Data-Driven Shear Strength Prediction of FRP-Reinforced Concrete Beams without Stirrups Based on Machine Learning Methods

Abstract

1. Introduction

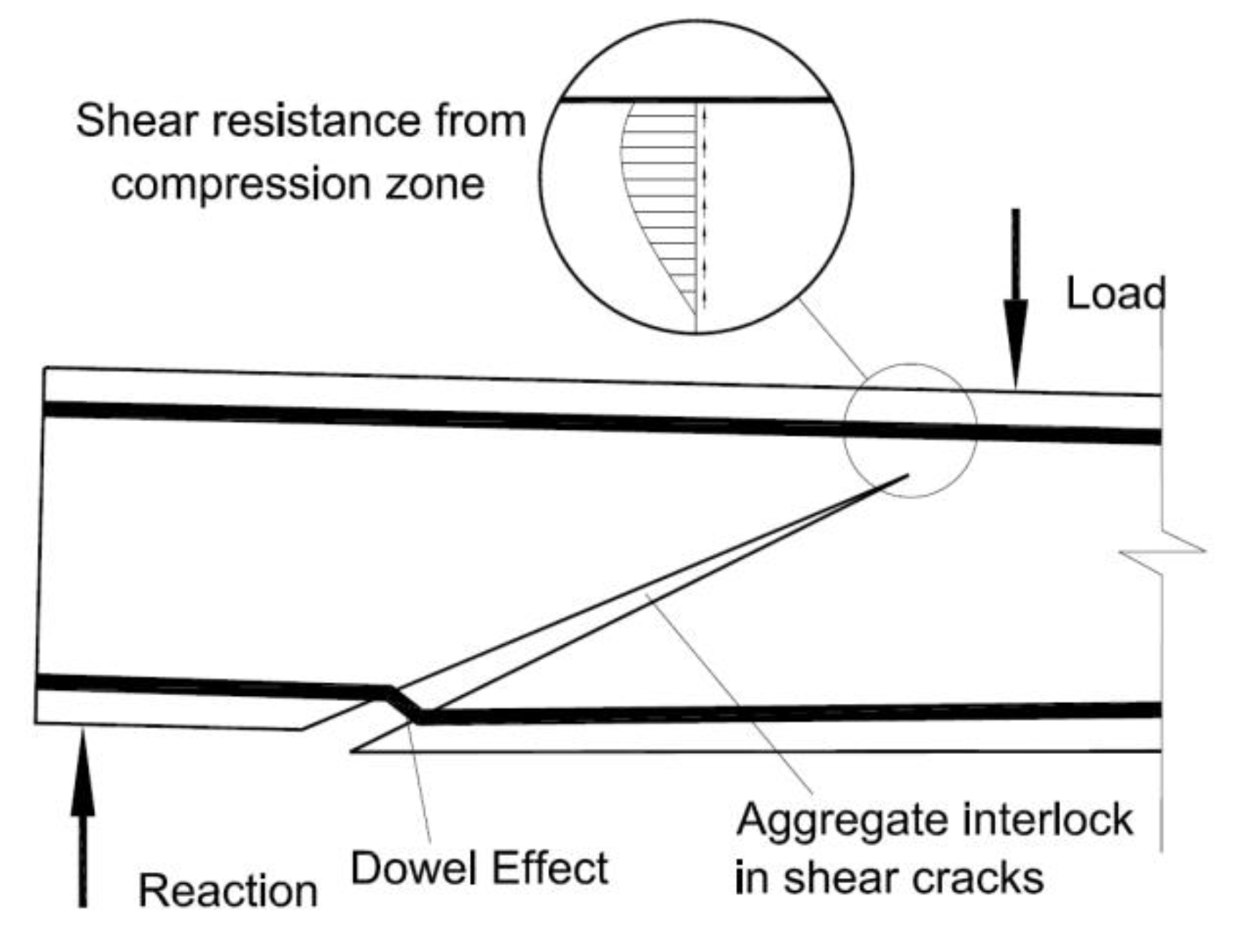

2. Shear Design Provisions and Machine Learning Approaches

2.1. Codified Shear Design Provisions

