Synthesis and Characterization of Sustainable Eco-Friendly Alkali-Activated High-Content Iron Ore Tailing Bricks

Abstract

:1. Introduction

2. Materials and Methods

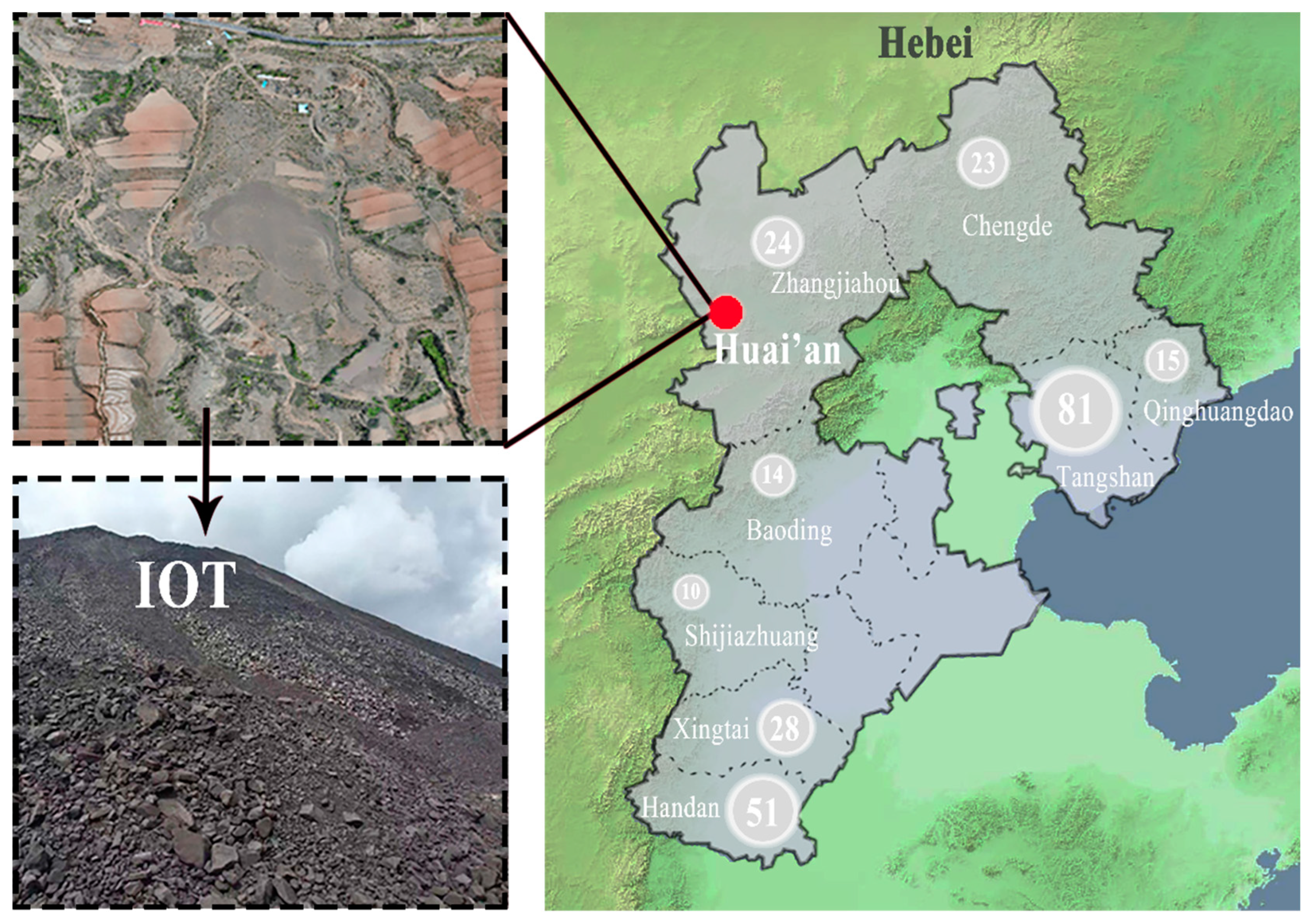

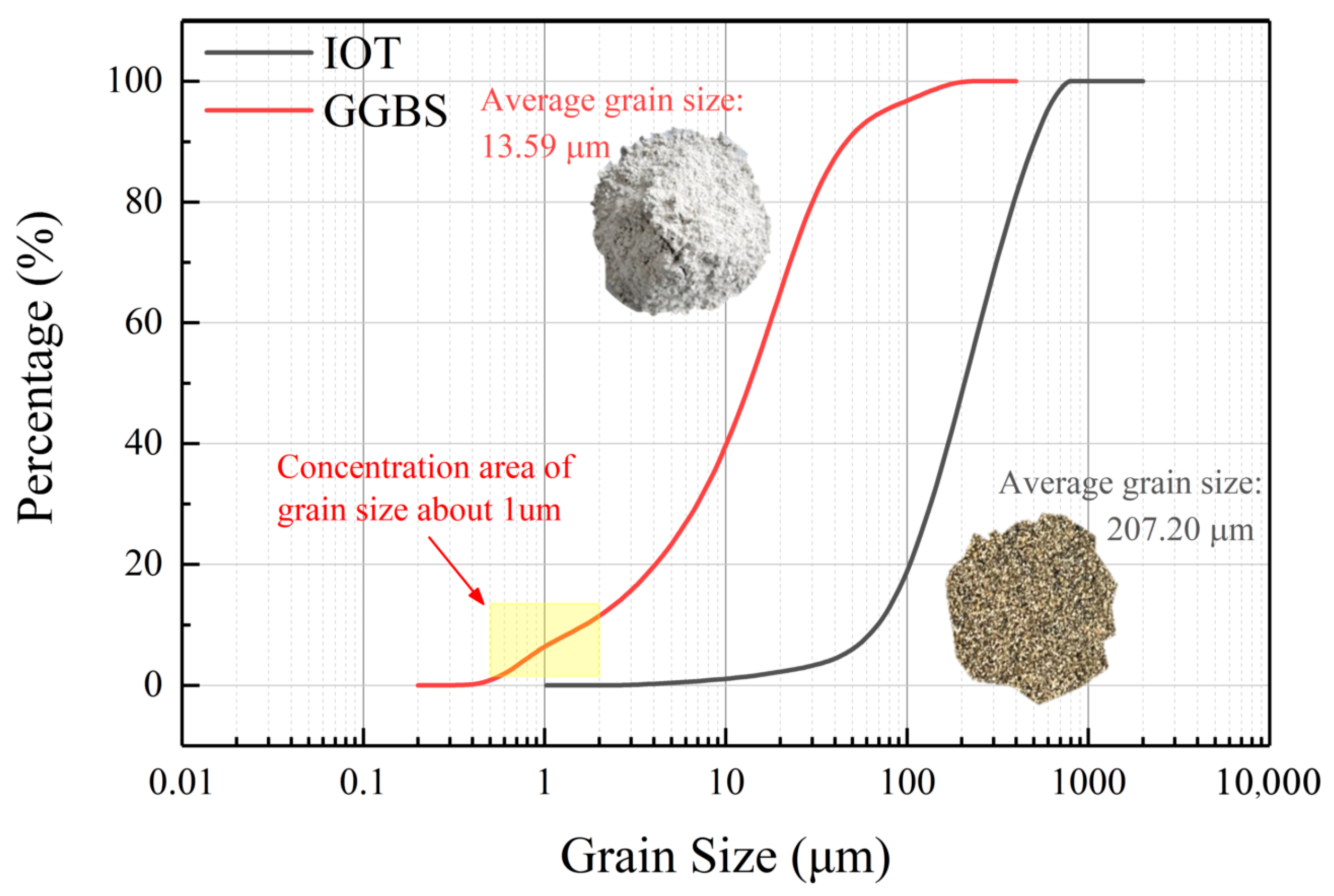

2.1. Materials

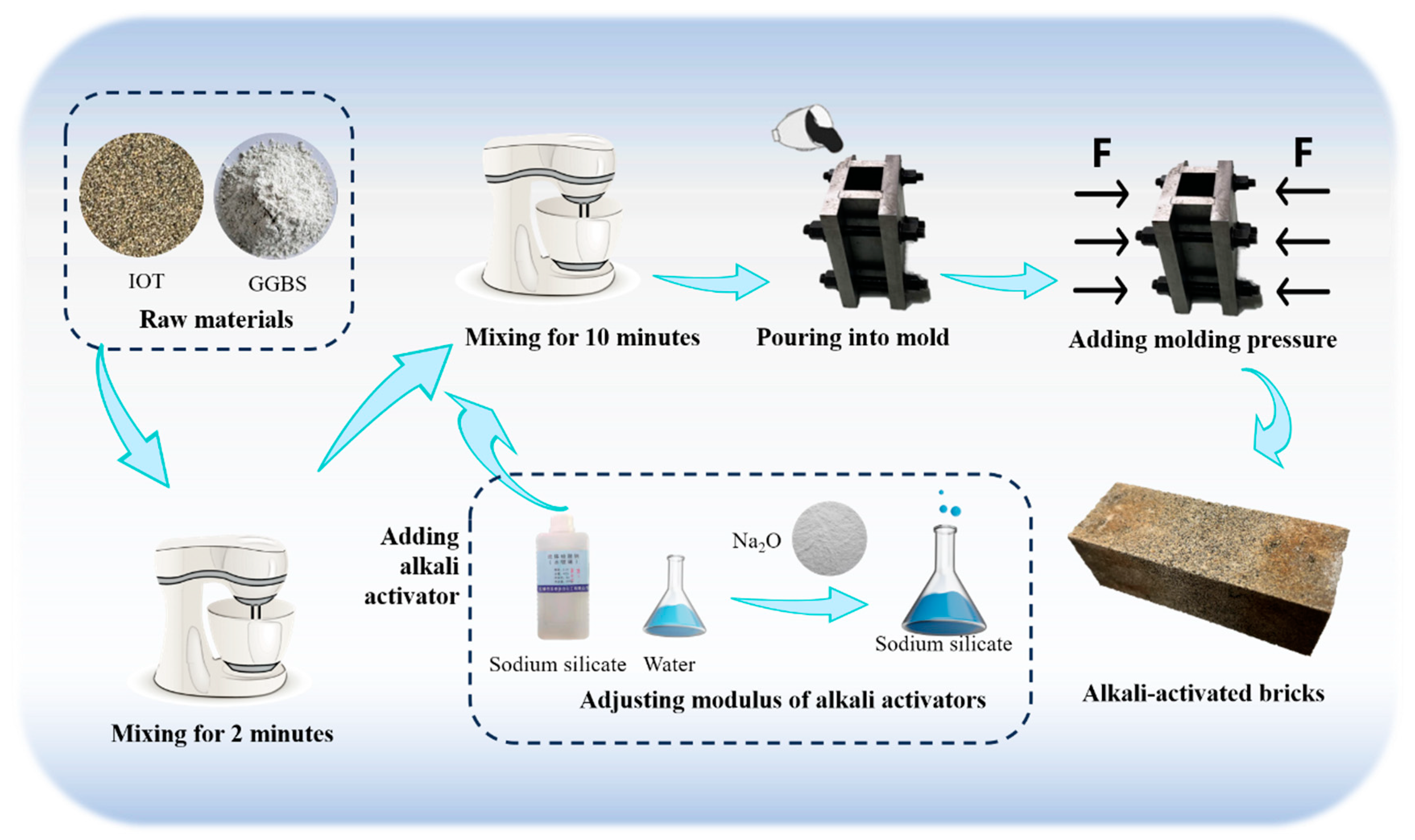

2.2. Sample Preparation

2.3. Test Methods

3. Results and Discussion

3.1. Effect of the Raw Material Mixing Ratio on the Brick Properties

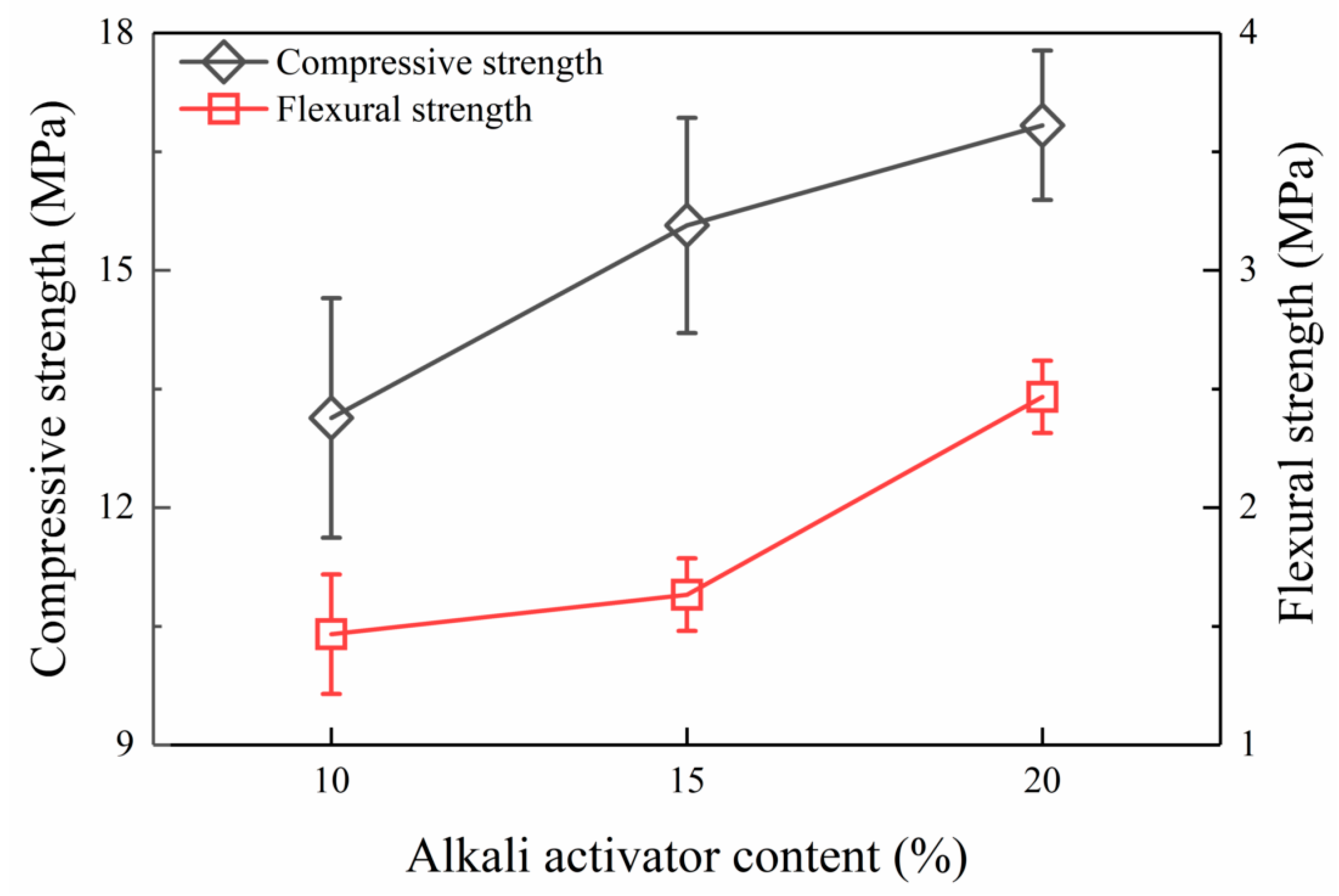

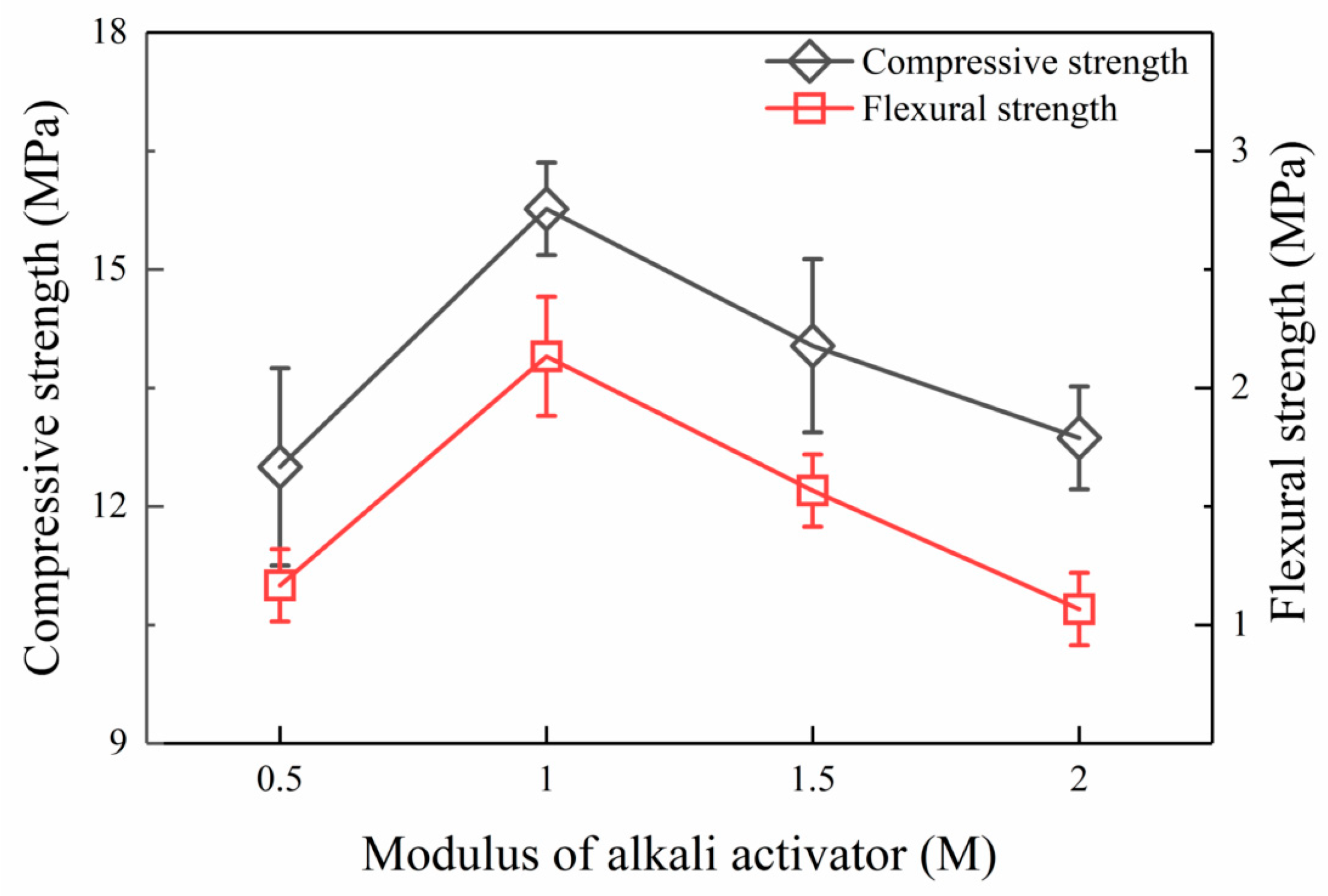

3.2. Effect of the Content and Modulus of Alkaline Activator on the Brick Properties

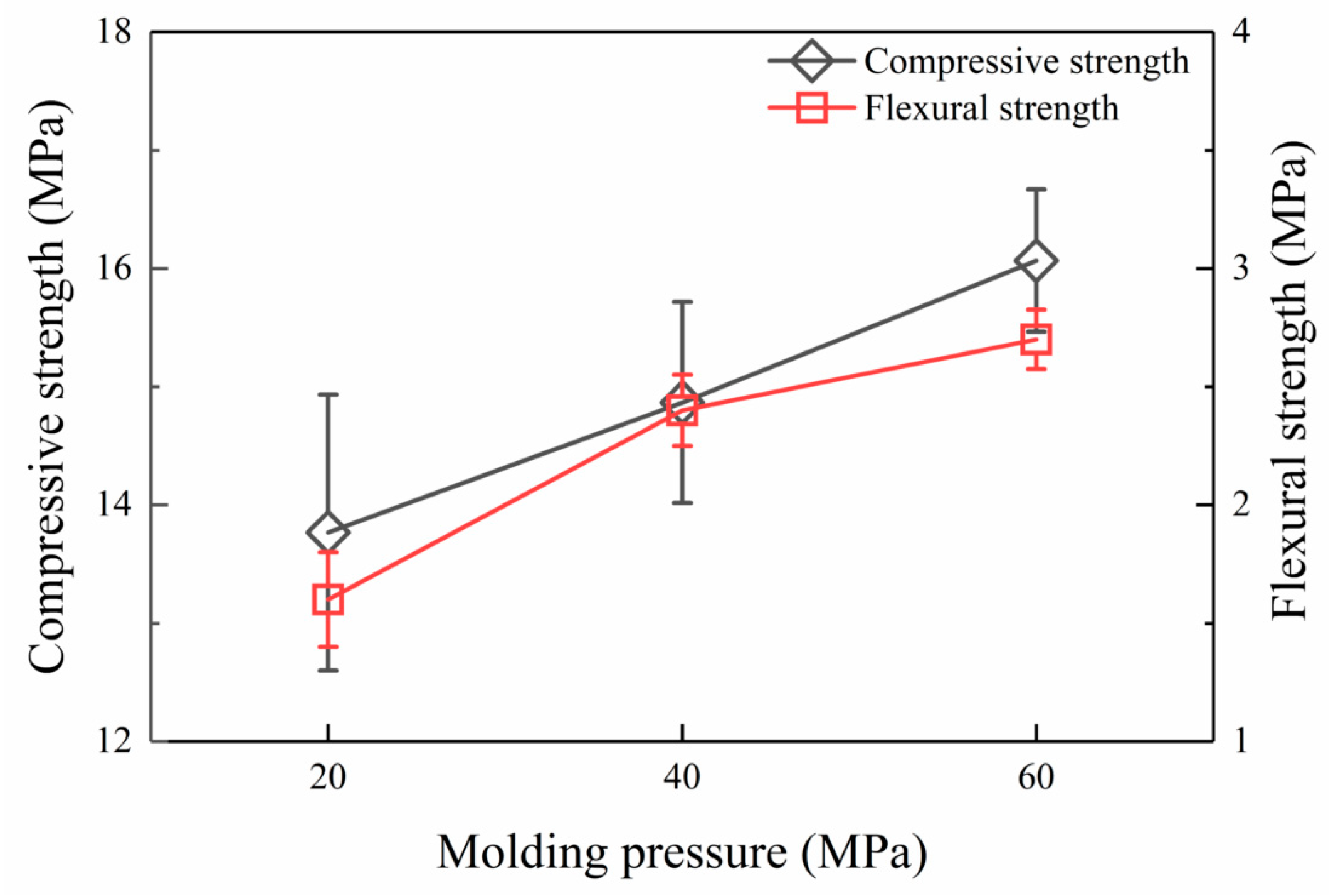

3.3. Effect of the Molding Pressure on the Brick Properties

3.4. Effect of the Grain Size Gradation of IOT on the Brick Properties

