Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete

Abstract

:1. Introduction

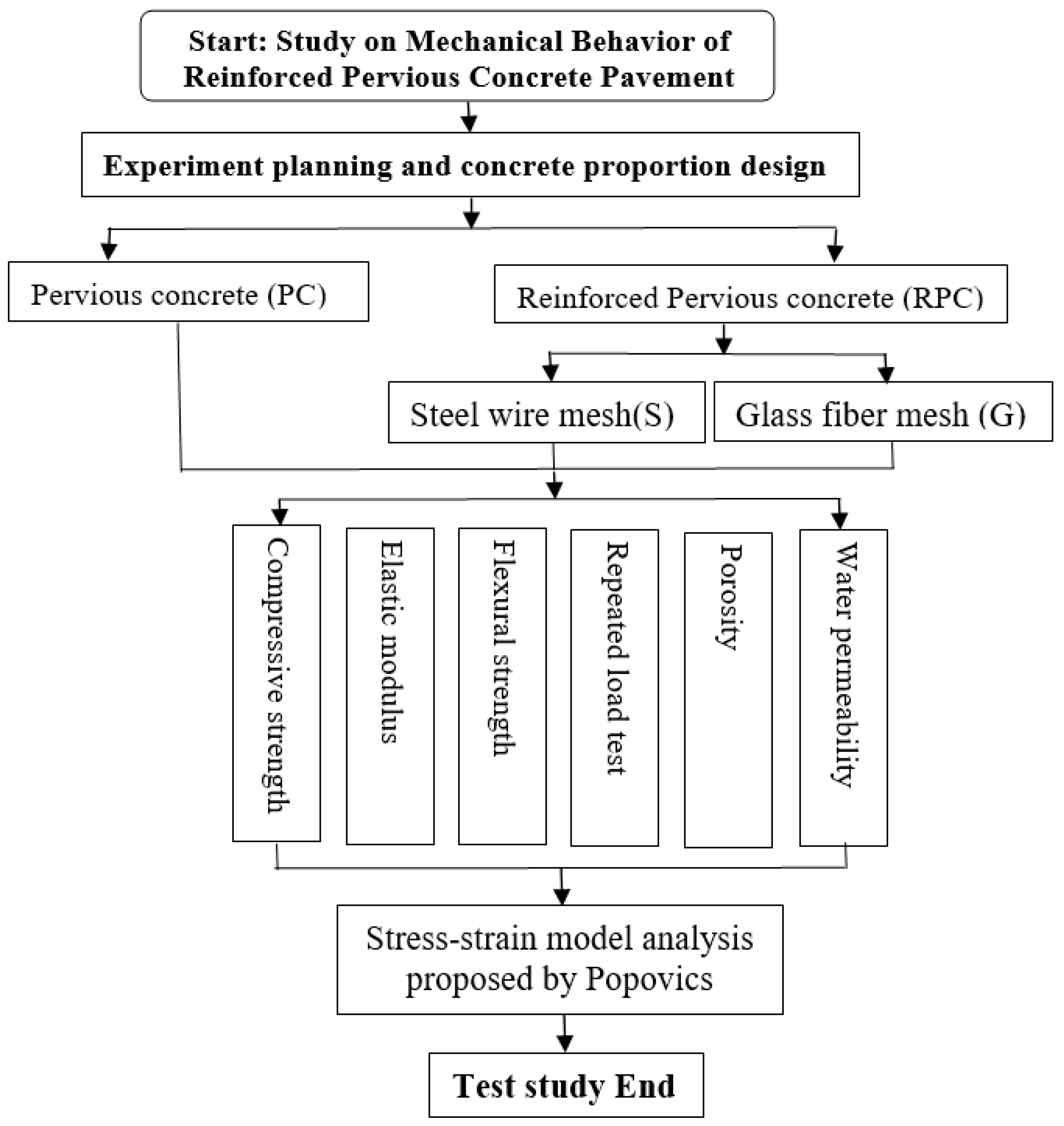

2. Materials and Methods

2.1. Raw Material

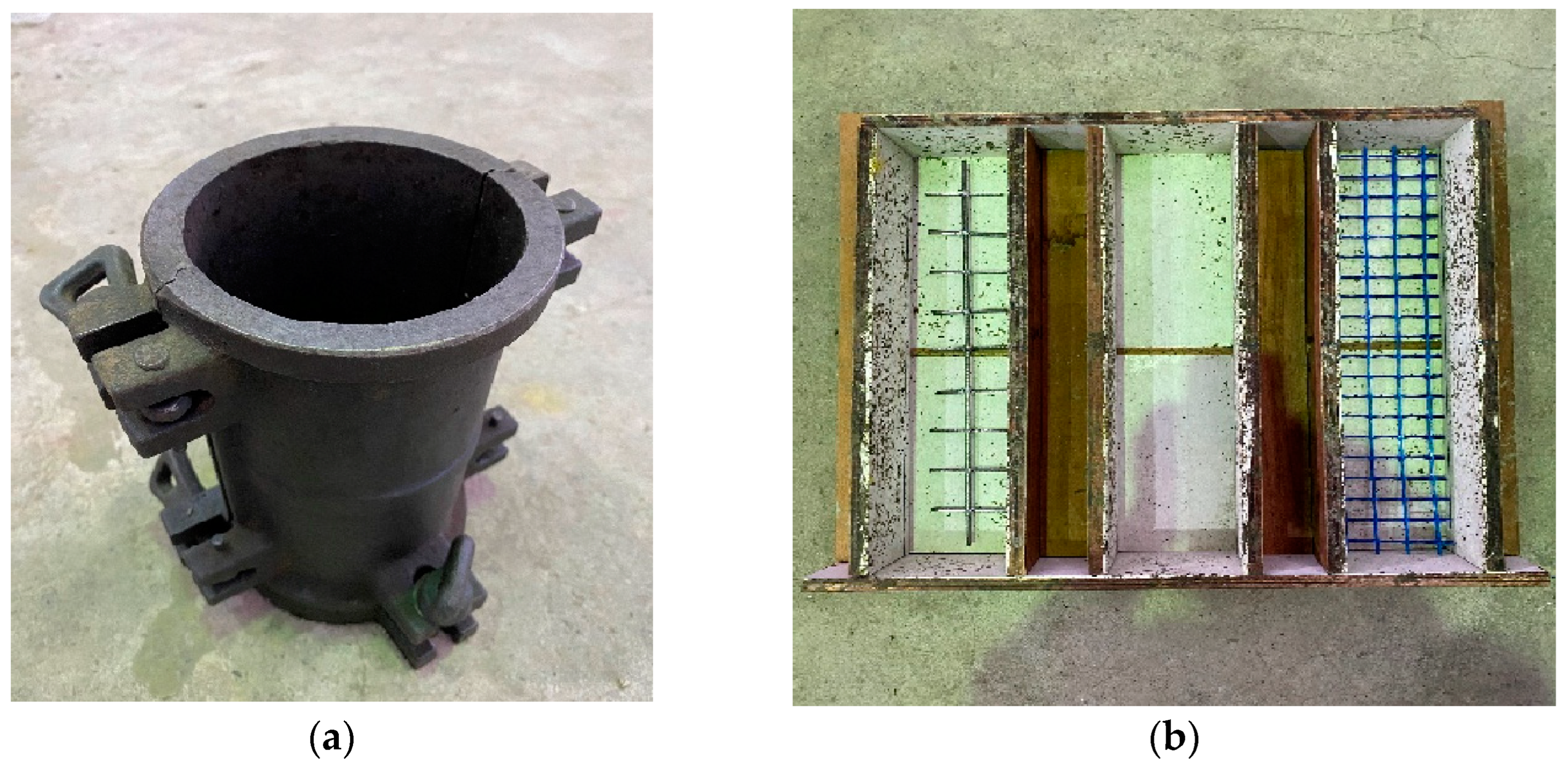

2.2. Test Specimens and Methods

2.2.1. Compressive Strength Test

