Abstract

The reliable bond of steel fibers to concrete matrix is fundamental to ensure they work together under internal and external actions throughout their service life. Due to the lack of research on the long-term bond property, this paper conducted an experimental study on the bond of hook-end steel fiber in the manufactured sand mortars with different water to binder ratios cured for different ages from 7 days to 360 days. The characteristic pull-out load-slip curves are measured, and bond performance indexes at different curing ages are analyzed by using the multi-index synthetical evaluation method. The results show that the bond strengths, the fiber strength use efficiency, the debonding work and the pull-out work increased with the increase in curing age up to to 90 days, which became stable with little variation with the follow-up curing age. The variations are closely associated with the development of mortar strength. Steel fibers embedded in high-strength mortar presented a higher debonding ductility and a lower slipping ductility. In addition, the prediction formulas of long-term debonding strength, bond strength and residual bond strength are proposed.

1. Introduction

A reliable bond is the foundation of steel fiber combined with cementitious materials [1,2,3]. It significantly affects the mechanical properties of steel fiber reinforced concrete (SFRC), both on the scales of materials and structures by confining the appearance of initial micro-cracks in SFRC, and enhancing the post-cracking behaviors due to the stress transfer of steel fibers bridging cracks [4,5].

Normally, research on the bonds of steel fibers to concrete matrix have been conducted on dog-bone shape specimens of fibers embedded in mortar cured for 28 days as per the standard method [6]. The chemical adhesive, physical friction and mechanical anchoring have been recognized as three actions acted on the interface between steel fibers and mortar, while the deformed geometry and size of steel fiber, and the mortar strength are domain to the bond behavior [7,8,9]. However, since the strength development of mortar changes with the increasing curing age [10,11,12,13], the bond of steel fiber to mortar should possess an inherent time-varying nature [14]. This induces a doubt regarding if the bond is consistent to the change in the compressive ability or tensile strength of the mortar.

A few studies investigated the effect of curing age from 1 day to 28 days on the bond properties of straight-smooth steel fiber embedded in mortar with a compressive strength of 45 MPa [15], and on those of brass-coated straight steel fibers embedded in ultra-high-performance SFRC with a compressive strength of 129.6 MPa and a tensile strength of 11.11 MPa [16]. Results indicated that a fast increase of the bond strength presented with the curing age from 1 day to 7 days, and a slower growth from 7 days to 28 days. This was attributed to the increase in the strength of concrete matrix with the increase in curing age.

Meanwhile, some studies focused on the bond at a much longer curing age. The study of Wu [17] reported that for the brass-coated straight steel fiber embedded in ultra-high strength cement mortar with compressive strength of 90–116 MPa and the flexural strength of 19–25 MPa, the bond strength increased quickly from 1 day to 7 days, slowly from 7 days to 28 days and then gently from 28 days to 91 days. A similar result was obtained by Gray [18] on the bond strength of straight-smooth steel fiber to mortar with a compressive strength of 45 MPa, whether the specimens were cured in water or a fog room from 7 days to 90 days. Lex [19] investigated the bond strength of brass-coated straight steel fibers embedded in mortar with compressive strength about 70 MPa. With a rapid increase before 28 days and a continuous increase up to 56 days, the bond strength decreased at 120 days in water curing in contrast to that which monotonically increased in air conditions. Jewell [20] reported about the effect of curing age on the bond strength of straight-smooth steel fiber embedded in the ordinary Portland cement paste and the calcium sulfoaluminate cement paste. The bond strength of steel fibers increased from 1 day to 28 days and decreased a little at 56 days, even if the compressive strength of the pastes increased monotonically, and calcium sulfoaluminate cement paste contributes to a larger bond strength and energy consumption.

Given this information, there has been a lack of study on the bond strength of steel fiber at a much longer curing age than 120 days, and no study has been conducted on the long-term bond strength of deformed steel fibers which have been widely applied in engineering practice. This is not commensurate to the vast research of SFRC with deformed steel fibers. Moreover, there is lack of a deep understanding on how the bond changed with the time-dependent properties of concrete matrix [17,21]. This raises a topic of research on the relationship of the bond of steel fiber to the strength of concrete matrix. A systematical experiment needs to be conducted in terms of comprehensively understanding the bond mechanisms and ensuring the reliability of SFRC structures.

Therefore, in this paper, the pull-out test was carried out for the hook-end steel fiber embedded in manufactured sand mortar. The compressive strength of mortar at 28 days varied from 41.4 MPa to 102.5 MPa, and the curing ages extended from 7 days to 360 days. Based on the complete pull-out load-slip curves (PL-S curves) of test specimens, the characteristic PL-S curves are obtained for each trial of tests. The long-term bond strength, bond energy and bond toughness were assessed by the multi-index synthetical evaluation method. Formulas are proposed to build the relationships of bond properties with mortar strength.

2. Experimental Work

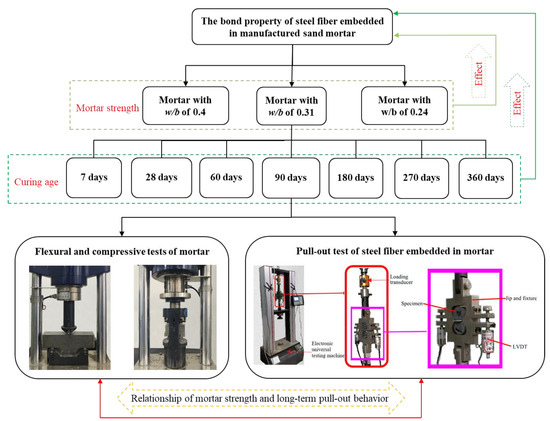

This experimental program was designed as seen in Figure 1, to investigate the effect of curing age on the bond property of hook-end steel fiber embedded in manufactured sand mortars with different strength. Compressive and flexural tests were carried out to investigate the corresponding performance of mortars.

