1. Introduction

Due to material performance degradation, overloading, corrosive environments, and other effects, the performance of a bridge structure will gradually degrade, leading to potential safety hazards. In August 2008, the I-35W Bridge in the United States suddenly collapsed during rush hour, resulting in 13 deaths and 145 injuries [

1]. In April 1987, the Schoharie Creek Bridge in New York, USA, collapsed, resulting in 10 deaths [

2]. To avoid bridge accidents, structural health monitoring and condition assessments are usually implemented to evaluate the technical condition of existing bridge structures. A baseline finite element (FE) model, which can reflect the structural behavior of the actual bridge, is widely used in bridge condition assessment. However, due to the simplifications in FE modeling and the uncertainties in material properties, and also the errors of boundary conditions, the initial FE model established according to the design drawings usually fails to represent the actual bridge. Thus, updating the initial FE model, called FE model updating, according to the experimentally measured results, is necessary [

3,

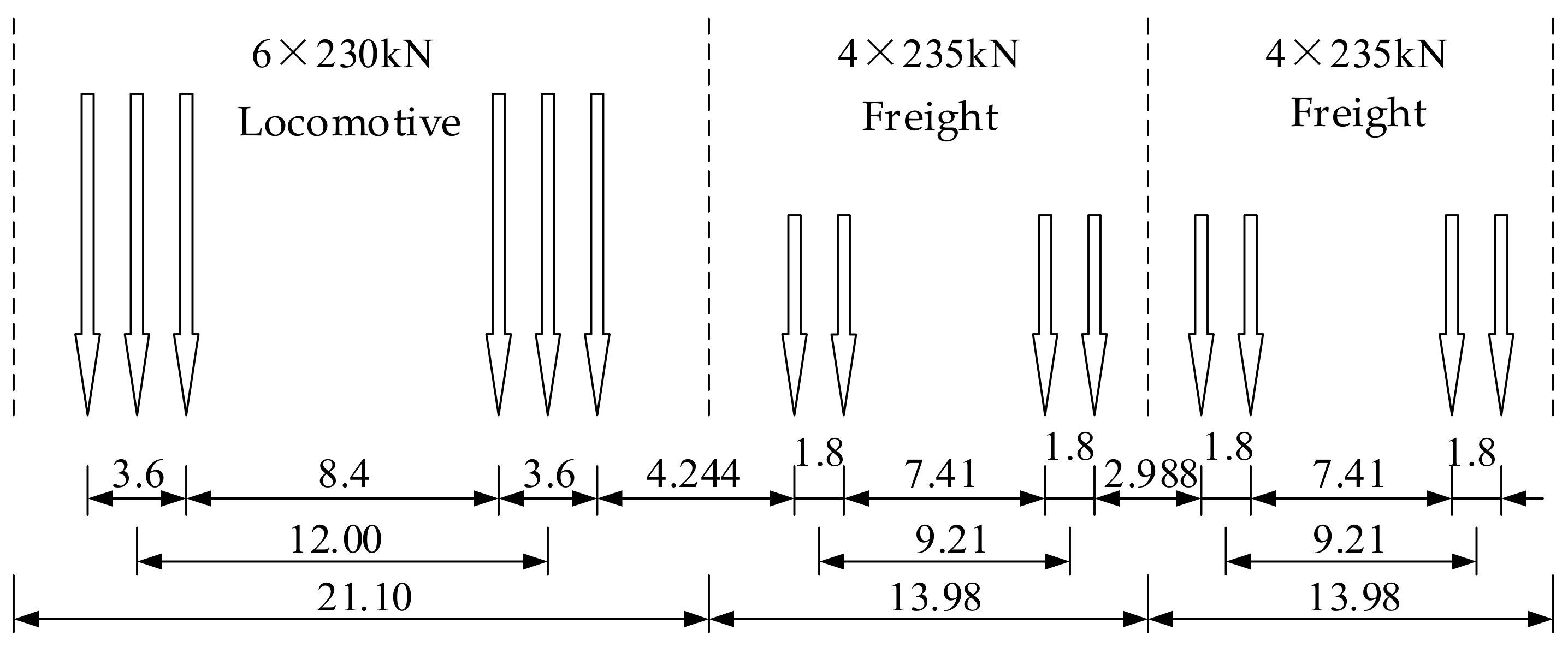

4,

5,

6]. Many studies regarding FE model updating have been published in the past decade. A detailed overview of FE model updating can be found in reference [

7].

FE model updating is essentially defined as an optimization problem with an objective function, which is usually expressed by the discrepancies between FE-calculated structural responses (such as displacement and modal parameters) and the experimentally measured ones. The objective function of bridge FE model updating usually has the characteristics of multi-dimensionality, high nonlinearity, and multiple local extremes. Traditional optimization algorithms, such as gradient-based algorithms [

8,

9] and the Newton iteration method [

10,

11], easily fall into the local optimum when dealing with such optimization problems. Consequently, these algorithms find it difficult to obtain the global optimal solution of the objective function. In recent years, metaheuristic algorithms, such as particle swarm optimization algorithm (PSO) [

12,

13], bee colony algorithm (BCA) [

14,

15], ant colony algorithm [

16,

17], and gravitational search algorithm (GSA) [

18,

19], which are based on intelligent optimization theory, have been developed and widely used in multidisciplinary optimization problems. For example, Huang et al. [

20] proposed a nondestructive global damage identification method based on vibration and successfully applied the method to three-span continuous beams and two-span steel grids in multiple damage scenarios. Huang et al. [

21] proposed a structural damage identification method based on support vector machine (SVM) and moth-flame optimization (MFO) and successfully applied the method to a simply-supported beam and an actual bridge engineering example. It is generally accepted that, compared with traditional algorithms, metaheuristic algorithms have certain advantages in dealing with nonlinear and multi-extremum issues [

22].

