Fracture Toughness of Reactive Powder Fibrous Concrete Composites under Pure and Mixed Modes (I/III)

Abstract

:1. Introduction

2. Materials and Methods

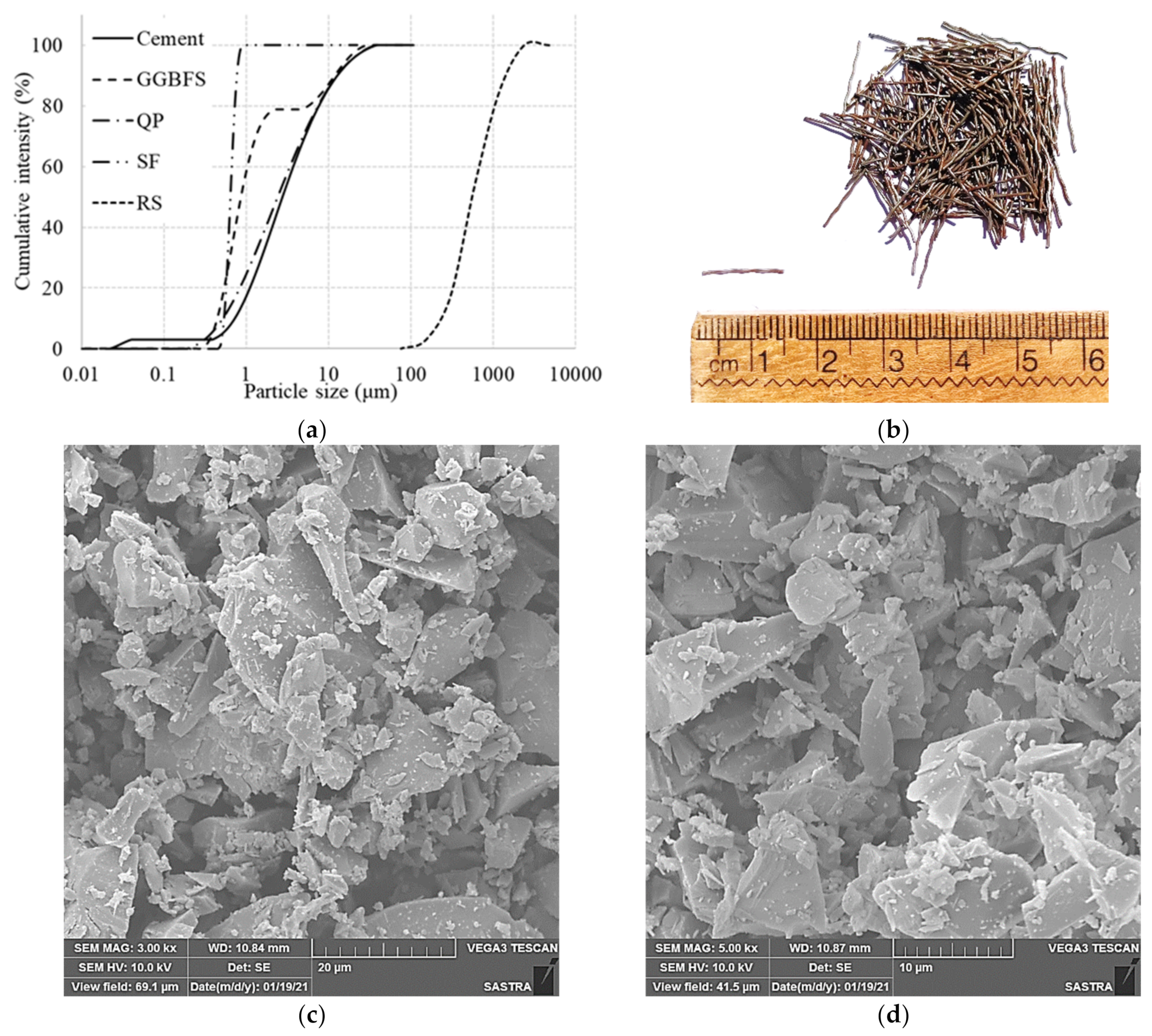

2.1. Materials Used

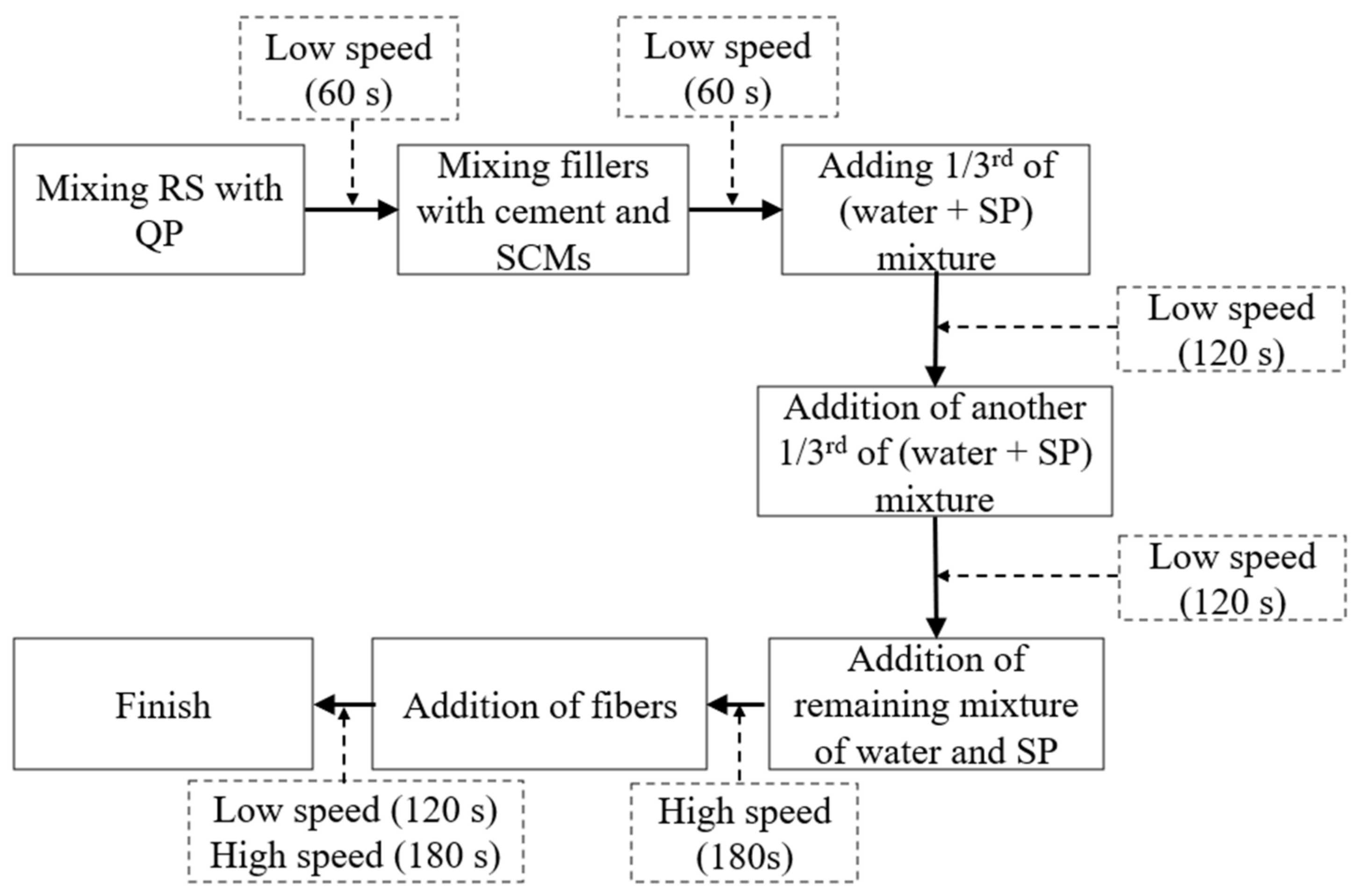

2.2. Preparation RPC Mixes

2.3. Evaluation of Workability of RPC Mixes

2.4. Preparation and Testing of Specimens

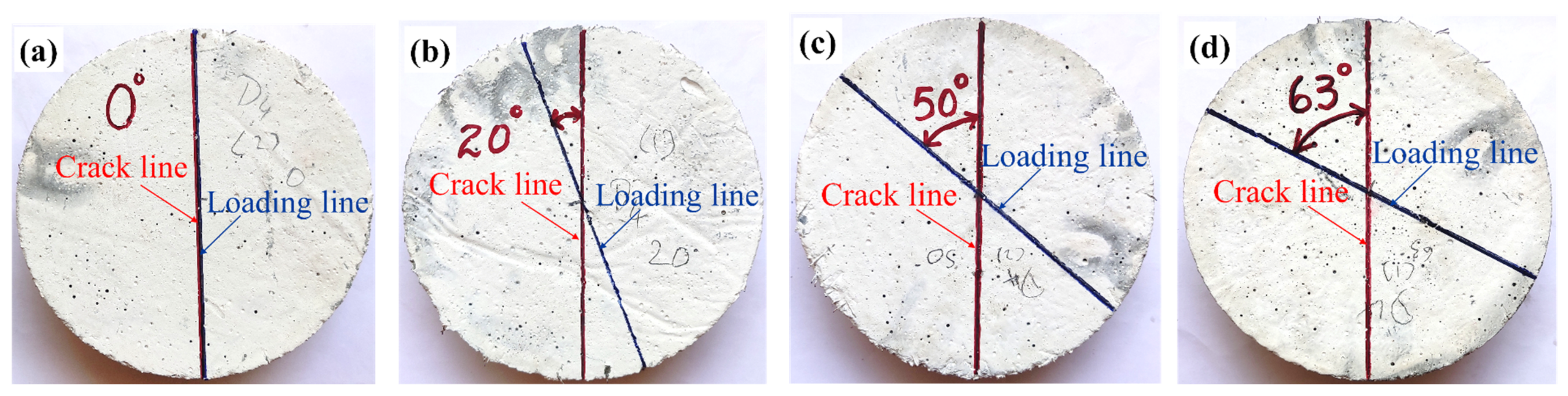

Preparation and Testing of ENDB Specimens

3. Results and Discussions

3.1. Workability of RPC Mixes

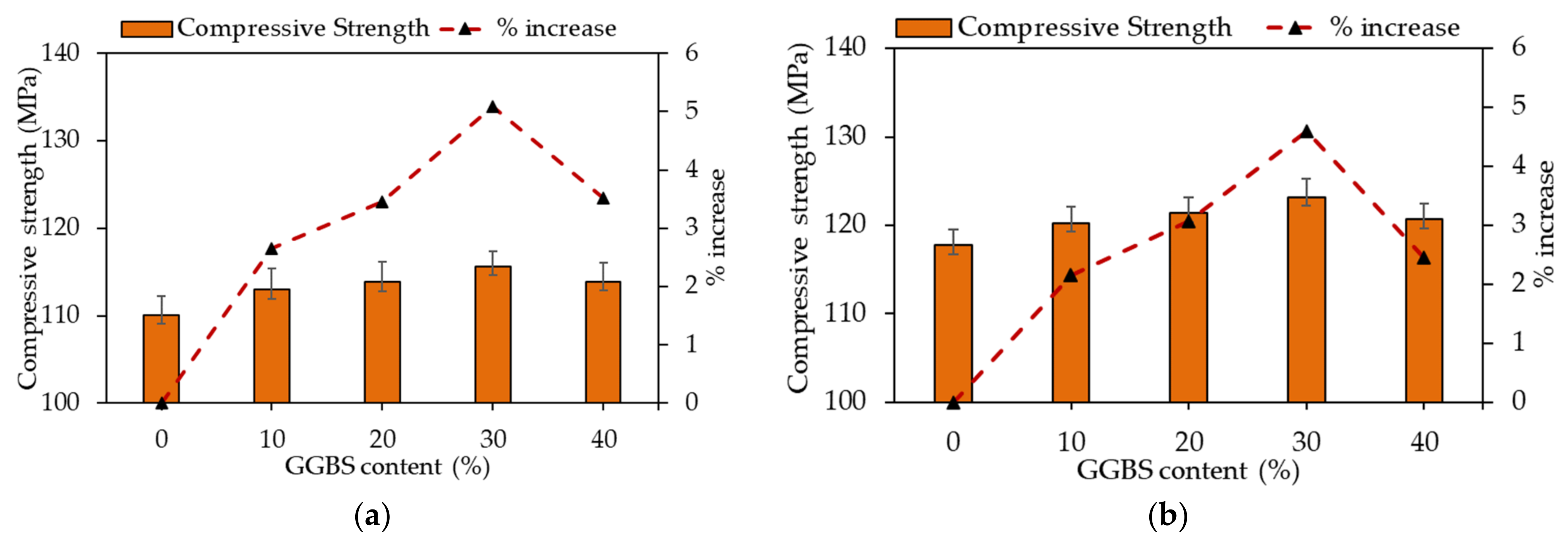

3.2. Compressive Strength

3.3. Splitting Tensile Strength

3.4. Fracture Toughness

3.4.1. Effect of Addition of GGBS on Pure Mode I Fracture Toughness

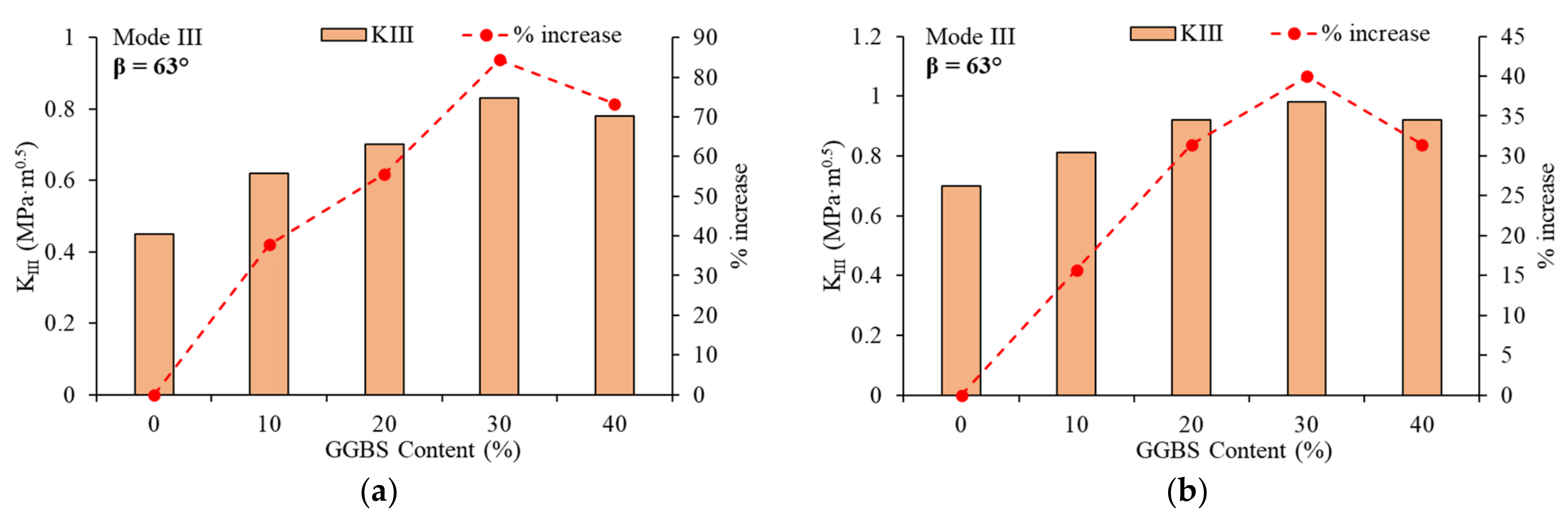

3.4.2. Effect of Addition of GGBS on Pure Mode III Fracture Toughness

3.4.3. Effect of Addition of GGBS on Mixed-Mode I/III Fracture Toughness

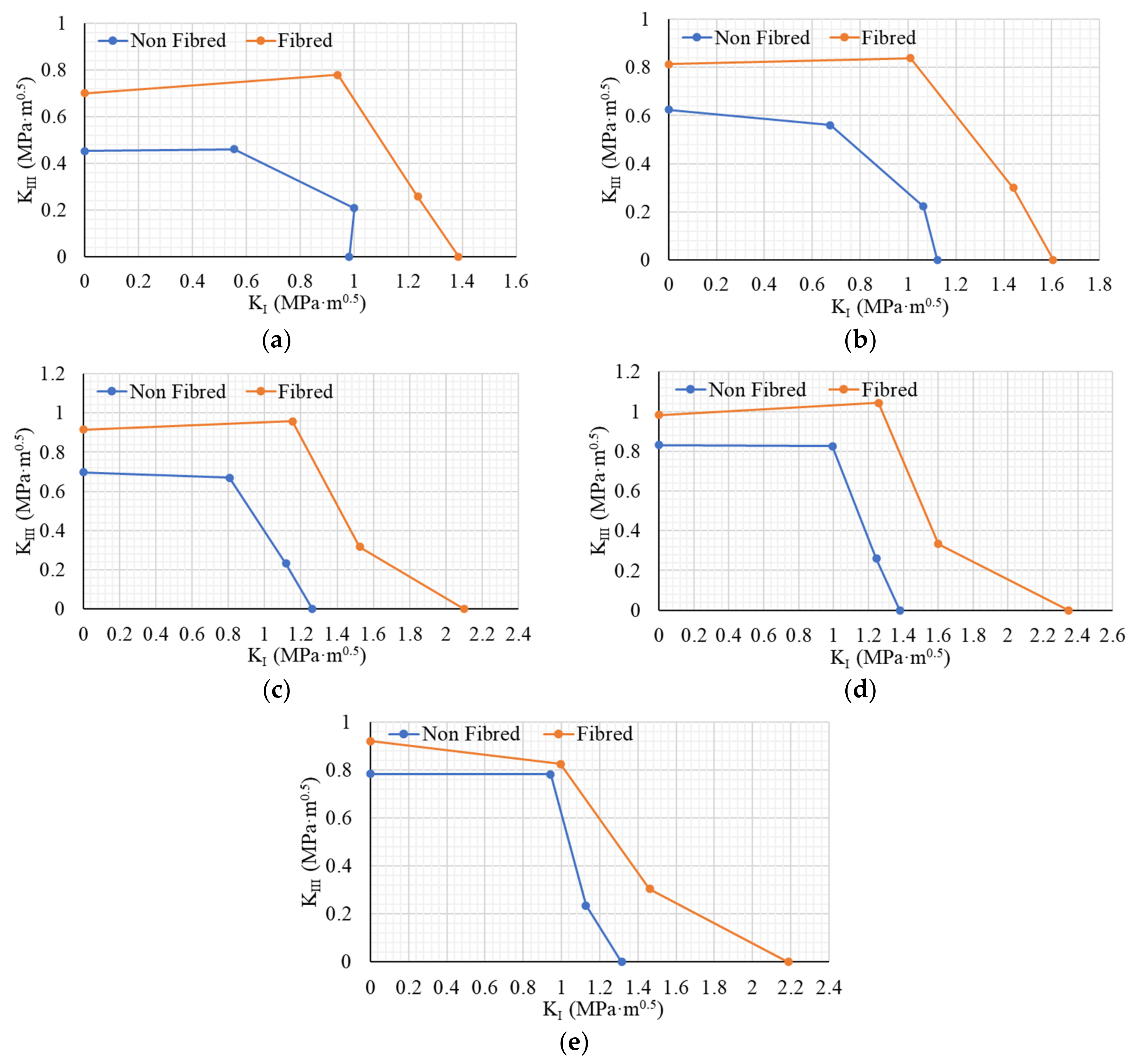

3.4.4. Effect of Addition of Fibres on Fracture Toughness

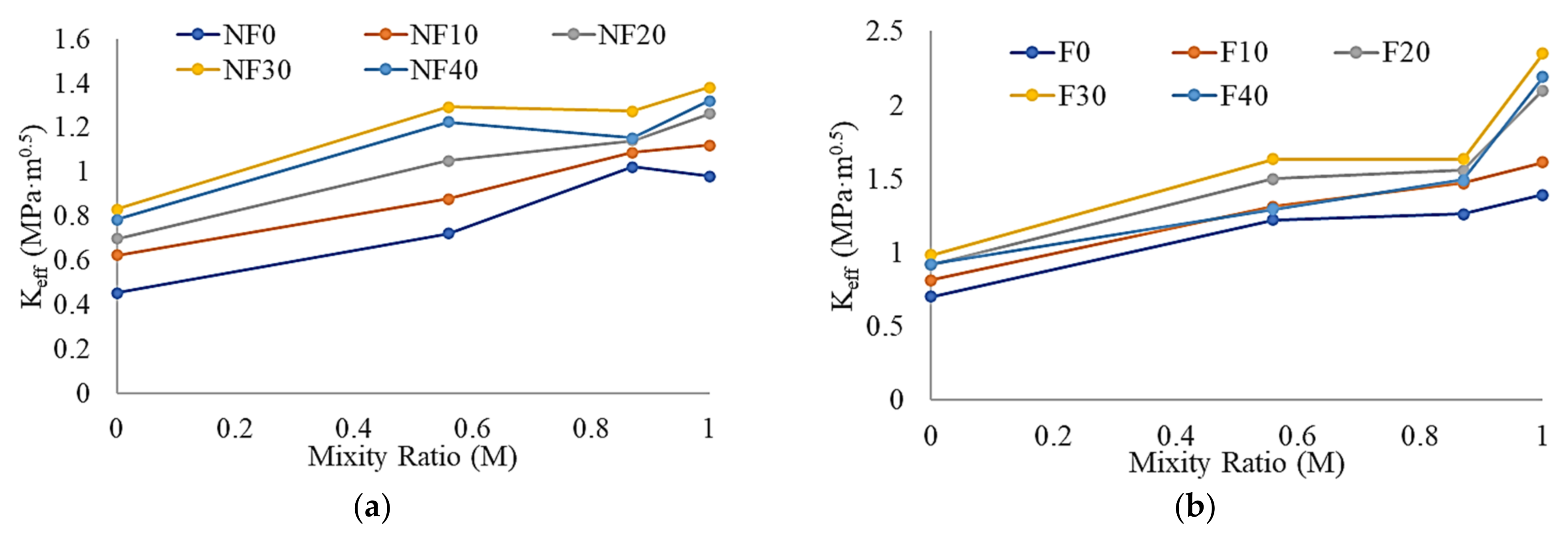

3.4.5. Effect of Mode of Loading on Fracture Toughness of RPC Mixes

