Abstract

Significant volumes of plantation hardwood are available in Australia to produce value-added engineered wood products such as cross-laminated timber (CLT). To validate the possibility of utilising this available resource, the bending structural properties of plantation Eucalyptus nitens solid board and finger-jointed feedstock were measured. The studied CLT panels produced from finger-jointed lamellas were subjected to bending strength, bending stiffness, rolling shear strength in bending, and pure rolling shear tests to obtain characteristic design values. Solid and finger-jointed timber test results suggested that boards used in longitudinal lamellas have a bending strength of 36.0 MPa and a modulus of elasticity (MOE) of 13,000 MPa. Finger-jointed timber in crossed lamellas presented a declared bending strength of 25.0 MPa. CLT panels showed a bending strength of 24.0 MPa and a rolling shear strength of 2.0 MPa. The experimental results for the CLT panels evidenced that the CLT bending stiffness matches up very well with the modelled results when an MOE of 13,000 MPa is used to describe the stiffness of longitudinal boards. The results presented in this study establish a basis for the commercial use of Australian plantation hardwood CLT in structural applications such as floors and roofs in commercial and residential buildings.

1. Introduction

Half of Australia’s approximately 1,000,000 m3/year of sawlog-managed plantation hardwood to the year 2064 will originate from Tasmania. Similarly, 3,000,000 m3/year of the national total of 8,000,000 m3/year of fibre-managed plantation hardwoods will originate from Tasmania for pulp production [1]. This volume of local resources offers significant opportunities for Australia to establish local manufacturing of wood products for the construction industry rather than importing value-added wood products. By 2050, the number of new dwellings in Australia per annum is expected to increase by 50% to 259,000 [2], and on a global scale the demand for wood products is expected to quadruple. According to recent research, we are already witnessing exponential growth with mass timber [3]. Since 2017, targeted research has been widely published exploring sawlog- and fibre-managed hardwood resources for mass timber products and, more specifically, cross-laminated timber (CLT) [4,5,6,7,8,9,10,11,12,13,14,15,16,17]. Several constraints and commercial opportunities associated with the use of this resource in mass timber products are further summarised by Gutierrez et al. [18]. Unfortunately, one of the biggest hurdles to commercialisation for this resource is the lack of existing mass timber research, test results, standards and codes designed for fibre-managed plantation hardwoods. All current standards have been developed for softwoods which possess very different characteristics and performances.

Most research has focused on the mechanical properties of CLT from softwood species including Scots pine, Norway spruce, Western larch, European larch and Douglas fir. Ehrhart et al. [19] reviewed and investigated CLT panels’ shear properties from European softwood and hardwood timber species. Niederwestberg et al. [20] performed a theoretical and experimental investigation on the shear stiffness of CLT panels made from spruce species. Ma et al. [21] investigated the flexural properties of the CLT made from low-value sugar maple timber species with different layer configurations. Mohd Yusof et al. [22] performed tests evaluating the adhesion performance of CLT panels made from Acacia mangium. Hindman et al. [23] evaluated the mechanical properties of southern pine using American standards test methods. O’Ceallaigh et al. [24] worked on the impact of panel layup on the bending and shear properties of CLT panels manufactured from Irish Sitka spruce.

Li et al. [25] conducted an experimental and theoretical study on CLT panels made from Australian radiata pine. These researchers evaluated the effect of layer thickness on the bending properties of the CLT panels. They claimed that increasing the panel thickness had a negative impact on the flexural properties of the CLT panels. Navaratnam et al. [26] investigated the shear behaviour of Australian Pinus radiata CLT panels. They showed that the influence of panel thickness on the panel’s bending strength is insignificant. Li et al. [27] investigated the rolling shear properties of Australian radiata pine CLT panels with different layer thicknesses. They found that there is a relationship between the results from short-span bending and planar shear tests, which allows the short-span bending test to be used for evaluating the shear properties of three-layer CLT panels.

Despite all these advances in understanding CLT’s structural performance, experimental studies on the effects of the timber feedstock, finger joint strength and panel thickness on the mechanical properties of hardwood CLT thickness are still limited. A recent series of experimental and theoretical investigations on the bending properties and shear performance of CLT panels made from Eucalyptus species have been conducted [4,5,6,7,17,28]. These researchers demonstrated that hardwood species like Eucalyptus can be used commercially in flooring applications for residential or commercial buildings. Liao et al. [28] reported the feasibility of manufacturing CLT using fast-grown E. urophylla × E. grandis through various bending tests. They obtained comparable results for the mechanical properties of the CLT panels to those of commercial softwood CLT panels. Nero et al. [29] compared and characterised the shear performance of CLT specimens made from Eucalyptus nitens, Norway spruce and radiata pine timber species. They highlighted that the rolling shear properties of E. nitens were higher than for the two other species when the load direction was parallel to the annual rings.

There are two sources of standards for CLT production, the European EN 16351 [30] and the North American ANSI/APA PRG-320 [31]. Neither of these standards support hardwood CLT; however, EN 16351 does acknowledge poplar. Most of the tests from these standards have been conducted on softwood species and, as a consequence, the adhesive system and technical standards are focused and designed for their application [32]. This has become a significant barrier for hardwood timber to become an accepted material for CLT production because CLT is regulated based on the European standard (EN 16351) but current CLT production is governed by the material characteristics and variabilities [33]. E. nitens is a variable material in terms of physical and mechanical properties [5]. Given that the findings on plantation hardwood CLT are still based on a limited amount of research, which have been all conducted with solid timber boards, more research and test data are needed to understand the influence of finger joints and the panel thickness of CLT to determine the structural and mechanical properties of this product.

A critical aspect of this study is the focus on evaluating the effects of finger joints on both timber material and CLT made from E. nitens. Structural finger joints are used when strength is paramount in the overall performance of the product. Finger joints are used in structural timber for end-jointing a lamella for large, laminated beams and panels in which the length of the element exceeds the length of the available timber. Finger joints are also used to improve some timber properties such as MOR and MOE by removing strength-reducing characteristics such as knots, cracks, splits and other natural strength reducing features [34]. The defect-free pieces are finger jointed back together, giving particular attention to the selection and preparation of material, formation of joint profile/geometry, application of adhesive, assembly of joint and curing of adhesive. There are numerous studies that investigate finger joint performance and the influence on laminated beams and CLT panels. Various research investigates the impact of finger joint length, profile/geometry, grade, machining and production parameters, environmental conditions, the glue and its application [35,36,37,38,39,40,41,42,43,44,45,46]. The literature consistently notes that an increase in the length of finger joints results in higher MOE and MOR due to an increased glue bonding area at the local finger joint. Moreover, it is critical to correctly match and monitor finger joint geometries in production to ensure their quality. Similarly, production parameters such as the type of glue (typically one-component polyurethane adhesive) and the end pressure applied to solidify the joint are important variables.

This paper aims to characterise the structural performance of E. nitens feedstock to accurately describe the bending strength and stiffness of E. nitens CLT panels. The intended use is as load-bearing elements in floor applications. This research validates the actual and declared values reported by a commercial CLT manufacturer in Tasmania (Cusp Building Solutions), which is producing commercial CLT building components with Tasmanian plantation E. nitens. The research highlights the structural performance of solid and finger-jointed feedstock used in production to manufacture plantation hardwood CLT and the subsequent CLT bending strength, bending stiffness, and rolling shear strength properties. The results are intended to showcase how this resource performs and how to predict the behaviour of CLT panels when feedstock properties are known.

2. Materials and Methods

2.1. Timber Resource

The timber used to manufacture the finger-jointed lamellas and CLT panels was sourced from 20 to 25-year-old plantation E. nitens in Tasmania, Australia. Green boards were air seasoned and then kiln dried to a nominal moisture content (MC) of 12% +/− 2% for manufacturing finger joints and CLT panels. The average basic density of the E. nitens timber used to produce CLT was 570 kg/m3 (SD = 60 kg/m3) at 11% MC.

2.2. Adhesive

Liquid one-component polyurethane (1C-PUR) with an isocyanate prepolymer basis was used as the adhesive to manufacture structural finger joints and CLT panels. The glue is classified as a Type I adhesive in Australia in accordance with AS/NZS 4364 [47]. Glues with different open times were used for each process. The finger joints were manufactured with a 10 min open time, and the subsequent CLT was manufactured with 40 min open-time glue. The glue rates for both finger joints and CLT were between 160 and 180 g/m2. No primer was used in the manufacturing. Curing times varied between two to five times the open time, depending on the environmental conditions during manufacturing. Bond quality for finger joints and CLT panels was assessed as part of the routine tests specified in the manufacturing standards and quality assurance framework.

2.3. Finger Joint Manufacturing Process

Finger-jointed lamellas (25 mm thickness) were manufactured to the requirements given in AS/NZS 5068 [48] using a vertical finger joint geometry that allows the joint to self-interlock and maintain the required pressure for the glue to be fully cured. The finger jointer was a Stirling M-Series heavy-duty finger-jointer press with an adhesive application. Finger flank surfaces were covered with adhesive as per the glue rates specified by the glue supplier. Critical parameters such as shook feedstock dimensions, timber MC (12%), environmental conditions (temperature and humidity to optimise glue open/close times), glue rates (180 g/m2), glue spread (consistent application), pressure (3–4.5 MPa) and finger joint geometry (10 and 15 mm length) were monitored during manufacturing. Finger joint strength and bond quality were monitored through ongoing testing according to the production requirements specified in AS/NZS 5068 [48].

2.4. CLT Manufacturing Process

Cross-laminated timber panels were manufactured with layers of finger-jointed lamellas of 25 mm thickness, following the requirements prescribed in ISO 16696-2016 [49]. Each layer was oriented perpendicular to the previous layer, except for panels with double outer layers where the first and last two layers are oriented in the same direction (Table 1). CL3, CL5 and CL7 correspond to panels of three, five and seven 25 mm layers, with nominal thicknesses of 75, 125 and 175 mm, respectively. CL3, CL5 and CL7 are single-layer panels with finger joint lengths of 10 mm. 5NS refers to a five-layer panel with single lamellas and finger joint lengths of 15 mm, and 5ND refers to a five-layer panel with double outer lamellas oriented longitudinally with finger joint lengths of 15 mm. The CLT panels were pressed using a Woodtech Fankhauser GmbH vacuum press with an adhesive application gantry. The vacuum pressure target was between 50 to 100 mbar, equivalent to a pressure of 0.09 MPa on the billet face. The panels were pressed for the required time to achieve good bond quality with a glue line thickness below 0.3 mm. Critical variables such as sizing tolerance, surface quality, grades, MC, environmental conditions, glue spread, glue rates, side pressure, vertical pressure, assembly time and pressing time were controlled and monitored during the manufacturing process.

