Utilization of BIM in Steel Building Projects: A Systematic Literature Review

Abstract

:1. Introduction

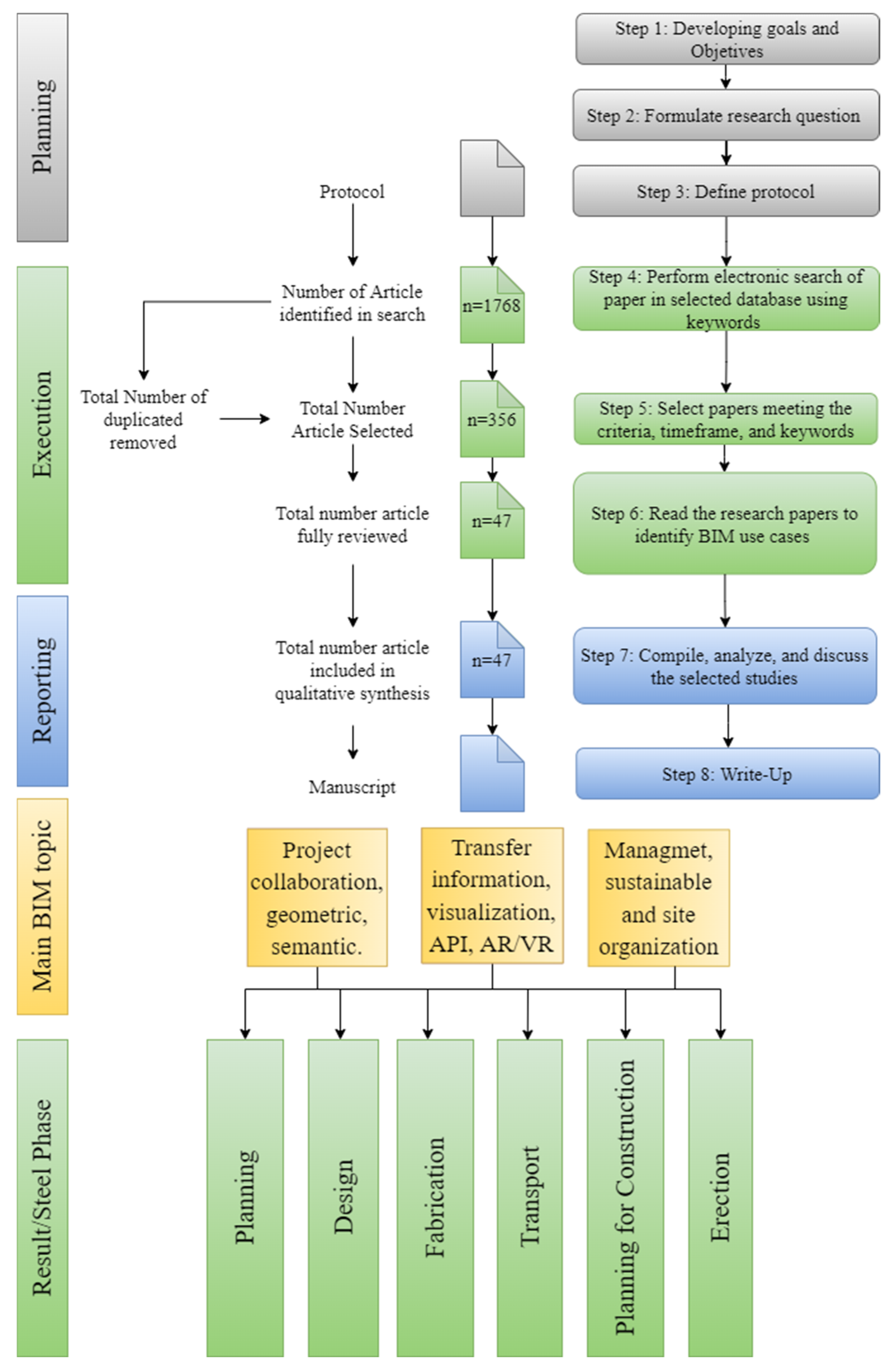

2. Materials and Methods

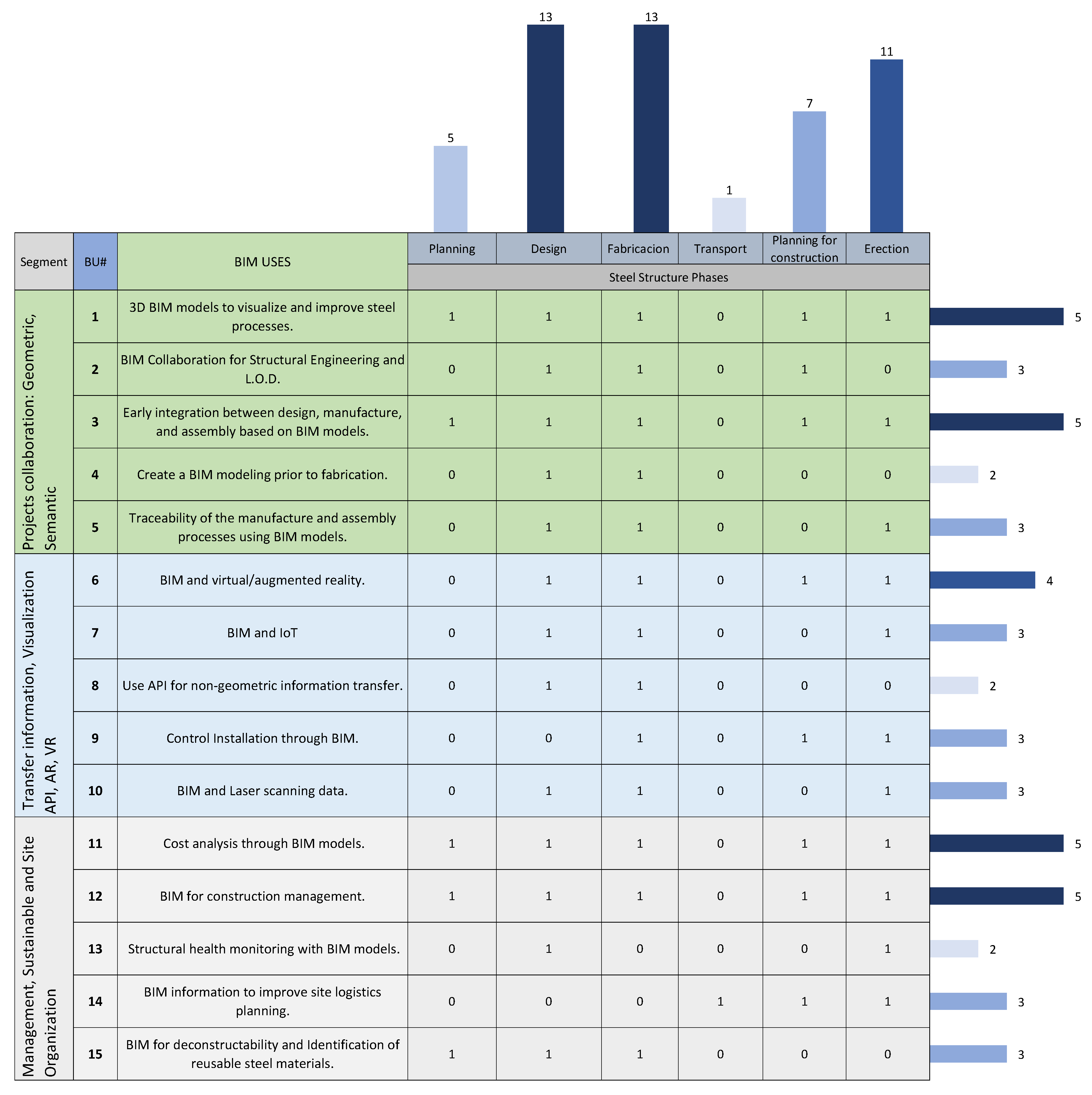

3. Results

4. Discussion

- Use of 3D BIM in collaborative steel building projects: Geometric and semantic.

- Utilization of BIM information in steel building projects: Transfer information, visualization API, AR, and VR.

- Use of BIM in Steel Project Management, Sustainable, and Site Organization.

