Investigation of Crack Repairing Technique to Delay Fracture Initiation of Steel Members Subjected to Low Cycle Fatigue

Abstract

1. Introduction

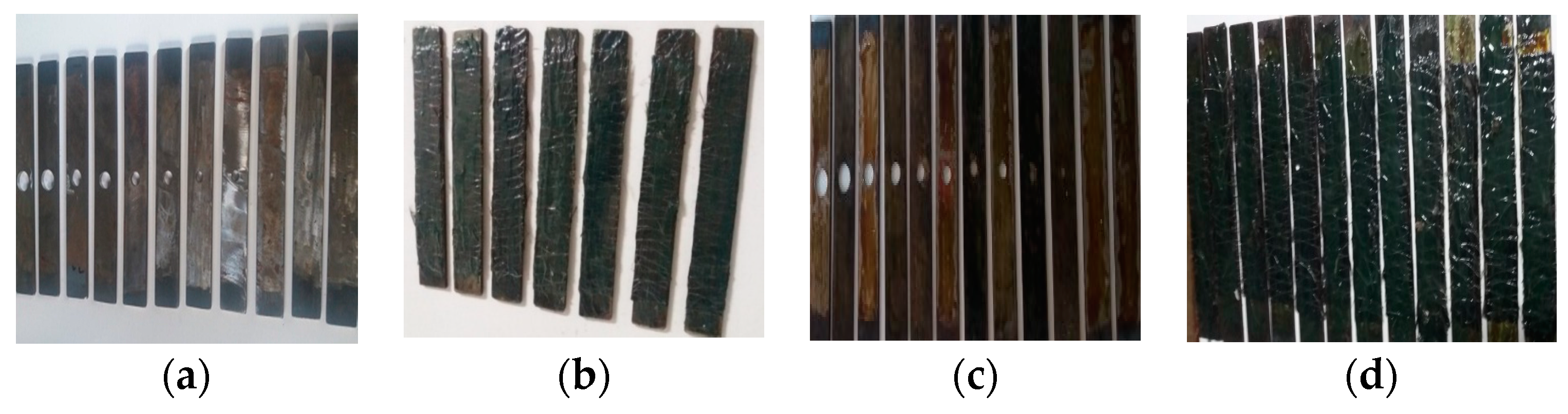

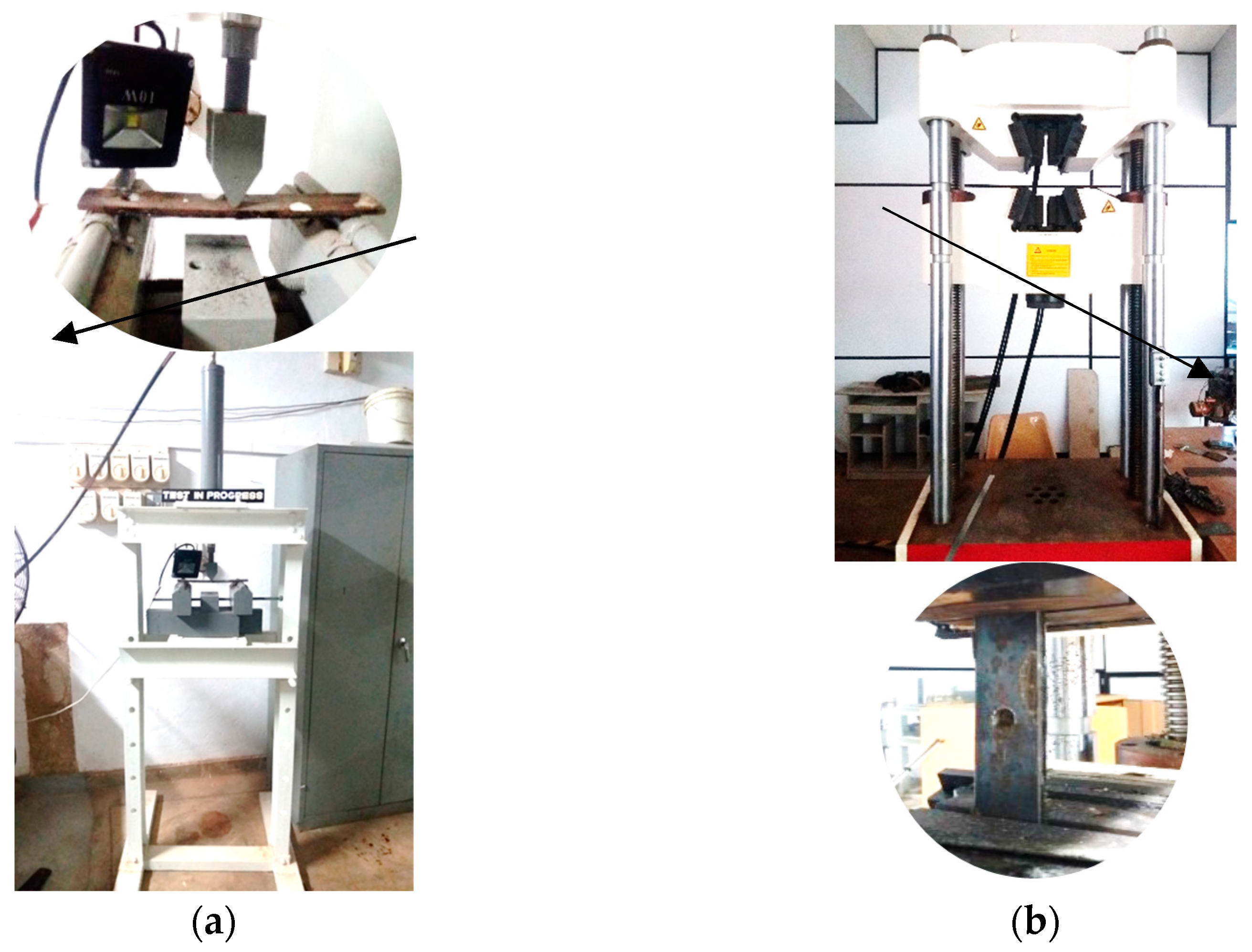

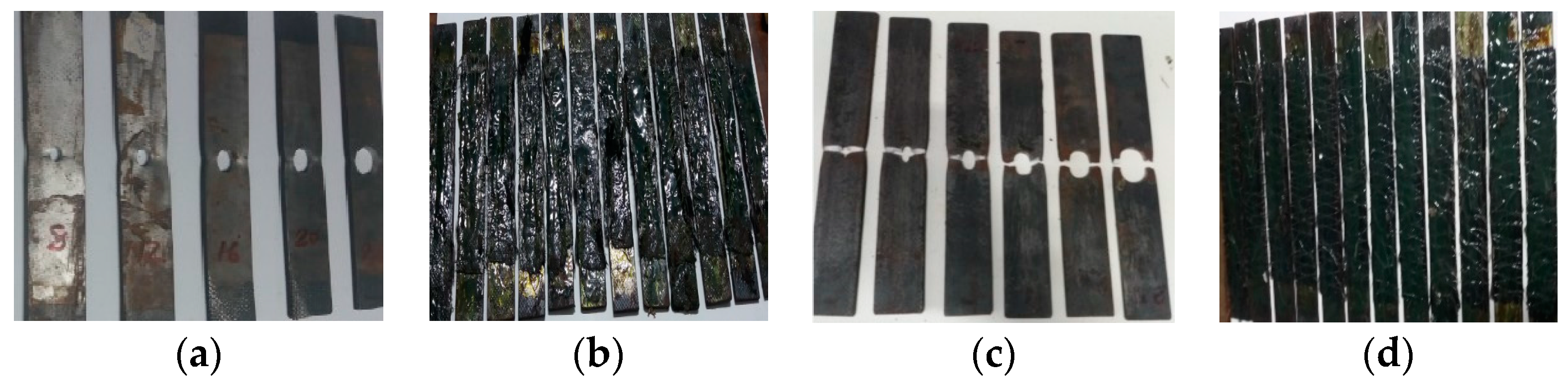

2. Methodology

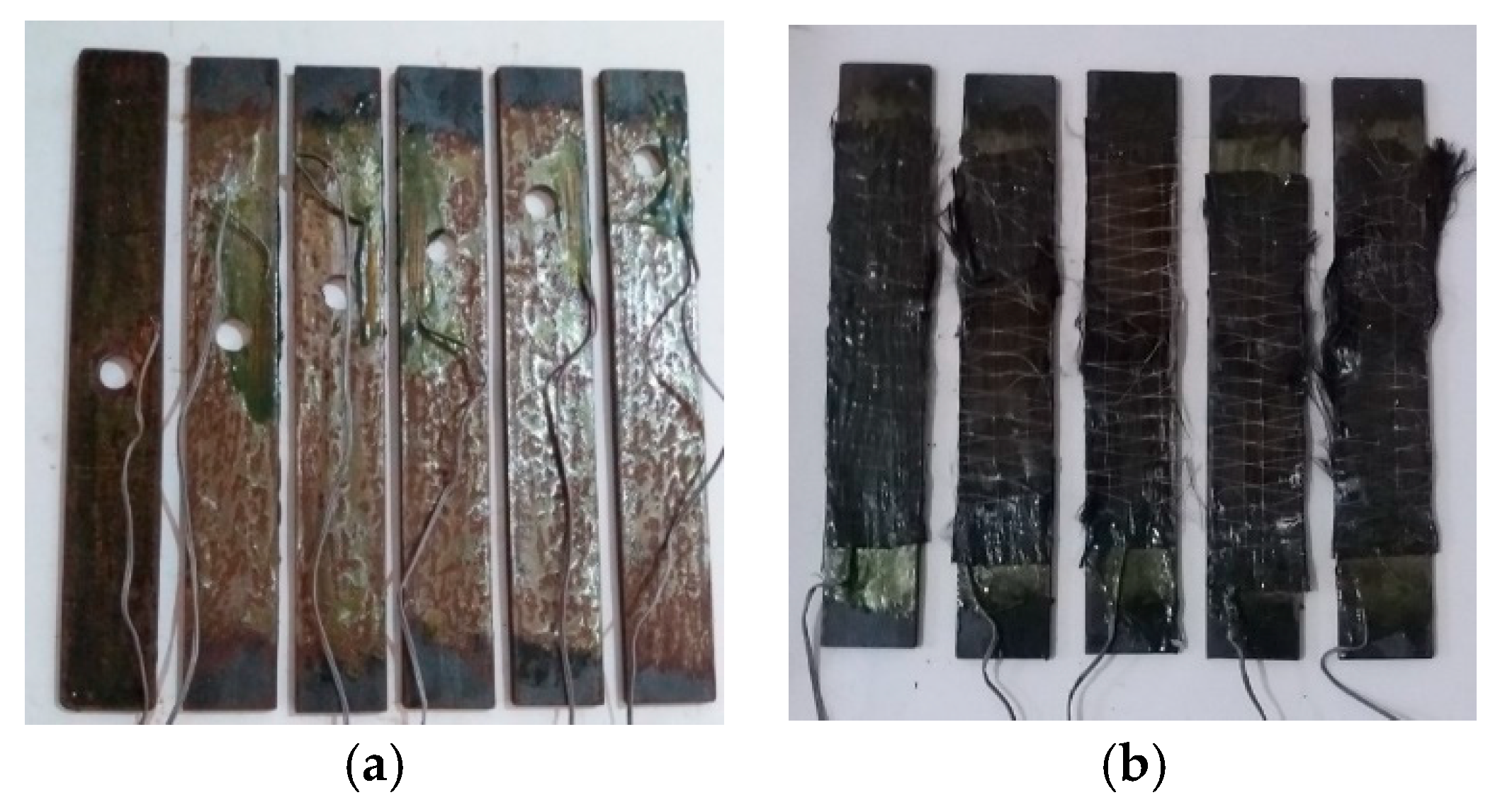

3. Test Setup and Materials

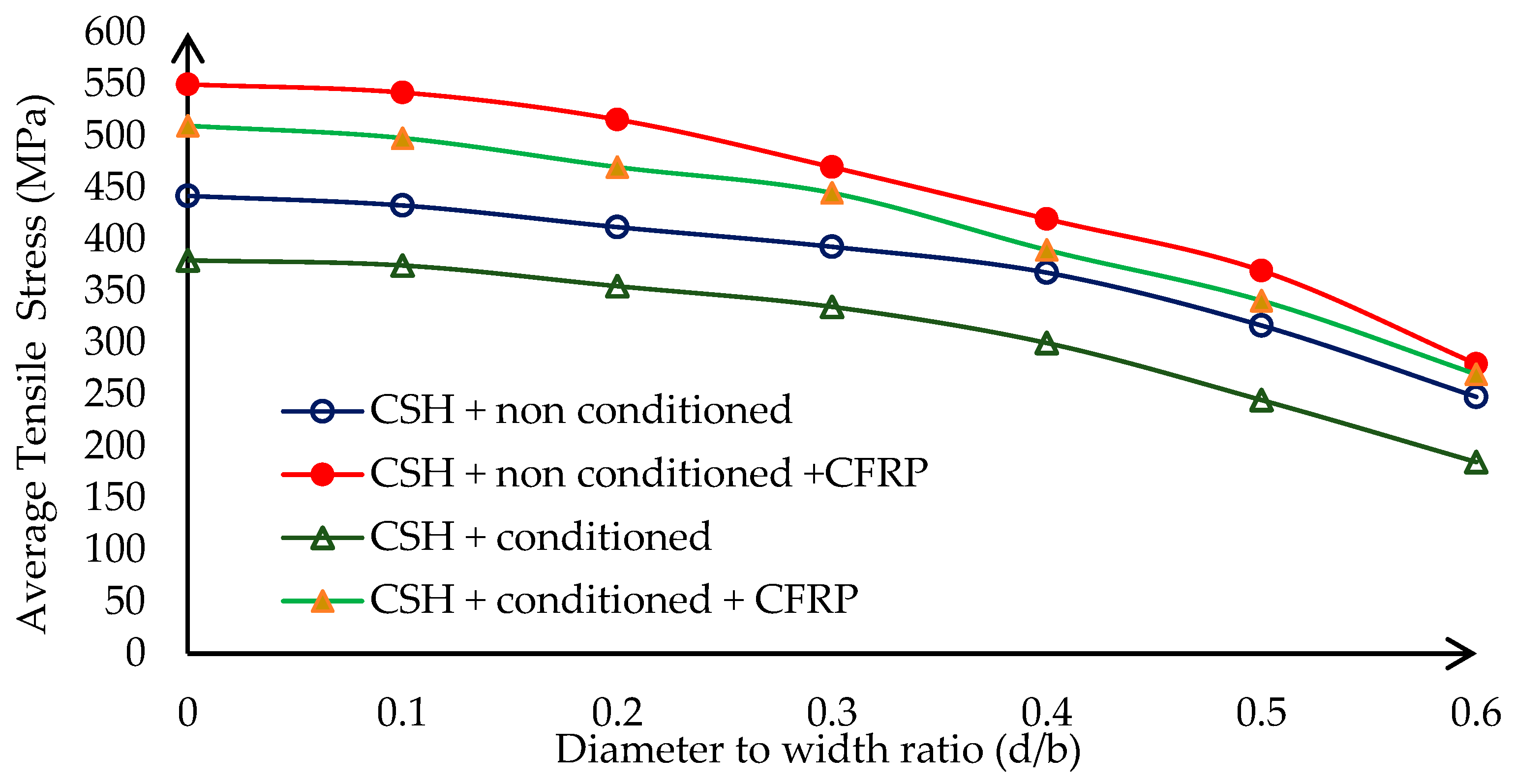

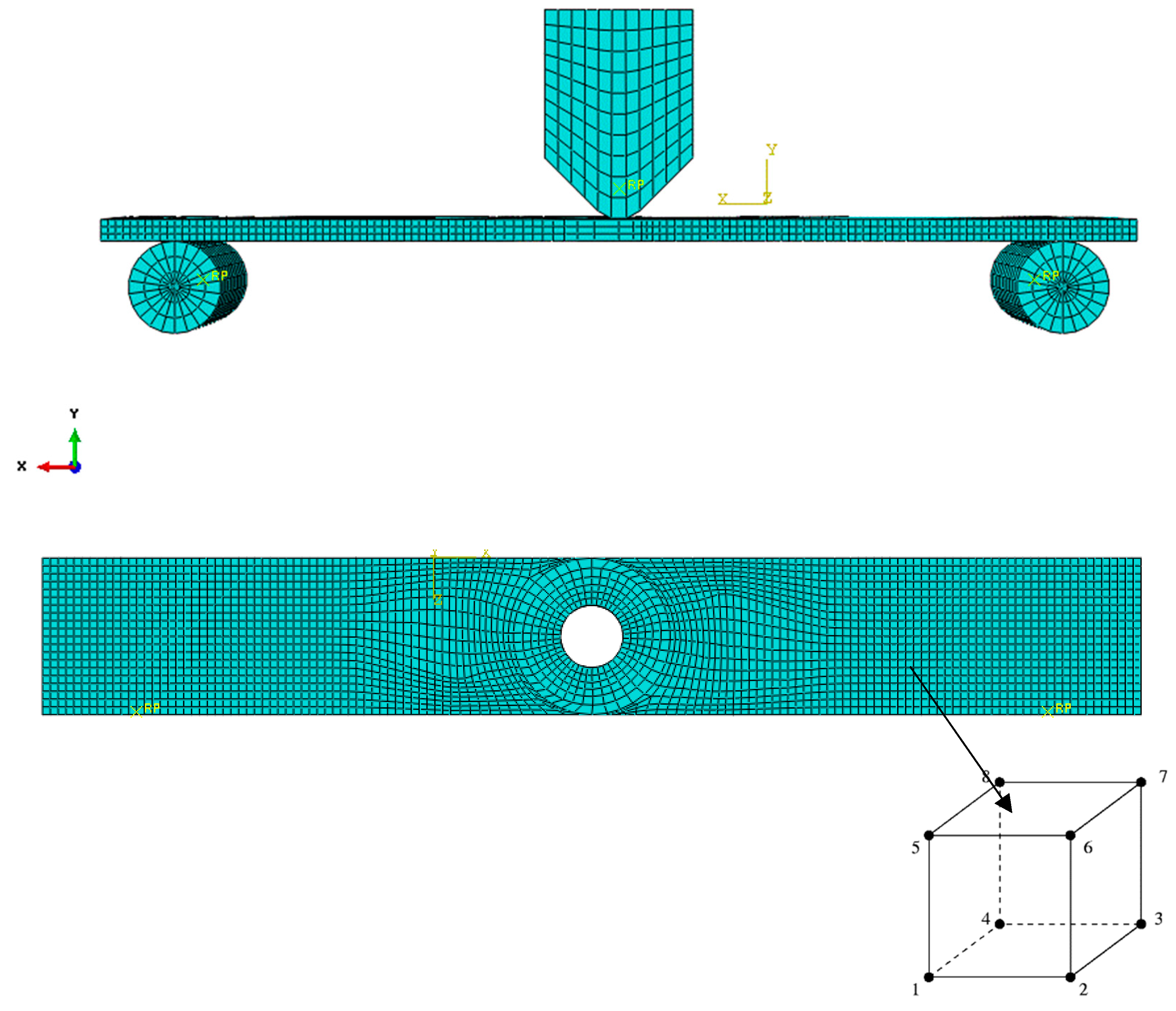

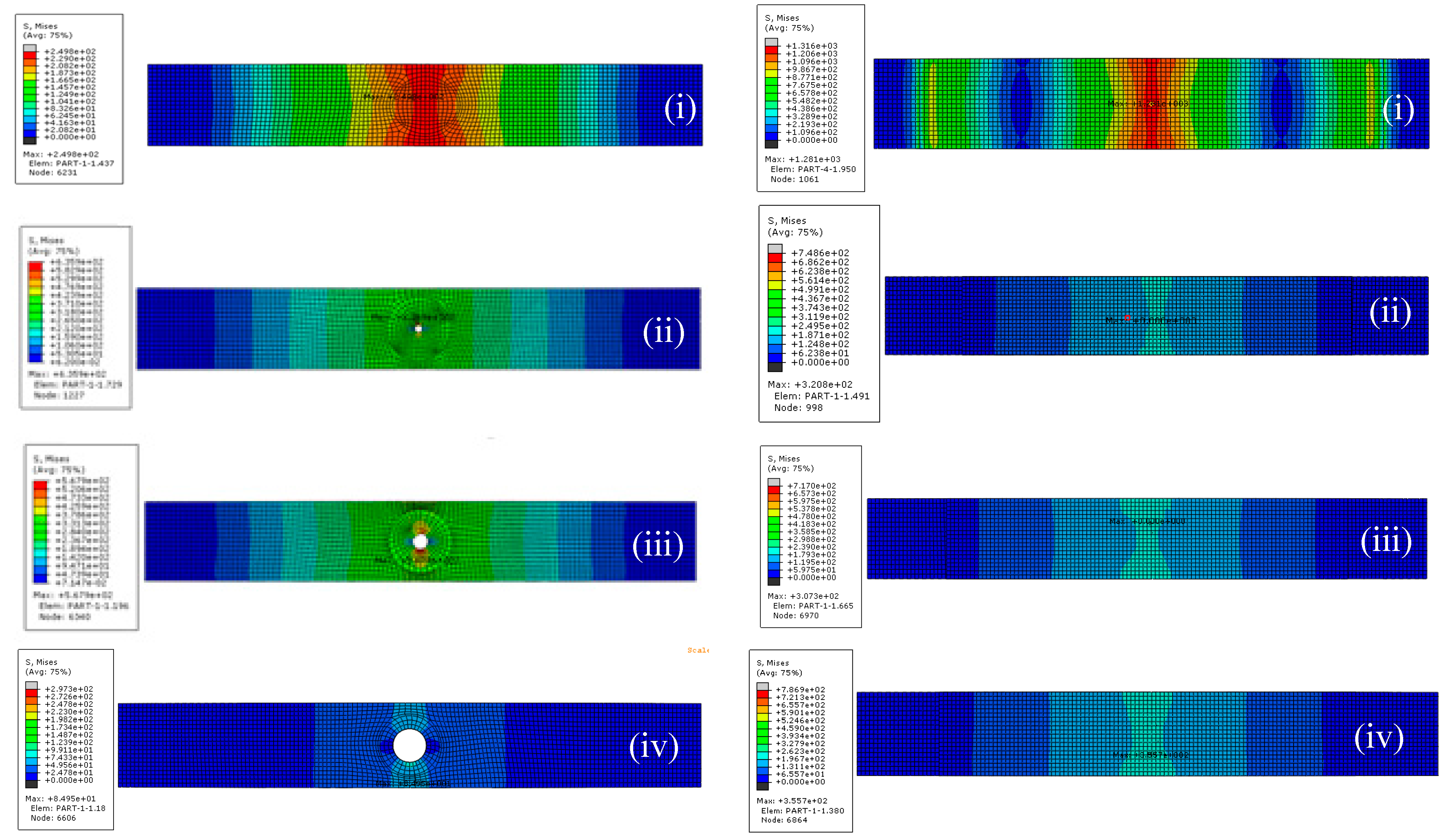