Table 1.

Manufactured CLT panels’ description.

2.5. Structural Tests on Solid Timber and Finger Joints

Bending strength tests were conducted following the recommendations described in AS 4063.1 [50] for solid timber specimens and AS 5068 [48] for production control of finger-jointed timber. The specimens were broken using a four-point bending testing machine and the mid-span deflection was measured using a high-precision laser sensor to calculate the modulus of elasticity (E or MOE). The bending strength (fb or MOR) and the MOE were calculated using Equations (1) and (2), respectively.

where fb is the MOR, L is the test span, a is the distance between the loading point and the nearest support and equal to L/3 ± 1.5 d, Fult is the maximum applied load at failure point, b is the width of the specimen, d is the thickness of the specimen, e is the measurement of the vertical displacement, F is the measurement of the force and ΔF/Δe is the linear elastic slope of the load-displacement graph. The sample depth is equivalent to the lamella thickness, which is 25 mm, the test span would vary between 450 and 500 mm, and the width of the specimens would vary between 90 and 110 mm.

2.6. Structural Tests on CLT

2.6.1. Out-Of-Plane Bending Tests

The CLT panels were tested to obtain the out-of-plane bending properties following the recommendations described in EN 16351 [30]. To calculate the bending strength and stiffness, the standard specifies the span and number of test specimens based on thickness (h) and width of specimen. Therefore, four-point bending tests were conducted over spans of 24 h to 30 h (except for CL7 samples which were over 21 h in accordance with EN 408 [51]) (Figure 1). The load was applied with an MTS loading frame, and the displacements were measured using a high precision laser sensor to measure the “local” and “global” displacements as detailed in EN 408 [51] and EN 16351 [30]. For the CLT tests, the theoretical bending strength was calculated where failure was observed. Stress calculations were performed using the mechanical properties of the laminates as detailed in Section 3.1. The global displacements were used to calculate the global stiffness (EImg), which accounts for both shear and bending deformations. The local displacements were used to calculate the local stiffness (EIml), which only accounts for bending deformations. Equations (3) and (4) were used to obtain the global and local stiffness based on EN 408 [51].

where a is the distance between the loading head and the nearest support, l1 is equal to the gauge length for the local displacement measurement, L is the test span, F1 and F2 are the loads corresponding to 10% and 40% of the ultimate load (Fult), respectively, and e1 and e2 are the corresponding displacements at loads F1 and F2, respectively. G is the shear modulus, and b is width of the panel.

Figure 1.

Bending tests on E. nitens CLT panels.

The bending strength (fb) of the CLT panels was obtained by using the shear analogy theory which takes the shear deformation of the cross layers into consideration as shown in Equation (5).

where Mult is the maximum applied bending moment at failure point, E1 is the MOE in the outermost longitudinal lamella, h is the panel thickness and EImg is the global bending stiffness of the panel.

2.6.2. Rolling Shear Tests in Bending

The CLT panels were tested as per EN 16351 [30] to obtain the rolling shear strength and stiffness derived from bending tests (Figure 2). A test span of 12 h was used to force rolling shear failures in the specimens. The specimens were tested in four-point bending with an MTS machine, and the displacements were measured using a high precision laser sensor to measure the “local” and “global” displacements as detailed in EN 408 [51] and EN 16351 [30]. Maximum shear stress was calculated using Equation (6) below.

where Ieff was calculated using the shear analogy theory, Vmax related to the maximum experimental shear force and Q is the static moment of area for the cross section.

Figure 2.

Rolling shear strength and stiffness tests derived from short span bending tests on E. nitens CLT panels.

2.6.3. Pure Rolling Shear Tests

To obtain the rolling shear strength and stiffness properties, EN 16351 [30] stipulates a minimum of 12 test specimens; therefore, 14 three-layer CLT specimens (75 mm thickness) were tested in this study. The geometrical arrangement of each specimen was selected to keep the angle of inclination to a minimum to reduce the effect of perpendicular load actions, as shown in Figure 3. The rolling shear strength was calculated using Equations (7) and (8).

where Fmax is the applied force at failure, θ is the angle of inclination equal to 11.5°, l is the depth of the shear area of the specimen, w is the width of the shear area of the specimen and t is the thickness of the specimen.

Figure 3.

Rolling shear strength and stiffness derived from pure rolling shear tests on E. nitens CLT panels.

2.7. Modelling CLT Mechanical Properties

The theoretical maximum bending stress and stiffness were calculated using the shear analogy method. Stress calculations were performed using the mechanical properties of the laminates. Equation (9) enables calculation of the theoretical CLT bending stiffness based on the mechanical and geometrical properties of each layer [52]. This value was later used as an input in the bending strength calculation, presented in Equation (10) [26]. This equation considers the shear deformation of the cross layers on the final strength. Both theoretical bending strength and stiffness were used to compare the experimental results against the theoretical models to validate the use of the shear analogy method in plantation hardwood CLT elements subjected to bending.

where bi is the width, hi is the thickness, Ai is the area of each layer, zi is the distance from the centroid of each layer and the neutral axis, Ei is the MOE for longitudinal layers, Mult is the maximum applied bending moment at failure point and EIeff is effective bending stiffness.

3. Results

3.1. Solid and Finger-Jointed Timber Strength and Stiffness

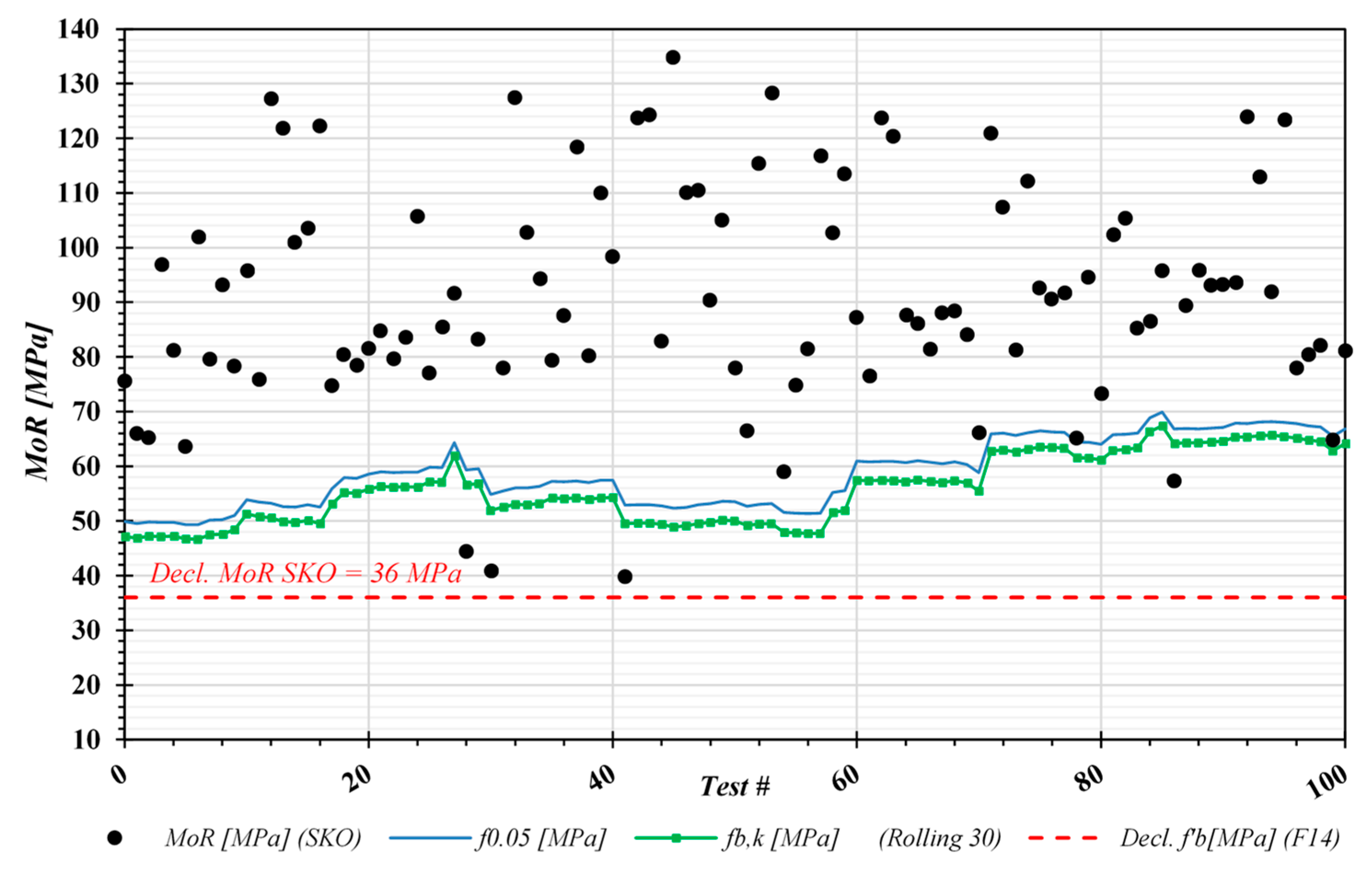

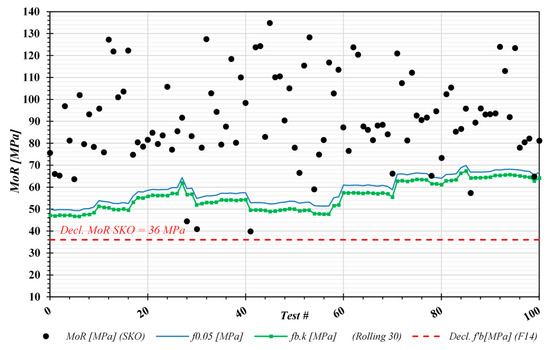

Figure 4 presents the bending strength results of solid timber specimens over 100 tests. The blue line shows the fifth percentile, and the green line shows the characteristic strength of the last 30 tests calculated as per AS 4063.2 [53]. The red dotted line is the value declared as the bending strength of E. nitens boards for longitudinal lamellas. As is evident, all values were above the declared MOR equal to 36 MPa. In addition, the rolling characteristic bending strength was slightly below the fifth percentile, as it was already accounting for the spread of the test results, as established in AS 4063.2 [53]. These results showed that, despite the variation in timber properties and characteristics, the bending strength for longitudinal lamellas of CLT was always equal or superior to the declared property.