Figure 1.

Experimental program.

2.1. Materials and Mixture Proportions

The normal Portland cement, class-II fly ash, silica fume and grain granulated blast-furnace slag-powder (GGBS) were used as binder materials. The cement had a fineness of 8.6% passing 45 μm screen, a density of 3195 kg/m3, a consistency of 26.6%, a compressive strength of 53.8 MPa and a flexural strength of 8.83 MPa at curing age of 28 days. The fly ash had a fineness of 0.1% passing 45 μm screen, a density of 2349 kg/m3, a specific surface area of 406 m2/kg and a strength activity index of 80.9%. The silica fume had the percentage of SiO2 of 91.3%, a density of 2040 kg/m3 and a strength activity index of 101.4%. GGBS had a fineness of 1.0% passing 45 μm screen, a density of 2950 kg/m3, a specific surface area of 439 m2/kg, a fluidity ratio of 97%, and the strength activity indexes of 76.0% and 97.6% at 7 days and 28 days, respectively. Their physical and mechanical properties met the specifications of China standards GB175 [22] and GB/T 51003 [23]. Manufactured sand was used as aggregate with the fineness modulus of 2.73, an apparent density of 2740 kg/m3, and a stone-powder content of 7.3%, a bulk density of 1620 kg/m3 and a closed pack density of 1850 kg/m3. The polycarboxylic acid superplasticizer was PCA-I with a water reduction of 30% and a solid content of 35%. The mixture water was tap water. The hook-end steel fiber was used with a nominal length lf of 29.8 mm, a diameter df of 0.5 mm, and a tensile strength fsf of 1150 MPa.

The details of mixture proportion and the fresh performance of mortar are presented in Table 1. Three mortars with water to binder ratio w/b of 0.40, 0.31 and 0.24 were designed, named as M40, M31 and M24 in succession.

Table 1.

Mixture proportion and workability of mortars.

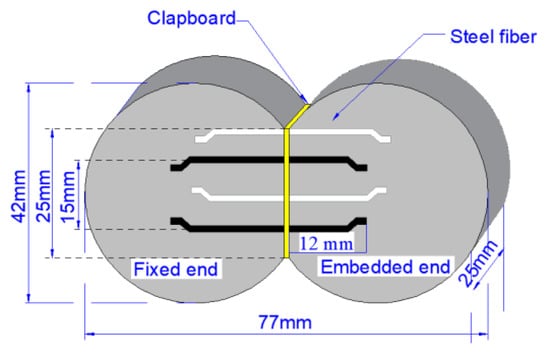

2.2. Sample Design and Preparation

The bond performance of steel fiber embedded in mortar was measured with the pull-out test of dog-bone shape specimens. As shown in Figure 2, for each specimen, four steel fibers were first fixed by clapboard to keep the embedded length lf,em of 12 mm, then mortar was casted in the dog-bone shape mold. Three series of pull-out test were designed with the steel fibers embedded in mortars M40, M31 and M24, respectively. Each series has seven trials of tests corresponding to curing ages of 7, 28, 60, 90, 180, 270 and 360 days. Four pull-out specimens were cast as a group of each trial. Therefore, eighty-four specimens in twenty-one groups were tested in this study. Accompanied with the pull-out specimens, three prism specimens of 40 mm × 40 mm × 160 mm were cast as a group for a mortar. Thus, sixty-three mortar specimens in twenty-one groups were cast to determine the long-term compressive and flexural strengths of mortar. All specimens were casted in the lab room, and cured for designed curing age under the condition with a temperature of 20 ± 2 °C and humidity higher than 95%.

Figure 2.

Pull-out specimen design.

2.3. Test Method

The compressive and flexural strength tests of mortar were carried out as per the specification of China code GB/T17671 [24] and the European Standard BSEN 196-1 [25].

The same as the previous study [8,9], the pull-out test was in accordance with the specification of China code CECS 13 [6]. The uniaxial tension was exerted by an electronic universal testing machine with a limit of 10 kN. The loading speed is 0.3 mm/min. The relative displacement between fibers and mortar was obtained by the average displacements of two linear variable displacement transducers (LVDTs). The test was finished when the relative displacement exceeded 6.5 mm. Finally, the pull-out load-slip curve (PL-S curve) of each specimen was determined.

2.4. The Pull-Out Evaluation Method

In this test, the four PL-S curves determined for each trial at a curing age should be treated as a characteristic PL-S curve [9]. Therefore, the validity of the four PL-S curves was firstly judged by excluding the curve with peak load exceeds 15% of the average peak load. A valid trial of the test should use no fewer than three valid PL-S curves. Secondly, the valid PL-S curve was transformed to be a unit curve with the pull-out load divided by its peak load and the slip divided by the corresponding slip at peak load. Thirdly, for the valid PL-S curves of each trial, the ascending segment of the unit curve was obtained by averaging the slip ratios corresponding to the same load ratio, the descending segment of the unit curve was obtained by averaging the load ratios corresponding to the same slip ratio. Finally, the characteristic PL-S curve is obtained by the unit curve multiplying the average peak load and corresponding slip.

