Abstract

Fatigue damage can develop within asphalt pavement due to the continuous impact of driving loads and natural elements. Understanding the process of asphalt mixtures’ fatigue damage is crucial for guiding the design, maintenance, and repair of asphalt pavement. This research aims to establish a model that characterizes the mixtures’ modulus decay under a three-dimensional (3-D) stress state. Firstly, asphalt mixes were subjected to direct tensile (DT), indirect tensile (IDT), unconfined compressive (UC) strength and fatigue tests, and the resulting data were analyzed. Then, modulus decay models under DT, IDT, and UC conditions were established, and the modulus decay patterns under the three loading modes were compared and analyzed. Finally, using the fatigue stress strength ratio Δ (a fatigue resistance index for asphalt mixtures that takes into account the impacts of stress state and loading rate), a unified characterization model for asphalt mixes’ modulus decay under a 3-D stress state was created. According to the study’s findings, asphalt mixes’ modulus decay during fatigue damage exhibits obvious nonlinear characteristics. While the asphalt mixes’ modulus decay law with various loading modalities is similar under the same conditions, the decay rate may differ. Essentially, the speed of the modulus decay of a certain asphalt mixture primarily depends on the value of Δ during service. A larger Δ indicates a faster modulus decay. This study offers a theoretical foundation for the conversion from material fatigue damage to structural fatigue damage, which is vital for enhancing the asphalt pavements’ construction quality and longevity.

1. Introduction

1.1. Background

In the discipline of solid mechanics, known as fatigue damage mechanics [1,2,3], the evolution of damage factors [4], like internal stress, strain, and modulus of materials subjected to repeated loading over time, is primarily studied. Due to factors like vehicular loads and natural environmental conditions, asphalt pavement may suffer from fatigue damage within the structure [5,6]. With the accumulation of damage, the materials and structural performance of the pavement will progressively deteriorate until they eventually fail [7]. Optimizing the design of the pavement structure and carrying out the necessary maintenance procedures throughout its service life is crucial for improving the construction quality and durability of asphalt pavements. Further, investigating the development process of asphalt mixes’ fatigue damage is critical for optimizing pavement structure design and making informed maintenance decisions [8,9].

Therefore, numerous indoor experimental studies have been conducted by road researchers on asphalt mixtures [10,11,12,13,14,15], simulating various service conditions of asphalt pavement through diverse fatigue test methods. The asphalt mixes’ fatigue performance was examined in these investigations, and fatigue damage models were suggested for several scenarios.

Specifically, Zheng et al. [10] established a nonlinear fatigue damage equation for asphalt mixes based on the S-N fatigue equation and damage mechanics theory. Zhou et al. [11] simulated the asphalt mixes’ fatigue damage process using three-point bending fatigue tests and a nonlinear finite element method, respectively. They predicted asphalt concrete specimens’ fatigue life and crack length during unstable fracture. To evaluate the stiffness variations of two types of asphalt mixes at rest brought on by temperature, fatigue damage growth, and healing, Daniel et al. [12] used the impact resonance method. Shan et al. [13] utilized CT scanning technology to capture internal cross-sectional images of asphalt mixtures at various stages of fatigue damage during IDT fatigue testing. Subsequently, they examined the progression of fatigue damage over time. Based on four-point bending tests, Izaks et al. [14] found that developing High Modulus Asphalt Concrete (HMAC) mixtures with high fatigue resistance performance using RA content up to 70% by using polymer-modified bitumen binder is possible. Lv et al. [15] conducted small-scale accelerated pavement tests on asphalt mixtures using the Model Moving Load Simulator (MMLS3) to evaluate their fatigue damage performance.

It should be noted that one crucial mechanical parameter that plays a significant role in determining the asphalt pavement’s service life is the modulus of pavement material [16,17,18]. An essential factor to take into account in pavement design and maintenance is the decay pattern of the modulus, which can serve as a general measure of asphalt pavement’s damage law [18,19,20,21,22]. Thus, according to the strain equivalence assumption of viscoelastic damage mechanics theory, some scholars defined the reduction in modulus (stiffness) as a damage variable to study the asphalt mixes’ fatigue damage features. For example, Zhou et al. [20] established a damage evolution equation considering the joint impact of fatigue and creep damage effects. Based on the small-scale accelerated pavement test results, Lv et al. [15] established a stiffness decrease equation for asphalt mixes and proposed the corresponding reduction law during fatigue. Lv et al. [21] also analyzed the modulus decay characteristics of asphalt mixtures with various loading circumstances. By utilizing DT fatigue testing, Liu et al. [22] revealed the attenuation law of remaining strength and dynamic modulus. Additionally, they established a coupled fatigue damage evolution model of remaining strength and dynamic modulus.

However, two aspects need to be noted when studying the modulus decay law of asphalt mixtures. Firstly, the modulus of asphalt pavement materials has a specific stress dependence. As asphalt pavement materials are viscoelastic and composed of multiple phases, scales, and components, their modulus is not an inherent property of asphalt mixtures and is influenced by stress states [23,24]. Secondly, the modulus of asphalt pavement materials is influenced by the pavement’s structure. Modulus levels and stress states change as a result of the different layers of asphalt mixture that make up the pavement structure.

During the actual service period, asphalt pavement structures experience a 3-D stress condition [25]. Consequently, there may be significant discrepancies between the results of indoor material tests conducted using one particular stress condition and the actual pavement service state, which hinders the precise assessment of the asphalt pavement structures’ fatigue performance and impedes scientific maintenance decision-making. Although full-scale accelerated loading tests [26,27,28] can provide a more realistic simulation of the actual service state of asphalt pavement, their high testing costs and lengthy testing cycles have limited their widespread use. Therefore, an urgent need is to develop a model that can accurately reflect the modulus decay of asphalt mixtures under actual 3-D service conditions through indoor experiments.