3.5. Microstructure of the Specimens

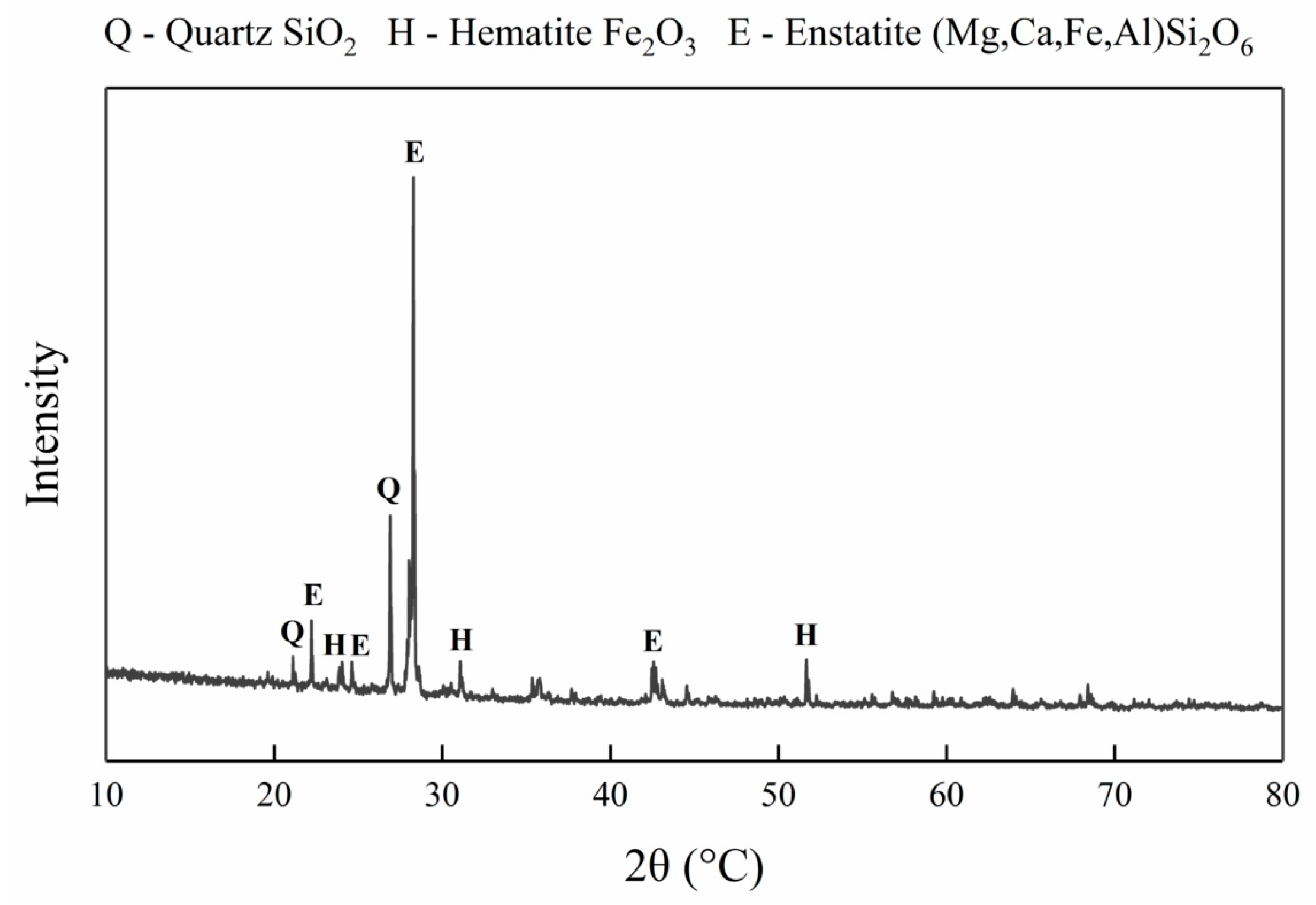

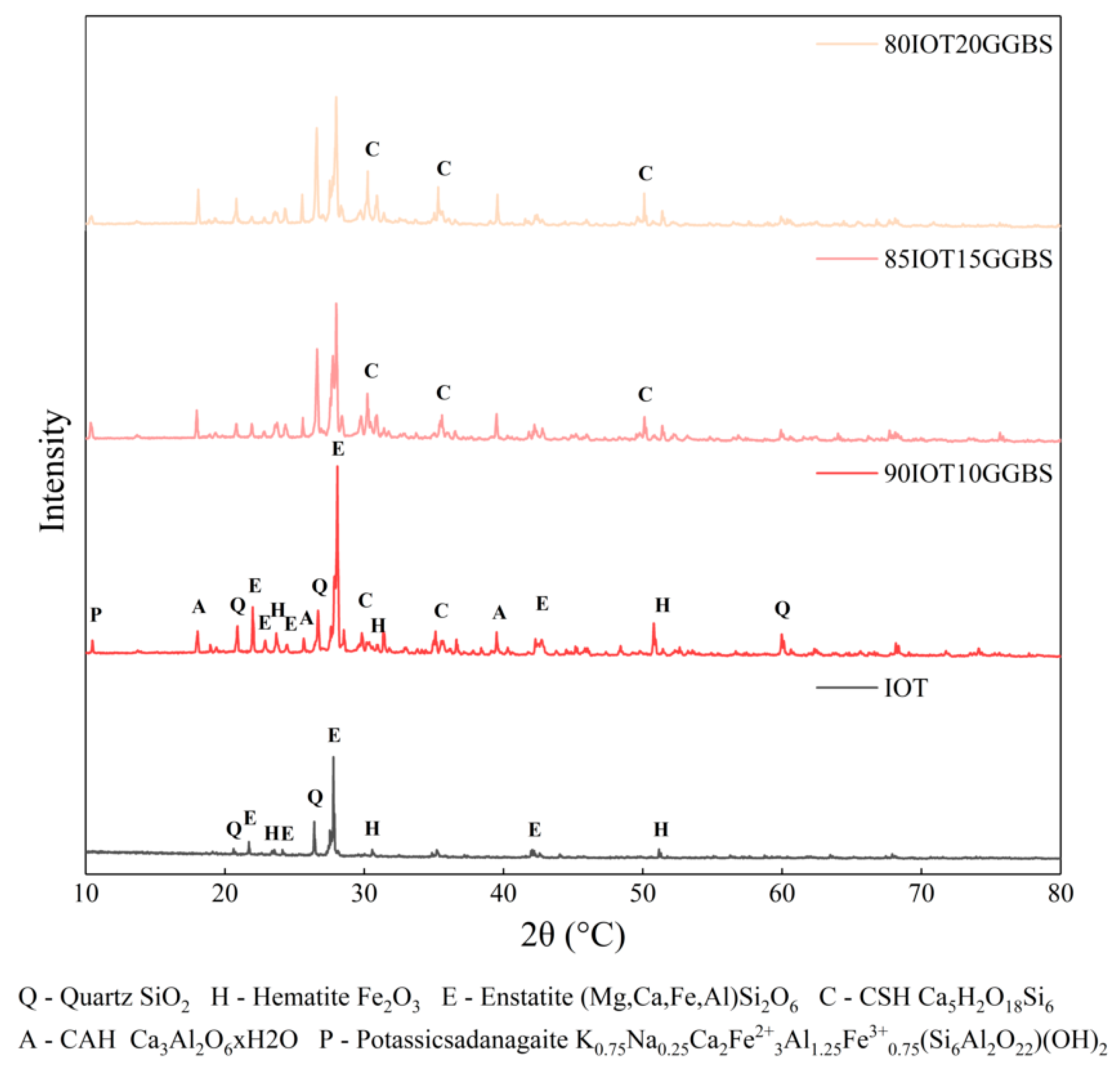

3.5.1. XRD Analysis

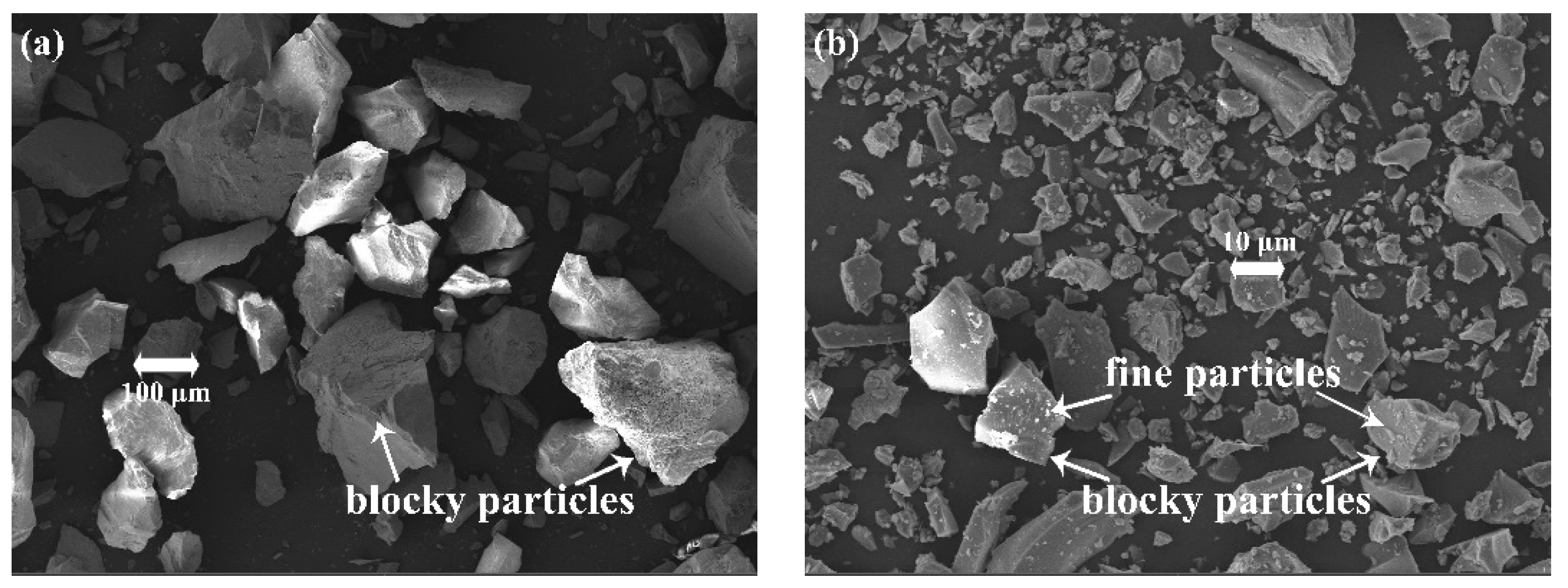

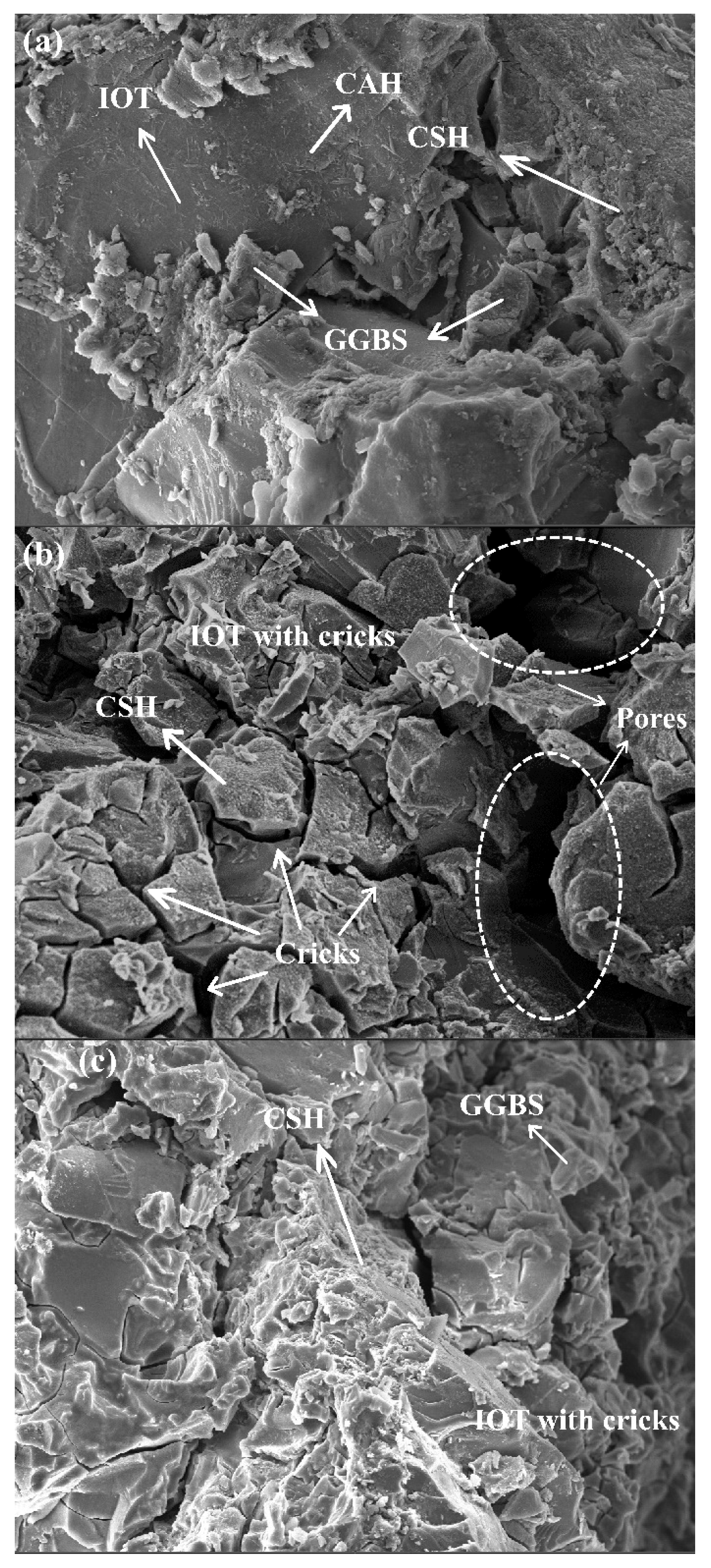

3.5.2. SEM Analysis

3.5.3. FTIR Analysis

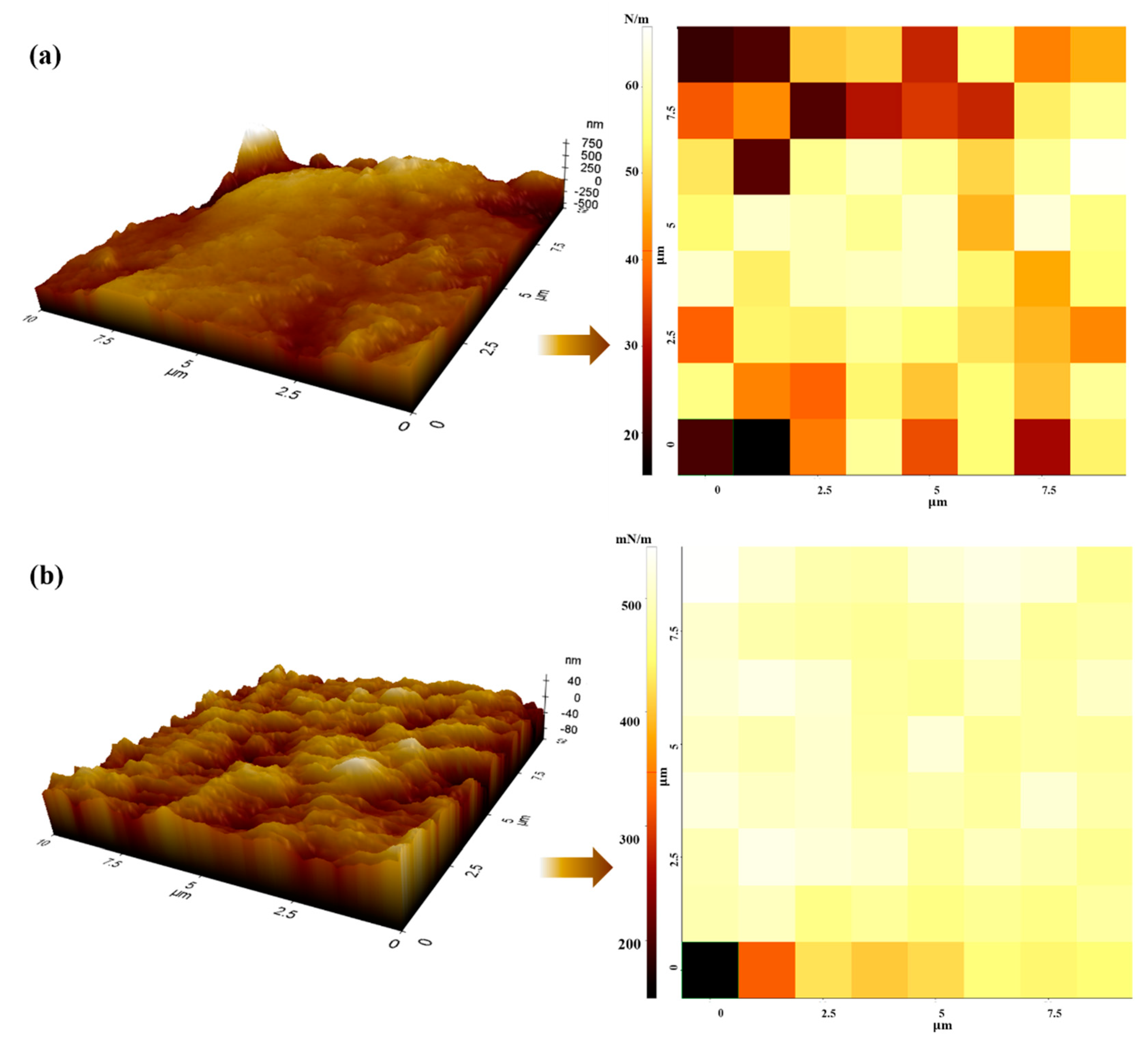

3.5.4. AFM Analysis

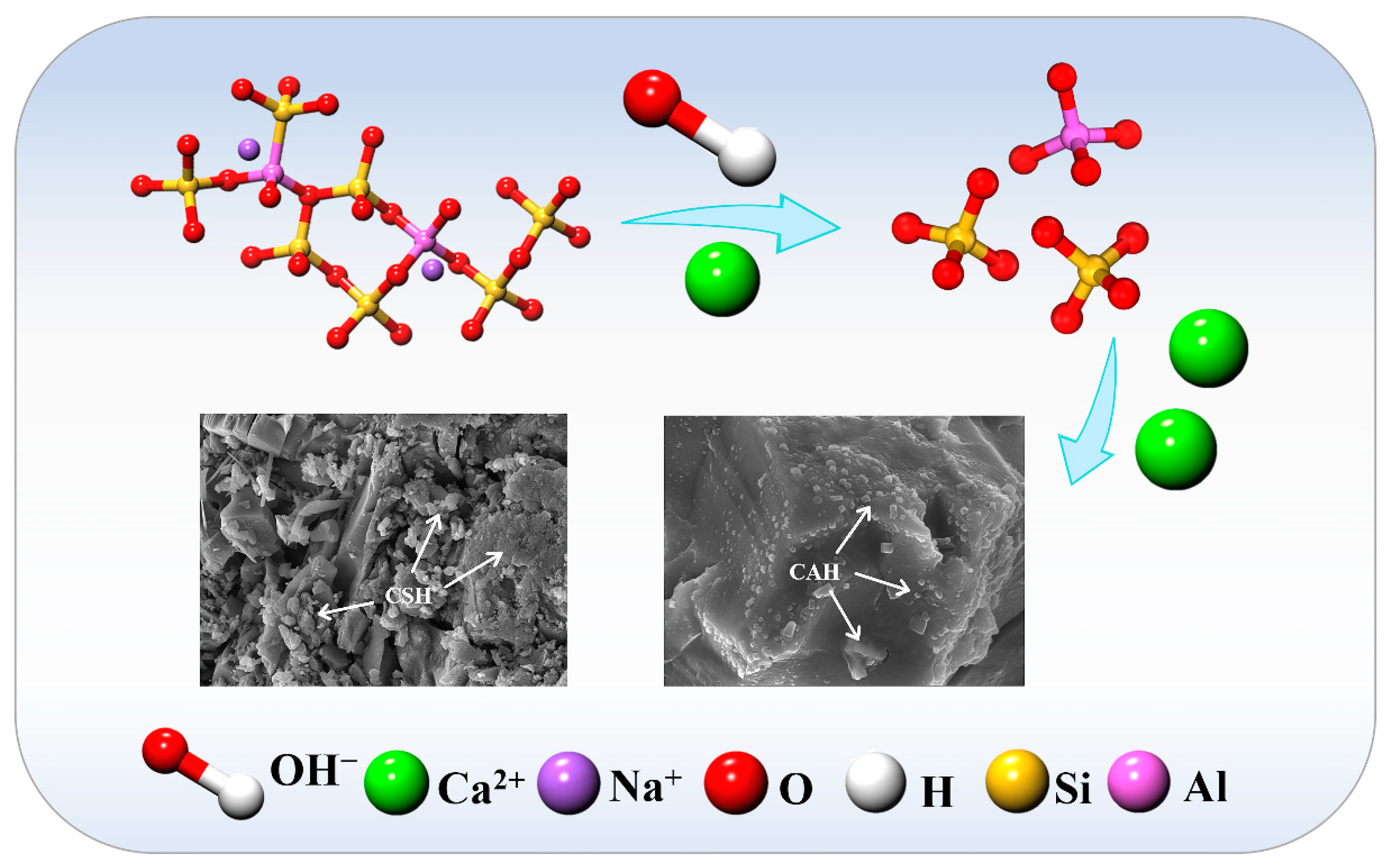

3.6. Reaction Mechanism of Alkali-Activated IOT-GGBS Mixtures

4. Conclusions

- (1)

- To fully utilize IOT and meet the Chinese JC/T422-2007 MU25 standard, a recommended IOT-to-GGBS ratio of 85:15 was proposed. At this ratio, the pores between the IOT particles were effectively filled with GGBS particles, resulting in bricks with a compressive strength of 31.72 MPa and a flexural strength of 2.83 MPa.

- (2)

