Preliminary Study on the Behaviour of Fibre-Reinforced Polymer Piles in Sandy Soils

Abstract

:1. Introduction

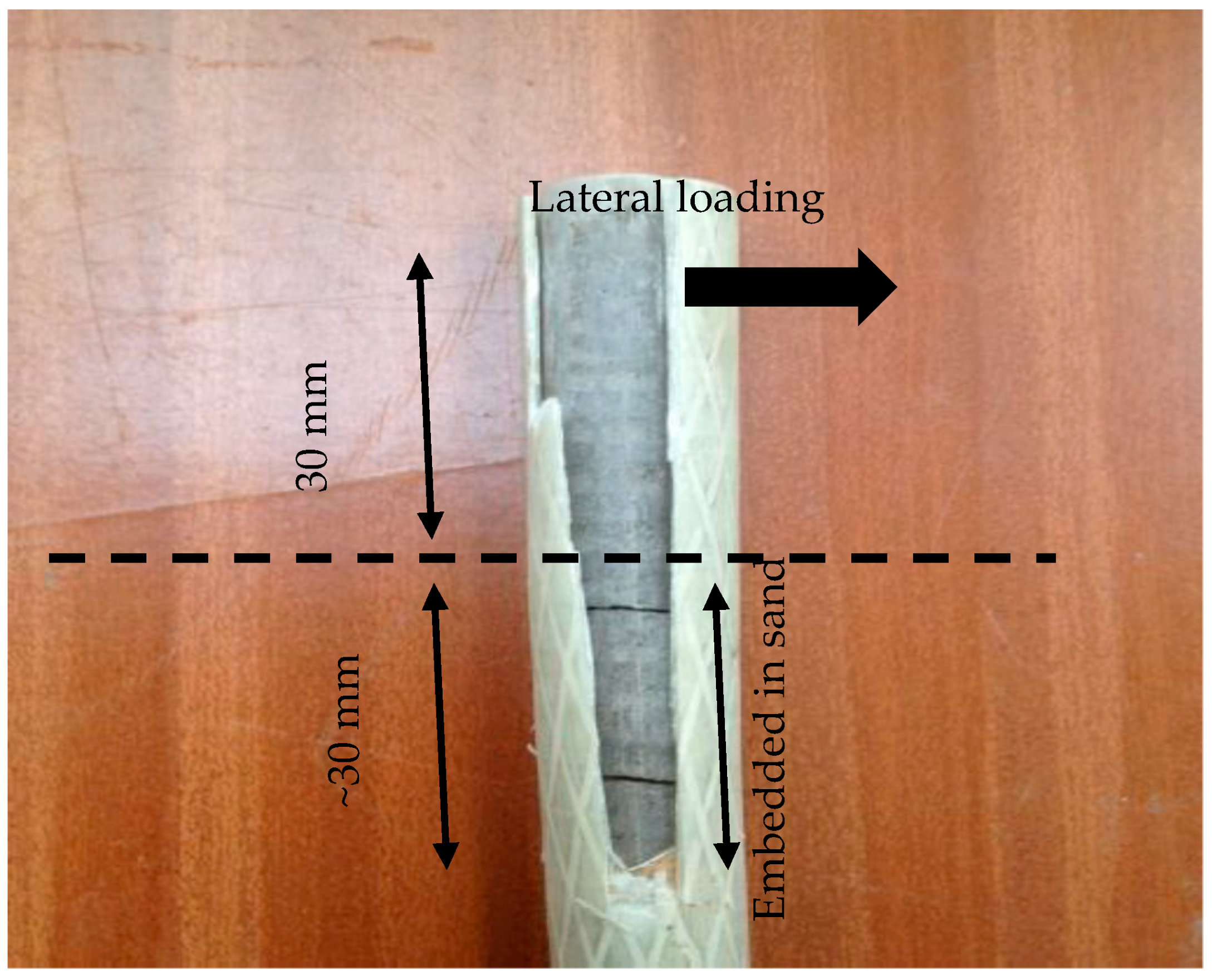

2. Materials and Methods

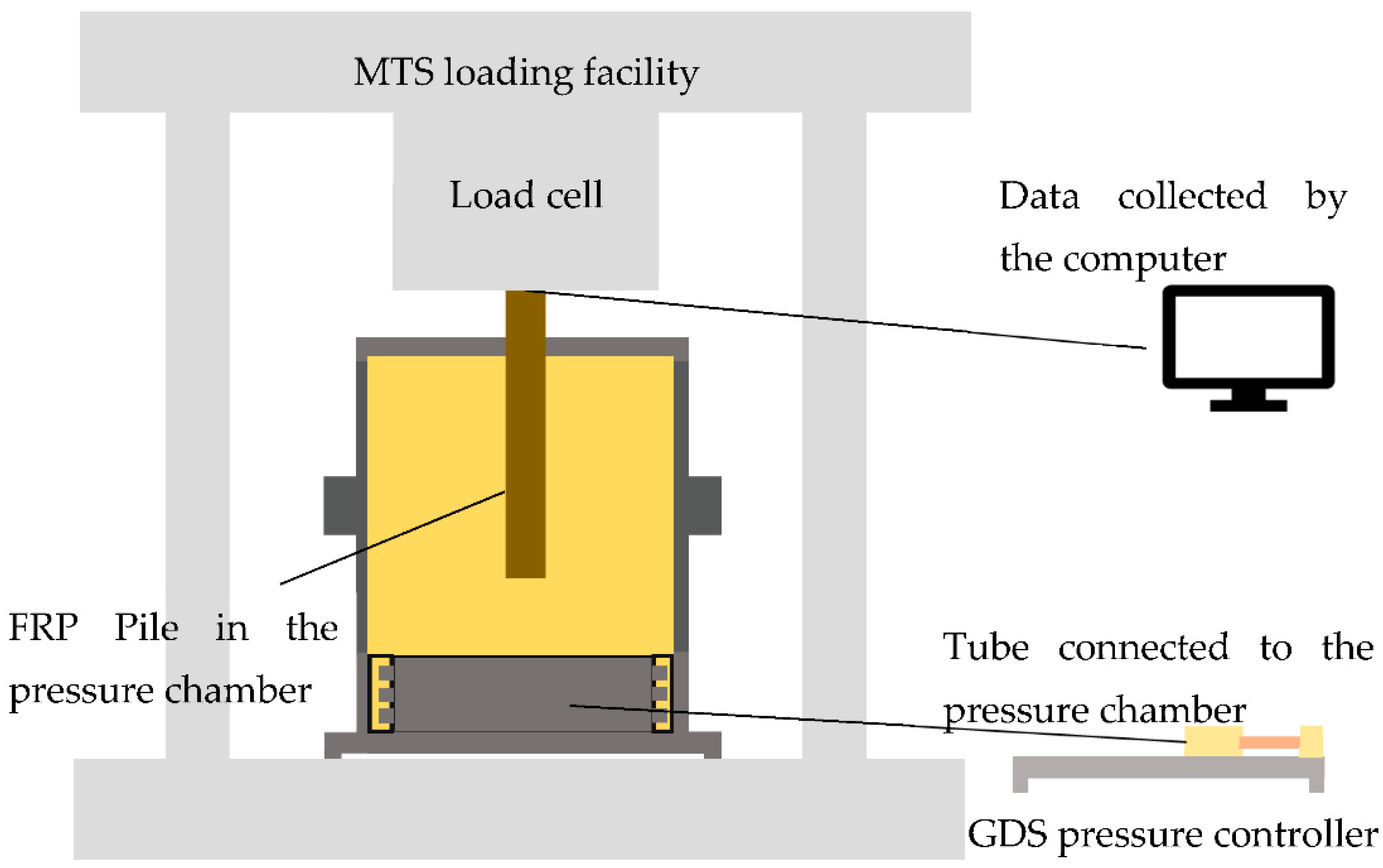

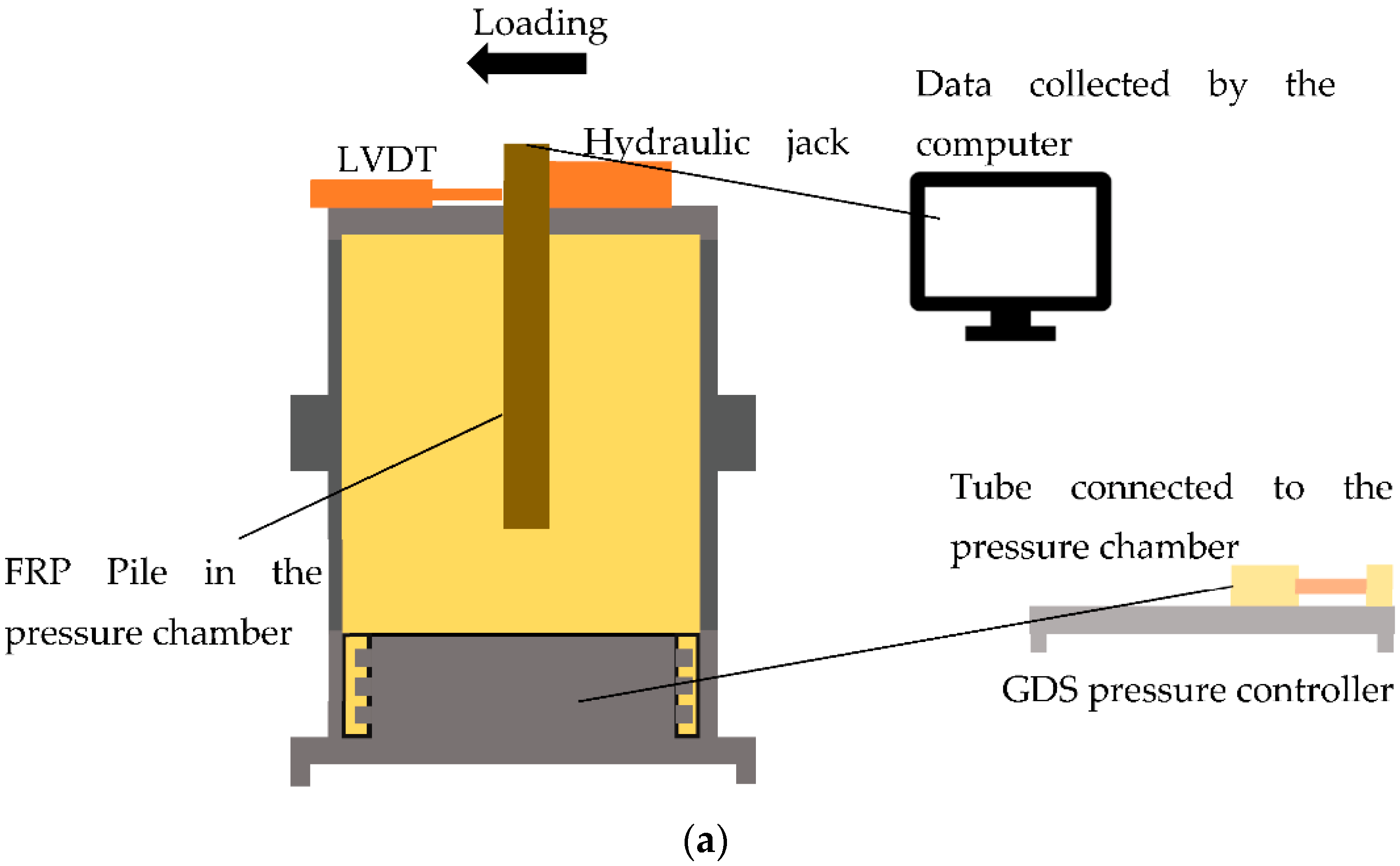

2.1. Experimental Apparatus

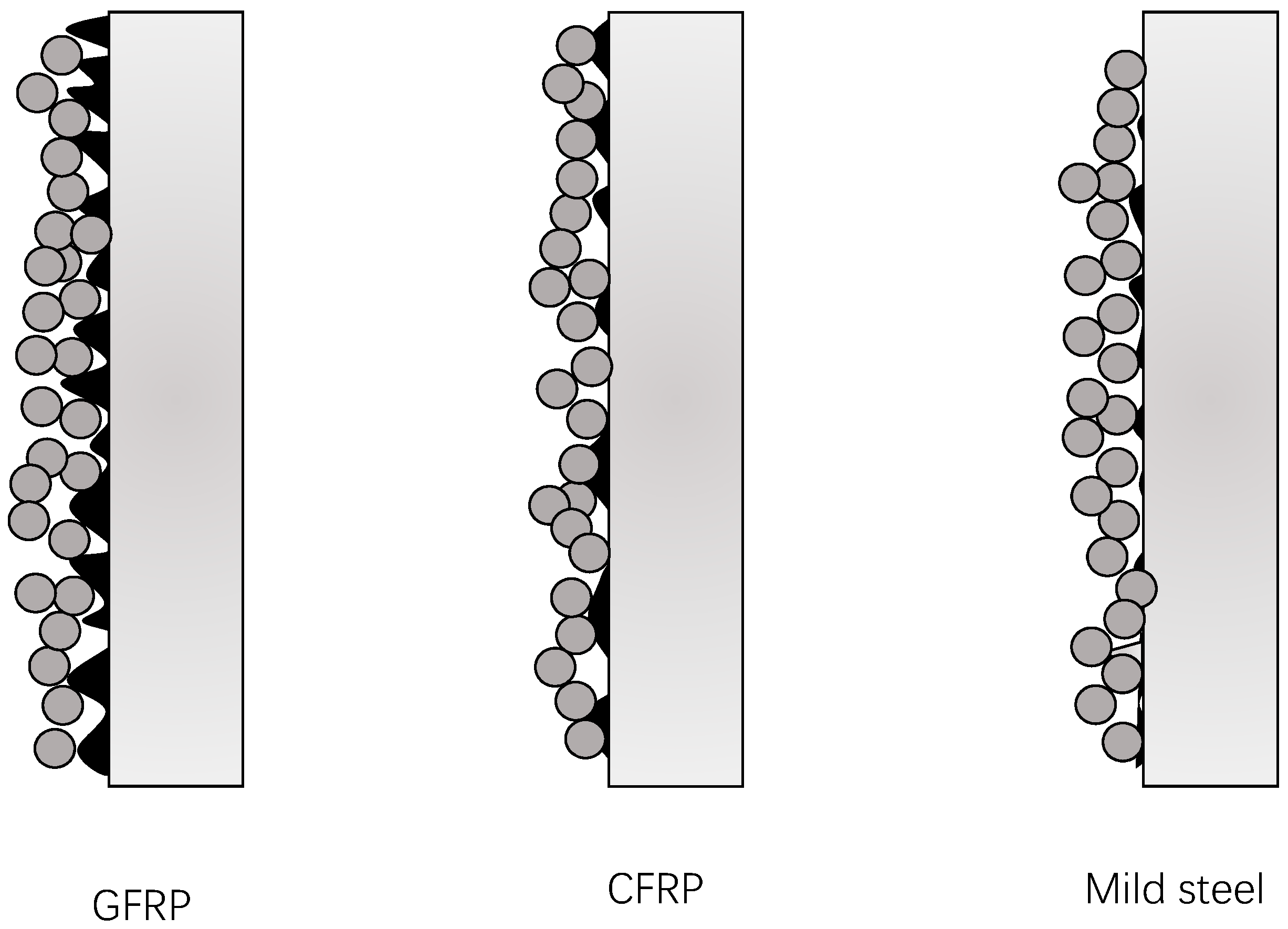

2.2. CFRP, GFRP, and Mild Steel Tube

2.3. Mortar

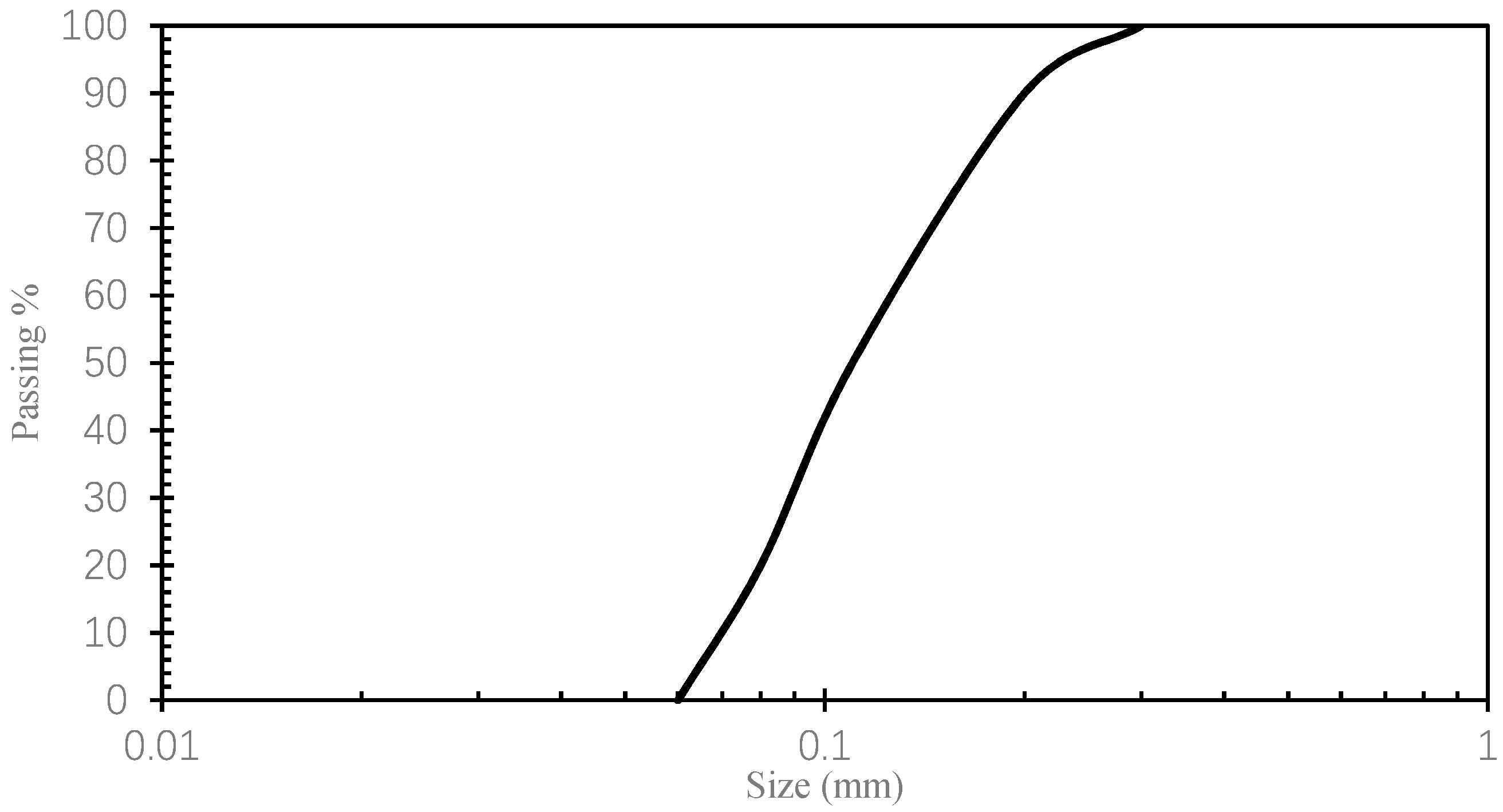

2.4. Sand

3. Methods

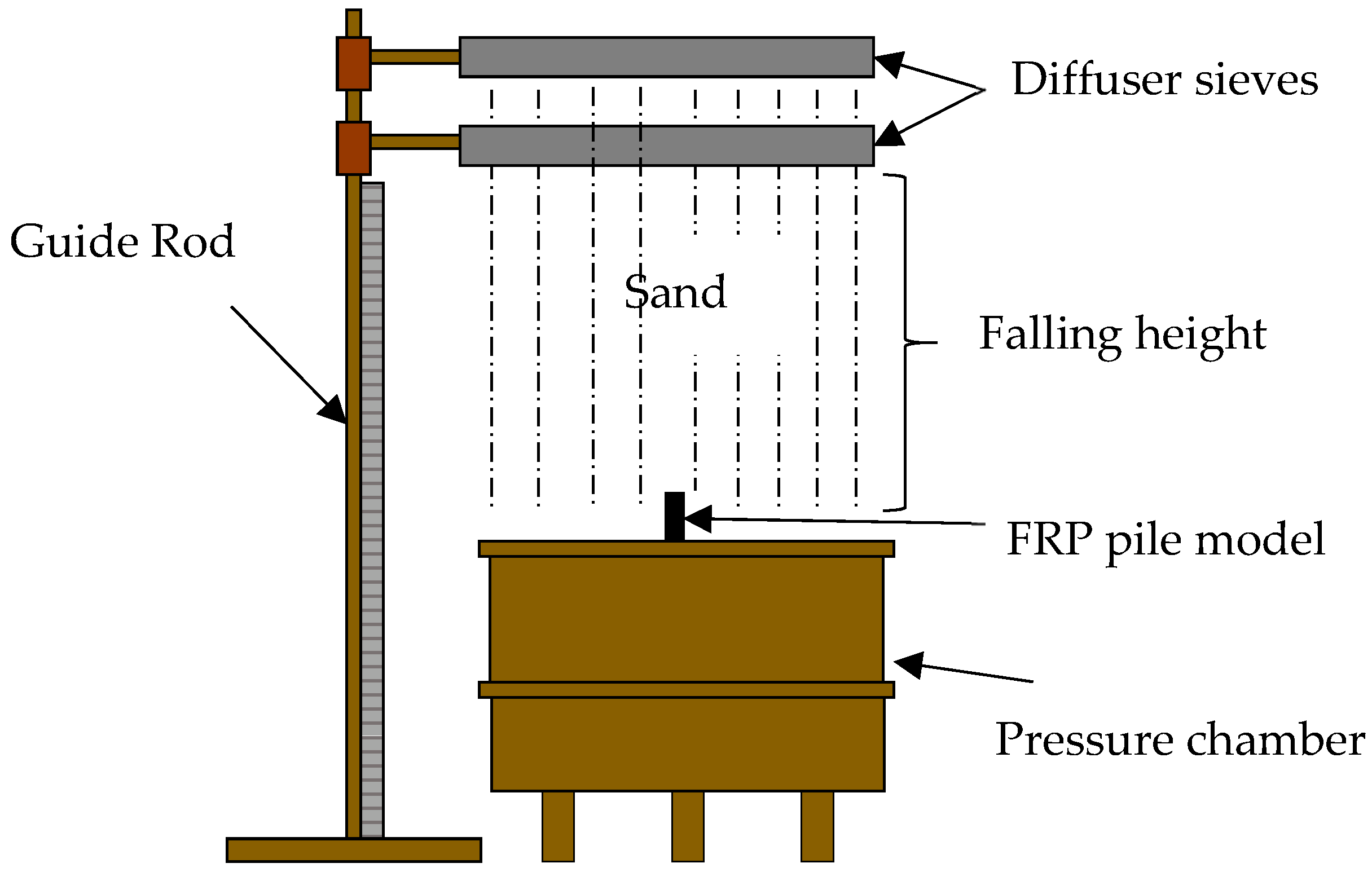

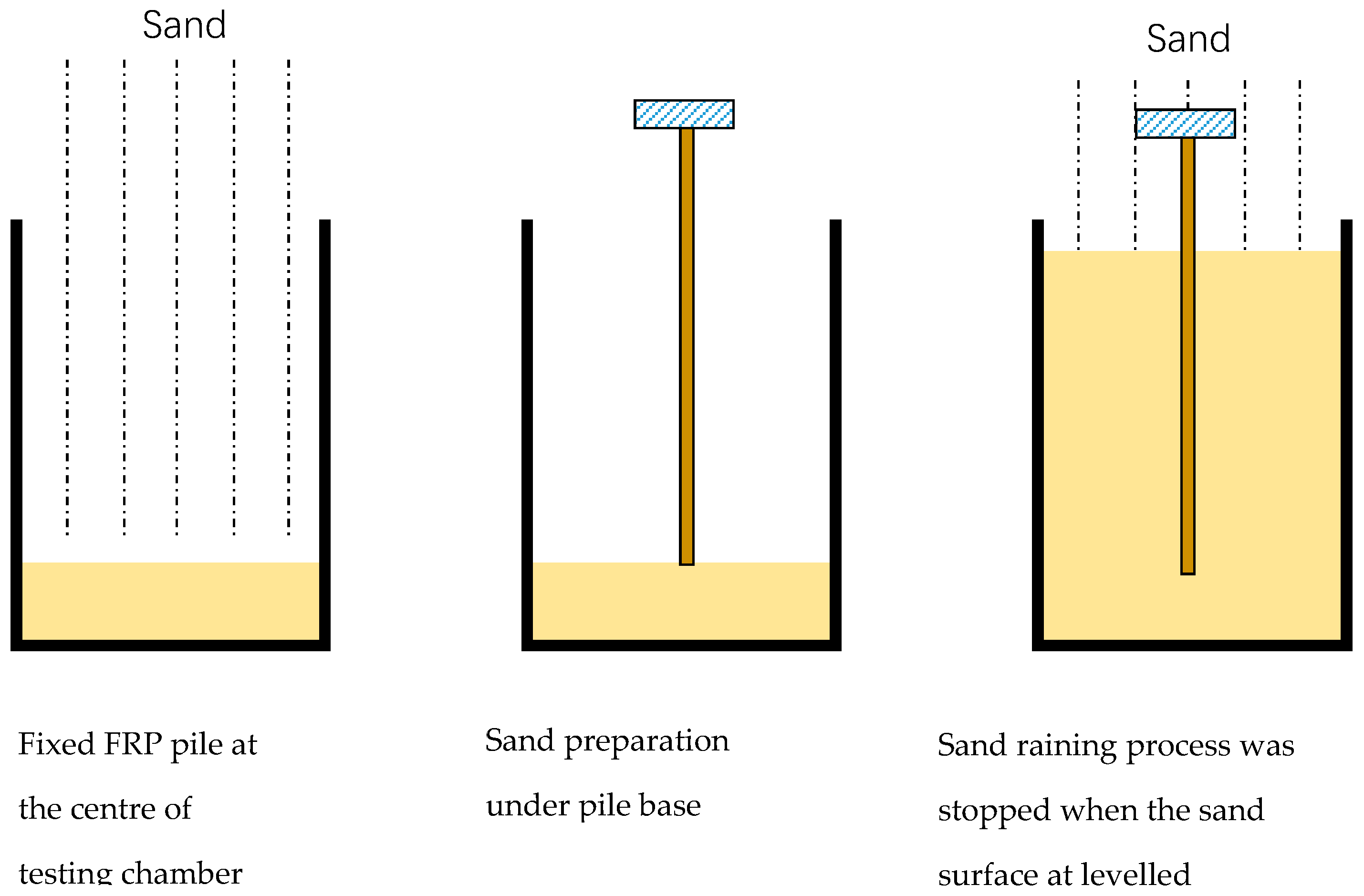

3.1. Preparation Procedures

3.2. Experimental Program

4. Results

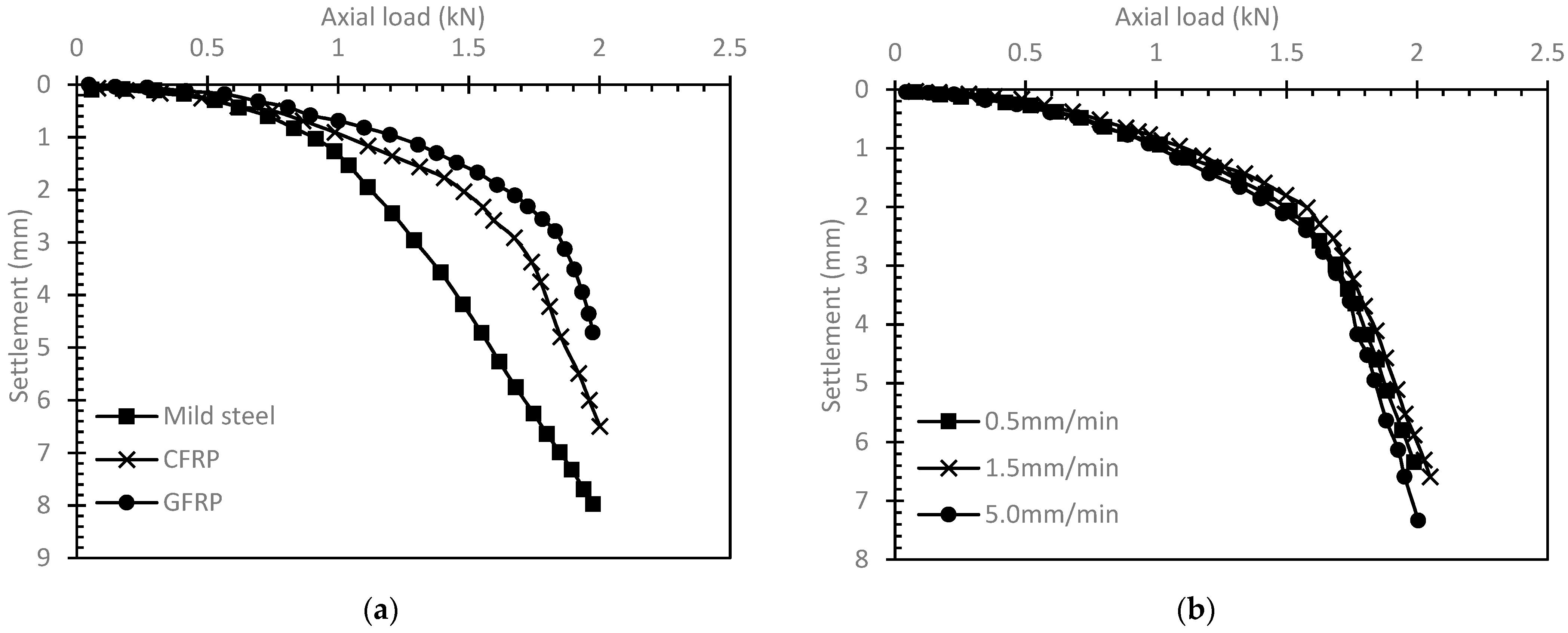

4.1. Factors Affecting FRP Pile Behaviour under an Axial Load

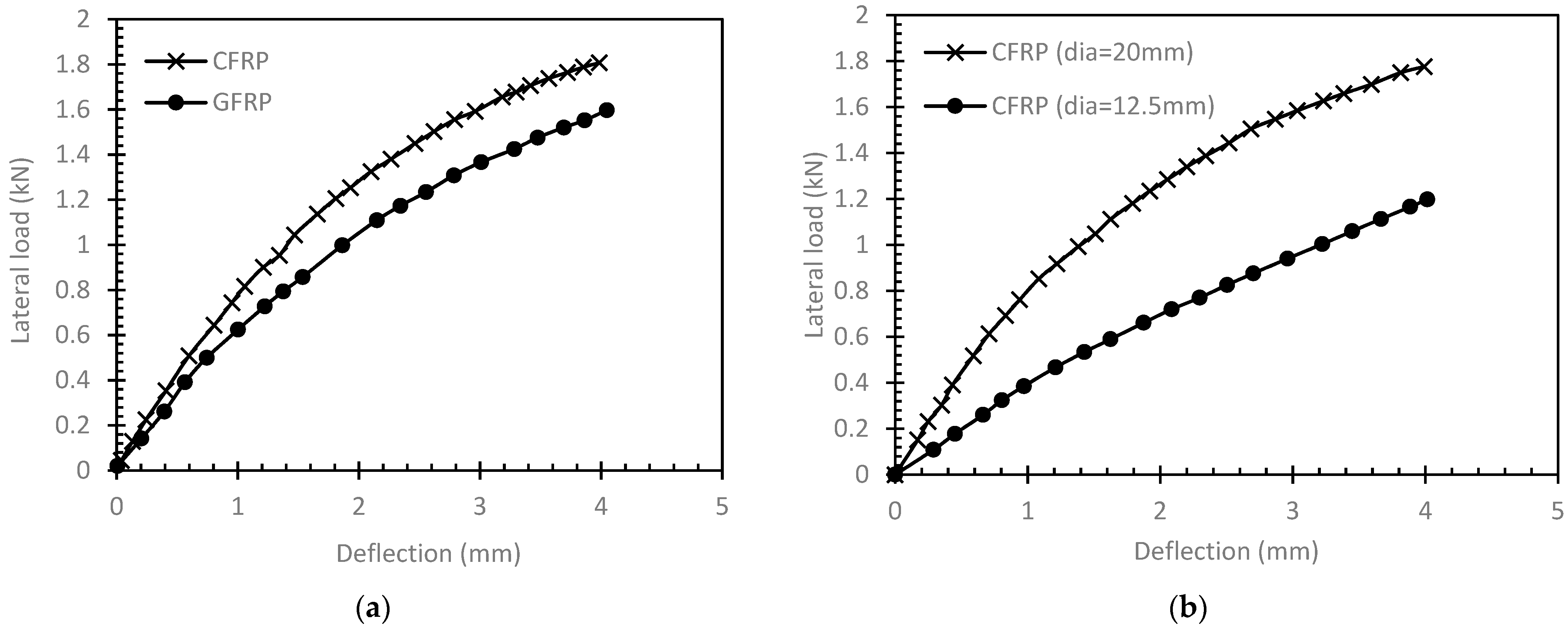

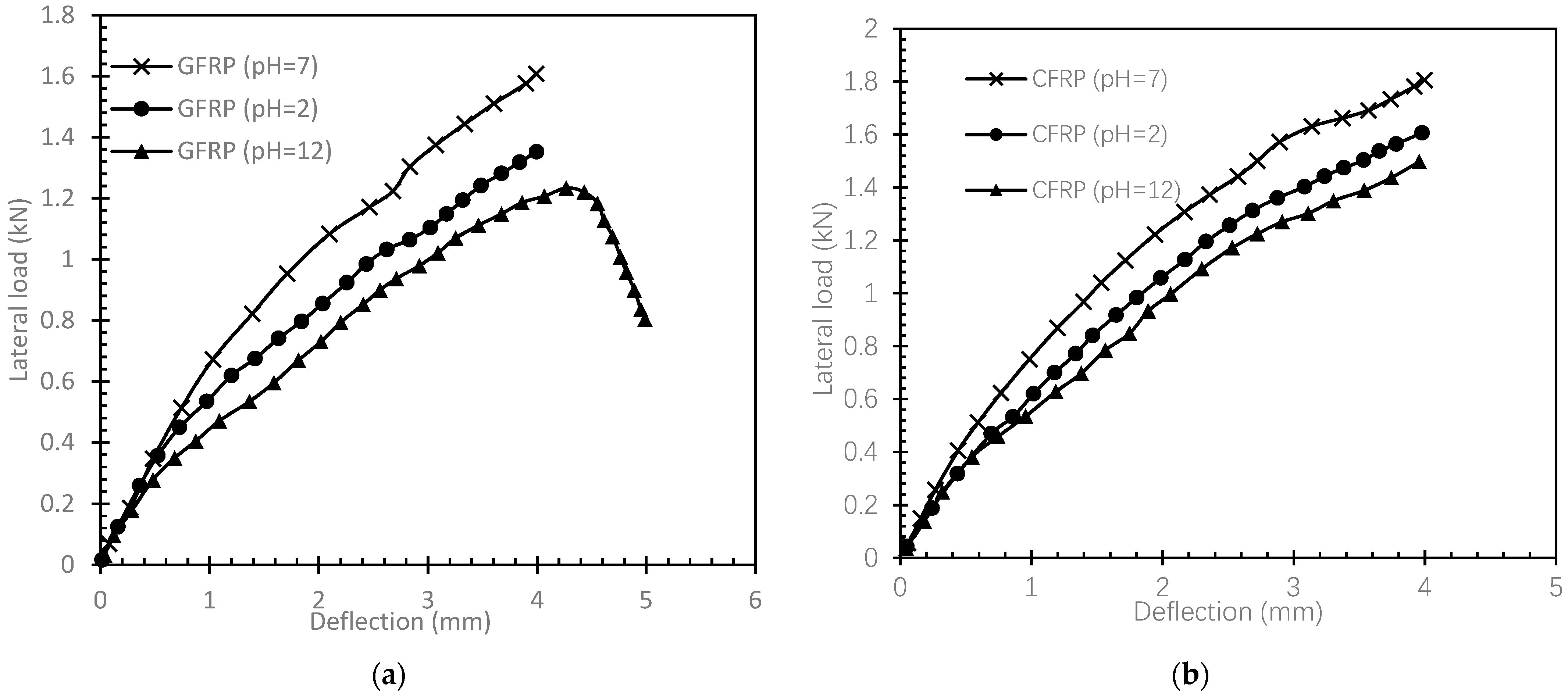