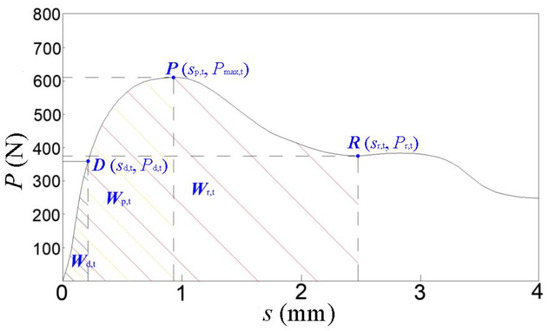

The bond properties of steel fiber in mortar can be evaluated by the multi-index synthetical indices based on the characteristic PL-S curve [8,9]. For the convenience of explanation, the three key points D, P and R on the characteristic PL-S curve are marked in Figure 3. They are the points with the slope of the curve changing suddenly in ascending portion, at peak and in descending portion, successively. The pull-out loads and slips at D, P and R are successively represented by the debonding load Pd,t and slip sd,t, the peak load Pmax,t and slip sp,t, and the residual load Pr,t and slip sr,t.

Figure 3.

Schematic diagram of three key points and pull-out works.

Corresponding to the three points, the debonding strength τd,t, bond strength τmax,t and residual bond strength τres,t can be calculated as follow:

At the point P, the pull-out load reaches the peak. This means the maximum use of steel fiber with a peak tensile stress σp,t which can be further represented by the strength use efficiency usf,t:

where fsf is the tensile strength of steel fiber.

At points D and R, the strength ratios ude,t and ures,t of hook-end steel fiber at t days are calculated as:

As presented in Figure 3, the debonding work Wd,t, the slipping work Wp,t and the pull-out work Wr,t are the areas under the PL-S curve with the slip from 0 to the key points D, P and R, respectively. They represent the dispersion energy to reach a bond-slip feature. Formulas are listed as follow:

Thus, the debonding energy ratio Rd,t, the slipping energy ratio Rdp,t and the pull-out energy ratio Rpr,t of hook-end steel fiber at t days are calculated as follow:

3. Test Results and Analyses

3.1. Strength Development of Mortar

Table 2 presents the compressive strength fcm,t and flexural strength ftm,t of mortar at different curing ages. Generally, due to a rich content of tricalcium silicate, dicalcium silicate and tetracalcium aluminate at the early ages [9,10,11,12], the quick hydration caused a rapid increase in the strength of mortar. With the increase in curing age, the growth of the strength became slower with a decreased hydration rate due to the gradual consumption of tricalcium silicate and other substances involved in the hydration [26,27].

Table 2.

Test strengths of mortars at different curing ages.

Meanwhile, the strength development of mortar related to the water to binder ratio and the mineral admixture content. With the fly ash as the mineral admixture, the mortars M40 and M31 presented a similar development of compressive strength that was lower at the early curing age and a bit of higher growth at a later curing age. The compressive strength fcm,7 only reached 31.3% and 42.7% of the fcm,360, and the fcm,28 just reached 54.8% and 65.3%. This is a typical characteristic of strength development of cement matrix mixed with fly ash [28,29]. The activity of fly ash can be excited after the hydration of cement which provides enough Ca (OH)2 to generate the secondary hydration. With the GGBS and silica fume as mineral admixture, the mortar M24 presented a higher compressive strength at early age and a slow growth at latter. The compressive strength fcm,7 and fcm,28 reached 62.6% and 81.7% of the fcm,360, respectively. This came from a higher activity of GGBS to participate the hydration of cementitious to promote the strength growth. Silica fume has the functions of filling and hydration to optimize the interfacial transition zone, refine the pore structure, and significantly improves the early strength of matrix [16]. Moreover, the binary addition of silica fume and GGBS can promote the strength development at early and later ages [30].

Compared with the compressive strength, the flexural strength seems to increase faster in the early age, while undergoing lower growth in the latter. The flexural strength ftm,7 was more than 80% of the ftm,360 for M31 and M24, and could reach 56.3% for M40.

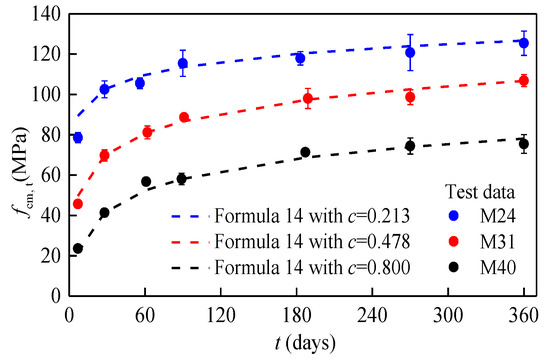

Referring to the compressive strength development of concrete [10,11], the long-term compressive strength of mortar can be predicted by Formula (14).

where, c is the regression coefficient determined by tests data. It is 0.800 for M40 with Adj. R2 of 0.989, 0.478 for M31 with Adj. R2 of 0.990, and 0.213 for M24 with Adj. R2 of 0.905. Figure 4 presents the comparison of the calculated to the test compressive strength. Good fitness can be obtained from these curves with the experimental results.

Figure 4.

Comparison of calculated to test compressive strength of mortars at different curing ages.