5. Conclusions and Future Research Directions

5.1. Future Research Directions

5.2. Use of 3D BIM in Collaborative Steel Building Projects: Geometric and Semantic

5.3. Utilization of BIM Information in Steel Building Projects: Information Transfer, Visualization API, AR, and VR

5.4. Use of BIM for Steel Project Management, Sustainability, and Site Organization

5.5. Contribution to Scientific Community

5.6. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gutowski, T.; Cooper, D.; Sahni, S. Why We Use More Materials. Philos. Trans. A Math. Phys. Eng. Sci. 2017, 375, 20160368. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Luo, S.S.; Wang, H. Research on a Complete Set of Technologies for Assembled Residential Buildings with Steel-Structure Based on House Type Modularization and Component Standardization. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 022063. [Google Scholar] [CrossRef]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef] [Green Version]

- Hadiwattege, C.; Kandemulla, L. Cost Benefits of Steel Compared to In-Situ Concrete in Sri Lankan Building Construction. August 2018. Available online: http://dl.lib.mrt.ac.lk/handle/123/13441 (accessed on 12 April 2022).

- Ia, R.; Haggag, S.Y.; Mahdi, I.; Elhegazy, H.M. Construction Performance Control in Steel Structures Projects. Ind. Eng. Manag. 2016, 5, 201. [Google Scholar] [CrossRef]

- Kim, K.; Kim, G.; Kim, K.; Lee, Y.; Kim, J. Real-Time Progress Management System for Steel Structure Construction. J. Asian Archit. Build. Eng. 2009, 8, 111–118. [Google Scholar] [CrossRef]

- Thomas, H.R.; Ellis, R.D. Construction Site Management and Labor Productivity Improvement. ASCE Publ. 2017. [Google Scholar] [CrossRef]

- Mellado, F.; Lou, E.C.W.; Becerra, C.L.C. Synthesising Performance in the Construction Industry. Eng. Constr. Archit. Manag. 2019, 27, 579–608. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The Project Benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Succar, B. Building Information Modelling Framework: A Research and Delivery Foundation for Industry Stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Miettinen, R.; Paavola, S. Beyond the BIM Utopia: Approaches to the Development and Implementation of Building Information Modeling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Peng, S.; Phil-Ebosie, O. Digital Twin Aided Sustainability and Vulnerability Audit for Subway Stations. Sustainability 2020, 12, 7873. [Google Scholar] [CrossRef]

- Moretti, N.; Xie, X.; Merino, J.; Brazauskas, J.; Parlikad, A.K. An openBIM Approach to IoT Integration with Incomplete As-Built Data. Appl. Sci. 2020, 10, 8287. [Google Scholar] [CrossRef]

- Qiu, Q.; Wang, M.; Guo, J.; Liu, Z.; Wang, Q. An Adaptive Down-Sampling Method of Laser Scan Data for Scan-to-BIM. Autom. Constr. 2022, 135, 104135. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.P.; Chen, W.; Chen, K. Digital Twins for Construction Sites: Concepts, LoD Definition, and Applications. J. Manag. Eng. 2022, 38. [Google Scholar] [CrossRef]

- Manzoor, B.; Othman, I.; Gardezi, S.S.S.; Harirchian, E. Strategies for Adopting Building Information Modeling (BIM) in Sustainable Building Projects—A Case of Malaysia. Buildings 2021, 11, 249. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the Relationship between Building Information Modelling (BIM) Implementation Barriers, Usage and Awareness on Building Project Lifecycle. Build. Environ. 2022, 207, 108556. [Google Scholar] [CrossRef]

- Ghaleb, H.; Alhajlah, H.H.; Bin Abdullah, A.A.; Kassem, M.A.; Al-Sharafi, M.A. A Scientometric Analysis and Systematic Literature Review for Construction Project Complexity. Buildings 2022, 12, 482. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, J.C.P.; Wang, Q. Semi-automated Generation of Parametric BIM for Steel Structures Based on Terrestrial Laser Scanning Data. Autom. Constr. 2020, 112, 103037. [Google Scholar] [CrossRef]

- Shin, T.S. Building Information Modeling (BIM) Collaboration from the Structural Engineering Perspective. Int. J. Steel Struct. 2017, 17, 205–214. [Google Scholar] [CrossRef]

- Stojanovska-Georgievska, L.; Sandeva, I.; Krleski, A.; Spasevska, H.; Ginovska, M.; Panchevski, I.; Ivanov, R.; Perez Arnal, I.; Cerovsek, T.; Funtik, T. BIM in the Center of Digital Transformation of the Construction Sector—The Status of BIM Adoption in North Macedonia. Buildings 2022, 12, 218. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Zlatanova, S.; Sepasgozar, S.; Aleksandrov, M. Onsite Quality Check for Installation of Prefabricated Wall Panels Using Laser Scanning. Buildings 2021, 11, 412. [Google Scholar] [CrossRef]

