Preliminary Study on the Emission Dynamics of TVOC and Formaldehyde in Homes with Eco-Friendly Materials: Beyond Green Building

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Methods and Procedures

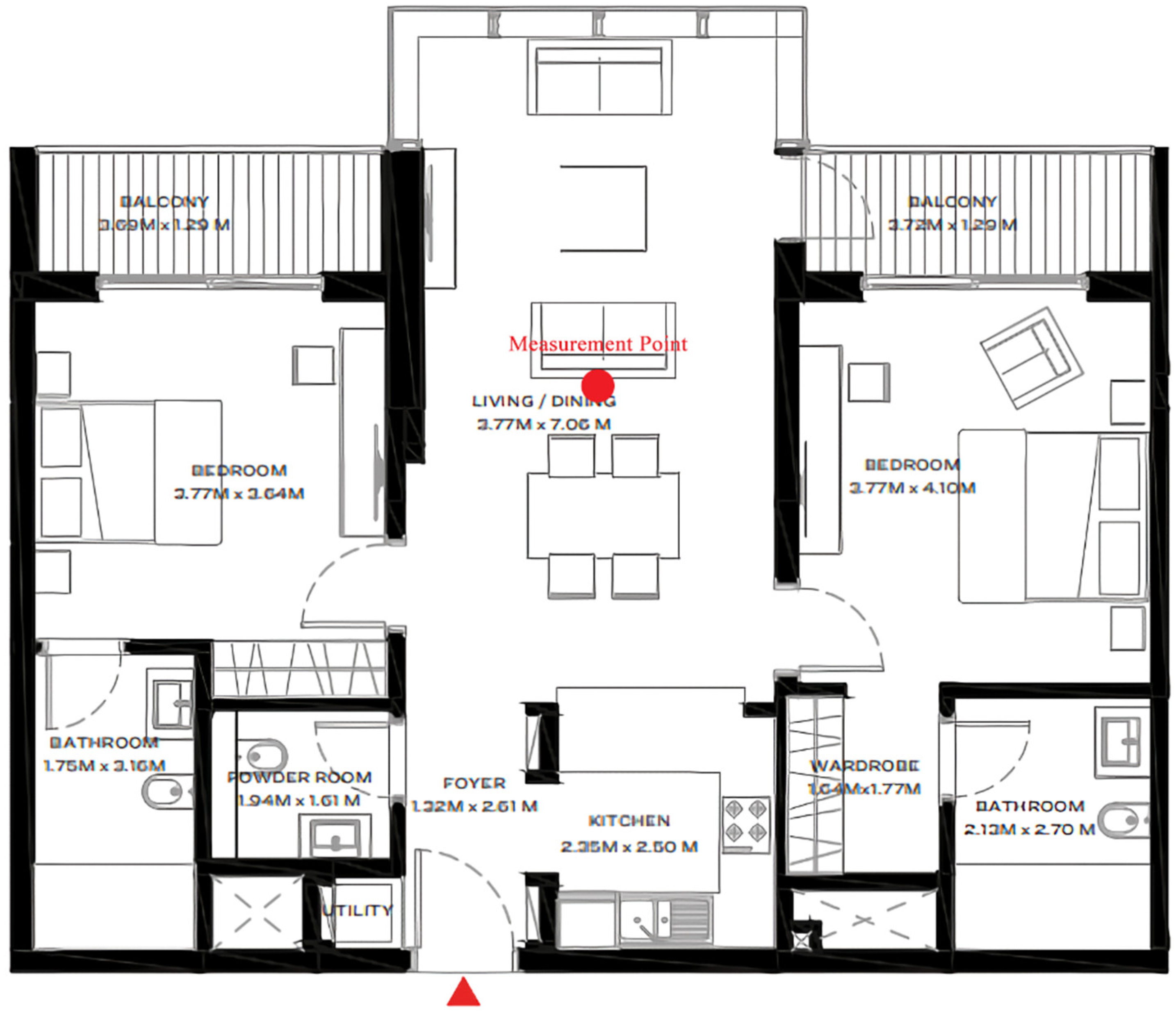

2.2. Target Building Status

2.3. Measurements

2.4. Sample Collection and Analysis Method

3. Results

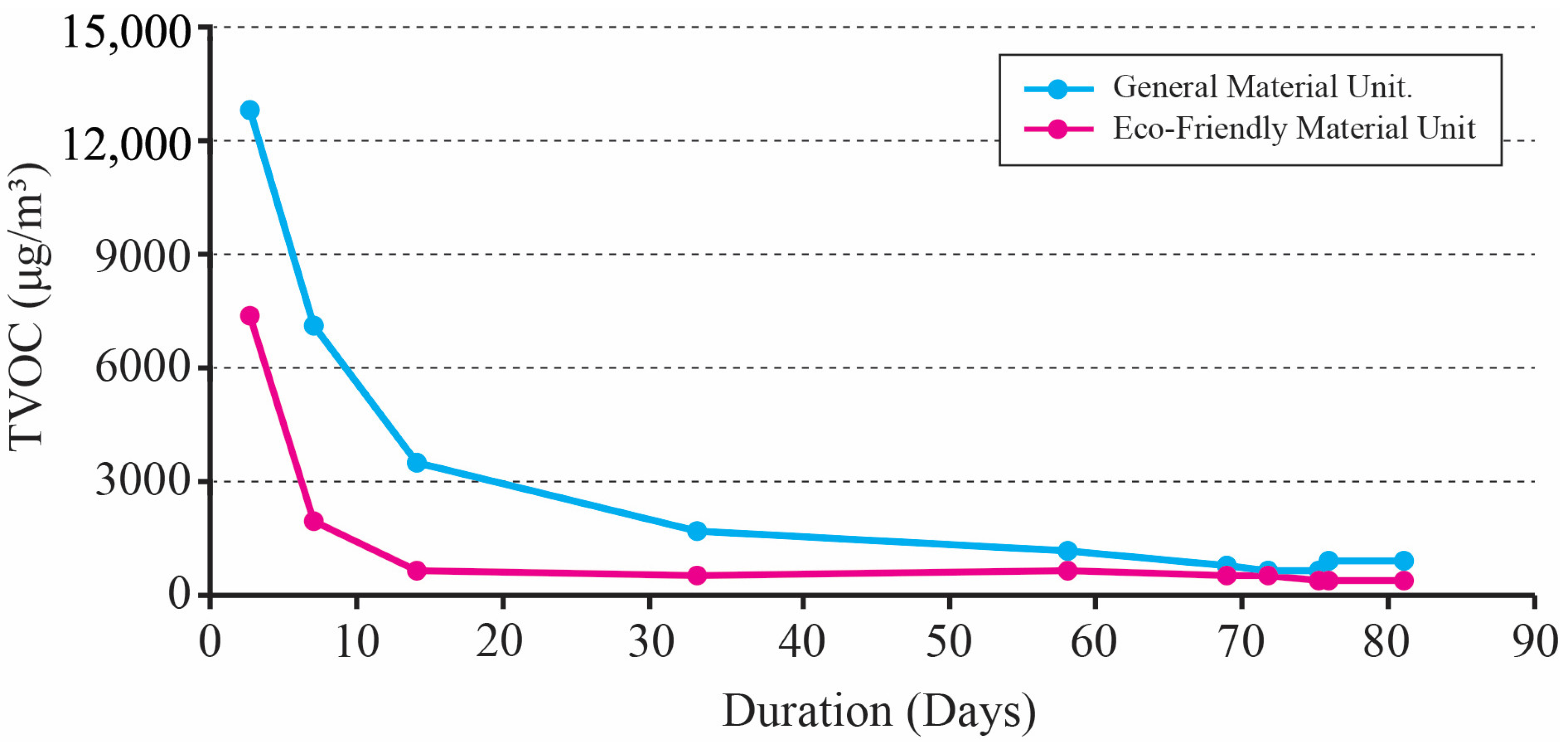

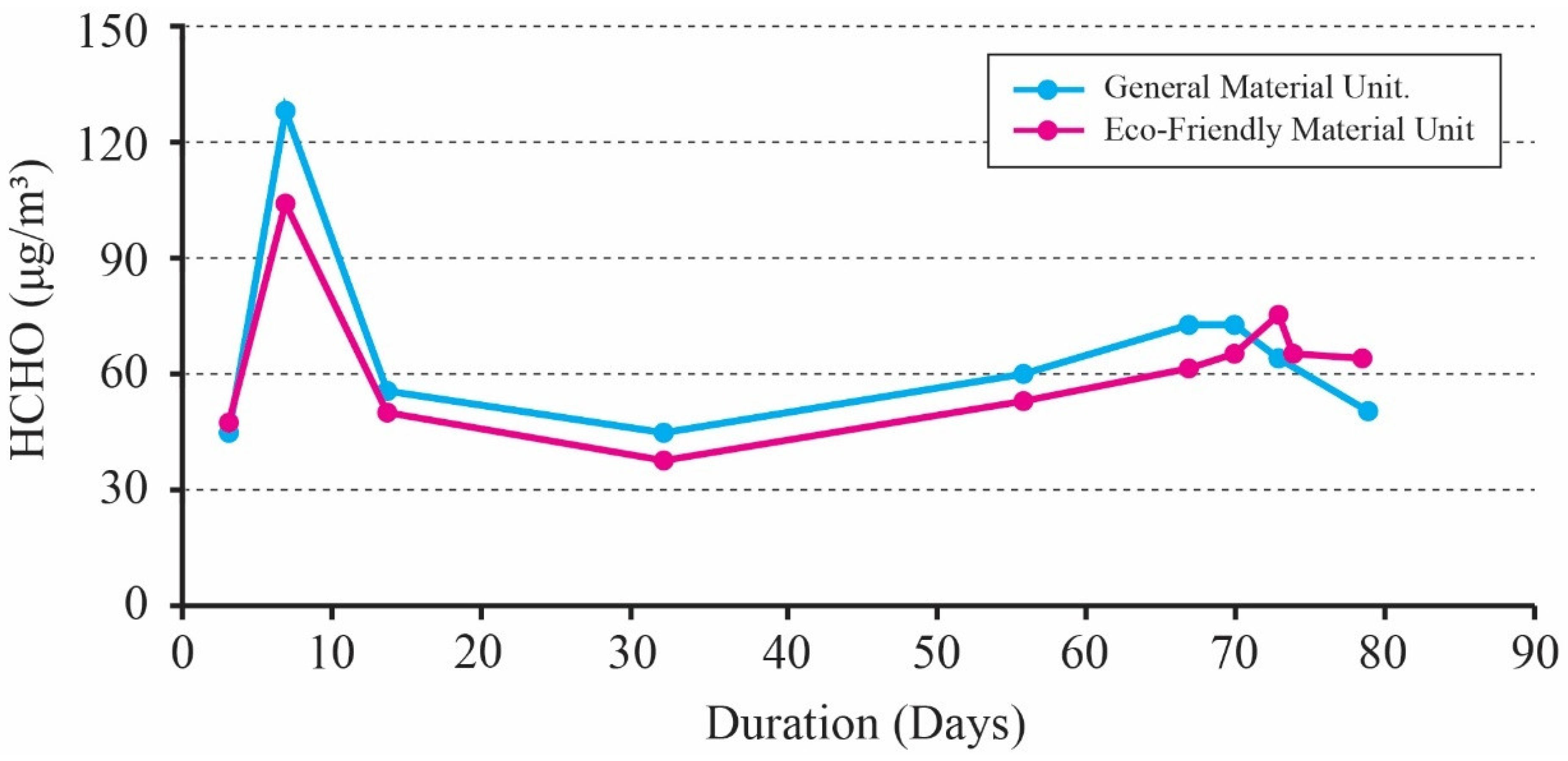

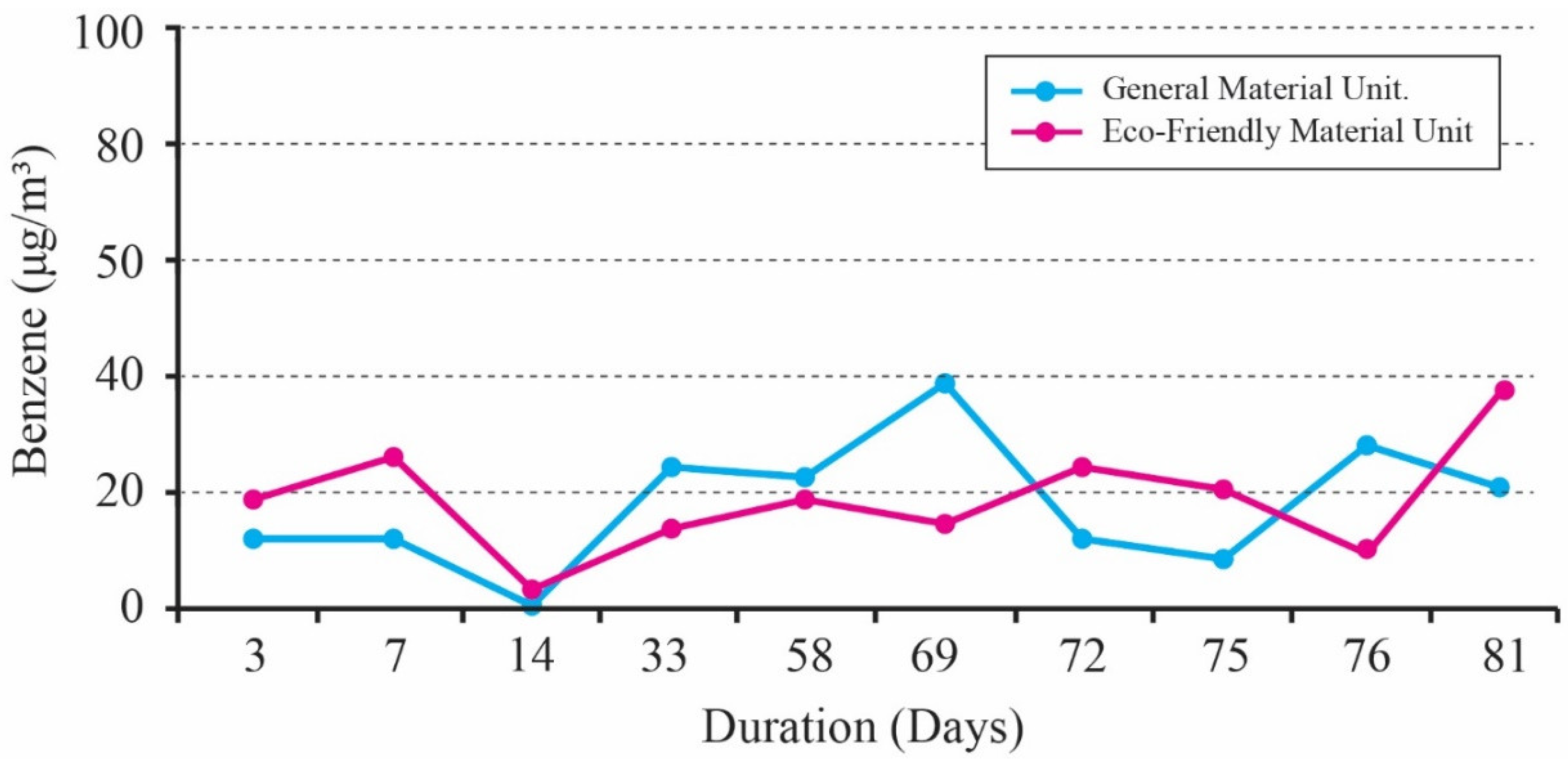

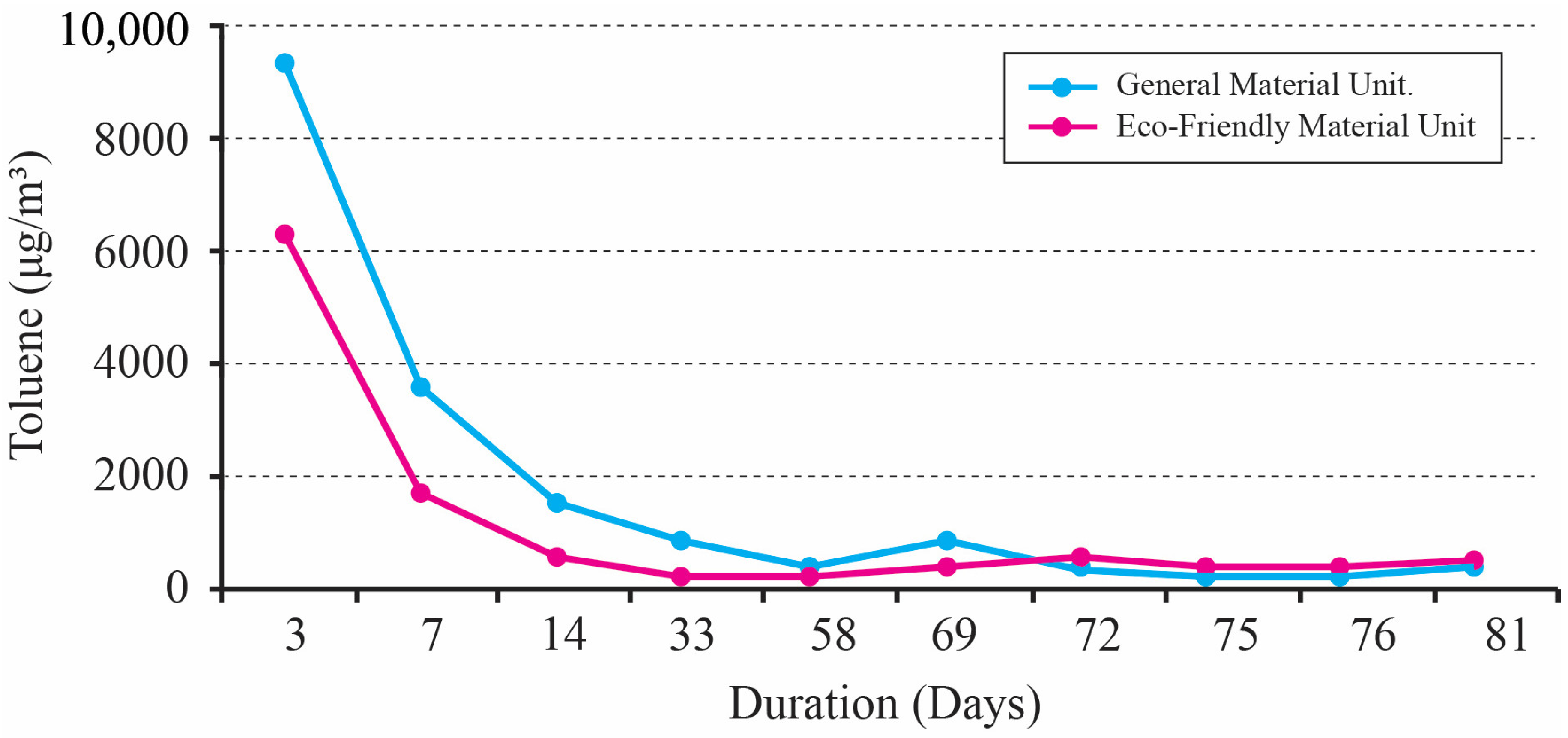

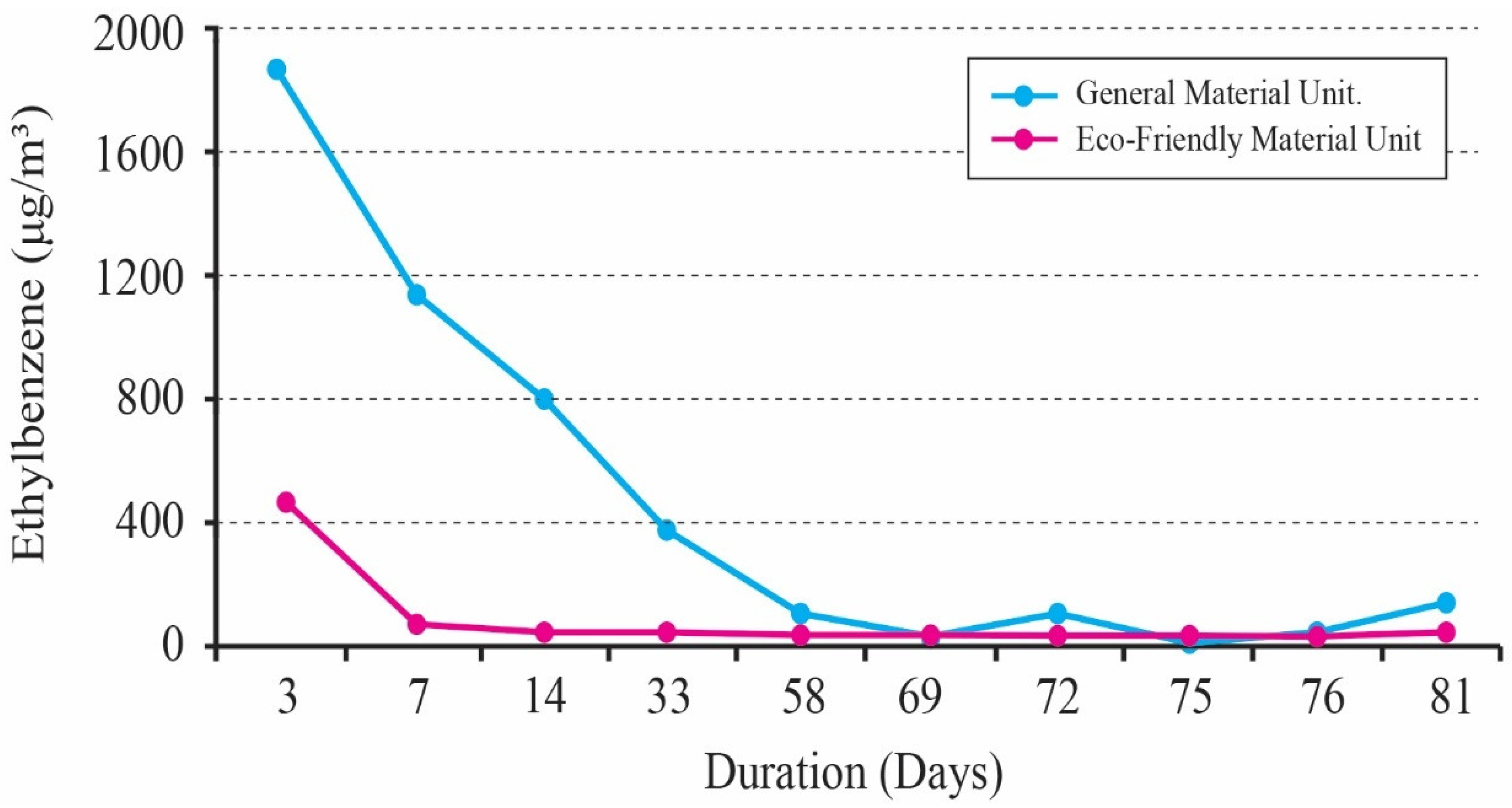

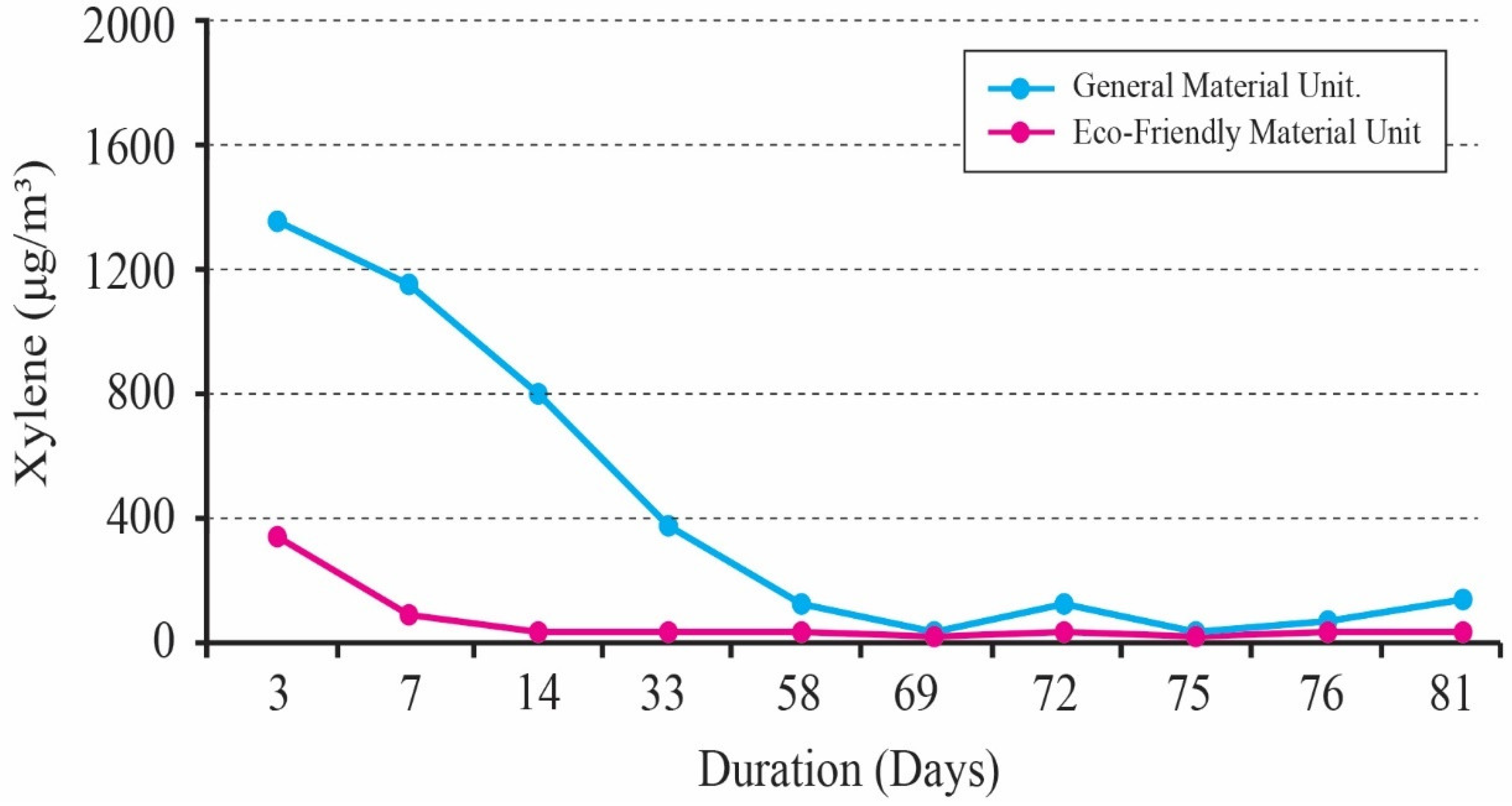

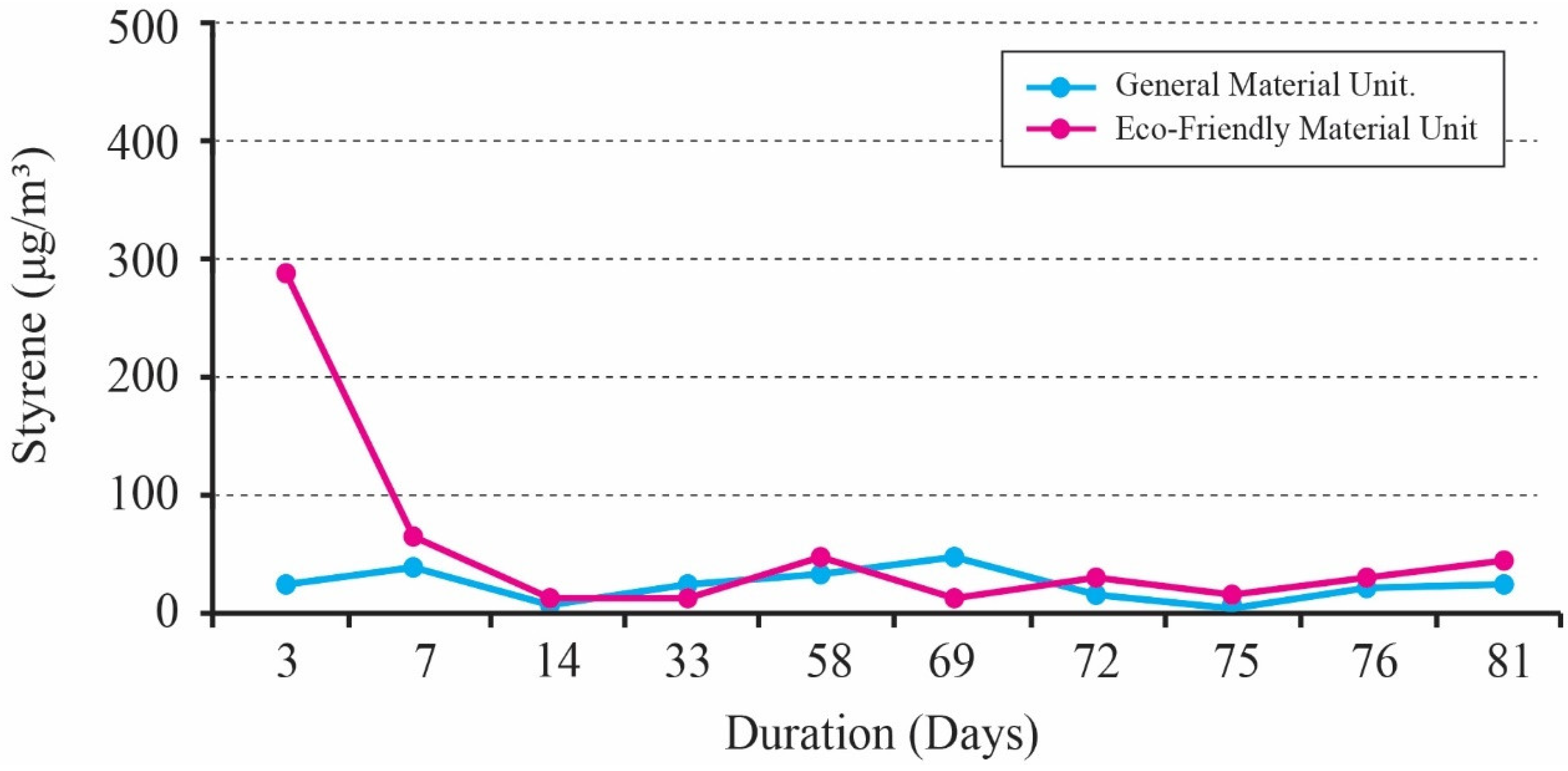

3.1. Comparison of VOC and HCHO Emission Concentrations over Time between General and Eco-Friendly Material

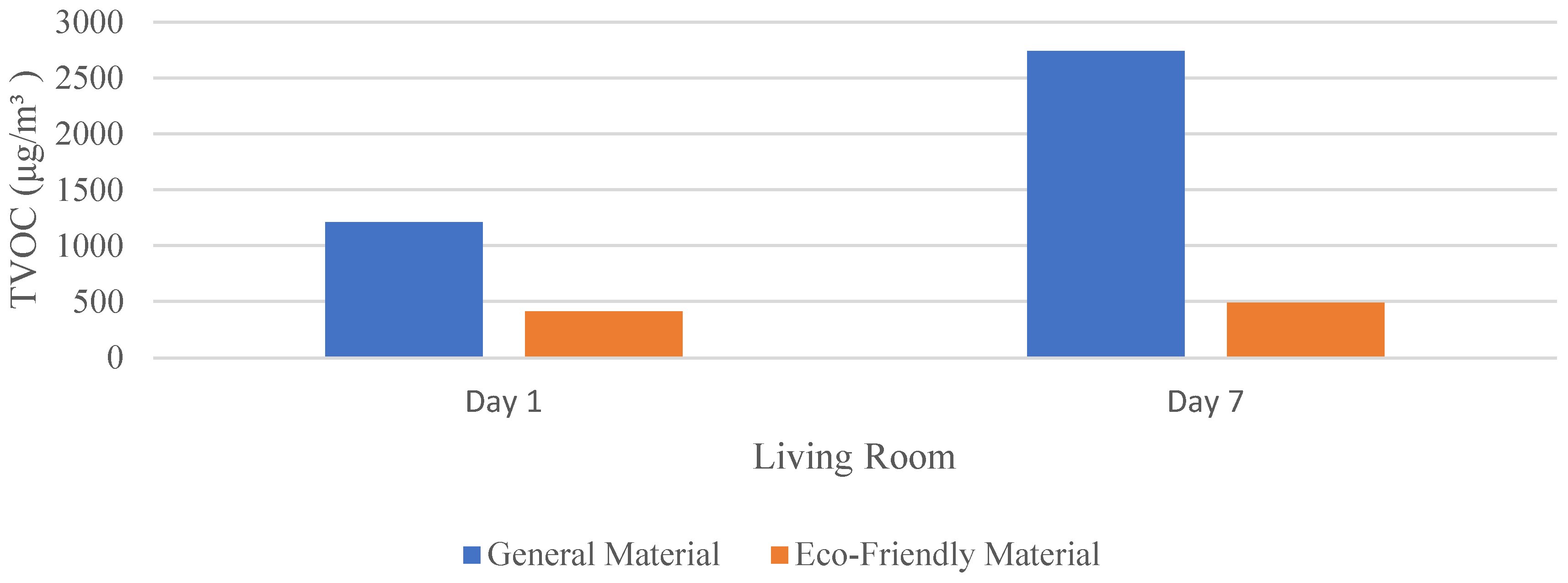

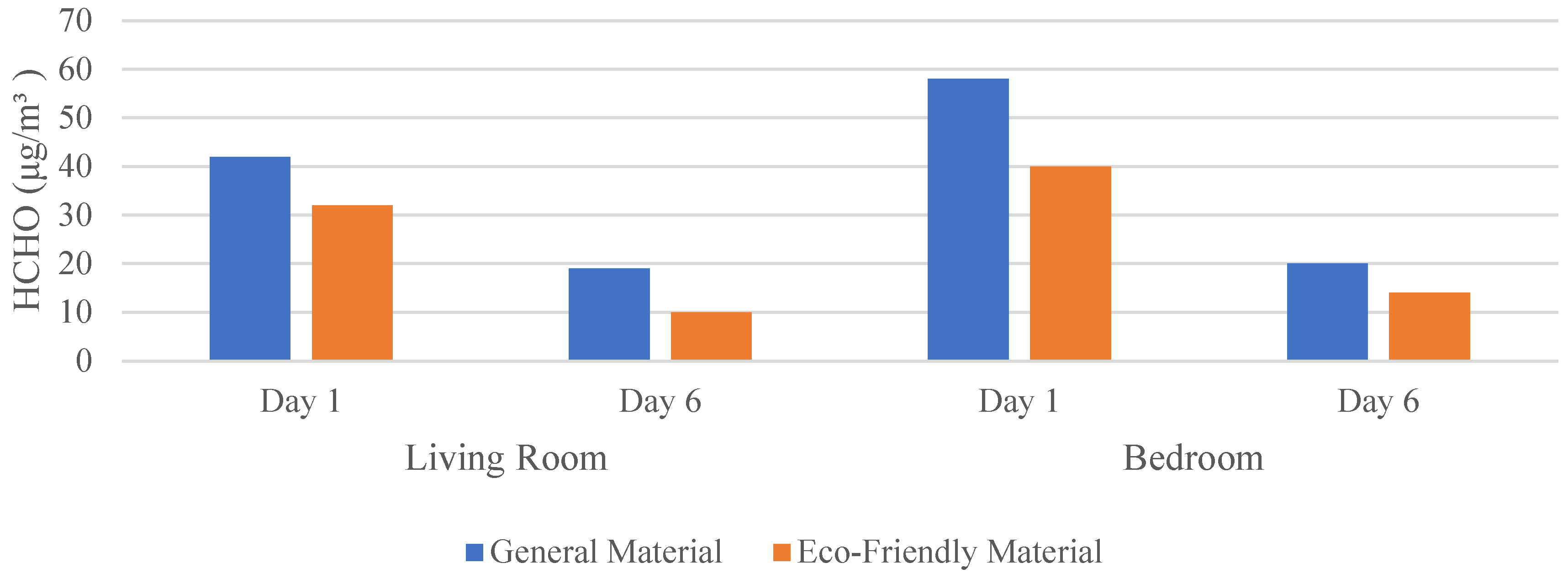