This study focuses on understanding the process of fatigue damage in asphalt mixtures under the three-dimensional service condition, which is crucial for guiding the design and maintenance of asphalt pavement structures. On the basis of the fatigue stress strength ratio Δ as a measure of durability against fatigue [29], a unified characterization model for the asphalt mixes’ modulus decay under a 3-D stress condition was developed. The findings of this study provide a theoretical foundation for the reasonable conversion of structural fatigue damage from material fatigue damage, allowing for a more realistic characterization of the asphalt pavement structures’ fatigue damage patterns through indoor material tests, which is beneficial for improving asphalt pavements’ construction quality and service life.

1.2. Objective

This paper aims to establish a model that characterizes the asphalt mixtures’ modulus decay under a 3-D stress state during the fatigue damage. Strength and fatigue tests were conducted under the DT, IDT, and UC modes. The primary objectives of this research are as follows:

- (1)

- The relationship between the asphalt mixtures’ strength and loading rate was established.

- (2)

- The conventional S-N fatigue equations for asphalt mixtures under the DT, IDT, and UC modes were obtained and analyzed. Additionally, the normalized fatigue equation for asphalt mixtures under the various modes was established based on the fatigue stress strength ratio Δ.

- (3)

- Through stress-controlled fatigue tests, the modulus decay equations of asphalt mixtures under the DT, IDT, and UC modes were developed and compared.

- (4)

- A unified characterization model for the modulus decay of asphalt mixture under the 3-D stress state was established based on the fatigue stress strength ratio Δ.

2. Materials and Methodology

2.1. Materials

2.1.1. Asphalt

Table 1 displays the conventional performance test outcomes of the high-content (30%) rubber-modified asphalt employed in this investigation. The test methods followed the specification JTG E20-2011 [30].

Table 1.

Performance test outcomes of the asphalt in this investigation.

2.1.2. Aggregate and Filler

Limestone aggregate and limestone mineral powder filler were utilized in this study. The aggregate density and mechanical index test results are presented in Table 2 and Table 3, respectively. Table 4 shows the basic technical indicators of the filler. Each index complies with the JTG F40-2004 specification [31].

Table 2.

Density and water absorption of limestone aggregate.

Table 3.

Technical indexes of limestone aggregate.

Table 4.

Technical indexes of filler.

2.1.3. Mix Design

The SAC-13 graded rubber asphalt mixture [32,33,34] was utilized in this study. The design principle of the SAC mix is to form a skeleton with coarse aggregates and fill the voids in the structure with fine aggregates and asphalt. SAC asphalt mixture has excellent high-temperature deformation resistance, water damage resistance, and slip resistance [35]. Additionally, it has advantages such as small segregation, easy compaction, and asphalt conservation [36].

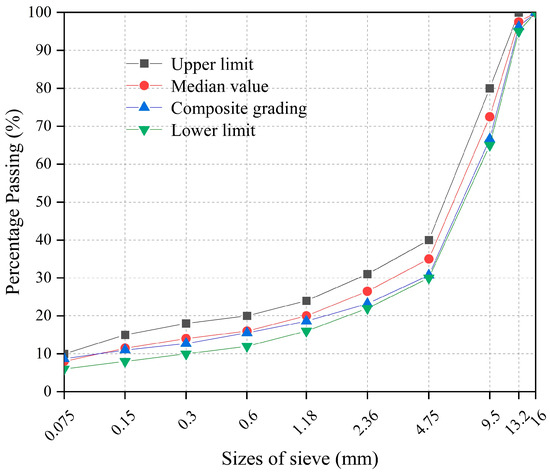

The grading design for SAC-13 [35,36] was conducted, which included a maximum particle size of 13.2 mm, a control percent passing of 30% for the 4.75 mm sieve, and 8% for the 0.075 mm sieve. The grading curve is plotted as shown in Figure 1, and the final asphalt mixture asphalt–aggregate ratio is 5.5%. Table 5 displays the Marshall performance indicators of the SAC-13 mixes at the optimal asphalt–aggregate ratio.

Figure 1.

SAC-13 gradation curve.

Table 5.

Marshall performance indicators.

2.2. Experiment Approach

This study tested asphalt mixtures for strength and fatigue using the DT, IDT, and UC modes. The strength test adopts two methods: stress and displacement control. The fatigue test determines a sample’s fatigue life by using a stress-control mode and counting the number of loading cycles till a specimen fails, either marked by obvious fracture cracking or deformation. Strength and fatigue tests were conducted on an MTS testing machine. LVDT sensors are utilized during the fatigue test to detect real-time specimen displacement, allowing for the analysis of modulus changes throughout the process. Testing is consistently conducted at 15 ± 1 °C, and the specimen should be insulated at that temperature for 4 h or more before the test.

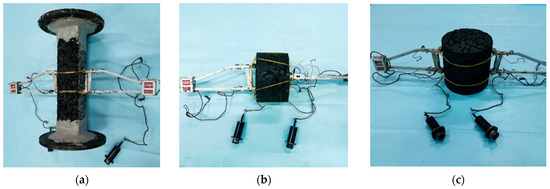

2.2.1. Specimen Preparation

The DT samples were created following the guidelines of specification JTG E20-2011 [30]. Initially, a rectangular specimen (length and width of 300 mm, thickness of 50 mm) was molded using an Asphalt Mixer Wheel Grinding Machine. Subsequently, it was divided into beam samples (length of 250 mm, width and height of 50 mm). The asphalt mixture beam specimen is fixed between two circular iron plates with joints using epoxy stone dry-hanging adhesive, which has a higher tensile strength than the asphalt mixture and causes minimal deformation, ensuring accurate test results. Two displacement sensors are symmetrically attached on either side during fatigue testing of the asphalt mixture beam specimen. Refer to Figure 2a for the DT specimen.

Figure 2.

Specimen preparation. (a) DT specimen. (b) IDT specimen. (c) UC specimen.

The SGC rotary compactor was utilized to create cylindrical IDT specimens with a height and diameter of 100 ± 2 mm. The compaction process involved a vertical loading pressure of 600 ± 18 kPa, an effective internal rotation angle of 1.16 ± 0.02°, and a compaction speed of 30 ± 0.5 r/min. Afterward, the specimens were cut into 60 ± 2 mm height and 100 ± 2 mm diameter specimens for indirect tensile testing, as displayed in Figure 2b.