Although the metaheuristic algorithm is superior to traditional optimization algorithms to a certain extent, it is still limited by the characteristics of the algorithm itself [

22,

23]. There is a contradiction between the population’s diversity and the algorithm’s convergence speed in the search process. Especially in actual engineering cases, most of them have multiple extreme points, and the algorithm easily falls into the local optimum. Therefore, the metaheuristic algorithm’s performance needs to be improved. On this issue, some relevant research has been conducted. Ding et al. [

24] introduced two local search strategies into the artificial bee colony algorithm to improve the identification accuracy of the algorithm. The authors proved that the improved algorithm could provide more accurate results using incomplete modal data through a case study of a real structure. To solve the problem of premature convergence in the ant colony algorithm, Yang [

25] utilized step control parameters to improve the performance of the standard ant colony algorithm. Their study shows that the improved ant colony algorithm can provide better results. Jiang et al. [

26] divided the population into several subpopulations by combining the concepts of PSO, competitive evolution, and complex shuffle to solve the local convergence problem. Each subpopulation independently executes the standard PSO, and after several iterations the subpopulations are mixed to ensure information sharing. The authors applied the improved algorithm to hydrological model updating and proved that the improved PSO could jump out the local minimums. Marzband et al. [

27] proposed an optimization method based on GSA. A control parameter was added to the GSA algorithm to adjust the searching ability of the algorithm in later stages to avoid premature inaccuracies. The improved GSA algorithm was applied to a real-time energy management system of the microgrid to achieve the highest efficiency, improve the efficiency of economic dispatch, and obtain the best performance. The above studies aim to optimize and improve the algorithm parameters of a particular algorithm, while some other studies integrate two optimization algorithms to improve the algorithms’ performance. Wang et al. [

28] introduced the artificial fish swarm algorithm to construct an entropy path planning model of the hybrid ant colony and artificial fish swarm algorithm to improve the convergence speed and accuracy of the algorithm. Based on the combination of GSA and PSO, Hu et al. [

29] changed the constant acceleration coefficient into an exponential function and proposed an improved PSO-GSA algorithm to solve the robot’s surface water quality and movement direction. The results showed that the hybrid algorithm can improve the local convergence problem of the standard algorithm. Huang et al. [

30] introduced Levy-flight in the whale optimization algorithm to increase the diversity of the population to solve the problems of premature maturity and slow convergence of the whale optimization algorithm. The improved whale optimization algorithm was applied to the damage identification of three examples. To improve the sampling efficiency of standard Metropolis-Hastings (MH), Luo et al. [

31] introduced the particle position update mechanism of PSO into the MH algorithm and formed the MH-PSO hybrid Markov chain Monte Carlo sampling method. The sampling method was successfully applied to the Bayesian model updating of a cantilever beam and ASCE benchmark frame.

The abovementioned improvement strategy is only applicable to one metaheuristic algorithm. Most metaheuristic algorithms receive inspiration from random phenomena and swarm intelligence behaviors in nature, and the random search module is introduced based on the heuristic algorithm, making the metaheuristic algorithm more widely applicable. This study proposes an improvement strategy that is generally applicable to different metaheuristic algorithms to improve the metaheuristic algorithm’s local convergence and search accuracy. Based on the idea of survival of the fittest in biological evolution, the improvement strategy adds random crossover and mutation calculations within the standard metaheuristic algorithm to improve the position of the population in the search space to jump out of the local optimum and improve the search accuracy.

The framework of this paper is as follows.

Section 2 introduces the basic theory of FE model updating, based on the kriging surrogate model.

Section 3 presents the metaheuristic algorithm and the improvement strategy and verifies the results of the improvement through benchmark functions.