2.2. Machine Learning Models

2.2.1. Linear Regression

2.2.2. Decision Trees

2.2.3. Random Forests

2.2.4. XGBoost

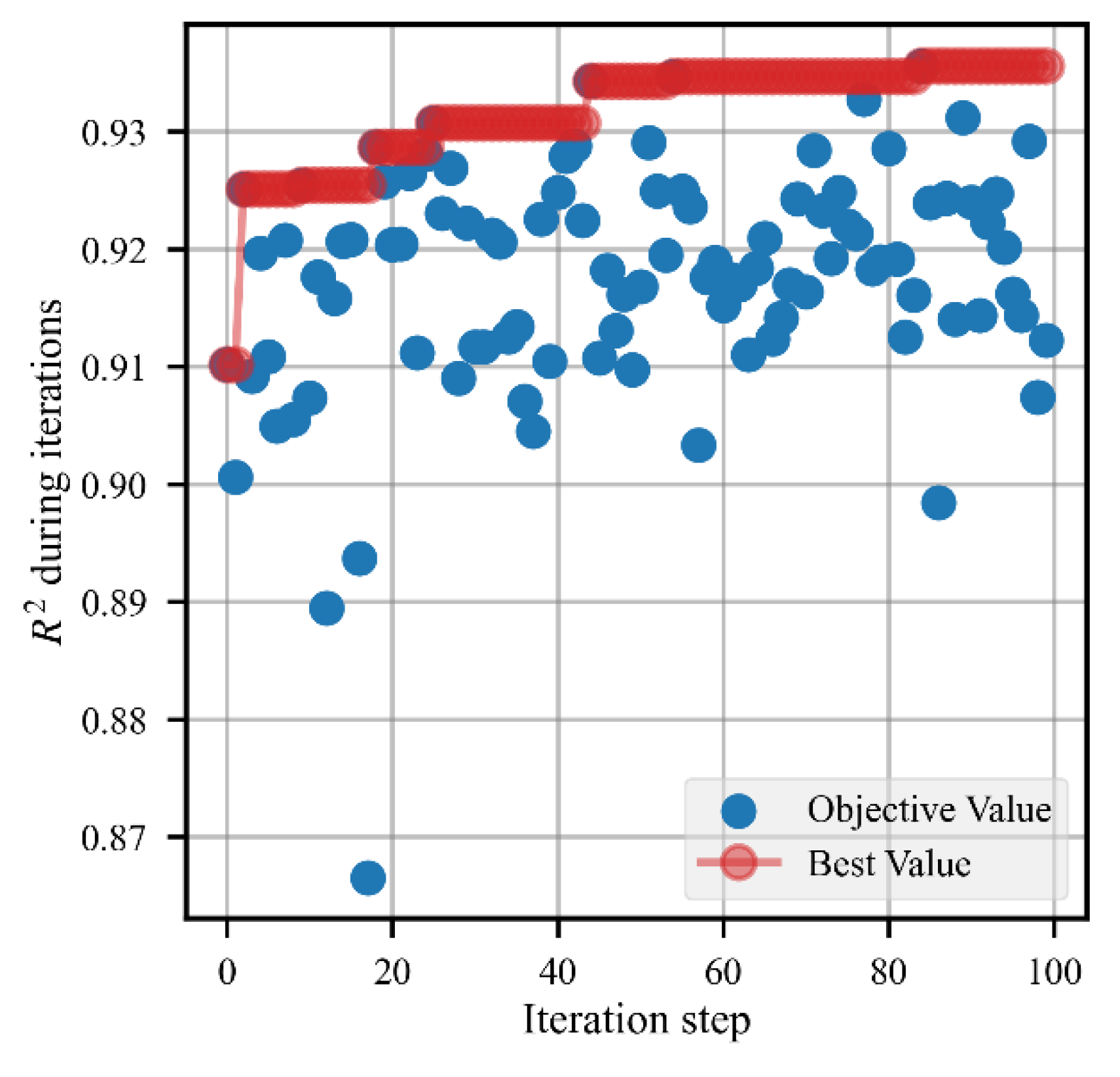

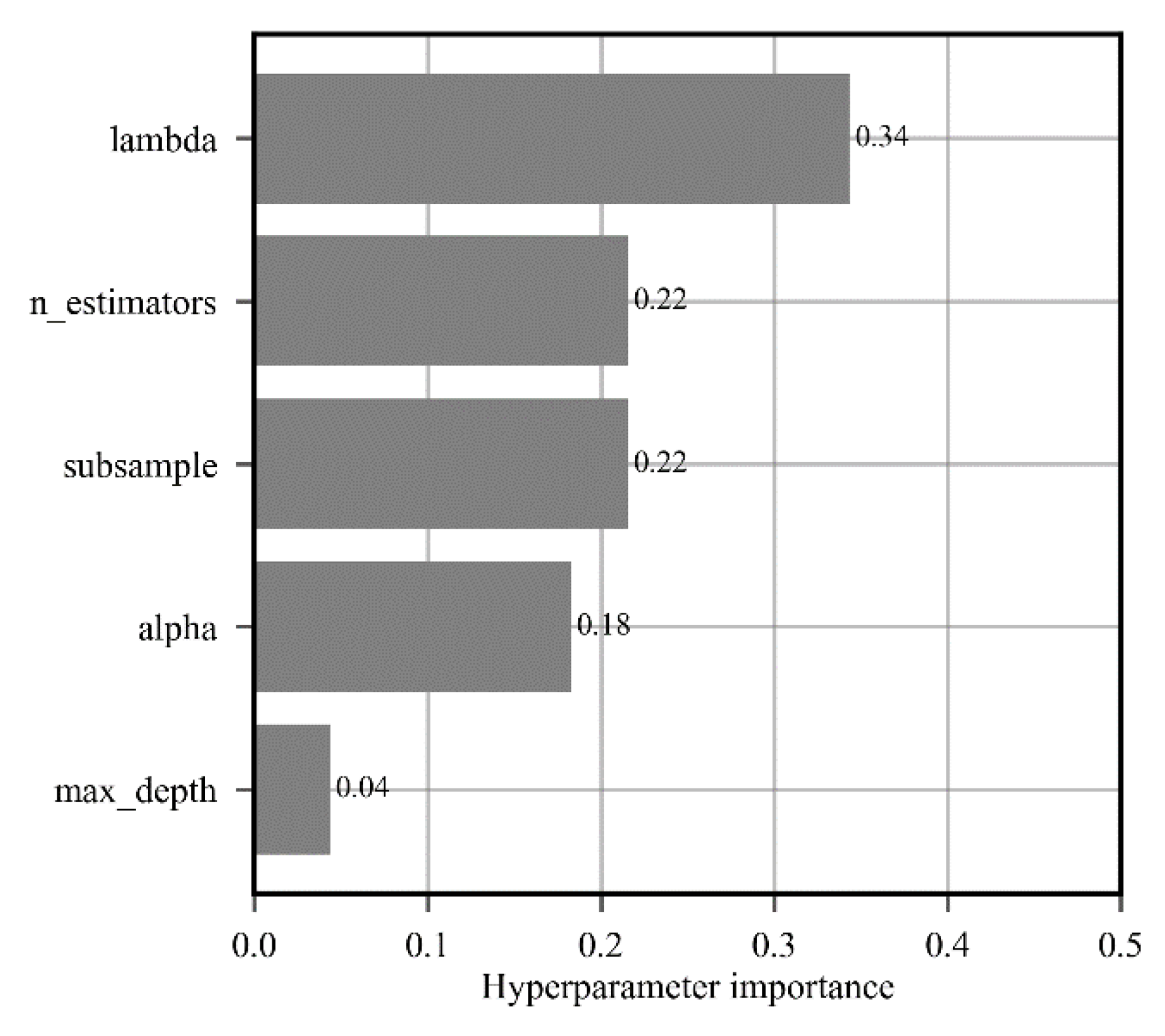

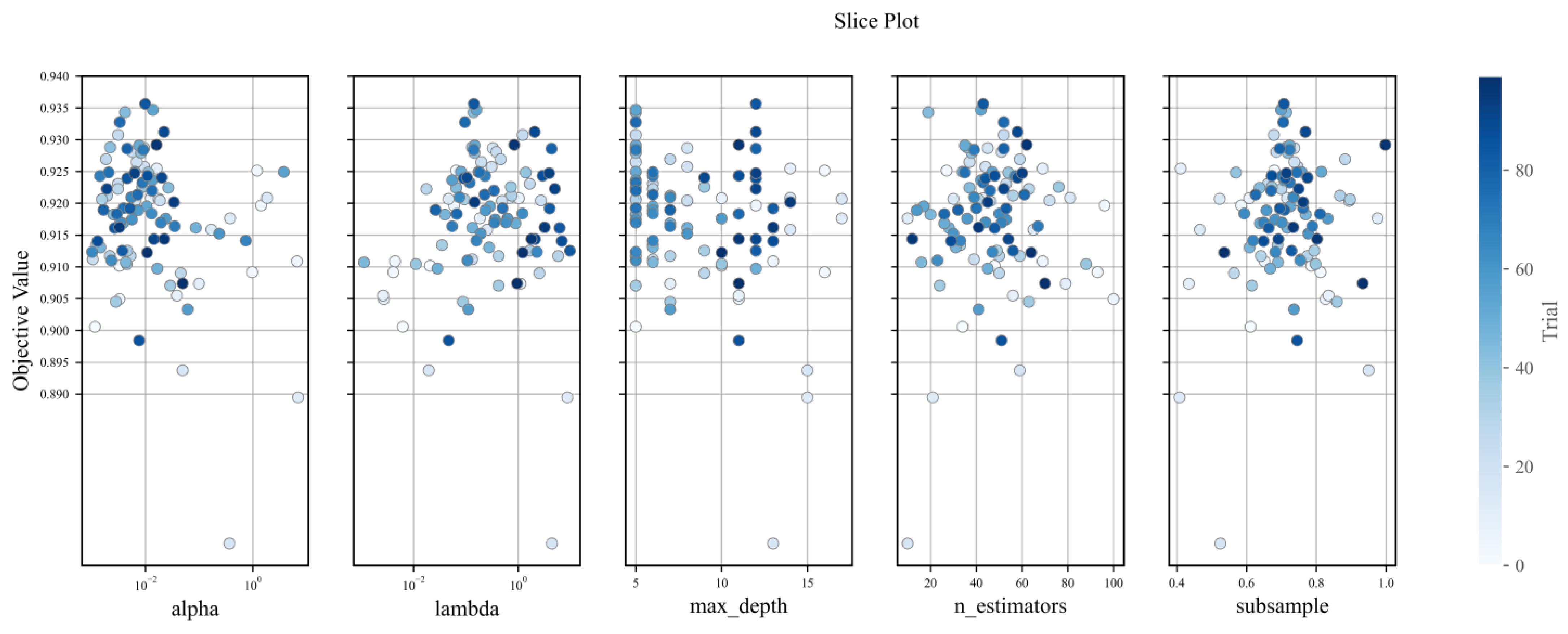

2.3. Bayesian Optimization

