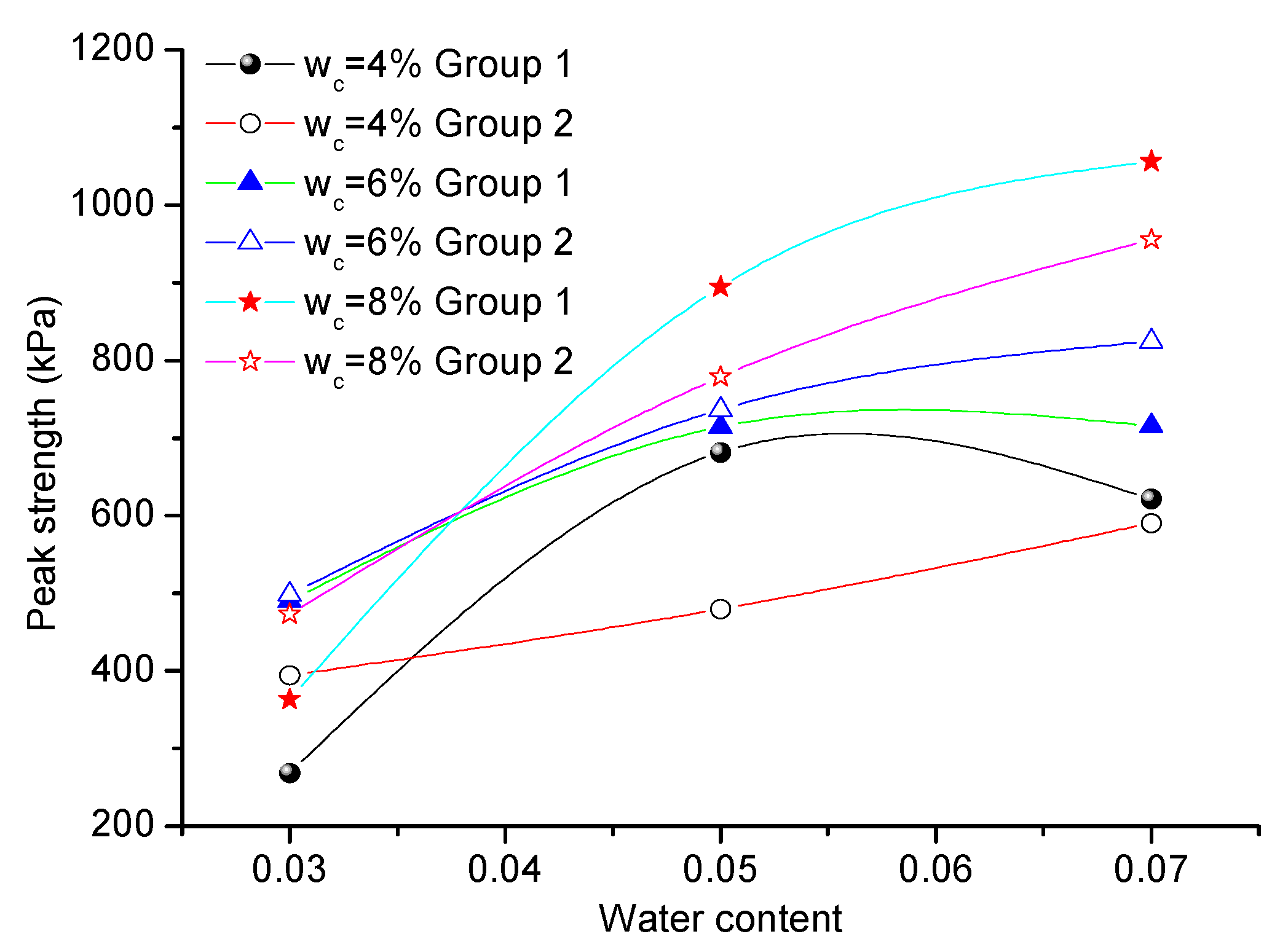

3.2. Influence of Water Contents on the Compressive Strength

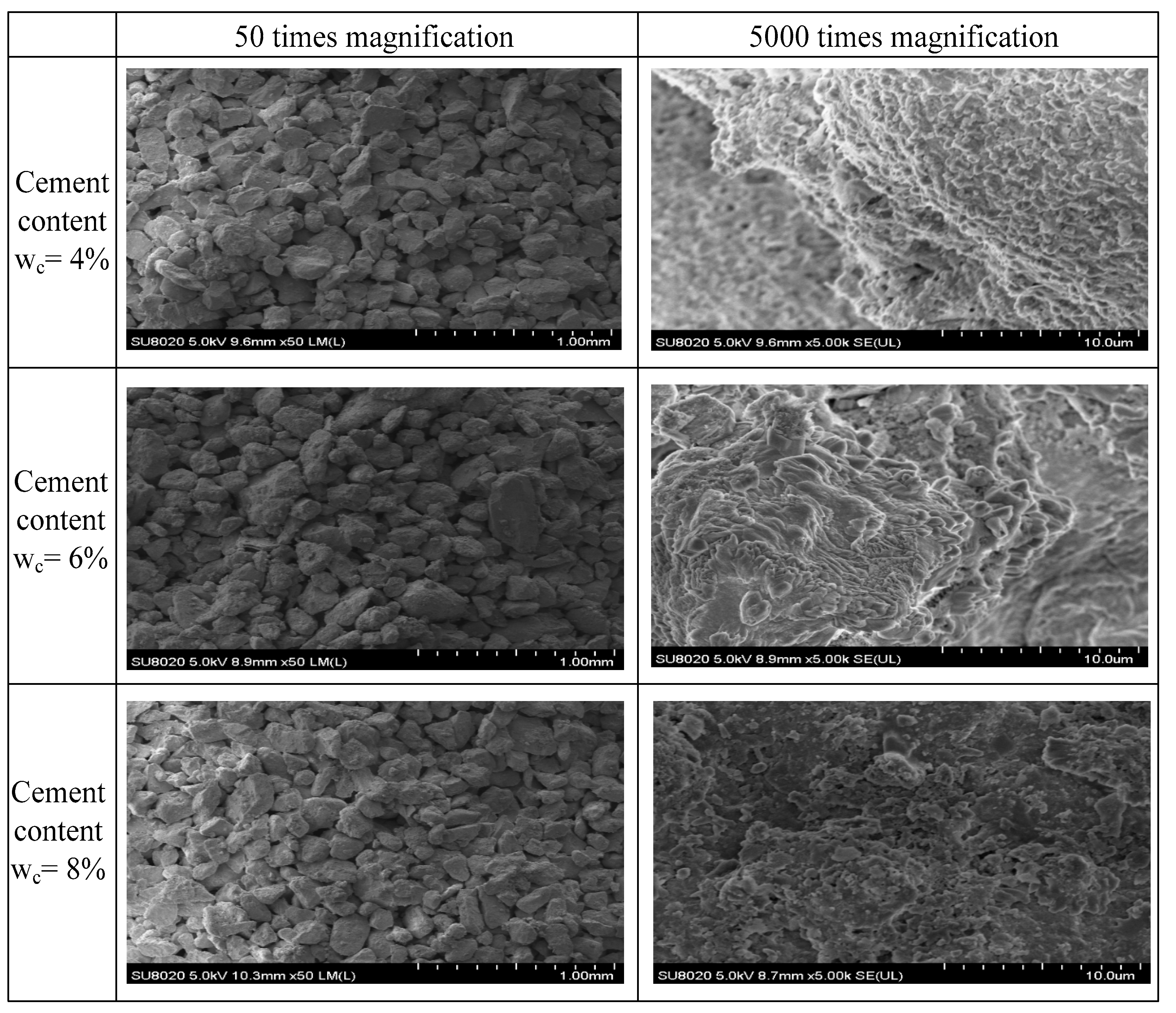

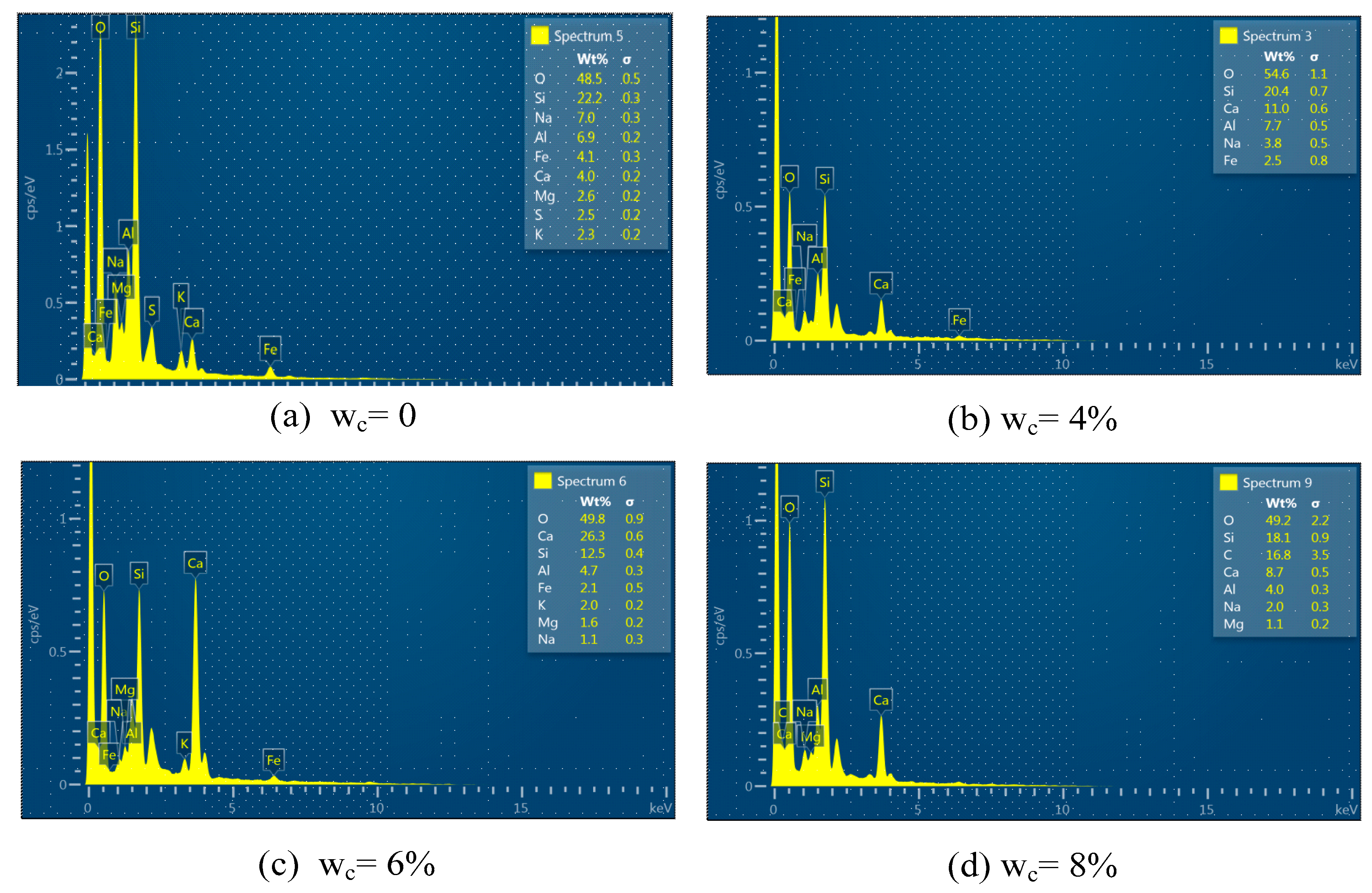

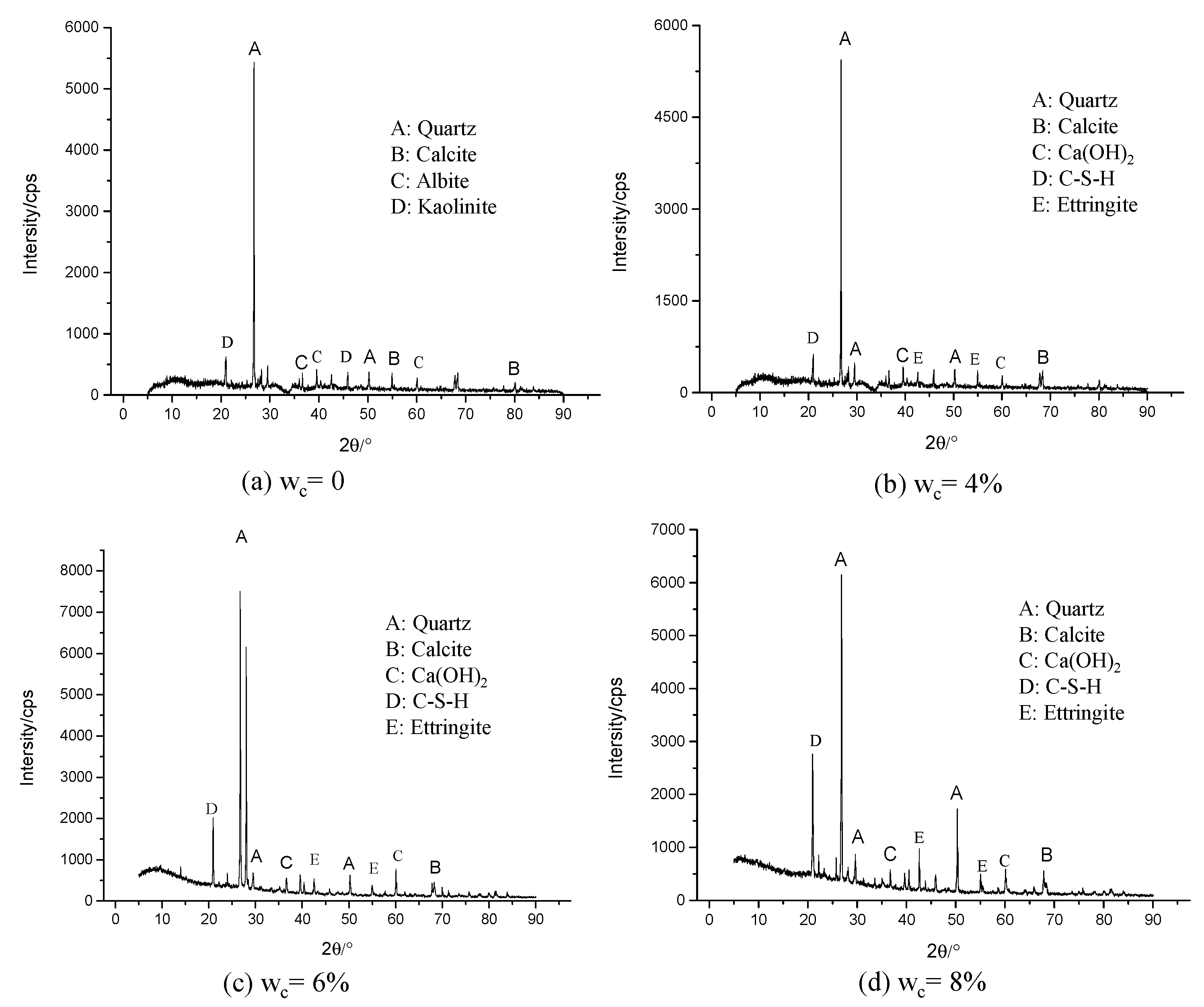

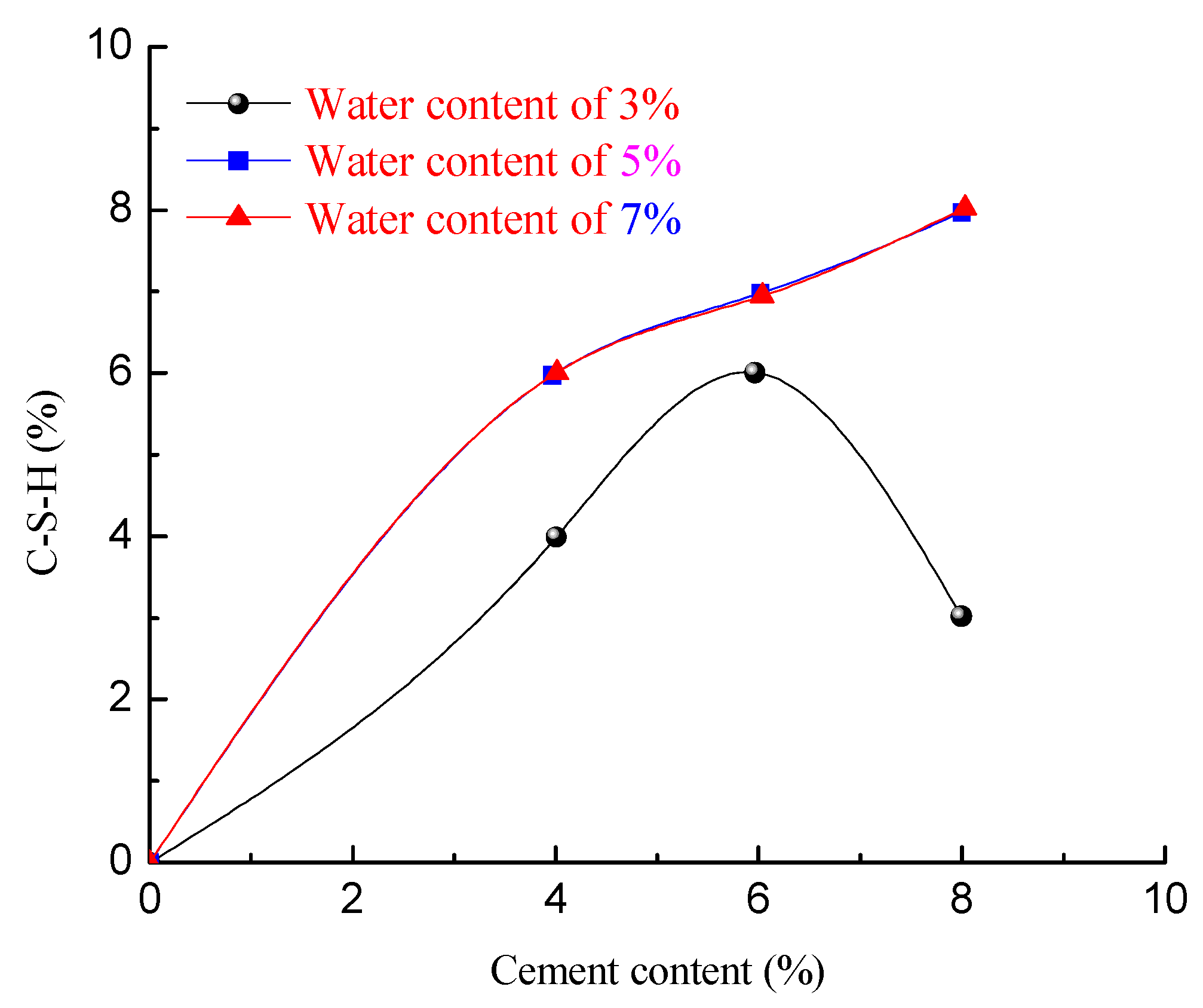

3.3. Microstructures of Cement-Stabilized Aeolian Sand

4. Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Sanad, H.; Ismael, N.; Nayfeh, A. Geotechnical properties of dune sands in Kuwait. Eng. Geol. 1993, 34, 45–52. [Google Scholar] [CrossRef]

- Al-Taie, A.J.; Al-Shakarchi, Y.J.; Mohammed, A.A. Investigation of geotechnical specifications of sand dune soil: A case study around Baiji in Iraq. IIUM Eng. J. 2013, 14, 121–132. [Google Scholar] [CrossRef]

- Padmakumar, G.; Srinivas, K.; Uday, K.; Iyer, K.; Pathak, P.; Keshava, S.; Singh, D. Characterization of aeolian sands from Indian desert. Eng. Geol. 2012, 139, 38–49. [Google Scholar] [CrossRef]

- Elipe, M.G.; López-Querol, S. Aeolian sands: Characterization, options of improvement and possible employment in construction—The State-of-the-art. Constr. Build. Mater. 2014, 73, 728–739. [Google Scholar] [CrossRef]

- Deb, K.; Konai, S. Bearing capacity of geotextile-reinforced sand with varying fine fraction. Geomech. Eng. 2014, 6, 33–45. [Google Scholar] [CrossRef]

- Al-Abdullah, S.F. An approach in improving the properties of sand dunes. J. Eng. 2006, 13, 930–939. [Google Scholar]

- Wang, W.F.; Fan, J.T.; Zhang, W.M.; Qu, J.J.; Lin, B. Research on the Protective Effect of Nylon Mesh Fence on the Top of Dunhuang Mogao Grottoes. Chin. Desert 2005, 25, 640–648. [Google Scholar]

- Liu, J.; Bai, Y.; Song, Z.; Kanungo, D.P.; Wang, Y.; Bu, F.; Chen, Z.; Shi, X. Stabilization of sand using different types of short fibers and organic polymer. Constr. Build. Mater. 2020, 253, 119164. [Google Scholar] [CrossRef]