The UC samples, with a height and diameter of 100 ± 2 mm, were produced using the SGC rotary compactor. This method is consistent with the indirect stretching method discussed earlier. The unconfined compressive specimen is shown in Figure 2c.

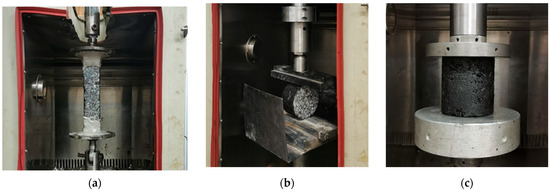

2.2.2. Strength Test Approach

The MTS testing machines were employed to conduct the strength tests. For the stress-control mode DT, IDT, and UC strength tests, eight loading rates ranging from 0.02 MPa/s to 6 MPa/s were utilized. Before the fatigue test, displacement-control mode strength tests were performed. During the displacement-control mode, the loading rates for the DT, IDT, and UC strength tests were maintained at 5 mm/min, 50 mm/min, and 2 mm/min, respectively, following JTG E20-2011 standards [30]. Each group of tests consisted of three parallel specimens, and the maximum load (N) was recorded upon specimen failure. The DT, IDT, and UC strength tests are shown in Figure 3.

Figure 3.

Strength test of asphalt mixture. (a) DT strength test. (b) IDT strength test. (c) UC strength test.

The formula for calculating DT strength:

where represents DT strength (MPa); is the maximum load (N) at the point of specimen failure; represents the length and width of the cross section ( mm); is the cross-sectional area (mm2).

The formula for calculating IDT strength:

where represents IDT strength (MPa); denotes specimen height (mm); is the maximum test load (N).

The formula for calculating UC strength:

where represents UC strength (MPa); is the maximum load (N) at the point of specimen failure; denotes specimen diameter (mm); is the cross-sectional area (mm2).

2.2.3. Fatigue Test Approach

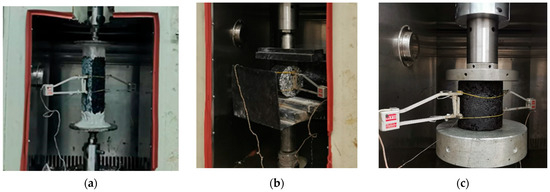

In this study, the selection of stress levels for the DT, IDT, and UC fatigue tests was based on the strength (static load strength) under displacement-control mode, respectively. Moreover, the selected stress level should not exceed the static load strength. Four specimens were tested in parallel for fatigue at each stress level, with a loading frequency of 10 Hz and a continuous haversine wave loading waveform. Refer to Figure 4 for the fatigue test schematic diagram.

Figure 4.

Fatigue test of asphalt mixture. (a) DT fatigue test. (b) IDT fatigue test. (c) UC fatigue test.

2.3. Derivation of Modulus Decay Equation

2.3.1. Damage Variables Based on Modulus

When subjected to the factors such as forces, temperature, and loading speed, micro-defects can form within a material. These defects can nucleate, expand, and converge, ultimately leading to material failure [7]. Variations in macroscopic physical variables like modulus, stress, and strength frequently accompany this process of material deterioration. Specific physical quantities can be defined as damage variables to study the microscopic changes within materials during the damage process, and corresponding fatigue damage models can be established to describe the damage process [4].

In 1963, the mechanist Rabotnov used the following damage factor to describe the damage and study the constitutive equations of metal materials [37].

where is the effective bearing area; is the nominal area, which is the area in the undamaged state.

The fatigue test of the mixes allows for continuous measurement of the modulus, enabling the asphalt mixes’ modulus decay during the test to be used as a damage variable. In this study, a damage factor formula based on the modulus was defined to describe damage in fatigue tests, as shown below.

where is the damage variable of the specimen; is the modulus of the material after fatigue; is the initial modulus of the specimen.

2.3.2. Nonlinear Fatigue Damage Equation for Asphalt Mixes

Creating a fatigue damage model is crucial in studying material fatigue damage, as it links the number of load actions to the resulting material damage. On the one hand, materials’ nonlinear fatigue damage law is related to their initial damage state, and the amount of damage that occurs at different damage stages, even under the same load state, is not the same. On the other hand, the nonlinear fatigue damage law of materials varies with different load levels during cyclic loading. The most intuitive manifestation of the nonlinearity of material fatigue damage is that the image describing the material fatigue damage model is nonlinear. Equation (6) is a commonly used nonlinear fatigue damage model considering the influence of stress amplitude.

By integrating Equation (6), the fatigue damage variable formula can be derived as follows:

Correspondingly, Equation (8) is the expression of the material fatigue equation:

where , and are the material parameters linked to the average stress, temperature, and stress amplitude; represents the damage variable; stands for the number of cycles of load in the fatigue test; represents the fatigue life of the material.

2.3.3. Modulus Decay Equation

Fatigue tests allow for continuous modulus measurement without affecting asphalt mixture performance. The modulus steadily decreases as internal damage accumulates within the material, making it an effective measure for describing damage in asphalt mixtures. The simultaneous Equations (5) and (7) are as follows:

The modulus decay equation can be obtained by eliminating the damage variable in Equation (9).

Let , then:

where is the modulus decay equation parameter, which can be fitted through fatigue tests; is the effective modulus; is the initial modulus; represents the number of load cycles in the fatigue test; denotes the fatigue life.

3. Results and Discussion

3.1. Asphalt Mixture Strength and Fatigue Test Results Analysis

3.1.1. Analysis of Strength Test Results

Displacement-controlled strength tests for asphalt mixture were performed implementing the procedure in Section 2.2.2, and the experimental results are shown in Table 6.

Table 6.

Displacement-controlled strength test results.

A stress-control mode was adopted to perform the DT, IDT, and UC strength tests at various loading rates to investigate the impact of the loading rate on asphalt mix strength. The experiment outcomes, presented in Table 7, provide insights into the viscoelastic behavior of asphalt mixtures.

Table 7.

Strength test results by stress-controlled mode.

