Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry

Abstract

:1. Introduction

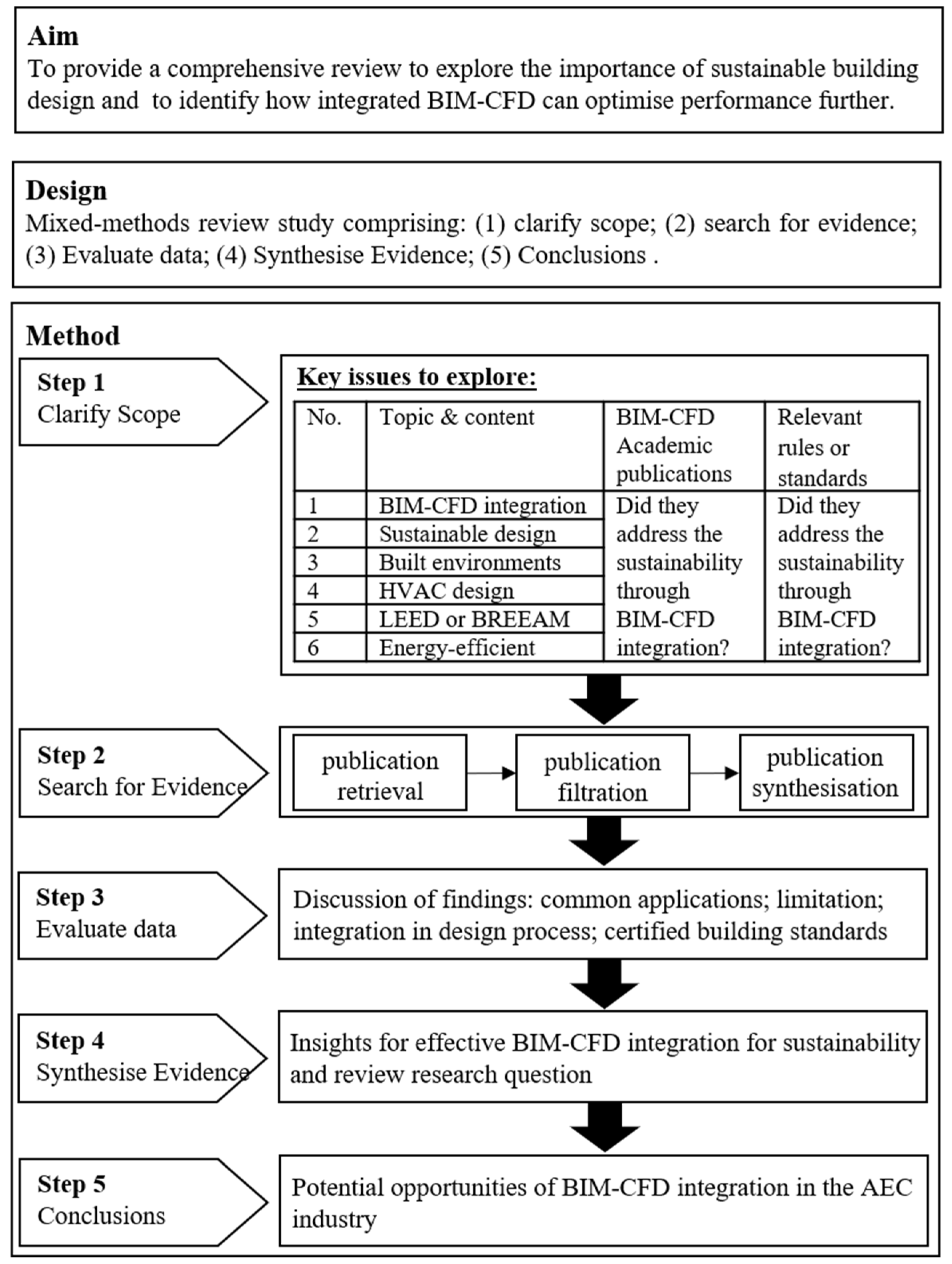

2. Review Methodology

3. Bibliometric Analysis

3.1. Journal Analysis

3.2. Publication Year Analysis

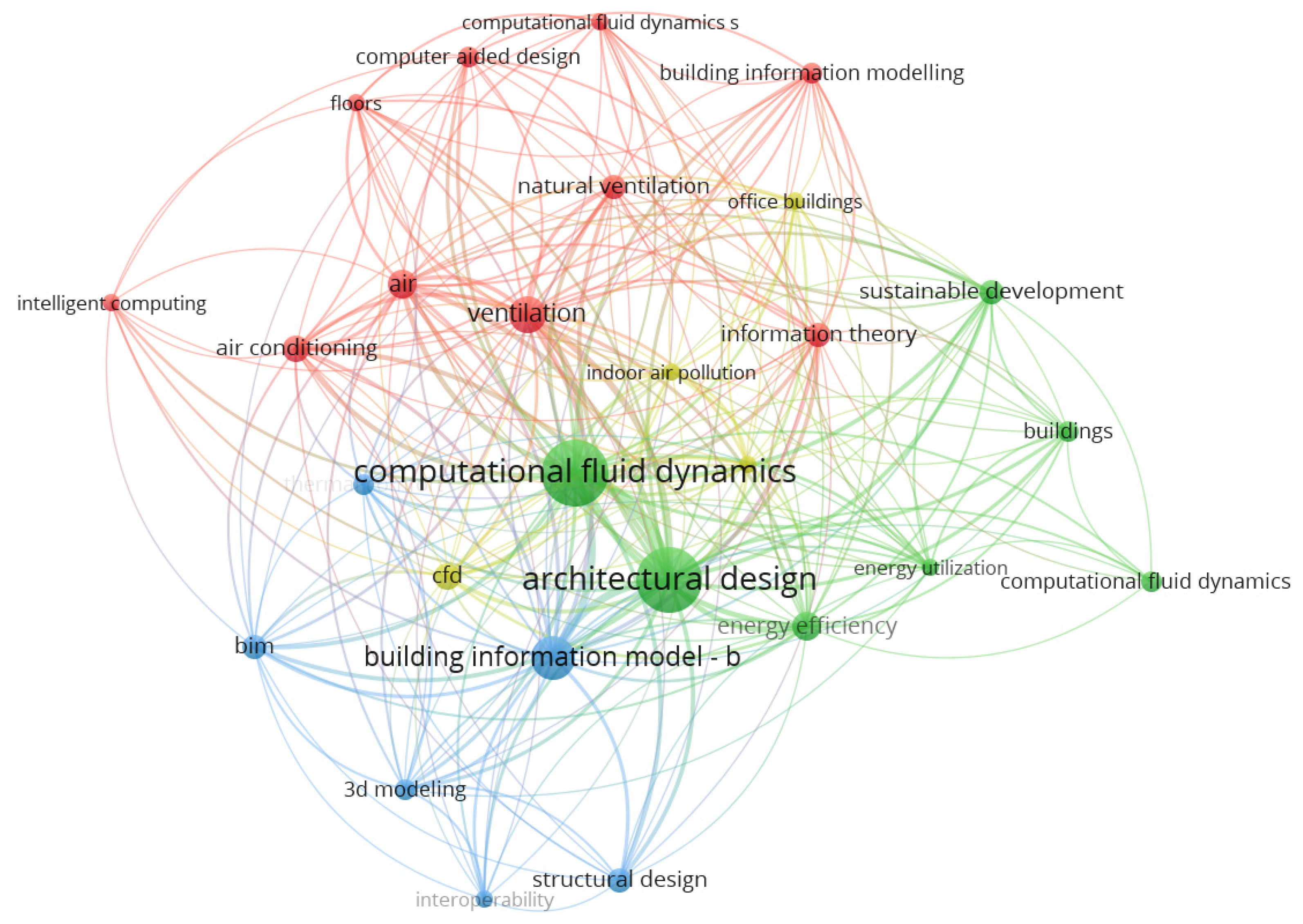

3.3. Keyword Analysis

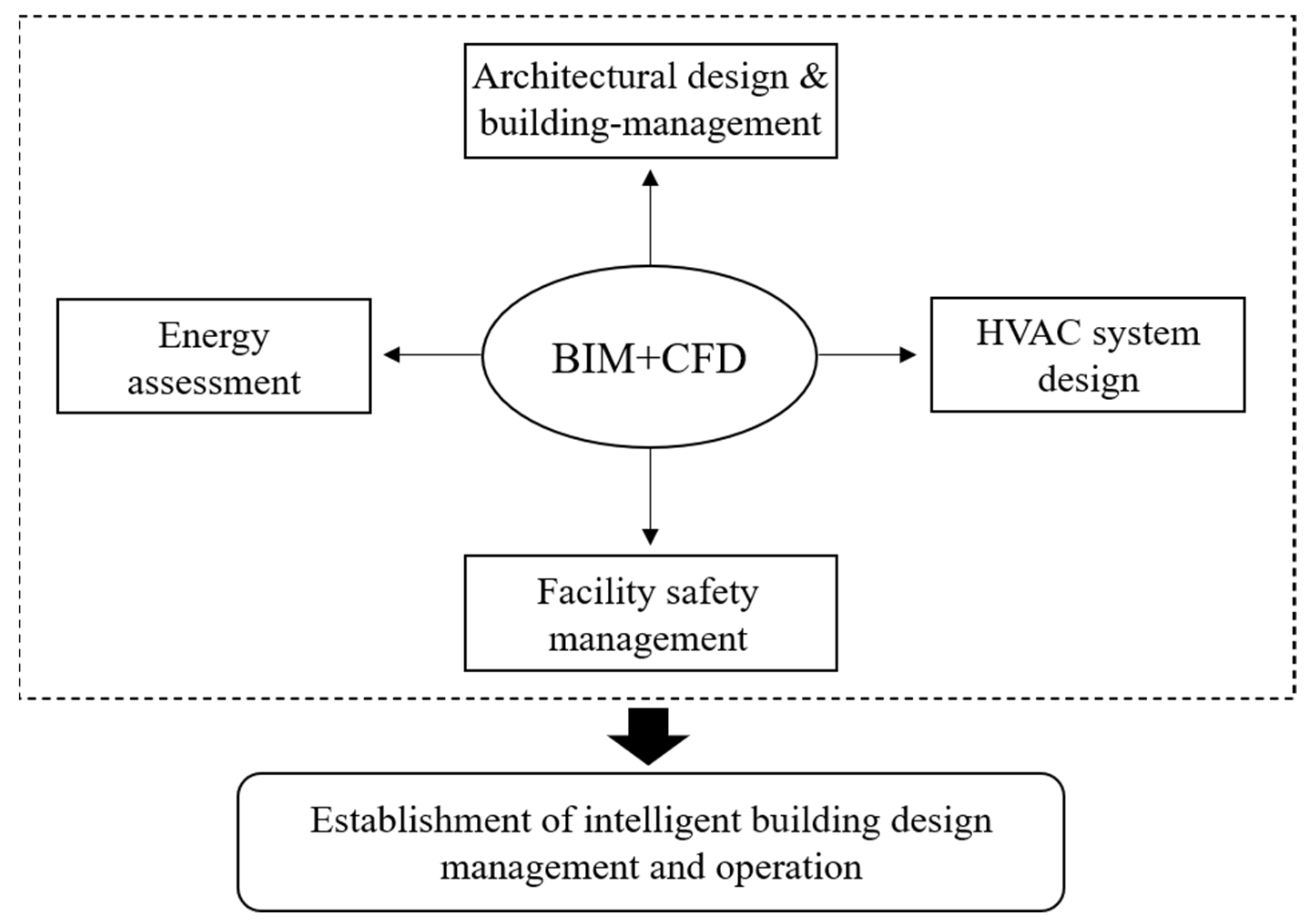

4. Analysis of BIM and CFD Integration in Different Sectors

4.1. Sector 1: Architectural Design and Building Management

4.1.1. Building Operation and Maintenance

4.1.2. Architectural Design Optimization for Sustainability

4.2. Sector 2: Energy Assessment

4.2.1. Energy Consumption/Performance Evaluation

4.2.2. Green Building Design

4.3. Sector 3: HVAC Design Requirements

4.3.1. Thermal Comfort/Heat Transfer Assessment

4.3.2. Air/Wind (Flow and Quality) and Ventilation Analysis

4.4. Facility Safety Management

Fire Simulation and Emergency Response

5. Discussion and Insights for Effective Adoption of BIM and CFD Integration Technology

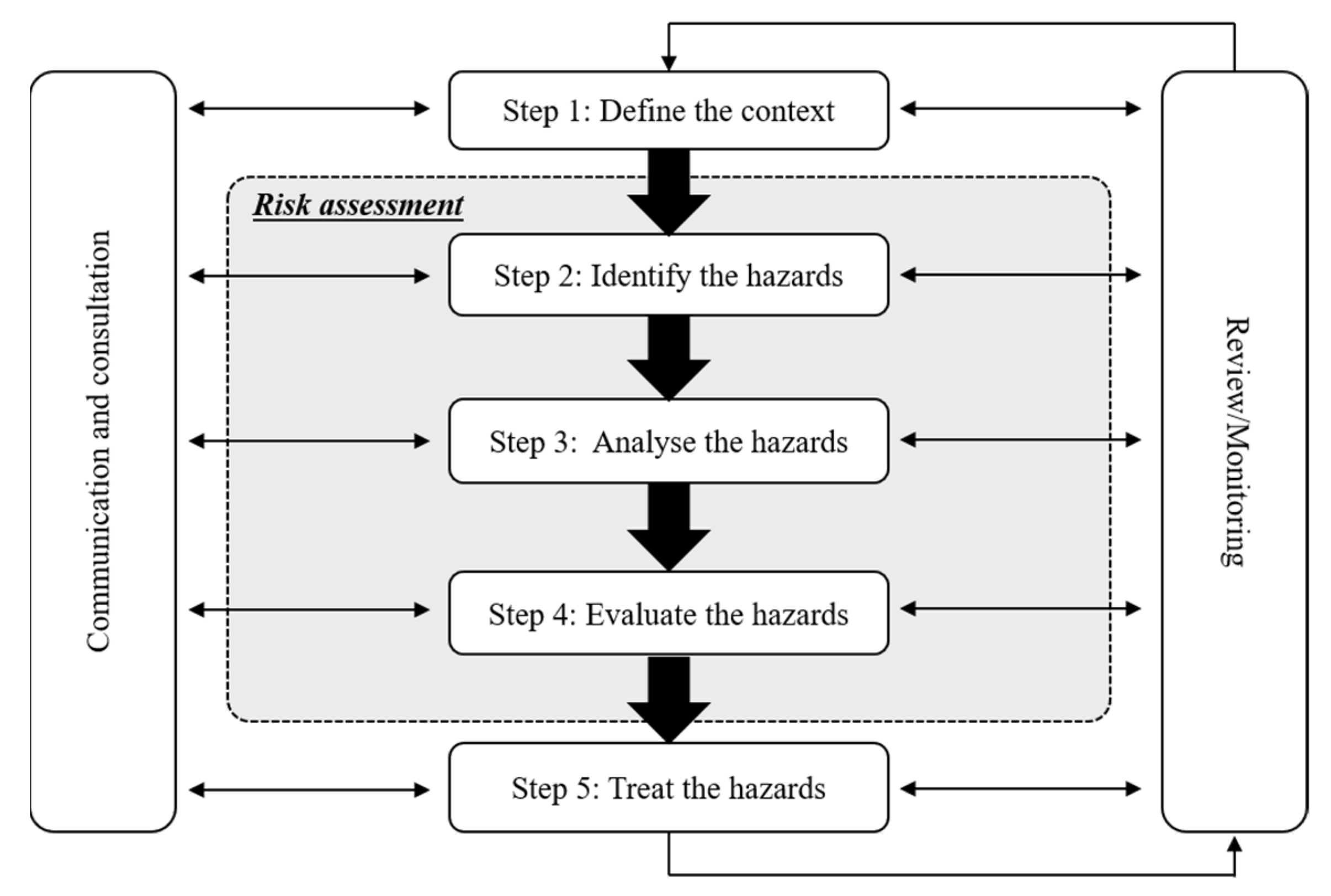

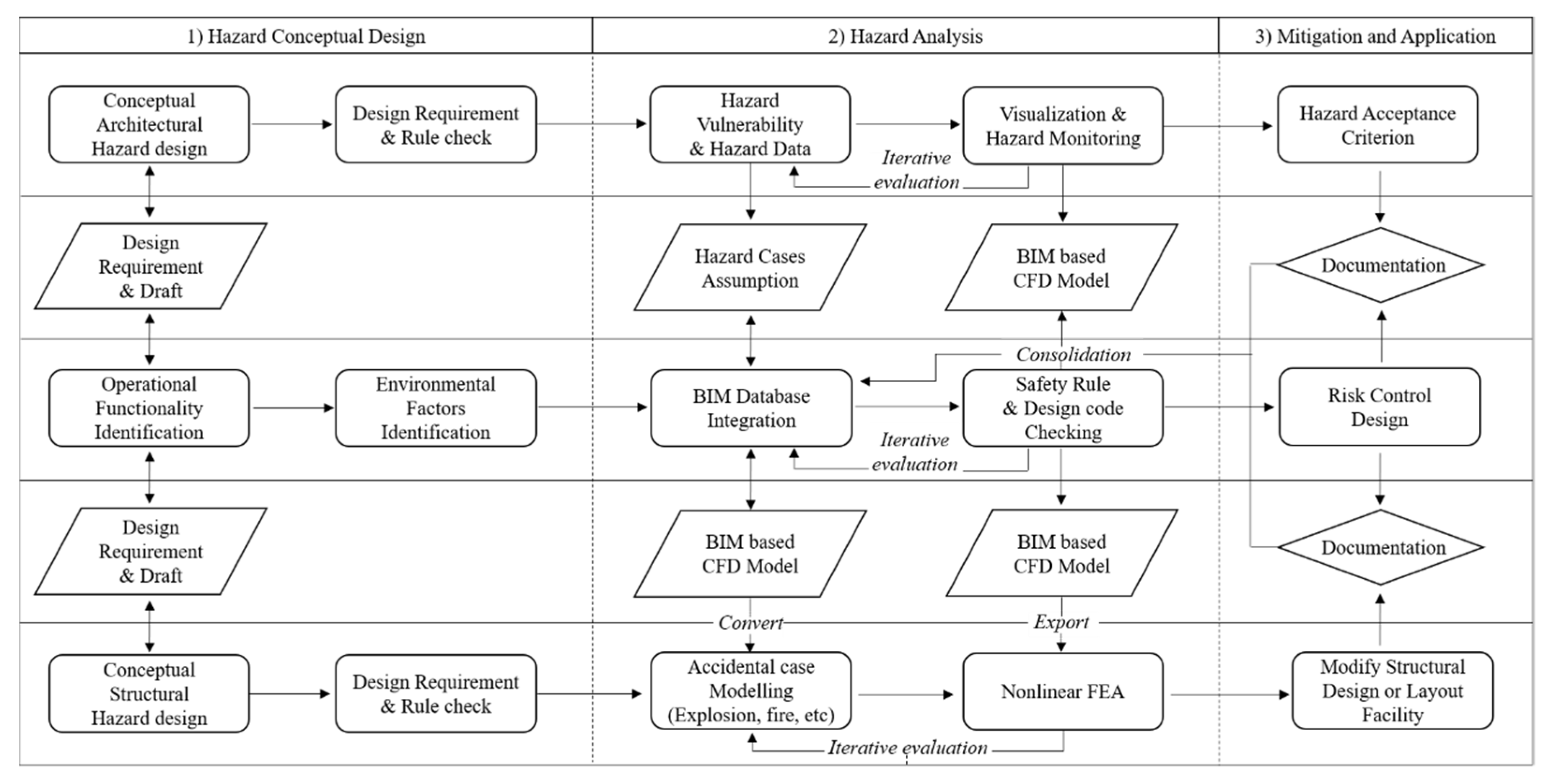

5.1. Integrating Quantitative and Qualitative Hazard Analysis Based on BIM and CFD Integration

5.1.1. The Fundamentals of Hazard Analysis

5.1.2. Application of Integrated BIM and CFD for a Comprehensive Hazard Analysis

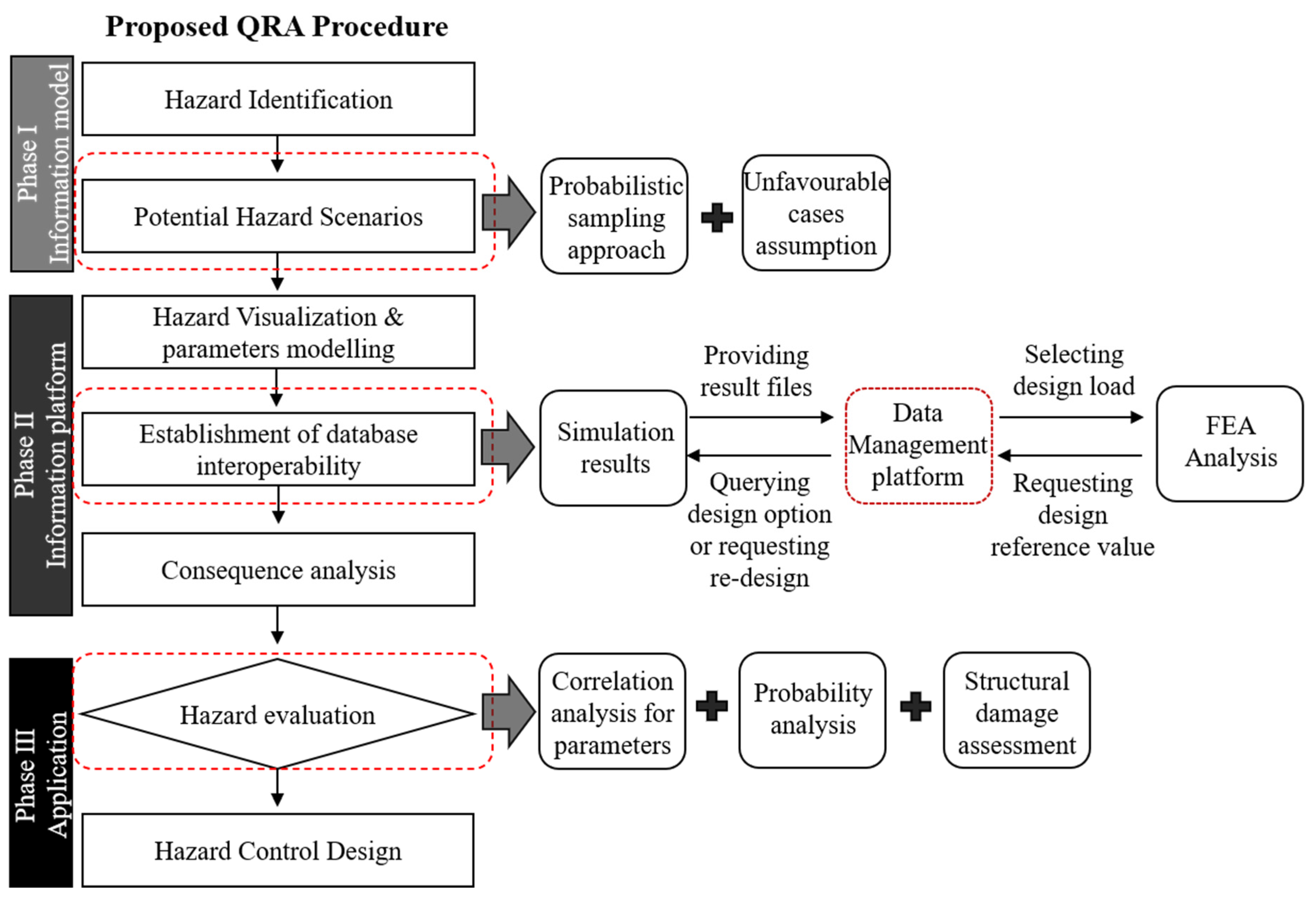

5.2. Framework of a Proposed Comprehensive Hazard Analysis Using BIM and CFD

5.2.1. Phase I: Hazard Information Model

5.2.2. Phase II: Hazard Information Platform

5.2.3. Phase III: Application

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| Abbreviation | Definition |

| BIM | Building Information Modeling |

| CFD | Computational Fluid Dynamics |