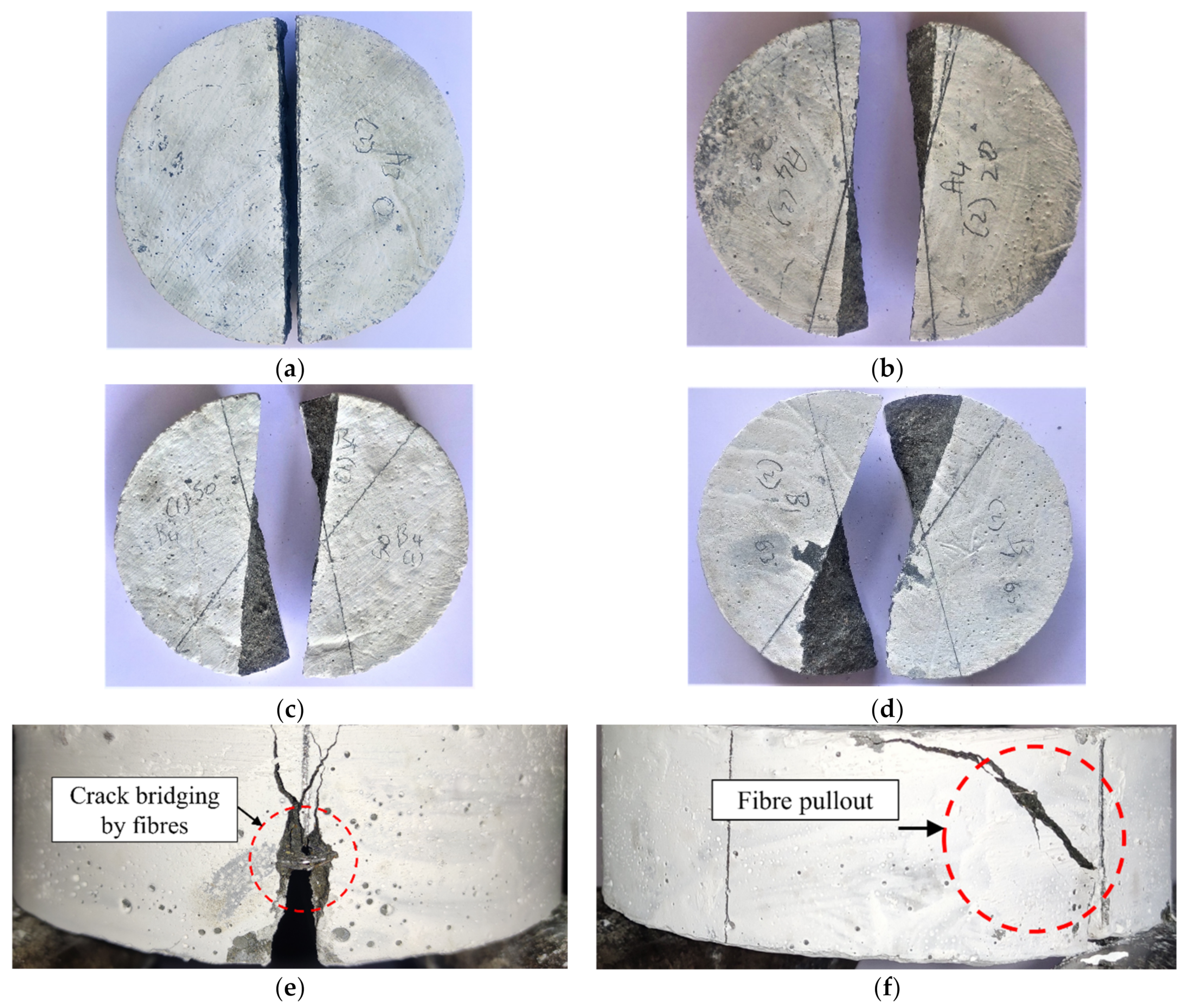

3.5. Failure Patterns

3.6. Morphology Assessment by SEM

4. Conclusions

- The compressive strength of RPC mixes was significantly improved due to the partial replacement of OPC with GGBS. The non-fibrous and fibrous mixes with 30% OPC replaced with GGBS showed the highest compressive strength values. This phenomenon is attributed to the pore filling ability of GGBS particles and the densification matrices due to the production of supplementary C–S–H gel and pozzolanic action of GGBS. Further fibres bridged across the cracks and helped improve the mix’s integrity, thereby contributing to the improvement in compressive strength.

- The splitting tensile strength of RPC mixes was also highly influenced by the addition of GGBS. Non-fibrous mixes exhibited considerably low values of splitting tensile strength. This can be due to the high brittleness of the mixes associated with the densification of matrices and pozzolanic action of GGBS. The fibrous mix with 30% OPC replaced with GGBS exhibited the highest