3. Database

4. Evaluation Methodology

4.1. Artificially Selected Features

4.2. Performance Measures

5. Implementation of the Predictive Model

6. Evaluation, Results and Analysis

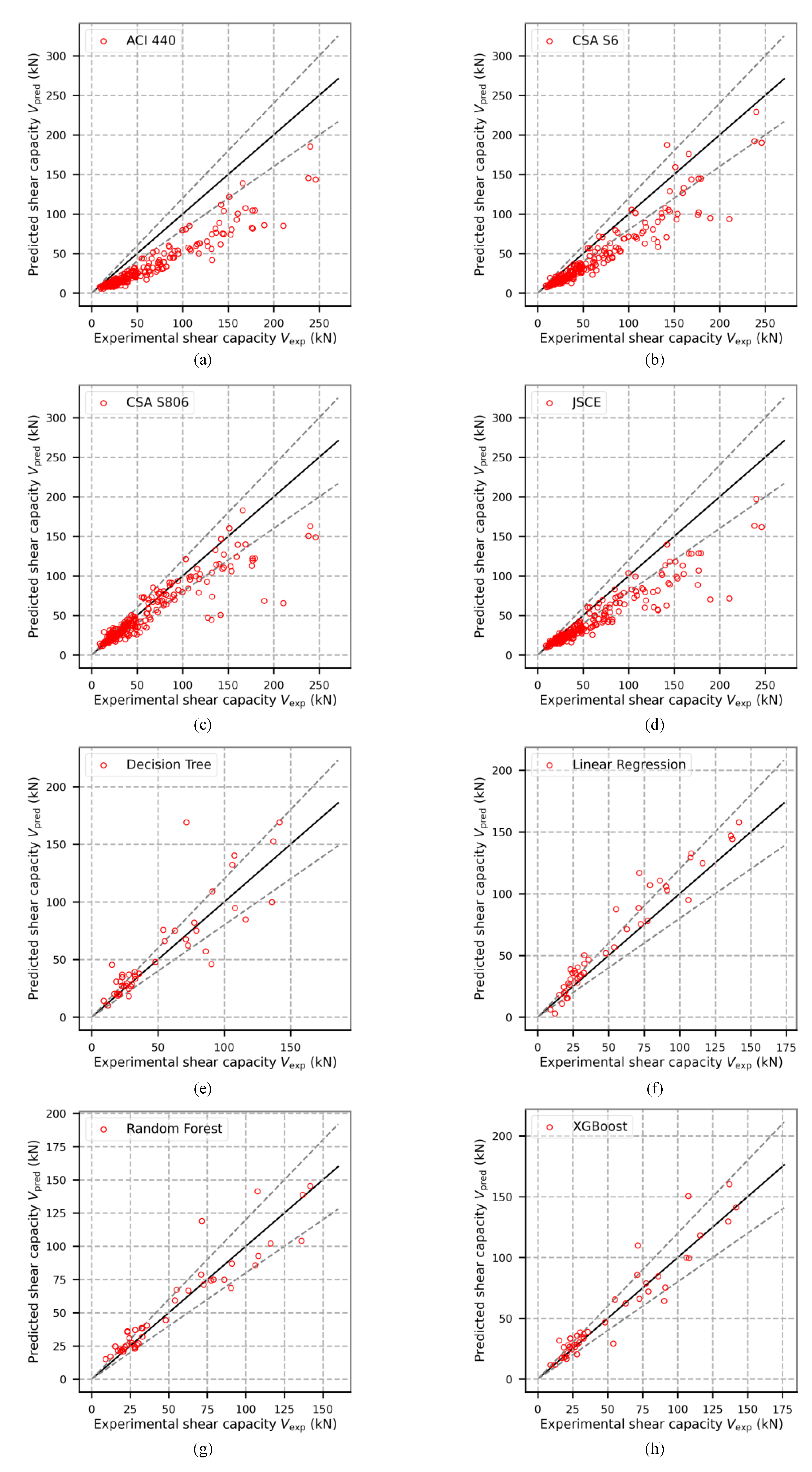

6.1. Performance Evaluation

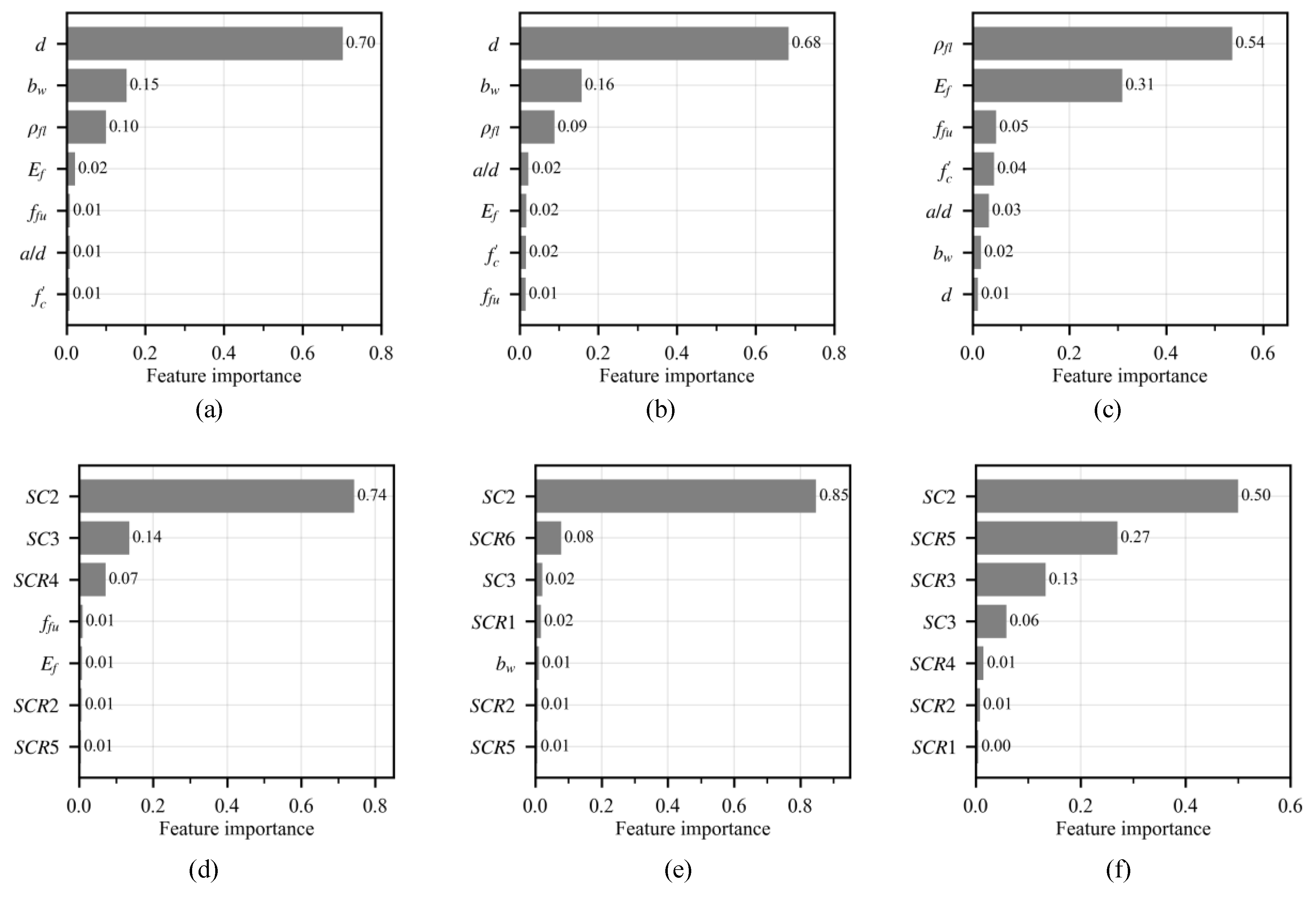