| AEC | Architecture, Engineering and Construction |

| IPD | Integrated Project Delivery |

| IoT | Internet of Things |

| GIS | Geographical Information Systems |

| HVAC | Heating Ventilation and Air Conditioning |

| PPD | Predicted Percentage of Dissatisfied |

| PMV | Predicted Mean Vote |

| ATF | Active Transparent Façade |

| PCM | Phase Change Materials |

References

- Zhu, J.; Chen, Y.; Zhang, L.; Guo, B.; Fan, G.; Guan, X.; Zhao, R. Revealing the doping mechanism of barium in sulfoaluminate cement clinker phases. J. Clean. Prod. 2021, 295, 126405. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, L.; Guo, B.; Chen, Y.; Fan, G.; Jin, Z.; Guan, X.; Zhu, J. Unveiling substitution preference of chromium ions in sulphoaluminate cement clinker phases. Compos. Part B Eng. 2021, 222, 109092. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Yang, S. Experimental study of predamaged columns strengthened by HPFL and BSP under combined load cases. Struct. Infrastruct. Eng. 2020, 17, 1210–1227. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Deng, Y. Temperature gradient modeling of a steel box-girder suspension bridge using Copulas probabilistic method and field monitoring. Adv. Struct. Eng. 2021, 24, 947–961. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Chen, X. Effects of actual loading waveforms on the fatigue behaviours of asphalt mixtures. Int. J. Fatigue 2021, 151, 106386. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, Z. Numerical Modeling of Response of CFRP—Concrete Interfaces Subjected to Fatigue Loading. J. Compos. Constr. 2021, 25, 04021043. [Google Scholar] [CrossRef]