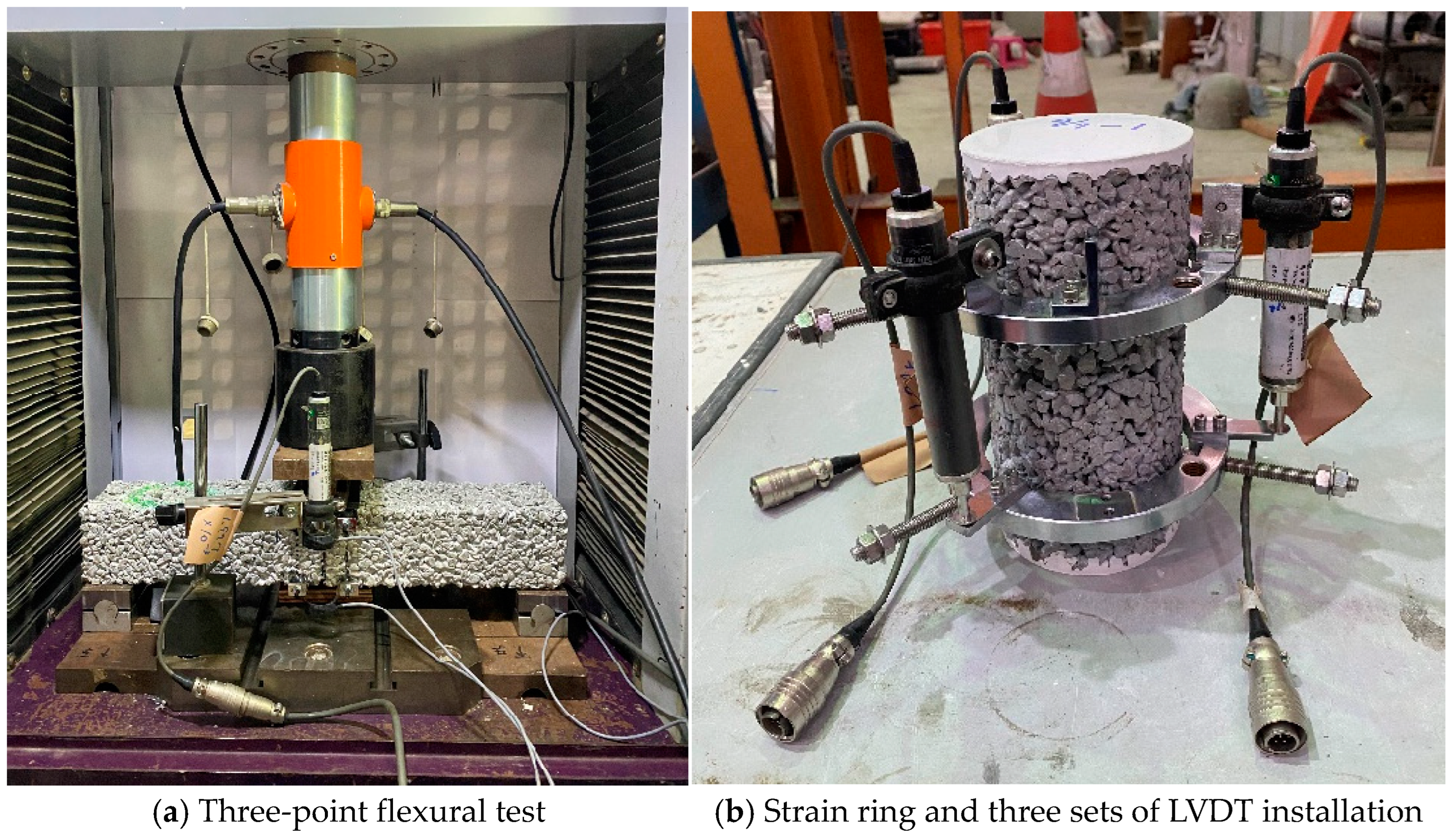

2.2.2. Flexural Strength Test

2.2.3. Elastic Modulus Test

2.2.4. Measurement of Water Permeability Coefficient

2.2.5. Porosity Measurement Test

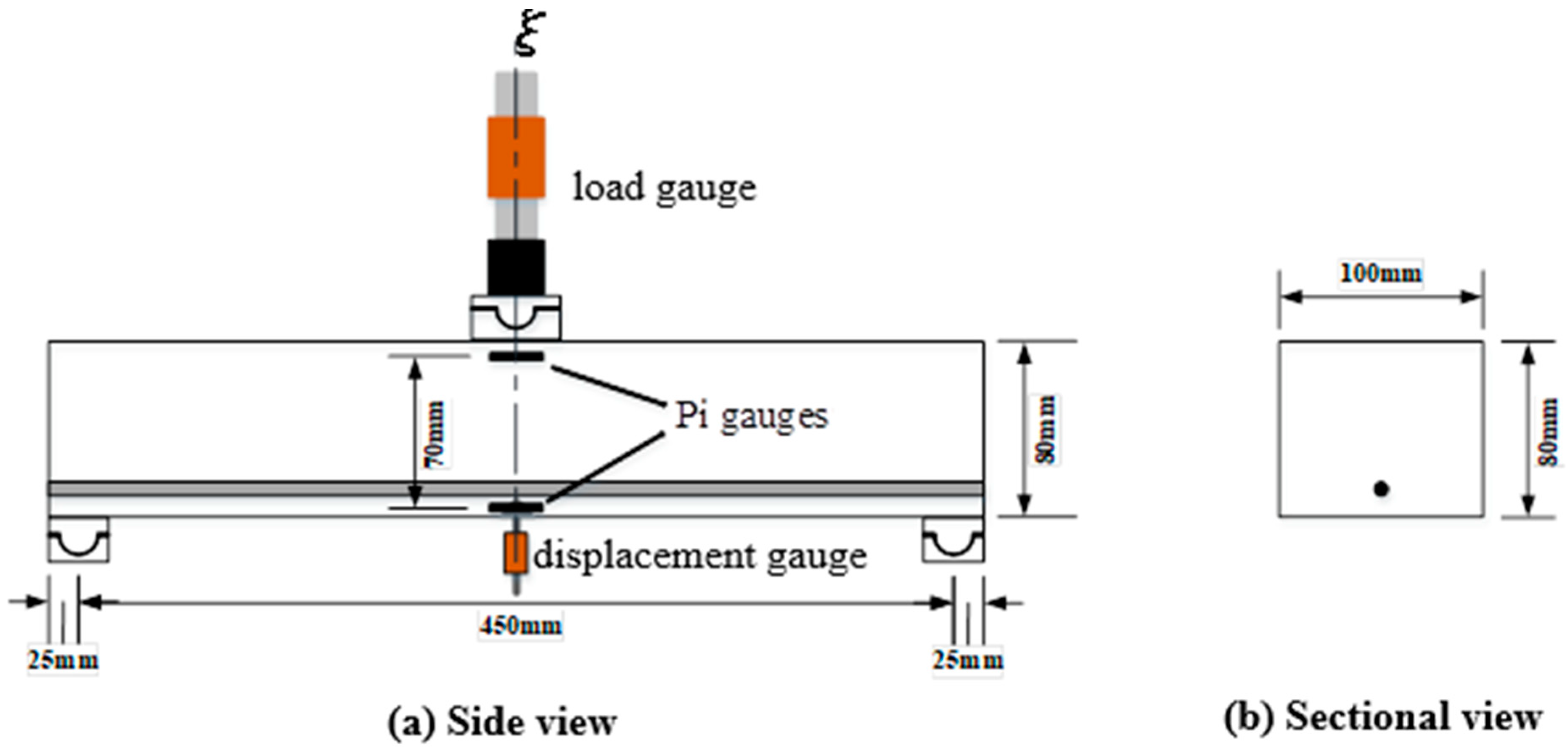

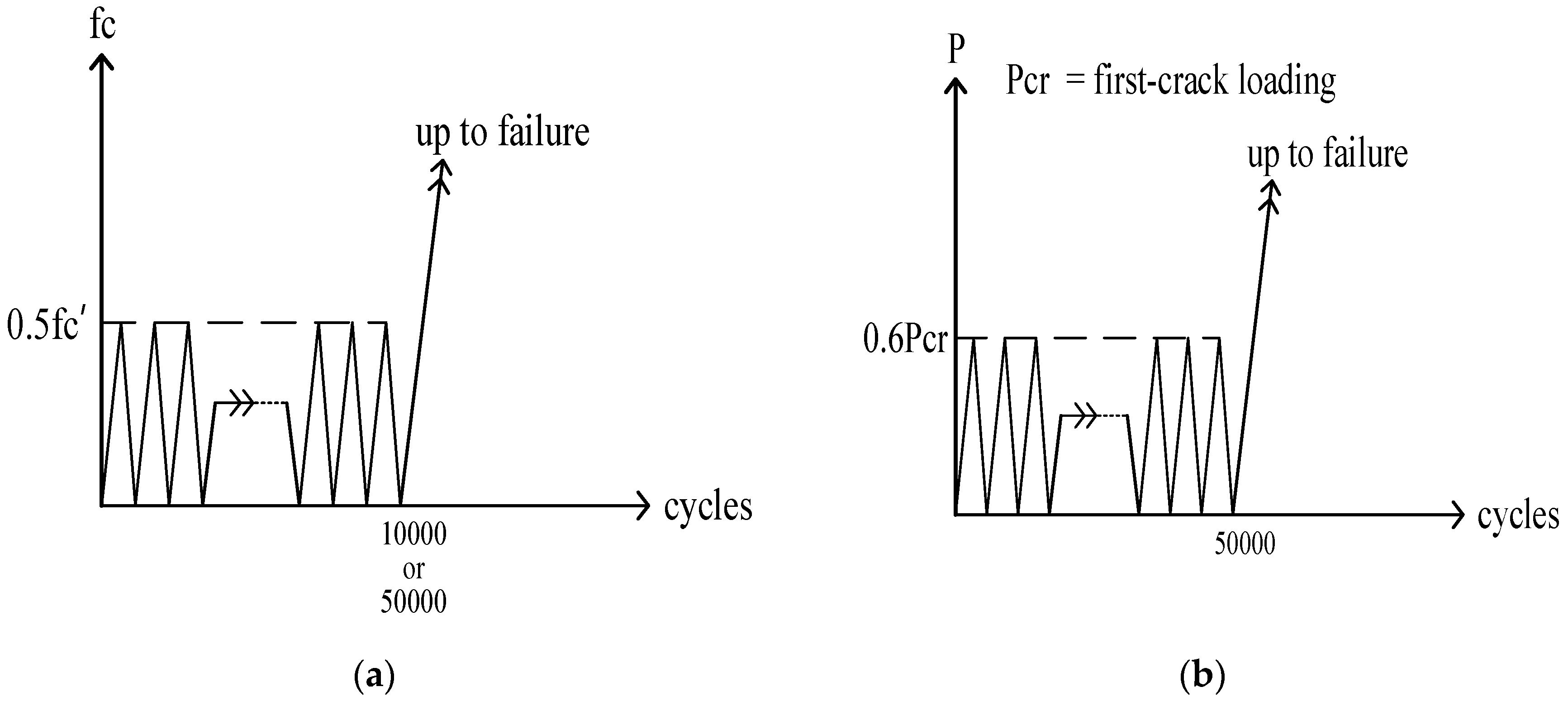

2.2.6. Repeated Load Test