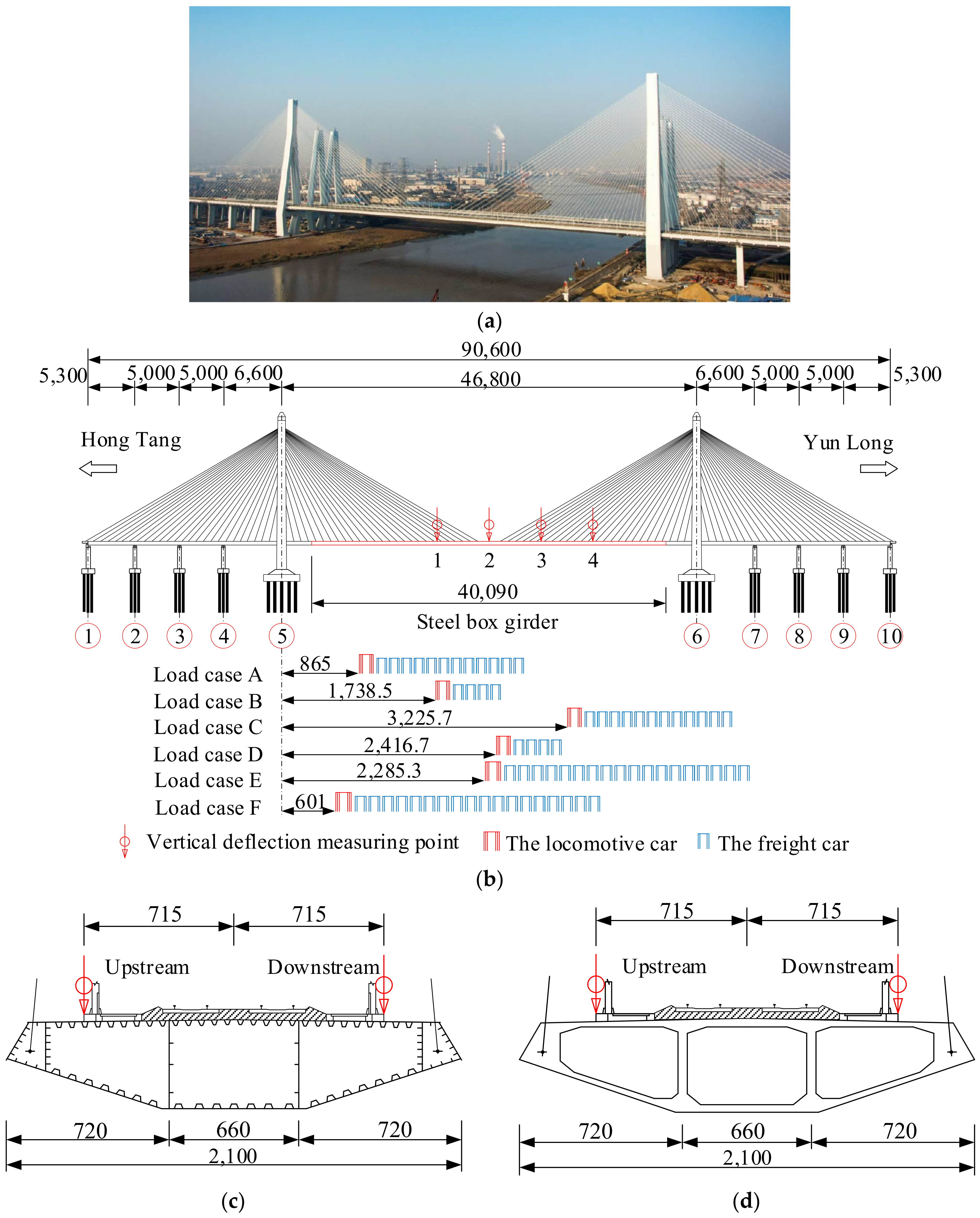

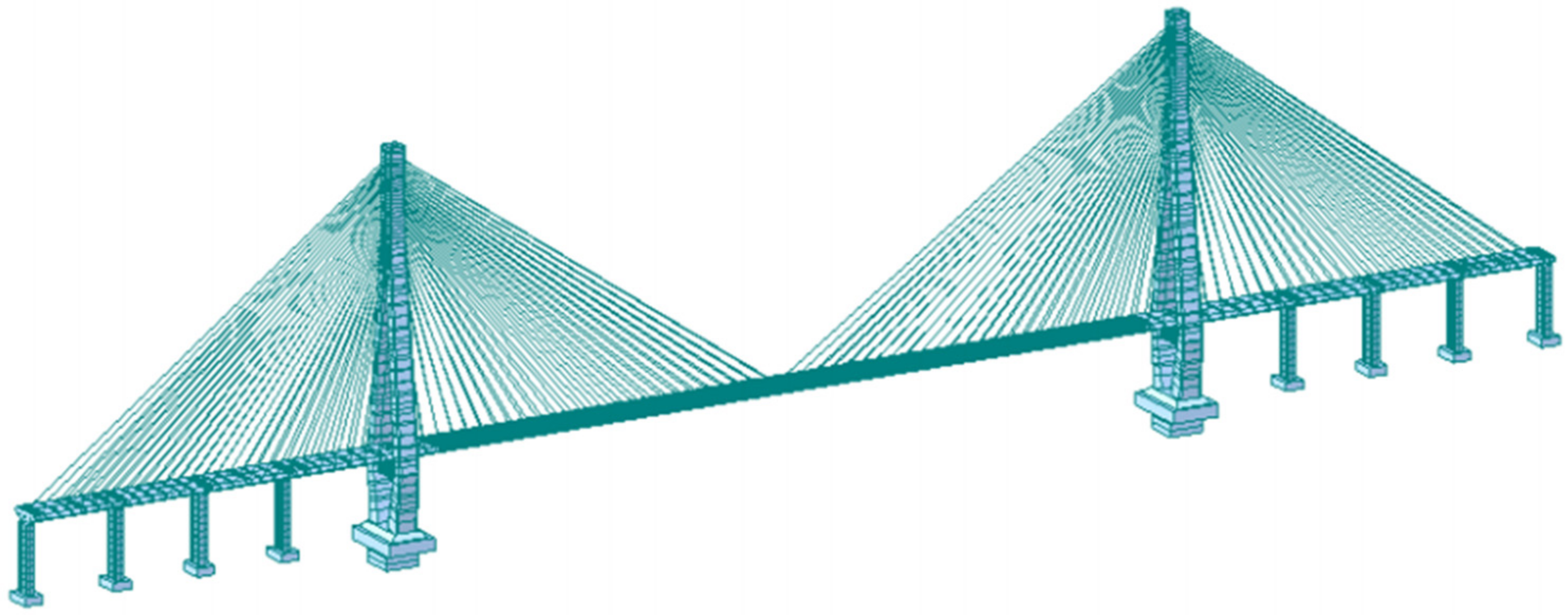

Section 4 numerically investigates the performance of the improvement strategy through FE model updating of a space truss structure. In

Section 5, the FE model updating of a full-scale long-span hybrid girder cable-stayed railway bridge is implemented based on the proposed algorithm. The basic information of the bridge, the in situ testing, the initial FE model, the kriging model, and the updating results, using the improved metaheuristic algorithms, are introduced and discussed. The conclusions are made in the final section.

2. Model Updating Assisted with the Kriging Model

The essence of FE model updating is to reduce the error between the FE-calculated response values and the experimentally measured ones by updating the structural design parameters in the FE model. Therefore, the objective function

can be defined as:

where

x is the design parameter to be updated;

is the residual function between the calculated value and the measured value of the

i-th type of structural response;

m is the number of the kinds of structural responses considered in model updating;

is the weighting coefficient of the

i-th residual function; and

and

are the upper and lower bounds of the

m-th design parameter to be updated, respectively.

The iterative method is widely used to obtain the minimum value of the objective function in a design space. However, due to the implicit functional relationship between the structural response and the design parameters, the FE model calculates the residual function in each iteration, which is very time-consuming, especially for complex FE models of bridge structures. Surrogate models, such as polynomial response surface, radial basis function, and the kriging model, have been used for model updating to improve calculation efficiency. Study [

32] has shown that the kriging model predicts the value of each point in the design space and gives each point’s prediction error. Therefore, the kriging model was selected as the surrogate model in FE model updating to save computational cost. The primary process of FE model updating based on the kriging model can be divided into three steps. Firstly, the data samples of structural responses and design parameters are generated by the design of the experiment with the aid of the initial FE model. The commonly used experimental design methods include central composite design, D-optimal design, uniform design, and latin hypercube design. Then, the kriging model is established based on the data samples using mathematical regression. An accuracy test of the kriging model is usually evaluated before it is applied within FE model updating. Finally, the optimization algorithm is applied to find the minimum of the objective function in the design space.

The kriging model comprises a deterministic regression model and a random process. The structural response matrix

can be expressed as the function of the design parameter

x in the kriging model, and the formula is represented by:

where

n is the number of structural responses;

is the polynomial regression model, which approximates the model at the global scale;

is the regression coefficient;

is a polynomial function of the structural design parameters; and

is a random process matrix with a mean value of 0 and a covariance of

, which provides a local approximation of the model. The kriging model has been successfully applied to model updating, geological parameter analysis, and within multidisciplinary research fields [

33,

34,

35,

36]. A detailed description of the kriging model can be found therein.