- Chenari, R.J.; Pishkhani, S.S.; Fard, M.K.; Sosahab, J.S. Experimental and numerical investigation of dynamic properties of soil stabilized by young Vetiver. Ital. Geotech. J. 2018, 52, 49–58. [Google Scholar]

- Chenari, R.J.; Fatahi, B.; Ghorbani, A.; Alamoti, M.N. Evaluation of strength properties of cement stabilized sand mixed with EPS beads and fly ash. Geomech. Eng. 2018, 14, 533–544. [Google Scholar]

- Pongsivasathit, S.; Horpibulsuk, S.; Piyaphipat, S. Assessment of mechanical properties of cement stabilized soils. Case Stud. Constr. Mater. 2019, 11, e00301. [Google Scholar] [CrossRef]

- Akili, W.; Monismith, C. Permanent deformation characteristics of cement-emulsion stabilized sand. In Proceedings Association of Asphalt Paving Technologists Technical Sessions; Association of Asphalt Paving Technologists: Lino Lakes, MN, USA, 1978; Volume 47, pp. 281–301. [Google Scholar]

- Al-Abdulwahhab, H.; Bayomy, F.; Al-Halhouli, A. Evaluation of Emulsified, Asphalt-Treated Sand for Low-Volume Roads and Road Bases. Transp. Res. Rec. 1987, 1106, 71–80. [Google Scholar]

- Wahhab, H.; Abduljauwad, S. A study of soil stabilization in the Eastern Province of Saudi Arabia. In Proceedings of the 11th International Road Federation World Meeting, Seoul, Republic of Korea, April 1989; Volume 3, pp. 117–120. [Google Scholar]

- Shooshpasha, I.; Shirvani, R.A. Effect of cement stabilization on geotechnical properties of sandy soils. Geomech. Eng. 2015, 8, 17–31. [Google Scholar] [CrossRef]

- Shalabi, F.I.; Mazher, J.; Khan, K.; Alsuliman, M.; Almustafa, I.; Mahmoud, W.; Alomran, N. Cement-stabilized waste sand as sustainable construction materials for foundations and highway roads. Materials 2019, 12, 600. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, S.; Khan, Q.; Ku, T. Effect of sand on the stiffness characteristics of cement-stabilized clay. Constr. Build. Mater. 2020, 264, 120192. [Google Scholar] [CrossRef]

- Du, J.; Zheng, G.; Liu, B.; Jiang, N.-J.; Hu, J. Triaxial behavior of cement-stabilized organic matter–disseminated sand. Acta Geotech. 2021, 16, 211–220. [Google Scholar] [CrossRef]

- Mola-Abasi, H.; Khajeh, A.; Naderi Semsani, S. Variables controlling tensile strength of stabilized sand with cement and zeolite. J. Adhes. Sci. Technol. 2018, 32, 947–962. [Google Scholar] [CrossRef]

- Hashemi, M.; Massart, T.; Salager, S.; Herrier, G.; François, B. Pore scale characterization of lime-treated sand–bentonite mixtures. Appl. Clay Sci. 2015, 111, 50–60. [Google Scholar] [CrossRef]

- Mola-Abasi, H.; Kordtabar, B.; Kordnaeij, A. Effect of natural zeolite and cement additive on the strength of sand. Geotech. Geol. Eng. 2016, 34, 1539–1551. [Google Scholar] [CrossRef]

- Wei, X.; Ku, T. New design chart for geotechnical ground improvement: Characterizing cement-stabilized sand. Acta Geotech. 2020, 15, 999–1011. [Google Scholar] [CrossRef]

- Wei, X.; Liu, H.; Ku, T. Microscale analysis to characterize effects of water content on the strength of cement-stabilized sand–clay mixtures. Acta Geotech. 2020, 15, 2905–2923. [Google Scholar] [CrossRef]

- Jumassultan, A.; Sagidullina, N.; Kim, J.; Ku, T.; Moon, S.-W. Performance of cement-stabilized sand subjected to freeze-thaw cycles. Geomech. Eng. 2021, 25, 41–48. [Google Scholar]

- ShahriarKian, M.; Kabiri, S.; Bayat, M. Utilization of Zeolite to Improve the Behavior of Cement-Stabilized Soil. Int. J. Geosynth. Ground Eng. 2021, 7, 35. [Google Scholar] [CrossRef]