- Diakite, A.A.; Zlatanova, S. Automatic Geo-referencing of BIM in GIS Environments Using Building Footprints. Comput. Environ. Urban Syst. 2020, 80, 101453. [Google Scholar] [CrossRef]

- Schiavi, B.; Havard, V.; Beddiar, K.; Baudry, D. BIM Data Flow Architecture with AR/VR Technologies: Use Cases in Architecture, Engineering and Construction. Autom. Constr. 2022, 134, 104054. [Google Scholar] [CrossRef]

- García-Pereira, I.; Portalés, C.; Gimeno, J.; Casas, S. A Collaborative Augmented Reality Annotation Tool for the Inspection of Prefabricated Buildings. Multimed. Tool. Appl. 2019, 79, 6483–6501. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to Digital Twins: A Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Chen, L.K.; Yuan, R.P.; Ji, X.J.; Lu, X.Y.; Xiao, J.; Tao, J.B.; Kang, X.; Li, X.; He, Z.H.; Quan, S.; et al. Modular Composite Building in Urgent Emergency Engineering Projects: A Case Study of Accelerated Design and Construction of Wuhan Thunder God Mountain/Leishenshan Hospital to COVID-19 Pandemic. Autom. Constr. 2021, 124, 103555. [Google Scholar] [CrossRef]

- Chen, H.M.; Huang, P.H. 3D AR-Based Modeling for Discrete-Event Simulation of Transport Operations in Construction. Autom. Constr. 2013, 33, 123–136. [Google Scholar] [CrossRef]

- Nguyen, T.B.; Tran, A.B.; Phan, H.T.; Do, Q.H.; Nguyen, Q.T. Exploitation of Digital Data from Building Information Models in Virtual Reality Technology. Lect. Notes Civ. Eng. 2022, 203, 1833–1840. [Google Scholar] [CrossRef]

- Isikdag, U.; Zlatanova, S.; Underwood, J. An Opportunity Analysis on the Future Role of BIMs in Urban Data Management. In Urban and Regional Data Management, UDMS Annual 2011; Zlatanova, L., Rumor, F., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA; London, UK, 2012; pp. 25–36. [Google Scholar]

- Liu, L.; Li, B.; Zlatanova, S.; van Oosterom, P. Indoor Navigation Supported by the Industry Foundation Classes (IFC): A Survey. Autom. Constr. 2021, 121, 10436. [Google Scholar] [CrossRef]

- Chen, S.; Wu, J.; Shi, J. A BIM Platform for the Manufacture of Prefabricated Steel Structure. Appl. Sci. 2020, 10, 8038. [Google Scholar] [CrossRef]

- Tricco, A.C.; Tetzlaff, J.; Moher, D. The Art and Science of Knowledge Synthesis. J. Clin. Epidemiol. 2011, 64, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Paul, J.; Lim, W.M.; O’Cass, A.; Hao, A.W.; Bresciani, S. Scientific Procedures and Rationales for Systematic Literature Reviews (SPAR-4-SLR). Int. J. Consum. Stud. 2021, 45, 1–16. [Google Scholar] [CrossRef]

- Hijazi, A.A.; Perera, S.; Calheiros, R.N.; Alashwal, A. Rationale for the Integration of BIM and Blockchain for the Construction Supply Chain Data Delivery: A Systematic Literature Review and Validation through Focus Group. J. Constr. Eng. Manag. 2021, 147, 03121005. [Google Scholar] [CrossRef]

- Valdés, H.; Correa, C.; Mellado, F. Proposed Model of Sustainable Construction Skills for Engineers in Chile. Sustainability 2018, 10, 3093. [Google Scholar] [CrossRef] [Green Version]

- Boland, A.; Cherry, G.; Dickson, R. Doing a Systematic Review: A Student’s Guide; Sage: Los Angeles, CA, USA, 2017. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Andreini, D.; Bettinelli, C. Business Model Innovation: From Systematic Literature Review to Future Research Directions, 1st ed.; International Series in Advanced Management Studies; Springer International Publishing: Cham, Switzerland, 2017; p. 189. [Google Scholar]

- Kim, S.W.; Brown, R.D. Urban Heat Island (UHI) Intensity and Magnitude Estimations: A Systematic Literature Review. Sci. Total Environ. 2021, 779, 146389. [Google Scholar] [CrossRef]