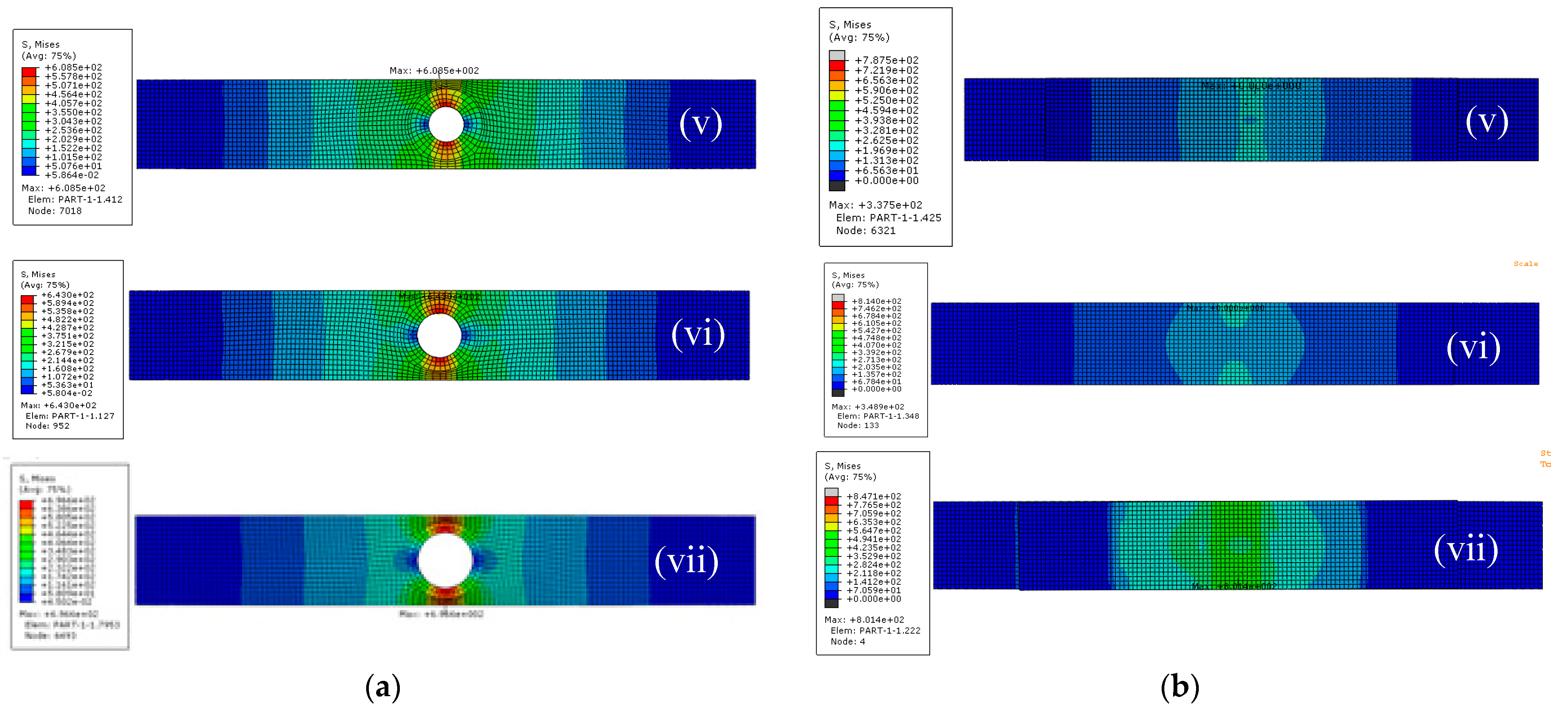

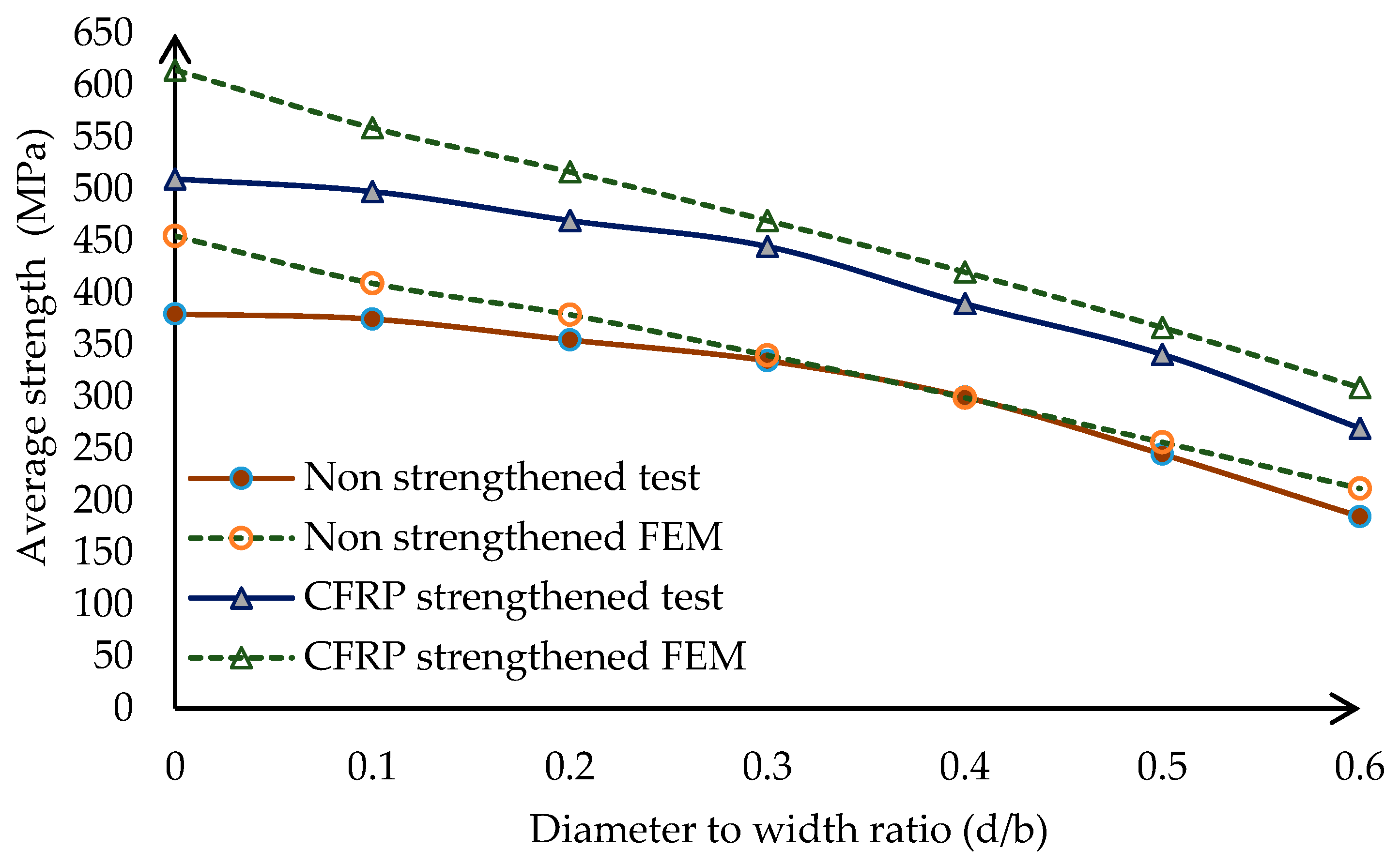

4. Results

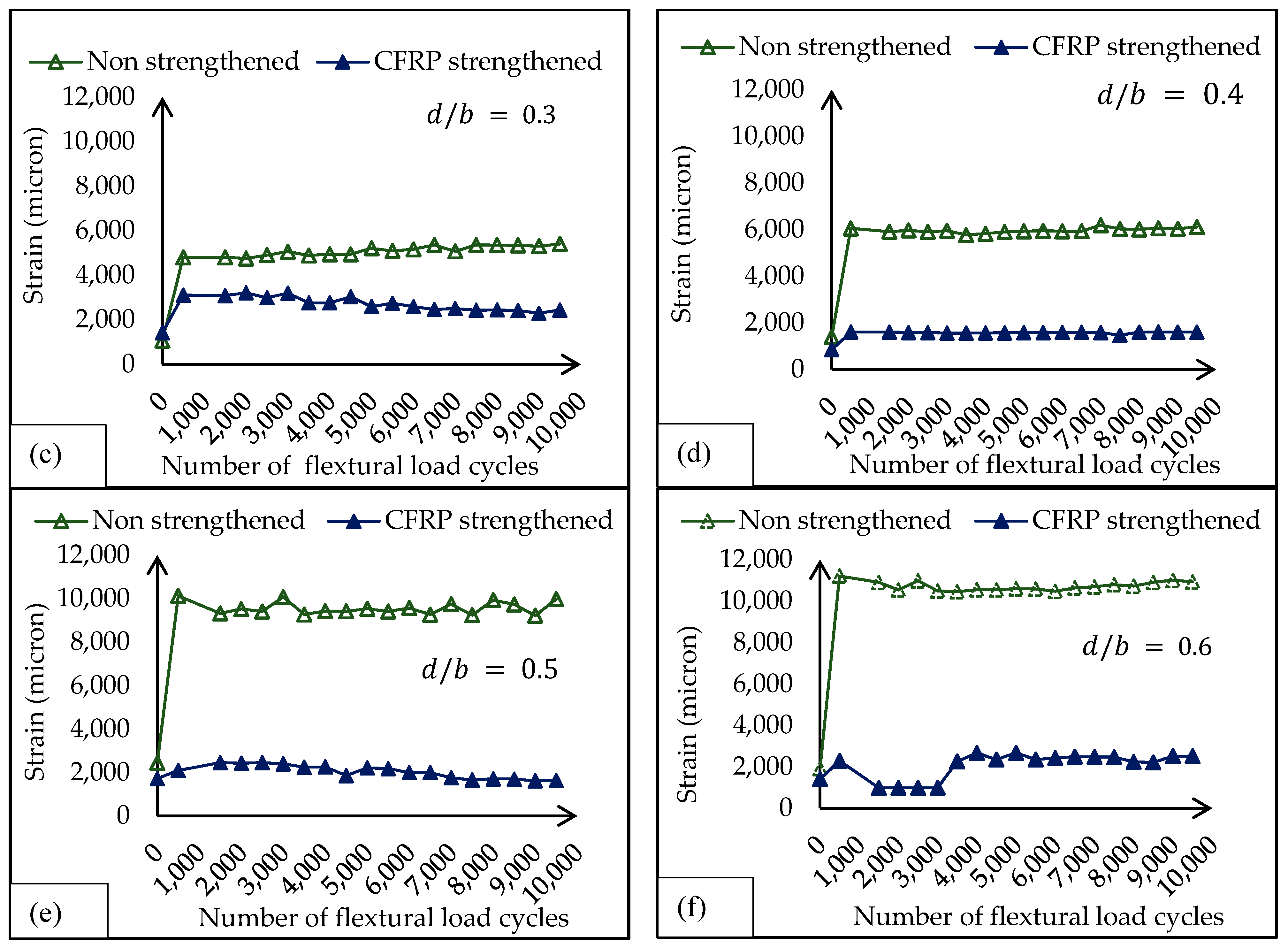

4.1. Effects of CSH Diameter

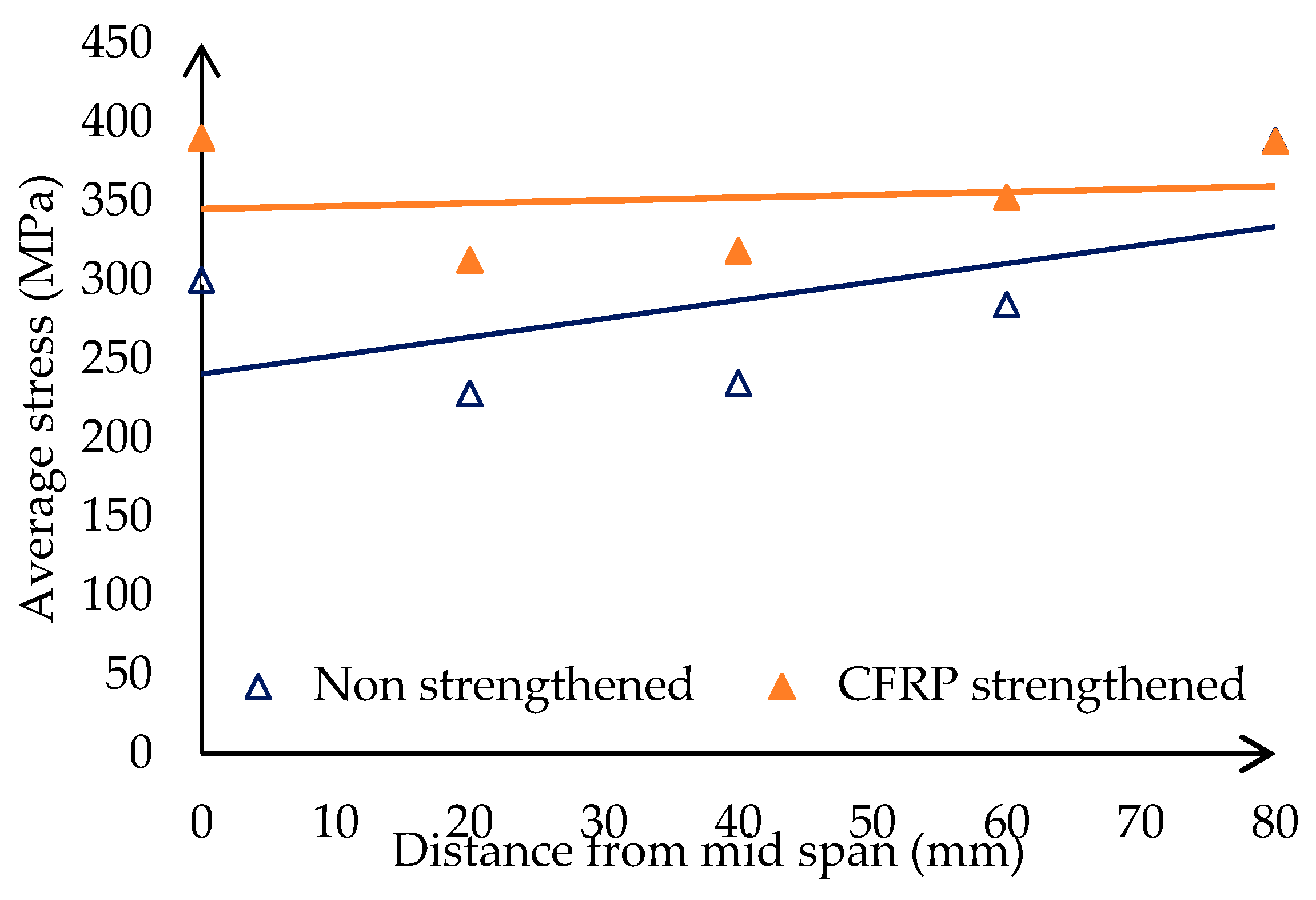

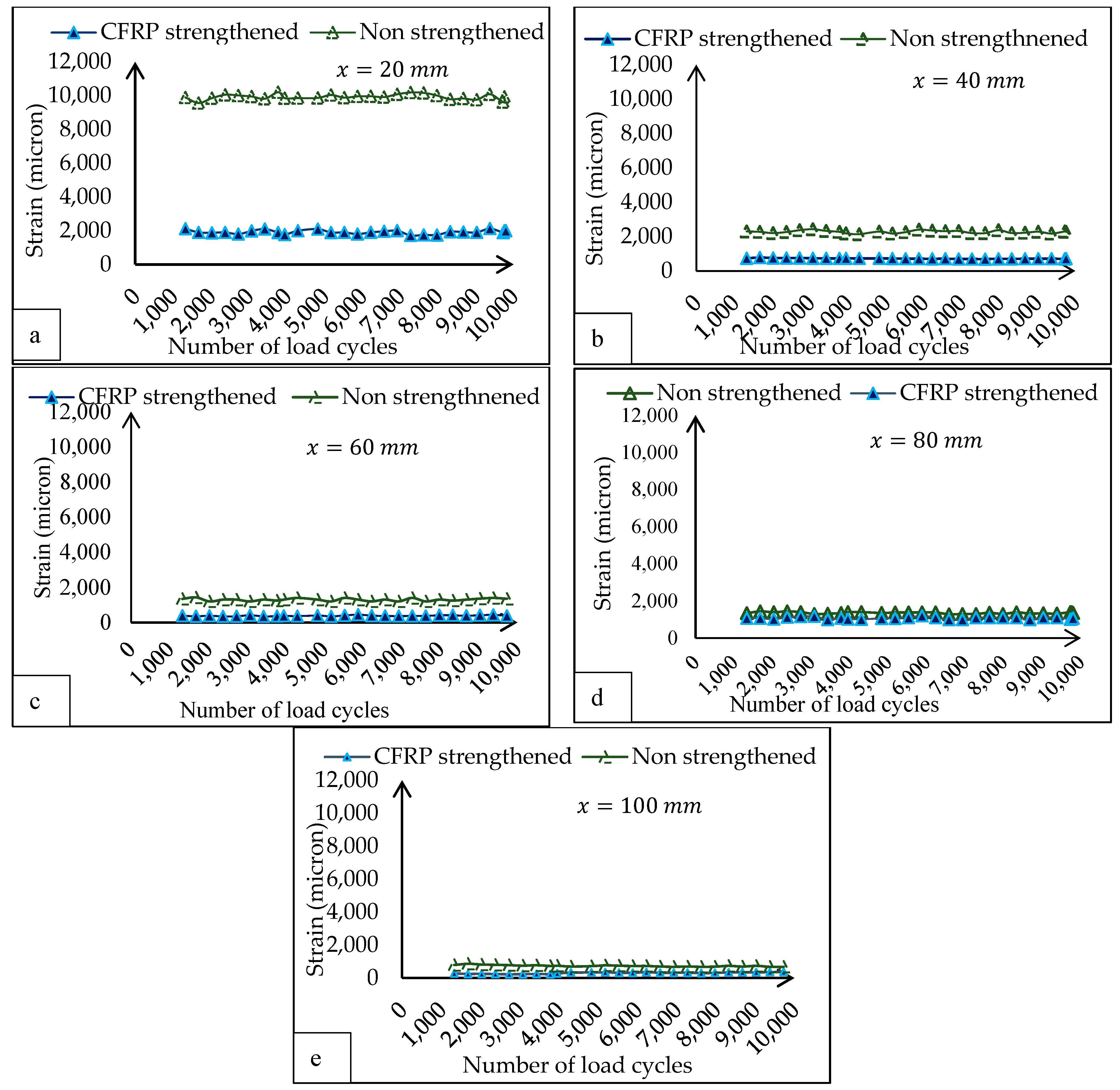

4.2. Effects of the Offset Distance of CSH

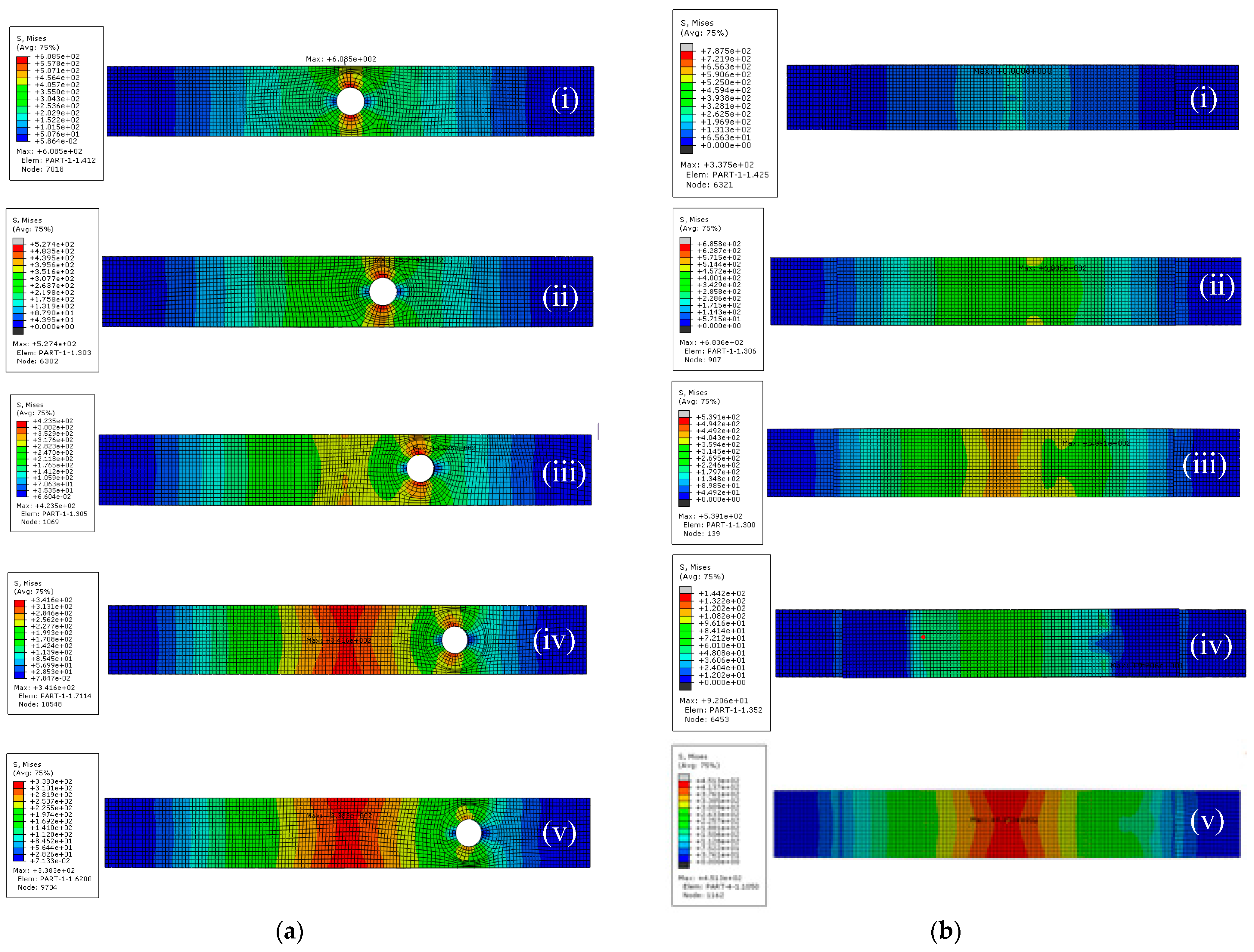

5. Finite Element Modelling (FEM)

5.1. Validation

5.2. Parametric Study