3. Improvement Strategy of Metaheuristic Algorithm

3.1. Metaheuristic Algorithm

The metaheuristic algorithm improves on the heuristic algorithm, which combines random and local search algorithms. Metaheuristics are an iterative generation process; through the intelligent combination of different concepts, the process realizes the exploration and development of a search space by the heuristic algorithm. Learning strategies acquire and master information to discover near-optimal solutions in this process. Typical metaheuristic algorithms include GSA, simulated annealing algorithm (SA), genetic algorithm (GA), and PSO. GSA is taken as an example to illustrate the idea of a metaheuristic algorithm in this section.

GSA is an intelligent search algorithm that simulates the law of universal gravitation. Each particle in GSA can be regarded as an individual with its own position and moving speed. It can retain the optimal position that the particles have found so far and the global optimal position that all particles can find currently. In the standard GSA, the attraction

between particles

i and

j can be expressed as:

where

is the position of the

i-th individual in

d-dimensional space at time

t;

is the mass of individual

i at time

t;

is the mass of individual at time

t;

ε is a small constant; and

is the Euclidean distance between particles

i and

j, which can be expressed as:

represents the constant coefficient of universal gravitation at time

t, which can be defined as:

where

represents the initial value of the constant coefficient;

denotes the descent coefficient; and

T is the total number of iterations. Therefore, the resultant force

of the

i-th individual in the

d-dimensional space can be expressed by:

where

N is the number of particle populations and

rand is a random number between 0 and 1. The acceleration

of a particle

i at time

t instant can be expressed as:

where

is the inertial mass of the particle

i at time

t. The speed at which particles

i move in

d-dimensional space and the update of their position can be expressed as:

where

and

represent the moving speed and position of the

t-th particle, respectively. The inertial mass of

i-th particle

at the

t-th time step can be expressed as:

where

denotes the best solution of the individual at the

t-th time step.

and

denote the worst and best fitness of the individual in the population at the

t-th time step, respectively. Assuming that the gravitational mass

and inertial mass of the individual

are equal to the mass of the individual

, it follows that:

It is known that when the particle’s fitness is greater, the mass of the particle will be more prominent, and its moving speed will be slower, which will continue to attract particles with poor fitness to move to the position with better fitness.

3.2. Improvement Strategy

As previously mentioned, the metaheuristic algorithm easily falls into local optimal values because of the limitation of the algorithm itself when the search reaches the later stage, thus reducing the search accuracy and efficiency. This study proposes an improvement strategy that is generally applicable to different metaheuristic algorithms. The proposed improvement strategy introduces random crossover and mutation into a standard metaheuristic algorithm, improving the algorithm’s searching ability at the later stage. The idea of using GA to improve the performance of the algorithm has already been adopted in multi-objective optimization; for examples of this, see Deb et al. [

37] and Li and Zhang [

38]. However, local convergence is a complex issue for metaheuristic algorithms. It is affected by many factors such as the algorithm’s parameters, the definition of the optimization problem, termination criterion, etc. Although the improvement strategy can improve the performance of the standard algorithm to a certain extent, the improvement strategy is not free from local convergence problems. The detailed procedure for the improvement is described as follows.

The proposed method firstly generates an initial population with the population number of , calculating the fitness value of all particles and sorting the particles. Then, the algorithm divides the particles into optimal and inferior solution groups according to fitness values; the first 50% of the particles with better fitness values are regarded as the optimal solution group, and the last 50% of the particles with worse fitness are regarded as the inferior solution group. Since the individual particles of the optimal solution group are excellent, the random crossover operation is applied for the optimal solution group, which can retain the population information of the optimal solution group and ensure the algorithm’s search accuracy. However, inferior solutions require more remarkable changes to generate new offspring. The mutation operation is applied for the inferior solution group, which can enrich population diversity, help the metaheuristic algorithm to jump out of the local optimal solution, and improve the search ability in the later stage of the algorithm.

For example, all particles of PSO move in the direction of the particle with the best fitness value during optimization, resulting in a gradual decrease in the diversity of particles, with the particles often not being able to escape from the local optimal solution. In the case of the PSO algorithm falling into the local optimal solution, the mutation operation of the improvement strategy can enrich population diversity so that the algorithm can jump out of the local optimal solution and find the global optimal solution.

This study introduces a random judge condition to judge whether the algorithm entered into the later searching stage or not. If a random number

rand(0, 1) in each generation satisfies the following condition, the random crossover and mutation are applied to the two particles group. The condition is:

where

Gmax is the maximum generation;

t is the current generation; and

e is the natural index. It can be concluded from Equation (13) that with a generation’s increase, the probability of implementing random crossover and mutation operation also increases.

It is worth mentioning that the two particles for the random crossover operation in the improved algorithm are randomly selected, which can be expressed by:

where

represents the offspring generated from the optimal solution set;

and

represent random particles without duplication in the optimal solution set;

is an integer ranging from 1 to

;

is a random number ranging from 0 to 1;

represents the number of population particles within the optimal solution group; the size is

. The mutation operation is applied for the inferior solution group, which can be expressed as:

where

represents the offspring generated from the inferior solution group;

represents the

i-th particle in the inferior solution group according to the fitness;

and

, respectively, denote the upper and lower bound for all possible values of each particle, which are global variables;

,

rand represents the random number between 0 and 1; and

represents the current number of iterations.

A new population is obtained by merging and , and the size of the new population is consistent with the size of the initial population. Then, the population is merged with the initial population to form an expanded population. The expanded population is rearranged according to the fitness, and finally, the optimal half-population is selected as a new iterative population for updating iteration.

3.3. Algorithm Procedure

The procedure of the improved algorithm is described as follows.