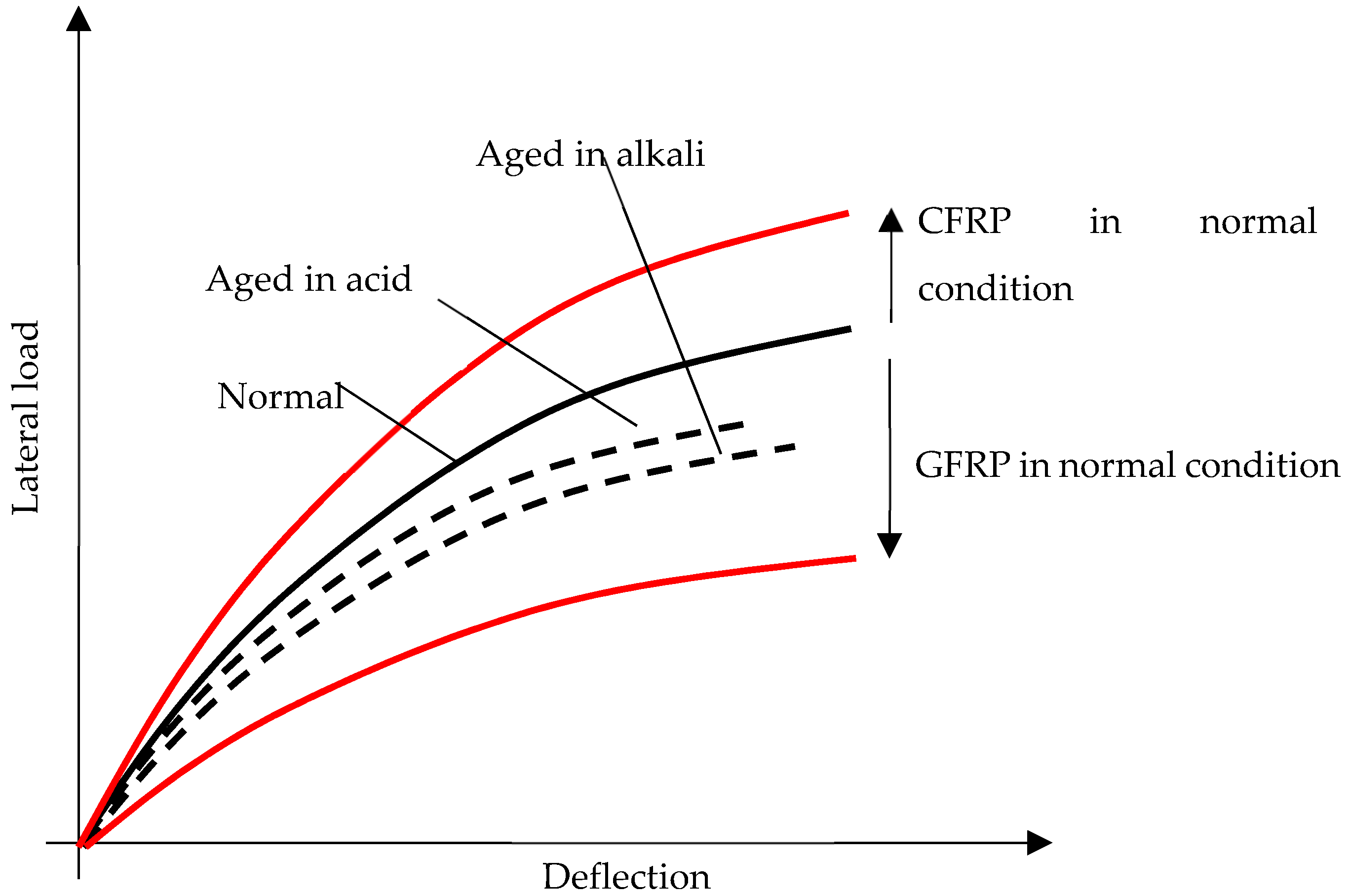

4.2. Factors Affecting FRP Pile Behaviour under a Lateral Load

5. Discussion

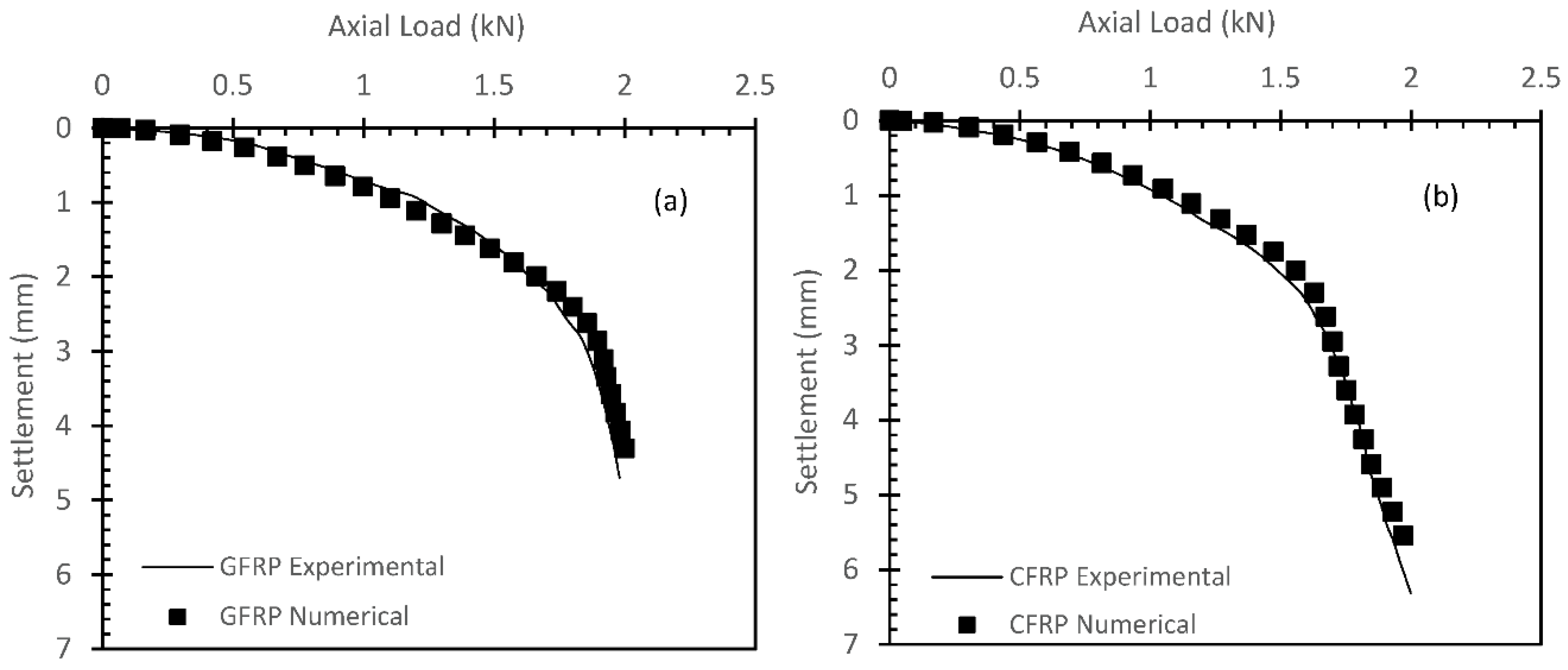

6. Numerical Modelling of Sand Type Influence

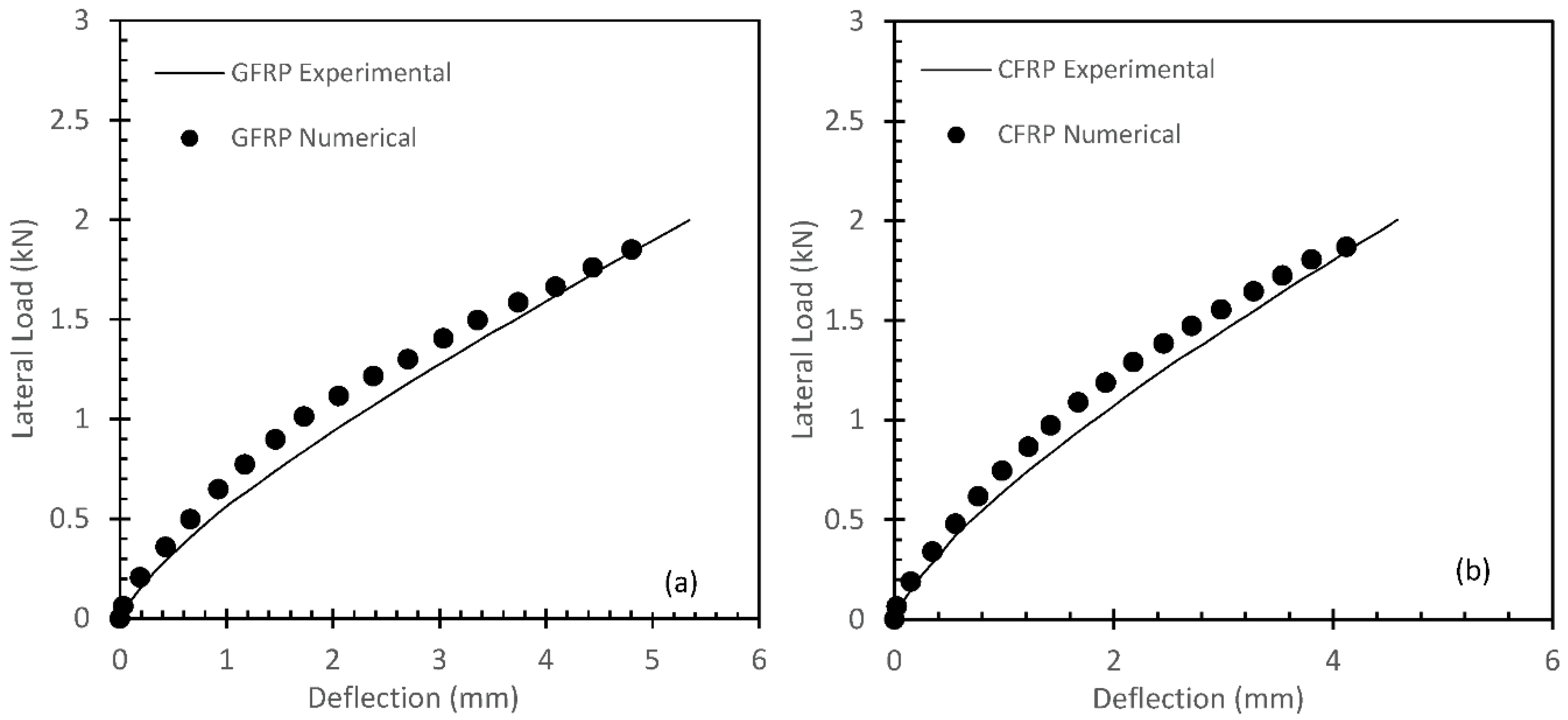

6.1. Model Construction and Validation

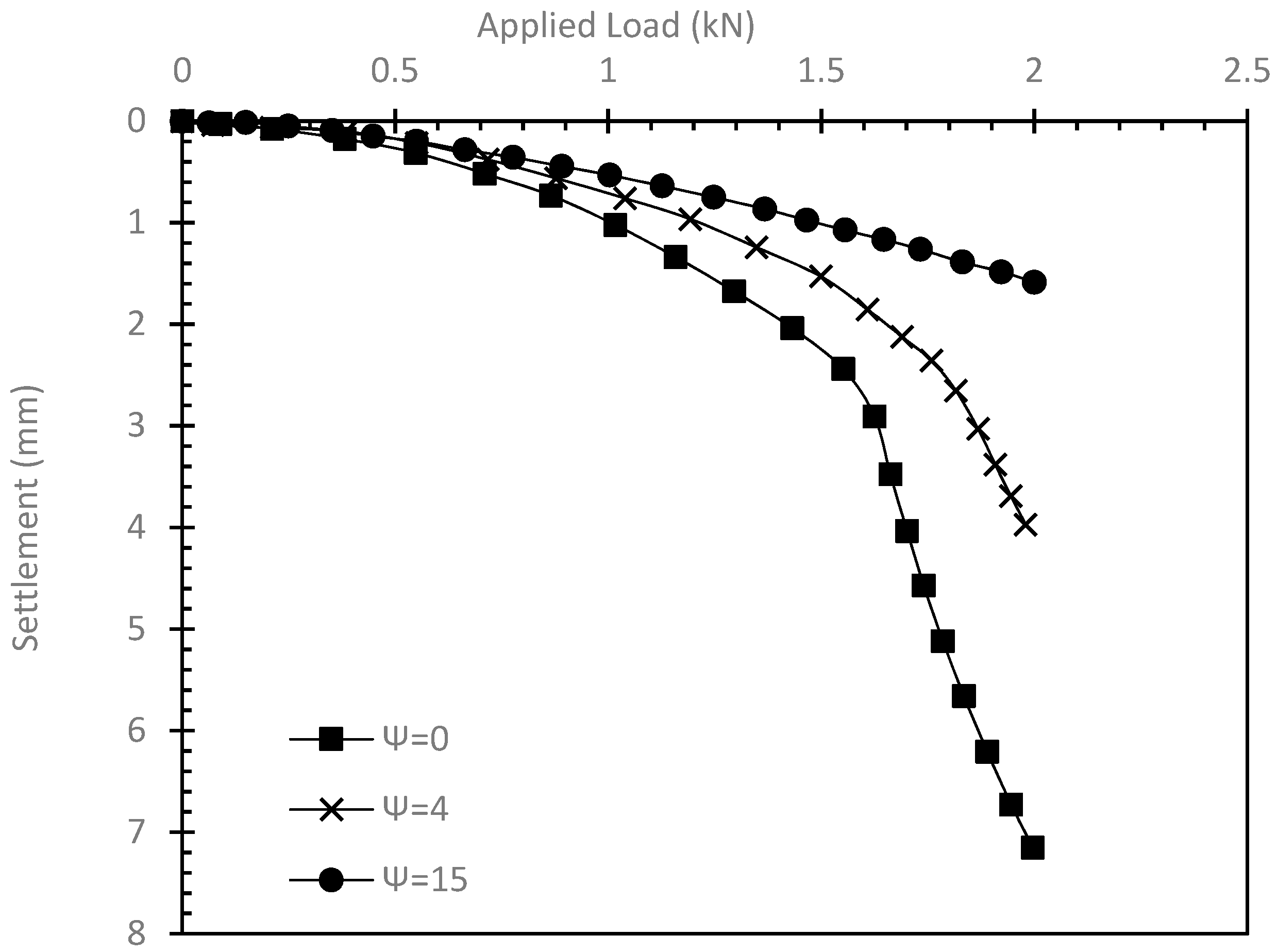

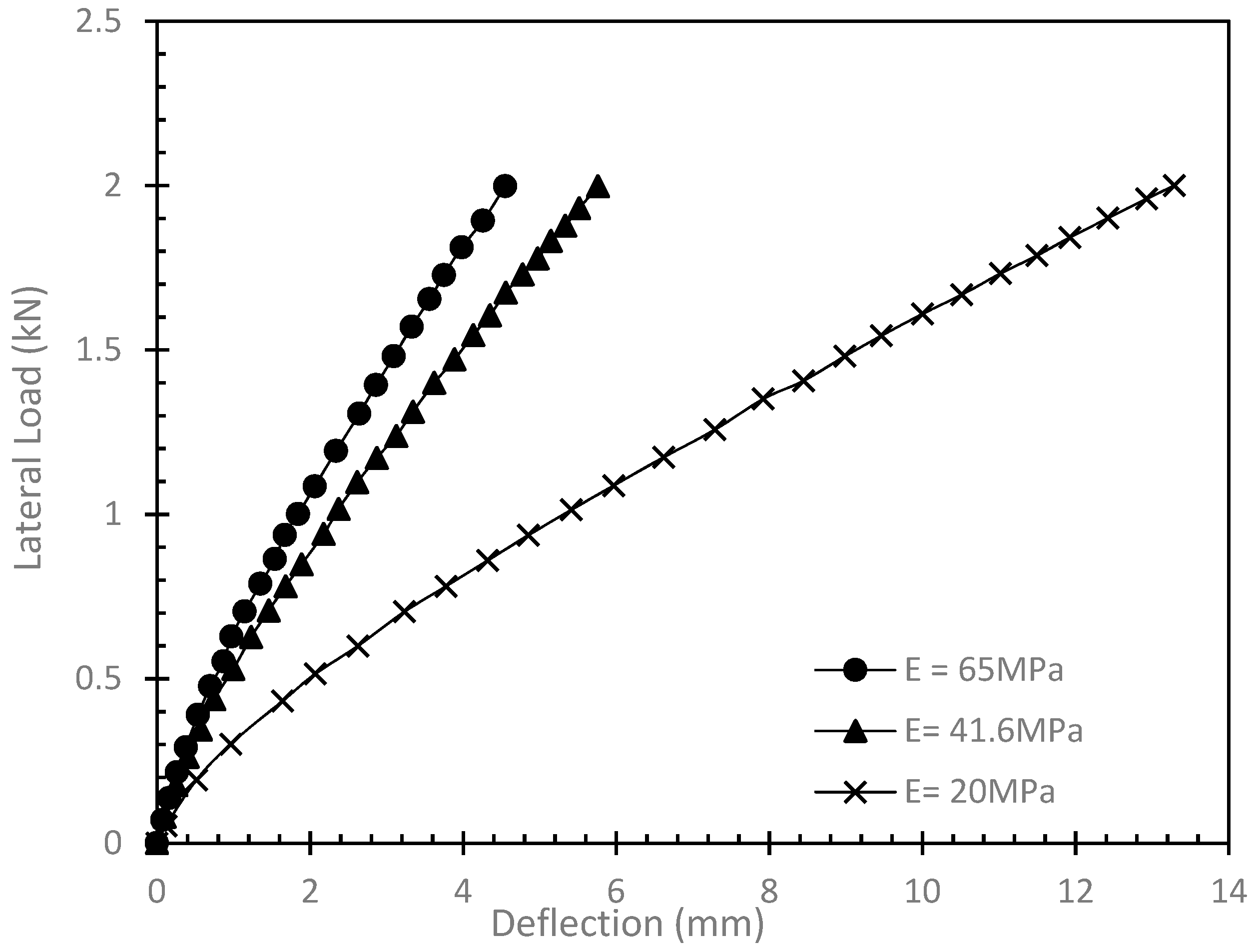

6.2. Parametric Study of Dilation (ψ) and Young’s Modulus (E) Influence

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shaia, H. Behaviour of Fibre Reinforced Polymer Composite Piles: Experimental and Numerical Study. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2013. [Google Scholar]