Figure 4.

Bending strength of solid timber specimens over 100 tests.

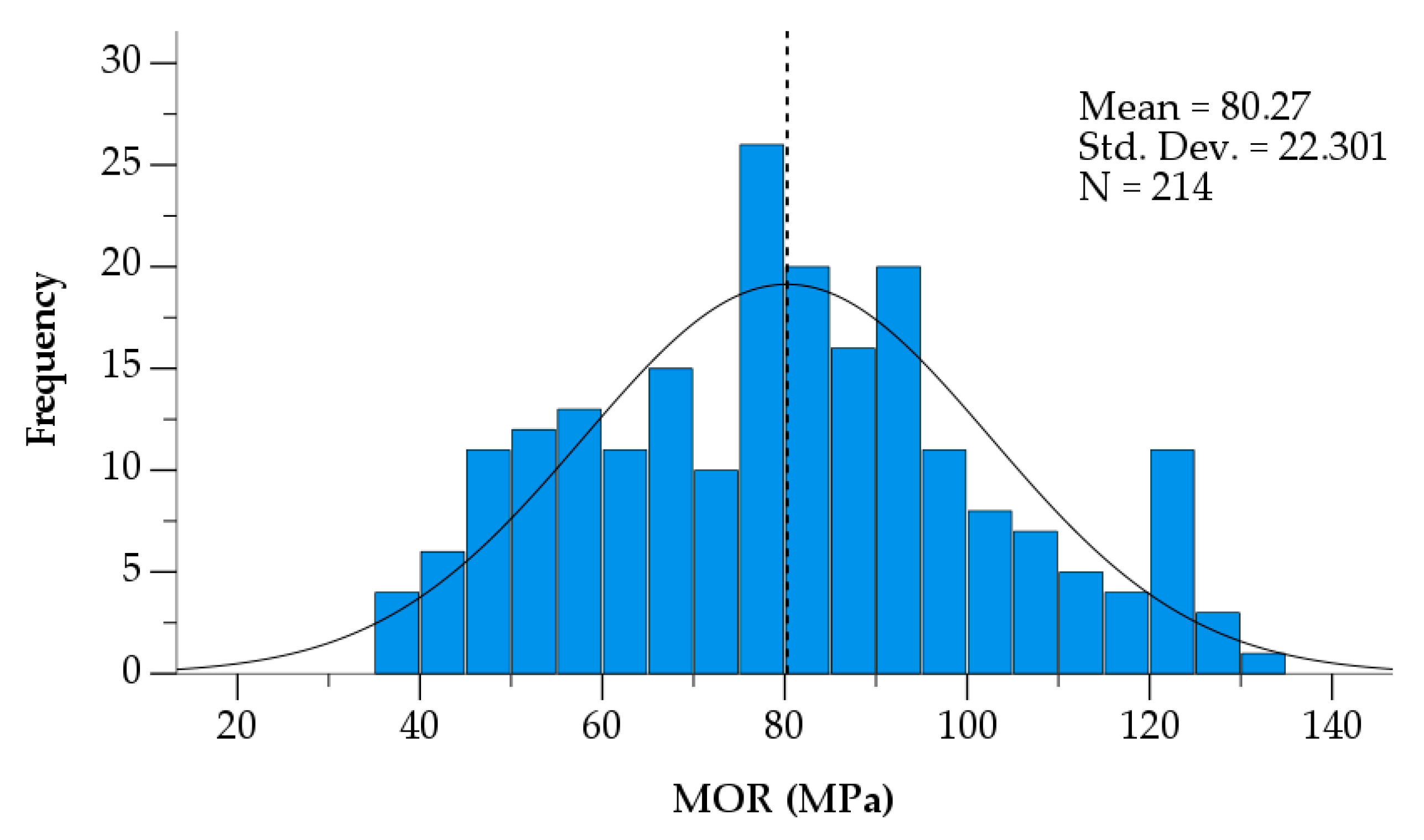

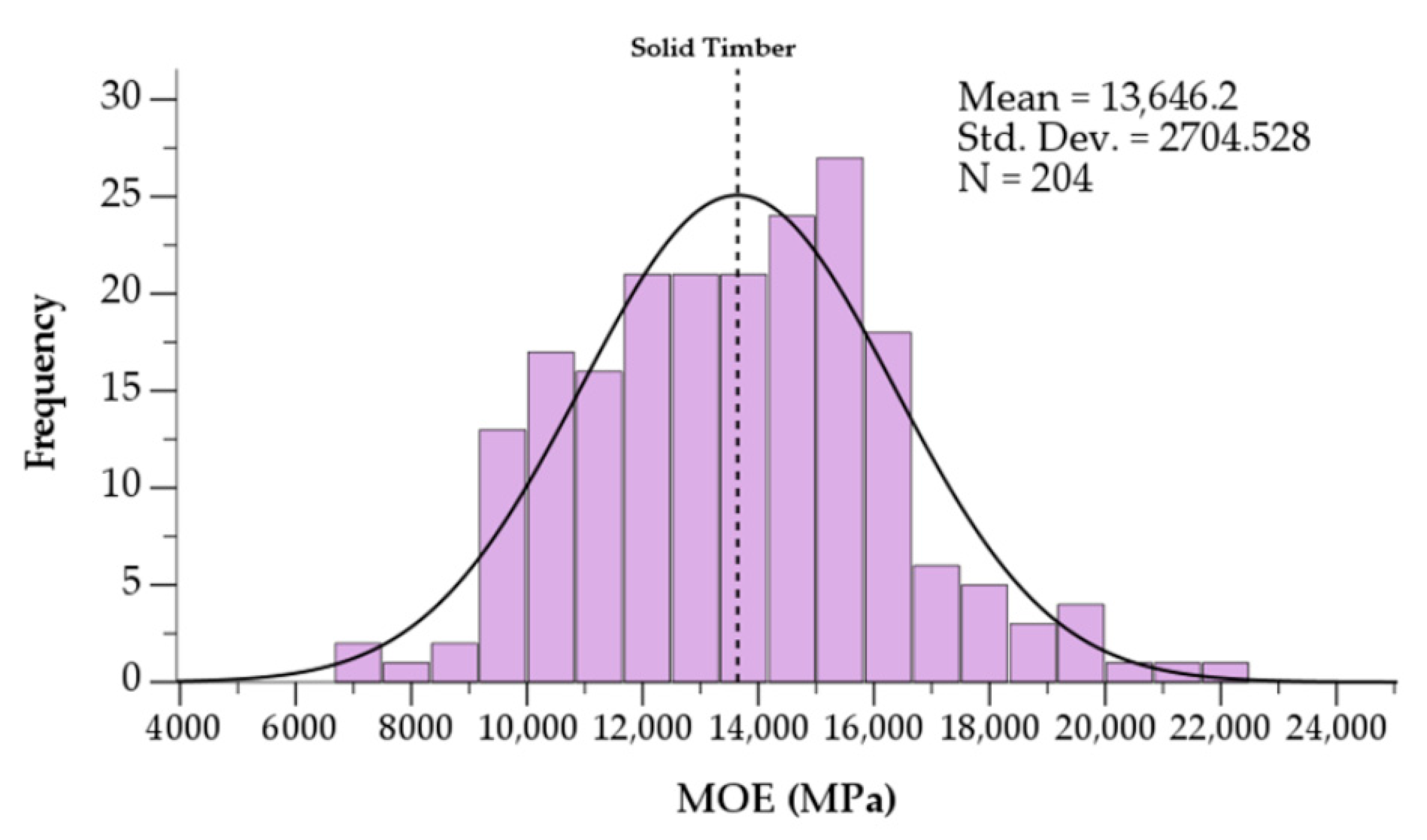

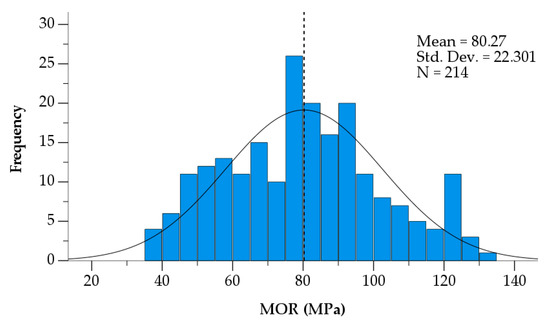

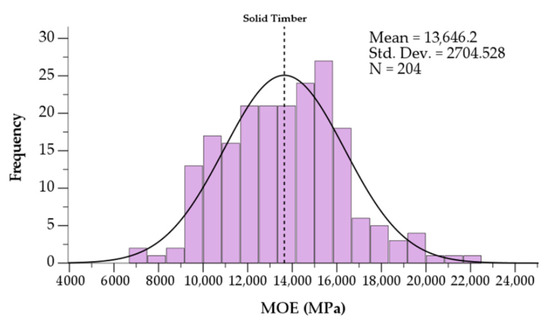

Figure 5 and Figure 6 illustrate the MOR and MOE of a population of solid timber samples taken from the outer layers of E. nitens CLT. As can be observed, the average MOR was 80.27 MPa and the average MOE was 13,646 MPa. The population shows a normal distribution with the fifth percentile above the declared property for longitudinal lamellas.

Figure 5.

Histogram of MOR of solid timber specimens from the outer layers of E. nitens CLT for a population of 214 specimens.

Figure 6.

Histogram of MOE of solid timber specimens from the outer layers of E. nitens CLT for a population of 204 specimens.