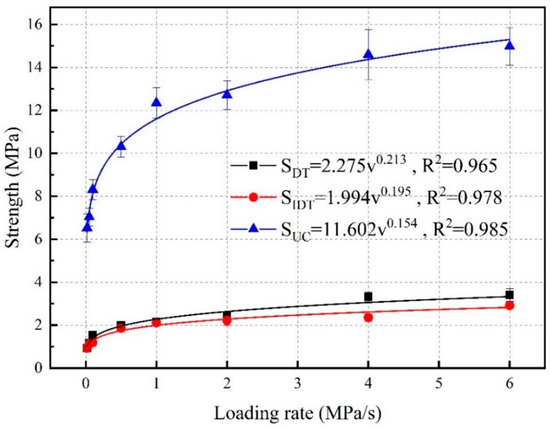

Equation (12) shows that the strength and loading rate were fitted using a power function equation. The curves are displayed in Figure 5.

where is the strength of asphalt mixture; and are the equation parameters; is the loading rate.

Figure 5.

Fitting results of strength and loading rate.

Figure 5 demonstrates that the loading rate positively affects the strength of asphalt mixtures for all stress states, but the pace of increase reduces with higher loading rates. Unconfined compressive mode yields much higher strength values than the direct and indirect tensile modes, while the direct and indirect tensile modes produce similar strength values at the same loading rate.

3.1.2. Analysis of Fatigue Test Results

Fatigue experiments were performed on asphalt mixtures by applying the experimental procedure outlined in Section 2.2.3. Before the fatigue test, a displacement-control mode strength test was conducted, and the outcomes are presented in Table 6. On this basis, five stress levels ranging from 0.2 MPa to 1 MPa were chosen for the DT and IDT fatigue tests, while UC fatigue experiments were performed at stress levels of 1.5 MPa, 2 MPa, 2.5 MPa, 3 MPa, and 3.5 MPa. The fatigue test data are summarized in Table 8.

Table 8.

Fatigue test results of asphalt mixture.

Equation (13) is the S-N fatigue model based on phenomenological methods [38,39].

Equation (14) is the formula for calculating .

where is the fatigue life; and are the regression parameters; is the nominal stress ratio; is the static load strength; is the stress levels of fatigue test.

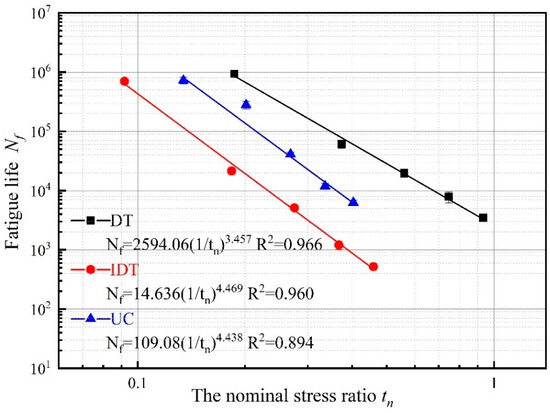

Figure 6 illustrates the fitting of the S-N fatigue formulas for asphalt mixtures under various stress states (loading modes) using Equation (12), founded on the fatigue experiment data obtained from the DT, IDT, and UC modes.

Figure 6.

S-N fatigue equations under different stress states.

Upon examining Figure 6, it is apparent that the S-N equation of asphalt concrete displays noteworthy discrepancies when subjected to the different loading modes. It is evident in the considerable variation in the fatigue equation parameter values obtained from the three methods, resulting in a substantial separation between the fatigue equation curves under the DT, IDT, and UC modes. The fundamental reason for this phenomenon is that the nominal stress ratio , which serves as a fatigue resistance indicator, fails to account for the impact of the stress state and loading rate on asphalt mixtures as viscoelastic materials. Hence, to accurately assess the fatigue and damage properties of the mixtures, it is imperative to employ a fatigue resistance index that considers the material’s 3-D stress condition and loading rate. This approach can significantly mitigate the influence of the experimental loading modes, specimen geometry, and size.

3.2. The Modulus Decay Law of Asphalt Mix with Various Stress States

3.2.1. Fitting Results of Modulus Decay Equation with Various Stress States

This study defines the modulus’ attenuation as a fatigue damage variable, and the focus of this section is to investigate asphalt mixes’ modulus decay equation under various stress conditions during fatigue testing. A modulus value can be calculated in each load cycle of the fatigue test. The calculation method for modulus is as follows.

where is the stress level of fatigue test; is the strain; is the modulus of asphalt mixture.

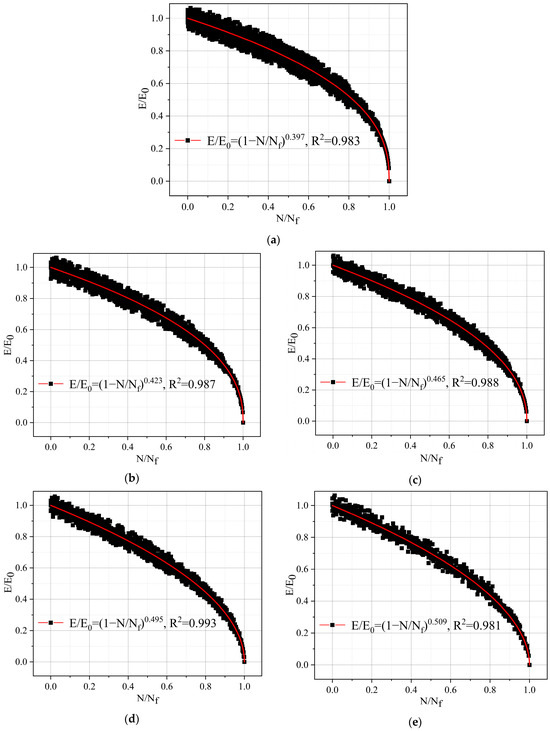

The Equation (11) derived in Section 2.3.3 was used to fit the modulus ratio and fatigue life ratio . The fitted modulus decay model parameter of DT, IDT, and UC are summarized in Table 9, Table 10 and Table 11. Examples of modulus decay curves (one of the four parallel UC experiments) are shown in Figure 7.

Table 9.