- Wang, M.; Yang, X.; Wang, W. Establishing a 3D aggregates database from X-ray CT scans of bulk concrete. Constr. Build. Mater. 2022, 315, 125740. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Shou, W.; Ngo, T.; Sadick, A.-M.; Wang, X. Computer Vision Techniques in Construction: A Critical Review. Arch. Comput. Methods Eng. 2020, 28, 3383–3397. [Google Scholar] [CrossRef]

- Zhang, C.; Kordestani, H.; Masri, S.F.; Wang, J.; Sun, L. Data-driven system parameter change detection for a chain-like uncertainties embedded structure. Struct. Control Health Monit. 2021, 28, e2821. [Google Scholar] [CrossRef]

- Chong, H.-Y.; Lee, C.-Y.; Wang, X. A mixed review of the adoption of Building Information Modelling (BIM) for sustainability. J. Clean. Prod. 2017, 142, 4114–4126. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chong, H.-Y. Setting new trends of integrated Building Information Modelling (BIM) for construction industry. Constr. Innov. 2015, 15, 2–6. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. J. Clean. Prod. 2021, 278, 123505. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W. Identifying and prioritizing the benefits of integrating BIM and sustainability practices in construction projects: A Delphi survey of international experts. Sustain. Cities Soc. 2018, 40, 16–27. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.; Wong, J.K.; Chan, A.P. Barriers to the integration of BIM and sustainability practices in construction projects: A Delphi survey of international experts. J. Build. Eng. 2018, 20, 60–71. [Google Scholar] [CrossRef]