3. Results and Discussion

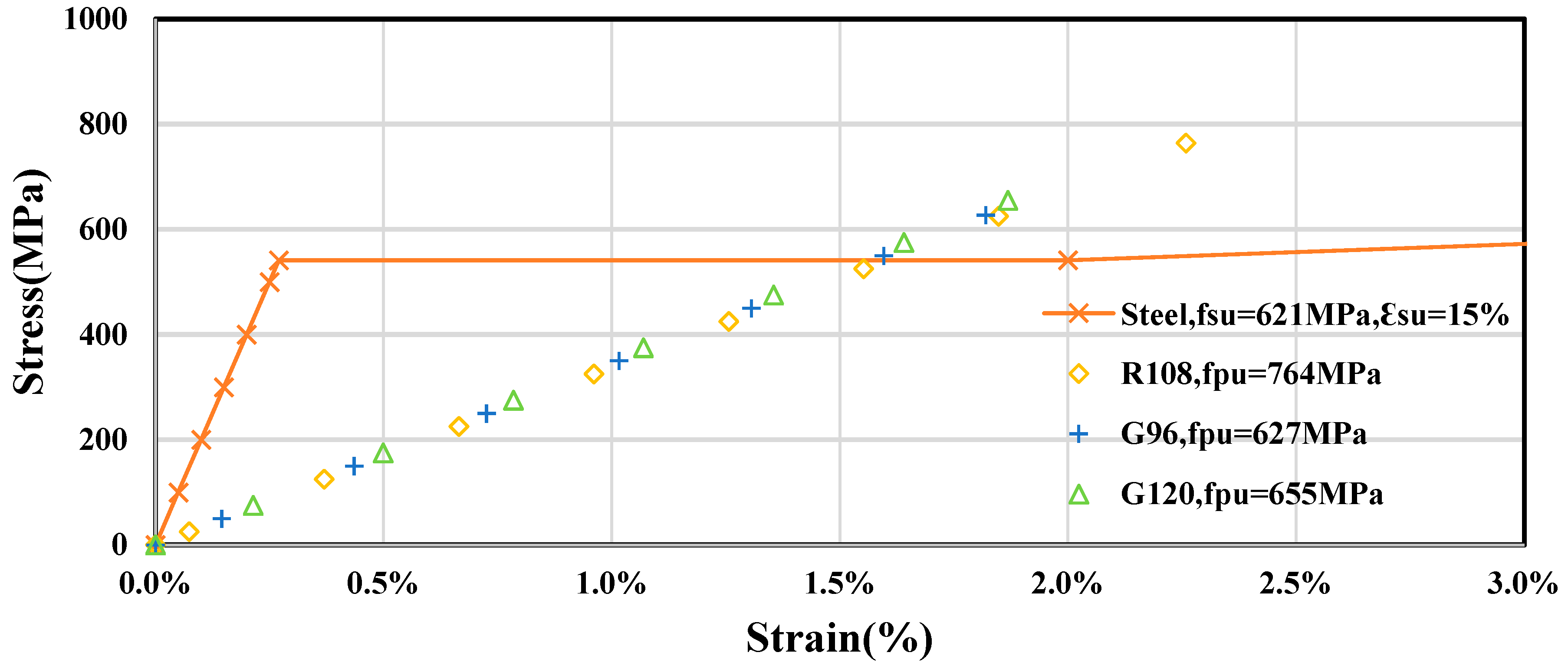

3.1. Results of Material Testing of Pervious Concrete and Reinforcing Material

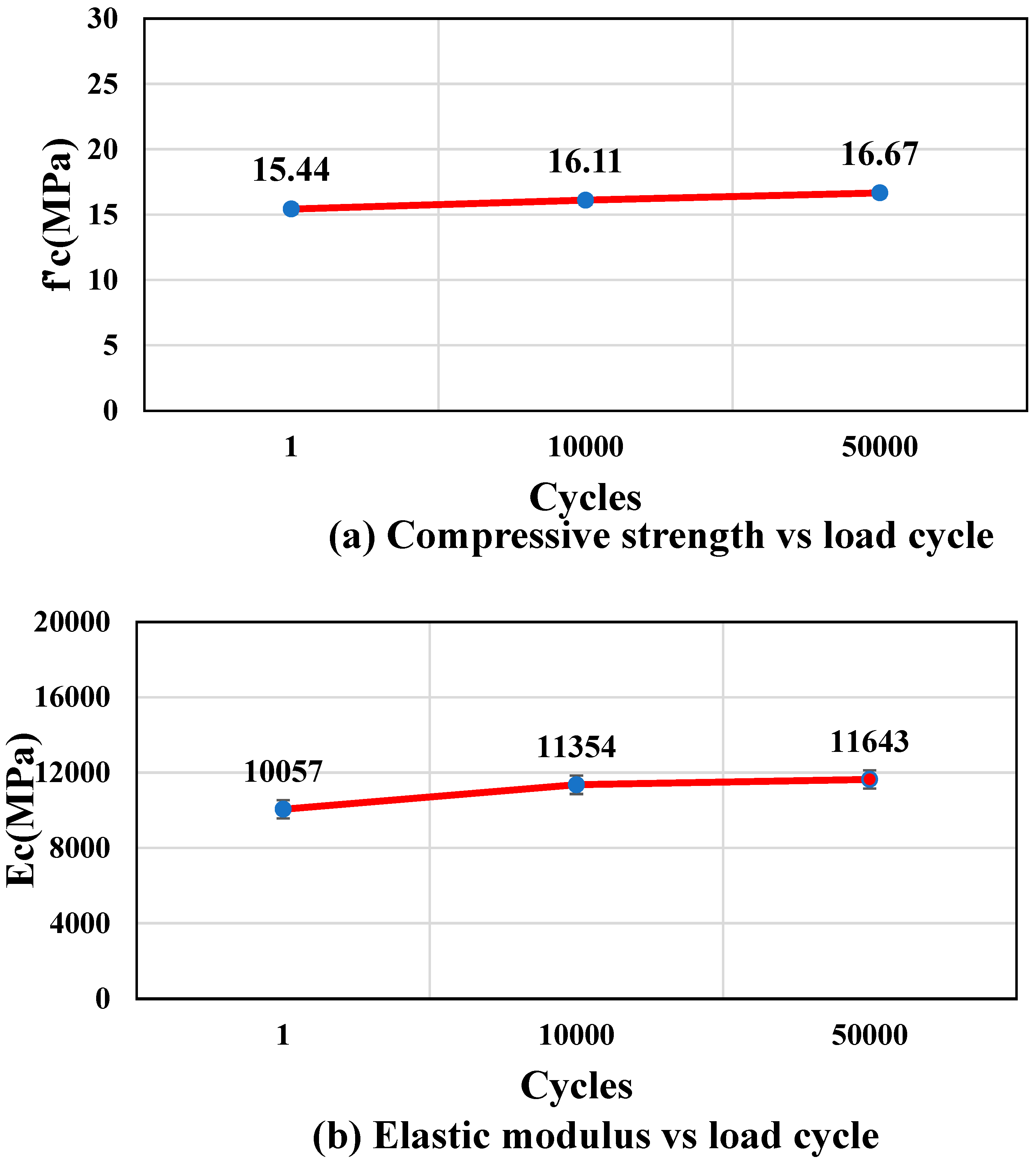

3.2. Repeated Load Test Results of Pervious Concrete Cylindrical Specimen

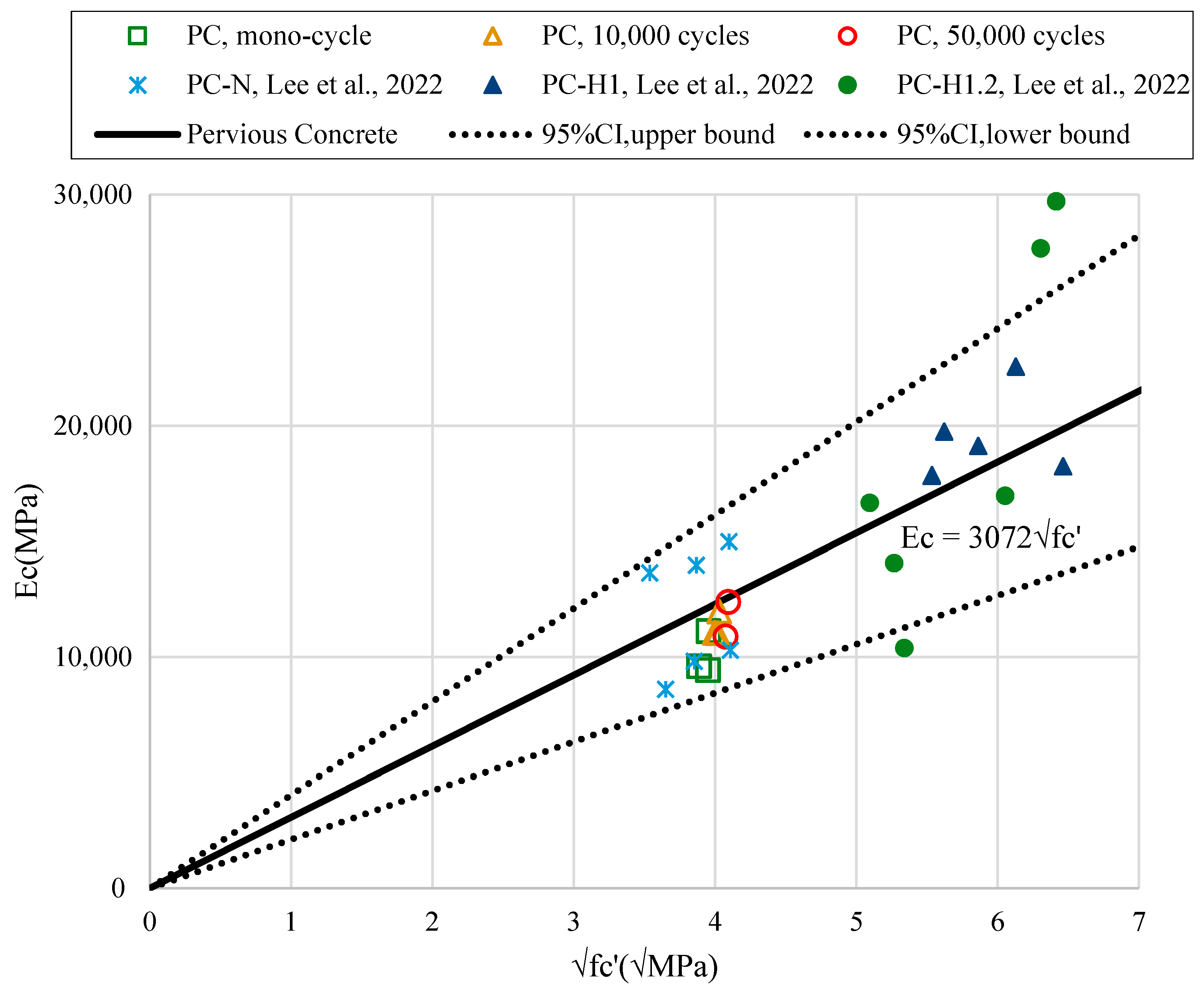

