Axial Compression Prediction and GUI Design for CCFST Column Using Machine Learning and Shapley Additive Explanation

Abstract

1. Introduction

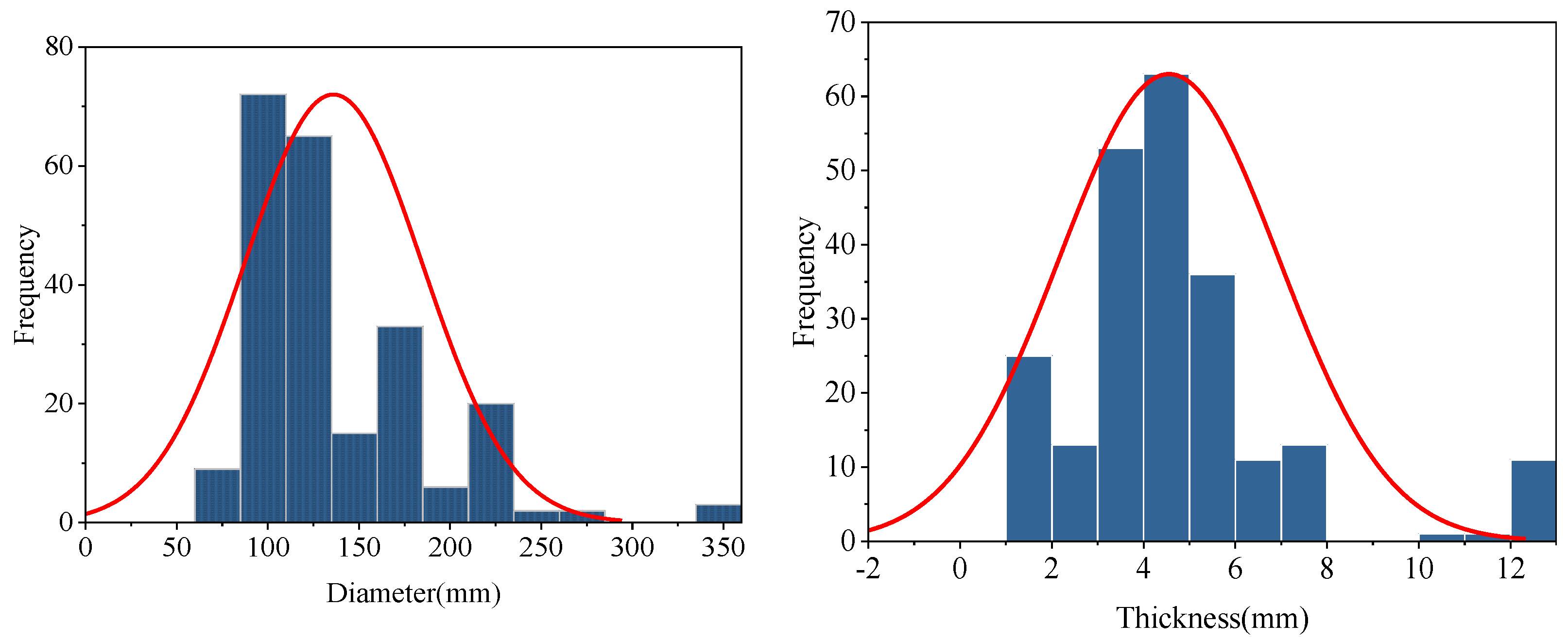

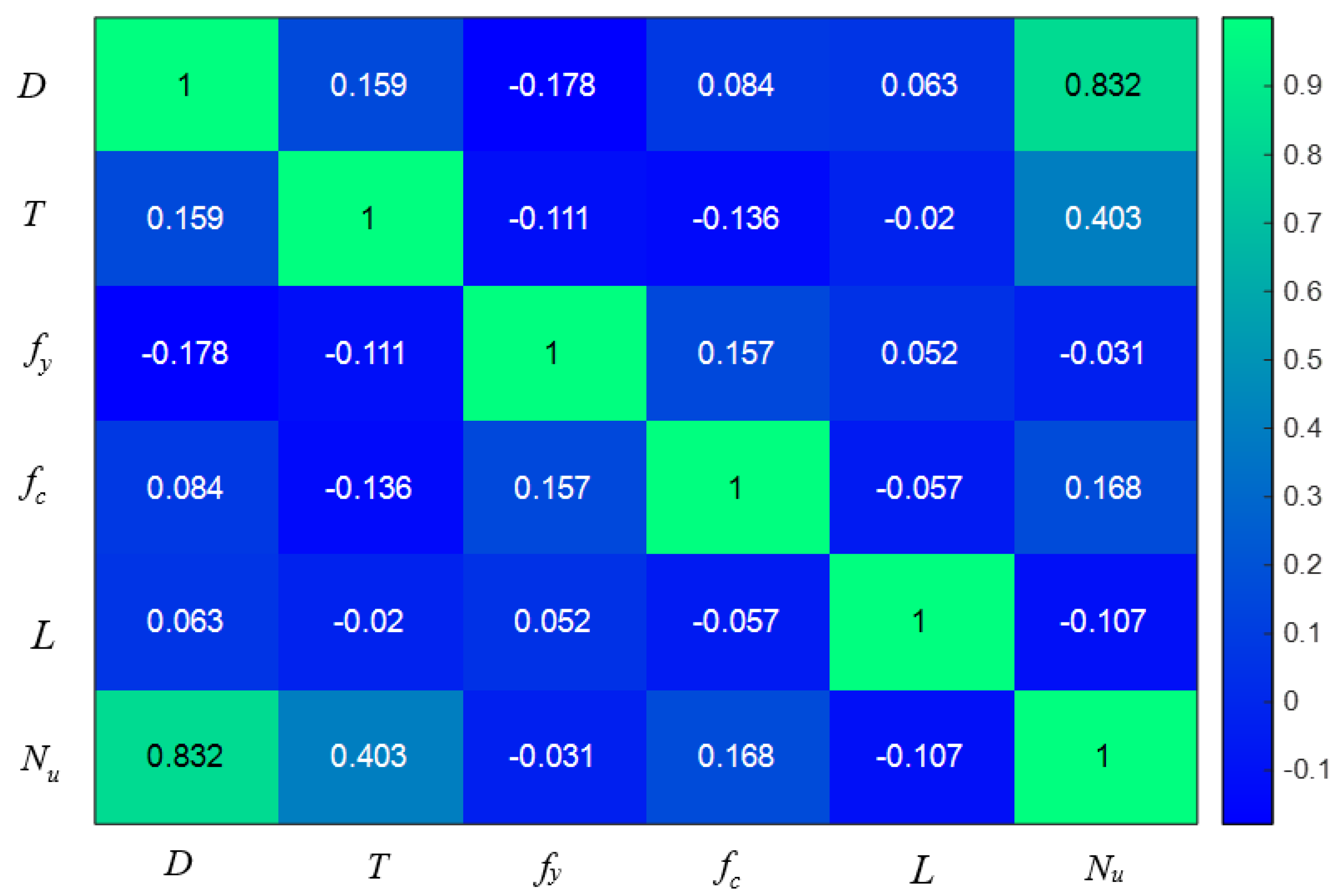

2. Dataset Description and Analysis

3. Prediction Models

3.1. Performance Indices of Models

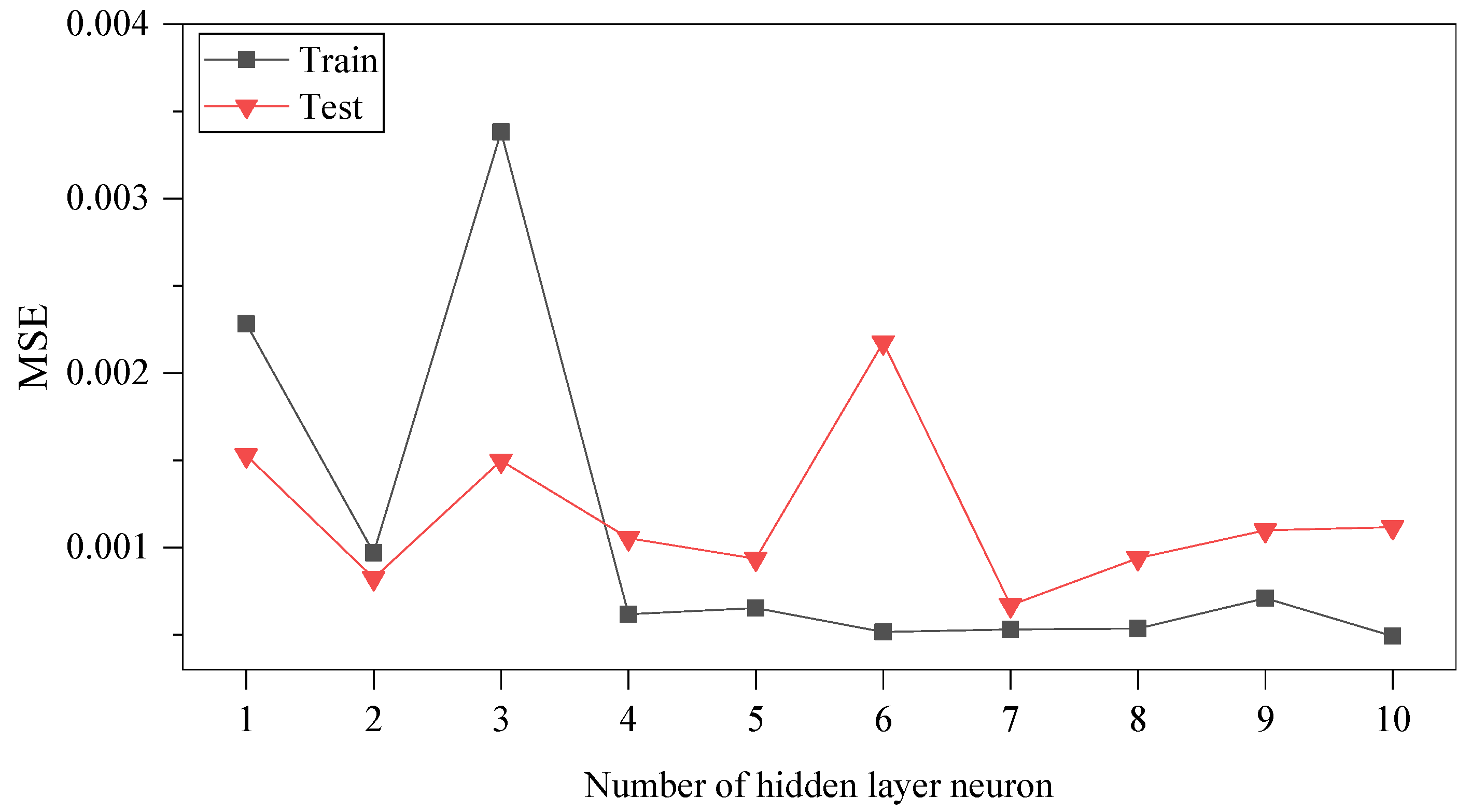

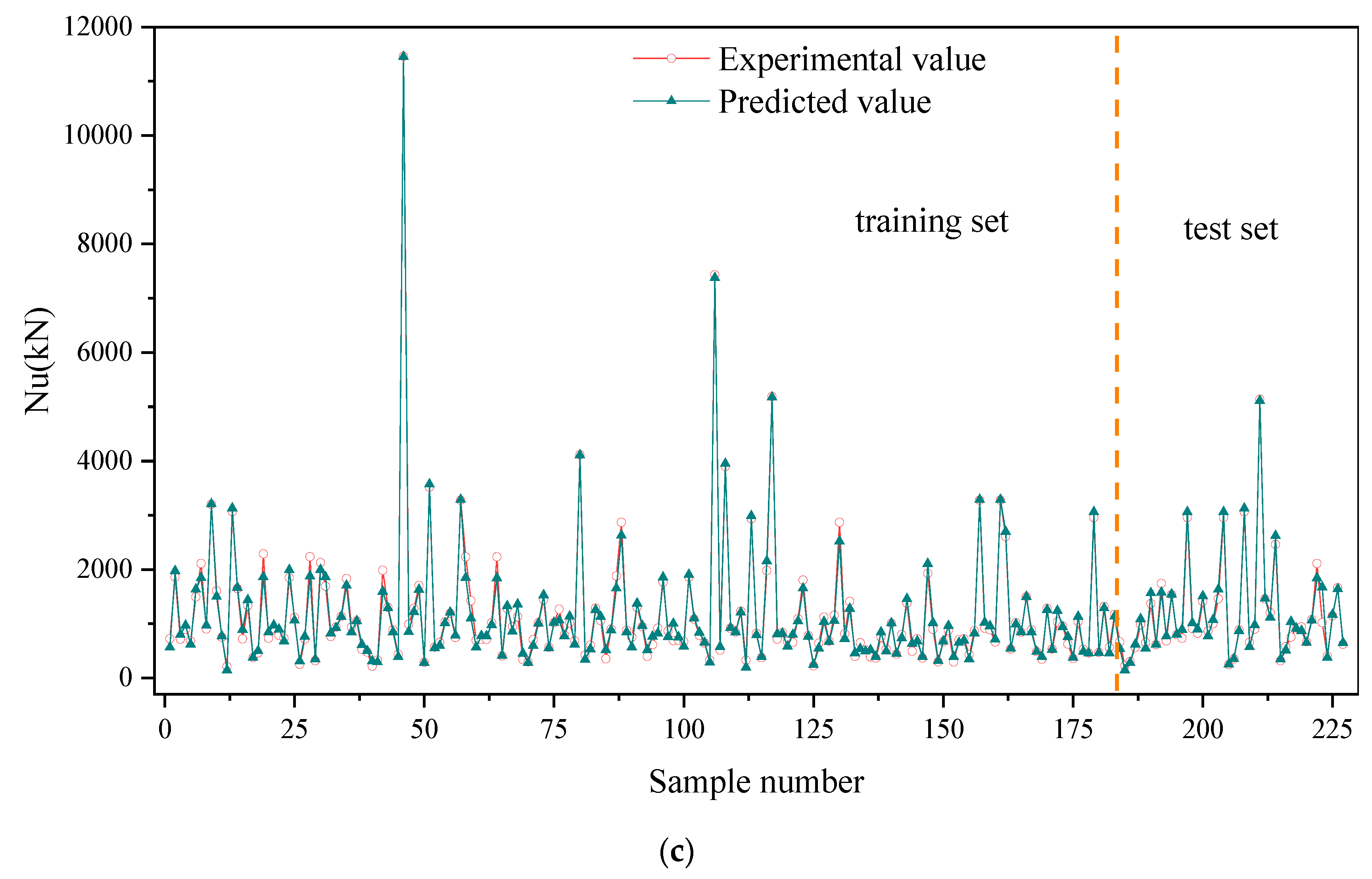

3.2. PSO-ANN Neural Network