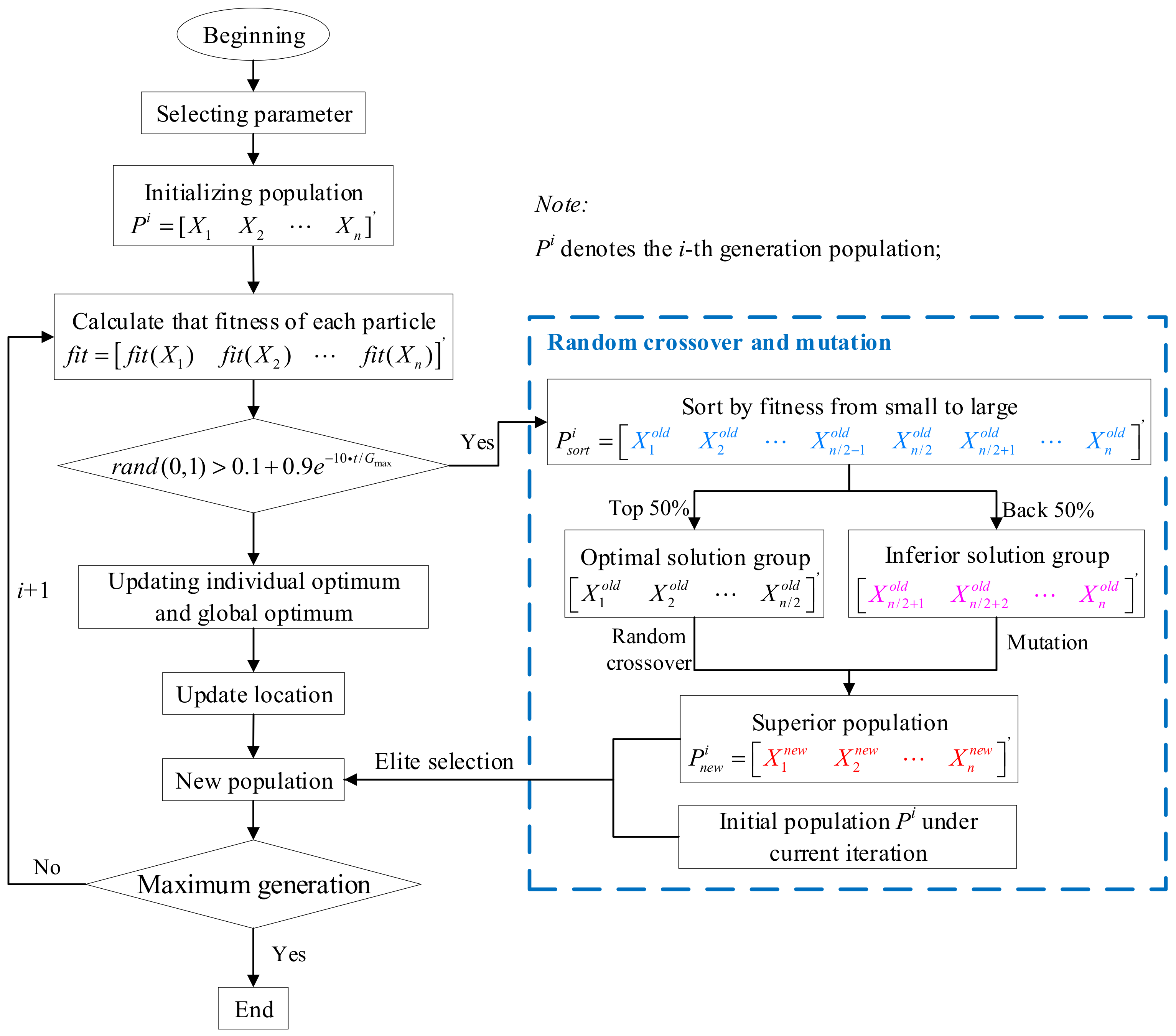

Figure 1 shows the flow chart of the improved algorithm.

Step 1: Initialize the parameters of the algorithm;

Step 2: Randomly generate an initial population;

Step 3: Calculate the fitness of the initial population and initializing an individual optimal value and a global optimal value;

Step 4: Judge whether random crossover and mutation should be implemented or not. If , enter step 5, otherwise, enter step 7;

Step 5: Dividing the particles into two groups: optimal and inferior, according to the fitness values. The random crossover and mutation are respectively implemented in the optimal and inferior groups to generate new offspring;

Step 6: Elite selection. Merging the offspring generated by random crossover and mutation into one group further establishes an expanded population with the initial population under the current generation. Sorting the expanded population according to fitness and selecting the half of the population which has better fitness as the elite population to participate in the next iteration;

Step 7: Updating the velocity and position of the particles using Equations (8) and (9);

Step 8: Updating the individual optimal value and the global optimal value of particles;

Step 9: Judge whether that iteration termination standard is met; if the algorithm reaches the maximum iteration times, terminate the algorithm; otherwise, jump to step 3;

3.4. Benchmark Functions

To test the effectiveness of the improvement strategy, the performance of three typical metaheuristic algorithms, including PSO, GSA, SA, artificial fish swarm algorithm (AFSA), artificial ant colony (ABC) algorithm, and their respective improved versions, IPSO, IGSA, ISA, IAFSA, and IABC, are compared based on benchmark functions. Furthermore, to test the generality and effectiveness of the improved strategy, the PSOGA and the IPSO are compared based on benchmark functions. PSOGA [

39] is a hybrid algorithm proposed by Kao and Zahara in 2008. At present, the PSOGA algorithm has been widely applied in the comparison of improvement strategies and optimization problems in the engineering field. The population size of all algorithms is set to 50, and the maximum number of iterations is 100 to ensure the comparability of each algorithm. For PSO, the learning factors

and

are 1.5 and 0.5, respectively, and the inertia constant is 0.726. These parameters are the default parameters of standard PSO and have been proved suitable for various optimization problems. For GSA, the universal gravitation coefficient is 10 and the descent coefficient is 20. For SA, the attenuation parameter is 0.95, the initial temperature is 50, and the final temperature is 0. For AFSA, the field of view is 0.025, the step size is 0.3, and the crowding factor is 0.1. For ABC, the number of observed bees and the number of employed bees take the same value of 50.

The two benchmark functions are the Ackley’s path function and the sum of different power function, represented by

f1 and

f2, respectively. The

f1 is a multimodal function that has several extreme points but only one global optimal point. The

f2 is a unimodal function. The objective functions

f1 and

f2 can be defined as:

where

xi denotes the

i-th design variable; and

e is the natural index.