3.3. Results of Stress and Strain Model of Pervious Concrete

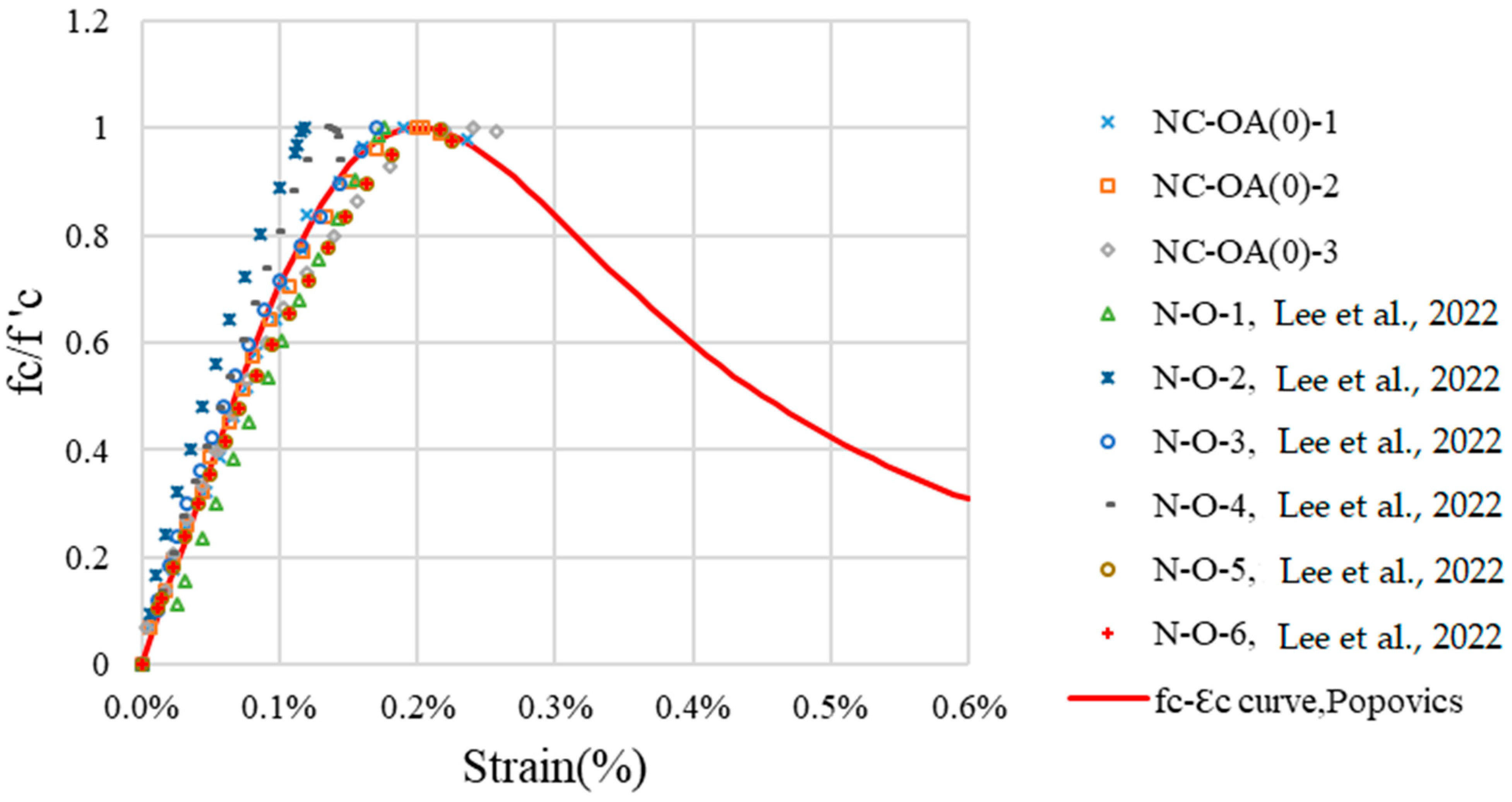

3.3.1. Single Compressive Stress–Strain Curve

3.3.2. Compressive and Single Compressive Stress–Strain Curves after Repeated Loading

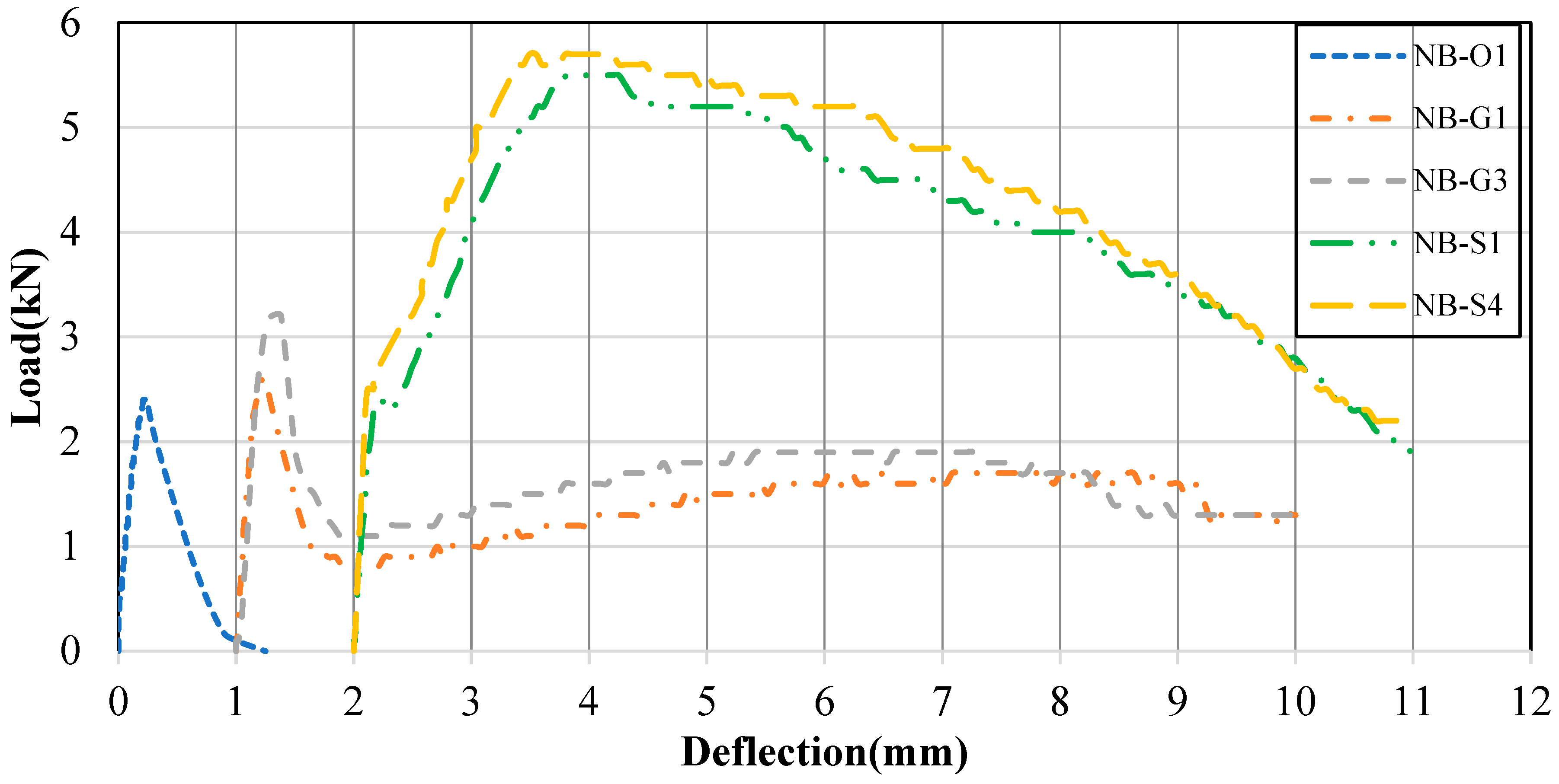