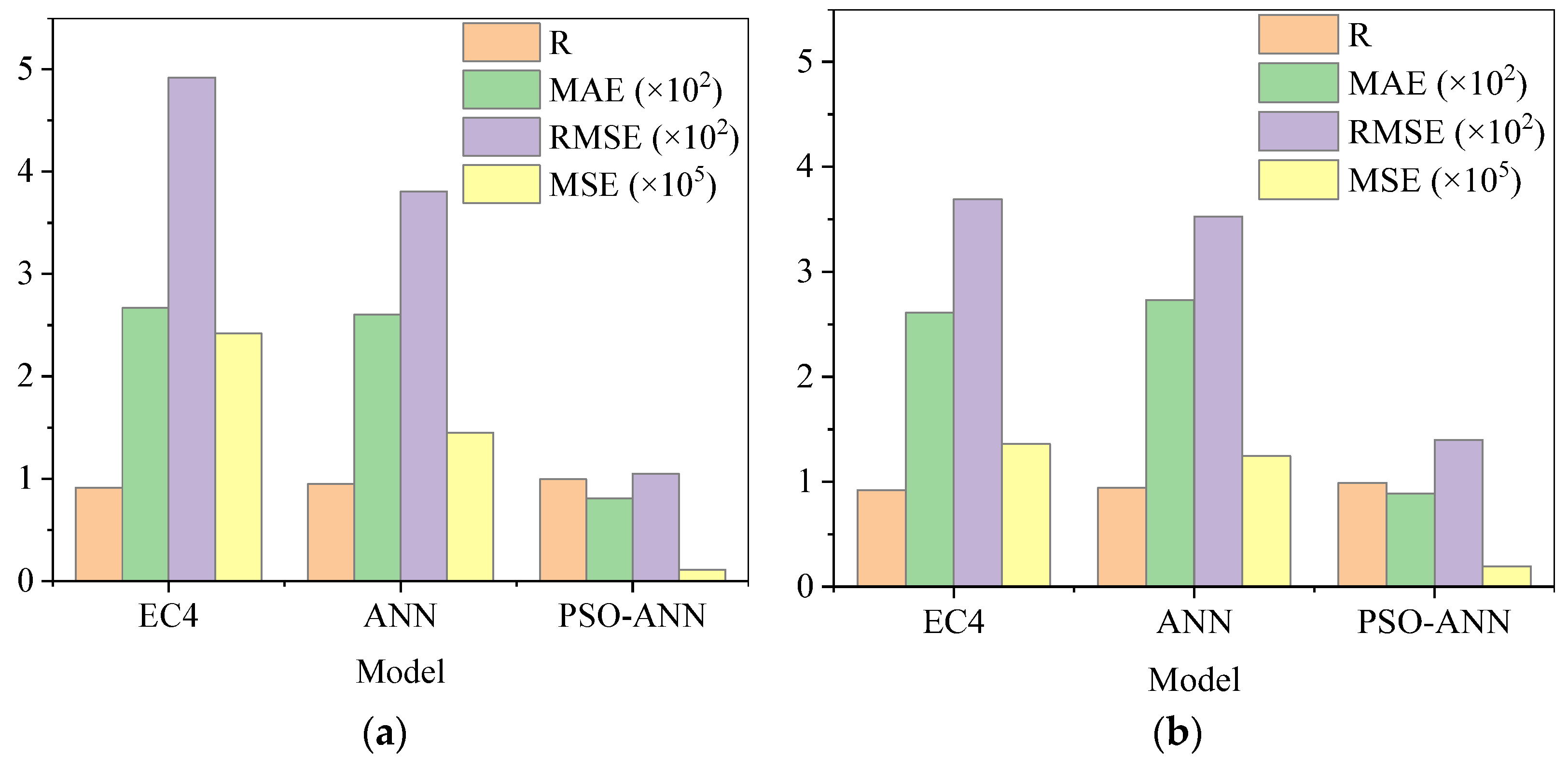

3.3. Comparison of Prediction Models

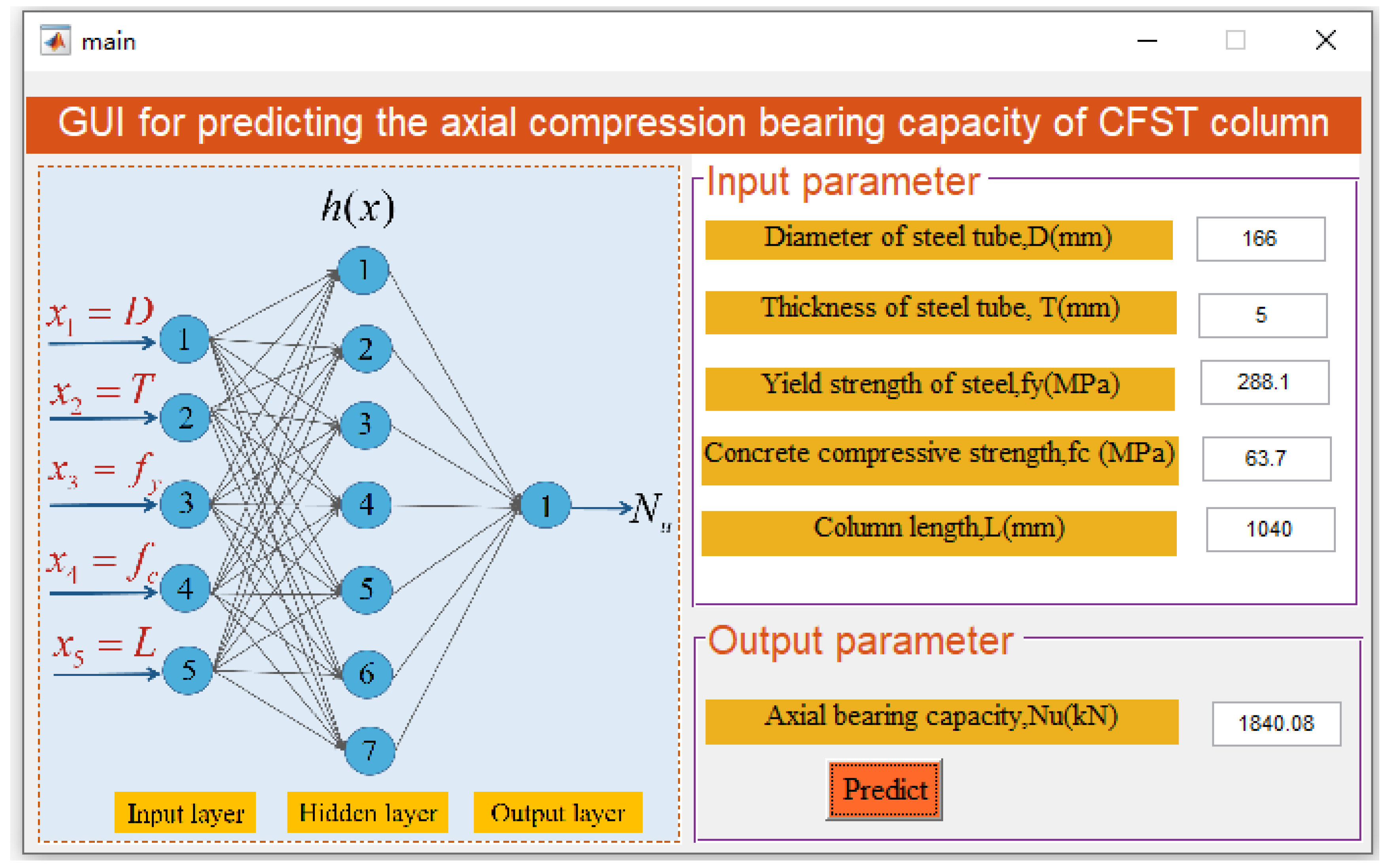

3.4. Development of Interactive Graphical User Interface

4. Influence of Design Parameters on Axial Bearing Capacity

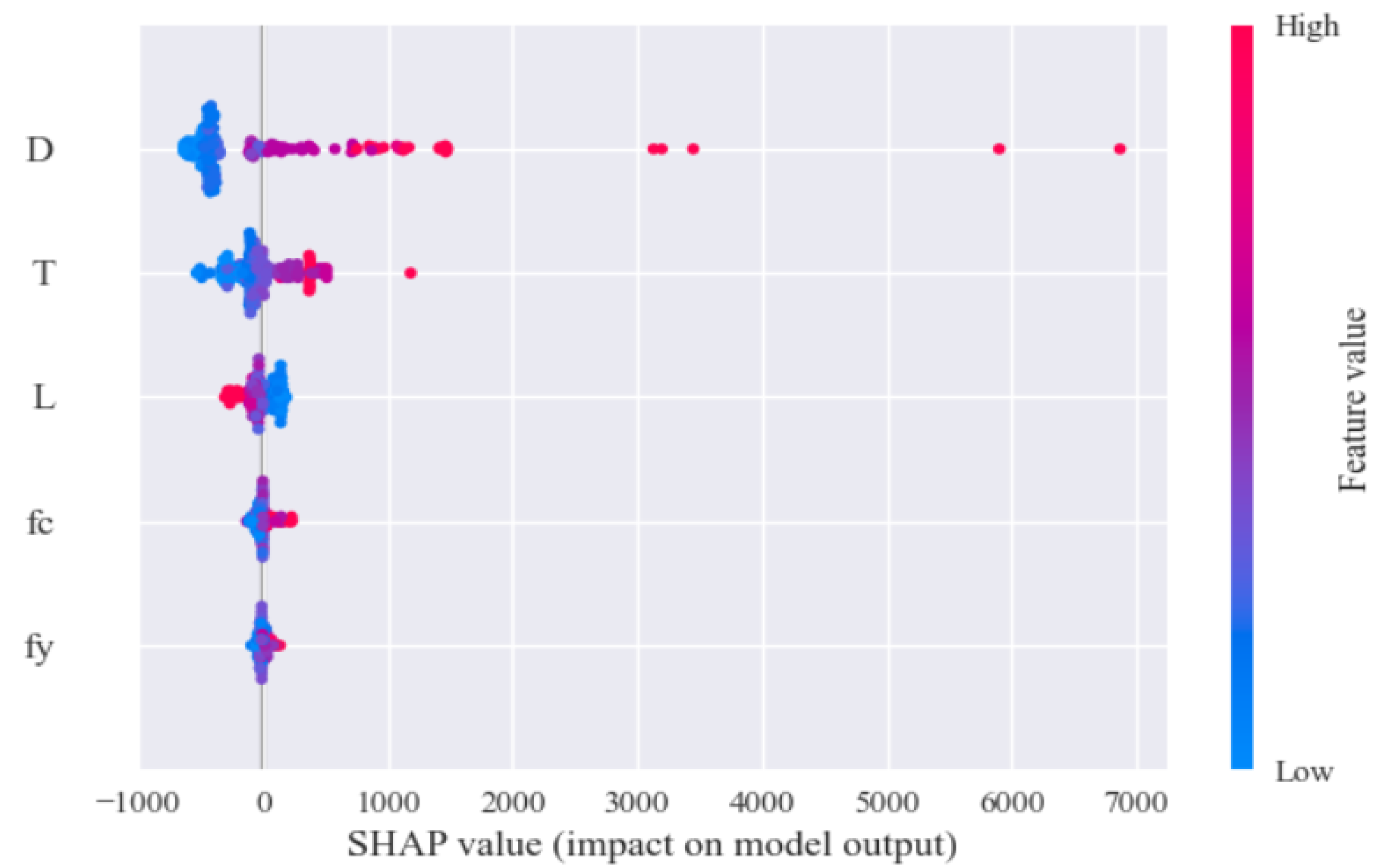

4.1. SHAP-Based Importance Factor Identification

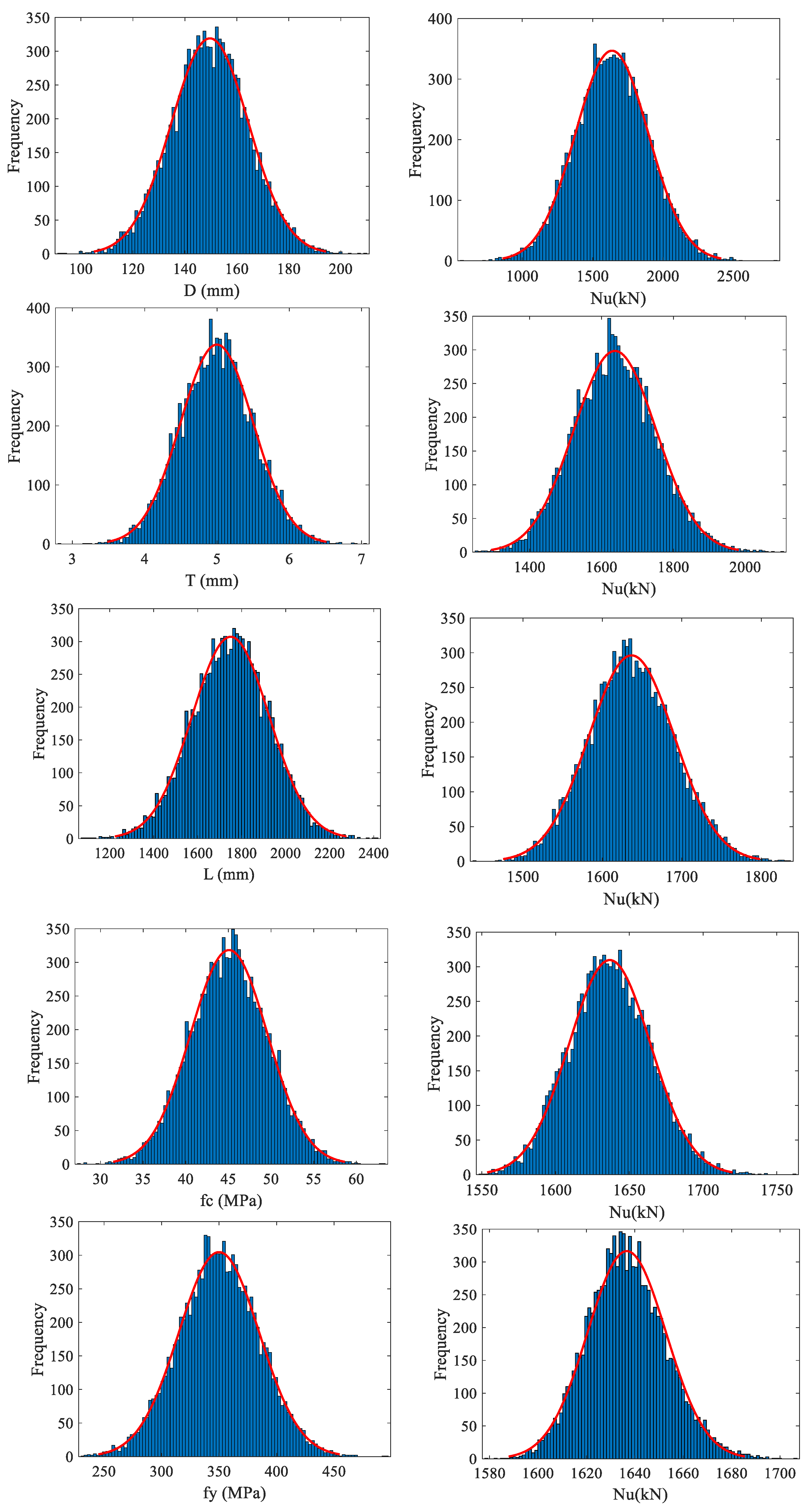

4.2. Quantification of the Influence Degree of Design Parameters on Bearing Capacity

5. Conclusions

- (1)

- The PSO-ANN model can accurately capture the nonlinear relationship between the five input parameters and the axial bearing capacity of CCFST columns with a correlation coefficient of 0.99 for both training and test sets.

- (2)

- The prediction performance of the PSO-ANN model proposed is superior to that of the EC4 and original ANN model with regard to the R, MAE, RMSE, and MSE.

- (3)

- A GUI using MATLAB was developed tentatively to achieve automatic output and display of the axial bearing capacity of CCFST columns under manual keying of input variables, which could help structural designers in determining some initial estimates of the outcomes before performing any extensive laboratory or fieldwork.

- (4)

- Among the five design parameters affecting the bearing capacity of the CCFST column, diameter is the dominant factor, followed by steel tube thickness, length, compressive strength of concrete, and yield strength of steel. Except for the length, the increase of the other four parameters plays a positive role in the axial capacity, and the fluctuation of diameter in a random environment can lead to the variation of bearing capacity beyond its own variation range.