The dimensions of both functions are set as 2, and the corresponding function graphs are plotted in

Figure 2a,b, respectively. The two functions are utilized to test the convergence accuracy of the algorithm and the ability to jump out of local optimal solution. The global optimal values of the two test functions are

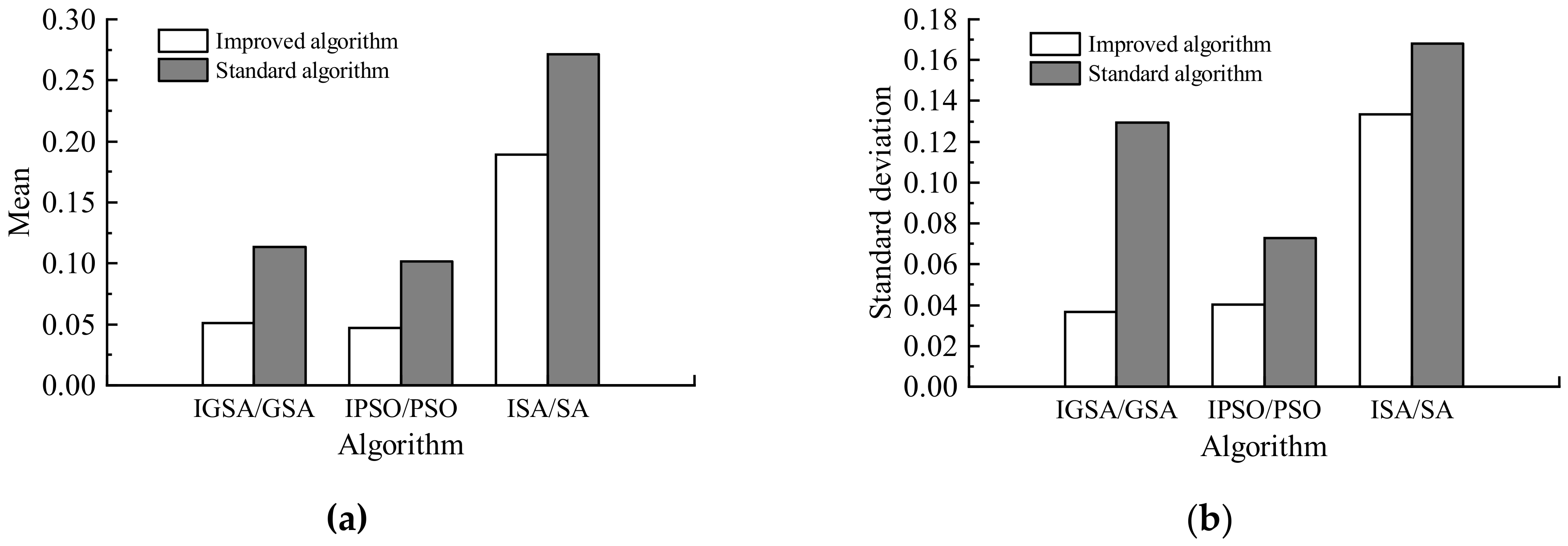

. To eliminate the influence of randomness in the algorithm, each algorithm is independently run 100 times with MATLAB R2018a. The CPU is i5-9400F@2.90 GHz, and the memory size is 16 GB. The statistical results, including the mean value and standard deviation of the 100 independent runs, are employed to evaluate the searching accuracy and stability of each algorithm, respectively.

Table 1 shows the mean and standard deviation of the two functions obtained from the 100 independent runs of the 5 algorithms. It can be seen that the mean and standard deviation values of both test functions obtained from the improved algorithms are smaller than those obtained from standard algorithms. For example, the mean and standard deviation values of

f1 obtained from standard GSA are 6.71 × 10

−1 and 1.83 × 10

−2, respectively, while corresponding values obtained from IGSA are 5.50 × 10

−2 and 7.43 × 10

−3. This comparison indicates that the searching accuracy of IGSA is far better than GSA. Similar conclusions can be made for the other four algorithms. It can be seen from

Table 1 that the mean and standard deviation of

f1 obtained from PSOGA are 4.41 × 10

−1 and 2.57 × 10

−1, respectively, while corresponding values obtained from IPSO are 3.10 × 10

−1 and 1.38 × 10

−2. From the comparison of the above results, it can be found that in the case of multiple local optimal solutions, IPSO has a greater probability of jumping out of the local optimal solution. In order to better demonstrate the generality of the improvement strategy, the following numerical and engineering cases mainly compare GSA, PSO, and SA and the corresponding improved algorithms.

Figure 3 shows the convergence curves of each algorithm for the two functions. The solid lines represent the convergence curves of the standard algorithms, while the dotted lines denote the convergence curves of the improved algorithms. It can be seen that compared with the standard algorithms, all improved algorithms have a higher capability to jump out of the local minimum and converge to a global minimum. For example, the standard GSA fell into a local minimum in generation 5, with an average fitness value of 1.2492 when searching the global minimum of

f1, whereas the IGSA reached a far smaller value of 0.3099. A similar situation can be found in the other two algorithms.