- Piroozfar, P.; Farr, E.R.P.; Zadeh, A.H.M.; Inacio, S.T.; Kilgallon, S.; Jin, R. Facilitating building information modelling (BIM) using Integrated Project Delivery (IPD): A UK perspective. J. Build. Eng. 2019, 26, 100907. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S.; Hosseini, M.R.; Abu-Samra, S.; Gaterell, M. Integrated project delivery with BIM: An automated EVM-based approach. Autom. Constr. 2019, 106, 102907. [Google Scholar] [CrossRef]

- Colombo, E.; Zwahlen, M.; Frey, M.; Loux, J. Design of a glazed double-façade by means of coupled CFD and building performance simulation. Energy Procedia 2017, 122, 355–360. [Google Scholar] [CrossRef]

- Guo, W.; Liu, X.; Yuan, X. A Case Study on Optimization of Building Design Based on CFD Simulation Technology of Wind Environment. Procedia Eng. 2015, 121, 225–231. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Liu, X.; Yuan, X. Study on Natural Ventilation Design Optimization Based on CFD Simulation for Green Buildings. Procedia Eng. 2015, 121, 573–581. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2020, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Kwok, H.H.; Cheng, J.C.; Li, A.T.; Tong, J.C.; Lau, A.K. Multi-zone indoor CFD under limited information: An approach coupling solar analysis and BIM for improved accuracy. J. Clean. Prod. 2020, 244, 118912. [Google Scholar] [CrossRef]

- Park, D.Y.; Chang, S. Effects of combined central air conditioning diffusers and window-integrated ventilation system on indoor air quality and thermal comfort in an office. Sustain. Cities Soc. 2020, 61, 102292. [Google Scholar] [CrossRef]

- Liu, T.; Lee, W. Evaluating the influence of transom window designs on natural ventilation in high-rise residential buildings in Hong Kong. Sustain. Cities Soc. 2020, 62, 102406. [Google Scholar] [CrossRef]