3.4. Results of Mechanical Behavior of Beams under Repeated Loading and Single Loading

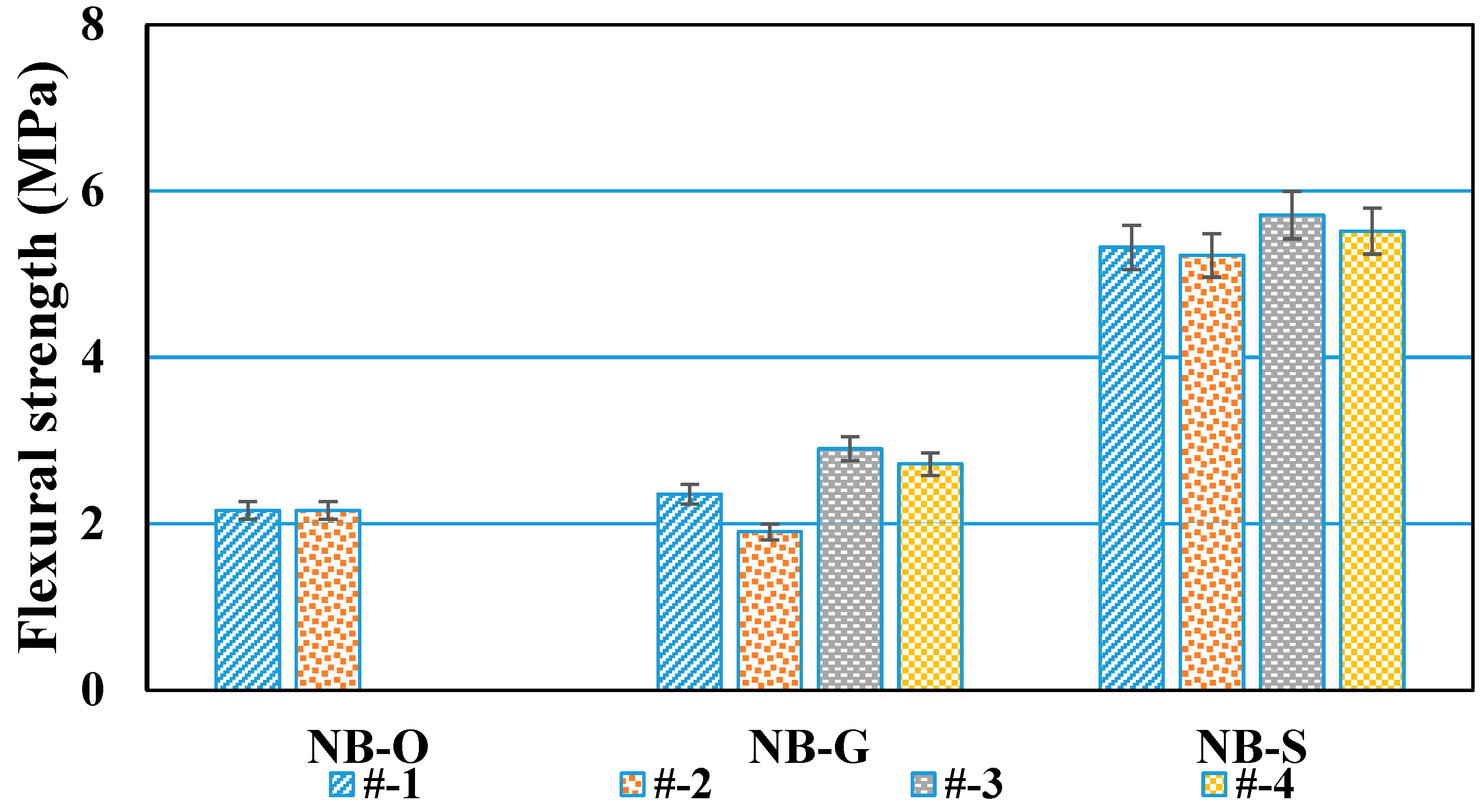

3.4.1. Beam Bending Strength

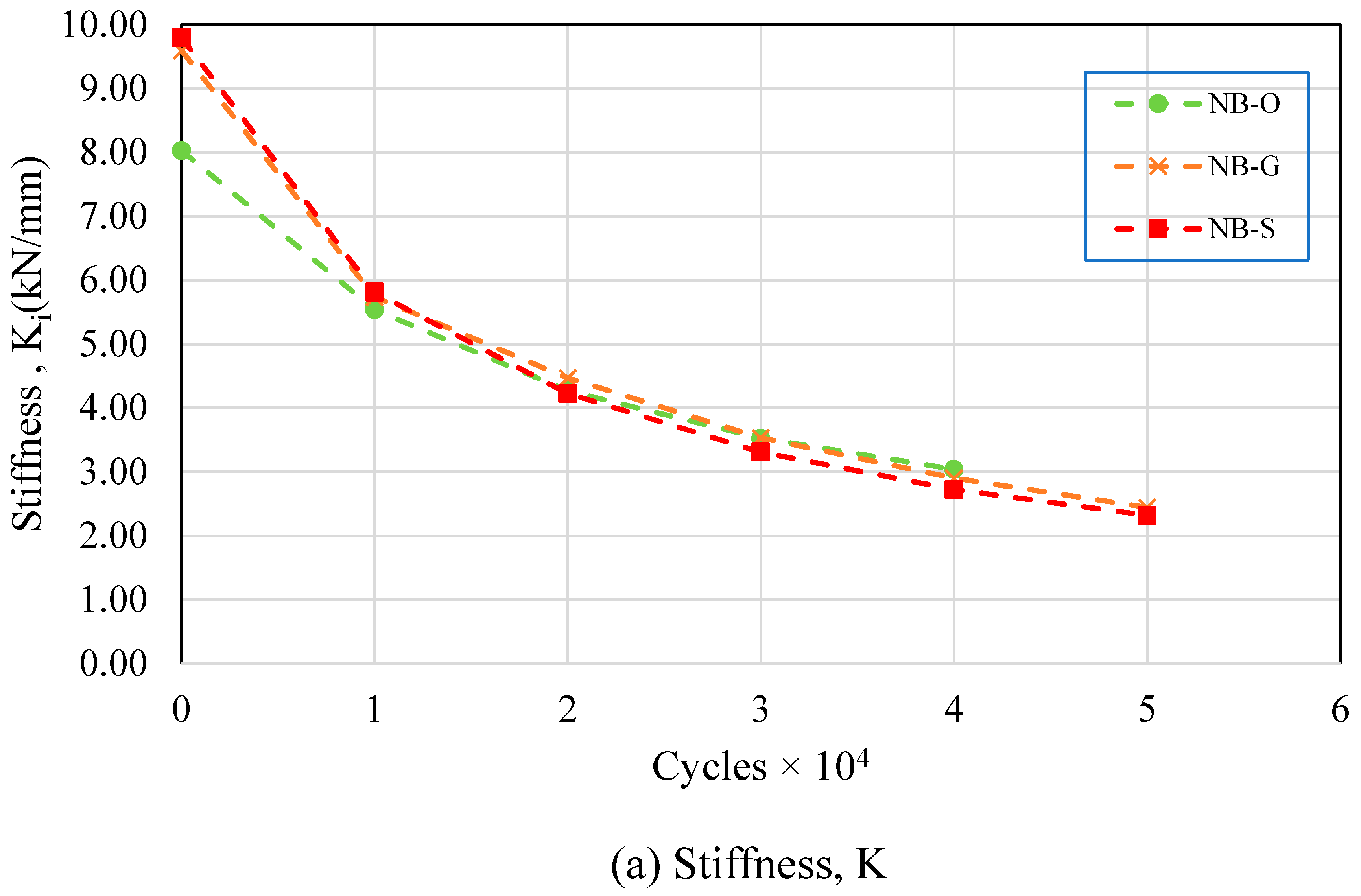

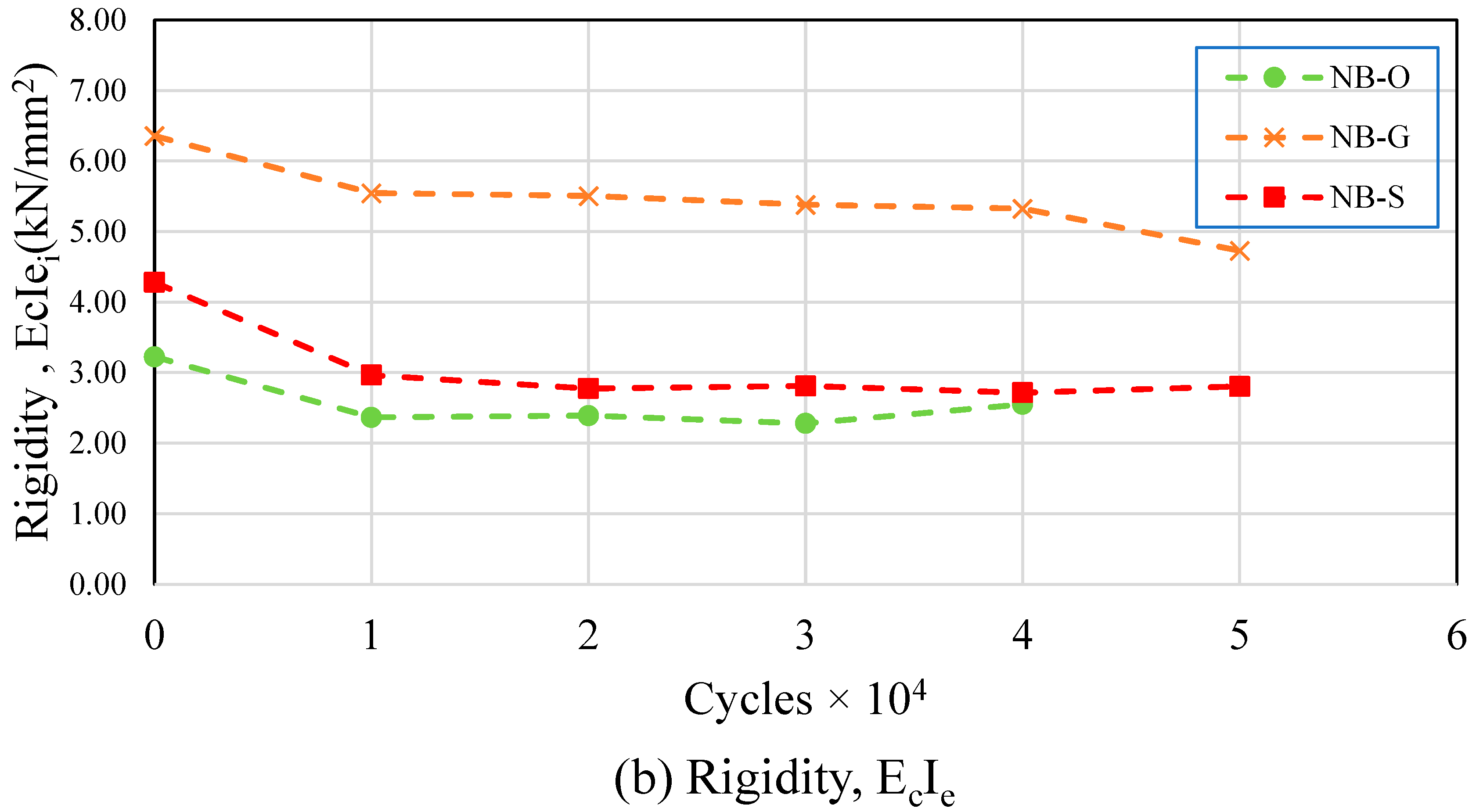

3.4.2. Force Behavior of Beams during Repeated Loading

4. Conclusions

- Variations in the compressive strength and elastic modulus were observed between single and repeated loading conditions. Repeated loading led to a slight increase in both compressive strength (8%) and elastic modulus (16%) due to a compaction effect.