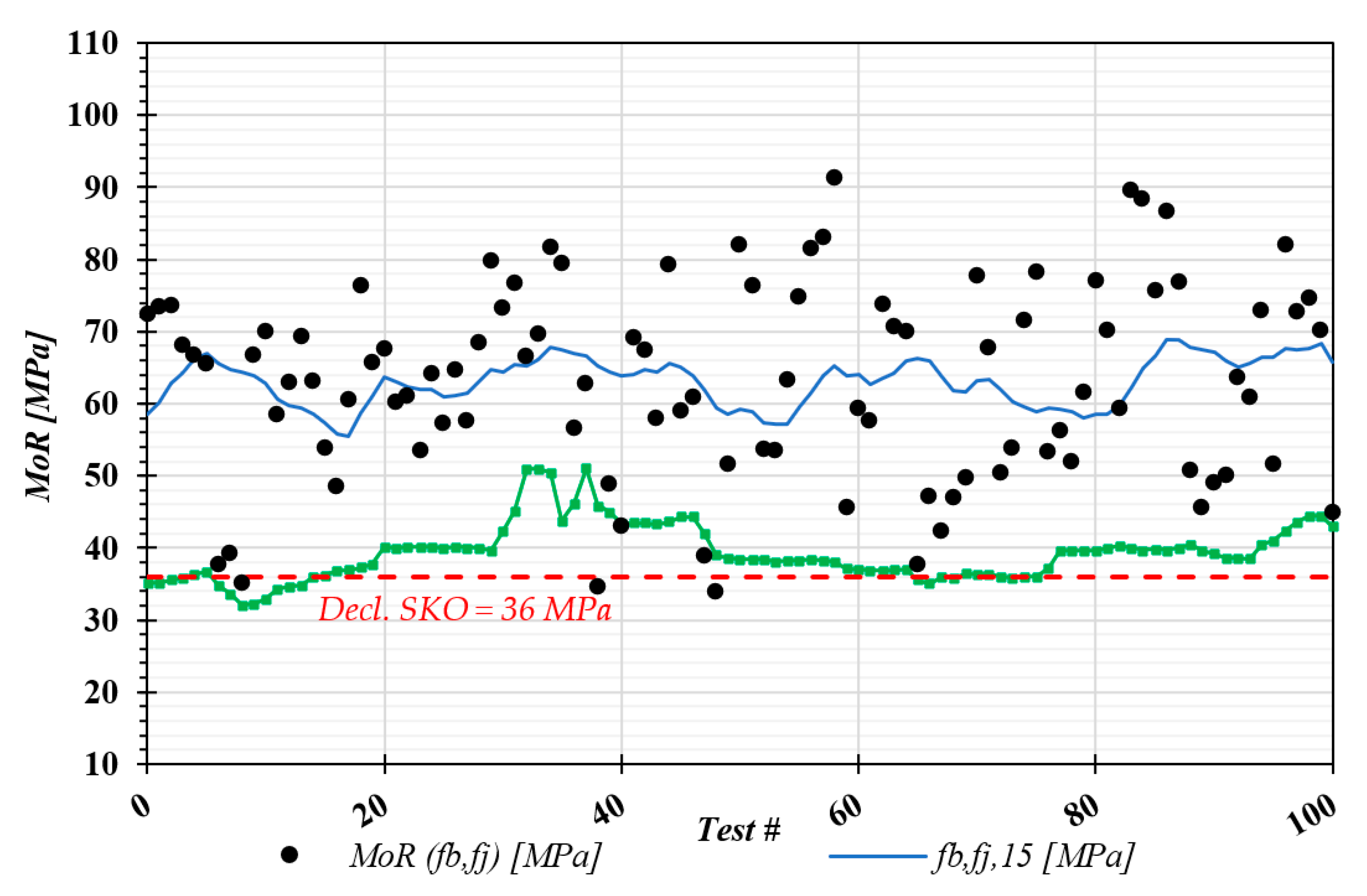

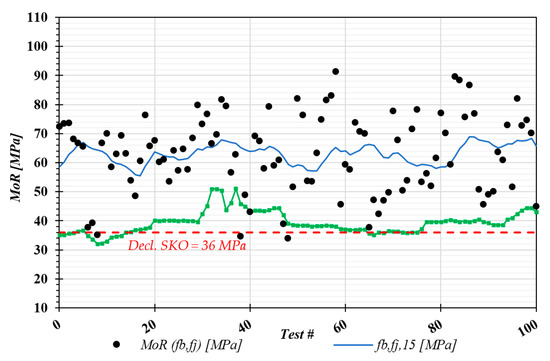

Figure 7 presents the bending strength of finger-jointed lamellas tested as per AS 5068 [48] for 100 specimens, with a finger joint length of 15 mm. The graph shows the average bending strength of the last rolling fifteen test results and the characteristic bending strength of the rolling 30 test results. The dotted line shows the declared bending strength for the longitudinal lamella. The strength of finger joints was lower than the reported bending strength of solid timber. Nevertheless, the results show the characteristic strength was consistently equal or superior to the declared strength for longitudinal lamellas, which is equal to 36 MPa. Only three out of 100 tests were below the declared value, which is allowed as long as the average value is higher than the declared property after accounting for the spread of the results.

Figure 7.

Bending strength of finger-jointed timber over 100 tests (finger length = 15 mm).

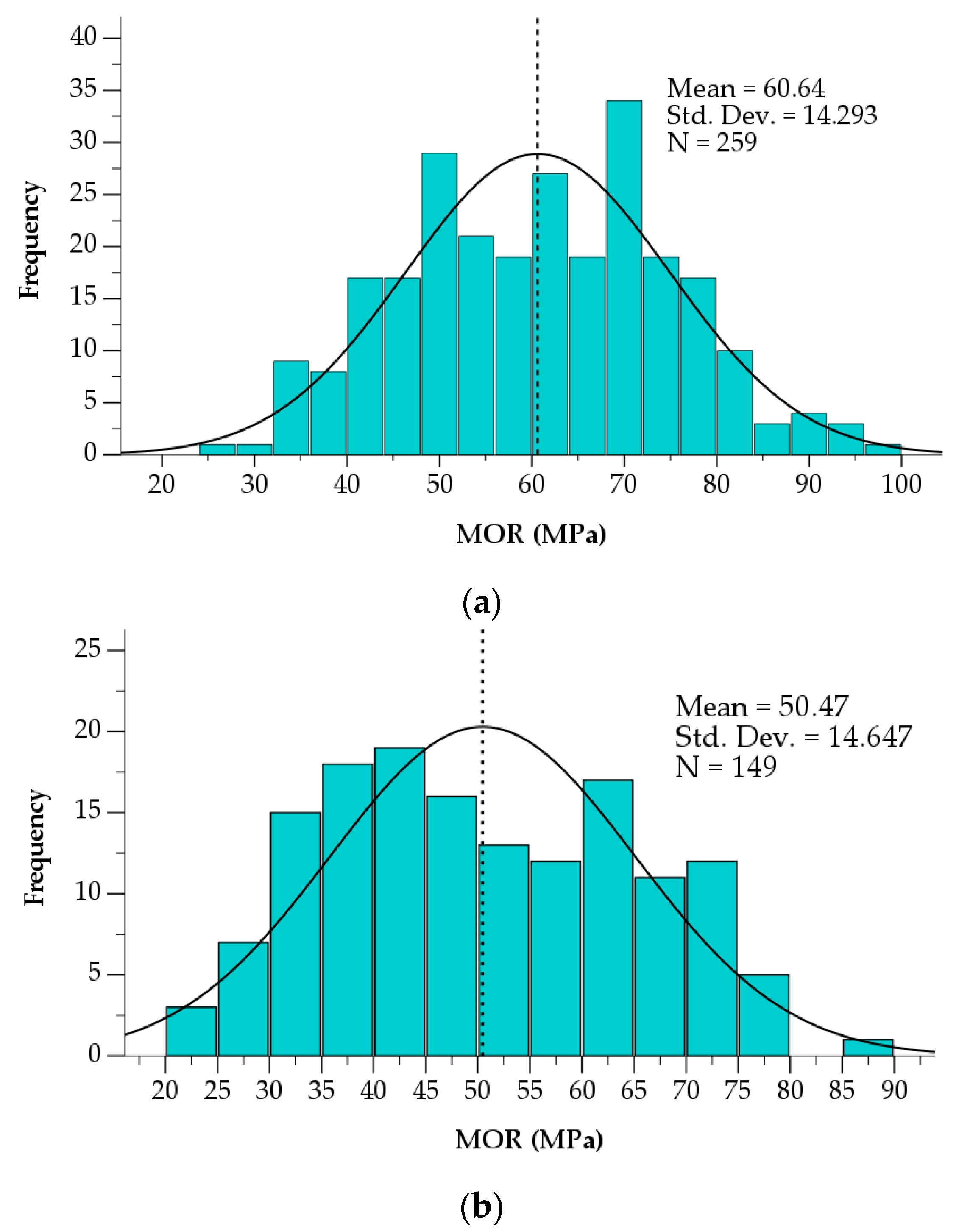

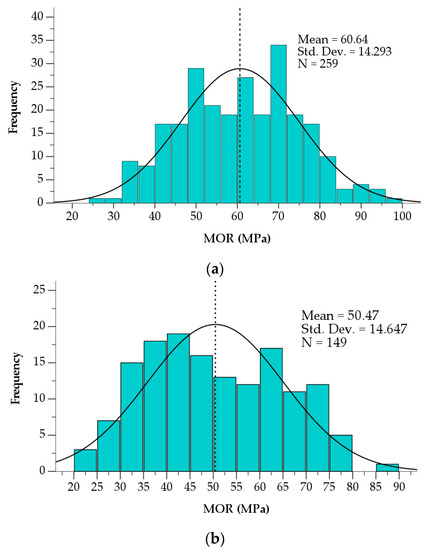

Finger joint strength needs to be constantly monitored and controlled in both longitudinal and crossed lamellas. Figure 8 presents the bending strength distribution for both types of boards with 15 mm finger joints. The histogram in Figure 8a shows the finger joint strength for the longitudinal lamellas used in CLT, which are the ones that take all the longitudinal stiffness and strength in one-way flooring applications, while the histogram in Figure 8b shows the strength for the crossed finger-jointed lamellas used in CLT. It can be observed from the graph that the average MOR of longitudinal lamellas was equal to 60.6 MPa (SD = 14.3 MPa) whereas the MOR for crossed lamellas was equal to 50.47 MPa (SD = 14.3 MPa), with both having a finger joint length of 15 mm. The finger joint bending strength was also calculated in lamellas with finger joints of 10 mm. However, these lamellas showed lower strength than those with the 15 mm finger joints. The average MOR of longitudinal lamellas with 10 mm finger joints equalled 47.8 MPa (SD = 9.3 MPa). As the 10 mm finger joint presented a lower strength, this geometry was disregarded for the second iteration of CLT production, and these lamellas were no longer used. Therefore, no graphs and analysis are presented for this finger joint profile.