- Vera-Puerto, I.; Valdes, H.; Correa, C.; Agredano, R.; Vidal, G.; Belmonte, M.; Olave, J.; Arias, C. Proposal of Competencies for Engineering Education to Develop Water Infrastructure Based on “Nature-Based Solutions” in the Urban Context. J. Clean. Prod. 2020, 265, 121717. [Google Scholar] [CrossRef]

- Stern, C.; Jordan, Z.; McArthur, A. Developing the Review Question and Inclusion Criteria. Am. J. Nurs. 2014, 114, 53–56. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D. Moher, D. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 178–189. [Google Scholar] [CrossRef]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; SAGE Publications: New York, NY, USA, 2018; p. 472. [Google Scholar]

- Pellicer, E.; Correa, C.L.; Yepes, V.; Alarcón, L.F. Organizational Improvement through Standardization of the Innovation Process in Construction Firms. Eng. Manag. J. 2012, 24, 40–53. [Google Scholar] [CrossRef]

- Xie, Y.F.; Li, C.X.; Li, Z.H. Smart Building Materials of BIM and RFID in LifeCycle Management of Steel Structure. Key Eng. Mater. 2016, 723, 736–740. [Google Scholar]

- An, S.; Martinez, P.; Al-Hussein, M.; Ahmad, R. Automated Verification of 3D Manufacturability for Steel Frame Assemblies. Autom. Constr. 2020, 118, 103287. [Google Scholar] [CrossRef]

- Case, F.; Beinat, A.; Crosilla, F.; Alba, I.M. Virtual Trial Assembly of a Complex Steel Structure by Generalized Procrustes Analysis Techniques. Autom. Constr. 2014, 37, 155–165. [Google Scholar] [CrossRef]

- Yoo, M.; Ham, N. Productivity Analysis of Documentation Based on 3D Model in Plant Facility Construction Project. Appl. Sci. 2020, 10, 1126. [Google Scholar] [CrossRef] [Green Version]

- Laefer, D.F.; Truong-Hong, L. Toward Automatic Generation of 3D Steel Structures for Building Information Modelling. Autom. Constr. 2017, 74, 66–77. [Google Scholar] [CrossRef]

- Erfurth, L. BIM im Stahlbau: Etablierte Arbeitsweisen und neue Wege. Stahlbau 2019, 88, 214–222. [Google Scholar] [CrossRef]

- Tian, J.; Luo, S.; Wang, X.; Hu, J.; Yin, J. Crane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based on BIM and UAV. Adv. Civ. Eng. 2021, 2021, 5512229. [Google Scholar] [CrossRef]

- Barg, S.; Flager, F.; Fischer, M. An Analytical Method to Estimate the Total Installed Cost of Structural Steel Building Frames during Early Design. J. Build. Eng. 2018, 15, 41–50. [Google Scholar] [CrossRef]

- Wei, L.S.; Wei, Q.; Sun, K. Development of BIM Technology in Steel Structure Design Software. Appl. Mech. Mater. 2014, 501–504, 2546–2549. [Google Scholar]

- Malik, N.; Ahmad, R.; Al-Hussein, M. Generation of Safe Tool-Paths for Automatic Manufacturing of Light Gauge Steel Panels in Residential Construction. Autom. Constr. 2019, 98, 46–60. [Google Scholar] [CrossRef]

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing Risk in Modular Construction Using Dimensional and Geometric Tolerance Strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Bartenbach, J.; Schindler, S.; Schulze, F.; Kulzer, W. Stahlbau unter Nutzung von BIM in einem heterogenen Softwareumfeld. Stahlbau 2019, 88, 786–795. [Google Scholar] [CrossRef]

- Zhu, A.; Pauwels, P.; de Vries, B. Smart Component-Oriented Method of Construction Robot Coordination for Prefabricated Housing. Autom. Constr. 2021, 129, 103778. [Google Scholar] [CrossRef]

- Yoo, W.S.; Lee, H.J.; Kim, D.I.; Kang, K.I.; Cho, H. Genetic Algorithm-Based Steel Erection Planning Model for a Construction Automation System. Autom. Constr. 2012, 24, 30–39. [Google Scholar] [CrossRef]

- Wang, W.C.; Weng, S.W.; Wang, S.H.; Chen, C.Y. Integrating Building Information Models with Construction Process Simulations for Project Scheduling Support. Autom. Constr. 2014, 37, 68–80. [Google Scholar] [CrossRef]