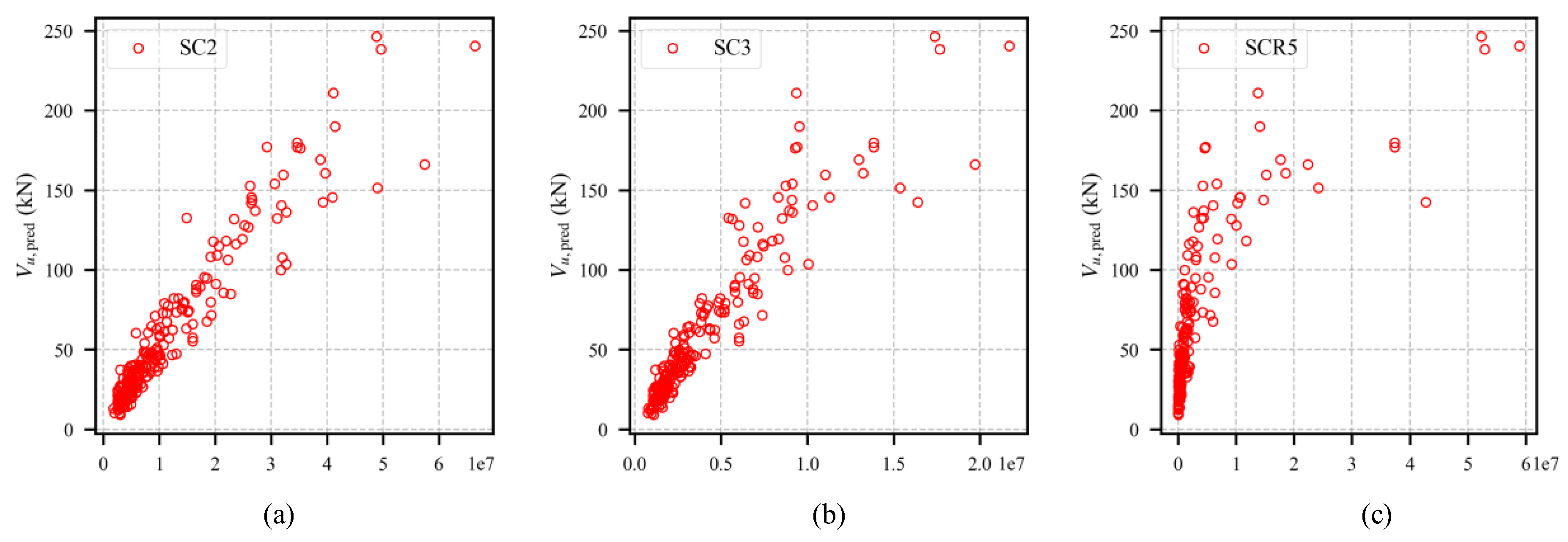

6.2. Feature Importance Analysis

7. Experimental Verification and Parametric Analysis

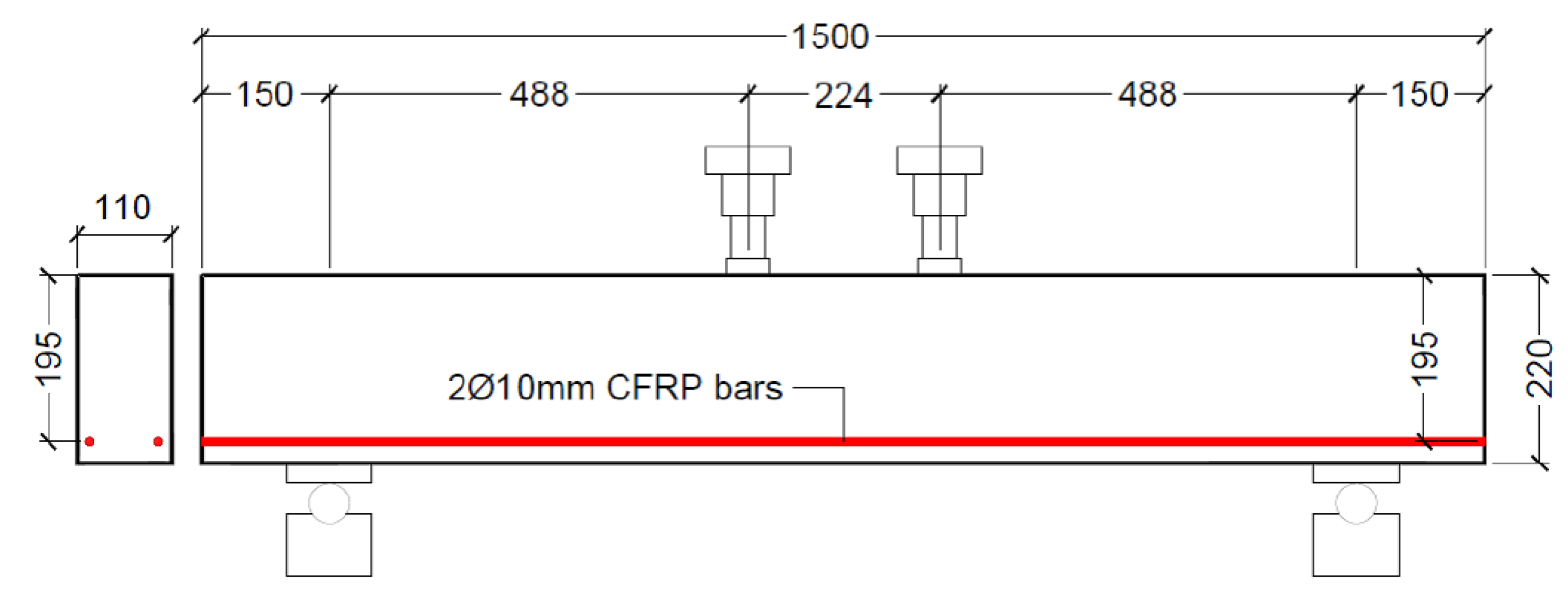

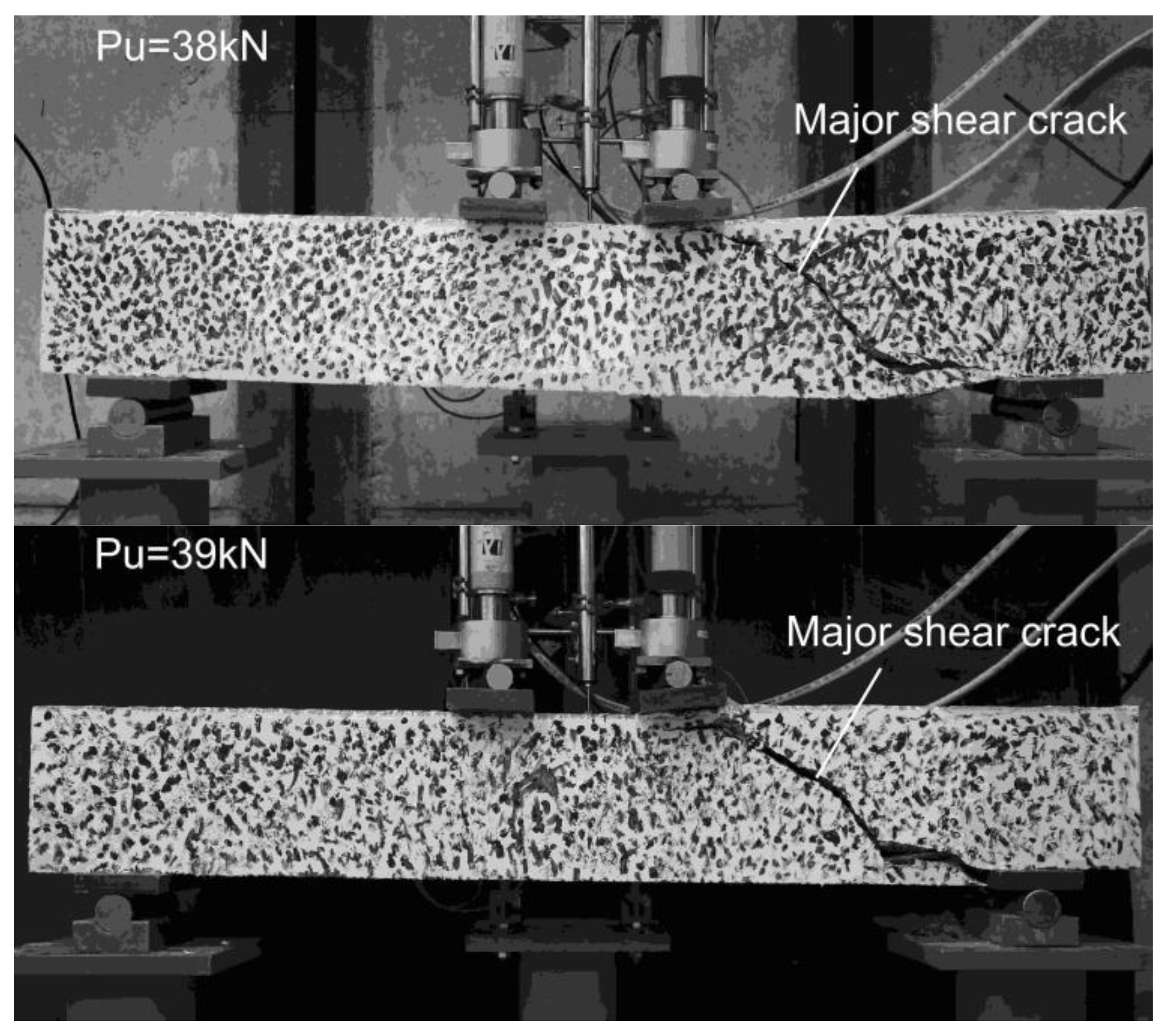

7.1. Test Verification

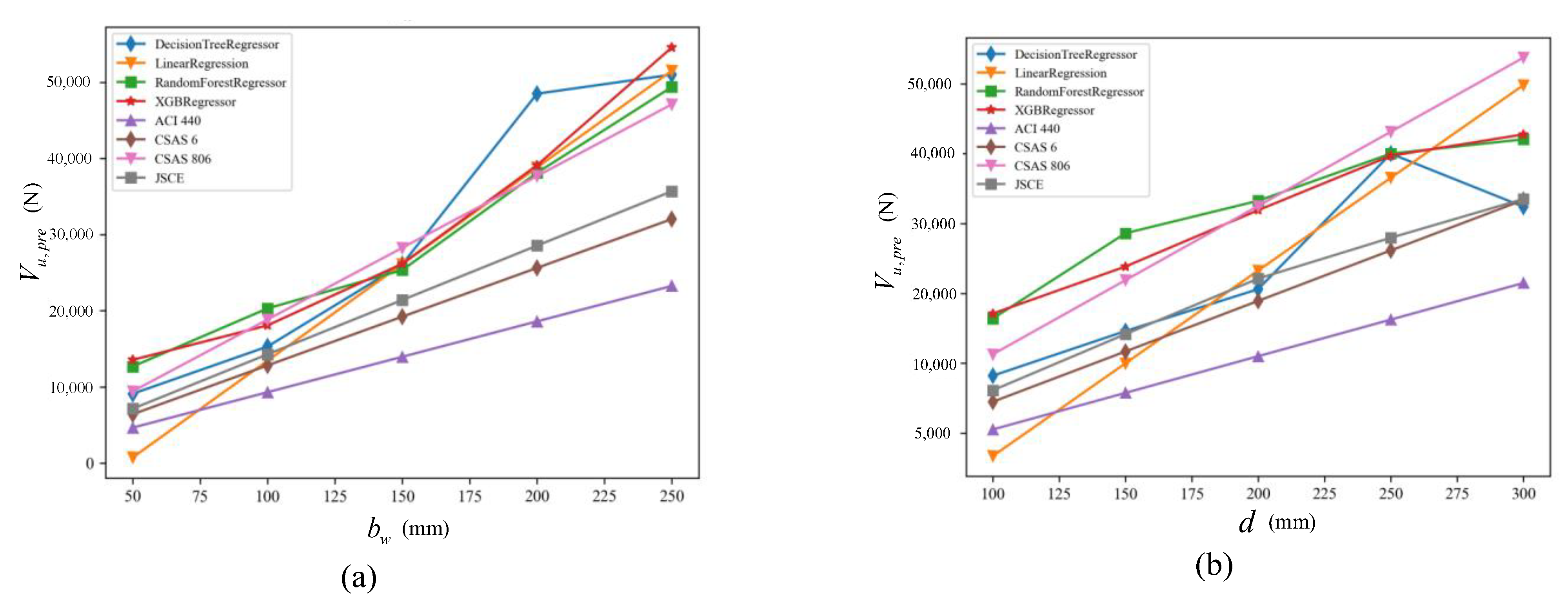