- Dong, B.; O’Neill, Z.; Li, Z. A BIM-enabled information infrastructure for building energy Fault Detection and Diagnostics. Autom. Constr. 2014, 44, 197–211. [Google Scholar] [CrossRef]

- Kim, K.; Kim, G.; Yoo, D.; Yu, J. Semantic material name matching system for building energy analysis. Autom. Constr. 2013, 30, 242–255. [Google Scholar] [CrossRef]

- Mytafides, C.K.; Dimoudi, A.; Zoras, S. Transformation of a university building into a zero energy building in Mediterranean climate. Energy Build. 2017, 155, 98–114. [Google Scholar] [CrossRef]

- Sun, S.; Kensek, K.; Noble, D.; Schiler, M. A method of probabilistic risk assessment for energy performance and cost using building energy simulation. Energy Build. 2016, 110, 1–12. [Google Scholar] [CrossRef]

- Singh, P.; Sadhu, A. Multicomponent energy assessment of buildings using building information modeling. Sustain. Cities Soc. 2019, 49, 101603. [Google Scholar] [CrossRef]

- Perng, J.-W.; Kuo, Y.-C.; Chang, Y.-T.; Chang, H.-H. Power Substation Construction and Ventilation System Co-Designed Using Particle Swarm Optimization. Energies 2020, 13, 2314. [Google Scholar] [CrossRef]

- Van Druenen, T.; van Hooff, T.; Montazeri, H.; Blocken, B. CFD evaluation of building geometry modifications to reduce pedestrian-level wind speed. Build. Environ. 2019, 163, 106293. [Google Scholar] [CrossRef]

- Weerasuriya, A.; Zhang, X.; Gan, V.J.; Tan, Y. A holistic framework to utilize natural ventilation to optimize energy performance of residential high-rise buildings. Build. Environ. 2019, 153, 218–232. [Google Scholar] [CrossRef]

- Fukuda, T.; Yokoi, K.; Yabuki, N.; Motamedi, A. An indoor thermal environment design system for renovation using augmented reality. J. Comput. Des. Eng. 2019, 6, 179–188. [Google Scholar] [CrossRef]

- Alizadeh, M.; Sadrameli, S. Numerical modeling and optimization of thermal comfort in building: Central composite design and CFD simulation. Energy Build. 2018, 164, 187–202. [Google Scholar] [CrossRef]

- Natephra, W.; Yabuki, N.; Fukuda, T. Optimizing the evaluation of building envelope design for thermal performance using a BIM-based overall thermal transfer value calculation. Build. Environ. 2018, 136, 128–145. [Google Scholar] [CrossRef]

- Al-Saggaf, A.; Nasir, H.; Taha, M. Quantitative approach for evaluating the building design features impact on cooling energy consumption in hot climates. Energy Build. 2020, 211, 109802. [Google Scholar] [CrossRef]

- Liu, S.; Meng, X.; Tam, C.M. Building information modeling based building design optimization for sustainability. Energy Build. 2015, 105, 139–153. [Google Scholar] [CrossRef]

- Edwards, R.E.; Lou, E.C.; Bataw, A.; Kamaruzzaman, S.N.; Johnson, C. Sustainability-led design: Feasibility of incorporating whole-life cycle energy assessment into BIM for refurbishment projects. J. Build. Eng. 2019, 24, 100697. [Google Scholar] [CrossRef]

- Schlueter, A.; Geyer, P. Linking BIM and Design of Experiments to balance architectural and technical design factors for energy performance. Autom. Constr. 2018, 86, 33–43. [Google Scholar] [CrossRef]

- Park, C.W.; Park, J.; Kim, N.; Kim, Y. Modeling water flow on Façade. Autom. Constr. 2018, 93, 265–279. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Palumbo, M.; Haddad, A. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J. Build. Eng. 2017, 14, 115–126. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Kim, J.B.; Jeong, W.; Clayton, M.J.; Haberl, J.S.; Yan, W. Developing a physical BIM library for building thermal energy simulation. Autom. Constr. 2015, 50, 16–28. [Google Scholar] [CrossRef]

- Ham, Y.; Golparvar-Fard, M. Mapping actual thermal properties to building elements in gbXML-based BIM for reliable building energy performance modeling. Autom. Constr. 2015, 49, 214–224. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, X.; Zhang, C.; Wang, H.; Zhang, Y. 3D real-time volumetric particle tracking velocimetry—A promising tool for studies of airflow around high-rise buildings. Build. Environ. 2020, 178, 106930. [Google Scholar] [CrossRef]

- Du, Y.; Blocken, B.; Pirker, S. A novel approach to simulate pollutant dispersion in the built environment: Transport-based recurrence CFD. Build. Environ. 2020, 170, 106604. [Google Scholar] [CrossRef]

- Ding, C.; Lam, K.P. Data-driven model for cross ventilation potential in high-density cities based on coupled CFD simulation and machine learning. Build. Environ. 2019, 165, 106394. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, M.H.; Lefrançois, M.; Pauwels, P.; Hviid, C.A.; Karlshøj, J. Managing interrelated project information in AEC Knowledge Graphs. Autom. Constr. 2019, 108, 102956. [Google Scholar] [CrossRef]

- Porter, S.; Tan, T.; Wang, X.; Pareek, V. LODOS—Going from BIM to CFD via CAD and model abstraction. Autom. Constr. 2018, 94, 85–92. [Google Scholar] [CrossRef]

- Abdelalim, A.; O’Brien, W.; Shi, Z. Data visualization and analysis of energy flow on a multi-zone building scale. Autom. Constr. 2017, 84, 258–273. [Google Scholar] [CrossRef]

- Kim, H.; Shen, Z.; Kim, I.; Kim, K.; Stumpf, A.; Yu, J. BIM IFC information mapping to building energy analysis (BEA) model with manually extended material information. Autom. Constr. 2016, 68, 183–193. [Google Scholar] [CrossRef]

- Dabbagh, M.; Krarti, M. Evaluation of the performance for a dynamic insulation system suitable for switchable building envelope. Energy Build. 2020, 222, 110025. [Google Scholar] [CrossRef]

- Phillips, R.; Troup, L.; Fannon, D.; Eckelman, M.J. Triple bottom line sustainability assessment of window-to-wall ratio in US office buildings. Build. Environ. 2020, 182, 107057. [Google Scholar] [CrossRef]

- Utkucu, D.; Sözer, H. Interoperability and data exchange within BIM platform to evaluate building energy performance and indoor comfort. Autom. Constr. 2020, 116, 103225. [Google Scholar] [CrossRef]

- Venkatraj, V.; Dixit, M.K.; Yan, W.; Lavy, S. Evaluating the impact of operating energy reduction measures on embodied energy. Energy Build. 2020, 226, 110340. [Google Scholar] [CrossRef]

- Singh, M.M.; Geyer, P. Information requirements for multi-level-of-development BIM using sensitivity analysis for energy performance. Adv. Eng. Inform. 2020, 43, 101026. [Google Scholar] [CrossRef]

- Najjar, M.K.; Tam, V.W.Y.; Di Gregorio, L.T.; Evangelista, A.C.J.; Hammad, A.W.A.; Haddad, A. Integrating Parametric Analysis with Building Information Modeling to Improve Energy Performance of Construction Projects. Energies 2019, 12, 1515. [Google Scholar] [CrossRef] [Green Version]