- Soh, M.F.; Bigras, D.; Barbeau, D.; Doré, S.; Forgues, D. Bim Machine Learning and Design Rules to Improve the Assembly Time in Steel Construction Projects. Sustainability 2021, 14, 10288. [Google Scholar] [CrossRef]

- Costin, A.; Hu, H.; Medlock, R. Building Information Modeling for Bridges and Structures: Outcomes and Lessons Learned from the Steel Bridge Industry. Transp. Res. Rec. 2021, 2675, 576–586. [Google Scholar] [CrossRef]

- Tavares, P.; Costa, C.M.; Rocha, L.; Malaca, P.; Costa, P.; Moreira, A.P.; Sousa, A.; Veiga, G. Collaborative Welding System Using BIM for Robotic Reprogramming and Spatial Augmented Reality. Autom. Constr. 2019, 106, 102825. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, S.; Liao, L.; Zhang, L. A Digital Construction Framework Integrating Building Information Modeling and Reverse Engineering Technologies for Renovation Projects. Autom. Constr. 2019, 102, 45–58. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A Review of Building Information Modeling (BIM) and the Internet of Things (IoT) Devices Integration: Present Status and Future Trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Scianna, A.; Gaglio, G.F.; La Guardia, M. Structure Monitoring with BIM and IoT: The Case Study of a Bridge Beam Model. ISPRS Int. J. Geo Inf. 2022, 11, 173. [Google Scholar] [CrossRef]

- Jeong, W.; Chang, S.; Son, J.; Yi, J.S. BIM-Integrated Construction Operation Simulation for Just-in-Time Production Management. Sustainability 2016, 8, 1106. [Google Scholar] [CrossRef] [Green Version]

- Yoo, M.; Kim, J.; Choi, C. Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs. Appl. Sci. 2019, 9, 1732. [Google Scholar] [CrossRef] [Green Version]

- Oti, A.H.; Tizani, W. BIM Extension for the Sustainability Appraisal of Conceptual Steel Design. Adv. Eng. Inform. 2015, 29, 28–46. [Google Scholar] [CrossRef]

- Mischo, H.; Seifried, J.; Thiele, K.; Schanzenbach, S.; Grassl, M. Vom 3-D-Laserscan zum BIM-Modell. Bautechnik 2019, 96, 564–571. [Google Scholar] [CrossRef]

- Kim, M.K.; Wang, Q.; Park, J.W.; Cheng, J.C.P.; Sohn, H.; Chang, C.C. Automated Dimensional Quality Assurance of Full-Scale Precast Concrete Elements Using Laser Scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Framework for Construction System Selection Based on Life Cycle Cost and Sustainability Assessment. J. Clean. Prod. 2019, 241, 118397. [Google Scholar] [CrossRef]

- Nekouvaght Tak, A.; Taghaddos, H.; Mousaei, A.; Hermann, U.R. Evaluating Industrial Modularization Strategies: Local vs. Overseas Fabrication. Autom. Constr. 2020, 114, 103175. [Google Scholar] [CrossRef]

- Yu, J.; Wang, J.; Hua, Z.; Wang, X. BIM-Based Time-Cost Optimization of a Large-Span Spatial Steel Structure in an Airport Terminal Building. J. Facil. Manag. 2021. [Google Scholar] [CrossRef]

- Navaratnam, S.; Satheeskumar, A.; Zhang, G.; Nguyen, K.; Venkatesan, S.; Poologanathan, K. The Challenges Confronting the Growth of Sustainable Prefabricated Building Construction in Australia: Construction Industry Views. J. Build. Eng. 2022, 48, 103935. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, L. Rapid Structural Condition Assessment Using Radio Frequency Identification (RFID) Based Wireless Strain Sensor. Autom. Constr. 2015, 54, 1–11. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site Logistics Planning and Control for Engineer-to-Order Prefabricated Building Systems Using BIM 4D Modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Asgari Siahboomy, M.; Sarvari, H.; Chan, D.W.M.; Nassereddine, H.; Chen, Z. A Multi-criteria Optimization Study for Locating Industrial Warehouses with the Integration of BIM and GIS Data. Archit. Eng. Des. Manag. 2021, 17, 478–495. [Google Scholar] [CrossRef]