Modulus decay equation parameters fitting results of DT.

Table 10.

Modulus decay equation parameters fitting results of IDT.

Table 11.

Modulus decay equation parameters fitting results of UC.

Figure 7.

Modulus decay curves at different stress levels under UC mode. (a) 1.5 MPa. (b) 2.0 MPa. (c) 2.5 MPa. (d) 3.0 MPa. (e) 3.5 MPa.

Figure 7 shows that the parameter in the modulus decay equation positively correlates with the stress level. It means that as the stress level increases, the dynamic modulus decays faster.

3.2.2. Comparative Analysis of Modulus Decay Law under Different Stress States

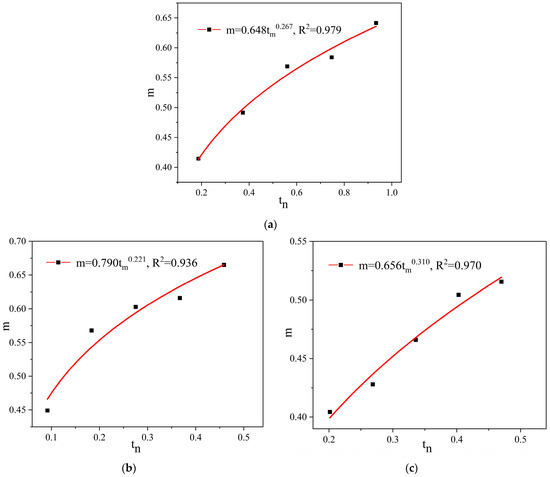

Because the stress levels during fatigue testing differ between the UC mode and DT/IDT modes, the modulus decay equations for the three modes cannot be directly compared. To address this, the nominal stress ratio was obtained by dividing the stress levels equally by the static load strength for dimensionless processing. As a result, the modulus decay equations under the DT, IDT, and UC modes could be compared by examining the parameter under the same nominal stress ratio. The values and nominal stress ratios for each mode were fitted using a power function, and the resulting fitting curves are displayed in Figure 8.

Figure 8.

Fitting curves of parameter and under the different loading modes. (a) DT. (b) IDT. (c) UC.

Figure 8 displays that the parameter in the mixes’ modulus decay equation rises as the nominal stress ratio increases. The corresponding fitting equations are presented below.

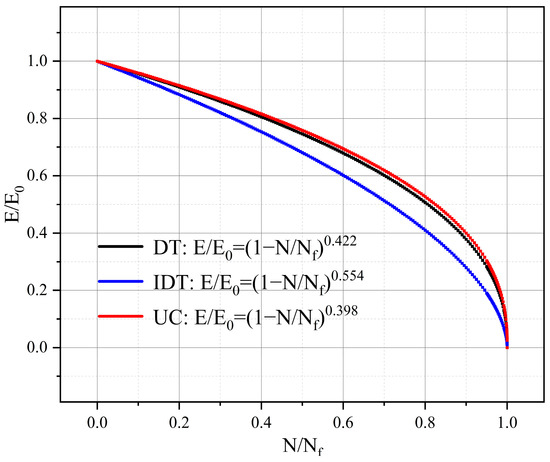

In an effort to contrast and analyze the modulus decay patterns with various stress states, it is essential to ensure that the fatigue test load levels remain consistent, i.e., the nominal stress ratio should be the same. Taking , the modulus decay equations for the DT, IDT, and UC modes are:

The modulus decay curves were plotted according to Equations (19)–(21), as shown in Figure 9.

Figure 9.

Modulus decay curves under the different loading modes when = 0.2.

Figure 9 suggests that the modulus decay patterns are generally similar under the different loading modes despite differences in the stress states. The decay of the modulus first occurs in the stable decay stage, followed by the rapid decay stage. However, the value of the mixes’ modulus decay curve varies under the different loading modes, even when subjected to the same nominal stress ratio. The modulus decay rate from fast to slow is IDT > DT > UC.

This result is likely because the does not consider how the loading rate and stress condition affect asphalt mixtures. To address this, the next step in this study will be to establish a unified model for describing asphalt mixes’ modulus decay pattern under a 3-D stress condition, using the fatigue stress strength ratio Δ as a fatigue resistance index.

3.3. Unified Characterization Model for Modulus Decay of Asphalt Mixture under the 3-D Stress State

3.3.1. Fatigue Stress Strength Ratio and Normalized Fatigue Equation

The stress condition inside asphalt pavement is highly complex under actual driving loads. Asphalt mixtures’ strength and fatigue behavior are affected by the stress state and loading rate. Traditional phenomenological fatigue analysis methods fail to consider these factors, resulting in an unscientific approach. To overcome this, Lv et al. [29,39] proposed a novel approach for analyzing the fatigue characteristic of asphalt mix, which accounts for the actual pavement service conditions and utilizes the idea of a 3-D stress state strength yield surface. This compensates for the limitations of traditional fatigue performance analysis methods that do not consider the impacts of stress conditions and loading rates. The fatigue stress strength ratio Δ is served as a fatigue resistance index, with Equation (22) defining its formula.

where represents the initial equivalent stress, while represents the equivalent stress at the point of fatigue failure.

The formula for equivalent stress is:

where is the first principal stress; is the second principal stress; is the third principal stress.

Equation (22) shows the ratio of the stress level to material resistance during asphalt mixture fatigue testing. Using the ratio Δ, which considers the stress state and loading rate, a normalized fatigue equation is established as follows.

where represents fatigue life; represents the regression parameter.

The initial equivalent stress of the fatigue test and the equivalent stress during fatigue failure can be calculated according to Table 12 and Table 13, respectively.

Table 12.

Calculation method of .

Table 13.

Calculation method of .

In this study, the fatigue tests apply a haversine waveform load. The loading rate can be calculated by the test’s loading frequency (loading cycle T) and stress level .

Based on Equation (24) and the power function equations established in Section 3.1.1 for the strength and loading rate of asphalt mixtures in the DT, IDT, and UC modes, the ultimate strength at various stress levels can be determined. Thus, can be calculated. Table 14 displays the calculated Δ values.

Table 14.