values of splitting tensile strength. In addition to the densification of matrices due to the action of GGBS, the ability of steel fibres in bridging over the cracks, and thereby delaying the failure process, helped in attaining a higher value of splitting tensile strength.

- Partial replacement of OPC with GGBS significantly improved pure mode I, pure mode III, and mixed-mode I/III fracture toughness of RPC mixes. Sudden brittle failure was observed in the case of non-fibrous specimens. However, ductile failure was observed in the case of fibrous specimens. The fibrous mix with 30% OPC replaced with GGBS exhibited the highest mode I, mode III, and mixed-mode I/III fracture toughness values. This can also be attributed to the pozzolanic action of GGBS and the ability of steel fibres in crack bridging.

- The addition of short macro steel fibres helped improve the mode I fracture toughness significantly. However, it did not contribute much in the case of mode III loadings. This behaviour is due to the inability of fibres to bridge across the wider crack paths in the case of tearing.

- Significant microstructure refinement was observed in the SEM micrographs of GGBS modified RPC mixes. This ascertains the better filling of micropores and thereby the densification of matrices. Improved density will result in better strength characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alaloul, W.S.; Musarat, M.A.; Rabbani, M.B.A.; Iqbal, Q.; Maqsoom, A.; Farooq, W. Construction Sector Contribution to Economic Stability: Malaysian GDP Distribution. Sustainability 2021, 13, 5012. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive Powder Concrete with High Ductility and 200–800 MPa Compressive Strength. Mater. Sci. 1994, 144, 507–518. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Cooper, D. Energy Efficiency for Buildings; UNEP: Paris, France, 2015. [Google Scholar]

- Asrani, N.P.; Murali, G.; Parthiban, K.; Surya, K.; Prakash, A.; Rathika, K.; Chandru, U. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: Experiments and modelling. Constr. Build. Mater. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Vasilca, I.