- Ness, D.; Swift, J.; Ranasinghe, D.C.; Xing, K.; Soebarto, V. Smart Steel: New Paradigms for the Reuse of Steel Enabled by Digital Tracking and Modelling. J. Clean. Prod. 2015, 98, 292–303. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging Building Materials in a Circular Economy: A BIM-Based Whole-Life Performance Estimator. Resour. Conserv. Recy. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Basta, A.; Serror, M.H.; Marzouk, M. A BIM-Based Framework for Quantitative Assessment of Steel Structure Deconstructability. Autom. Constr. 2020, 111, 103064. [Google Scholar] [CrossRef]

- Liu, Z.S.; Wu, X.F.; Xu, R.L. Applied Research of BIM Technology on Prestressed Steel Structures in Xuzhou Stadium. Appl. Mech. Mater. 2013, 444–445, 971–975. [Google Scholar]

- Martinez, P.; Ahmad, R.; Al-Hussein, M. A Vision-Based System for Pre-Inspection of Steel Frame Manufacturing. Autom. Constr. 2019, 97, 151–163. [Google Scholar] [CrossRef]

- Akanmu, A.; Okoukoni, F. Swarm Nodes for Automated Steel Installation Tracking: A Case Study. Autom. Constr. 2018, 90, 294–302. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Cho, C. Framework for Automated Generation of Constructible Steel Erection Sequences Using Structural Information of Static Indeterminacy Variation in BIM. KSCE J. Civ. Eng. 2020, 24, 3169–3178. [Google Scholar] [CrossRef]

- Liao, X.M.; Fang, Z.Y.; Yu, J.S.; Yang, Y.G.; Yang, S. Applications of BIM in Erecting Steel Structure. Appl. Mech. Mater. 2012, 193–194, 1440–1443. [Google Scholar]

| Criteria | Inclusion | Exclusion |

|---|---|---|

| 1 | Articles that discuss BIM in the steel building project | Articles that do not discuss BIM in the steel building projects |

| 2 | Articles that are in WOS and/or Scopus | Articles that are not in WOS and/or Scopus |

| 3 | Articles that were published in 2012–2022 | Article published before 2012 |

| K1: Steel | K6: Prefabrication | |

| K2: Building Information Modeling | K7: Impact business | |

| K3: Detailing | K8: Innovation industry | |

| K4: Construction | K9: Structures | |

| K5: Manufacturing | K10: Projects performance | |

| Combinations | Results from database | |

| WoS | Scopus | |

| C1: K1 AND K2 AND K3 | 118 | 19 |

| C2: K1 AND K2 AND K4 | 267 | 327 |

| C3: K1 AND K2 AND K5 | 94 | 64 |

| C4: K1 AND K2 AND K6 | 12 | 9 |

| C5: K1 AND K2 AND K7 | 3 | 9 |

| C6: K1 AND K2 AND K8 | 22 | 6 |

| C7: K1 AND K2 AND K9 | 420 | 319 |

| C8: K1 AND K2 AND K10 | 35 | 44 |

| TITLE-ABS-KEY | C1: Steel AND Building Information Modeling AND Detailing | |

| C2: Steel AND Building Information Modeling AND Construction | ||

| C3: Steel AND Building Information Modeling AND Manufacturing | ||

| C4: Steel AND Building Information Modeling AND Prefabrication | ||

| C5: Steel AND Building Information Modeling AND Impact business | ||

| C6: Steel AND Building Information Modeling AND Innovation industry | ||

| C7: Steel AND Building Information Modeling AND Structures | ||

| C8: Steel AND Building Information Modeling AND Projects performance | ||

| Screening Step | Number of Articles in Sample |

|---|---|

| Original sample | 1768 |

| Duplicates removed | 643 |

| After cut-off point | 356 |

| Unrelated articles removed | 309 |

| Articles that could be retrieved | 47 |

| Final sample | 47 |

| Source | Quartile | Impact Factor |

|---|---|---|

| Advanced Engineering Informatics | Q1 | 6.41 |

| Advances in Civil Engineering | Q3 | 1.8 |

| Applied Mechanics and Materials | Q2 | 3.15 |

| Applied Sciences | Q2 | 2.736 |

| Architectural Engineering and Design Management | Q2 | 2.19 |

| Automation in Construction | Q1 | 9.16 |

| Bautechnik | Q3 | 0.35 |

| Conservation and Recycling | Q1 | 9.93 |

| ISPRS International Journal of Geo-Information | Q1 | 2.899 |

| International Journal of Steel Structures | Q2 | 1.33 |

| Journal of Building Engineering | Q1 | 5.7 |

| Journal of Cleaner Production | Q1 | 9.297 |

| Journal of Facilities Management | Q2 | 2.19 |

| Key Engineering Materials | Q4 | 0.45 |

| KSCE Journal of Civil Engineering | Q2 | 1.97 |

| Stahlbau | Q3 | 0.23 |

| Sustainability (Switzerland) | Q1 | 3.48 |

| Transportation Research Record: Journal of the Transportation Research Board | Q2 | 1.81 |