- Guades, E.; Aravinthan, T.; Islam, M.; Manalo, A. A Review on the Driving Performance of FRP Composite Piles. Compos. Struct. 2012, 94, 1932–1942. [Google Scholar] [CrossRef]

- Feng, B.; Zhu, Y.-H.; Xie, F.; Chen, J.; Liu, C.-B. Experimental Investigation and Design of Hollow Section, Centrifugal Concrete-Filled GFRP Tube Columns. Buildings 2021, 11, 598. [Google Scholar] [CrossRef]

- Alampalli, S.; O’Connor, J.; Yannotti, A.P.; Luu, K.T. FRPs for Bridge Construction and Rehabilitation in New York. In Materials and Construction: Exploring the Connection; ASCE: Reston, VA, USA, 1999; pp. 345–350. [Google Scholar]

- Gresil, M.; Revol, V.; Kitsianos, K.; Kanderakis, G.; Koulalis, I.; Sauer, M.-O.; Trétout, H.; Madrigal, A.-M. EVITA Project: Comparison between Traditional Non-Destructive Techniques and Phase Contrast X-ray Imaging Applied to Aerospace Carbon Fibre Reinforced Polymer. Appl. Compos. Mater. 2017, 24, 513–524. [Google Scholar] [CrossRef] [Green Version]

- Taipalus, R.; Harmia, T.; Friedrich, K. Short Fibre Reinforced PP/PANI-Complex Blends and Their Mechanical and Electrical Properties. Appl. Compos. Mater. 1999, 6, 167–175. [Google Scholar] [CrossRef]

- Kuboki, T.; Gallagher, E.; Jar, P.-Y.; Cheng, J.J.R. A New Method to Quantify Delamination Resistance of Fibre Reinforced Polymers (FRP) under Transverse Loading. Appl. Compos. Mater. 2005, 12, 93–108. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Breidt, C. Impact Resistance of Short Fibre/Particle Reinforced Epoxy. Appl. Compos. Mater. 2004, 11, 1–15. [Google Scholar] [CrossRef]