- The strength of the bricks was enhanced by increasing the content of the alkali activator. When the content of the alkali activator reached 20%, the brick exhibited a compressive strength of 16.83 MPa and a flexural strength of 2.46 MPa. However, an excessively high modulus of the alkali activator led to the saturation of active Si, resulting in extensive encapsulation of particles by C-S-H gel and thus hindering the reaction. The optimal modulus of the alkali activator was determined to be 1.0 M, which yielded the highest compressive strength of 16.10 MPa and flexural strength of 2.13 MPa.

- (3)

- Using a molding pressure of 60 MPa, the brick achieved a compressive strength of 16.02 MPa and a flexural strength of 2.72 MPa. Elevating the molding pressure assisted in expelling air trapped within the pores, facilitating the infiltration of the alkali activator into the interior of the raw materials and enhancing the contact between particles.

- (4)

- Bricks prepared predominantly with fine-grained IOT exhibited a higher compressive strength compared to those dominated by coarse-grained IOT. The influence of the IOT grain size distribution on flexural strength was relatively minor, with fluctuations not exceeding 0.25 MPa.

- (5)

- For the IOT-GGBS alkali-activated system, IOT primarily functioned as aggregates and participated partially in the reaction, whereas GGBS served as the alkali-activated precursors, undergoing extensive reaction to produce C-S-H gel and C-A-H, thereby providing robust bonding within the system. Furthermore, an increase in the GGBS content might have led to the fragmentation of some