- (5)

- The research in this paper can assist or partially replace laboratory compression experiments of CCFST columns to achieve time and cost savings, and it can also be used as a convenient and reliable candidate for decision-making in the field of CCFST column construction and design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, H.J.; Park, H.G.; Choi, I.R. Compression loading test for concrete-filled tubular columns with high-strength steel slender section. J. Constr. Steel Res. 2019, 159, 507–520. [Google Scholar] [CrossRef]

- Huang, Z.C.; Li, D.X.; Uy, B.; Thai, H.T.; Hou, C. Local and post-local buckling of fabricated high-strength steel and composite columns. J. Constr. Steel Res. 2019, 154, 235–249. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, Y.; Chen, Z.; Yan, J.-B.; Zheng, Z. Axial compressive performance of CFRP confined rectangular CFST columns using high-strength materials with moderate slenderness. Constr. Build. Mater. 2021, 299, 123912. [Google Scholar] [CrossRef]

- Chen, D.D.; Montano, V.; Huo, L.S.; Song, G.B. Depth detection of subsurface voids in concrete-filled steel tubular (CFST) structure using percussion and decision tree. Measurement 2020, 163, 107869. [Google Scholar] [CrossRef]

- Zhou, J.; Fang, X.D.; Jiang, Y. Cyclic behavior of concrete-encased high-strength concrete-filled steel tube composite walls: An experiment. Struct. Concr. 2021, 22, 691–708. [Google Scholar] [CrossRef]

- Kang, W.H.; Uy, B.; Tao, Z.; Hicks, S. Design strength of concrete-filled steel columns. Adv. Steel Constr. 2014, 11, 20. [Google Scholar]

- Wang, Z.-B.; Tao, Z.; Han, L.-H.; Uy, B.; Lam, D.; Kang, W.-H. Strength, stiffness and ductility of concrete-filled steel columns under axial compression. Eng. Struct. 2017, 135, 209–221. [Google Scholar] [CrossRef]

- Hou, C.; Han, L.H.; Zhao, X.L. Concrete-filled circular steel tubes subjected to local bearing force: Finite element analysis. Thin Wall Struct. 2014, 77, 109–119. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, Z.B.; Yu, Q. Finite element modelling of concrete-filled steel stub columns under axial compression. J. Constr. Steel Res. 2013, 89, 121–131. [Google Scholar] [CrossRef]

- Liu, D.L.; Gho, W.M. Axial load behaviour of high-strength rectangular concrete-filled steel tubular stub columns. Thin Wall Struct. 2005, 43, 1131–1142. [Google Scholar] [CrossRef]

- Liu, D.L.; Gho, W.M.; Yuan, H. Ultimate capacity of high-strength rectangular concrete-filled steel hollow section stub columns. J. Constr. Steel Res. 2003, 59, 1499–1515. [Google Scholar] [CrossRef]

- Han, L.H.; An, Y.F. Performance of concrete-encased CFST stub columns under axial compression. J. Constr. Steel Res. 2014, 93, 62–76. [Google Scholar] [CrossRef]

- Lai, M.H.; Ho, J.C.M. Confinement effect of ring-confined concrete-filled-steel-tube columns under uni-axial load. Eng. Struct. 2014, 67, 123–141. [Google Scholar] [CrossRef]

- Han, L.H.; He, S.H.; Liao, F.Y. Performance and calculations of concrete filled steel tubes (CFST) under axial tension. J. Constr. Steel Res. 2011, 67, 1699–1709. [Google Scholar] [CrossRef]

- Abed, F.; AlHamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Han, L.H.; Liu, W.; Yang, Y.F. Behaviour of concrete-filled steel tubular stub columns subjected to axially local compression. J. Constr. Steel Res. 2008, 64, 377–387. [Google Scholar] [CrossRef]

- Evirgen, B.; Tuncan, A.; Taskin, K. Structural behavior of concrete filled steel tubular sections (CFT/CFSt) under axial compression. Thin Wall Struct. 2014, 80, 46–56. [Google Scholar] [CrossRef]

- Ho, N.X.; Le, T.T. Effects of variability in experimental database on machine-learning-based prediction of ultimate load of circular concrete-filled steel tubes. Measurement 2021, 176, 109198. [Google Scholar] [CrossRef]

- Zhai, Q.; Zhang, J.C.; Xiao, J.H.; Du, G.F.; Huang, Y.S. Feasibility of piezoceramic transducer-enabled active sensing for the monitoring cross-shaped concrete filled steel tubular (CCFST) columns under cyclic loading. Measurement 2021, 182, 109646. [Google Scholar] [CrossRef]

- Abdalla, S.; Abed, F.; AlHamaydeh, M. Behavior of CFSTs and CCFSTs under quasi-static axial compression. J. Constr. Steel Res. 2013, 90, 235–244. [Google Scholar] [CrossRef]

- Shen, Q.; Wang, J.; Wang, J.; Ding, Z. Axial compressive performance of circular CFST columns partially wrapped by carbon FRP. J. Constr. Steel Res. 2019, 155, 90–106. [Google Scholar] [CrossRef]

- Gupta, A.; Mohan, R.; Bisht, H.; Sharma, A. Experimental testing and numerical modelling of CFST columns under axial compressive load. Asian J. Civ. Eng. 2022, 23, 415–424. [Google Scholar] [CrossRef]

- Dai, X.H.; Lam, D.; Jamaluddin, N.; Ye, J. Numerical analysis of slender elliptical concrete filled columns under axial compression. Thin Wall Struct. 2014, 77, 26–35. [Google Scholar] [CrossRef]

- Ahmadi, M.; Naderpour, H.; Kheyroddin, A. ANN Model for Predicting the Compressive Strength of Circular Steel-Confined Concrete. Int. J. Civ. Eng. 2017, 15, 213–221. [Google Scholar] [CrossRef]

- Jayalekshmi, S.; Jegadesh, J.S.S.; Goel, A. Empirical Approach for Determining Axial Strength of Circular Concrete Filled Steel Tubular Columns. J. Inst. Eng. Ser. A 2018, 99, 257–268. [Google Scholar] [CrossRef]

- Guneyisi, E.M.; Gultekin, A.; Mermerdas, K. Ultimate capacity prediction of axially loaded CFST short columns. Int. J. Steel Struct. 2016, 16, 99–114. [Google Scholar] [CrossRef]

- Mansouri, I.; Chacon, R.; Hu, J.W. Improved predictive model to the cross-sectional resistance of CFT. J. Mech. Sci. Technol. 2017, 31, 3887–3895. [Google Scholar] [CrossRef][Green Version]

- Moon, J.; Kim, J.J.; Lee, T.H.; Lee, H.E. Prediction of axial load capacity of stub circular concrete-filled steel tube using fuzzy logic. J. Constr. Steel Res. 2014, 101, 184–191. [Google Scholar] [CrossRef]