Figure 8.

Histograms of MOR of finger-jointed timber (finger length = 15 mm); longitudinal lamellas (a) and cross lamellas (b).

Table 2 summarises the average strength and stiffness results for the longitudinal and crossed lamellas used to manufacture CLT panels. Additionally, the table presents the declared properties chosen to design and characterise the properties of the feedstock required to manufacture the CLT panels based on the properties of the individual longitudinal lamellas.

Table 2.

Average strength and stiffness of the boards used in CLT panels.

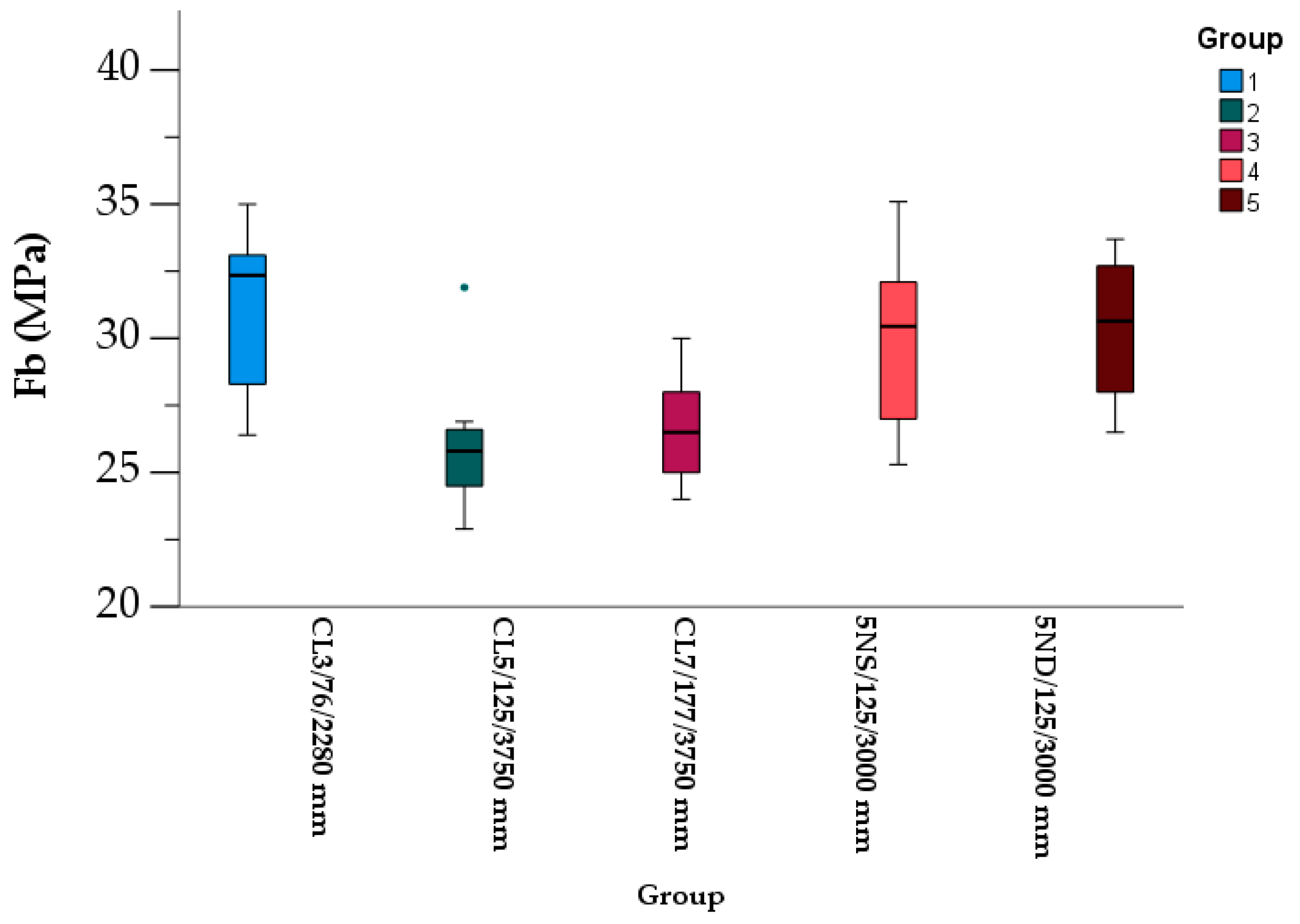

3.2. CLT Bending Strength Out-Of-Plane

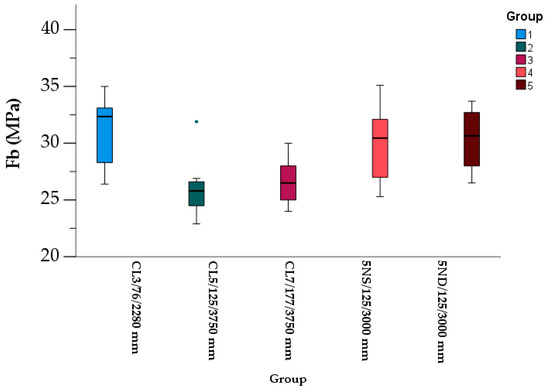

Figure 9 presents the results of bending tests performed on panels with different thickness, spans and layup configurations as presented in Table 1. This first round of tests was performed on panels with finger-jointed lamellas with a finger joint length of 10 mm, then panels with finger-jointed lamellas of 15 mm finger joint lengths were tested to assess the strength with this geometry. Panel 5NS corresponds to five-layer panels with finger joint length of 15 mm and single layers oriented perpendicular to each other. Panel 5ND is a five-layer panel with finger joint length of 15 mm where the outer two layers are oriented in the same direction.

Figure 9.

Box plots for CLT bending strength (fb) of E. nitens panels with different layups and different finger joint lengths.

The five-layer CLT panel (5NS) with 15 mm finger joints had 16% and 17% higher strength than the CL5 and CL7, respectively, which were manufactured with 10 mm finger joints. The three-layer panel (CL3) displayed a higher average strength than the CL5 and CL7 with the same finger joint geometry, but the strength was very similar to the 5NS panel with 15 mm finger joints. As the results from all groups were quite different, it is better to analyse them separately. However, the design values can be taken from the most conservative values out of all the test results, and therefore, the declared CLT bending strength was calculated from the results of all test specimens.

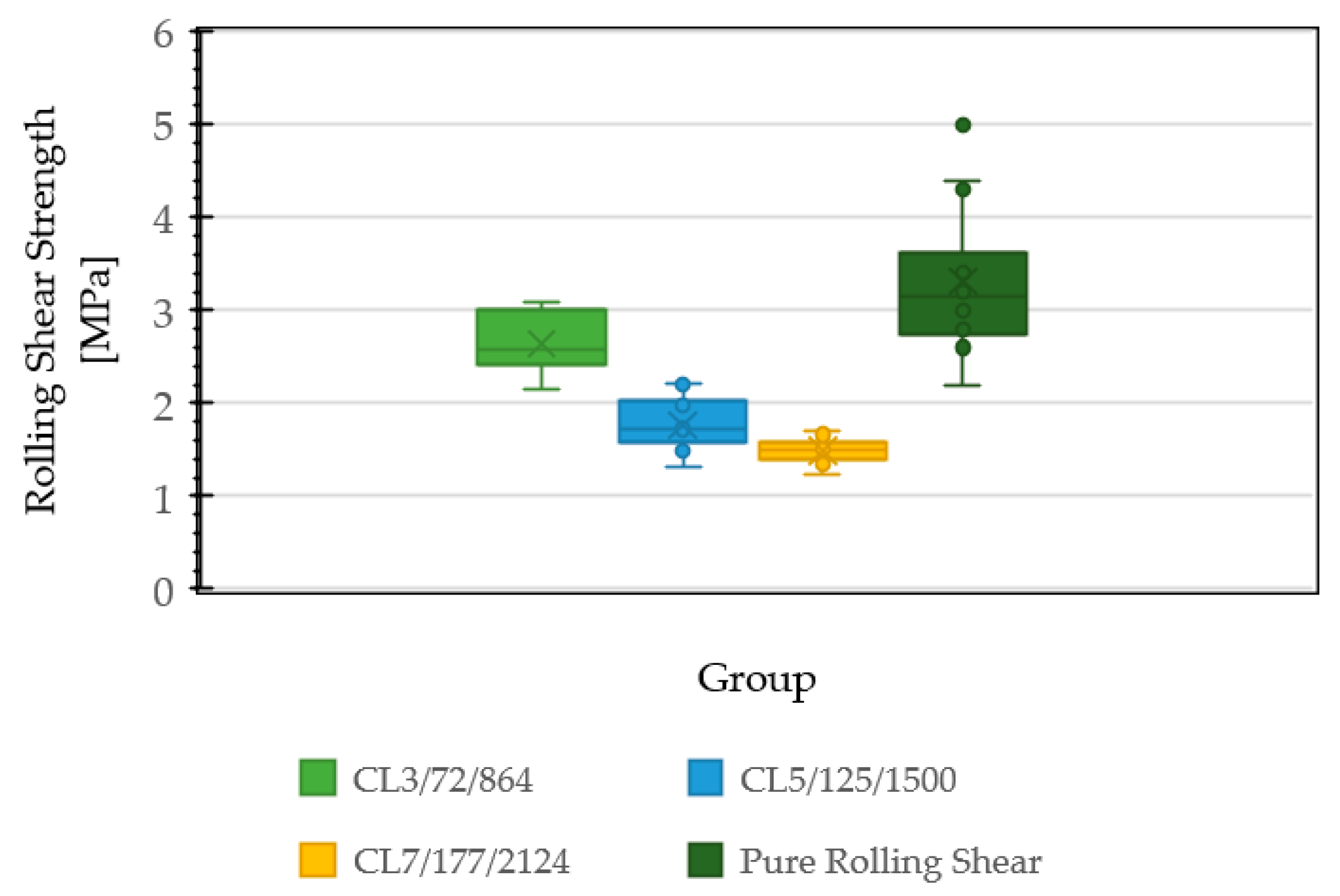

3.3. CLT Rolling Shear Strength

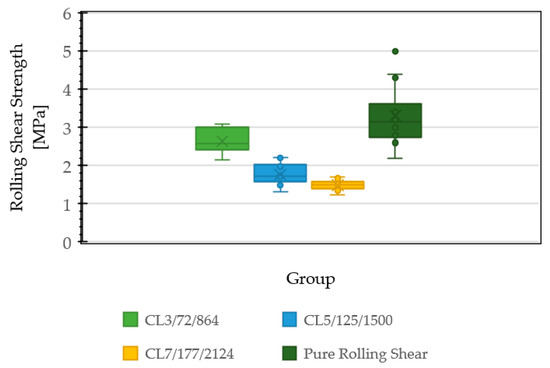

Two different types of tests were performed to obtain the rolling shear strength (rolling shear by bending test and pure rolling shear). The rolling shear calculated through the bending tests with short spans did not show the expected failure modes, as all the samples failed with a rupture of the tensile side (bending failure mode) due to the low strength of the finger-jointed lamellas. Therefore, only pure rolling shear tests were considered to obtain the declared rolling shear properties of the panels.

