1. Introduction

Global construction is a

$12 trillion (USD) industry, accounting for close to 13.5% of global GDP [

1]. However, in terms of sector productivity, construction lags manufacturing and the total world economy. “Globally, construction sector labor productivity growth averaged 1 percent a year over the past two decades, compared with 2.8 percent for the total world economy and 3.6 percent for manufacturing” [

2]. There are strong indications from professionals and researchers in the construction industry that advanced digital technology (DT) can play a pivotal role, either directly or as a catalyst, in improving construction productivity. However, it is also a fact that construction is traditionally slow in adopting technology. Despite being sluggish as compared to the service and the manufacturing industries, construction has been incorporating digital technology gradually over the last two decades—as “technology-push” continues to overcome customary and traditional passivity. BIM, or building information modeling, is a prime example of a digital technology that took a long time to gain acceptance in the mainstream construction industry. It is now widely accepted and is proving itself almost essential in the industry. It is more apparent now than ever before in the wake of the COVID-19 crisis. A recent IFS study based on a survey reported that companies concerned with economic disruption were 20% more likely to plan increased spending on digital transformation [

3]. It appears that the construction industry is ready to embrace a technological revolution to address these issues and that the global pandemic is perhaps the catalyst that the industry needed. Numerous studies listed contemporary digital technologies suitable for use and application in construction. For instance, PwC [

4] lists eight essential technologies that are making large impacts on the business of construction. They are artificial intelligence, virtual reality, augmented reality, blockchain, drones, Internet of Things (IoT), robotics, and 3D printing.

The early months of 2020 witnessed the rise of the COVID-19 pandemic, which had its adverse effects on almost all regions and industry sectors in the globe. However, many claim that the Architecture, Engineering, and Construction (AEC) industry was one of the sectors that was hit the hardest by the pandemic. According to a recent Los Angeles investigation, construction crews reported the highest number of positive cases when compared to workers in other sectors, such as transport and manufacturing [

5]. It is with no doubt that the COVID-19 pandemic affected the United Arab Emirates (UAE) AEC industry in many ways. Dadlani [

6] explained how precautionary measures were enforced in construction companies to ensure prioritization of health and safety of workers. These measures included frequent disinfection programs, social distancing measures, construction worker body temperature checks, and isolation rooms in the event of workers showing any symptoms of the coronavirus. Additionally, during the first six months of 2020, contract awards in the GCC region fell by 20%; this coincided with an increase in payment delays and disputes [

7]. In addition, supply chains and subcontractors in the UAE were pressurized by such marketing challenges, causing some of them to go out of business [

8].

The premise of this research is that most construction organizations’ (owner, consultants, and contractors) investment in digital technology prior to the pandemic was inadequate to deal with the demands imposed by the crisis. It is likely that several technologies already available and deployed were not utilized at the expected and optimum level. The pandemic abruptly made them more useful than before. As an example, the use of technology necessary for virtual meetings can be cited. This technology has become essential during the lockdown phase, although it most likely remained underutilized before the crisis. Perhaps it was not considered necessary or did not have the necessary bandwidth for smooth operations. Therefore, it is important to assess the level of use and investments in digital technology before, during, and after the pandemic. The main goal of this paper is to investigate the use and investment in digital technology for construction projects amid, and in the aftermath of, the COVID-19 pandemic in the context of the UAE construction industry.

The rest of the paper is organized as follows. A literature review about the benefits of digital technology applications in the AEC industry is discussed in the next section. It is followed by an elaborate explanation of three facets of digital technology applications—data acquisition, processing of information, and communication. The section afterward explains the methodology adopted in this research. The goal was to differentiate between the levels of usage and investment in the three digital technology categories across the three groups, namely, pre-, during, and post-COVID-19. Finally, the results are interpreted and discussed in order to draw significant conclusions that provide valuable insights regarding usage and investments in digital technology in construction in the context of the UAE (United Arab Emirates).

2. Background

Digital technology, although not new and having existed for some time, was not utilized extensively prior to the “lockdown” situation caused by the pandemic. The AEC industry has been incorporating digital technology gradually over the last two decades but remains sluggish as compared to other sectors, such as the service and the manufacturing industries, for instance. Ironically, the COVID-19 pandemic has developed an urgency towards adopting new technologies that will play a key role in reshaping the future of the AEC industry, allowing collaboration, data-driven decision-making, and greater control. The utilization of such technologies shall also facilitate the move towards a sustainable future for contractors and developers [

9]. Wallet [

10] noted that this pandemic has provided a silver lining, as construction professionals grew more confident in dealing with these technologies, which not only helped keep the industry moving during those drastic times but also provided cost and time saving tools that construction professionals can benefit from in the long run.