IOT particles into smaller fragments, which then formed more stable aggregates under the influence of the C-S-H gel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anjum, F.; Naz, M.Y.; Ghaffar, A.; Kamran, K.; Shukrullah, S.; Ullah, S. Sustainable Insulating Porous Building Materials for Energy-Saving Perspective: Stones to Environmentally Friendly Bricks. Constr. Build. Mater. 2022, 318, 125930. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Mackinnon, I.D.; Allen, C.; Gu, Y.; Xi, Y. Thermal Behaviors of Clay Minerals as Key Components and Additives for Fired Brick Properties: A Review. J. Build. Eng. 2023, 66, 105802. [Google Scholar] [CrossRef]

- Tanash, A.O.; Muthusamy, K.; Yahaya, F.M.; Ismail, M.A. Potential of Recycled Powder from Clay Brick, Sanitary Ware, and Concrete Waste as a Cement Substitute for Concrete: An Overview. Constr. Build. Mater. 2023, 401, 132760. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of Eco-Friendly Bricks from Copper Mine Tailings through Geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Harech, M.; Labbilta, T.; Anasser, I.; El Hafiane, Y.; Abouliatim, Y.; Nibou, L.; Smith, A.; Mesnaoui, M. From by-Product to Sustainable Building Material: Reusing Phosphate Washing Sludge for Eco-Friendly Red Brick Production. J. Build. Eng. 2023, 78, 107575. [Google Scholar] [CrossRef]

- Li, Y.; Ma, X.; Chen, Y.; Kang, X.; Yang, B. Superhydrophobicity Mechanism and Nanoscale Profiling of Pdms-Modified Kaolinite Nanolayers Via Ab Initio-Md Simulation and Atomic Force Microscopy Study. Langmuir 2023, 39, 8548–8558. [Google Scholar] [CrossRef]