-S.; Nen, M.; Chivu, O.; Radu, V.; Simion, C.-P.; Marinescu, N. The Management of Environmental Resources in the Construction Sector: An Empirical Model. Energies 2021, 14, 2489. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Yazici, H.; Yardımcı, M.Y.; Yiğiter, H.; Aydın, S.; Türkel, S. Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cem. Concr. Compos. 2010, 32, 639–648. [Google Scholar] [CrossRef]

- Cheyrezy, M.; Maret, V.; Frouin, L. Microstructural analysis of RPC (Reactive Powder Concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Yazıcı, H.; Yiğiter, H.; Karabulut, A.; Baradan, B. Utilization of fly ash and ground granulated blast furnace slag as an alternative silica source in reactive powder concrete. Fuel 2008, 87, 2401–2407. [Google Scholar] [CrossRef]

- Megat Johari, M.A.; Brooks, J.J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Pal, S.C.; Mukherjee, A.; Pathak, S.R. Investigation of hydraulic activity of ground granulated blast furnace slag in concrete. Cem. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- Yeau, K.Y.; Kim, E.K. An experimental study on corrosion resistance of concrete with ground granulate blast-furnace slag. Cem. Concr. Res. 2005, 35, 1391–1399. [Google Scholar] [CrossRef]

- Teng, S.; Lim, T.Y.D.; Divsholi, B.S. Durability and mechanical properties of high strength concrete incorporating ultra fine Ground Granulated Blast-furnace Slag. Constr. Build. Mater. 2013, 40, 875–881. [Google Scholar] [CrossRef]

- Kim, H.; Koh, T.; Pyo, S. Enhancing flowability and sustainability of ultra high performance concrete incorporating high replacement levels of industrial slags. Constr. Build. Mater. 2016, 123, 153–160. [Google Scholar] [CrossRef]

- Golewski, G.; Sadowski, T. Fracture Toughness at Shear (Mode II) of Concretes Made of Natural and Broken Aggregates. In Brittle Matrix Composites 8; Brandt, A.M., Li, V.C., Marshall, I.H., Eds.; Woodhead Publishing: Cambridge, UK, 2006; pp. 537–546. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, G. Effect of aggregate kind and graining on modelling of plain concrete under compression. Comput. Mater. Sci. 2008, 43, 119–126. [Google Scholar] [CrossRef]