4. Numerical Simulation

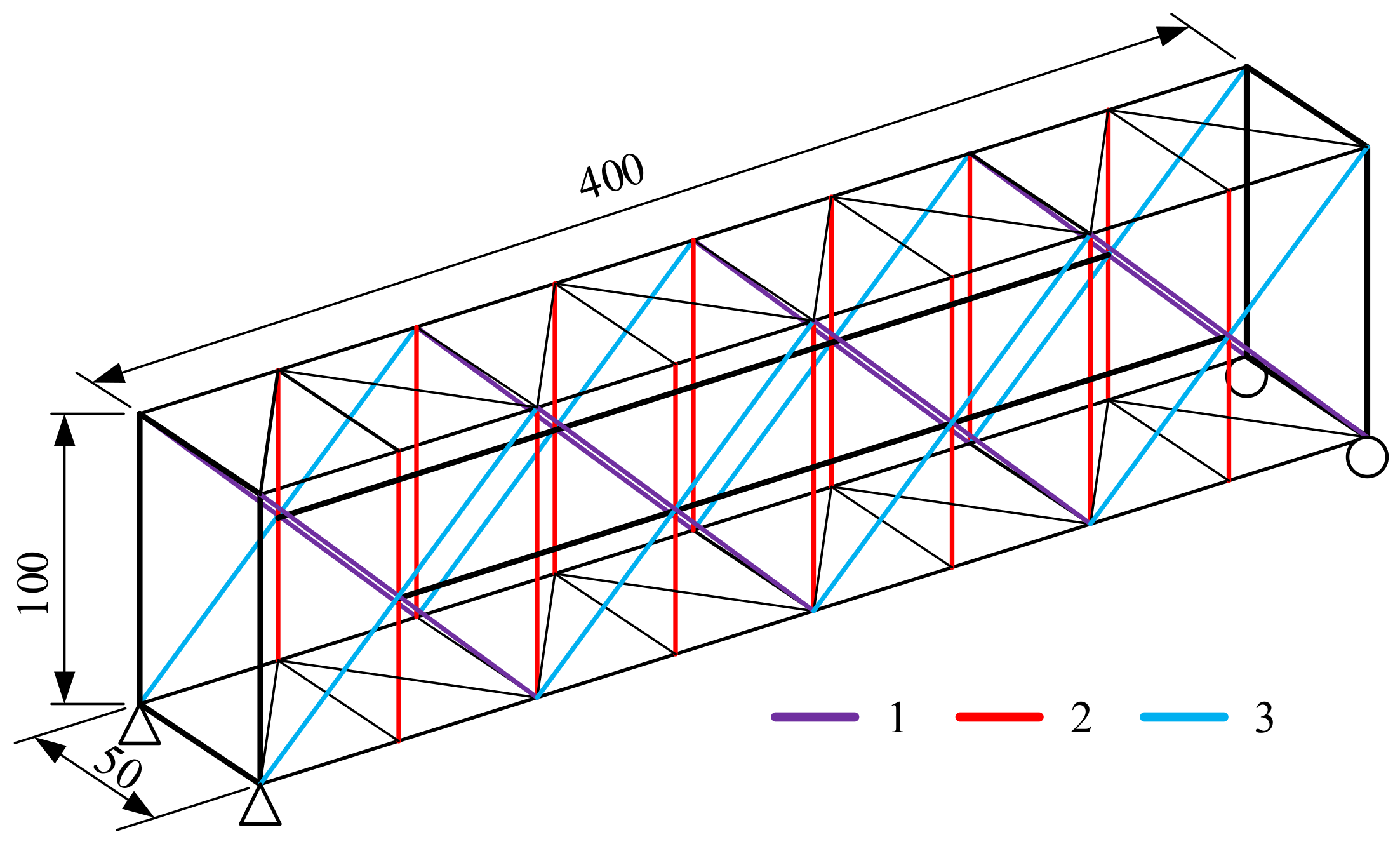

This section numerically updates the FE model of a simply supported space truss structure to test the effectiveness of the improvement strategy in FE model updating. Compared with the actual engineering structure, the damage location in the numerical example is known, and there is no updating parameter selection problem. Therefore, it can more accurately reflect the effectiveness of the improved heuristic algorithm. The truss structure is shown in

Figure 4. The structural parameters are as follows: the span of the truss is 4 m, the height is 1 m, the elastic modulus of the material is set as 100 GPa, the density is 7850 kg/m

3, and the section area of the beam element is 1.717 × 10

−3 m

2. The FE model was established by ANSYS, and the beam element was used to simulate the truss members.

The truss’s diagonal members are divided into three groups according to the color, as illustrated in

Figure 4. The elastic modulus of each group and the first six frequencies are taken as the design parameters and responses, respectively. The damage scenario is as follows: the elastic modulus of the first and second group of members is reduced by 30%, and the elastic modulus of the third group of members is increased by 30%.

Figure 5 shows the first 6 mode shape of the truss.

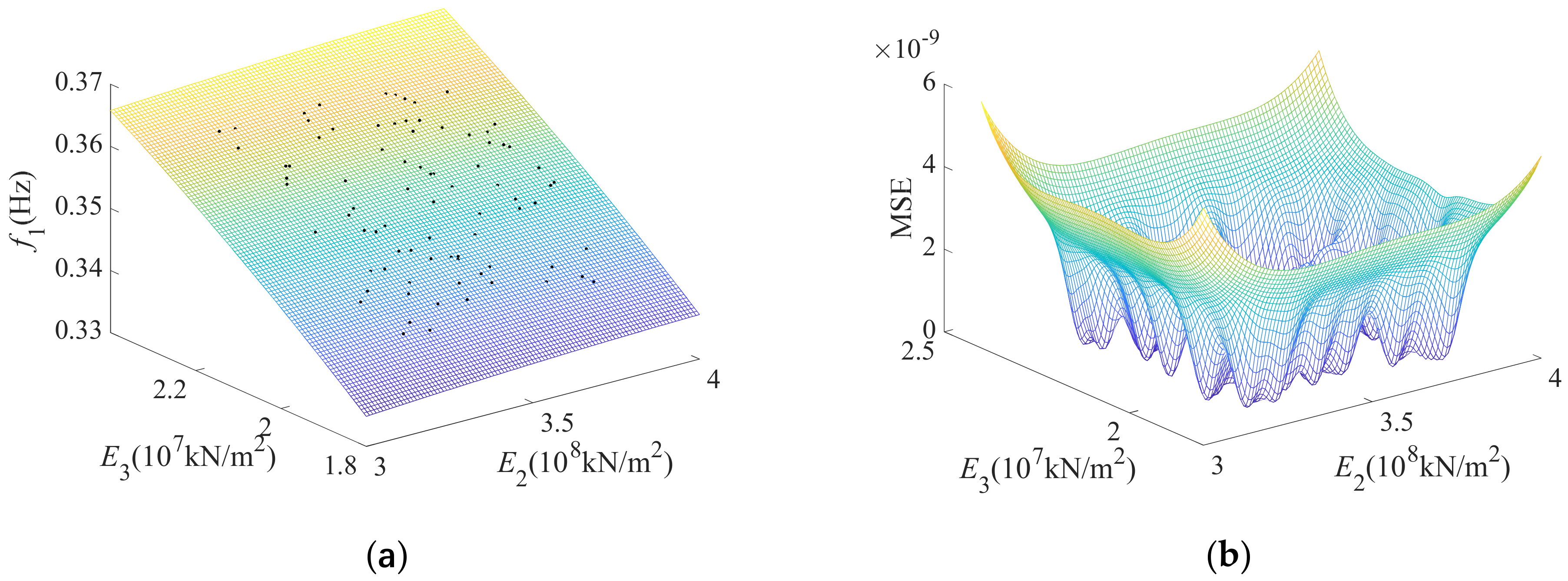

To conveniently establish the kriging model, the relative value of the changed elastic modulus and the initial elastic modulus is taken as the design variable, and the sixth order frequency is taken as the response. The latin hypercube sampling method was used to design the experiment for the data samples of updating parameters. The three design parameters were sampled 36 times, and the sampling range of the parameters was set within ±30% of their initial values. Then the updating parameters were brought into the initial FE model to obtain the frequency. Finally, the kriging model was established by using the sample points as the input and the modal frequency response as the output.