- This investigation reported the strength losses which were in the range of 13% to 25% compared to the non-conditioned CSH with the diameter ranging from 4 mm to 25 mm.

- This investigation reported the tensile strength enhancement with CFRP which is in the range of 32% to 45% compared to the non-strengthened CSH with the diameter range change from 4 mm to 25 mm.

- This study recorded a strength increase with respect to off-set distance, which was in the range of 36% to 131% compared to the CSH at the midpoint.

- CFRP-strengthened CSH reported significant strength gain and it’s variation were recorded as 19% to 42% with respect to offset distance.

- Failure mode was observed as de-lamination of the CFRP layer with the fatigue load as well as the tensile load.

- A sound numerical model was developed based on material properties capable of simulating the fatigue behaviour of the CSH subjected to cyclic flexural loading.

- Design guidelines for the CSH technique summarized in Table 3.

6. Engineering Implications

7. Conclusions and Recommendations

- Introduced design guidelines to decide the appropriate size of the CSH for crack control on steel structures due to fatigue.

- The CSH effectively recovers the strength losses in the range of 32% to 45% with respect to the non-strengthened condition.

- The proposed method exhibits a significant capacity enhancement for crack controls, and it is strongly recommended to improve the service life of steel infrastructures under fatigue load.

- This developed numerical model can be effectively utilized to estimate the effects of unknown parameters of the CSH under a fatigue response.

8. Future Works

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wijesuriya, H.S. Predicting fretting fatigue crack propagation using finite element analysis. In Proceedings of the 2018 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 30 May–1 June 2018. [Google Scholar]

- Committee on Fatigue and Fracture Reliability of the Committee on Structural Safety and Reliability of the Structural Division, American Society of Civil Engineers. Fatigue reliability: Development of criteria for design. J. Struct. Div. 1982, 108, 71–88. [Google Scholar] [CrossRef]

- Fisher, J.W.; Barthelemy, B.M.; Mertz, D.R.; Edinger, J.A. Fatigue Behavior of Full-Scale Welded Bridge Attachments; NCHRP Report 227; Transportation Research Board, National Research Council: Washington, DC, USA, 1980.