- Chen, X.; Yan, J.J.; Yang, H.Q. Influence of Aggregates on Cracking Sensitivity of Concrete. Appl. Mech. Mater. 2012, 204–208, 3299–3302. [Google Scholar] [CrossRef]

- Meyer, C.; Peng, X. A comprehensive description for damage of concrete subjected to complex loading. Struct. Eng. Mech. 1997, 5, 679–689. [Google Scholar] [CrossRef]

- Wang, L.; Li, G.; Li, X.; Guo, F.; Tang, S.; Lu, X.; Hanif, A. Influence of reactivity and dosage of MgO expansive agent on shrinkage and crack resistance of face slab concrete. Cem. Concr. Compos. 2022, 126, 104333. [Google Scholar] [CrossRef]

- An, Q.; Chen, X.; Wang, H.; Yang, H.; Yang, Y.; Huang, W.; Wang, L. Segmentation of Concrete Cracks by Using Fractal Dimension and UHK-Net. Fractal Fract. 2022, 6, 95. [Google Scholar] [CrossRef]

- Santosh, M.; Ghosh, M.A. Multi-scale identification of concrete material parameters. Theor. Appl. Fract. Mech. 2014, 75, 8–15. [Google Scholar] [CrossRef]

- Di Prisco, M.; Ferrara, L.; Meftah, F.; Pamin, J.; De Borst, R.; Mazars, J.; Reynouard, J.M. Mixed mode fracture in plain and reinforced concrete: Some results on benchmark tests. Int. J. Fract. 2000, 103, 127–148. [Google Scholar] [CrossRef]

- Abid, S.R.; Murali, G.; Amran, M.; Vatin, N.; Fediuk, R.; Karelina, M. Evaluation of mode II fracture toughness of hybrid fibrous geopolymer composites. Materials 2021, 14, 349. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Ayatollahi, M.R. Brittle fracture evaluation of a fine grain cement mortar in combined tensile-shear deformation. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 987–994. [Google Scholar] [CrossRef]

- Mirsayar, M.M.; Razmi, A.; Berto, F. Tangential strain-based criteria for mixed-mode I/II fracture toughness of cement concrete. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 129–137. [Google Scholar] [CrossRef]

- Razmi, A.; Mirsayar, M.M. On the mixed mode I/II fracture properties of jute fiber-reinforced concrete. Constr. Build. Mater. 2017, 148, 512–520. [Google Scholar] [CrossRef]

- Lo, K.W.; Zhong, K.; Tamilselvan, T.; Ong, K.C.G.; Wee, T.H. Mixed mode I-III fracture testing of cement mortar. ACI Mater. J. 2002, 99, 435–440. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. The fracture toughness the K IIIc of concretes with F fly ash (FA) additive. Constr. Build. Mater. 2017, 143, 444–454. [Google Scholar] [CrossRef]

- Song, L.; Huang, S.M.; Yang, S.C. Experimental investigation on criterion of three-dimensional mixed-mode fracture for concrete. Cem. Conc. Res. 2004, 34, 913–916. [Google Scholar] [CrossRef]

- Xu, S.; Guo, K.; Li, Q.; Yin, X.; Huang, B. Shear fracture performance of the interface between ultra-high toughness cementitious composites and reactive powder concrete. Compos. Struct. 2021, 275, 114403. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. Determination of mode III fracture toughness for different materials using a new designed test configuration. Mater. Des. 2015, 86, 863–871. [Google Scholar] [CrossRef]

- IS 12269; Ordinary Portland Cement, 53 Grade Specification. Bureau of Indian Standards: New Delhi, India, 2013.

- IS 383; Coarse and Fine Aggregate for Concrete—Specification. Bureau of Indian Standards: New Delhi, India, 2016.

- ASTM C1437-01; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM: Philadelphia, PA, USA, 2015.

- ASTM C230; Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM: Philadelphia, PA, USA, 2014.

- IS 516; Method of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: Philadelphia, PA, USA, 2001.

- Zappalorto, M.; Lazzarin, P. Three-dimensional elastic stress fields ahead of notches in thick plates under various loading conditions. Eng. Fract. Mech. 2013, 108, 75–88. [Google Scholar] [CrossRef]

- Kotousov, A.; Lazzarin, P.; Berto, F.; Pook, L.P. Three-dimensional stress states at crack tip induced by shear and anti-plane loading. Eng. Fract. Mech. 2013, 108, 65–74. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zappalorto, M.; Berto, F. Three-dimensional stress fields due to notches in plates under linear elastic and elastic-plastic conditions. Fatigue Fract. Eng. Mater. Struct. 2014, 38, 140–153. [Google Scholar] [CrossRef]

- Pook, L.P.; Berto, F.; Campagnolo, A.; Lazzarin, P. Coupled fracture mode of a cracked disc under anti-plane loading. Eng. Fract. Mech. 2014, 128, 22–36. [Google Scholar] [CrossRef] [Green Version]

- Pook, L.P.; Campagnolo, A.; Berto, F.; Lazzarin, P. Coupled fracture mode of a cracked plate under anti-plane loading. Eng. Fract. Mech. 2015, 134, 391–403. [Google Scholar] [CrossRef]