- The compressive strength (fc′) was determined to be around 15 MPa. Empirical formulas for elastic modulus and cracking modulus, as derived in Equations (4) and (6), are useful for pervious concrete component design.

- This study applied the Popovics stress–strain curve theory, finding that the compressive behavior aligns with typical pervious concrete behavior (Equation (5)).

- Popovics stress–strain curves after single compression and repeated loading exhibited similar trends (correspondence only reaching strain values of 0.25%), with data after 10,000 and 50,000 loading cycles slightly exceeding the recommended single compression curve.

- Pervious concrete initially displayed greater stiffness and section rigidity in single loading but showed a reduction in stiffness and section rigidity with an increased number of repeated loading cycles.

- The addition of steel wire mesh to pervious concrete significantly improved flexural strength, approximately doubling that of ordinary pervious concrete, and enhanced ductility in the reinforced specimens.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Asaeda, T.; Ca, V.T. Characteristics of Permeable Pavement during Hot Summer Weather and Impact on the Thermal Environment. Build. Environ. 2000, 35, 363–375. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression Response of Normal and High Strength Pervious Concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- Bhutta, M.A.R.; Tsuruta, K.; Mirza, J. Evaluation of High-Performance Porous Concrete Properties. Constr. Build. Mater. 2012, 31, 67–73. [Google Scholar] [CrossRef]

- Kevern, J.T. Operation, and Maintenance of Pervious Concrete Pavements. In Proceedings of the 90th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Ahmad, O.A.; Awwad, M. Effects of Polypropylene Fibers Additions on Compressive and Tensile Strengths of Concrete. Int. J. Civ. Environ. Eng. 2015, 37, 1365–1372. [Google Scholar]

- Meng, X.; Chi, Y.; Jiang, Q.; Liu, R.; Wu, K.; Li, S. Experimental Investigation on the Flexural Behavior of Pervious Concrete Beams Reinforced with Geogrids. Constr. Build. Mater. 2019, 215, 275–284. [Google Scholar] [CrossRef]

- Lee, M.-G.; Wang, W.-C.; Wang, Y.-C.; Lin, Y.-C.; Hsieh, Y.-C. Mechanical Properties of High Strength Pervious Concrete with Steel Fiber or Glass Fiber. Buildings 2022, 12, 620. [Google Scholar] [CrossRef]

- Collins, M.P.; Mitchell, D. Prestressed Concrete Structures; Prentice-Hall: New Jersey, NJ, USA, 1991. [Google Scholar]

- Moehle, J. Seismic Design of Reinforced Concrete Buildings; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Whitney, C.S. Design of Reinforced Concrete Members Under Flexure or Combined Flexure and Direct Compression. ACI J. Proc. 1937, 33, 483–498. [Google Scholar]

- Popovics, S. A Review of Stress-Strain Relationships for Concrete. ACI J. 1970, 67, 243–248. [Google Scholar]

- Rangelov, M.; Nassiri, S.; Haselbach, L.; Englund, K. Using carbon fiber composites for reinforcing pervious concrete. Constr. Build. Mater. 2016, 126, 875–885. [Google Scholar] [CrossRef]

- Oni, B.; Xia, J.; Liu, M. Mechanical properties of pressure moulded fiber reinforced pervious concrete pavement brick. Case Stud. Constr. Mater. 2020, 13, e00431. [Google Scholar]

- Tang, C.-W.; Cheng, C.-K.; Ean, L.-W. Mix design and engineering properties of fiber-reinforced pervious concrete using lightweight aggregates. Appl. Sci. 2022, 12, 524. [Google Scholar] [CrossRef]

- Akand, L.; Yang, M.; Wang, X. Effectiveness of chemical treatment on polypropylene fibers as reinforcement in pervious concrete. Constr. Build. Mater. 2018, 163, 32–39. [Google Scholar] [CrossRef]

- Khodaii, A.; Fallah, S.; Nejad, F.M. Effects of geosynthetics on reduction of reflection cracking in asphalt overlays. Geotext. Geomembr. 2009, 27, 1–8. [Google Scholar] [CrossRef]

- Itani, H.; Saad, G.; Chehab, G. The use of geogrid reinforcement for enhancing the performance of concrete overlays: An experimental and numerical assessment. Constr. Build. Mater. 2016, 124, 826–837. [Google Scholar] [CrossRef]

- Ferrotti, G.; Canestrari, F.; Pasquini, E.; Virgili, A. Experimental evaluation of the influence of surface coating on fiberglass geogrid performance in asphalt pavements. Geotext. Geomembr. 2012, 34, 11–18. [Google Scholar] [CrossRef]

- Ferrotti, G.; Canestrari, F.; Virgili, A.; Grilli, A. A strategic laboratory approach for the performance investigation of geogrids in flexible pavements. Constr. Build. Mater. 2011, 25, 2343–2348. [Google Scholar] [CrossRef]

- Sangthongtong, A.; Semvimol, N.; Rungratanaubon, T.; Duangmal, K.; Joyklad, P. Mechanical Properties of Pervious Recycled Aggregate Concrete Reinforced with Sackcloth Fibers (SF). Infrastructures 2023, 8, 38. [Google Scholar] [CrossRef]

- Sakib, N.; Bhasin, A.; Islam, M.K.; Khan, K.; Khan, M.I. A review of the evolution of technologies to use sulphur as a pavement construction material. Int. J. Pavement Eng. 2021, 22, 392–403. [Google Scholar] [CrossRef]

- Amin, M.N.; Iqtidar, A.; Khan, K.; Javed, M.F.; Shalabi, F.I.; Qadir, M.G. Comparison of machine learning approaches with traditional methods for predicting the compressive strength of rice husk ash concrete. Crystals 2021, 11, 779. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Aslam, F.; Ahmad, A.; Al-Faiad, M.A. Comparison of Prediction Models Based on Machine Learning for the Compressive Strength Estimation of Recycled Aggregate Concrete. Materials 2022, 15, 3430. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in bending performance of reinforced concrete beams produced with waste lathe scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance assessment of fiber-reinforced concrete produced with waste lathe fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Stel’Makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’Nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.I.; Deifalla, A.F.; Ahmad, M.; Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Skaf, M.; Manso, J.M. Shrinkage prediction of recycled aggregate structural concrete with alternative binders through partial correction coefficients. Cem. Concr. Compos. 2022, 129, 104506. [Google Scholar] [CrossRef]

- Liang, C.; You, J.; Gu, F.; Gao, Y.; Yang, G.; He, Z.; Hou, S.; Duan, S. Enhancing the elastic modulus of concrete prepared with recycled coarse aggregates of different quality by chemical modifications. Constr. Build. Mater. 2022, 360, 129590. [Google Scholar] [CrossRef]

- Duan, Z.; Lv, Z.; Xiao, J.; Liu, C.; Nong, X. Study on the Performance of Recycled Coarse and Fine Aggregates as Microbial Carriers Applied to Self-Healing Concrete. Materials 2023, 16, 2371. [Google Scholar] [CrossRef]

- Hussain, H.K.; Abbas, A.M.; Ojaimi, M.F. Fiber-Type Influence on the Flexural Behavior of RC Two-Way Slabs with an Opening. Buildings 2022, 12, 279. [Google Scholar] [CrossRef]

- Tang, B.; Fan, M.; Yang, Z.; Sun, Y.; Yuan, L. A comparison study of aggregate carbonation and concrete carbonation for the enhancement of recycled aggregate pervious concrete. Constr. Build. Mater. 2023, 371, 130797. [Google Scholar] [CrossRef]

- Bagherzadeh, F.; Shafighfard, T. Ensemble Machine Learning approach for evaluating the material characterization of carbon nanotube-reinforced cementitious composites. Case Stud. Constr. Mater. 2022, 17, e01537. [Google Scholar] [CrossRef]

- ASTM C39/C39M-16; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016; pp. 1–8.