Figure 6 plots the kriging response surface model and the corresponding mean square error (MSE) for the first-order frequency versus the updating parameters

E1 and

E2. The surface represents the kriging model response surface, the scattered points represent the sample points, and the sample points are located on the curved surface. It can be seen from the MSE surface that the maximum error is less than 4 × 10

−7, indicating that the kriging model has high accuracy and can replace the FE model in predicting the structural response.

The first six frequency residuals of the truss are used to construct the objective function, and the three standard optimization algorithms and the corresponding improved algorithms are used to find the global minimum of the objective function. The objective function is expressed by:

where

fit(

x) represents the objective function;

represents the updating parameter;

represent the weight factor, which is set to 1 [

6];

is the

i-th order frequency value calculated by the kriging response surface model; and

is the

i-th order frequency value calculated by the FE model.

Regarding the algorithm parameters, in order to ensure the comparability between different algorithms, the population size of each algorithm is 50, and the maximum number of iterations is 100. For PSO, the learning factors and are 1.5 and 0.5, respectively, and the inertia constant is 0.726. For GSA, the universal gravitation coefficient is 10, and the descent coefficient is 20. The attenuation parameter of the SA algorithm is 0.95, the initial temperature is set at 50, and the final temperature is set to 0.

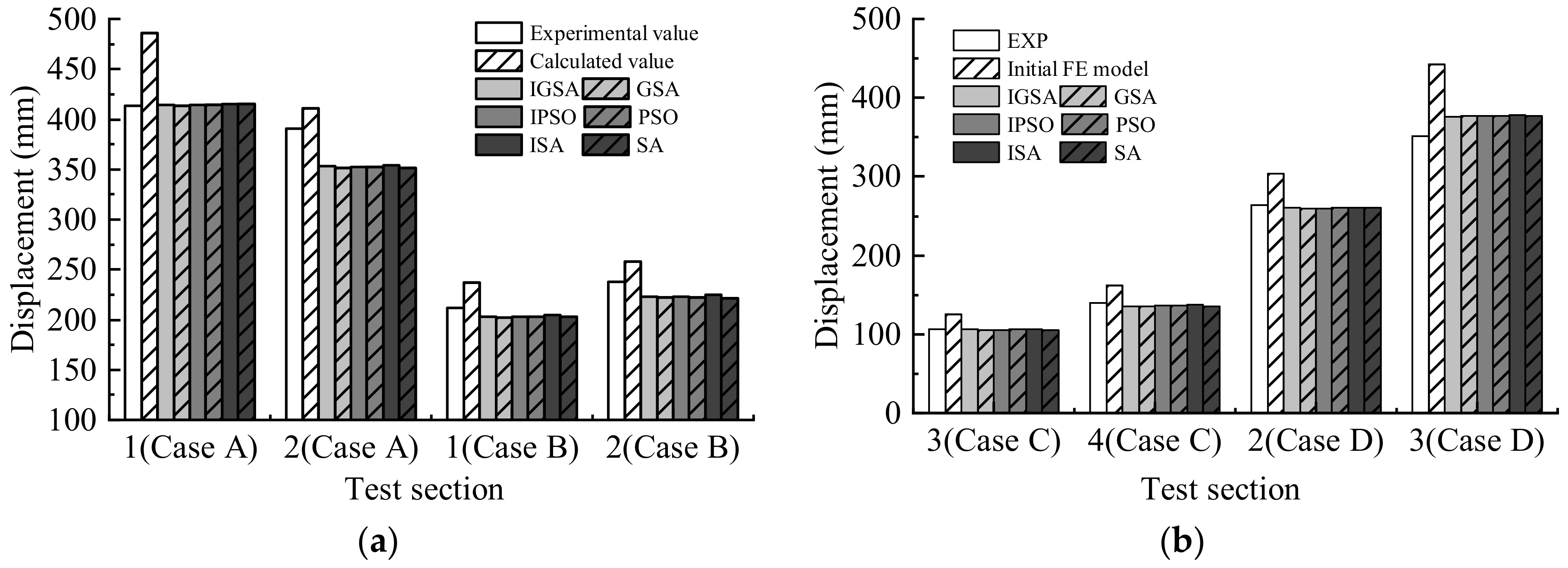

Table 2 shows the change in updating parameters in different algorithms. The relative error means the discrepancy of the updating parameters between the updated model and the predetermined damage value. The smaller the relative error, the higher the updated model’s accuracy. It can be seen from

Table 2 that relative errors obtained with improved algorithms are all smaller than that obtained with standard algorithms. For example, the relative errors of

E1 obtained from IGSA and GSA are 0.74% and 5.49%. These data indicate that the improved algorithms are better than standard algorithms in model updating. Nevertheless, the updating results of each algorithm still need further discussion.

Table 3 compares the first six frequencies of the truss structure obtained from the initial FE model and the updated FE model. The frequencies of the damage model are also listed for comparison. It can be seen that the maximum relative errors of the six frequencies obtained from the initial FE model and updated FE model are 6.29% and 1.44%, respectively, indicating that the accuracy of the updated FE model has been greatly improved. All relative errors of the updated FE model, obtained with improved algorithms, are smaller than 1%. The improved algorithms obtained a more accurate updated FE model than the standard algorithms.

Table 4 summarizes the statistical results of the updating results obtained from 100 independent runs of each algorithm. It can be seen that all improved algorithms have a smaller mean and standard deviation value compared with the standard algorithms. This result indicates that the improved algorithm has higher searching accuracy and stability than standard algorithms.