- Shapiro, A.F. The merging of neural networks, fuzzy logic, and genetic algorithms. Insur. Math. Econ. 2002, 31, 115–131. [Google Scholar] [CrossRef]

- Lyu, F.; Fan, X.Y.; Ding, F.X.; Chen, Z.W. Prediction of the axial compressive strength of circular concrete-filled steel tube columns using sine cosine algorithm-support vector regression. Compos. Struct. 2021, 273, 114282. [Google Scholar] [CrossRef]

- Sarir, P.; Shen, S.L.; Wang, Z.F.; Chen, J.; Horpibulsuk, S.; Pham, B.T. Optimum model for bearing capacity of concrete-steel columns with AI technology via incorporating the algorithms of IWO and ABC. Eng. Comput. 2021, 37, 797–807. [Google Scholar] [CrossRef]

- Pham, B.T.; Jaafari, A.; Prakash, I.; Bui, D.T. A novel hybrid intelligent model of support vector machines and the MultiBoost ensemble for landslide susceptibility modeling. Bull. Eng. Geol. Environ. 2019, 78, 2865–2886. [Google Scholar] [CrossRef]

- Ly, H.-B.; Le, L.M.; Phi, L.V.; Phan, V.-H.; Tran, V.Q.; Pham, B.T.; Le, T.-T.; Derrible, S. Development of an AI Model to Measure Traffic Air Pollution from Multisensor and Weather Data. Sensors 2019, 19, 4941. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.Y.; Yuan, B.Y.; Li, X.; Tian, D.; Mu, W.S. Evaluation on risks of sustainable supply chain based on optimized BP neural networks in fresh grape industry. Comput. Electron. Agr. 2021, 183, 105988. [Google Scholar]

- Ben Chaabene, W.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- Cao, Y.; Zandi, Y.; Agdas, A.S.; Wang, Q.F.; Qian, X.M.; Fu, L.J.; Wakil, K.; Selmi, A.; Issakhov, A.; Roco-Videla, A. A review study of application of artificial intelligence in construction management and composite beams. Steel Compos. Struct. 2021, 39, 685–700. [Google Scholar]

- Lan, T.; Hu, H.; Jiang, C.; Yang, G.; Zhao, Z. A comparative study of decision tree, random forest, and convolutional neural network for spread-F identification. Adv. Space Res. 2020, 65, 2052–2061. [Google Scholar] [CrossRef]

- Khan, M.A.; Memon, S.A.; Farooq, F.; Javed, M.F.; Aslam, F.; Alyousef, R. Compressive Strength of Fly-Ash-Based Geopolymer Concrete by Gene Expression Programming and Random Forest. Adv. Civ. Eng. 2021, 2021, 6618407. [Google Scholar] [CrossRef]

- Farooq, F.; Nasir Amin, M.; Khan, K.; Rehan Sadiq, M.; Faisal Javed, M.; Aslam, F.; Alyousef, R. A Comparative Study of Random Forest and Genetic Engineering Programming for the Prediction of Compressive Strength of High Strength Concrete (HSC). Appl. Sci. 2020, 10, 7330. [Google Scholar] [CrossRef]

- Han, B.; Wu, Y.; Liu, L. Prediction and uncertainty quantification of compressive strength of high-strength concrete using optimized machine learning algorithms. Struct. Concr. 2022, 1–14. [Google Scholar] [CrossRef]

- Sousa-Ferreira, I.; Sousa, D. A review of velocity-type PSO variants. J. Algorithms Comput. Technol. 2016, 11, 23–30. [Google Scholar] [CrossRef]

- Thangaraj, R.; Pant, M.; Abraham, A.; Bouvry, P. Particle swarm optimization: Hybridization perspectives and experimental illustrations. Appl. Math. Comput. 2011, 217, 5208–5226. [Google Scholar] [CrossRef]

- Wu, Y.; Li, S. Damage degree evaluation of masonry using optimized SVM-based acoustic emission monitoring and rate process theory. Measurement 2022, 190, 110729. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y. Prediction and feature analysis of punching shear strength of two-way reinforced concrete slabs using optimized machine learning algorithm and Shapley additive explanations. Mech. Adv. Mater. Struct. 2022, 1–11. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Tran, M.T.; Kim, S.; Bakhshpoori, T.; Deo, R.C. Shear strength prediction of steel fiber reinforced concrete beam using hybrid intelligence models: A new approach. Eng. Struct. 2018, 177, 244–255. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Wang, Y.; Xia, Y.; Guo, Z. Identification of grouting compactness in bridge bellows based on the BP neural network. Structures 2021, 32, 817–826. [Google Scholar] [CrossRef]

- Tran, V.-L.; Kim, S.-E. A practical ANN model for predicting the PSS of two-way reinforced concrete slabs. Eng. Comput. 2021, 37, 2303–2327. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y. Hybrid machine learning model and Shapley additive explanations for compressive strength of sustainable concrete. Constr. Build. Mater. 2022, 330, 127298. [Google Scholar] [CrossRef]

- Chen, H.; Li, X.; Wu, Y.; Zuo, L.; Lu, M.; Zhou, Y. Compressive Strength Prediction of High-Strength Concrete Using Long Short-Term Memory and Machine Learning Algorithms. Build. Basel 2022, 12, 302. [Google Scholar] [CrossRef]

- Mangalathu, S.; Shin, H.; Choi, E.; Jeon, J.-S. Explainable machine learning models for punching shear strength estimation of flat slabs without transverse reinforcement. J. Build. Eng. 2021, 39, 102300. [Google Scholar] [CrossRef]