- Tushar, Q.; Bhuiyan, M.; Sandanayake, M.; Zhang, G.K. Optimizing the energy consumption in a residential building at different climate zones: Towards sustainable decision making. J. Clean. Prod. 2019, 233, 634–649. [Google Scholar] [CrossRef]

- Maciel, A.C.F.; Carvalho, M.T. Operational energy of opaque ventilated façades in Brazil. J. Build. Eng. 2019, 25, 100775. [Google Scholar] [CrossRef]

- Mao, N.; Hao, J.; Cui, B.; Li, Y.; Song, M.; Xu, Y.; Deng, S. Energy performance of a bedroom task/ambient air conditioning (TAC) system applied in different climate zones of China. Energy 2018, 159, 724–736. [Google Scholar] [CrossRef]

- Abanda, F.; Byers, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Shan, X.; Luo, N.; Sun, K.; Hong, T.; Lee, Y.-K.; Lu, W.-Z. Coupling CFD and building energy modelling to optimize the operation of a large open office space for occupant comfort. Sustain. Cities Soc. 2020, 60, 102257. [Google Scholar] [CrossRef]

- Jalaei, F.; Guest, G.; Gaur, A.; Zhang, J. Exploring the effects that a non-stationary climate and dynamic electricity grid mix has on whole building life cycle assessment: A multi-city comparison. Sustain. Cities Soc. 2020, 61, 102294. [Google Scholar] [CrossRef]

- Yoo, W.; Kim, H.; Shin, M. Stations-oriented indoor localization (SOIL): A BIM-Based occupancy schedule modeling system. Build. Environ. 2020, 168, 106520. [Google Scholar] [CrossRef]

- Hiyama, K.; Kato, S.; Kubota, M.; Zhang, J. A new method for reusing building information models of past projects to optimize the default configuration for performance simulations. Energy Build. 2014, 73, 83–91. [Google Scholar] [CrossRef]

- Wehkamp, S.; Schmeling, L.; Vorspel, L.; Roelcke, F.; Windmeier, K.-L. District Energy Systems: Challenges and New Tools for Planning and Evaluation. Energies 2020, 13, 2967. [Google Scholar] [CrossRef]

- Pučko, Z.; Maučec, D.; Šuman, N. Energy and Cost Analysis of Building Envelope Components Using BIM: A Systematic Approach. Energies 2020, 13, 2643. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Hammad, A.W.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Sadeghifam, A.N.; Meynagh, M.M.; Tabatabaee, S.; Mahdiyar, A.; Memari, A.; Ismail, S. Assessment of the building components in the energy efficient design of tropical residential buildings: An application of BIM and statistical Taguchi method. Energy 2019, 188, 116080. [Google Scholar] [CrossRef]

- Zhong, H.-Y.; Jing, Y.; Liu, Y.; Zhao, F.-Y.; Liu, D.; Li, Y. CFD simulation of “pumping” flow mechanism of an urban building affected by an upstream building in high Reynolds flows. Energy Build. 2019, 202, 109330. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A.M. Automated Building Energy Modeling and Assessment Tool (ABEMAT). Energy 2018, 147, 15–24. [Google Scholar] [CrossRef]

- GhaffarianHoseini, A.; Zhang, T.; Nwadigo, O.; GhaffarianHoseini, A.; Naismith, N.; Tookey, J.; Raahemifar, K. Application of nD BIM Integrated Knowledge-based Building Management System (BIM-IKBMS) for inspecting post-construction energy efficiency. Renew. Sustain. Energy Rev. 2017, 72, 935–949. [Google Scholar] [CrossRef] [Green Version]

- Cho, Y.K.; Ham, Y.; Golpavar-Fard, M. 3D as-is building energy modeling and diagnostics: A review of the state-of-the-art. Adv. Eng. Inform. 2015, 29, 184–195. [Google Scholar] [CrossRef]

- Gökçe, H.U.; Gökçe, K.U. Multi dimensional energy monitoring, analysis and optimization system for energy efficient building operations. Sustain. Cities Soc. 2014, 10, 161–173. [Google Scholar] [CrossRef]

- Gökçe, H.U.; Gökçe, K.U. Integrated System Platform for Energy Efficient Building Operations. J. Comput. Civ. Eng. 2014, 28, 05014005. [Google Scholar] [CrossRef]

- Lagüela, S.; Vilariño, L.D.; Martínez-Sánchez, J.; Armesto, J. Automatic thermographic and RGB texture of as-built BIM for energy rehabilitation purposes. Autom. Constr. 2013, 31, 230–240. [Google Scholar] [CrossRef]

- Welle, B.; Rogers, Z.; Fischer, M. BIM-Centric Daylight Profiler for Simulation (BDP4SIM): A methodology for automated product model decomposition and recomposition for climate-based daylighting simulation. Build. Environ. 2012, 58, 114–134. [Google Scholar] [CrossRef]

- Yang, Z.; Ghahramani, A.; Becerik-Gerber, B. Building occupancy diversity and HVAC (heating, ventilation, and air conditioning) system energy efficiency. Energy 2016, 109, 641–649. [Google Scholar] [CrossRef] [Green Version]

- Chong, A.; Xu, W.; Chao, S.; Ngo, N.-T. Continuous-time Bayesian calibration of energy models using BIM and energy data. Energy Build. 2019, 194, 177–190. [Google Scholar] [CrossRef]

- Prajongsan, P.; Sharples, S. Enhancing natural ventilation, thermal comfort and energy savings in high-rise residential buildings in Bangkok through the use of ventilation shafts. Build. Environ. 2012, 50, 104–113. [Google Scholar] [CrossRef]

- Elshafei, G.; Negm, A.; Bady, M.; Suzuki, M.; Ibrahim, M.G. Numerical and experimental investigations of the impacts of window parameters on indoor natural ventilation in a residential building. Energy Build. 2017, 141, 321–332. [Google Scholar] [CrossRef]

- Aflaki, A.; Hirbodi, K.; Mahyuddin, N.; Yaghoubi, M.; Esfandiari, M. Improving the air change rate in high-rise buildings through a transom ventilation panel: A case study. Build. Environ. 2019, 147, 35–49. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Cheung, H. Sensitivity analysis of design parameters and optimal design for zero/low energy buildings in subtropical regions. Appl. Energy 2018, 228, 1280–1291. [Google Scholar] [CrossRef]

- Adamu, Z.A.; Price, A.D.; Cook, M.J. Performance evaluation of natural ventilation strategies for hospital wards—A case study of Great Ormond Street Hospital. Build. Environ. 2012, 56, 211–222. [Google Scholar] [CrossRef] [Green Version]

- Jalaei, F.; Jalaei, F.; Mohammadi, S. An integrated BIM-LEED application to automate sustainable design assessment framework at the conceptual stage of building projects. Sustain. Cities Soc. 2020, 53, 101979. [Google Scholar] [CrossRef]

- El-Diraby, T.; Krijnen, T.; Papagelis, M. BIM-based collaborative design and socio-technical analytics of green buildings. Autom. Constr. 2017, 82, 59–74. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Z.; Chang, R.; Li, Y. Building Information Modeling (BIM) for green buildings: A critical review and future directions. Autom. Constr. 2017, 83, 134–148. [Google Scholar] [CrossRef]

- Ilhan, B.; Yaman, H. Green building assessment tool (GBAT) for integrated BIM-based design decisions. Autom. Constr. 2016, 70, 26–37. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Lu, L. A comprehensive review on passive design approaches in green building rating tools. Renew. Sustain. Energy Rev. 2015, 50, 1425–1436. [Google Scholar] [CrossRef]