- Sveinsdottir, S.L. Experimental Research on Strengthening of Concrete Beams by the Use of Epoxy Adhesive and Cement Based Bonding Material. Master’s Thesis, Haskolinn, Reykjavik Univercity Iceland, Reykjavík, Iceland, 2012. [Google Scholar]

- Fish, P.; Schroeder, C.; Connor, R.J.; Sauser, P. Fatigue and Fracture Library for the Inspection, Evaluation, and Repair of Vehicular Steel Bridges; Purdue University: West Lafayette, IN, USA, 2015. [Google Scholar]

- Ishikawa, T.; Matsumoto, R.; Hattori, A.; Kawano, H.; Yamada, K. Reduction of stress concentration at edge of stop hole by closing crack surface. J. Soc. Mater. Sci. 2013, 62, 33–38. [Google Scholar] [CrossRef][Green Version]

- Dexter, R.J.; Ocel, J.M. Manual for Repair and Retrofit of Fatigue Cracks in Steel Bridges (No. FHWA-IF-13-020); Federal Highway Administration: Washington, DC, USA, 2013.

- Rolfe, S.T.; Barsom, J.M. Fracture and Fatigue Control in Structures: Applications of Fracture Mechanics; ASTM International: West Conshohocken, PA, USA, 1977. [Google Scholar]

- Brown, J.D.; Lubitz, D.J.; Cekov, Y.C.; Frank, K.H.; Keating, P.B. Evaluation of Influence of Hole Making upon the Performance of Structural Steel Plates and Connections (No. FHWA/TX-07/0-4624-1). 2007. Available online: https://trid.trb.org/view/849447 (accessed on 12 August 2022).

- Bocciarelli, M.; Colombi, P.; Fava, G.; Poggi, C. Fatigue performance of tensile steel members strengthened with CFRP plates. Compos. Struct. 2009, 87, 334–343. [Google Scholar] [CrossRef]

- Chandrathilaka, E.R.K.; Gamage, J.C.P.H.; Fawzia, S. Mechanical characterization of CFRP/steel bond cured and tested at elevated temperature. Compos. Struct. 2019, 207, 471–477. [Google Scholar] [CrossRef]

- Yuan, H.; Teng, J.G.; Seracino, R.; Wu, Z.S.; Yao, J. Full-range behavior of FRP-to-concrete bonded joints. Eng. Struct. 2004, 26, 553–565. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhao, X.L.; Al-Mahaidi, R. The effect of fatigue loading on bond strength of CFRP bonded steel plate joints. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures, Hong Kong, China, 7–9 December 2005; pp. 459–464. [Google Scholar]

- Tang, J.H.; Sridhar, I.; Srikanth, N. Static and fatigue failure analysis of adhesively bonded thick composite single lap joints. Compos. Sci. Technol. 2013, 86, 18–25. [Google Scholar] [CrossRef]

- Kalavagunta, S.; Naganathan, S.; Mustapha, K.N.B. Axially loaded steel columns strengthened with CFRP. Jordan J. Civ. Eng. 2014, 8, 58–69. [Google Scholar] [CrossRef]

- Cadei, J.C.; Stratford, T.J.; Duckett, W.G.; Hollaway, L.C. Strengthening Metallic Structures Using Externally Bonded Fibre-Reinforced Polymers; Ciria: London, UK, 2004. [Google Scholar]

- Gite, B.E.; Margaj, M.S.R.; Carbon Fibre as a Recent Material Use in Construction. Civil Engineering Portal. 2013. Available online: https://www.engineeringcivil.com/carbon-fibre-as-a-recent-material-use-in-construction.html (accessed on 14 July 2022).

- ASTM D790-17; Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM Standards: West Conshohocken, PA, USA, 1997.

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM Standards: West Conshohocken, PA, USA, 2014.

- Silva, M.A.L.; Dedigamuwa, K.V.; Gamage, J.C.P.H. Performance of severely damaged reinforced concrete flat slab-column connections strengthened with Carbon Fiber Reinforced Polymer. Compos. Struct. 2021, 255, 112963. [Google Scholar] [CrossRef]

- Coffin, L.F., Jr. A study of the effects of cyclic thermal stresses on a ductile metal. Trans. Am. Soc. Mech. Eng. 1954, 76, 931–949. [Google Scholar] [CrossRef]

| Series | Geometry | Conditioning Type | No of Samples |

|---|---|---|---|

| S1 | strengthened CSH with varying diameter | Non conditioned | 24 |

| S2 | strengthened CSH with varying diameter | 10,000 cycles | 36 |

| S3 | non-strengthened CSH with change in position | 10,000 cycles | 15 |

| S4 | strengthened CSH with change in position | 10,000 cycles | 15 |

| Material Property | Steel | Epoxy Adhesive | CFRP |

|---|---|---|---|

| Average tensile strength (MPa) | 583 | 25 | 1575 |

| Average elastic modulus (GPa) | 200 | 0.579 | 175 |

| Average Poisson’s ratio | 0.3 | 0.3 | 0.3 |

| Category | Parameter | Range of Operation |

|---|---|---|

| Geometry | Diameter to width ratio (d/b) | ≤ 0.2 |

| Thickness to diameter ratio (t/b) | ≤ 0.5 | |

| Diameter to crack length ratio (d/L) | ≥ 0.4 | |

| Diameter to offset distance ratio (d/x) | ≤ 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abeygunasekara, S.; Gamage, J.C.P.; Fawzia, S. Investigation of Crack Repairing Technique to Delay Fracture Initiation of Steel Members Subjected to Low Cycle Fatigue. Buildings 2023, 13, 2958. https://doi.org/10.3390/buildings13122958

Abeygunasekara S, Gamage JCP, Fawzia S. Investigation of Crack Repairing Technique to Delay Fracture Initiation of Steel Members Subjected to Low Cycle Fatigue. Buildings. 2023; 13(12):2958. https://doi.org/10.3390/buildings13122958

Chicago/Turabian StyleAbeygunasekara, Sampath, Jeeva Chandanee Pushpakumari Gamage, and Sabrina Fawzia. 2023. "Investigation of Crack Repairing Technique to Delay Fracture Initiation of Steel Members Subjected to Low Cycle Fatigue" Buildings 13, no. 12: 2958. https://doi.org/10.3390/buildings13122958

APA StyleAbeygunasekara, S., Gamage, J. C. P., & Fawzia, S. (2023). Investigation of Crack Repairing Technique to Delay Fracture Initiation of Steel Members Subjected to Low Cycle Fatigue. Buildings, 13(12), 2958. https://doi.org/10.3390/buildings13122958