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–5.

- ASTM C469/C469M-22; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–6.

- ACI 522R-10; Pervious Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2010; pp. 1–5.

- Kia, A.; Wong, H.S.; Cheeseman, C.R. High-strength clogging resistant permeable pavement. Int. J. Pavement Eng. 2021, 22, 271–282. [Google Scholar] [CrossRef]

- Hatanaka, S.; Okamoto, T.; Kajio, S.; Kunieda, M.; Mishima, N.; Hiraiwa, T. Technical Committee Report on Establishment of Construction Standards and Quality Assurance System for Performance-Based Design of Porous Concrete. JCI 2015, 343. (In Japanese) [Google Scholar]

- Avanaki, M.J.; Abedi, M.; Hoseini, A.; Maerefat, M.S. Effects of fiber volume fraction and aspect ratio on mechanical properties of hybrid steel fiber reinforced concrete. J. New Approaches Civ. Eng. 2018, 2, 49–64. [Google Scholar]

| Sieve Size | Individual Fraction Retained by Mass (%) | Passing by Mass (%) | Cumulative Retained by Mass (%) |

|---|---|---|---|

| 9.5 mm | 0 | 100 | 0 |

| #4 (4.75 mm) | 72.3 | 27.7 | 72.3 |

| #8 (2.36 mm) | 22.5 | 5.2 | 94.8 |

| #16 | 2.0 | 3.2 | 96.8 |

| #30 | 1.2 | 2.0 | 98.0 |

| #50 | 2.0 | 0 | 100 |

| #100 | 0 | 0 | 100 |

| Pan | 0 | 0 | 100 |

| Fineness modulus = 5.62 | |||

| Grid Type | R108 | G96 | G120 |

|---|---|---|---|

| Grid size (mm) | 9 × 9 | 25 × 25 | 40 × 40 |

| Grid weight (g/m2) | 140 | 130 | 145 |

| Chemical coating | Alkali resistant | ||

| Pervious Concrete | Mean | Standard Deviation | Coefficient of Variation (%) | ACI 522R-10 Standard |

|---|---|---|---|---|

| Water permeability coefficient (cm/s) | 2.39 | 0.20 | 8.17 | ≥0.1 |

| Porosity (%) | 20.35 | 1.82 | 8.96 | 18~35 |

| Mesh | Code | Width | Diameter/ Thickness (mm) | AS * (mm2) | fu * (MPa) | Δ * (%) | EC (MPa) |

|---|---|---|---|---|---|---|---|

| Glass fiber | R108 | 0.39 | 0.91 | 0.35 | 764 | 2.26 | 33,825 |

| G96 | 0.51 | 1.99 | 1.02 | 627 | 1.82 | 34,461 | |

| G120 | 0.61 | 3.26 | 1.98 | 655 | 1.87 | 35,059 | |

| Steel wire | D5 | - | 5 | 19.63 | 621 | 15 | 200,000 |

| Specimen# | (MPa) | (MPa) | |

|---|---|---|---|

| NC-O1(0)-1 | 15.59 | 0.0019 | 9438 |

| NC-O1(0)-2 | 15.62 | 0.0020 | 11,125 |

| NC-O1(0)-3 | 15.10 | 0.0024 | 9608 |

| N-O-1 [7] | 13.32 | 0.0018 | 8605 |

| N-O-2 [7] | 12.51 | 0.0012 | 13,650 |

| N-O-3 [7] | 16.79 | 0.0017 | 14,985 |

| N-O-4 [7] | 14.95 | 0.0013 | 13,984 |

| N-O-5 [7] | 16.87 | 0.0021 | 10,306 |

| N-O-6 [7] | 14.83 | 0.0031 | 9816 |

| Mean | 15.06 | 0.002 | 11,280 |

| Standard deviation | 1.43 | 0.0006 | 2322 |

| CV (%) | 9.5 | 29.4 | 20.6 |

| Parameter | fc′ (MPa) | εc′ (%) | Ec′ (MPa) | Ec (MPa) | n | k | k, suggest |

|---|---|---|---|---|---|---|---|

| Mean | 15.06 | 0.002 | 7530 | 11,280 | 3.01 | 0.91 | 1 |

| Specimen# | fr | fc′ | k | |

|---|---|---|---|---|

| NB-O1 | 2.16 | 15.44 | 3.93 | 0.55 |

| NB-O2 | 2.16 | 15.44 | 3.93 | 0.55 |

| NB-G1 | 2.36 | 15.44 | 3.93 | 0.60 |

| NB-G2 | 1.90 | 15.44 | 3.93 | 0.48 |

| NB-G3 | 2.90 | 15.44 | 3.93 | 0.74 |

| NB-G4 | 2.72 | 15.44 | 3.93 | 0.69 |

| NB-S1 | 5.32 | 15.44 | 3.93 | 1.35 |

| NB-S2 | 5.23 | 15.44 | 3.93 | 1.33 |

| NB-S3 | 5.71 | 15.44 | 3.93 | 1.45 |

| NB-S4 | 5.52 | 15.44 | 3.93 | 1.40 |

| N-O-1 [7] | 3.01 | 14.88 | 3.86 | 0.78 |

| N-O-2 [7] | 3.33 | 15.19 | 3.90 | 0.85 |

| N-O-3 [7] | 2.71 | 15.35 | 3.92 | 0.69 |

| Mean | 3.47 | 15.37 | 3.92 | 0.86 |

| Specimen# | Cycles | (a) | (b) | (c) = (a)/(b) | ||

|---|---|---|---|---|---|---|

| NB-O (no wire mesh) | 1 | 1.5 | 0.1869 | 8.03 | 3.23 | 1.00 |

| 10,000 | 1.5 | 0.2708 | 5.54 | 2.37 | 0.73 | |

| 20,000 | 1.5 | 0.3513 | 4.27 | 2.39 | 0.74 | |

| 30,000 | 1.5 | 0.4253 | 3.53 | 2.28 | 0.71 | |

| 40,000 | 1.5 | 0.4933 | 3.04 | 2.55 | 0.79 | |

| 50,000 | - | - | - | - | - | |

| NB-G (glass fiber mesh) | 1 | 1.5 | 0.1564 | 9.59 | 6.36 | 1.00 |

| 10,000 | 1.5 | 0.2613 | 5.74 | 5.55 | 0.87 | |

| 20,000 | 1.5 | 0.3356 | 4.47 | 5.51 | 0.87 | |

| 30,000 | 1.5 | 0.4247 | 3.53 | 5.38 | 0.85 | |

| 40,000 | 1.5 | 0.5169 | 2.90 | 5.33 | 0.84 | |

| 50,000 | 1.5 | 0.6137 | 2.44 | 4.73 | 0.74 | |

| NB-S (steel mesh) | 1 | 1.8 | 0.1837 | 9.80 | 4.28 | 1.00 |

| 10,000 | 1.8 | 0.3097 | 5.81 | 2.97 | 0.69 | |

| 20,000 | 1.8 | 0.4259 | 4.23 | 2.78 | 0.65 | |

| 30,000 | 1.8 | 0.5440 | 3.31 | 2.81 | 0.66 | |

| 40,000 | 1.8 | 0.6611 | 2.72 | 2.72 | 0.63 | |

| 50,000 | 1.8 | 0.7753 | 2.32 | 2.81 | 0.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.-G.; Wang, Y.-C.; Wang, W.-C.; Chien, H.-J.; Cheng, L.-C. Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete. Buildings 2023, 13, 2880. https://doi.org/10.3390/buildings13112880

Lee M-G, Wang Y-C, Wang W-C, Chien H-J, Cheng L-C. Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete. Buildings. 2023; 13(11):2880. https://doi.org/10.3390/buildings13112880

Chicago/Turabian StyleLee, Ming-Gin, Yung-Chih Wang, Wei-Chien Wang, Hung-Jen Chien, and Li-Chi Cheng. 2023. "Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete" Buildings 13, no. 11: 2880. https://doi.org/10.3390/buildings13112880

APA StyleLee, M.-G., Wang, Y.-C., Wang, W.-C., Chien, H.-J., & Cheng, L.-C. (2023). Experimental Study on the Mechanical Properties of Reinforced Pervious Concrete. Buildings, 13(11), 2880. https://doi.org/10.3390/buildings13112880