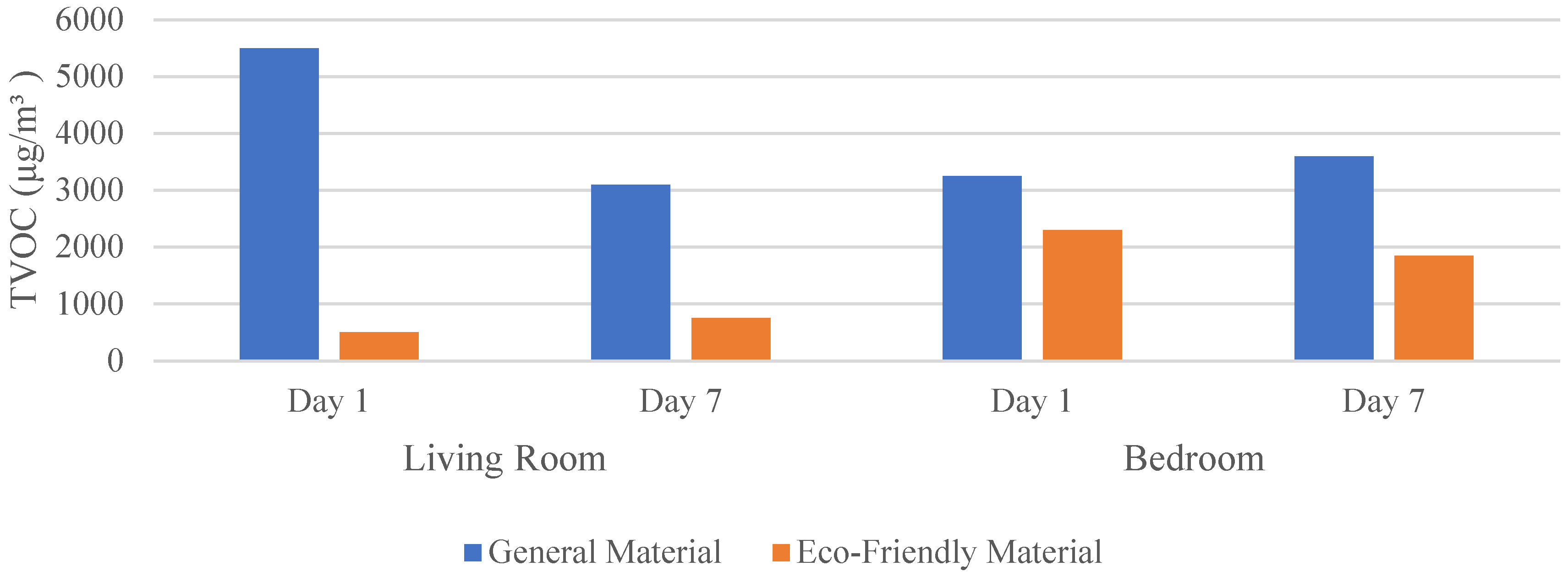

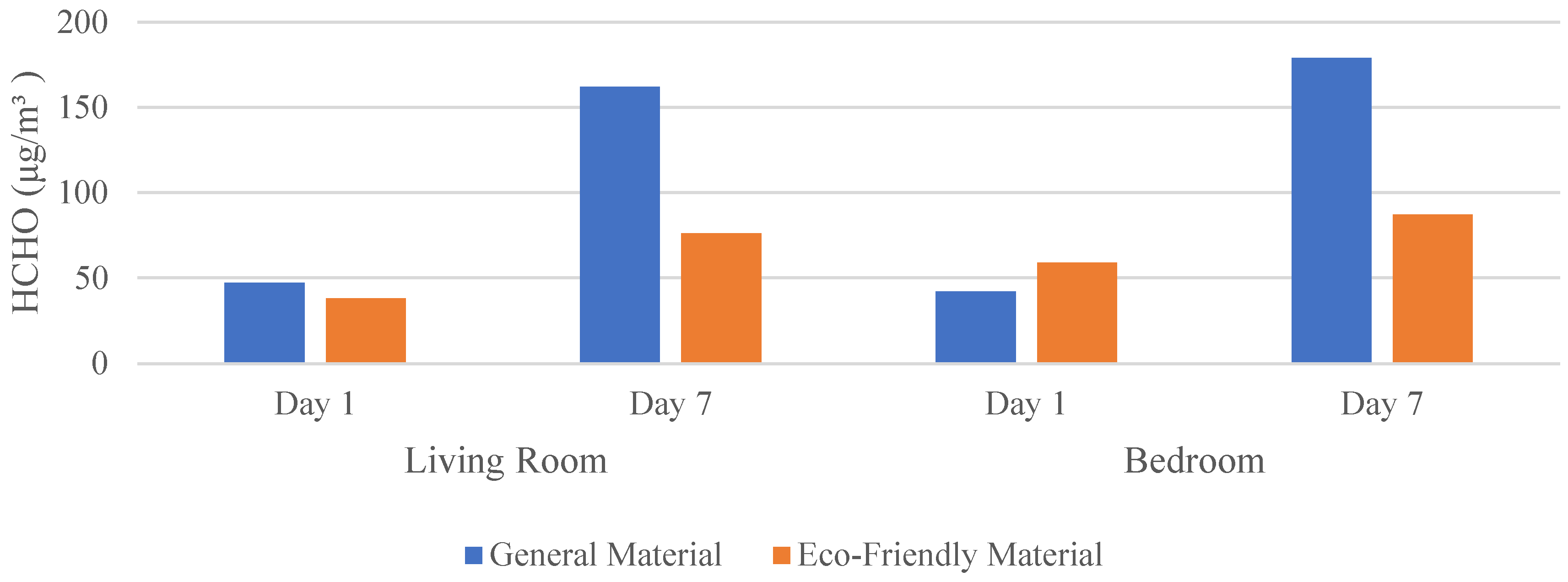

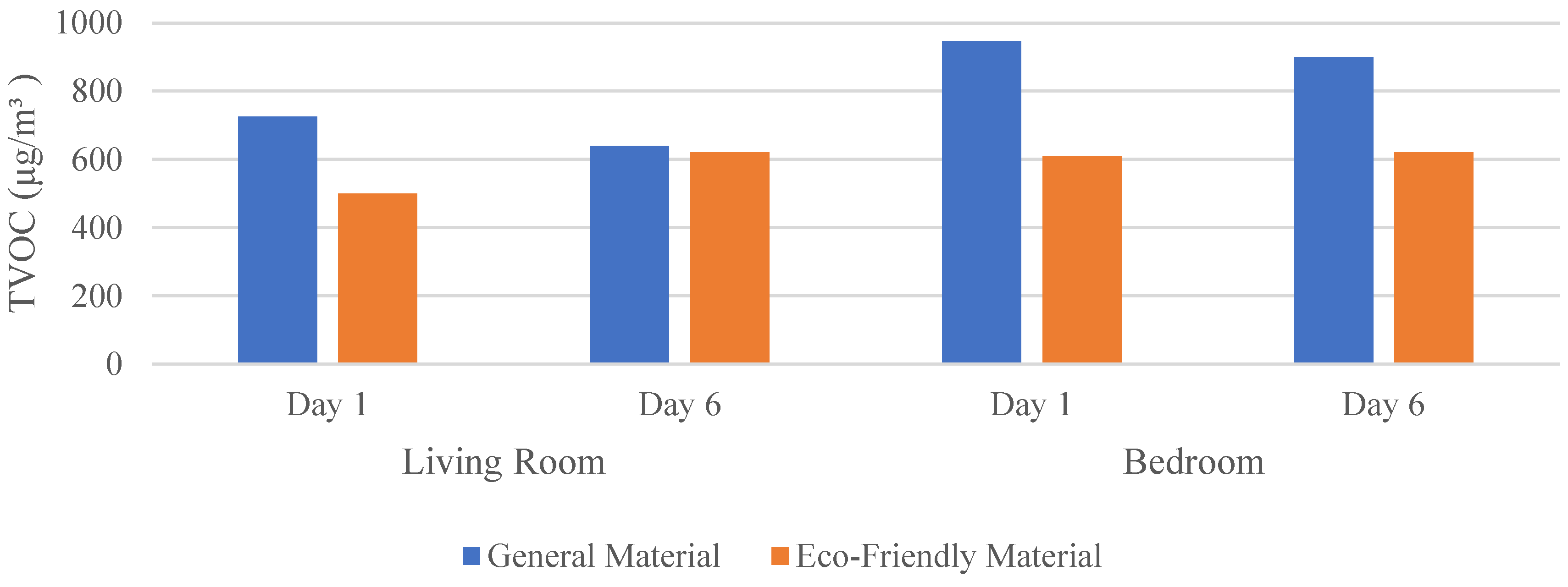

3.2. Comparison of TVOC and HCHO Emission Concentrations by Locations between General and Eco-Friendly Material

3.2.1. Parquet Flooring

3.2.2. Wallpaper

3.2.3. Built-in Furniture

3.2.4. Kitchen Furniture

3.2.5. Door/Window Frame

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Sun, J.; Zhao, J.; Zhang, W.; Zhou, J.; Xu, L.; Guo, H.; Liu, Y.; Zhang, D. Eco-friendly wood plastic composites with biomass-activated carbon-based form-stable phase change material for building energy conversion. Ind. Crops Prod. 2023, 197, 116573. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Yang, G.; Han, L.; Xing, B.; Lv, X. Influence of crumb rubber particle size and SBS structure on properties of CR/SBS composite modified asphalt. Constr. Build. Mater. 