| Number of BIM Uses by Phases | |||||

|---|---|---|---|---|---|

| Planning | Design | Fabrication | Transport | Planning for Construction | Erection |

| 5 | 13 | 13 | 1 | 7 | 11 |

| BIM Utilization | BIM use in Application Phase | 3D Software Tools | Source |

|---|---|---|---|

| 3D BIM models to visualize and improve steel processes. | Planning, design, fabrication, and planning for construction. | Tekla, Navisworks, Revit, ArchiCAD, SketchUp. | [20,33,47,48,49,50,51,52,74] |

| BIM Collaboration for Structural Engineering and L.O.D. | Design, fabrication, and planning for construction. | Tekla, Revit, MicroStation. | [20,53,54,57,70] |

| Early integration between design, manufacture, and assembly based on BIM models. | Planning, design, fabrication, planning for construction, and erection. | Tekla, Navisworks, Revit, MicroStation. | [51,52,54,56,57,58,59,60,61,83] |

| Create a BIM modeling before fabrication. | Design and fabrication. | Tekla, Revit. | [33,48,50,54,55,56,62,63] |

| Quality control and traceability of the manufacture and assembly processes using BIM models. | Design, fabrication, and erection. | SolidWorks, Revit, Tekla. | [56,58,64,68,84] |

| BIM and virtual/augmented reality | Design, fabrication, and planning for construction erection. | Revit, Tekla. | [64,65] |

| BIM and IoT | Design, fabrication, and erection. | Revit, Tekla. | [66,67,83] |

| Use API for non-geometric information transfer. | Design and fabrication. | Revit, Navisworks. | [68,85] |

| Control installation through BIM. | Fabrication, planning for construction, and erection. | Revit, Navisworks, Tekla. MicroStation | [53,69,84,86] |

| BIM and Laser scanning data. | Design, fabrication, and erection. | Revit, Tekla, AECOsim, FARO SCENE. | [19,70,71] |

| Cost analysis through BIM models. | Planning, design, and fabrication, planning for construction. | Tekla, MASTAN2, STAAD Pro, SAP2000, Revit. | [54,57,73,74,75] |

| BIM for construction management. | Planning, design, and fabrication, planning for construction. | Revit, Civil 3D, MS Projet, Navisworks, Tekla, ArchiCAD, Synchro Pro. | [28,29,52,58,60,61,62,64,69,70,76,82,83,86,87] |

| Structural health monitoring with BIM models. | Designand erection. | Revit, Tekla, ArchiCAD. | [77,85] |

| BIM information to improve site logistics planning. | Transport, planning for construction,and erection. | Revit, Tekla, Synchro Pro, MicroStation | [28,53,59,60,62,63,78,79,87] |

| BIM for de-constructability and identification of reusable steel materials | Planning, design, and fabrication. | Revit, Dynamo. | [65,80,81,82] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avendaño, J.I.; Zlatanova, S.; Domingo, A.; Pérez, P.; Correa, C. Utilization of BIM in Steel Building Projects: A Systematic Literature Review. Buildings 2022, 12, 713. https://doi.org/10.3390/buildings12060713

Avendaño JI, Zlatanova S, Domingo A, Pérez P, Correa C. Utilization of BIM in Steel Building Projects: A Systematic Literature Review. Buildings. 2022; 12(6):713. https://doi.org/10.3390/buildings12060713

Chicago/Turabian StyleAvendaño, José Ignacio, Sisi Zlatanova, Alberto Domingo, Pedro Pérez, and Christian Correa. 2022. "Utilization of BIM in Steel Building Projects: A Systematic Literature Review" Buildings 12, no. 6: 713. https://doi.org/10.3390/buildings12060713

APA StyleAvendaño, J. I., Zlatanova, S., Domingo, A., Pérez, P., & Correa, C. (2022). Utilization of BIM in Steel Building Projects: A Systematic Literature Review. Buildings, 12(6), 713. https://doi.org/10.3390/buildings12060713