- He, Z.; Kotousov, A.; Berto, F. Effect of vertex singularities on stress intensities near plate free surfaces. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 860–869. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zappalorto, M. A three-dimensional stress field solution for pointed and sharply radiused V-notches in plates of finite thickness. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 1105–1119. [Google Scholar] [CrossRef]

- Mansourian, A.; Hashemi, S.; Aliha, M.R.M. Evaluation of pure and mixed modes (I/III) fracture toughness of Portland cement concrete mixtures containing reclaimed asphalt pavement. Constr. Build. Mater. 2018, 178, 10–18. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Denneman, E.; Kearsley, E.P.; Visser, A.T. Splitting tensile test for fibre reinforced concrete. Mater. Struct. 2011, 44, 1441–1449. [Google Scholar] [CrossRef]

- Taerwe, L. Brittleness versus Ductility of High Strength Concrete. Struct. Eng. Int. 1991, 1, 40–45. [Google Scholar] [CrossRef]

- Honarvar Gheitanbaf, E. Fracture Toughness of Ultra High Performance Concrete. Master’s Thesis, University of New Mexico, Albuquerque, New Mexico, 2011. [Google Scholar]

- Aliha, M.R.M.; Razmi, A.; Mousavi, A. Fracture study of concrete composites with synthetic fibers additive under modes I and III using ENDB specimen. Constr. Build. Mater. 2018, 190, 612–622. [Google Scholar] [CrossRef]

- Yang, H.M.; Zhang, S.M.; Wang, L.; Chen, P.; Shao, D.K.; Tang, S.W.; Li, J.Z. High-ferrite Portland cement with slag: Hydration, microstructure, and resistance to sulfate attack at elevated temperature. Cem. Concr. Compos. 2022, 130, 104560. [Google Scholar] [CrossRef]

| Oxide | OPC (%) | GGBS (%) | SF (%) | QP (%) |

|---|---|---|---|---|

| Calcium oxide (CaO) | 63.23 | 43.10 | 0.29 | 0.01 |

| Silicon dioxide (SiO2) | 24.63 | 32.40 | 98.70 | 99.50 |

| Aluminium oxide (Al2O3) | 6.76 | 15.70 | 0.29 | 0.08 |

| Magnesium oxide (MgO) | 2.19 | 6.62 | 0.11 | 0.01 |

| Sulfur trioxide (SO3) | 1.54 | 1.61 | 0.03 | - |

| Iron oxide (Fe2O3) | 0.53 | 0.48 | 0.03 | 0.04 |

| Sodium oxide (Na2O) | 0.44 | 0.23 | - | - |

| Potassium oxide (K2O) | 0.68 | 0.54 | 88 PPM 1 | - |

| Mix ID | OPC (kg/m3) | SF (kg/m3) | GGBS (kg/m3) | RS (kg/m3) | QP (kg/m3) | Water (L/m3) | SP (L/m3) | Fibres (vol. %) |

|---|---|---|---|---|---|---|---|---|

| NF0 1 | 960 | 144 | - | 1017 | 115 | 163 | 34 | - |

| NF10 | 864 | 144 | 96 | 1017 | 115 | 163 | 34 | - |

| NF20 | 768 | 144 | 192 | 1017 | 115 | 163 | 34 | - |

| NF30 | 672 | 144 | 288 | 1017 | 115 | 163 | 34 | - |

| NF40 | 576 | 144 | 384 | 1017 | 115 | 163 | 34 | - |

| F0 | 960 | 144 | - | 1017 | 115 | 163 | 34 | 2 |

| F10 | 864 | 144 | 96 | 1017 | 115 | 163 | 34 | 2 |

| F20 | 768 | 144 | 192 | 1017 | 115 | 163 | 34 | 2 |

| F30 | 672 | 144 | 288 | 1017 | 115 | 163 | 34 | 2 |

| F40 | 576 | 144 | 384 | 1017 | 115 | 163 | 34 | 2 |

| Mode | I | I/III | I/III | III |

|---|---|---|---|---|

| β | 0° | 20° | 50° | 63° |

| YI | 0.323 | 0.269 | 0.1 | 0 |

| YIII | 0 | 0.056 | 0.083 | 0.073 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sreenath, S.; Mohan, K.S.R.; Murali, G. Fracture Toughness of Reactive Powder Fibrous Concrete Composites under Pure and Mixed Modes (I/III). Buildings 2022, 12, 599. https://doi.org/10.3390/buildings12050599

Sreenath S, Mohan KSR, Murali G. Fracture Toughness of Reactive Powder Fibrous Concrete Composites under Pure and Mixed Modes (I/III). Buildings. 2022; 12(5):599. https://doi.org/10.3390/buildings12050599

Chicago/Turabian StyleSreenath, Sreekumaran, Kaliyaperumal Saravana Raja Mohan, and Gunasekaran Murali. 2022. "Fracture Toughness of Reactive Powder Fibrous Concrete Composites under Pure and Mixed Modes (I/III)" Buildings 12, no. 5: 599. https://doi.org/10.3390/buildings12050599

APA StyleSreenath, S., Mohan, K. S. R., & Murali, G. (2022). Fracture Toughness of Reactive Powder Fibrous Concrete Composites under Pure and Mixed Modes (I/III). Buildings, 12(5), 599. https://doi.org/10.3390/buildings12050599