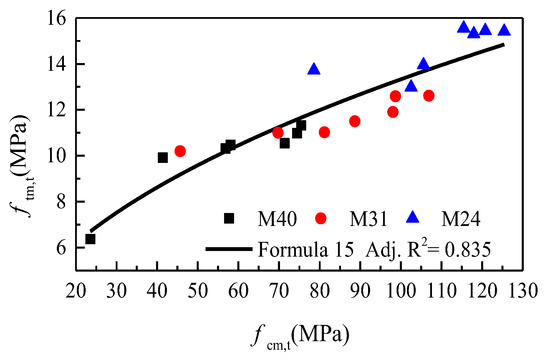

The relationship between the tensile and compressive strengths of concrete is always described by the power function, and it was not affected by the curing age [31]. Thus, the relationship of flexural strength and compressive strength of mortar is expressed as Formula (15) in this study. Where the regression coefficients of 1.491 and 0.476 are determined by the fitted test data. Figure 5 presents the comparison of the fitted curve with test data.

Figure 5.

The relationship of flexural strength and compressive strength.

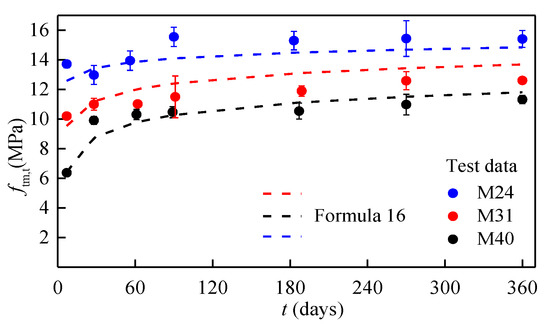

Then, the Formula (16) is obtained as follow,

As shown in Figure 6, the calculated curves fit well with the test data; the average ratios of calculated to test values of ftm,t for M40, M31 and M24 are 0.999, 1.060 and 0.965 with variation coefficients of 0.064, 0.057 and 0.046, respectively.

Figure 6.

Comparison of calculated to test flexural strength of mortars at different curing ages.

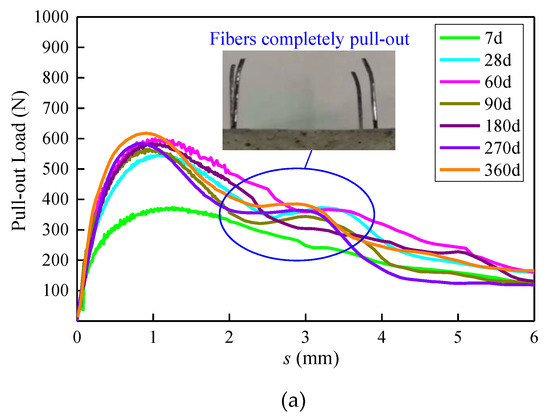

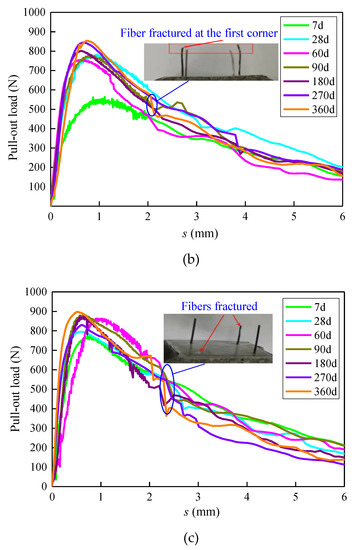

3.2. Characteristics on PL-S Curves of Steel Fiber at Different Curing Ages

Figure 7 shows the characteristic PL-S curves of steel fiber in M40, M31 and M24 at different curing age. Similar shapes are presented on all characteristic curves. The peak pull-out loads, the slopes of ascending and descending portions gradually increase with the curing age. Especially the PL-S curves of M40 and M31 in 7 days are significantly flatting with lower peak loads compared with the curves after 28 days. This is consistent with the mortar strength development discussed above.

Figure 7.

The characteristic PL-S curves at different curing ages. (a) M40 (b) M31 (c) M24.

In the characteristic PL-S curves of M40, the pull-out load and slip varies continuously, corresponding to the failure of fibers pulled out with the whole-fiber hook ends being straightened. The descending portion of curves after 28 days have an obvious “step” shape.

The pull-out load and slip of M31 varies continuously at 7 to 180 days with the steel fibers which were basically pulled out with straightened fiber ends. The pull-out load drops abruptly in the descending portion of the curves at 270 and 360 days, corresponding to the failure of one or two fibers fractured at the first corner of the hook-end.

With continuous variation in the pull-out load and slip, the characteristic PL-S curves of M24 were basically pulled out with straightened fiber hook ends at 7 and 28 days. While the pull-out load drops abruptly in the descending portion after 60 days, corresponding to the fracture of one or two fibers.

The fiber is aligned embedded in the mortar in this study, while the hook-end has a certain angle of 45° with the fiber length. It means that the hook-end of fiber is inclined with the pull-out load direction. The hook-end of fiber is not only subjected to the bond stress of the mortar at the contact surface, but also subjected to the local pressure stress of the mortar [32] during the pull-out process. Therefore, the maximum local tensile stress of the fiber will appear at the hook-end. In this study, the mortar strength gradually increases with the curing age. When the strength of mortar is higher than a certain value, the local tensile stress of the fiber hook-end may reach its tensile strength, and a fracture occurs. At this time, the pull-out load slip curve will be sharply reduced.

The loads and slips extracted for three points D, P and R presented in Figure 3 are listed in Table 3. The curing age and mortar strength has little influence on the debonding slip, except that the sd,t at 7 days to 60 days increase with the decrease in mortar strength. sp,t and sr,t of all tests decrease with the increasing curing age and mortar strength.