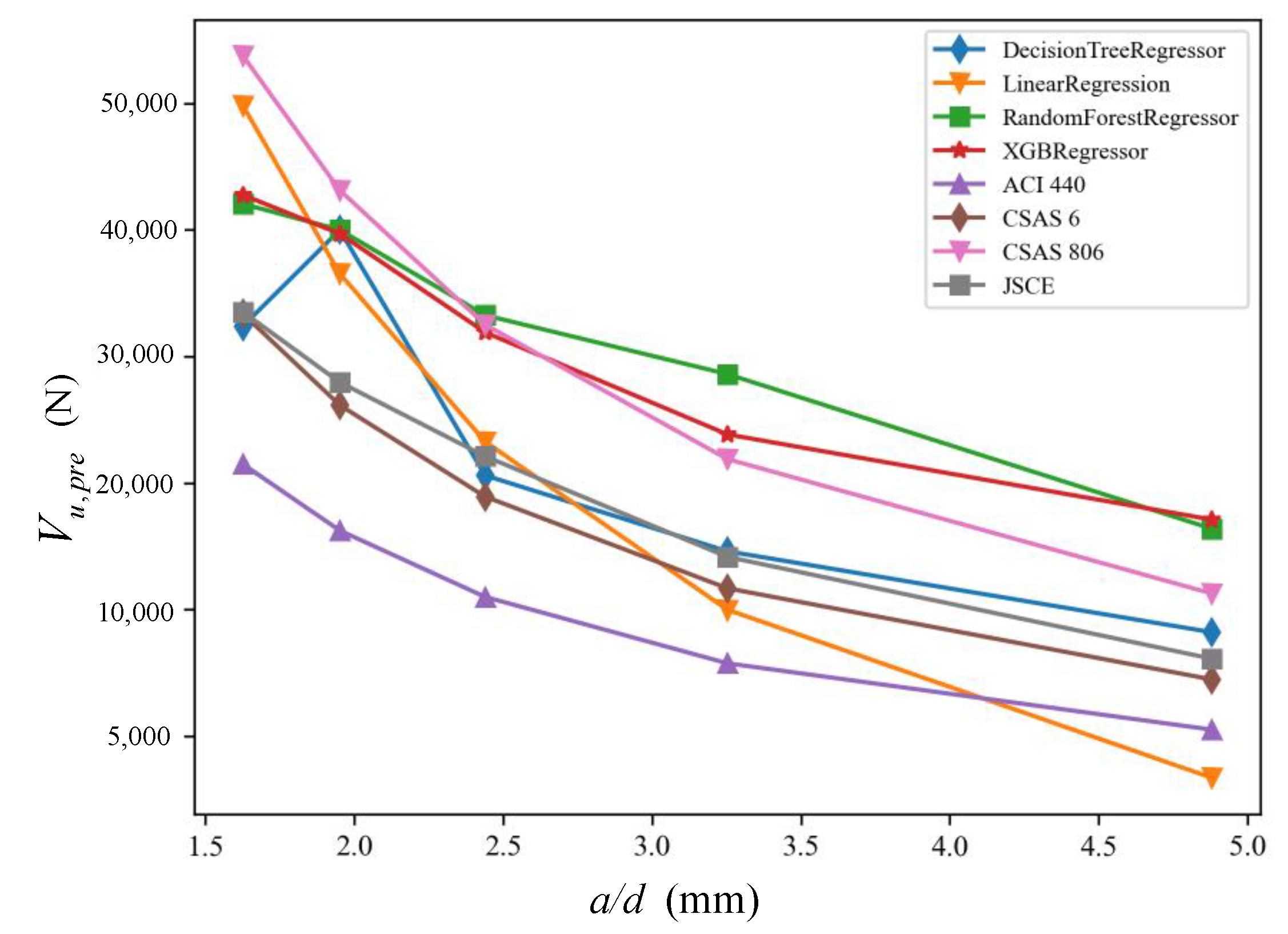

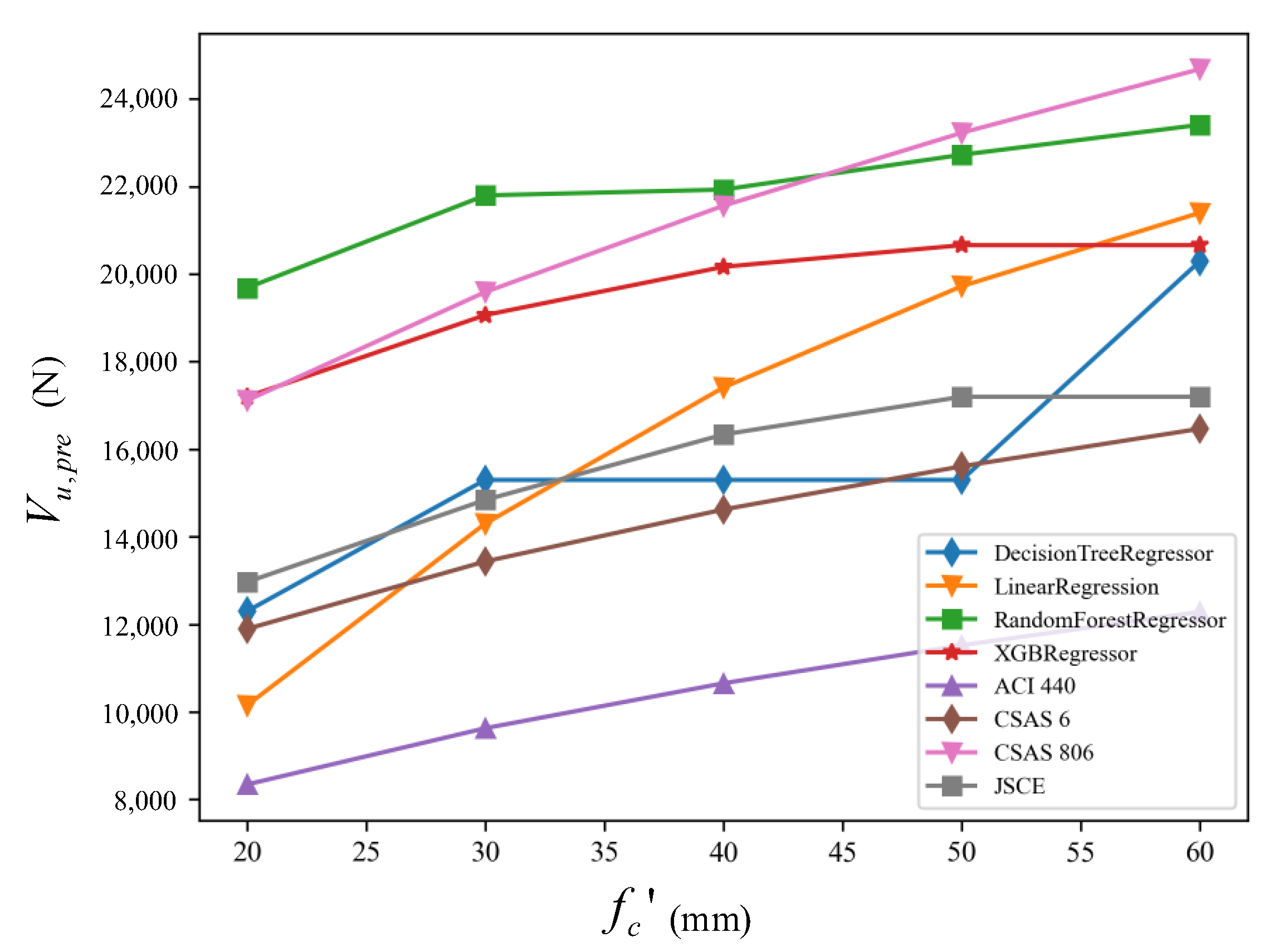

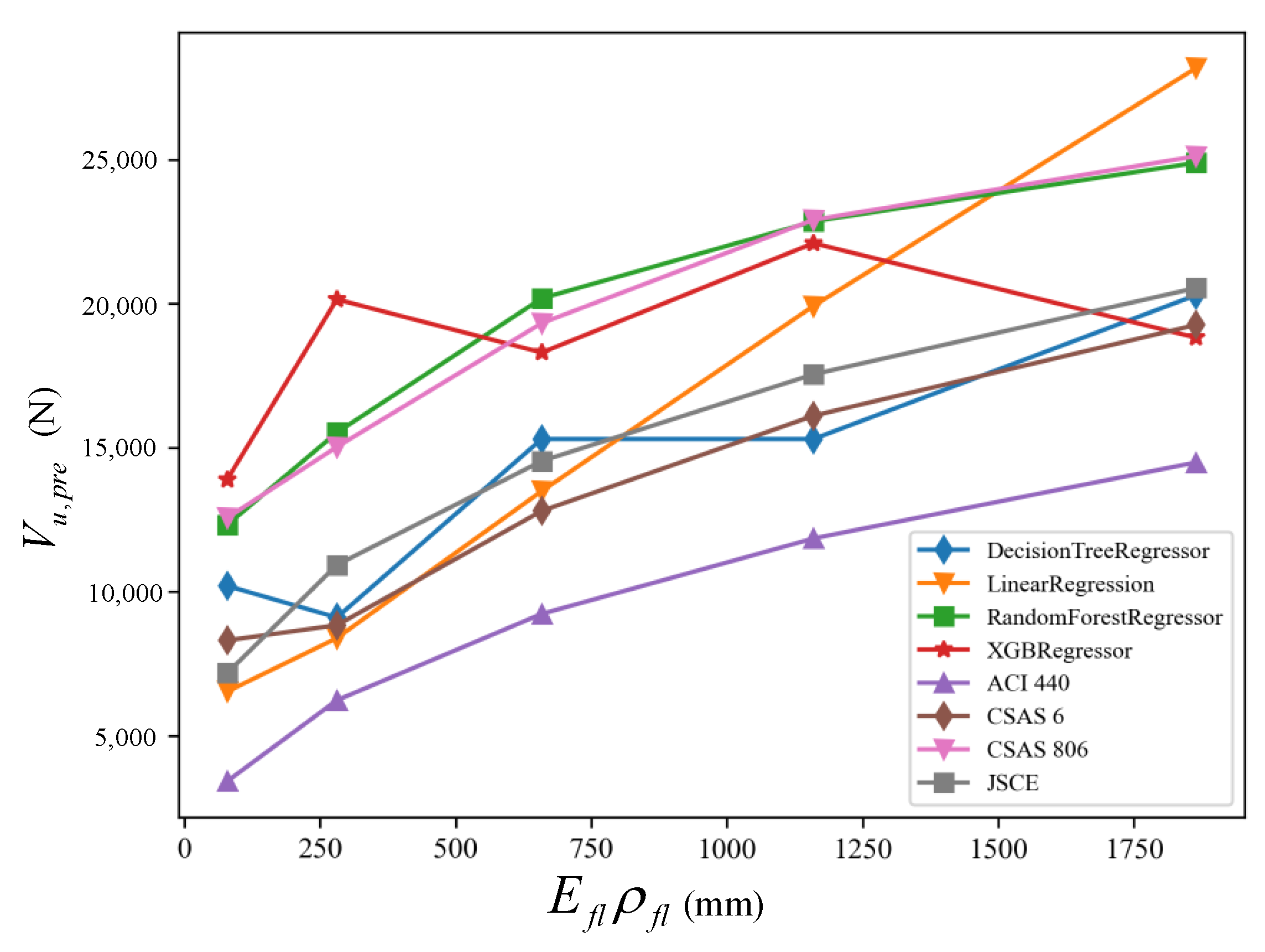

7.2. Parametric Analysis

8. Conclusions

- 1.

- The codified shear design provisions provide conservative predictions with large variations with the mean ratio of varying from 1.07 to 1.86 and the corresponding standard deviation varying from 0.21 to 0.31. The shear-carrying mechanism of FRP-reinforced concrete beams without stirrups could not be accurately described by the parameters of the design provisions.

- 2.