2020, 235, 117517. [Google Scholar] [CrossRef]

- Jung, C.; Awad, J. The improvement of indoor air quality in residential buildings in Dubai, UAE. Buildings 2021, 11, 250. [Google Scholar] [CrossRef]

- Surawattanasakul, V.; Sirikul, W.; Sapbamrer, R.; Wangsan, K.; Panumasvivat, J.; Assavanopakun, P.; Muangkaew, S. Respiratory symptoms and skin sick building syndrome among office workers at University Hospital, Chiang Mai, Thailand: Associations with indoor air quality, AIRMED Project. Int. J. Environ. Res. Public Health 2022, 19, 10850. [Google Scholar] [CrossRef] [PubMed]

- Awad, J.; Jung, C. Evaluating the indoor air quality after renovation at the Greens in Dubai, United Arab Emirates. Buildings 2021, 11, 353. [Google Scholar] [CrossRef]

- Alfuraty, A.B. Sustainable Environment in Interior Design: Design by Choosing Sustainable Materials. IOP Conf. Ser. Mater. Sci. Eng. 2020, 881, 012035. [Google Scholar] [CrossRef]

- Samuel, A.K.; Mohanan, V.; Sempey, A.; Garcia, F.Y.; Lagiere, P.; Bruneau, D.; Mahanta, N. A Sustainable Approach for a Climate Responsive House in UAE: Case Study of SDME 2018 BAITYKOOL Project. In Proceedings of the 2019 International Conference on Computational Intelligence and Knowledge Economy, ICCIKE 2019, Dubai, United Arab Emirates, 11–12 December 2019; pp. 816–823. [Google Scholar] [CrossRef]

- Taleb, H.M. Using passive cooling strategies to improve thermal performance and reduce energy consumption of residential buildings in U.A.E. buildings. Front. Archit. Res. 2014, 3, 154–165. [Google Scholar] [CrossRef]