- Wu, I.-C.; Chang, S. Visual Req calculation tool for green building evaluation in Taiwan. Autom. Constr. 2013, 35, 608–617. [Google Scholar] [CrossRef]

- Solla, M.; Ismail, L.H.; Shaarani, A.S.M.; Milad, A. Measuring the feasibility of using of BIM application to facilitate GBI assessment process. J. Build. Eng. 2019, 25, 100821. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, S.; Cortés-Pérez, J.P.; Muriel, P.P.; Tormo-Molina, R.; Maya-Manzano, J.M. Environmental impact assessment of Pinaceae airborne pollen and green infrastructure using BIM. Autom. Constr. 2018, 96, 494–507. [Google Scholar] [CrossRef]

- Sattary, S.; Thorpe, D. Potential carbon emission reductions in australian construction systems through bioclimatic principles. Sustain. Cities Soc. 2016, 23, 105–113. [Google Scholar] [CrossRef]

- Rocha, A.; Pinto, D.; Ramos, N.M.; Almeida, R.M.; Barreira, E.; Simões, M.L.; Martins, J.P.; Pereira, P.F.; Sanhudo, L. A case study to improve the winter thermal comfort of an existing bus station. J. Build. Eng. 2020, 29, 101123. [Google Scholar] [CrossRef]

- Sporr, A.; Zucker, G.; Hofmann, R. Automatically Creating HVAC Control Strategies Based on Building Information Modeling (BIM): Heat Provisioning and Distribution. Energies 2020, 13, 4403. [Google Scholar] [CrossRef]

- Kahsay, M.T.; Bitsuamlak, G.T.; Tariku, F. Effect of window configurations on its convective heat transfer rate. Build. Environ. 2020, 182, 107139. [Google Scholar] [CrossRef]

- Lundqvist, P.; Risberg, M.; Westerlund, L. Air heating system design for a sub-Arctic climate using a CFD technique. Build. Environ. 2019, 160, 106164. [Google Scholar] [CrossRef]

- Bouhal, T.; Meghari, Z.; Fertahi, S.E.-D.; El Rhafiki, T.; Kousksou, T.; Jamil, A.; Ben Ghoulam, E. Parametric CFD analysis and impact of PCM intrinsic parameters on melting process inside enclosure integrating fins: Solar building applications. J. Build. Eng. 2018, 20, 634–646. [Google Scholar] [CrossRef]

- Jain, M.; Pathak, K. Thermal modelling of insulator for energy saving in existing residential building. J. Build. Eng. 2018, 19, 62–68. [Google Scholar] [CrossRef]

- Mei, S.-J.; Hu, J.-T.; Liu, D.; Zhao, F.-Y.; Wang, H.-Q. Thermal buoyancy driven flows inside the industrial buildings primarily ventilated by the mechanical fans: Local facilitation and infiltration. Energy Build. 2018, 175, 87–101. [Google Scholar] [CrossRef]

- Ceranic, B.; Beardmore, J.; Cox, A. Rapid deployment modular building solutions and climatic adaptability: Case based study of a novel approach to “thermal capacity on demand”. Energy Build. 2018, 167, 124–135. [Google Scholar] [CrossRef]

- Morón, C.; Saiz, P.; Ferrández, D.; Felices, R. Comparative Analysis of Infrared Thermography and CFD Modelling for Assessing the Thermal Performance of Buildings. Energies 2018, 11, 638. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Balas, C.; Fernández-Nieto, E.; Narbona-Reina, G.; Sendra, J.J.; Suárez, R. Thermal 3D CFD Simulation with Active Transparent Façade in Buildings. Energies 2018, 11, 2265. [Google Scholar] [CrossRef] [Green Version]

- Torregrosa-Jaime, B.; González, B.; Martínez, P.J.; Payá-Ballester, G. Analysis of the Operation of an Aerothermal Heat Pump in a Residential Building Using Building Information Modelling. Energies 2018, 11, 1642. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Wang, M.; Wang, M.; Wang, Y. Predictive accuracy of Boussinesq approximation in opposed mixed convection with a high-temperature heat source inside a building. Build. Environ. 2018, 144, 349–356. [Google Scholar] [CrossRef]

- Natephra, W.; Motamedi, A.; Yabuki, N.; Fukuda, T. Integrating 4D thermal information with BIM for building envelope thermal performance analysis and thermal comfort evaluation in naturally ventilated environments. Build. Environ. 2017, 124, 194–208. [Google Scholar] [CrossRef]

- Golovina, O.; Teizer, J.; Pradhananga, N. Heat map generation for predictive safety planning: Preventing struck-by and near miss interactions between workers-on-foot and construction equipment. Autom. Constr. 2016, 71, 99–115. [Google Scholar] [CrossRef]

- Lamnatou, C.; Mondol, J.; Chemisana, D.; Maurer, C. Modelling and simulation of Building-Integrated solar thermal systems: Behaviour of the coupled building/system configuration. Renew. Sustain. Energy Rev. 2015, 48, 178–191. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelaty, A. Monitoring thermal comfort in subways using building information modeling. Energy Build. 2014, 84, 252–257. [Google Scholar] [CrossRef]

- Ghiaus, C.; Ahmad, N. Thermal circuits assembling and state-space extraction for modelling heat transfer in buildings. Energy 2020, 195, 117019. [Google Scholar] [CrossRef]

- Tien, P.W.; Calautit, J.K. Numerical analysis of the wind and thermal comfort in courtyards “skycourts” in high rise buildings. J. Build. Eng. 2019, 24, 100735. [Google Scholar] [CrossRef]

- Tian, G.; Fan, Y.; Wang, H.; Peng, K.; Zhang, X.; Zheng, H. Studies on the thermal environment and natural ventilation in the industrial building spaces enclosed by fabric membranes: A case study. J. Build. Eng. 2020, 32, 101651. [Google Scholar] [CrossRef]

- Ghadikolaei, F.M.; Ossen, D.R.; Mohamed, M.F. Effects of wing wall at the balcony on the natural ventilation performance in medium-rise residential buildings. J. Build. Eng. 2020, 31, 101316. [Google Scholar] [CrossRef]

- Nguyen, Y.; Wells, J. A numerical study on induced flowrate and thermal efficiency of a solar chimney with horizontal absorber surface for ventilation of buildings. J. Build. Eng. 2020, 28, 101050. [Google Scholar] [CrossRef]

- Zhang, X.; Weerasuriya, A.U.; Tse, K.T. CFD simulation of natural ventilation of a generic building in various incident wind directions: Comparison of turbulence modelling, evaluation methods, and ventilation mechanisms. Energy Build. 2020, 229, 110516. [Google Scholar] [CrossRef]

- Albuquerque, D.P.; Mateus, N.; Avantaggiato, M.; da Graça, G.C. Full-scale measurement and validated simulation of cooling load reduction due to nighttime natural ventilation of a large atrium. Energy Build. 2020, 224, 110233. [Google Scholar] [CrossRef]

- Albuquerque, D.P.; Sandberg, M.; Linden, P.; da Graça, G.C. Experimental and numerical investigation of pumping ventilation on the leeward side of a cubic building. Build. Environ. 2020, 179, 106897. [Google Scholar] [CrossRef]

- Izadyar, N.; Miller, W.; Rismanchi, B.; Garcia-Hansen, V. A numerical investigation of balcony geometry impact on single-sided natural ventilation and thermal comfort. Build. Environ. 2020, 177, 106847. [Google Scholar] [CrossRef]