Table 3.

The loads and slips at key points of the characteristic PL-S curves.

3.3. Bond Strength Development of Steel Fiber in Mortar

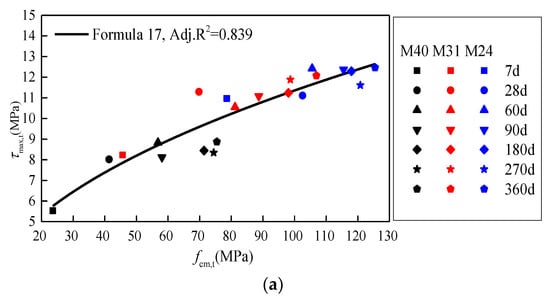

Test results of debonding strength τd,t, bond strength τmax,t and residual bond strength τres,t related to the compressive strength of mortar are presented in Figure 8. Power function can be used for describing the relationships. By fitting regression with Adj. R2 of 0.839, 0.814 and 0.645, respectively, formulas are expressed as follow,

Figure 8.

Relationship of bond strengths and compressive strength of mortar. (a) τmax,t (b) τd,t (c) τres,t.

Combined with Formula (14), Formulas (20)–(22) are obtained. The average ratios and corresponding variation coefficients of tested to the calculated values of bond strengths for M40, M31 and M24 are listed in Table 4.

Table 4.

Comparison results between test and calculated values of bond strengths.

It is noted that the bond strengths of the same steel fiber in mortar with the same strength were smaller in a previous study [8]. This is due to the different characteristics of river sand and manufactured sand used for mortars in the previous study and this experiment. Due to the rough surface of manufactured sand [33,34], the density and the interfacial transition zone of matrix is improved [35,36], which is beneficial to the bond performance of steel fiber to mortar.

3.4. The Strength Ratios Development of Steel Fiber in Mortar

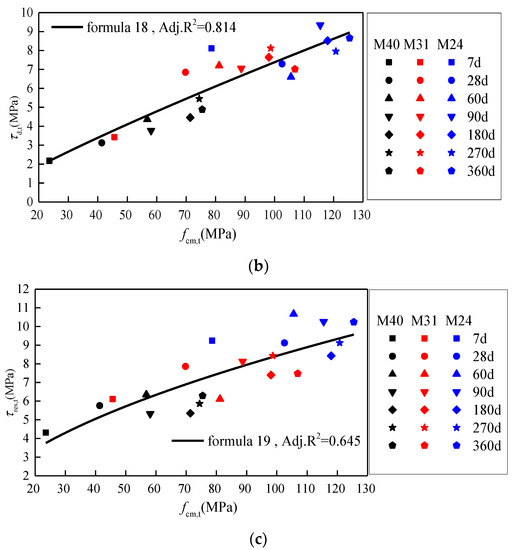

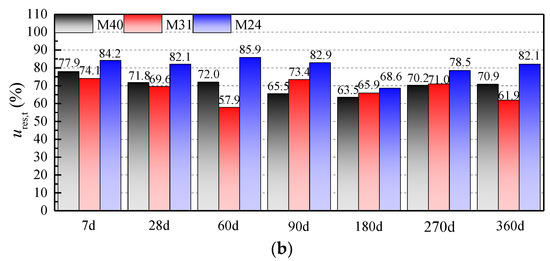

Figure 9 displays the strength use efficiency usf,t of steel fibers in M40, M31 and M24.The usf,t of steel fiber in M40 ranged from 41.4% to 68.5% with the curing age from 7 to 360 days. The usf,t of steel fiber in M31 increased from 62.4% to 88.8% from 7 to 180 days, and were higher than 90% at 270 days and 360 days. The usf,t of steel fiber in M24 ranged from 85.7% to 88.1% with the curing age from 7 to 28 days, and are above 90% from 60 to 360 days. Compared with the failure modes, when the strength use efficiency reaches 90%, the possibility of fiber fracture increases.

Figure 9.

The usf,t of steel fibers in M40, M31 and M24.

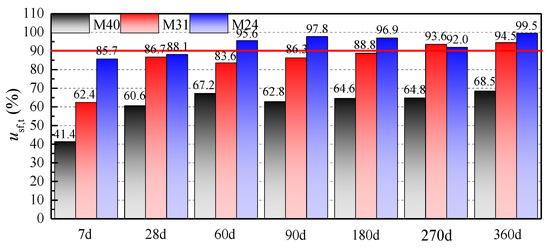

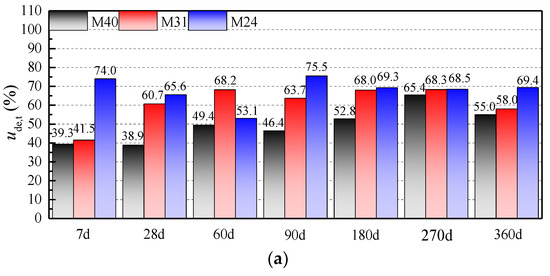

Figure 10 displays the strength ratios ude,t and ures,t of steel fibers in M40, M31 and M24, which reflects the debonding resistance of steel fiber during the ascending loading portion and the loss rate of bond strength during the descending loading portion, respectively. The ude,t of steel fiber in M40 tended to increase with the curing age from 7 to 360 days. The ude,t of steel fiber in M31 increased from 7 to 28 days, and ranged from 58.0% to 68.3% at the curing age from 60 to 360 days. No obvious regularity was observed in the ude,t of steel fiber in M24, which ranged from 53.1% to 75.5% with the curing age from 7 to 360 days. The ude,t increase with the decrease in water to binder ratio w/b at the same curing age, which means steel fiber will have better debonding resistance in mortar with low w/b. The increase in chemical adhesion with the decrease in w/b is greater than that of mechanical anchorages and physical fraction in this study. The ures,t of steel fibers in M40, M31 and M24 are ranged from 63.5 to 77.9 %, 57.7 to 74.1% and 68.6 to 85.9% with the curing age from 7 to 360 days, successively. No obvious influence of curing age was observed on the ures,t. The ures,t of steel fiber in M24 are higher than those in M31 and M24 at same curing age. It may be due to the addition of silica fume in M24.