- Xin, Y.; Robert, D.; Mohajerani, A.; Tran, P.; Pramanik, B.K. Energy Efficiency of Waste Reformed Fired Clay Bricks-from Manufacturing to Post Application. Energy 2023, 282, 128755. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, F.; Li, W.; Liu, R.; Li, G.; Wei, J. Test Research on the Effects of Mechanochemically Activated Iron Tailings on the Compressive Strength of Concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Liu, X.; Duan, P.; Yang, H.; Jiang, T.; Wang, D.; Liu, R. Current Situation and Comprehensive Utilization of Iron Ore Tailing Resources. J. Min. Sci. 2006, 42, 403–408. [Google Scholar] [CrossRef]

- Wang, C.-L.; Ni, W.; Zhang, S.-Q.; Wang, S.; Gai, G.-S.; Wang, W.-K. Preparation and Properties of Autoclaved Aerated Concrete Using Coal Gangue and Iron Ore Tailings. Constr. Build. Mater. 2016, 104, 109–115. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, S.; Zhou, Y.; Zhang, C.; Meng, T.; Jiang, S.; Liu, L.; Hu, G. Effect of Incorporation of Rice Husk Ash and Iron Ore Tailings on Properties of Concrete. Constr. Build. Mater. 2022, 238, 127584. [Google Scholar] [CrossRef]

- Zhang, N.; Tang, B.; Liu, X. Cementitious Activity of Iron Ore Tailing and Its Utilization in Cementitious Materials, Bricks and Concrete. Constr. Build. Mater. 2021, 288, 123022. [Google Scholar] [CrossRef]

- Zhao, J.; Ni, K.; Su, Y.; Shi, Y. An Evaluation of Iron Ore Tailings Characteristics and Iron Ore Tailings Concrete Properties. Constr. Build. Mater. 2021, 286, 122968. [Google Scholar] [CrossRef]

- Schoenberger, E. Environmentally Sustainable Mining: The Case of Tailings Storage Facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Ma, X.-Y.; Kang, X.; Su, C.-X.; Chen, Y.-Q.; Sun, H.-M. Effects of Water Chemistry on Microfabric and Micromechanical Properties Evolution of Coastal Sediment: A Centrifugal Model Study. Sci. Total Environ. 2023, 866, 161343. [Google Scholar] [CrossRef]

- Suzuki, Y.; Takenaka, C.; Tomioka, R.; Tsubota, H.; Takasaki, Y.; Umemura, T. Accumulation of Arsenic and Copper by Bryophytes Growing in an Aquatic Environment near Copper Mine Tailings. Mine Water Environ. 2016, 35, 265–272. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W.; Ren, D. Fresh Properties, Compressive Strength and Microstructure of Fly Ash Geopolymer Paste Blended with Iron Ore Tailing under Thermal Cycle. Constr. Build. Mater. 2016, 118, 76–88. [Google Scholar] [CrossRef]

- Zhao, F.-Q.; Zhao, J.; Liu, H.-J. Autoclaved Brick from Low-Silicon Tailings. Constr. Build. Mater. 2009, 23, 538–541. [Google Scholar] [CrossRef]

- Alves, P.; Dias, D.A.; Pontinha, A.D.R. Silica Aerogel-Rubber Composite: A Sustainable Alternative for Buildings’ Thermal Insulation. Molecules 2022, 27, 7127. [Google Scholar] [CrossRef]

- Almeida, V.O.; Silvestro, L.; Gleize, P.J.; Kirchheim, A.P.; Schneider, I.A. Schneider. Application of Leached Iron Ore Tailings to Produce Sustainable Cements. Constr. Build. Mater. 2023, 377, 131095. [Google Scholar] [CrossRef]

- Huang, S.; Pi, Z.; Cai, C.; Li, H. Utilization of High-Sulfur Iron Ore Tailings in Cement Mortar by Considering the Influence of Curing Temperature and Tailing Content. J. Build. Eng. 2023, 74, 106826. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of Iron Ore Tailings as Replacement for Fine Aggregate in Concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, X.; Qiu, J.; Liu, J.; Zhao, Y.; Li, X. Effects of Iron Ore Tailings on the Compressive Strength and Permeability of Ultra-High Performance Concrete. Constr. Build. Mater. 2020, 260, 119917. [Google Scholar] [CrossRef]

- Fontes, W.C.; Mendes, J.C.; Da Silva, S.N.; Peixoto, R.A.F. Mortars for Laying and Coating Produced with Iron Ore Tailings from Tailing Dams. Constr. Build. Mater. 2016, 112, 988–995. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Fontes, M.; Ribeiro, J.C.L.; Vieira, C.M.F.; Pacheco, A.A.; de Azevedo, A.R. Technical and Environmental Assessment of the Incorporation of Iron Ore Tailings in Construction Clay Bricks. Constr. Build. Mater. 2019, 227, 116669. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, T.; Zhao, Y.; Bao, S. Preparation of Eco-Friendly Construction Bricks from Hematite Tailings. Constr. Build. Mater. 2011, 25, 2107–2111. [Google Scholar] [CrossRef]

- Yang, C.; Cui, C.; Qin, J.; Cui, X. Characteristics of the Fired Bricks with Low-Silicon Iron Tailings. Constr. Build. Mater. 2014, 70, 36–42. [Google Scholar] [CrossRef]

- Luo, L.; Li, K.; Fu, W.; Liu, C.; Yang, S. Preparation, Characteristics and Mechanisms of the Composite Sintered Bricks Produced from Shale, Sewage Sludge, Coal Gangue Powder and Iron Ore Tailings. Constr. Build. Mater. 2020, 232, 117250. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Chen, T.; Chen, Y.; Bao, S. Preparation of High Strength Autoclaved Bricks from Hematite Tailings. Constr. Build. Mater. 2012, 28, 450–455. [Google Scholar] [CrossRef]

- Liu, J.; Ge, X.; Liu, P.; Song, G.; Hu, Z. Experimental Study on the Preparation of Cementitious Materials from Iron Ore Tailings by Activation. Constr. Build. Mater. 2023, 385, 131409. [Google Scholar] [CrossRef]

- Thejas, H.K.; Hossiney, N. Alkali-Activated Bricks Made with Mining Waste Iron Ore Tailings. Case Stud. Constr. Mater. 2022, 16, e00973. [Google Scholar] [CrossRef]

- Ali, H.A.; Sun, K.; Xuan, D.; Lu, J.-X.; Cyr, M.; Poon, C.S. Recycling of High-Volume Waste Glass Powder in Alkali-Activated Materials: An Efflorescence Mitigation Strategy. J. Build. Eng. 2023, 65, 105756. [Google Scholar] [CrossRef]

- Gokul, V.; Steffi, D.A.; Kaviya, R.; Harni, C.; Dharani, S. Alkali Activation of Clayey Soil Using Ggbs and Naoh. Mater. Today Proc. 2021, 43, 1707–1713. [Google Scholar] [CrossRef]

- Liu, G.; Rong, H.; Wang, J. Valorization of Converter Steel Slag in Sustainable Mortars by a Combined Alkali and Carbonation Activation. J. Clean. Prod. 2022, 370, 133519. [Google Scholar] [CrossRef]

- Alam, S.; Das, S.K.; Rao, B.H. Strength and Durability Characteristic of Alkali Activated Ggbs Stabilized Red Mud as Geo-Material. Constr. Build. Mater. 2019, 211, 932–942. [Google Scholar] [CrossRef]

- Lee, S.K.; Stebbins, J.F. Stebbins. Disorder and the Extent of Polymerization in Calcium Silicate and Aluminosilicate Glasses: O-17 Nmr Results and Quantum Chemical Molecular Orbital Calculations. Geochim. Et Cosmochim. Acta 2006, 70, 4275–4286. [Google Scholar] [CrossRef]

- Stebbins, J.F.; Xu, Z. Nmr Evidence for Excess Non-Bridging Oxygen in an Aluminosilicate Glass. Nature 1997, 390, 60–62. [Google Scholar] [CrossRef]