Figure 10 presents the results of the experimental tests conducted for both bending and pure rolling shear tests to calculate the rolling shear strength of E. nitens CLT. The graph shows that the rolling shear strength obtained with pure rolling shear tests was significantly higher than the one obtained through bending tests. The average rolling shear obtained from the pure rolling shear tests was 3.3 MPa (SD = 0.7 MPa), whereas the results for rolling shear strength calculated for the panels tested in bending were 2.6, 1.8 and 1.5 MPa for the CL3, CL5 and CL7 samples (SD = 0.3, 0.3 and 0.1 MPa), respectively. As no rolling shear failures were observed in the bending tests, the rolling shear strength results obtained from testing panels CL3, CL5 and CL7 were omitted for obtaining the declared rolling shear strength used to design the E. nitens CLT panels.

Figure 10.

Box plots for CLT rolling shear strength (fs) of E. nitens panels with different layups and different finger joint lengths. Results for CL3, CL5 and CL7 panels were obtained through bending tests, whereas pure rolling shear tests were performed only on 3-layer panels.

Table 3 summarises the average bending and rolling shear strength results obtained from testing E. nitens CLT panels. Additionally, the table presents the preferred properties to design the E. nitens CLT, after accounting for the variation and spread in the results.

Table 3.

Bending properties of the tested CLT panels.

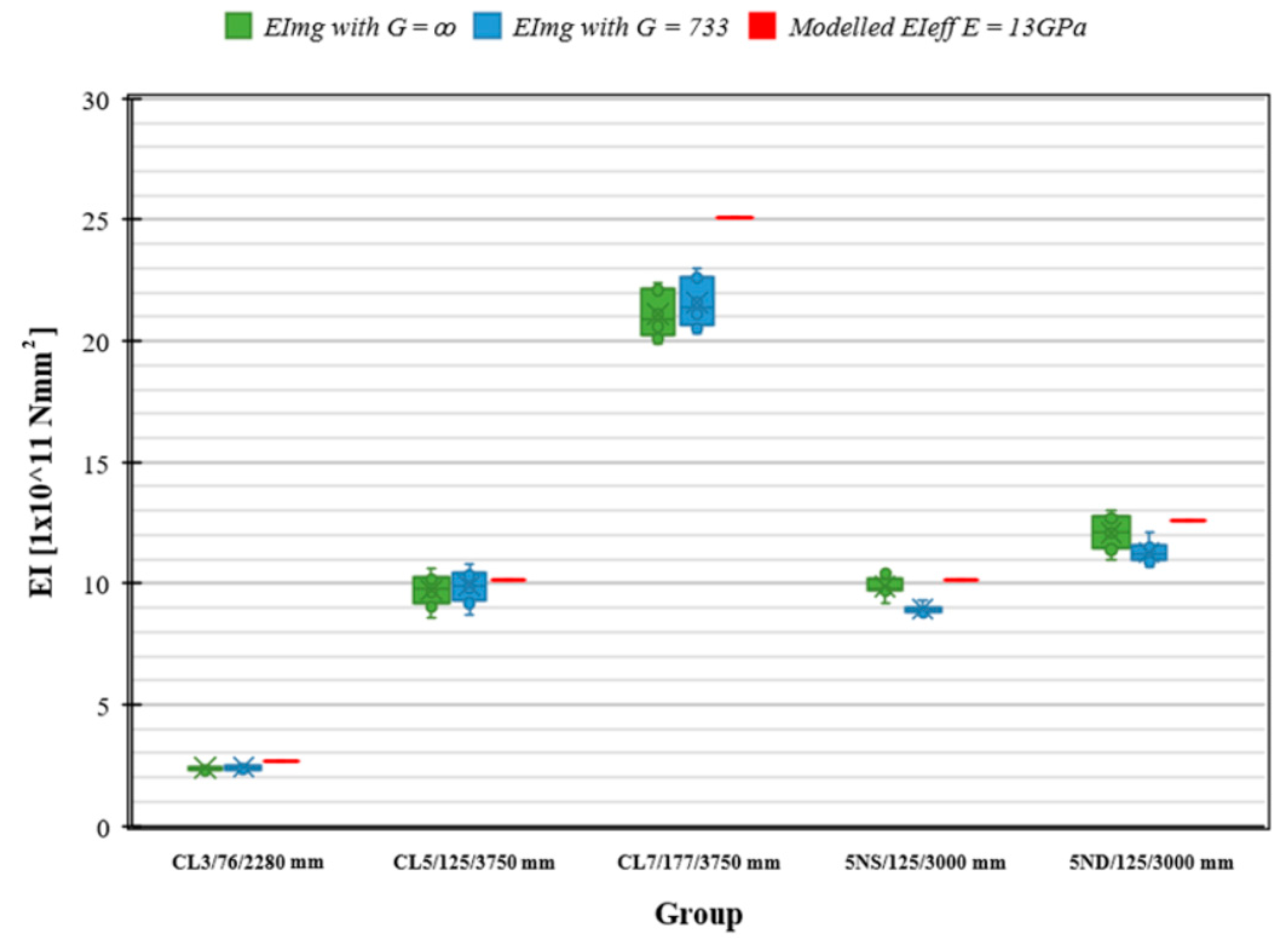

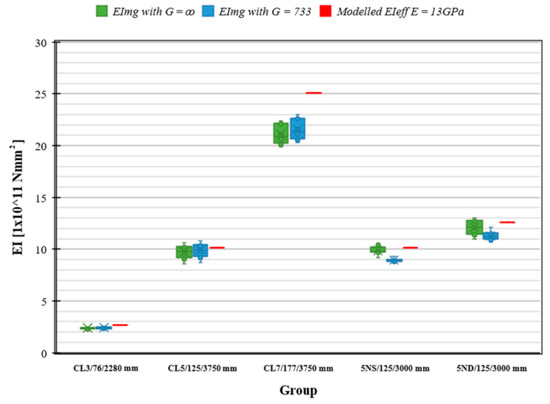

3.4. Experimental and Modelled Bending Stiffness (EI)

Figure 11 shows the bending stiffness obtained in the tests performed on the CLT panels with different geometries and configurations. Furthermore, the experimental tests results are compared against the modelled stiffness obtained by the shear analogy method presented in Section 2.7. As expected, thicker panels presented higher stiffness. It can be observed that the finger joint geometry did not affect the stiffness because group CL5 had a similar stiffness to group 5NS. However, there was a significant stiffness gain in panels with double outer lamellas, in both experimental and modelled results, since panels from the 5ND group presented higher stiffness than group 5NS. From the graph, it can be observed that all the experimental results matched very well with the modelled results when an MOE of 13,000 MPa was used to describe the stiffness of the longitudinal boards.

Figure 11.

Box plots for CLT bending stiffness of E. nitens panels with different layups and different finger joint lengths, with the modelled bending stiffness using the shear analogy method.

4. Discussion

The results showed that the average MOE of the feedstock was 13,646 MPa, which was larger than those reported by Pangh et al. [17] for E. nitens boards. The characteristic MOE values of the feedstock were similar to the E. nitens feedstock reported by Ettelaei et al. [5]. The average value for the bending strength of the longitudinal lamellas was significantly higher than the average bending strength reported for the crossed layers. These results reflect the visual and mechanical characteristics of the two grades created to manufacture the panels to optimise the resource.

Finger joint bending test results demonstrated that 15 mm finger lengths have approximately 26 % higher MOR than lamellas with finger joints of 10 mm of the same grade, as reported by Franke et al. [46]. CLT panels manufactured with 15 mm finger lengths also proved stronger, with an average bending strength up to 17% higher than those manufactured with 10 mm fingers. These results enabled the manufacturer to conclude that E. nitens CLT should be manufactured with 15 mm finger lengths, as these showed better performance in both lamella and panel.

The average bending strength value for the three, five and seven-layer CLT panels were, respectively, 31.3 MPa, 26.0 MPa and 26.8 MPa. The results showed that there was no relationship between the bending strength and panel thickness, which agrees with Li et al. [25]. In addition, Navaratnam et al. [26] highlighted there was no significant impact of the panel thickness on the bending strength. The obtained bending strength values for the three- and five-layer CLT panels were also higher than those obtained from Australian radiata three- and five-layer CLT panels [26].

Although the design values for the CLT were calculated using all test results (with both 10 and 15 mm finger-jointed lamellas) to account for the worst-case scenario, the manufacturing specifications require the panels to be manufactured with 15 mm fingers, which proved to be stronger. This allowed the manufacturer to demonstrate the theoretical method’s validity and achieve a minimum number of tested samples to calculate the design parameter values with a larger sample size. Nevertheless, future research can focus on taking advantage of the higher strength of 15 mm finger joints to claim a higher design bending strength for CLT panels manufactured exclusively with this finger joint geometry.