- Schneider, K.; Lauke, B. Determination of Compressive Properties of Fibre-Reinforced Polymers in the In-Plane Direction According to ISO 14126. Part 2: A Critical Investigation of Failure Behaviour. Appl. Compos. Mater. 2007, 14, 177–191. [Google Scholar] [CrossRef]

- Alshimmeri, A.J.H.; Jaafar, E.K.; Shihab, L.A.; Al-Maliki, H.N.G.; Al-Balhawi, A.; Zhang, B. Structural Efficiency of Non-Prismatic Hollow Reinforced Concrete Beams Retrofitted with CFRP Sheets. Buildings 2022, 12, 109. [Google Scholar] [CrossRef]

- Kaw, A.K. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Fam, A.Z.; Rizkalla, S.H. Flexural Behavior of Concrete-Filled Fiber-Reinforced Polymer Circular Tubes. J. Compos. Constr. 2002, 6, 123–132. [Google Scholar] [CrossRef]

- Tuakta, C. Use of Fiber Reinforced Polymer Composite in Bridge Structures. Ph.D. Thesis, Massachusetts Institute of Technology, Massachusetts, UK, 2005. [Google Scholar]

- Nanni, A.; Bradford, N.M. FRP Jacketed Concrete under Uniaxial Compression. Constr. Build. Mater. 1995, 9, 115–124. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Ehsani, M.R.; Li, M.-W. Strength and Ductility of Concrete Columns Externally Reinforced with Fiber Composite Straps. Struct. J. 1994, 91, 434–447. [Google Scholar]

- Mirmiran, A.; Shahawy, M. A New Concrete-Filled Hollow FRP Composite Column. Compos. Part B Eng. 1996, 27, 263–268. [Google Scholar] [CrossRef]

- Fardis, M.N.; Khalili, H. Concrete Encased in Fiberglass-Reinforced Plastic. J. Proc. 1981, 78, 440–446. [Google Scholar]

- Al Abadi, H.; El-Naga, H.A.; Shaia, H.; Paton-Cole, V. Refined Approach for Modelling Strength Enhancement of FRP-Confined Concrete. Constr. Build. Mater. 2016, 119, 152–174. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, C.; Yan, L.; Kasal, B. Flexural Behavior of U-Shape FRP Profile-RC Composite Beams with Inner GFRP Tube Confinement at Concrete Compression Zone. Compos. Struct. 2018, 184, 674–687. [Google Scholar] [CrossRef]

- Huang, L.; Chen, L.; Yan, L.; Kasal, B.; Jiang, Y.; Liu, C. Behavior of Polyester FRP Tube Encased Recycled Aggregate Concrete with Recycled Clay Brick Aggregate: Size and Slenderness Ratio Effects. Constr. Build. Mater. 2017, 154, 123–136. [Google Scholar] [CrossRef]

- Iskander, M.G.; Hassan, M. State of the Practice Review in FRP Composite Piling. J. Compos. Constr. 1998, 2, 116–120. [Google Scholar] [CrossRef]