- Compared to the design provisions, ML models significantly improve the prediction accuracy and reduce the variations, with the mean ratio of of the ML models varying from 1.03 to 1.10 and the standard deviation varying from 0.09 to 0.20. XGBoost is the best model with the least dispersion, yielding the largest R2 of 0.92 as well as the smallest RMSE of 13.03 and MAE of 8.34, respectively.

- 3.

- With artificially selected features, the effectiveness of the proposed ML models is further improved. The mean ratio of of the ML models varies from 0.97 to 1.02 and the corresponding standard deviation is reduced, varying from 0.06 to 0.15.

- 4.

- Nearly all the important features for the ML are the artificially selected ones, indicating that the importance of domain knowledge of shear strength of FRP-reinforced beams is effectively reflected in the four ML models. Further investigations on selecting more effective features could be undertaken to improve the validity of the ML models and to make the ML models more explainable.

- 5.

- For the singular validation test, the initial ML models and the shear design provisions provide similar inaccurate predictions with large variations, whilst the ML models with artificially selected features successfully yield acceptable predictions. Verified with the established database and the validation test, the ML models with artificially selected features show great potential in guiding the shear design of FRP-reinforced concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Pendhari, S.S.; Kant, T.; Desai, Y.M. Application of polymer composites in civil construction: A general review. Compos. Struct. 2008, 84, 114–124. [Google Scholar] [CrossRef]

- FIB (Fédération Internationale du Béton Lausanne, Switzerland). FRP Reinforcement in RC Structures; Bulletin No. 40; FIB: Lausanne, Switzerland, 2007. [Google Scholar]

- Xue, W.; Peng, F.; Zheng, Q. Design Equations for Flexural Capacity of Concrete Beams Reinforced with Glass Fiber–Reinforced Polymer Bars. J. Compos. Constr. 2016, 20, 04015069. [Google Scholar] [CrossRef]

- Bischoff, P.H.; Gross, S.P. Design approach for calculating deflection of FRP-reinforced concrete. J. Compos. Constr. 2011, 15, 490–499. [Google Scholar] [CrossRef]

- Burgoyne, C.J. Rational use of advanced composites in concrete. Proc. Inst. Civ. Eng.-Struct. Build. 2001, 146, 253–262. [Google Scholar] [CrossRef]

- Ibell, T.; Darby, A.; Denton, S. Research issues related to the appropriate use of FRP in concrete structures. Constr. Build. Mater. 2009, 23, 1521–1528. [Google Scholar] [CrossRef]

- Bentz, E.C.; Massam, L.; Collins, M.P. Shear strength of large concrete members with FRP reinforcement. J. Compos. Constr. 2010, 14, 637–646. [Google Scholar] [CrossRef]

- El-Sayed, A.K.; Soudki, K. Evaluation of Shear Design Equations of Concrete Beams with FRP Reinforcement. J. Compos. Constr. 2011, 15, 9–20. [Google Scholar] [CrossRef]

- Hoult, N.A.; Sherwood, E.G.; Bentz, E.C.; Collins, M.P. Does the use of FRP reinforcement change the one-way shear behavior of reinforced concrete slabs? J. Compos. Constr. 2008, 12, 125–133. [Google Scholar] [CrossRef]

- Nagasaka, T.; Fukuyama, H.; Tanigaki, M. Shear performance of concrete beams reinforced with FRP stirrups. Spec. Publ. 1993, 138, 789–812. [Google Scholar]

- Razaqpur, A.G.; Spadea, S. Shear strength of FRP reinforced concrete members with stirrups. J. Compos. Constr. 2015, 19, 04014025. [Google Scholar] [CrossRef]

- Yang, Y.; Orr, J.; Ibell, T. Shear behaviour of fabric formed T beams reinforced using W-FRP. Structures 2020, 24, 869–879. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Isgor, O.B. Proposed shear design method for FRP-reinforced concrete members without stirrups. ACI Struct. J. 2006, 103, 93. [Google Scholar]

- Tureyen, A.K.; Frosch, R.J. Concrete shear strength: Another perspective. Struct. J. 2003, 100, 609–615. [Google Scholar]

- Tureyen, A.K.; Frosch, R. Shear tests of FRP-reinforced concrete beams without stirrups. ACI Struct. J. 2002, 99, 427–434. [Google Scholar]

- ACI 440.1R-15; Guide for the Design and Construction of Concrete Reinforced with FRP Bars. ACI (American Concrete Institute): Farmington Hills, MI, USA, 2015.

- Peng, F.; Xue, W.; Xue, W. Database evaluation of shear strength of slender fiber-reinforced polymer-reinforced concrete members. ACI Struct. J. 2020, 117, 273–281. [Google Scholar]

- CNR-DT 203/2006; Guide for the Design and Construction of Concrete Structures Reinforced with Fiber-Reinforced Polymer Bars. CNR: Rome, Italy, 2007.

- CSA S806-12; Design and Construction of Building Structures with Fibre-Reinforced Polymers. CSA (Canadian Standards Association): Toronto, ON, Canada, 2012.

- CSA (Canadian Standards Association). Canadian Highway Bridge Design Code; CSA (Canadian Standards Association): Toronto, ON, Canada, 2014. [Google Scholar]

- IStructE. Interim Guidance on the Design of Reinforced Concrete Structures Using Fibre Composite Reinforcement; IStructE: London, UK, 1999. [Google Scholar]

- JSCE. Recommendation for Design and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; JSCE: Tokyo, Japan, 1997. [Google Scholar]

- Feng, D.-C.; Liu, Z.-T.; Wang, X.-D.; Chen, Y.; Chang, J.-Q.; Wei, D.-F.; Jiang, Z.-M. Machine learning-based compressive strength prediction for concrete: An adaptive boosting approach. Constr. Build. Mater. 2020, 230, 117000. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Rahman, J.; Ahmed, K.S.; Khan, N.I.; Islam, K.; Mangalathu, S. Data-driven shear strength prediction of steel fiber reinforced concrete beams using machine learning approach. Eng. Struct. 2021, 233, 111743. [Google Scholar] [CrossRef]

- Azadi Kakavand, M.R.; Sezen, H.; Taciroglu, E. Data-Driven Models for Predicting the Shear Strength of Rectangular and Circular Reinforced Concrete Columns. J. Struct. Eng. 2021, 147, 04020301. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, X.; Xu, J.; Chen, C.; Deresa, S.; Zhang, J. Machine Learning-Based Evaluation of Shear Capacity of Recycled Aggregate Concrete Beams. Materials 2020, 13, 4552. [Google Scholar] [CrossRef] [PubMed]

- Solhmirzaei, R.; Salehi, H.; Kodur, V.; Naser, M.Z. Machine learning framework for predicting failure mode and shear capacity of ultra high performance concrete beams. Eng. Struct. 2020, 224, 111221. [Google Scholar] [CrossRef]

- Uddin, M.N.; Yu, K.; Li, L.; Ye, J.; Tafsirojjaman, T.; Alhaddad, W. Developing machine learning model to estimate the shear capacity for RC beams with stirrups using standard building codes. Innov. Infrastruct. Solut. 2022, 7, 227. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Ebead, U.; Alam, M.S. Machine learning-based shear capacity prediction and reliability analysis of shear-critical RC beams strengthened with inorganic composites. Case Stud. Constr. Mater. 2022, 16, e01008. [Google Scholar] [CrossRef]

- Feng, D.-C.; Wang, W.-J.; Mangalathu, S.; Hu, G.; Wu, T. Implementing ensemble learning methods to predict the shear strength of RC deep beams with/without web reinforcements. Eng. Struct. 2021, 235, 111979. [Google Scholar] [CrossRef]

- Khaleghi, M.; Salimi, J.; Farhangi, V.; Moradi, M.J.; Karakouzian, M. Evaluating the behaviour of centrally perforated unreinforced masonry walls: Applications of numerical analysis, machine learning, and stochastic methods. Ain Shams Eng. J. 2022, 13, 101631. [Google Scholar] [CrossRef]