- Kang, X.; Zou, X.; Sun, H.-M.; Ma, X.-Y.; Chen, R.-P. Molecular Dynamics Simulations of Microstructure and Dynamic Shearing Behaviors of Kaolinite-Water-Salt System. Appl. Clay Sci. 2022, 218, 106414. [Google Scholar] [CrossRef]

- Young, G.; Yang, M. Preparation and Characterization of Portland Cement Clinker from Iron Ore Tailings. Constr. Build. Mater. 2019, 197, 152–156. [Google Scholar] [CrossRef]

- Li, L.; Zhang, H.; Guo, X.; Zhou, X.; Lu, L.; Chen, M.; Cheng, X. Pore Structure Evolution and Strength Development of Hardened Cement Paste with Super Low Water-to-Cement Ratios. Constr. Build. Mater. 2019, 227, 117108. [Google Scholar] [CrossRef]

- Wang, W.; Gan, Y.; Kang, X. Synthesis and Characterization of Sustainable Eco-Friendly Unburned Bricks from Slate Tailings. J. Mater. Res. Technol. 2021, 14, 1697–1708. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; Gu, X.; Nehdi, M.L.; Zhang, L.V. Mechanochemical Activation of Iron Ore Tailing-Based Ternary Supplementary Cementitious Materials. Constr. Build. Mater. 2022, 346, 128420. [Google Scholar] [CrossRef]

- Liu, M.; Yang, D.; Chen, L.; Chen, G.; Ma, Z. Effect of Silicate Modulus and Alkali Content on the Microstructure and Macroscopic Properties of Alkali-Activated Recycled Powder Mortar. Constr. Build. Mater. 2023, 397, 132365. [Google Scholar] [CrossRef]

- Che, J.; Yang, R.; Wang, J.; Liu, H.; Hu, Y.; Doh, S.I. Research on Basic Mechanical Properties of Different Modulus Alkaline Excited Ecc. Phys. Chem. Earth Parts A/B/C 2022, 128, 103233. [Google Scholar] [CrossRef]

- Wang, W.; Fan, C.; Wang, B.; Zhang, X.; Liu, Z. Workability, Rheology, and Geopolymerization of Fly Ash Geopolymer: Role of Alkali Content, Modulus, and Water–Binder Ratio. Constr. Build. Mater. 2023, 367, 130357. [Google Scholar] [CrossRef]

- Sun, B.; Sun, Y.; Ye, G.; De Schutter, G. A Mix Design Methodology of Slag and Fly Ash-Based Alkali-Activated Paste. Cem. Concr. Compos. 2022, 126, 104368. [Google Scholar] [CrossRef]

- Xia, D.; Chen, R.; Cheng, J.; Tang, Y.; Xiao, C.; Li, Z. Desert Sand-High Calcium Fly Ash-Based Alkali-Activated Mortar: Flowability, Mechanical Properties, and Microscopic Analysis. Constr. Build. Mater. 2023, 398, 131729. [Google Scholar] [CrossRef]

- Prasanphan, S.; Wannagon, A.; Kobayashi, T.; Jiemsirilers, S. Reaction Mechanisms of Calcined Kaolin Processing Waste-Based Geopolymers in the Presence of Low Alkali Activator Solution. Constr. Build. Mater. 2019, 221, 409–420. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Maheri, M.R.; Mehrali, M. Hot-Pressed Geopolymer. Cem. Concr. Res. 2017, 100, 14–22. [Google Scholar] [CrossRef]

- Bayrak, B.; Öz, A.; Benli, A.; Kavaz, E.; Kaplan, G.; Aydın, A.C. Physico-Mechanical and Shielding Properties of Alkali-Activated Slag Composites Incorporating Cement Clinker Aggregate: Effect of High Temperature and Particle Size. J. Build. Eng. 2023, 67, 105982. [Google Scholar] [CrossRef]

- Kang, X.; Gan, Y.; Chen, R.; Zhang, C. Sustainable Eco-Friendly Bricks from Slate Tailings through Geopolymerization: Synthesis and Characterization Analysis. Constr. Build. Mater. 2021, 278, 122337. [Google Scholar] [CrossRef]

- Labò, S.; Marini, A. In-Plane Flexural Behavior of Hollow Brick Masonry Walls with Horizontal Holes. Eng. Struct. 2022, 273, 115086. [Google Scholar] [CrossRef]

- Miah, J.; Babafemi, A.J.; Paul, S.C.; Kong, S.Y.; Li, Y.; Jang, J.G. Eco-Friendly Concrete with Chemically Treated End-of-Life Tires: Mechanical Strength, Shrinkage, and Flexural Performance of Rc Beams. Constr. Build. Mater. 2022, 351, 128970. [Google Scholar] [CrossRef]

- He, P.; Zhang, B.; Lu, J.-X.; Poon, C.S. Reaction Mechanisms of Alkali-Activated Glass Powder-Ggbs-Cac Composites. Cem. Concr. Compos. 2021, 122, 104143. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Utilization of Cement Kiln Dust (Ckd) to Enhance Mine Tailings-Based Geopolymer Bricks. Constr. Build. Mater. 2013, 40, 1002–1011. [Google Scholar] [CrossRef]

- Amin, N.U.; Faisal, M.; Muhammad, K.; Gul, S. Synthesis and Characterization of Geopolymer from Bagasse Bottom Ash, Waste of Sugar Industries and Naturally Available China Clay. J. Clean. Prod. 2016, 129, 491–495. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Biomass Fly Ash Geopolymer Monoliths for Effective Methylene Blue Removal from Wastewaters. J. Clean. Prod. 2018, 171, 783–794. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-Activated Mortars Blended with Glass Bottle Waste Nano Powder: Environmental Benefit and Sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of Glass Waste as an Activator in the Preparation of Alkali-Activated Slag. Mechanical Strength and Paste Characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Others |

|---|---|---|---|---|---|---|

| IOT | 54.41 | 13.84 | 13.01 | 8.30 | 4.63 | 5.81 |

| GGBS | 34.50 | 17.70 | 1.03 | 34.00 | 6.01 | 6.76 |

| Grain Size Interval (%) | IOT Type | |||

|---|---|---|---|---|

| <0.25 mm | 0.25–0.4 mm | >0.4 mm | ||

| Ratio | 2 | 3 | 5 | A |

| 3 | 3 | 4 | B | |

| 4 | 3 | 3 | C | |

| 6 | 2 | 2 | O | |

| (59.31) | (21.85) | (18.84) | ||

| Parameter | Raw Materials Ratio | Content of Alkali Activator | Modulus of Alkali Activator | Molding Pressure | Grain Size Ratio |

|---|---|---|---|---|---|

| Value/Ratio | 90:10 | 15% | 1.5 M | 20 MPa | 59.31:21.85:18:84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, X.; Li, Y.; Li, W.; Zhou, Y.; Cui, J.; Cai, B.; Zi, Y.; Fang, J.; Chen, Y.; Li, S.; et al. Synthesis and Characterization of Sustainable Eco-Friendly Alkali-Activated High-Content Iron Ore Tailing Bricks. Buildings 2023, 13, 2743. https://doi.org/10.3390/buildings13112743

Kang X, Li Y, Li W, Zhou Y, Cui J, Cai B, Zi Y, Fang J, Chen Y, Li S, et al. Synthesis and Characterization of Sustainable Eco-Friendly Alkali-Activated High-Content Iron Ore Tailing Bricks. Buildings. 2023; 13(11):2743. https://doi.org/10.3390/buildings13112743

Chicago/Turabian StyleKang, Xiangyang, Yanman Li, Wei Li, Yuxian Zhou, Jiarui Cui, Baohua Cai, Yong Zi, Jing Fang, Yongqing Chen, Senlin Li, and et al. 2023. "Synthesis and Characterization of Sustainable Eco-Friendly Alkali-Activated High-Content Iron Ore Tailing Bricks" Buildings 13, no. 11: 2743. https://doi.org/10.3390/buildings13112743

APA StyleKang, X., Li, Y., Li, W., Zhou, Y., Cui, J., Cai, B., Zi, Y., Fang, J., Chen, Y., Li, S., & Kang, X. (2023). Synthesis and Characterization of Sustainable Eco-Friendly Alkali-Activated High-Content Iron Ore Tailing Bricks. Buildings, 13(11), 2743. https://doi.org/10.3390/buildings13112743