- Jiang, C.; Li, D.; Zhang, P.; Li, J.; Wang, J.; Yu, J. Formaldehyde and volatile organic compound (VOC) emissions from particleboard: Identification of odorous compounds and effects of heat treatment. Build. Environ. 2017, 117, 118–126. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Abdelkareem, M.A.; Al-Alami, A.H.; Ramadan, M.; Mushtaha, E.; Wilberforce, T.; Olabi, A.G. State-of-the-art technologies for building-integrated photovoltaic systems. Buildings 2021, 11, 383. [Google Scholar] [CrossRef]

- Arar, M.; Jung, C.; Qassimi, N.A. Investigating the influence of the building material on the indoor air quality in apartment in Dubai. Front. Built Environ. 2022, 7, 804216. [Google Scholar] [CrossRef]

- Vu, H.T.; Liu, Y.; Tran, D.V. Nationalizing a global phenomenon: A study of how the press in 45 countries and territories portrays climate change. Glob. Environ. Change 2019, 58, 101942. [Google Scholar] [CrossRef] [PubMed]

- Jung, C.; Al Qassimi, N.; Arar, M.; Awad, J. The Analysis of Indoor Air Pollutants From Finishing Material of New Apartments at Business Bay, Dubai. Front. Built Environ. 2021, 7, 765689. [Google Scholar] [CrossRef]

- Al-Sallal, K.A.; Al-Rais, L.; Dalmouk, M.B. Designing a sustainable house in the desert of Abu Dhabi. Renew. Energy 2013, 49, 80–84. [Google Scholar] [CrossRef]

- He, C.; Morawska, L.; Gilbert, D. Particle deposition rates in residential houses. Atmos. Environ. 2005, 39, 3891–3899. [Google Scholar] [CrossRef]

- ASHRAE Standard 62.1-2019; Ventilation for Acceptable Indoor Air Quality. American Society of Heating. Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2005.