- Lee, C.; Bonacci, J.F.; Thomas, M.D.; Maalej, M.; Khajehpour, S.; Hearn, N.; Pantazopoulou, S.; Sheikh, S. Accelerated Corrosion and Repair of Reinforced Concrete Columns Using Carbon Fibre Reinforced Polymer Sheets. Can. J. Civ. Eng. 2000, 27, 941–948. [Google Scholar] [CrossRef]

- Green, M.F.; Bisby, L.A.; Fam, A.Z.; Kodur, V.K. FRP Confined Concrete Columns: Behaviour under Extreme Conditions. Cem. Concr. Compos. 2006, 28, 928–937. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Islam, M.M.; Aravinthan, T.; Manalo, A.; Lau, K. Effectiveness of Using Fibre-Reinforced Polymer Composites for Underwater Steel Pipeline Repairs. Compos. Struct. 2013, 100, 40–54. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Nusier, O.; Abdalla, K.; Alhassan, M.; Lagaros, N.D. NLFEA of Sulfate-Damaged Circular CFT Steel Columns Confined with CFRP Composites and Subjected to Axial and Cyclic Lateral Loads. Buildings 2022, 12, 296. [Google Scholar] [CrossRef]

- Li, W.; Wen, F.; Zhou, M.; Liu, F.; Jiao, Y.; Wu, Q.; Liu, H. Assessment and Prediction Model of GFRP Bars’ Durability Performance in Seawater Environment. Buildings 2022, 12, 127. [Google Scholar] [CrossRef]

- Triantafyllou, G.; Rousakis, T.; Karabinis, A. Corroded RC Beams at Service Load before and after Patch Repair and Strengthening with NSM CFRP Strips. Buildings 2019, 9, 67. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Frost, J.D. Buckling of Vertically Loaded Fiber-Reinforced Polymer Piles. J. Reinf. Plast. Compos. 1999, 18, 290–318. [Google Scholar] [CrossRef]

- Sakr, M.; El Naggar, M.H.; Nehdi, M. Wave Equation Analyses of Tapered FRP–Concrete Piles in Dense Sand. Soil Dyn. Earthq. Eng. 2007, 27, 166–182. [Google Scholar] [CrossRef]

- Broms, B.B. Lateral Resistance of Piles in Cohesionless Soils. J. Soil Mech. Found. Div. 1964, 90, 123–158. [Google Scholar] [CrossRef]

- Meyerhof, G.G. Behaviour of Pile Foundations under Special Loading Conditions: 1994 RM Hardy Keynote Address. Can. Geotech. J. 1995, 32, 204–222. [Google Scholar] [CrossRef]

- Giraldo Valez, J.; Rayhani, M.T. Axial and Lateral Load Transfer of Fibre-Reinforced Polymer (FRP) Piles in Soft Clay. Int. J. Geotech. Eng. 2017, 11, 149–155. [Google Scholar] [CrossRef]

- Giraldo, J.; Rayhani, M.T. Load Transfer of Hollow Fiber-Reinforced Polymer (FRP) Piles in Soft Clay. Transp. Geotech. 2014, 1, 63–73. [Google Scholar] [CrossRef]

- Riebel, F.; Keller, T. Long-Term Compression Performance of a Pultruded GFRP Element Exposed to Concrete Pore Water Solution. J. Compos. Constr. 2007, 11, 437–447. [Google Scholar] [CrossRef]

- Dayal, U.; Allen, J.H. The Effect of Penetration Rate on the Strength of Remolded Clay and Sand Samples. Can. Geotech. J. 1975, 12, 336–348. [Google Scholar] [CrossRef]

- Salini, U.; Girish, M.S. Lateral Load Capacity of Model Piles on Cohesionless Soil. Electron. J. Geotech. Eng. 2009, 14, 1–11. [Google Scholar]

- Xu, J.Z.; You, B.; Wang, B.G. Curing Process Simulation of Fiberglass-Reinforced Plastic (Frp) Pipes. Mater. Manuf. Processes 2009, 24, 657–666. [Google Scholar] [CrossRef]

- Lee, M.C.; Peppas, N.A. Water Transport in Epoxy Resins. Prog. Polym. Sci. 1993, 18, 947–961. [Google Scholar]

- Murphy, K.; Zhang, S.; Karbhari, V.M. Effect of Concrete Based Alkaline Solutions on Short Term Response of Composites. Soc. Adv. Mater. Process Eng. Evol. Revolut. Technol. New Millenium 1999, 44, 2222–2230. [Google Scholar]

- Katsuki, F.; Uomoto, T. Prediction of deterioration of frp rods due to alkali attack. In Proceedings of the Second International RILEM Symposium, Ghent, Belgium, 23–25 August 1995; CRC Press: Boca Raton, FL, USA, 1995; Volume 29, p. 82. [Google Scholar]

- Bisby, L.A. Durability of FRP Composites for Construction; Department of Civil Engineering, Queen’s University: Belfast, UK, 2006. [Google Scholar]

- Helwany, S. Applied Soil Mechanics with ABAQUS Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

| Name | Cement:Sand:Aggregate | Water/Cement | Silica Fume % | Superplasticiser % |

|---|---|---|---|---|

| Mortar | 1:2:0 | 0.4 | 10 to cement | 0.15 |

| Effect of Study | Pile Type | No. of Tests | Confined Pressure (kPa) | Relative Density % |

|---|---|---|---|---|

| Surface roughness | GFRP/CFRP/Mild steel | 3 | 250 | 80 |

| Loading rate | CFRP | 3 | 250 | 80 |

| Vertical pressure | GFRP | 2 | 250/100 | 80 |

| Relative density | GFRP | 2 | 250 | 80/60 |

| Study | Pile Type | No. of Tests | Confined Pressure (kPa) | Relative Density % |

|---|---|---|---|---|

| FRP type | GFRP/CFRP | 2 | 120 | 80 |

| Pile diameter | CFRP | 2 | 120 | 80 |

| Aging in the environment (pH = 2) | GFRP/CFRP | 2 | 120 | 80 |

| Aging in the environment (pH = 12) | GFRP/CFRP | 2 | 120 | 80 |

| Pile Type | Rt (µm) |

|---|---|

| GFRP | 27.3 |

| CFRP | 18.1 |

| Mild steel | 7.8 |

| Material | Model | Young’s Modulus, E, (MPa) | Poisson’s Ratio, υ | ϕ (°) | Ψ (°) |

|---|---|---|---|---|---|

| Pile | Elastic | 28,000 | 0.22 | ---- | --- |

| Sand | Mohr−Coulomb | 41.5 | 0.31 | 33 | 4 |

| Property | Symbol | Unit | CFRP | GFRP |

|---|---|---|---|---|

| Density | ρ | g/cm3 | 1.6 | 2 |

| Longitudinal Modulus * | E1 | MPa | 135,000 | 50,000 |

| Transverse in-Plane Modulus * | E2 | MPa | 10,000 | 40,000 |

| Transverse in-Plane Modulus * | E3 | MPa | 10,000 | 8500 |

| In-plane Shear Modulus ** | G12 | MPa | 5000 | 4300 |

| Out-of-Plane Shear Modulus ** | G23 | MPa | 1900 | 3500 |

| Out-of-Plane Shear Modulus ** | G13 | MPa | 5000 | 4300 |

| Major in-Plane Poisson’s ratio ** | υ12 | ---- | 0.3 | 0.27 |

| Out-of-Plane Poisson’s Ratio ** | υ23 | ---- | 0.5 | 0.5 |

| Out-of-Plane Poisson’s Ratio ** | υ13 | ---- | 0.3 | 0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Abuel-Naga, H.; Shaia, H.A.; Shang, Z. Preliminary Study on the Behaviour of Fibre-Reinforced Polymer Piles in Sandy Soils. Buildings 2022, 12, 1144. https://doi.org/10.3390/buildings12081144

Lu Y, Abuel-Naga H, Shaia HA, Shang Z. Preliminary Study on the Behaviour of Fibre-Reinforced Polymer Piles in Sandy Soils. Buildings. 2022; 12(8):1144. https://doi.org/10.3390/buildings12081144

Chicago/Turabian StyleLu, Yi, Hossam Abuel-Naga, Hussein A. Shaia, and Zhi Shang. 2022. "Preliminary Study on the Behaviour of Fibre-Reinforced Polymer Piles in Sandy Soils" Buildings 12, no. 8: 1144. https://doi.org/10.3390/buildings12081144

APA StyleLu, Y., Abuel-Naga, H., Shaia, H. A., & Shang, Z. (2022). Preliminary Study on the Behaviour of Fibre-Reinforced Polymer Piles in Sandy Soils. Buildings, 12(8), 1144. https://doi.org/10.3390/buildings12081144