The bending strength of the three-layer CLT panels was higher than those of three-layer non-edge-glued CLT panels made from Karamatsu larch (29.6 MPa) reported by He et al. [54]. The bending strength values of the CLT panels were lower than the E. nitens CLT without finger joints reported by Ettelaei et al. [4]. These researchers tested E. nitens CLT panels using high-grade boards in cross layers in one configuration and high-grade boards for outer layers in another configuration. This demonstrates that there is a possibility to manufacture panels with higher bending strength if finger joint strength and grading is improved. This agrees with Steiger et al. [55], who highlighted that adequate strength grading to improve the homogenisation of a CLT panel can improve overall CLT stiffness, much like the nature of finger jointing in this research which was used to improve visual grade homogenisation. In addition, they reported that the influence of natural features such as knots in smaller width specimens affect the load bearing behaviour, which could be further investigated for plantation hardwood CLT, which has a high presence of natural strength-reducing features.

The average rolling shear strength of the CLT panels was 3.3 MPa, similar to that of CLT panels made from the same species reported by Ettelaei et al. [6]. These researchers claimed that the rolling shear strength of CLT specimens made from high-class boards in outer layers and cross layer were, respectively, 3.4 MPa and 3.1 MPa. In panels manufactured with feedstock of high shear strength, bending tests are not very effective in capturing rolling shear failures since the governing failure mode is bending failure in the finger joints. Therefore, the rolling shear strength is underestimated as panels fail in bending rather than shear.

Given the various and frequent strength-reducing characteristics present in E. nitens, and the need to have various custom-length timber boards to manufacture CLT panels, the bond quality and strength of finger joints are critical for the performance of CLT, as they play a significant role in the final strength of the panels. Controlling variables such as the finger joint geometry, the adhesive, the amount of adhesive, the type of application, the clamping pressure and time are fundamental to achieve the desired strength [27]. A significant effort needs to be put into improving, controlling and monitoring the performance of E. nitens finger joint strength and bond quality [18].

The bond quality of the glue lines is critical for achieving an adequate shear and bending strength in CLT. No delamination was observed during the tests; therefore, a composite action of the lamellas can be assumed to calculate the strength and stiffness of the panels. Permanent quality control is required to test the performance of the glue lines. One-component polyurethane (Adhesive type 1 according to EN 15425 [56] and AS/NZS 4364 [47]) was used to manufacture the E. nitens panels. European standards were used to test the performance of the CLT glue lines. However, EN standards for CLT only cover certain species, and E. nitens is not included in that list [18]. The manufacturer involved in this research has worked closely with different glue manufacturers to ensure that the bond quality of their products meets the specific requirements prescribed in those standards and achieves the same performance levels as other products made of traditional wood species. Some relevant parameters controlled during the manufacturing process include environmental conditions, wood surface temperature, wood surface preparation, wood dimensions, wood MC, glue rates, glue spread, glue quality, applied pressure, assembly time and pressing time.

When comparing the modelled stiffness against the experimental test results, it can be observed that the models show good agreement with the experimental data. The models used the declared properties presented in the characterisation of the feedstock. These results demonstrated that the shear analogy method can be used to accurately predict the structural performance of CLT panels manufactured with plantation hardwoods grown in Tasmania, as has been demonstrated for panels manufactured with other species such as spruce or radiata pine [26]. If the feedstock quality (strength and stiffness), the finger joint strength and the bond quality is controlled and monitored during the manufacturing process, the mechanical properties of the boards can be used to accurately predict the structural performance of CLT panels used as load-bearing materials in flooring applications [57].

5. Conclusions

Results from bending tests in solid timber boards showed that the average MOR for E. nitens feedstock using longitudinal lamellas was 80.3 MPa and the average MOE was 13,646 MPa. After calculating the characteristic strength and stiffness as per AS 4063.1 [50], the declared MOR and MOE for the solid timber boards were 36 MPa and 13,000 MPa, respectively.

Two different grades were created for the longitudinal and crossed lamellas to manufacture CLT panels. The longitudinal and crossed lamellas with finger joints of 15 mm presented an average MOR of 60.6 MPa and 50.5 MPa, respectively. The declared properties disclosed for design were 36 and 25 MPa, respectively.

Finger joint tests showed that the bending strength of finger-jointed lamellas with 15 mm finger joints was significantly higher than those manufactured with 10 mm finger joints. This can be reflected in the bending strength of CLT panels.

The bending strength of CLT panels with 10 mm finger joints were relatively consistent with samples averaging 31.3 MPa for CL3, 26.0 MPa for CL5 and 26.8 MPa for CL7. CLT panels with finger joint lengths of 15 mm presented a slightly higher bending strength, as 5NS had an average bending strength of 30.0 MPa and 5ND was 30.3 MPa. Although the bending strengths of the two groups were slightly different, the declared property was calculated using the lowest strength; therefore, the design bending strength of E. nitens CLT was 24.0 MPa.

The mean maximum rolling shear stresses obtained from bending tests averaged 2.64, 1.76 and 1.49 MPa for the CL3, CL5 and CL7 samples, respectively, indicating lower shear stresses for thicker CLT sections, in line with existing research. When averaging all the tests results, the average shear strength was 1.9 MPa. However, these results from the bending tests were excluded to obtain the rolling shear strength of CLT as they did not show rolling shear failures, but rather finger joint failures in the tensile side of the panels.

The average rolling shear strength obtained from pure rolling shear tests was 3.3 MPa, and the design rolling shear strength of E. nitens was chosen as 2.0 MPa. These results also align with the recent literature on E. nitens.

The measured flexural stiffness showed very good agreement with the theoretical method (shear analogy) used to estimate the flexural stiffness of CLT. Results from the models and experiments demonstrated that the method can be safely used to predict the flexural strength and stiffness of E. nitens CLT based on the declared properties of the feedstock presented in this study.

Based on the results presented in this study, it can be concluded that the E. nitens CLT panels performed as predicted during testing and demonstrated out-of-plane performance comparable to that of existing CLT products on the market. With an appropriate quality assurance framework during manufacturing, the panels can be safely used in structural applications with respect to their out-of-plane flexural and shear performance. These data established a basis for the commercial use of Australian plantation hardwood CLT in structural applications such as floors and roofs in commercial and residential buildings.

Author Contributions

Conceptualization, M.G., A.E. and N.K.; methodology, M.G.; software, M.G. and A.E.; validation, M.G., A.E. and N.K.; formal analysis, M.G. and A.E.; investigation, M.G.; resources, M.G., N.K. and M.L.; data curation, A.E.; writing—original draft preparation, M.G., A.E. and N.K.; writing—review and editing, N.K. and M.L.; visualization, M.G. and A.E.; supervision, N.K. and M.L.; project administration, M.G. and N.K.; funding acquisition, N.K. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data unavailable due to privacy restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Legg, P.; Frakes, I.; Gavran, M. Australian Plantation Statistics and Log Availability Report 2021; ABARES research report; Australian Bureau of Agricultural and Resource Economics and Sciences: Canberra, Australia, 2021. [CrossRef]

- Australian Forest Products Association. Australia Faces a Critical Housing Timber Shortage by 2050: FWPA Report. 2022. Available online: https://ausfpa.com.au/australia-faces-a-critical-housing-timber-shortage-by-2050-fwpa-report/ (accessed on 1 November 2022).

- Kurzinski, S.; Crovella, P.; Kremer, P. Overview of Cross-Laminated Timber (CLT) and Timber Structure Standards Across the World. Mass Timber Constr. J. 2022, 5, 1–13. Available online: https://www.journalmtc.com/index.php/mtcj/article/view/29 (accessed on 1 November 2022).

- Ettelaei, A.; Taoum, A.; Shanks, J.; Nolan, G. Evaluation of the bending properties of novel cross-laminated timber with different configurations made of Australian plantation Eucalyptus nitens using experimental and theoretical methods. Structures 2022, 42, 80–90. [Google Scholar] [CrossRef]

- Ettelaei, A.; Taoum, A.; Nolan, G. Assessment of Different Measurement Methods/Techniques in Predicting Modulus of Elasticity of Plantation Eucalyptus nitens Timber for Structural Purposes. Forests 2022, 13, 607. [Google Scholar] [CrossRef]

- Ettelaei, A.; Taoum, A.; Shanks, J.; Nolan, G. Rolling Shear Properties of Cross-Laminated Timber Made from Australian Plantation Eucalyptus nitens under Planar Shear Test. Forests 2022, 13, 84. [Google Scholar] [CrossRef]

- Ettelaei, A.; Taoum, A.; Nolan, G. Rolling shear properties of cross-laminated timber made of fibre-managed plantation eucalyptus under short-span bending. Wood Mater. Sci. Eng. 2021, 17, 744–751. [Google Scholar] [CrossRef]

- Derikvand, M.; Jiao, H.; Kotlarewski, N.; Lee, M.; Chan, A.; Nolan, G. Bending performance of nail-laminated timber constructed of fast-grown plantation eucalypt. Eur. J. Wood Wood Prod. 2019, 77, 421–437. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Chan, A.; Nolan, G. Short-term and long-term bending properties of nail-laminated timber constructed of fast-grown plantation eucalypt. Constr. Build. Mater. 2019, 211, 952–964. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown Eucalyptus nitens H. Deane & Maiden lumber. Forests 2019, 10, 194. [Google Scholar]

- Derikvand, M.; Bignell, M.; Balasso, M.; Kotlarewski, N.; Jiao, H.; Lee, M.; Nolan, G. Multi-disciplinary optimisation of nail-laminated timber-concrete composite panels constructed of fibre-managed plantation eucalypt. In Proceedings of the 61st International Convention of Society of Wood Science and Technology and Japan Wood Research Society, Nagoya, Japan, 5–9 November 2018; pp. 1–6. [Google Scholar]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Chan, A.; Nolan, G. Visual stress grading of fibre-managed plantation Eucalypt timber for structural building applications. Constr. Build. Mater. 2018, 167, 688–699. [Google Scholar] [CrossRef]

- Derikvand, M.; Nolan, G.; Jiao, H.; Kotlarewski, N. What to do with structurally low-grade wood from Australia’s plantation eucalyptus; building application? BioResources 2017, 12, 4–7. [Google Scholar] [CrossRef]

- Jiao, H.; Nolan, G.; Lee, M.; Kotlarewski, N.; Derikvand, M. Developing High-Mass Laminated Flooring Products from Fibre-Managed Plantation Hardwood; Forest & Wood Products Australia: Melbourne, Australia, 2019. [Google Scholar]