Figure 10.

The strength ratios of steel fibers in M40, M31 and M24: (a) ude,t; (b) ures,t.

Based on the Formulars (21)–(23), the formulas of ude,t and ures,t can be expressed as Formulas (23) and (24). The average ratios and corresponding variation coefficients of calculated to the tested values of the strength ratios for steel fibers in M40, M31 and M24 are listed in Table 5.

Table 5.

Comparison results between calculated and test values of bond strengths.

3.5. Energy Dissipation in the Process of the Pull-Out Test

Table 6 presents the debonding work Wd,t, the slipping work Wp,t and the pull-out work Wr,t and their corresponding energy ratio Rd,t, Rdp,t and Rpr,t of steel fibers in M40, M31 and M24.

Table 6.

Energy dissipation in the process of pull-out test.

The Wd,t of steel fiber in M40 increased from 7 to 60 days, then kept constant at 41.2 N.mm with a variation coefficient of 0.38 after 60 days. The Wd,7 and Wd,28 are 29.4% and 52.9% of those at 360 days. The Wd,t of steel fiber in M31 increased from 7 days to 28 days, then kept constant of 70.3 N.mm with a variation coefficient of 0.08 after 28 days. The Wd,7 is 25.7% of the Wd,360, Wd,28 reaches 94.6% of the Wd,360. The Wd,t of steel fiber in M24 shows opposite regularity, which decreases from 7 to 360 days.

The curing age has little influence on the Wp,t. The Wp,t for M40, M31 and M24 kept constant at 403 N.mm, 421 N.mm and 395 N.mm, with variation coefficients of 0.13, 0.19 and 0.13, respectively. The Wp,t is slightly influenced by the mortar strength..

The Wr,t of M40 and M31 increased from 7 days to 28 days, then kept constant at 1166 N.mm with a variation coefficient of 0.13 and 1495 N.mm with a variation coefficient of 0.11 after 28 days. The Wr,t of M24 was constant at 1208 N.mm with a variation coefficient of 0.07. M31 had a higher Wr,t compared to that of M40 and M24 at the same curing age.

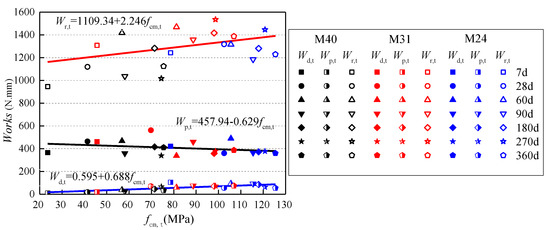

The relationship of bond works and the compressive strength of mortar are presented in Figure 11. The debonding work Wd,t is sensitive to the mortar strength, which increased with the compressive strength with Adj-R2 of 0.502. The slipping work Wp,t shows a slight decrease with the increase in the mortar strength. The pull-out work Wr,t shows a tendency to increase with the compressive strength in large discreteness.

Figure 11.

Relationship of bond work and compressive strength of mortar.

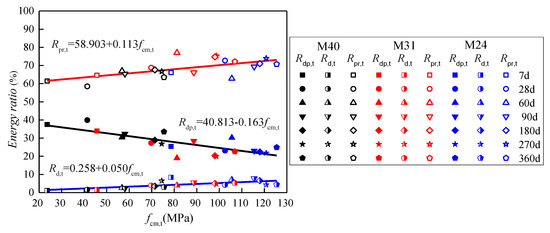

The Rd,t of M40 and M31 increased from 7 days to 90 days, then kept constant at 3.8% and 5.15% with a variation coefficient of 0.48 and 0.06 after 90 days. The Rd,t of M24 decreased from 7 days to 28 days, then kept constant at 5.73 with a variation coefficient of 0.28. The Rd,t at the same curing age tended to increase with the increase in mortar strength. However, all the Rd,t were smaller than 9% and with a high variation coefficient. This means that the energy dissipation capacity of steel fiber at the cracking resistance of SFRC plays a small part and is unstable in the whole pull-out process.

The Rdp,t of M40 and M31 decreased from 7 days to 90 days, then kept constant at 30.4% and 22.8% with a variation coefficient of 0.10 and 0.17 after 90 days. The Rdp,t of M24 kept constant at 24.4% with a variation coefficient of 0.11. The Rdp,t of M40 were higher than those of M31 and M24 at the same curing age.

The curing age has little influence on the Rpr,t. The Rpr,t of M40, M31 and M24 kept constant of 64.3%, 71.2% and 69.5% with variation coefficient of 0.05, 0.07 and 0.06 from 7 to 360 days, successively. The Rpr,t of M31 was higher than those of M40 and M24 at the same curing age. This indicates the energy dissipation capacity of steel fiber at the bearing capacity of SFRC plays an important role in the whole pull-out process.