The calculated Δ values.

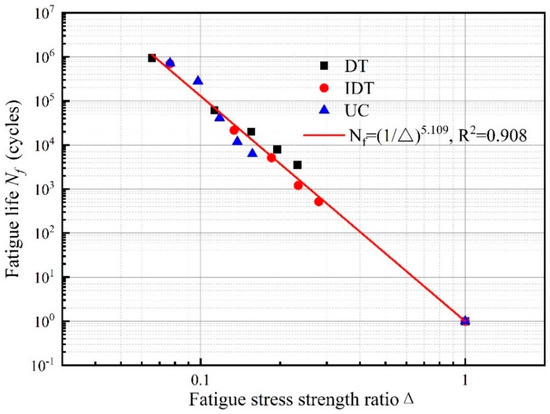

Based on the data of fatigue life (in Section 3.1.2) and the fatigue stress strength ratio, the normalized fatigue equation for various stress conditions can be fitted by Equation (24). The resulting curve for the asphalt mix is displayed in Figure 10.

Figure 10.

The normalized fatigue equation curve of asphalt mixture.

Figure 10 illustrates that the use of the fatigue stress strength ratio Δ has successfully achieved the uniform description of asphalt mixtures’ fatigue behavior with the various stress states. As a fatigue resistance indicator, the ratio Δ considers the impact of the loading mode and rate on asphalt mixtures and correlates with the stress state and vehicle speed within a pavement structure. Based on the ratio Δ, this study established a modulus decay model for asphalt mixes under a 3-D stress condition.

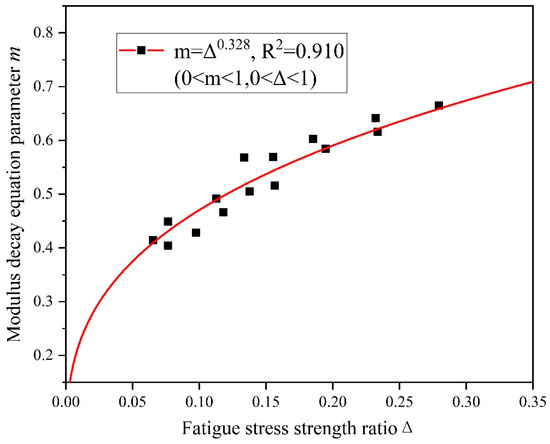

3.3.2. Establishment of the Modulus Decay Model under the 3-D Stress State

Section 3.2 developed the modulus decay equations of asphalt mixes under various stress conditions corresponding to the different loading modes. In Section 3.3.1, the fatigue stress strength ratios were calculated for the DT, IDT, and UC modes at different stress levels. Table 15 displays the values of the modulus decay equation parameter and the fatigue stress strength ratio Δ. and Δ are fitted using a power function equation, as shown in Figure 11.

Table 15.

The values of and Δ.

Figure 11.

The fitting results of and Δ.

By observing Figure 11, it is evident that the parameter in the modulus decay equation increases as the ratio Δ increases. The power function relationship equation between and Δ, obtained by fitting the data, is presented below.

Therefore, a modulus decay model of asphalt mixture under the 3-D stress condition, Equation (27), was established by uniting Equations (11) and (26).

where represents the modulus during fatigue, while is its initial value; represents the number of fatigue load cycles, while represents the fatigue life; is a parameter of the modulus decay equation that can be determined through fatigue tests; Δ is the fatigue stress strength ratio, which accounts for the effects of the stress state and loading rate, and represents the ratio of the stress level to material resistance during fatigue testing of asphalt mixtures; is the regression parameter.

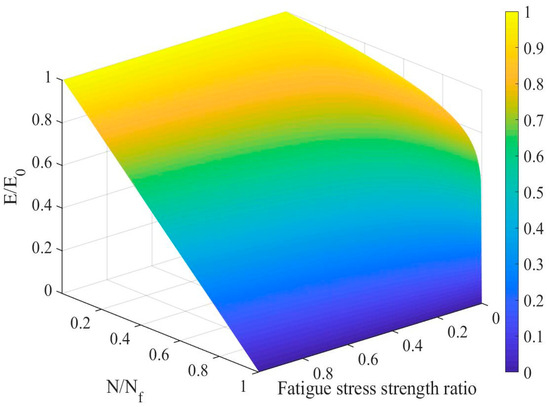

Figure 12 shows the modulus decay surface under the 3-D stress state, which was drawn using MATLAB R2018a based on Equation (27). The surface function is .

Figure 12.

Modulus decay curved surface under the three-dimensional stress state.

Figure 12 illustrates that the modulus decay model (27) can describe the modulus decay behavior under any service state (represented by fatigue stress strength ratio Δ). In asphalt pavement structures, the fatigue stress strength ratio at a given point continuously changes during service. Analyzing the variation law of the fatigue stress strength ratio at a particular point in the asphalt pavement structure under different fatigue life ratios, and using Equation (27), a structural modulus decay model can be established for that point in the asphalt pavement structure. Theoretically, the modulus decay curve of an asphalt pavement structure should be a curve on the asphalt mixes’ modulus decay curved surface under the 3-D stress condition. As a result, the relationship between material modulus decay and structural modulus decay has been established.

This study establishes a theoretical foundation for the reasonable conversion of structural fatigue damage from material fatigue damage, making it possible to characterize the fatigue damage pattern of asphalt pavement structural layers through indoor experiments.

4. Conclusions

This study investigated the fatigue damage properties of asphalt mixtures under the DT, IDT, and UC modes. Firstly, the strength and fatigue experiment results were analyzed, followed by establishing the modulus decay models under the different loading modes. The modulus decay patterns were then compared and analyzed. Using the fatigue stress strength ratio Δ as a measure of fatigue resistance, a unified description model for the modulus decay of asphalt mixtures under the 3-D stress condition was established. In summary, the study provides the following conclusions.

(1) The power function relationships between asphalt mixtures’ strength and loading rate are as follows.

The strength of the asphalt mixture rises with the loading rate during testing. However, under various loading approaches, the asphalt mixes’ strength varies even at the same loading rate.