- Zheng, X.; Montazeri, H.; Blocken, B. CFD simulations of wind flow and mean surface pressure for buildings with balconies: Comparison of RANS and LES. Build. Environ. 2020, 173, 106747. [Google Scholar] [CrossRef]

- Dai, Y.; Mak, C.M.; Ai, Z. Flow and dispersion in coupled outdoor and indoor environments: Issue of Reynolds number independence. Build. Environ. 2019, 150, 119–134. [Google Scholar] [CrossRef]

- Liu, T.; Lee, W. Using response surface regression method to evaluate the influence of window types on ventilation performance of Hong Kong residential buildings. Build. Environ. 2019, 154, 167–181. [Google Scholar] [CrossRef]

- Shi, Z.; Lu, Z.; Chen, Q. Indoor airflow and contaminant transport in a room with coupled displacement ventilation and passive-chilled-beam systems. Build. Environ. 2019, 161, 106244. [Google Scholar] [CrossRef]

- Yuan, C.; Shan, R.; Adelia, A.S.; Tablada, A.; Lau, S.K.; Lau, S.S.-Y. Effects of vertical farming on natural ventilation of residential buildings. Energy Build. 2019, 185, 316–325. [Google Scholar] [CrossRef]

- Lamberti, G.; Gorlé, C. Uncertainty quantification for modeling night-time ventilation in Stanford’s Y2E2 building. Energy Build. 2018, 168, 319–330. [Google Scholar] [CrossRef]

- Zucker, G.; Sporr, A.; Garrido-Marijuan, A.; Ferhatbegovic, T.; Hofmann, R. A ventilation system controller based on pressure-drop and CO2 models. Energy Build. 2017, 155, 378–389. [Google Scholar] [CrossRef]

- Habibi, S. Smart innovation systems for indoor environmental quality (IEQ). J. Build. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Liu, S.; Pan, W.; Cao, Q.; Long, Z.; Jiang, Y.; Chen, Q. CFD simulations of natural cross ventilation through an apartment with modified hourly wind information from a meteorological station. Energy Build. 2019, 195, 16–25. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Heidari, S.; Zamani, P. The impact of temperature difference of the sunny and shady yards on the natural ventilation of the vernacular buildings. J. Build. Eng. 2019, 26, 100880. [Google Scholar] [CrossRef]

- Yang, X.; Ergan, S. Leveraging BIM to Provide Automated Support for Efficient Troubleshooting of HVAC-Related Problems. J. Comput. Civ. Eng. 2016, 30, 04015023. [Google Scholar] [CrossRef]

- Yang, X.; Ergan, S. Design and Evaluation of an Integrated Visualization Platform to Support Corrective Maintenance of HVAC Problem–Related Work Orders. J. Comput. Civ. Eng. 2016, 30, 04015041. [Google Scholar] [CrossRef]

- Chen, Y.; Treado, S.J.; Messner, J. Building HVAC control knowledge data schema—Towards a unified representation of control system knowledge. Autom. Constr. 2016, 72, 174–186. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Zhang, Z.; Lu, X.; Zeng, X.; Guan, H. Post-earthquake fire simulation considering overall seismic damage of sprinkler systems based on BIM and FEMA P-58. Autom. Constr. 2018, 90, 9–22. [Google Scholar] [CrossRef]

- Chen, L.-C.; Wu, C.-H.; Shen, T.-S.; Chou, C.-C. The application of geometric network models and building information models in geospatial environments for fire-fighting simulations. Comput. Environ. Urban Syst. 2014, 45, 1–12. [Google Scholar] [CrossRef]

- Abolghasemzadeh, P. A comprehensive method for environmentally sensitive and behavioral microscopic egress analysis in case of fire in buildings. Saf. Sci. 2013, 59, 1–9. [Google Scholar] [CrossRef]

- Sun, Q.; Turkan, Y. A BIM-based simulation framework for fire safety management and investigation of the critical factors affecting human evacuation performance. Adv. Eng. Inform. 2020, 44, 101093. [Google Scholar] [CrossRef]

- Chen, A.Y.; Chu, J.C. TDVRP and BIM Integrated Approach for In-Building Emergency Rescue Routing. J. Comput. Civ. Eng. 2016, 30, 522. [Google Scholar] [CrossRef]

- Xu, Y.; Bai, Y.; Paik, J.K.; Dai, W. An improved method for quantitative risk assessment of unconfined offshore installations subjected to gas explosions. Structures 2020, 25, 566–577. [Google Scholar] [CrossRef]

| BIM | CFD | |

|---|---|---|

| Concept | Shared knowledge resources for various information throughout the life cycle of a facility | Digitalized and numerical analysis of fluid-flow phenomena |

| Elements | Standard data models Life cycle information | Physical model based on Navier–Stokes equations Boundary conditions |

| Methodology | BIM is implemented and interoperated according to requirements for design planning, construction management, and operation management | A common procedure is followed: preprocessing, solver adoption, and postprocessing, involving discretization methods, pressure-velocity coupling, etc. |

| Interlink |  | |

| Journal Title | Number of Selected Papers |

|---|---|

| Building and Environment | 22 |

| Energy and Buildings | 20 |

| Automation in Construction | 20 |

| Journal of Building Engineering | 13 |

| Sustainable Cities and Society | 8 |

| Energies | 8 |

| Energy | 6 |

| Journal of Computing and Civil Engineering | 4 |

| Journal of Cleaner Production | 3 |

| Renewable and Sustainable Energy Reviews | 3 |

| Journal of Computational Design and Engineering | 2 |

| Advanced Engineering Informatic | 2 |

| Applied Energy | 2 |

| Computers, Environment and Urban Systems | 1 |

| Safety Science | 1 |

| Total | 115 |

| Sectors | Subsectors | Related Research |

| Architectural design and building- management |

| [21,22,23,24,25,26,27,28] |

| [29,30,31,32,33,34,35,36,37,38,39,40,41] | |

| [42,43,44,45,46,47,48,49,50] | |

| Energy assessment |

| [51,52,53,54,55,56,57,58,59,60,61] |

| [49,50,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78] | |

| [79,80,81,82,83,84,85,86,87,88,89,90,91,92] | |

| HVAC system design |

| [21,27,33,34,42,43,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110] |

| [22,23,29,30,31,44,45,46,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127] | |

| [128,129,130] | |

| Facility safety management |

| [106,131,132,133,134,135] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, K.-Y.; Wang, X.; Wang, J.; Xu, S.; Shou, W.; Sun, Y. Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry. Buildings 2022, 12, 651. https://doi.org/10.3390/buildings12050651

Kang K-Y, Wang X, Wang J, Xu S, Shou W, Sun Y. Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry. Buildings. 2022; 12(5):651. https://doi.org/10.3390/buildings12050651

Chicago/Turabian StyleKang, Ki-Yeob, Xiangyu Wang, Jun Wang, Shuyuan Xu, Wenchi Shou, and Yanhui Sun. 2022. "Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry" Buildings 12, no. 5: 651. https://doi.org/10.3390/buildings12050651

APA StyleKang, K.-Y., Wang, X., Wang, J., Xu, S., Shou, W., & Sun, Y. (2022). Utility of BIM-CFD Integration in the Design and Performance Analysis for Buildings and Infrastructures of Architecture, Engineering and Construction Industry. Buildings, 12(5), 651. https://doi.org/10.3390/buildings12050651