The relationship of energy ratios and the compressive strength of mortar are presented in Figure 12. The Rd,t and the Rpr,t increased with the mortar compressive strength. The Rdp,t decreased with the increase in mortar compressive strength, which reflects the increase in bond brittleness with the mortar strength. This phenomenon needs to be paid attention in the normal serviceability of SFRC structures.

Figure 12.

Relationship of the energy ratio and the compressive strength of mortar.

3.6. Relationship of Bond Slips and Mortar Strength

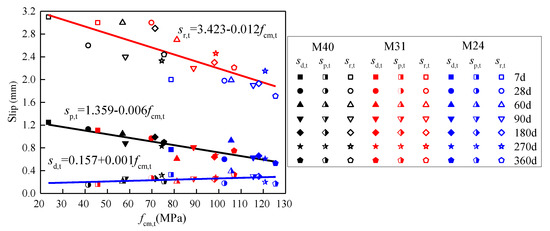

The relationship of slips and the compressive strength of mortar are presented in Figure 13. The slips sp,t and sr,t decrease with the increase in mortar compressive strength with Adj-R2 of 0.764 and 0.657, respectively. No regularity was observed in the slip sd,t.

Figure 13.

Relationship of bond slips and compressive strength of mortar.

4. Conclusions

This paper carried out the pull-out test of hook-end steel fiber embedded in manufactured sand mortar. Seven curing ages from 7 days to 360 days, and three water to binder ratios of mortar at 0.24, 0.31 and 0.40 were considered as the main factors. The pull-out load vs bond-slip curves were measured and treated to be a characteristic curve for a trial of tests. The values of load and slip at three key points at the characteristic pull-out load-slip curve are extracted. The bond strength, bond energy and bond toughness are analyzed and discussed based on the multi-index synthetical evaluation method. The conclusions can be drawn as follows:

With the increase in curing age, the debonding strength, the bond strength, the residual bond strength, the strength use efficiency, and the debonding work presented different developments for steel fiber embedded in mortar with different strengths. The variations are closely associated with the development of mortar strength. The bond strength, the fiber strength use efficiency, the debonding and pull-out work increased with the curing age from 7 days to 90 days and became stable in a slight range with the continuously increased curing age.

The addition of silica fume in mortar would reduce the loss rate of bond strength during the descending portion. Steel fiber embedded in mortar with a water to binder ratio of 0.31 has best bond energy and bond energy dissipation capacity.

More debonding ductility and less slipping ductility are observed for steel fibers embedded in high strength mortar. The slips at slipping and pull-out states decrease with the increase in mortar strength. The debonding, bond and residual bond strengths, debonding and pull-out works, debonding and pull-out energy ratios increase with the mortar strength.

The relationship of bond strength, bond slip, bond strength ratios, bond energy and energy ratios with mortar strength are analyzed, respectively. Good fitness for describing the relationships between bond strengths, bond strength ratios with compressive strength of mortar can be obtained by power functions.

Author Contributions

Conceptualization, X.D. and S.Z.; methodology, S.Z.; validation, X.D. and C.L.; formal analysis, M.Z.; investigation, J.D.; data curation, X.D.; writing—original draft preparation, X.D.; writing—review and editing, X.D. and H.W.; visualization, C.L.; supervision, S.Z.; funding acquisition, X.D. and S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 52108212, The Special Joint Research Project of Zhengzhou City and NCWU, Henan, China, grant number 2021014, and Natural Science Foundation of Henan, grant number 212300410192.

Data Availability Statement

Data is available with the first author and can be shared with anyone upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abdallah, S.; Fan, M.; Rees, D. Bonding mechanisms and strength of steel fiber–reinforced cementitious composites: Overview. J. Mater. Civil. Eng. 2018, 3, 04018001. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M.; Zhou, X.; Geyt, S. Anchorage effects of various steel fibre architectures for concrete reinforcement. Int. J. Concr. Struct. Mater. 2016, 3, 325–335. [Google Scholar]

- Cao, Y.Y.; Yu, Q.L. Effect of inclination angle on hooked end steel fiber pullout behavior in ultra-high performance concrete. Compos. Struct. 2018, 201, 151–160. [Google Scholar] [CrossRef]

- Zhang, D.; Shahin, M.; Yang, Y.; Liu, H.; Cheng, L. Effect of microbially induced calcite precipitation treatment on the bonding properties of steel fiber in ultra-high performance concrete. J. Build. Eng. 2022, 50, 104132. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, H.; Du, C.; Gao, D.; Yuan, J.; Wen, C. Experimental study on cracking behavior of steel fiber-reinforced concrete beams with BFRP bars under repeated loading. Compos. Struct. 2021, 267, 113878. [Google Scholar] [CrossRef]

- CECS 13:2009; Standard Test Methods for Fiber Reinforced Concrete. China Planning Press: Beijing, China, 2009.