- Moradi, M.J.; Khaleghi, M.; Salimi, J.; Farhangi, V.; Ramezanianpour, A.M. Predicting the compressive strength of concrete containing metakaolin with different properties using ANN. Measurement 2021, 183, 109790. [Google Scholar] [CrossRef]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Prediction of shear strength and behavior of RC beams strengthened with externally bonded FRP sheets using machine learning techniques. Compos. Struct. 2020, 234, 111698. [Google Scholar] [CrossRef]

- Chen, S.-Z.; Zhang, S.-Y.; Han, W.-S.; Wu, G. Ensemble learning based approach for FRP-concrete bond strength prediction. Constr. Build. Mater. 2021, 302, 124230. [Google Scholar] [CrossRef]

- Keshtegar, B.; Gholampour, A.; Thai, D.-K.; Taylan, O.; Trung, N.-T. Hybrid regression and machine learning model for predicting ultimate condition of FRP-confined concrete. Compos. Struct. 2021, 262, 113644. [Google Scholar] [CrossRef]

- Perera, R.; Arteaga, A.; Diego, A.D. Artificial intelligence techniques for prediction of the capacity of RC beams strengthened in shear with external FRP reinforcement. Compos. Struct. 2010, 92, 1169–1175. [Google Scholar] [CrossRef]

- Su, M.; Peng, H.; Yuan, M.; Li, S. Identification of the interfacial cohesive law parameters of FRP strips externally bonded to concrete using machine learning techniques. Eng. Fract. Mech. 2021, 247, 107643. [Google Scholar] [CrossRef]

- Naser, M.Z. Machine Learning Assessment of Fiber-Reinforced Polymer-Strengthened and Reinforced Concrete Members. Struct. J. 2020, 117, 237–251. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Abushanab, A.; Ebead, U.; Alnahhal, W. FAI: Fast, accurate, and intelligent approach and prediction tool for flexural capacity of FRP-RC beams based on super-learner machine learning model. Mater. Today Commun. 2022, 33, 104461. [Google Scholar] [CrossRef]

- Al-Hamrani, A.; Wakjira, T.G.; Alnahhal, W.; Ebead, U. Sensitivity analysis and genetic algorithm-based shear capacity model for basalt FRC one-way slabs reinforced with BFRP bars. Compos. Struct. 2023, 305, 116473. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Ibrahim, M.; Ebead, U.; Alam, M.S. Explainable machine learning model and reliability analysis for flexural capacity prediction of RC beams strengthened in flexure with FRCM. Eng. Struct. 2022, 255, 113903. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Al-Hamrani, A.; Ebead, U.; Alnahhal, W. Shear capacity prediction of FRP-RC beams using single and ensenble ExPlainable Machine learning models. Compos. Struct. 2022, 287, 115381. [Google Scholar] [CrossRef]

- Borisov, V.; Leemann, T.; Seßler, K.; Haug, J.; Pawelczyk, M.; Kasneci, G. Deep Neural Networks and Tabular Data: A Survey. IEEE Trans. Neural Netw. Learn. Syst. 2022, 1–21. [Google Scholar] [CrossRef]

- Shwartz-Ziv, R.; Armon, A. Tabular data: Deep learning is not all you need. Inf. Fusion 2022, 81, 84–90. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Hutter, F.; Hoos, H.; Leyton-Brown, K. An Efficient Approach for Assessing Hyperparameter Importance. In Proceedings of the 31st International Conference on Machine Learning, PMLR, Beijing, China, 21–26 June 2014; pp. 754–762. Available online: https://proceedings.mlr.press/v32/hutter14.html (accessed on 17 October 2022).

| Guidelines | Shear Design Provisions | |

|---|---|---|

| JSCE (1997) | where | (1) |

| ACI 440.1R (2015) | where | (2) |

| CSA S6 (2014) | where | (3) |

| CSA S806 (2012) | where ;; | (4) |

| Parameter | Mean | Max | Min | SD | COV | |

|---|---|---|---|---|---|---|

| Beam geometry | (mm) | 258.3 | 937 | 73 | 141.3 | 0.55 |

| (mm) | 221.2 | 457 | 89 | 95.1 | 0.43 | |

| 3.5 | 8 | 2.5 | 1.1 | 0.31 | ||

| Concrete | (MPa) | 46.2 | 102 | 20 | 17.1 | 0.37 |

| Reinforcement | (MPa) | 1091.5 | 2840 | 397 | 535.0 | 0.49 |

| (MPa) | 70.9 | 148 | 29 | 40.7 | 0.57 | |

| (%) | 1.2 | 11.46 | 0.11 | 1.4 | 1.17 | |

| Shear capacity | (kN) | 78.3 | 396.3 | 9.1 | 66.8 | 0.85 |

| Features | Feature Description | Notion | Calculation Method |

|---|---|---|---|

| Beam feature | Geometry | ||

| Concrete | |||

| Reinforcement | |||

| Shear capacity features | Shear capacity calculation | ||

| Provision | MAE | RMSE | R2 | |

|---|---|---|---|---|

| JSCE (1997) | 1.39 () | 22.31 () | 37.21 () | 0.77 () |

| ACI 440.1R (2015) | 1.86 () | 39.84 () | 60.08 () | 0.41 ( |

| CSA S6 (2014) | 1.49 () | 28.32 () | 35.82 () | 0.70 () |

| CSA S806 (2012) | 1.07 () | 20.07 () | 27.62 () | 0.80 () |

| Average | 1.49 () | 27.64 () | 40.18 () | 0.67 () |

| XGBoost | 1.03 () | 8.34 () | 13.03 () | 0.92 () |

| Decision Tree | 1.07 () | 12.51 () | 20.17 () | 0.82 () |

| Random Forest | 1.05 () | 11.37 () | 16.81 () | 0.91 () |

| Linear Regression | 1.10 () | 12.06 () | 19.69 () | 0.89 () |

| Average | 1.06 () | 11.07 () | 17.43 () | 0.89 () |

| XGBoost * | 1.00 () | 7.25 () | 11.91 () | 0.94 () |

| Decision Tree * | 1.02 () | 11.28 () | 17.34 () | 0.87 () |

| Random Forest * | 1.01 () | 9.32 () | 14.39 () | 0.91 () |

| Linear Regression * | 0.97 () | 10.06 () | 14.88 () | 0.91 () |

| Average | 1.00 () | 9.67 () | 14.63 () | 0.91 () |

| FRP Flexural Bar | Concrete | ||

|---|---|---|---|

| (mm2) | (MPa) | (MPa) | (MPa) |

| 142.6 | 143 | 2648 | 34.7 |

| Design Provision | (kN) | Modified ML Model | (kN) | ||

|---|---|---|---|---|---|

| JSCE (1997) | 33.9 | 0.57 | Linear Regression | 15.9 | 1.21 |

| ACI 440.1R (2015) | 10.2 | 1.90 | XGBoost Regressor | 20.9 | 0.92 |

| CSA S6 (2014) | 14.1 | 1.37 | Decision Tree Regressor | 15.3 | 1.26 |

| CSA S806 (2012) | 25.2 | 0.77 | Random Forest Regressor | 21.4 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Liu, G. Data-Driven Shear Strength Prediction of FRP-Reinforced Concrete Beams without Stirrups Based on Machine Learning Methods. Buildings 2023, 13, 313. https://doi.org/10.3390/buildings13020313

Yang Y, Liu G. Data-Driven Shear Strength Prediction of FRP-Reinforced Concrete Beams without Stirrups Based on Machine Learning Methods. Buildings. 2023; 13(2):313. https://doi.org/10.3390/buildings13020313

Chicago/Turabian StyleYang, Yuanzhang, and Gaoyang Liu. 2023. "Data-Driven Shear Strength Prediction of FRP-Reinforced Concrete Beams without Stirrups Based on Machine Learning Methods" Buildings 13, no. 2: 313. https://doi.org/10.3390/buildings13020313

APA StyleYang, Y., & Liu, G. (2023). Data-Driven Shear Strength Prediction of FRP-Reinforced Concrete Beams without Stirrups Based on Machine Learning Methods. Buildings, 13(2), 313. https://doi.org/10.3390/buildings13020313