- Kotlarewski, N.J.; Derikvand, M.; Lee, M.; Whiteroad, I. Machinability study of Australia’s dominate plantation timber resources. Forests 2019, 10, 805. [Google Scholar] [CrossRef]

- Kotlarewski, N.; Taylor, L.; Booth, P. Embracing natural timber features of plantation hardwood: Material-aware digital workflows in product design and development. In Proceedings of the 52nd International Conference of the Architectural Science Association (ANZAScA) Engaging Architectural Science: Meeting the Challenges of Higher Density, Melbourne, Australia, 28 November–1 December 2018. [Google Scholar]

- Pangh, H.; Hosseinabadi, H.Z.; Kotlarewski, N.; Moradpour, P.; Lee, M.; Nolan, G. Flexural performance of cross-laminated timber constructed from fibre-managed plantation eucalyptus. Constr. Build. Mater. 2019, 208, 535–542. [Google Scholar] [CrossRef]

- Gutierrez, M.; Kotlarewski, N.; Lee, M. Mass Timber Alternatives in Construction with Plantation Hardwoods. In Proceedings of the 2022 SWST International Conference, Kingscliff, Australia, 10–15 July 2022; pp. 33–41. [Google Scholar]

- Ehrhart, T.; Brandner, R. Rolling shear: Test configurations and properties of some European soft-and hardwood species. Eng. Struct. 2018, 172, 554–572. [Google Scholar] [CrossRef]

- Niederwestberg, J.; Zhou, J.; Chui, Y.-H. Comparison of Theoretical and Laboratory Out-of-Plane Shear Stiffness Values of Cross Laminated Timber Panels. Buildings 2018, 8, 146. [Google Scholar] [CrossRef]

- Ma, Y.; Musah, M.; Si, R.; Dai, Q.; Xie, X.; Wang, X.; Ross, R.J. Integrated experimental and numerical study on flexural properties of cross laminated timber made of low-value sugar maple lumber. Constr. Build. Mater. 2021, 280, 122508. [Google Scholar] [CrossRef]

- Mohd Yusof, N.; Md Tahir, P.; Lee, S.H.; Khan, M.A.; Mohammad Suffian James, R. Mechanical and physical properties of Cross-Laminated Timber made from Acacia mangium wood as function of adhesive types. J. Wood Sci. 2019, 65, 20. [Google Scholar] [CrossRef]

- Hindman, D.P.; Bouldin, J.C. Mechanical Properties of Southern Pine Cross-Laminated Timber. J. Mater. Civ. Eng. 2015, 27, 04014251. [Google Scholar] [CrossRef]

- O’Ceallaigh, C.; Sikora, K.; Harte, A. The Influence of Panel Lay-Up on the Characteristic Bending and Rolling Shear Strength of CLT. Buildings 2018, 8, 114. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Subhani, M.; Kremer, P.; Kafle, B.; Ghabraie, K. Experimental and numerical study on bending properties of heterogeneous lamella layups in cross laminated timber using Australian Radiata Pine. Constr. Build. Mater. 2020, 247, 118525. [Google Scholar] [CrossRef]

- Navaratnam, S.; Christopher, P.B.; Ngo, T.; Le, T.V. Bending and shear performance of Australian Radiata pine cross-laminated timber. Constr. Build. Mater. 2020, 232, 117215. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Subhani, M.; Kremer, P.; Li, H.; Anwar-Us-Saadat, M. Rolling shear properties of cross-laminated timber (CLT) made from Australian Radiata Pine—An experimental study. Structures 2021, 33, 423–432. [Google Scholar] [CrossRef]

- Liao, Y.; Tu, D.; Zhou, J.; Zhou, H.; Yun, H.; Gu, J.; Hu, C. Feasibility of manufacturing cross-laminated timber using fast-grown small diameter eucalyptus lumbers. Constr. Build. Mater. 2017, 132, 508–515. [Google Scholar] [CrossRef]

- Nero, R.; Christopher, P.; Ngo, T. Investigation of rolling shear properties of cross-laminated timber (CLT) and comparison of experimental approaches. Constr. Build. Mater. 2022, 316, 125897. [Google Scholar] [CrossRef]

- BS EN, 16351; Timber Structures—Cross-Laminated Timber—Requirements. British Standard: London, UK, 2015.

- ANSI/APA PRG 320; Standard for Performance-Rated Cross-Laminated Timber. American National Standard: Washington, DC, USA, 2020.

- Ammann, S.; Schlegel, S.; Beyer, M.; Aehlig, K.; Lehmann, M.; Jung, H.; Niemz, P. Quality assessment of glued ash wood for construction engineering. Eur. J. Wood Wood Prod. 2016, 74, 67–74. [Google Scholar] [CrossRef]

- Fink, G.; Kohler, J.; Brandner, R. Application of European design principles to cross laminated timber. Eng. Struct. 2018, 171, 934–943. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Finger-Jointed Wood Products; Research Paper FPL 382; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1981.

- Özçifçi, A.; Yapıcı, F. Structural performance of the finger-jointed strength of some wood species with different joint configurations. Constr. Build. Mater. 2008, 22, 1543–1550. [Google Scholar] [CrossRef]

- Bustos, C.; Beauregard, R.; Mohammad, M.; Hernández, R.E. Structural performance of finger-jointed black spruce lumber with different joint configurations. For. Prod. J. 2003, 53, 72–76. [Google Scholar]

- Bustos, C.; Hernández, R.E.; Beauregard, R.; Mohammad, M. Influence of machining parameters on the structural performance of finger-joined black spruce. Wood Fiber Sci. 2004, 359–367. [Google Scholar]

- Rao, S.; Gong, M.; Chui, Y.H.; Mohammad, M. Effect of end pressure on performance of structural finger-joined lumber fabricated using a short joint profile. Eur. J. Wood Wood Prod. 2014, 72, 143–145. [Google Scholar] [CrossRef]

- Frangi, A.; Bertocchi, M.; Clauß, S.; Niemz, P. Mechanical behaviour of finger joints at elevated temperatures. Wood Sci. Technol. 2012, 46, 793–812. [Google Scholar] [CrossRef]

- Habipi, B.; Ajdinaj, D. Wood finger-joint strength as function of finger length and slope positioning of tips. Int. J. Eng. Appl. Sci. 2015, 2, 257757. [Google Scholar]

- Lara-Bocanegra, A.J.; Majano-Majano, A.; Crespo, J.; Guaita, M. Finger-jointed Eucalyptus globulus with 1C-PUR adhesive for high performance engineered laminated products. Constr. Build. Mater. 2017, 135, 529–537. [Google Scholar] [CrossRef]

- Nogueira, R.D.S.; Moritani, F.Y.; Icimoto, F.H.; Dias, A.A.; Calil, C. Performance of one-component polyurethane (1C-PUR) adhesives in the production of finger-joints fabricated from four planted forest species. Eur. J. Wood Wood Prod. 2022, 80, 1421–1431. [Google Scholar] [CrossRef]

- Muthumala, C.K.; De Silva, S.; Alwis, P.L.A.G.; Arunakumara, K.K.I.U. Identification of the best finger joint configuration for Sri Lankan wood species based on the flexural strength. J. Indian Acad. Wood Sci. 2021, 18, 89–96. [Google Scholar] [CrossRef]

- Piao, C.; Monlezun, C.J.; Groom, L.; Gibson, M.D. Mechanical properties of finger-jointed round wood cores. Int. Wood Prod. J. 2013, 4, 107–115. [Google Scholar] [CrossRef]

- Baño, V.; Godoy, D.; Figueredo, D.; Vega, A. Characterization and structural performance in bending of CLT panels made from small-diameter logs of loblolly/slash pine. Materials 2018, 11, 2436. [Google Scholar] [CrossRef] [PubMed]

- Franke, B.; Schusser, A.; Müller, A. Analysis of finger joints from beech wood. In Proceedings of the World Conference in Timber Engineering WCTE 2014, Quebec City, QC, Canada, 10–14 August 2014. [Google Scholar]

- AS/NZS 43642010 Timber—Bond Performance of Structural Adhesives; Standards Australia and New Zealand: Sydney, Australia, 2010.

- Timber—Finger Joints in Structural Products—Production Requirements. AS/NZS5068:2006Standards Australia and New Zealand: Sydney, Australia, 2006.

- ISO 16696-1; Timber Structures—Cross Laminated Timber—Part 1: Component Performance, Production Requirements and Certification Scheme 2016. International Standardization Organization: Geneva, Switzerland, 2019.

- AS/NZS 4063.12010 Structural Timber—Characteristic Values of Strength Graded Timber; Standards Australia and Standards New Zealand: Sydney, Australia; Wellington, New Zealand, 2010.

- EN408 2012; Timber Structures: Structural Timber and Glue-Laminated Timber Determination of Some Physical and Mechanical Properties. German Institute for Standardisation: Berlin, Germanay, 2012.

- Karacabeyli, E.; Douglas, B. CLT handbook: Cross-laminated timber, US edition, FPInnovations. Can. J. Fish. Aquat. Sci. 2013, 70, 59. [Google Scholar]

- AS/NZS 4063.2Characterization of Structural Timber—Part 2: Determination of Characteristic Values; Standards Australia and New Zealand: Sydney, Australia, 2010.

- He, M.; Sun, X.; Ren, H.; Li, Z.; Feng, W. Experimental study on the system effect of bending cross-laminated timber fabricated with Karamatsu larch. Constr. Build. Mater. 2021, 299, 124271. [Google Scholar] [CrossRef]

- Steiger, R.; Gülzow, A.; Czaderski, C.; Howald, M.T.; Niemz, P. Comparison of bending stiffness of cross-laminated solid timber derived by modal analysis of full panels and by bending tests of strip-shaped specimens. Eur. J. Wood Wood Prod. 2012, 70, 141–153. [Google Scholar] [CrossRef]

- EN15425:2017; Adhesives—One Component Polyurethane (PUR) for Load-Bearing Timber Structures—Classification and Performance Requirements. CEN: Brussels, Belgium, 2017.

- Breneman, S. CLT Floor Design: Strength, Deflection and Vibrations; 2014. Available online: https://dokumen.tips/documents/clt-floor-design-strength-deflection-and-vibrations-a-clt-floor-design.html?page=1 (accessed on 18 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).