- Nguyen, M.S.T.; Kim, S.-E. A hybrid machine learning approach in prediction and uncertainty quantification of ultimate compressive strength of RCFST columns. Constr. Build. Mater. 2021, 302, 124208. [Google Scholar] [CrossRef]

| Parameter | Unit | Maximum Value | Minimum Value | Standard Deviation | Mean Value |

|---|---|---|---|---|---|

| D | mm | 355.6 | 76 | 48.565 | 135.971 |

| T | mm | 12.8 | 1.397 | 2.384 | 4.553 |

| fy | MPa | 605 | 200 | 64.3 | 344 |

| fc | MPa | 106 | 14.44 | 15.710 | 42.629 |

| L | mm | 5400 | 508 | 961.863 | 1722.351 |

| Nu | kN | 11,460 | 210.7 | 1160.625 | 1188.439 |

| Parameter | Settings |

|---|---|

| Neural network | |

| Input layer neurons | 5 |

| Hidden layer neurons | 7 |

| Output layer neurons | 1 |

| Epochs | 100 |

| Learning rate | 0.01 |

| Loss function | MSE |

| Back-propagation algorithm | Levenberg-Marquardt |

| Transfer function in hidden layer | Tansig |

| Transfer function in the output layer | Purelin |

| Alpha | 0.001 |

| Beta | 0.1 |

| Delata | 0.01 |

| Gama | 0.1 |

| Max_fail | 6 |

| Low_limit | 0.1 |

| Up_limiit | 0.5 |

| Particle swarm optimization algorithm | |

| Learning factor C1 | 1.5 |

| Learning factor C2 | 1.5 |

| Swarm size | 200 |

| Maxgen | 100 |

| Lower bound velocity | −5 |

| Upper bound velocity | 5 |

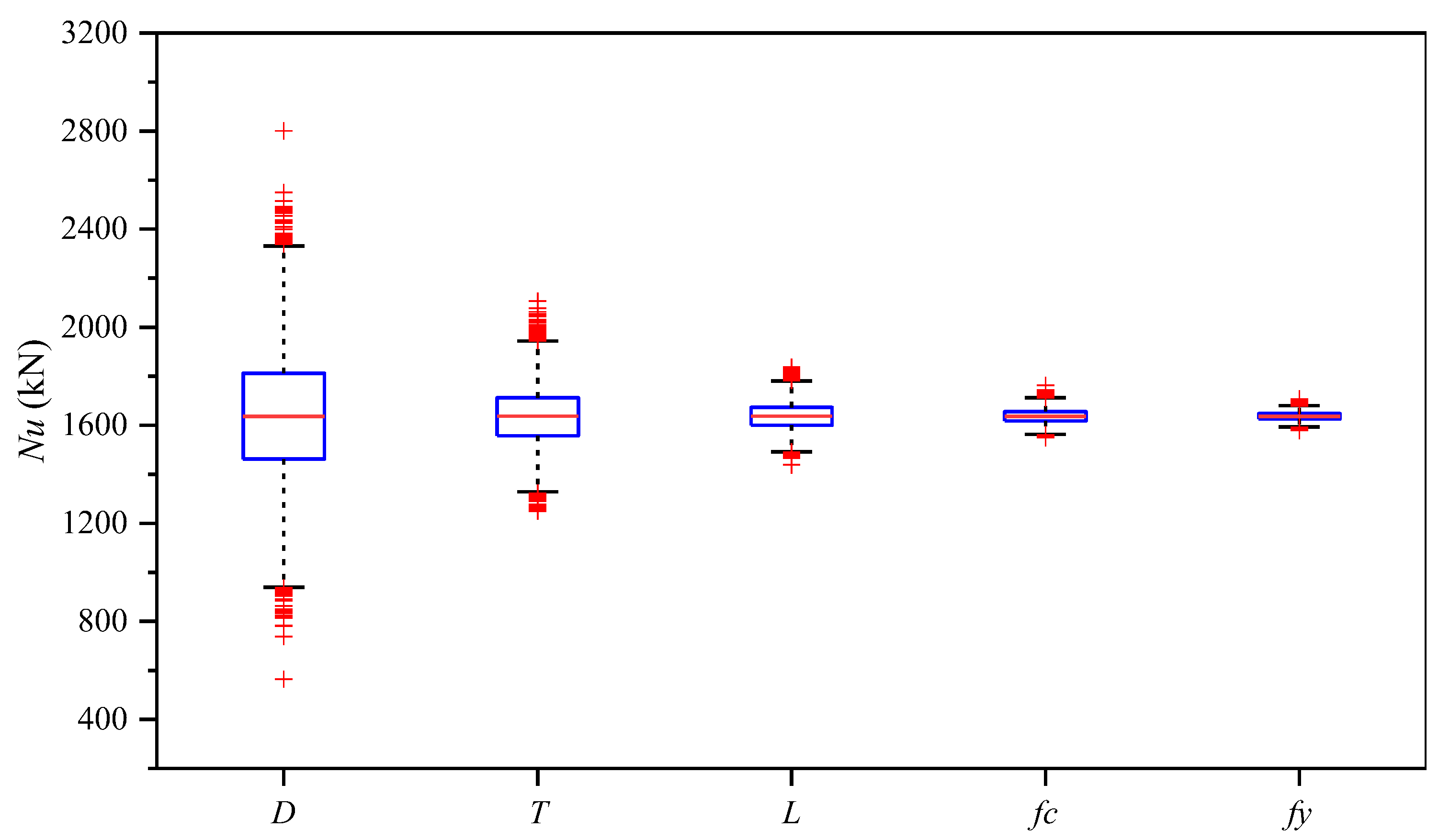

| Parameter | Unit | Mean Value | Standard Deviation | Coefficient of Variation | Sample Size | Distribution |

|---|---|---|---|---|---|---|

| D | mm | 150 | 15 | 10% | 10,000 | Normal distribution |

| T | mm | 5 | 0.5 | 10% | 10,000 | Normal distribution |

| L | mm | 1750 | 175 | 10% | 10,000 | Normal distribution |

| fc | MPa | 45 | 4.5 | 10% | 10,000 | Normal distribution |

| fy | MPa | 350 | 35 | 10% | 10,000 | Normal distribution |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wu, Y.; Zhou, Y. Axial Compression Prediction and GUI Design for CCFST Column Using Machine Learning and Shapley Additive Explanation. Buildings 2022, 12, 698. https://doi.org/10.3390/buildings12050698

Liu X, Wu Y, Zhou Y. Axial Compression Prediction and GUI Design for CCFST Column Using Machine Learning and Shapley Additive Explanation. Buildings. 2022; 12(5):698. https://doi.org/10.3390/buildings12050698

Chicago/Turabian StyleLiu, Xuerui, Yanqi Wu, and Yisong Zhou. 2022. "Axial Compression Prediction and GUI Design for CCFST Column Using Machine Learning and Shapley Additive Explanation" Buildings 12, no. 5: 698. https://doi.org/10.3390/buildings12050698

APA StyleLiu, X., Wu, Y., & Zhou, Y. (2022). Axial Compression Prediction and GUI Design for CCFST Column Using Machine Learning and Shapley Additive Explanation. Buildings, 12(5), 698. https://doi.org/10.3390/buildings12050698