(2) The conventional S-N fatigue equations of asphalt mix under the DT, IDT, and UC methods are as follows.

The S-N fatigue equation of the mix exhibits significant differences under the DT, IDT, and UC modes. This phenomenon can be attributed to the fact that the nominal stress ratio , as a fatigue resistance indicator, does not account for the impacts of the stress conditions and loading rates on asphalt mixtures as viscoelastic materials.

(3) The modulus decay patterns are generally similar across the different loading modes. Modulus decay occurs first in the stable decay stage and then in the rapid decay stage. However, the parameter of the modulus decay curve varies across the different loading modes under the same nominal stress ratio , with the modulus decay being fastest for IDT, followed by the DT and UC modes in descending order.

(4) Using the fatigue stress strength ratio Δ, the fatigue features of asphalt mixtures with various loading conditions can be uniformly described. The normalized fatigue equation for asphalt mixtures under different stress conditions was established.

The fatigue resistance index Δ considers the impact of the loading mode and rate on asphalt mixtures. It can correspond to the stress condition within the pavement structure and vehicle driving speed.

(5) A unified characterization model for the modulus decay of asphalt mixture under the 3-D stress state was established based on the ratio Δ.

This model comprehensively characterizes the asphalt mixes’ modulus decay law under various service conditions, providing a reference to understanding the fatigue damage behavior of asphalt pavement structures. The modulus decay curve of an asphalt pavement structure should theoretically be a curve in the modulus decay curved surface of asphalt mixture under the 3-D stress condition, thus establishing a relationship between material modulus decay and structural modulus decay.

Author Contributions

Conceptualization, Y.H., S.L. and Z.W.; methodology, S.L. and Z.W.; software, Y.H., S.L., Z.W. and H.M. (Huabao Ma); formal analysis, W.L., C.P. and H.M. (Huilin Meng); investigation, H.M. (Huilin Meng) and N.X.; resources, H.M. (Huabao Ma) and X.P.; data curation, Y.H.; writing—original draft, Y.H., S.L., Z.W., H.M. (Huabao Ma), W.L., C.P., H.M. (Huilin Meng) and N.X.; writing—review and editing, Y.H., S.L., Z.W. and X.P.; visualization, W.L. and C.P.; supervision, X.P.; project administration, Y.H.; funding acquisition, Y.H. and S.L. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the National Science Fund for Distinguished Young Scholars (No. 52225806), the National Natural Science Foundation of China (No. 52078063), the Science and Technology Project of Hebei Provincial Department of Transportation (No. TH-201918), and the Postgraduate Scientific Research Innovation Project of Changsha University of Science and Technology (No. CXCLY2022012 and No. CLSJCX22016).

Data Availability Statement

Some or all data, models, or code generated or used during the study are available from the corresponding author by request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ge, Z.-S.; Huang, X.-M. Prediction of asphalt mixtures fatigue properties using damage mechanics. J. Traffic Transp. Eng. 2003, 3, 40–42. [Google Scholar]

- Chow, C.L.; Wei, Y. A model of continuum damage mechanics for fatigue failure. Int. J. Fract. 1991, 50, 301–316. [Google Scholar] [CrossRef]

- Ritchie, R.O.; Gilbert, C.J.; McNaney, J.M. Mechanics and mechanisms of fatigue damage and crack growth in advanced materials. Int. J. Solids Struct. 2000, 37, 311–329. [Google Scholar] [CrossRef]

- Xiao, J.Q.; Ding, D.X.; Jiang, F.L.; Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock Mech. Min. Sci. 2010, 47, 461–468. [Google Scholar] [CrossRef]

- Yang, S.; Park, H.; Baek, C.; Li, M.E. Fatigue Cracking Characteristics of Asphalt Pavement Structure under Aging and Moisture Damage. Sustainability 2023, 15, 4815. [Google Scholar] [CrossRef]

- Le, X.Q.; Nguyen, M.L.; Hornych, P.; Nguyen, Q.T. Analysis of LVE behaviour and fatigue damage evolution of asphalt pavements with different interface conditions in an accelerated full-scale experiment. Int. J. Pavement Eng. 2022. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Rubio-Gámez, M.C. A review of fatigue damage in bituminous mixtures: Understanding the phenomenon from a new perspective. Constr. Build. Mater. 2016, 113, 927–938. [Google Scholar] [CrossRef]

- Liu, G.; Jia, Y.; Yang, T.; Du, H.; Zhang, J.; Zhao, Y. Fatigue performance evaluation of asphalt mixtures based on energy-controlled loading mode. Constr. Build. Mater. 2017, 157, 348–356. [Google Scholar] [CrossRef]

- Yao, Y.L.; Ren, Y.; Chen, S.F. Preventive maintenance timing of asphalt pavement. J. Chang. Univ. 2006, 26, 3438. [Google Scholar]

- Zheng, J.; Lu, S. Nonlinear Fatigue Damage Model for Asphalt Mixtures. China J. Highw. Transp. 2009, 22, 21–28. [Google Scholar]

- Zhou, Z.G.; Zhang, Q.P.; Yuan, X.X. Fatigue damage analysis of aspahlt mixture specimen during cyclic bending test. J. Cent. South Univ. Sci. Technol. 2011, 42, 1743–1751. [Google Scholar]

- Daniel, J.S.; Kim, Y.R. Laboratory Evaluation of Fatigue Damage and Healing of Asphalt Mixtures. J. Mater. Civ. Eng. 2001, 13, 434–440. [Google Scholar] [CrossRef]

- Shan, L.; Yang, H.; Guo, F.; Li, Z. Fatigue damage evolution in asphalt mixture based on X-ray CT images. Constr. Build. Mater. 2022, 358, 129242. [Google Scholar] [CrossRef]

- Izaks, R.; Rathore, M.; Haritonovs, V.; Zaumanis, M. Performance properties of high modulus asphalt concrete containing high reclaimed asphalt content and polymer modified binder. Int. J. Pavement Eng. 2022, 23, 2255–2264. [Google Scholar] [CrossRef]