- Chhun, K.T.; Choo, H.; Kaothon, P.; Yune, C.Y. Experimental study on the strength behavior of cement-stabilized sand with recovered carbon black. Geomech. Eng. 2020, 23, 31–38. [Google Scholar]

- Lu, X.L.; Yang, W.Z.; Cui, Q. Report on key technology of power transmission and transformation project under complicated geological environment. China Electric Power Research Institute, Beijing. 2014; unpublished work. [Google Scholar]

- Liu, G.; Cai, M.; Huang, M. Mechanical properties of brittle rock governed by micro-geometric heterogeneity. Comput. Geotech. 2018, 104, 358–372. [Google Scholar] [CrossRef]

- Liu, G.; Peng, J.; Zhang, Z.; Wang, Z.; Yang, Y. Numerical investigation of fluid-driven crack propagation and coalescence in granite specimen with two pre-existing flaws. J. Nat. Gas Sci. Eng. 2020, 75, 103132. [Google Scholar] [CrossRef]

- Wang, X.; Cai, M. A comprehensive parametric study of grain-based models for rock failure process simulation. Int. J. Rock Mech. Min. Sci. 2019, 115, 60–76. [Google Scholar] [CrossRef]

- Liu, G.; Cai, M. Modeling time-dependent deformation behavior of brittle rock using grain-based stress corrosion method. Comput. Geotech. 2020, 118, 103323. [Google Scholar] [CrossRef]

- Cardoso, R. Influence of Water–Cement Ratio on the Hydraulic Behavior of an Artificially Cemented Sand. Geotech. Geol. Eng. 2017, 35, 1513–1527. [Google Scholar] [CrossRef]

- Cardoso, R.; Ribeiro, D.; Néri, R. Bonding effect on the evolution with curing time of compressive and tensile strength of sand-cement mixtures. Soils Found. 2017, 57, 655–668. [Google Scholar] [CrossRef]

- Muhammad, N.; Siddiqua, S. Stabilization of silty sand using bentonite-magnesium-alkalinization: Mechanical, physicochemical and microstructural characterization. Appl. Clay Sci. 2019, 183, 105325. [Google Scholar] [CrossRef]

| No. a | Moisture Content (%) | Cement Content (%) |

|---|---|---|

| 3-4-1 | 3 | 4 |

| 3-4-2 | ||

| 3-6-1 | 6 | |

| 3-6-2 | ||

| 3-8-1 | 8 | |

| 3-8-2 | ||

| 5-4-1 | 5 | 4 |

| 5-4-2 | ||

| 5-6-1 | 6 | |

| 5-6-2 | ||

| 5-8-1 | 8 | |

| 5-8-2 | ||

| 7-4-1 | 7 | 4 |

| 7-4-2 | ||

| 7-6-1 | 6 | |

| 7-6-2 | ||

| 7-8-1 | 8 | |

| 7-8-2 |

| Water Content (%) | Cement Content (%) | Internal Friction Angle (°) | Cohesion (kPa) |

|---|---|---|---|

| 3 | 4 | 31.19 | 22.23 |

| 6 | 33.21 | 40.61 | |

| 8 | 32.43 | 22.61 | |

| 5 | 4 | 35.27 | 77.65 |

| 6 | 32.72 | 103.75 | |

| 8 | 33.81 | 117.78 | |

| 7 | 4 | 31.45 | 82.71 |

| 6 | 34.61 | 126.44 | |

| 8 | 36.74 | 164.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Q.; Liu, G.; Zhang, Z.; Fang, Y.; Gu, X. Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand. Buildings 2023, 13, 395. https://doi.org/10.3390/buildings13020395

Cui Q, Liu G, Zhang Z, Fang Y, Gu X. Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand. Buildings. 2023; 13(2):395. https://doi.org/10.3390/buildings13020395

Chicago/Turabian StyleCui, Qiang, Guang Liu, Zhenhua Zhang, Yiqiu Fang, and Xudong Gu. 2023. "Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand" Buildings 13, no. 2: 395. https://doi.org/10.3390/buildings13020395

APA StyleCui, Q., Liu, G., Zhang, Z., Fang, Y., & Gu, X. (2023). Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand. Buildings, 13(2), 395. https://doi.org/10.3390/buildings13020395