- Kakoulli, C.; Kyriacou, A.; Michaelides, M.P. A review of field measurement studies on thermal comfort, indoor air quality and virus risk. Atmosphere 2022, 13, 191. [Google Scholar] [CrossRef]

- Han, Y.; Yang, M.S.; Lee, S.-M.; Investigation on the Awareness and Preference for Wood Culture to Promote the Values of Wood: Ⅲ. Living Environment and Trend of Wood Utilization. J. Korean Wood Sci. Technol. 2022, 50, 375–391. [Google Scholar] [CrossRef]

- Burnard, M.D.; Kutnar, A. Wood and human stress in the built indoor environment: A review. Wood Sci. Technol. 2015, 49, 969–986. [Google Scholar] [CrossRef]

- Ikei, H.; Song, C.; Miyazaki, Y. Physiological effects of wood on humans: A review. J. Wood Sci. 2017, 63, 1–23. [Google Scholar] [CrossRef]

- Jung, C.; Mahmoud, N.S.A. Extracting the Critical Points of Formaldehyde (HCHO) Emission Model in Hot Desert Climate. Air Soil Water Res. 2022, 15, 11786221221105082. [Google Scholar] [CrossRef]

- Kelly, F.J.; Fussell, J.C. Improving indoor air quality, health and performance within environments where people live, travel, learn and work. Atmos. Environ. 2019, 200, 90–109. [Google Scholar] [CrossRef]

- Arar, M.; Jung, C. Analyzing the Perception of Indoor Air Quality (IAQ) from a Survey of New Townhouse Residents in Dubai. Sustainability 2022, 14, 15042. [Google Scholar] [CrossRef]

- Mushtaha, E.; Salameh, T.; Kharrufa, S.; Mori, T.; Aldawoud, A.; Hamad, R.; Nemer, T. The impact of passive design strategies on cooling loads of buildings in temperate climate. Case Stud. Therm. Eng. 2021, 28, 101588. [Google Scholar] [CrossRef]

- Mushtaha, E.; Alsyouf, I.; Al Labadi, L.; Hamad, R.; Khatib, N.; Al Mutawa, M. Application of AHP and a mathematical index to estimate livability in tourist districts: The case of Al Qasba in Sharjah. Front. Archit. Res. 2020, 9, 872–889. [Google Scholar] [CrossRef]

- Elnaklah, R.; Walker, I.; Natarajan, S. Moving to a green building: Indoor environment quality, thermal comfort and health. Build. Environ. 2021, 191, 107592. [Google Scholar] [CrossRef]

- Ebrahimi, P.; Khajeheian, D.; Fekete-Farkas, M. A SEM-NCA approach towards social networks marketing: Evaluating consumers’ sustainable purchase behavior with the moderating role of eco-friendly attitude. Int. J. Environ. Res. Public Health 2021, 18, 13276. [Google Scholar] [CrossRef]

- Elsaid, A.M.; Ahmed, M.S. Indoor air quality strategies for air-conditioning and ventilation systems with the spread of the global coronavirus (COVID-19) epidemic: Improvements and recommendations. Environ. Res. 2021, 199, 111314. [Google Scholar] [CrossRef]

- Leo Samuel, D.G.; Dharmasastha, K.; Shiva Nagendra, S.M.; Maiya, M.P. Thermal comfort in traditional buildings composed of local and modern construction materials. Int. J. Sustain. Built Environ. 2017, 6, 463–475. [Google Scholar] [CrossRef]

- Hussien, A.; Saleem, A.A.; Mushtaha, E.; Jannat, N.; Al-Shammaa, A.; Ali, S.B.; Assi, S.; Al-Jumeily, D. A statistical analysis of life cycle assessment for buildings and buildings’ refurbishment research. Ain Shams Eng. J. 2023, 14, 102143. [Google Scholar] [CrossRef]

- Michael, A.; Demosthenous, D.; Philokyprou, M. Natural ventilation for cooling in mediterranean climate: A case study in vernacular architecture of Cyprus. Energy Build. 2017, 144, 333–345. [Google Scholar] [CrossRef]

- Saljoughinejad, S.; Rashidi Sharifabad, S. Classification of climatic strategies, used in Iranian vernacular residences based on spatial constituent elements. Build. Environ. 2015, 92, 475–493. [Google Scholar] [CrossRef]

- Hayles, C.S. Environmentally sustainable interior design: A snapshot of current supply of and demand for green, sustainable or Fair Trade products for interior design practice. Int. J. Sustain. Built Environ. 2015, 4, 100–108. [Google Scholar] [CrossRef]

- Yang, S.; Wi, S.; Lee, J.; Lee, H.; Kim, S. Biochar-red clay composites for energy efficiency as eco-friendly building materials: Thermal and mechanical performance. J. Hazard. Mater. 2019, 373, 844–855. [Google Scholar] [CrossRef] [PubMed]

- Krishna, B.V.; Reddy, E.R. Applications of green materials for the preparation of eco-friendly bricks and pavers. Int. J. Eng. Technol. 2018, 7, 75–79. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Mohamad Zin, R.; Štreimikienė, D.; Mardani, A.; Ismail, M. The role of green building materials in reducing environmental and human health impacts. Int. J. Environ. Res. Public Health 2020, 17, 2589. [Google Scholar] [CrossRef]

- Wi, S.; Kim, M.G.; Myung, S.W.; Baik, Y.K.; Lee, K.B.; Song, H.S.; Kwak, M.-J.; Kim, S. Evaluation and analysis of volatile organic compounds and formaldehyde emission of building products in accordance with legal standards: A statistical experimental study. J. Hazard. Mater. 2020, 393, 122381. [Google Scholar] [CrossRef]

- Nasr, M.S.; Shubbar, A.A.; Abed, Z.A.A.R.; Ibrahim, M.S. Properties of eco-friendly cement mortar contained recycled materials from different sources. J. Build. Eng. 2020, 31, 101444. [Google Scholar] [CrossRef]

- Liu, Y.; Misztal, P.K.; Xiong, J.; Tian, Y.; Arata, C.; Weber, R.J.; Nazaroff, W.W.; Goldstein, A.H. Characterizing sources and emissions of volatile organic compounds in a northern California residence using space-and time-resolved measurements. Indoor Air 2019, 29, 630–644. [Google Scholar] [CrossRef]

- Hussien, A.; Jannat, N.; Mushtaha, E.; Al-Shammaa, A. A holistic plan of flat roof to green-roof conversion: Towards a sustainable built environment. Ecol. Eng. 2023, 190, 106925. [Google Scholar] [CrossRef]

- Sobha Realty. Sobha Hartland One Park Avenue. 2023. Available online: https://www.sobharealty.com/apartments-for-sale-in-dubai/one-park-avenue/ (accessed on 12 April 2023).

- Hong, Q.; Liu, C.; Hu, Q.; Zhang, Y.; Xing, C.; Su, W.; Ji, X.; Xiao, S. Evaluating the feasibility of formaldehyde derived from hyperspectral remote sensing as a proxy for volatile organic compounds. Atmos. Res. 2021, 264, 105777. [Google Scholar] [CrossRef]

- Huang, K.; Sun, W.; Feng, G.; Wang, J.; Song, J. Indoor air quality analysis of 8 mechanically ventilated residential buildings in northeast China based on long-term monitoring. Sustain. Cities Soc. 2020, 54, 101947. [Google Scholar] [CrossRef]

- Chen, Q.; Xiao, R.; Lei, X.; Yu, T.; Mo, J. Experimental and modeling investigations on the adsorption behaviors of indoor volatile organic compounds in an in-situ thermally regenerated adsorption-board module. Build. Environ. 2021, 203, 108065. [Google Scholar] [CrossRef]

- Liu, C.Y.; Tseng, C.H.; Wang, H.C.; Dai, C.F.; Shih, Y.H. The study of an ultraviolet radiation technique for removal of the indoor air volatile organic compounds and bioaerosol. Int. J. Environ. Res. Public Health 2019, 16, 2557. [Google Scholar] [CrossRef] [PubMed]

- Bahri, M.; Haghighat, F.; Kazemian, H.; Rohani, S. A comparative study on metal organic frameworks for indoor environment application: Adsorption evaluation. Chem. Eng. J. 2017, 313, 711–723. [Google Scholar] [CrossRef]

- Chang, T.; Wang, J.; Lu, J.; Shen, Z.; Huang, Y.; Sun, J.; Xu, H.; Wang, X.; Ren, D.; Cao, J. Evaluation of indoor air pollution during decorating process and inhalation health risks in Xi’an, China: A case study. Aerosol Air Qual. Res. 2019, 19, 854–864. [Google Scholar] [CrossRef]

- Caron, F.; Guichard, R.; Robert, L.; Verriele, M.; Thevenet, F. Behaviour of individual VOCs in indoor environments: How ventilation affects emission from materials. Atmos. Environ. 2020, 243, 117713. [Google Scholar] [CrossRef]

- van den Broek, J.; Cerrejon, D.K.; Pratsinis, S.E.; Güntner, A.T. Selective formaldehyde detection at ppb in indoor air with a portable sensor. J. Hazard. Mater. 2020, 399, 123052. [Google Scholar] [CrossRef]

- Harashima, H.; Sumiyoshi, E.; Ito, K. Numerical models for seamlessly predicting internal diffusion and re-emission of leaked liquid toluene from indoor mortar materials. J. Build. Eng. 2022, 57, 104976. [Google Scholar] [CrossRef]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and flexible indoor partitioning—A design conceptualization of innovative materials and value chains. Buildings 2019, 9, 194. [Google Scholar] [CrossRef]