- Lv, S.; Hu, L.; Xia, C.; Wang, X.; Borges Cabrera, M.; Guo, S.; Chen, J. Development of fatigue damage model of asphalt mixtures based on small-scale accelerated pavement test. Constr. Build. Mater. 2020, 260, 119930. [Google Scholar] [CrossRef]

- Rezazadeh Eidgahee, D.; Jahangir, H.; Solatifar, N.; Fakharian, P.; Rezaeemanesh, M. Data-driven estimation models of asphalt mixtures dynamic modulus using ANN, GP and combinatorial GMDH approaches. Neural Comput. Appl. 2022, 34, 17289–17314. [Google Scholar] [CrossRef]

- Vestena, P.M.; Schuster, S.L.; de Almeida, P.O., Jr.; Faccin, C.; Specht, L.P.; da Silva Pereira, D. Dynamic modulus master curve construction of asphalt mixtures: Error analysis in different models and field scenarios. Constr. Build. Mater. 2021, 301, 124343. [Google Scholar] [CrossRef]

- Wahengbam, R.D.; Rajbongshi, P. An approach for dynamic stiffness evaluation in asphalt concrete. Constr. Build. Mater. 2015, 96, 541–549. [Google Scholar] [CrossRef]

- Lv, S.; Yuan, J.; Liu, C.; Wang, J.; Li, J.; Zheng, J. Investigation of the fatigue modulus decay in cement stabilized base material by considering the difference between compressive and tensile modulus. Constr. Build. Mater. 2019, 223, 491–502. [Google Scholar] [CrossRef]

- Zhu, H.Z.; Yan, H.; Tang, B.M. Damage Model of Interaction Between Fatigue and Creep for Asphalt Mixture. China J. Highw. Transp. 2011, 24, 15–20. [Google Scholar]

- Lv, S.T.; Fan, X.Y.; Xia, C.D.; Zheng, J.L.; Chen, D.; You, L.Y. Characteristics of Moduli Decay for the Asphalt Mixture under Different Loading Conditions. Appl. Sci. 2018, 8, 840. [Google Scholar] [CrossRef]

- Liu, H.; Yang, X.; Xia, C.; Zheng, J.; Huang, T.; Lv, S. Nonlinear Fatigue Damage Model of Asphalt Mixture Based on Dynamic Modulus and Residual Strength Decay. Materials 2019, 12, 2236. [Google Scholar] [CrossRef]

- Zhu, J.; Ahmed, A.; Said, S.; Dinegdae, Y.; Lu, X. Experimental analysis and predictive modelling of linear viscoelastic response of asphalt mixture under dynamic shear loading. Constr. Build. Mater. 2022, 328, 127095. [Google Scholar] [CrossRef]

- Zhang, J.; Bao, L. Determination of asphalt mixture’s viscoelastic constitutive parameters for pavement response analysis using dynamic modulus transformation. Constr. Build. Mater. 2022, 315, 125729. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I.L. Near-Surface Pavement Failure Under Multiaxial Stress State in Thick Asphalt Pavement. Transp. Res. Rec. 2010, 2154, 91–99. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, K.; Li, J.; Luo, R.; Wang, L. Characterization of dynamic response of asphalt pavement in dry and saturated conditions using the full-scale accelerated loading test. Constr. Build. Mater. 2021, 312, 125355. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X. Performance evaluation of full-scale accelerated pavement using NDT and laboratory tests: A case study in Jiangsu, China. Case Stud. Constr. Mater. 2023, 18, e02083. [Google Scholar] [CrossRef]

- Ahmed, A.W.; Erlingsson, S. Numerical validation of viscoelastic responses of a pavement structure in a full-scale accelerated pavement test. Int. J. Pavement Eng. 2017, 18, 47–59. [Google Scholar] [CrossRef]

- Lv, S.; Wang, Z.; Zhu, X.; Yuan, J.; Peng, X. Research on strength and fatigue properties of asphalt mixture with different gradation curves. Constr. Build. Mater. 2023, 364, 129872. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Asphalt and Asphalts Mixtures for Highway Engineering. Renmin Communication Press: Beijing, China, 2011.

- JTG F40-2004; Technical Spcifications for Construction of Highway Asphalt Pavements. Renmin Communication Press: Beijing, China, 2004.

- Wang, F.; Li, Y.; Ma, G.; Ren, L. Pavement Performance and Application of New SAC13 Asphalt Mixture. Road Mach. Constr. Mech. 2009, 26, 39–42. [Google Scholar]

- Huang, Y.; Wang, X.D.; Liu, Z.H.; Zhou, X.Y.; Zhang, L. Experimental study on dynamic modulus of SAC-13 asphalt mixture with trapezoid beam test. J. Highw. Transp. Res. Dev. 2017, 34, 7–14. [Google Scholar]

- Xue, Z. Pavement Performance Study on Long Life Pavement of SAC-13. Highway 2013, 58, 40–44. [Google Scholar]

- Huang, W.; Huang, M.; Zheng, M.; Li, Y. Air void variation of asphalt rubber mixture grade SAC-13. J. Tongji Univ. 2012, 40, 685–690. [Google Scholar]

- Wang, F.Y.; Sha, Q.L.; Zhang, Y.; Dai, W.T. Application of aggregate gradation test methods of VCA_(DRF) and VCA_(AC) for SAC13. J. Jilin Univ. 2007, 7, 538–543. [Google Scholar]

- Bai, J.W.; Zhao, Y.R.; Shi, J.; He, X.Y. Damage degradation model of aeolian sand concrete under freeze-thaw cycles based on macro-microscopic perspective. Constr. Build. Mater. 2022, 327, 126885. [Google Scholar] [CrossRef]

- Fernández-Canteli, A.; Castillo, E.; Blasón, S. A methodology for phenomenological analysis of cumulative damage processes. Application to fatigue and fracture phenomena. Int. J. Fatigue 2021, 150, 106311. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, W.; Liu, K.; Lv, S.; Peng, X.; Yang, S.; Ding, S. Research on failure strength master curve and fatigue performance of asphalt mixture containing high-proportion reclaimed asphalt pavement. Constr. Build. Mater. 2023, 370, 130537. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).