- Wille, K.; Naaman, A. Pullout behavior of high-strength steel fibers embedded in ultra-high-performance concrete. ACI Mater. J. 2012, 4, 479–488. [Google Scholar]

- Ding, X.; Zhao, M.; Li, C.; Li, J.; Zhao, X. A multi-index synthetical evaluation of pull-out behaviors of hooked-end steel fiber embedded in mortars. Constr. Build. Mater. 2021, 276, 122–219. [Google Scholar] [CrossRef]

- Ding, X.; Geng, H.; Zhao, M.; Chen, Z.; Li, J. Synergistic bond properties of different deformed steel fibers embedded in mortars wet-sieved from self-compacting SFRC. Appl. Sci. 2021, 11, 10144. [Google Scholar] [CrossRef]

- Zhao, S.; Ding, X.; Zhao, M.; Li, C.; Pei, S. Experimental study on tensile strength development of concrete with manufactured sand. Constr. Build. Mater. 2017, 138, 247–253. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Xu, Y.; Li, F.; Zhao, S. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Jin, R.Y.; Qian, C.; Soboyejo, A. Non-linear and mixed regression models in predicting sustainable concrete strength. Constr. Build. Mater. 2018, 170, 142–152. [Google Scholar] [CrossRef]

- Li, C.; Wang, F.; Deng, X.; Li, Y.; Zhao, S. Testing and prediction of the strength development of recycled-aggregate concrete with large particle natural aggregate. Materials 2019, 12, 1891. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Zhao, D.; Liebscher, M.; Yin, B.; Yang, J.; Kaliskec, M.; Mechtcherine, V. An experimental and numerical study on the age depended bond-slip behavior between nano-silica modified carbon fibers and cementitious matrices. Cem. Concr. Compos. 2022, 128, 104416. [Google Scholar] [CrossRef]

- Zhao, N.; Qing, L.; Yang, Z.; Mu, R. Experimental and numerical studies on fiber pull-out of steel fiber reinforced cement mortar at different ages. Bulletin. Chin. Ceram. Soci. 2021, 7, 2165–2173. [Google Scholar]

- Krahl, P.; Gidrão, G.; Neto, R.; Carrazedo, R. Effect of curing age on pullout behavior of aligned and inclined steel fibers embedded in UHPFRC. Constr. Build. Mater. 2021, 266, 121188. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Comp. 2016, 71, 97–109. [Google Scholar] [CrossRef]

- Gray, R.; Johnston, C. The effect of matrix composition on fiber/matrix interfacial bond shear strength in fiber-reinforced mortar. Cem. Concr. Res. 1984, 14, 285–296. [Google Scholar] [CrossRef]

- Lex, H.; Moon, D.; Kim, D. Effects of ageing and storage conditions on the interfacial bond strength of steel fibers in mortars. Constr. Build. Mater. 2018, 170, 129–141. [Google Scholar]

- Jewell, R.; Mahboub, K.; Robl, T.; Bathke, A. Interfacial bond between reinforcing fibers and calcium sulfoaluminate cements: Fiber pullout characteristics. ACI Mater. J. 2015, 112, 39–48. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Z.; Shi, C.; Wu, Z.; Zhang, C. Steel fiber-matrix interfacial bond in ultra-high performance concrete: A review. Engineering 2022. [Google Scholar] [CrossRef]

- GB175-2007; Common Portland cement. China Building Industry Press: Beijing, China, 2007.

- GB/T 51003-2014; Technical Code for Application of Mineral Admixture. China Building Industry Press: Beijing, China, 2014.

- GB/T17671-1999; Method of testing cements-Determination of strength: The state bureau of Quality technical supervision. China Standard Press: Beijing, China, 1999.

- BSEN196-1: 2005; Methods of testing cement-Part 1: Determination of strength. British Standards Institution: London, UK, 2005.

- Monaco, M.; Aurilio, M.; Tafuro, A.; Guadagnuolo, M. Sustainable mortars for application in the cultural heritage field. Materials 2021, 14, 598. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Sihag, P.; Kurda, R.; Mahmood, W.; Ghafor, K.; Sarwar, W. ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J. Mater. Res. Technol. 2020, 9, 12416–12427. [Google Scholar] [CrossRef]

- Li, F.; Liu, C.; Pan, L.; Li, C. Machine-Made Sand Concrete, 1st ed.; China Water and Power Press: Beijing, China, 2014; pp. 61–82. [Google Scholar]

- Duan, F.; Zhang, H.; Niu, D.; Yuan, C. Study of the compressive strength change with age of ordinary concrete and mineral admixture concrete. Concrete 2011, 4, 58–60. [Google Scholar]

- Chen, H.; Zhang, D.; Zhu, J.; Wei, J. Experimental research on the high performance concrete with silica fume-slag composite. J. Huazhong Univ. Sci. Tech. 2005, 4, 90–92. [Google Scholar]

- Francois, D.L. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Ding, X.; Zhao, M.; Li, H.; Zhang, Y.; Liu, Y.; Zhao, S. Bond behaviors of steel fiber in mortar affected by inclination angle and fiber spacings. Materials 2022, 15, 6024. [Google Scholar]

- Arulmoly, B.; Konthesingha, C.; Nanayakkar, A. Performance evaluation of cement mortar produced with manufactured sand and offshore sand as alternatives for river sand. Constr. Build. Mater. 2021, 297, 123784. [Google Scholar] [CrossRef]

- Ren, Q.; Tao, Y.; Jiao, D.; Jiang, Z.; Ye, G.; Schutter, G. Plastic viscosity of cement mortar with manufactured sand as influenced by geometric features and particle size. Cem. Concr. Comp. 2021, 122, 104163. [Google Scholar] [CrossRef]

- Abu-Lebdeh, T.; Hamoush, S.; Heard, W.; Zornig, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Constr. Build. Mater. 2011, 25, 39–46. [Google Scholar] [CrossRef]

- Ding, X.; Lu, Y.; Han, B.; Zhao, M.; Chen, M.; Zhao, S. Experimental study on tensile properties of high-performance concrete with machine-made sand and fly-ash. In Proceedings of the International Conference on Architectural Engineering and New Materials, Guangzhou, China, 25 July 2015; pp. 164–172. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).