- Hoang, C.P.; Kinney, K.A.; Corsi, R.L. Ozone removal by green building materials. Build. Environ. 2009, 44, 1627–1633. [Google Scholar] [CrossRef]

- Liu, S.; Song, R.; Zhang, T.T. Residential building ventilation in situations with outdoor PM2.5 pollution. Build. Environ. 2021, 202, 108040. [Google Scholar] [CrossRef]

- Alonso, M.J.; Moazami, T.N.; Liu, P.; Jørgensen, R.B.; Mathisen, H.M. Assessing the indoor air quality and their predictor variable in 21 home offices during the COVID-19 pandemic in Norway. Build. Environ. 2022, 225, 109580. [Google Scholar] [CrossRef]

- Marques, A.C.; Mocanu, A.; Tomić, N.Z.; Balos, S.; Stammen, E.; Lundevall, A.; Abrahami, S.T.; Günther, R.; de Kok, J.M.M.; de Freitas, S.T. Review on adhesives and surface treatments for structural applications: Recent developments on sustainability and implementation for metal and composite substrates. Materials 2020, 13, 5590. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.E. Environmental sustainability in the textile industry. In Sustainability in the Textile Industry; Springer: Singapore, 2017; pp. 17–55. [Google Scholar]

- Blanchet, P.; Pepin, S. Trends in chemical wood surface improvements and modifications: A review of the last five years. Coatings 2021, 11, 1514. [Google Scholar] [CrossRef]

- Rudawska, A.; Szabelski, J.; Miturska-Barańska, I.; Doluk, E. Biological Reinforcement of Epoxies as Structural Adhesives. In Structural Adhesives: Properties, Characterization and Applications; Wiley: Hoboken, NJ, USA, 2023; pp. 31–104. [Google Scholar]

- Ahmad, J.; Arbili, M.M.; Deifalla, A.F.; Salmi, A.; Maglad, A.M.; Althoey, F. Sustainable concrete with partial substitution of paper pulp ash: A review. Sci. Eng. Compos. Mater. 2023, 30, 20220193. [Google Scholar] [CrossRef]

- Krzyżaniak, Ł.; Kuşkun, T.; Kasal, A.; Smardzewski, J. Analysis of the internal mounting forces and strength of newly designed fastener to joints wood and wood-based panels. Materials 2021, 14, 7119. [Google Scholar] [CrossRef]

- Foong, S.Y.; Liew, R.K.; Lee, C.L.; Tan, W.P.; Peng, W.; Sonne, C.; Tsang, Y.F.; Lam, S.S. Strategic hazard mitigation of waste furniture boards via pyrolysis: Pyrolysis behavior, mechanisms, and value-added products. J. Hazard. Mater. 2022, 421, 126774. [Google Scholar] [CrossRef] [PubMed]

- Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent advances on the development of protein-based adhesives for wood composite materials—A review. Molecules 2021, 26, 7617. [Google Scholar] [CrossRef]

- Sharma, B.; Shekhar, S.; Sharma, S.; Jain, P. The paradigm in conversion of plastic waste into value added materials. Clean. Eng. Technol. 2021, 4, 100254. [Google Scholar] [CrossRef]

- Gonzalez-Martin, J.; Kraakman, N.J.R.; Perez, C.; Lebrero, R.; Munoz, R. A state–of–the-art review on indoor air pollution and strategies for indoor air pollution control. Chemosphere 2021, 262, 128376. [Google Scholar] [CrossRef]

- Hernández-Gordillo, A.; Ruiz-Correa, S.; Robledo-Valero, V.; Hernández-Rosales, C.; Arriaga, S. Recent advancements in low-cost portable sensors for urban and indoor air quality monitoring. Air Qual. Atmos. Health 2021, 14, 1931–1951. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Kolajo, T.E.; Adedolu, O. Blended formaldehyde adhesive bonded particleboards made from groundnut shell and rice husk wastes. Clean Technol. Environ. Policy 2022, 24, 1653–1662. [Google Scholar] [CrossRef]

- Sobha Realty. One Park Avenue at Sobha Hartland–MBR City. 2023. Available online: https://sobha-residences.ae/one-park-avenue.php (accessed on 24 April 2023).

- Huang, K.; Song, J.; Feng, G.; Chang, Q.; Jiang, B.; Wang, J.; Sun, W.; Li, H.; Wang, J.; Fang, X. Indoor air quality analysis of residential buildings in northeast China based on field measurements and longtime monitoring. Build. Environ. 2018, 144, 171–183. [Google Scholar] [CrossRef]

- Ismaeel, W.S.; Mohamed, A.G. Indoor air quality for sustainable building renovation: A decision-support assessment system using structural equation modelling. Build. Environ. 2022, 214, 108933. [Google Scholar] [CrossRef]

- Alonso, M.J.; Wolf, S.; Jørgensen, R.B.; Madsen, H.; Mathisen, H.M. A methodology for the selection of pollutants for ensuring good indoor air quality using the de-trended cross-correlation function. Build. Environ. 2022, 209, 108668. [Google Scholar] [CrossRef]

| Sobha Hartland One Park Avenue | Experiment Contents | ||

|---|---|---|---|

| Material | Duration | Evaluation Criteria | |

| Unit 4A | General material | 81 days | Concentration changes over time |

| Unit 6B | Eco-friendly material | ||

| Unit 8C | General material | 14 days for each material | Changes in indoor pollutant concentration according to the construction location for each material |

| Unit 10D | Eco-friendly material | ||

| Classification | General Material | Eco-Friendly Material | ||

|---|---|---|---|---|

| Wallpaper (adhesive) | PVC-based wallpaper (general adhesive) | PP-based wallpaper (HCHO low-emission adhesive) | ||

| Parquet flooring (adhesive) | General flooring (Oil-based epoxy adhesive) | Hazardous chemical substance reduction floor (Urethane adhesive) | ||

| Window frame | Core material | Laminated wood E2 grade | Laminated wood E1 grade | |

| Surface material | HDF E2 grade LVL E2 grade | HDF E1 grade LVL E1 grade | ||

| Built-in Furniture | Core material | Body frame | PB E2 grade | PB E1 grade |

| Door | MDF E2 grade | MDF E1 grade | ||

| Surface material | PVC wrapping | LPM | ||

| Kitchen furniture | Core material | Body frame | PB E2 grade | PB E1 grade |

| Door | MDF E2 grade | MDF E1 grade | ||

| Surface material | Laquer paint | UV paint | ||

| Equipment | Analysis Conditions |

|---|---|

| GC/MSD | HP 6890/HP-5973N Column: HP-1 Capillary column(60 m × 0.32 mm × 5 μm) Column temperature: 40 °C (5 min) >> 70 °C (5 min) >> 150 °C (5 min) >> 200 °C (5 min)->220 °C (5 min) Ramp rate: 5 °C/min to 200 °C, 10 °C/min to 220 °C Column flow: 1 mL/min MS ion source temp: 230 °C |

| Equipment | Analysis Conditions |

|---|---|

| HPLC | Column: C-18 column (3.9 × 300 mm) waters U.S.A. Mobile phase: acetonitrile/water = 55:45 UV detector: 360 nm Flow rate: 1.0 mL/min Sample injection amount: 20 μL |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, C.; Abdelaziz Mahmoud, N.S.; Al Qassimi, N.; Elsamanoudy, G. Preliminary Study on the Emission Dynamics of TVOC and Formaldehyde in Homes with Eco-Friendly Materials: Beyond Green Building. Buildings 2023, 13, 2847. https://doi.org/10.3390/buildings13112847

Jung C, Abdelaziz Mahmoud NS, Al Qassimi N, Elsamanoudy G. Preliminary Study on the Emission Dynamics of TVOC and Formaldehyde in Homes with Eco-Friendly Materials: Beyond Green Building. Buildings. 2023; 13(11):2847. https://doi.org/10.3390/buildings13112847

Chicago/Turabian StyleJung, Chuloh, Naglaa Sami Abdelaziz Mahmoud, Nahla Al Qassimi, and Gamal Elsamanoudy. 2023. "Preliminary Study on the Emission Dynamics of TVOC and Formaldehyde in Homes with Eco-Friendly Materials: Beyond Green Building" Buildings 13, no. 11: 2847. https://doi.org/10.3390/buildings13112847

APA StyleJung, C., Abdelaziz Mahmoud, N. S., Al Qassimi, N., & Elsamanoudy, G. (2023). Preliminary Study on the Emission Dynamics of TVOC and Formaldehyde in Homes with Eco-Friendly Materials: Beyond Green Building. Buildings, 13(11), 2847. https://doi.org/10.3390/buildings13112847