Despite their attractive potential capabilities, many advanced digital technologies were viewed as tools that could lead to poor results and inefficiencies in the AEC industry prior to the new realization during the pandemic [

11]. For instance, Hinks and Allen [

12] discovered that videoconferencing was not in sync with existing processes. Even in the period post-2010, digital technologies remained in an “under-utilization” state. In a study conducted in 2014, only two out of 14 interviewed AEC firms mentioned that video conferencing software was being utilized to communicate information [

13]. To sum up, the capacity and value of digital technologies in the business context was poorly recognized by the AEC firms prior to the COVID-19 pandemic.

The disruptive nature of COVID-19 has pressured many AEC companies to immediately remodel their business strategies via the usage of digital technologies [

14]. In many cases, AEC firms lacked the essential digital infrastructure to make the move simple. As a result, obtaining necessary software packages and other resources posed significant challenges, leading to severe inefficiencies [

15]. For instance, in the early stages of the pandemic, it was reported that several coordination problems arose due to online communication. Considering a design consultant, such coordination issues caused a delay in the design process during work from home. Additionally, difficulties in meeting with clients were evident, as some of the online meetings turned out to be ineffective and unnecessarily prolonged [

16]. In many cases, organizations were required to make additional technological investments to improve their ability to work under the changed circumstances. Several businesses, for example, have invested in Virtual Private Networks (VPNs) to acquire remote access to resources and software packages. Only few companies reported that they already had cloud solutions in place to access licensed software and company databases, making the shift smooth [

15].

The benefits of using digital technology (DT) in the AEC industry are multifarious and significant. The adoption of technological innovation gives construction companies the opportunity to rebrand themselves as the providers of smart engineering solutions. In fact, adopting such technological innovations is a strategic decision to improve the image of the construction company and its reputation in the market. Not only this but digitalizing the construction industry makes it more appealing to young graduates, as it challenges the traditional notion of construction jobs being dangerous, difficult, and dirty [

17] in addition to being labeled as backward. Furthermore, the efficient use of emerging digital technology helps improve communication, collaboration, better project comprehension, improved information retrieval, and increased productivity rates as well as time and cost savings. These benefits contribute to offering a distinct advantage to the market as well as creating a healthier organizational culture where project team members feel more connected to each other through advanced means of communication that raise a sense of belonging and commitment to the construction project [

18].

The adoption of these technological innovations helps reduce the risks associated with construction projects by directing the construction industry away from the high-risk and towards the low-risk sector zone [

19]. In addition, the nature of today’s construction industry demands project teams that are geographically dispersed in different time zones across diverse organizational cultures and boundaries. It is only through using such advanced technological innovations that a collaborative project delivery system can be established where teams can work closely with various disciplines in an effective way [

20]. Besides, adopting technological innovations can also help improve the monitoring and inspection of construction sites. For instance, Zhou et al. [

21] introduced an AR technique to overlook the inspection process of segment displacement during tunneling construction. The technique enabled overlaying a quality control baseline model onto the real segment and reported the discrepancies.

Despite the benefits offered by digital technology, its adoption in the construction sector is still very low. In fact, Manyika [

22] stated that the level of digitalization index for the construction industry ranked the lowest among 22 other industries. Delgado et al. [

23] divided the challenges of creation of virtual environment in the construction industry, in terms of limitations, into three categories: social, technical, and economic limitations. The social limitations included (but were not limited to) lack of trained workforce, repugnance to change, and data privacy issues, whereas technical limitations included large space as well as prohibitive processing requirements, lack of user friendliness, and accuracy issues. Economic limitations included expensive hardware, expensive training needs, lack of client interest, and lack of funds for research and development. It can be concluded that the last one, namely, the economic issues, are mainly responsible for the lack of necessary investment for promoting digital technology in construction. Thus, in this paper the discourse is centered around the issue of investment in digital technology. To that end, digital technology applications are broken down into three facets: data acquisition, data processing, and data communication.

2.1. Data Acquisition

These are technology and tools in which their utilization in the construction industry would assist in a faster and more efficient data gathering. Regardless of whether the information is gathered onsite or offsite, the data are essential for a successful project delivery. Data acquisition tools include RFID (Radio Frequency Identification), drones, and 3D laser scanning. Drones, for instance, are aircrafts designed to fly without a pilot or passengers, controlled remotely using radio waves [

24]. These innovations have high mobility and visual data acquisition capabilities. As a matter of fact, drones can play a significant role in conducting quantitative analysis of productivity and safety-related metrics through the reconstruction of three-dimensional (3D) point clouds from video images produced by the drones [

25]. Furthermore, a site staff equipped with a drone can do the same job as multiple personnel without a drone. Thus, using drones can be a powerful tool to comply with the COVID-19 imposed social distancing measures, as the number of people on site would be few. While some firms may be facing major financial constraints to invest in drone technology, it is critical to note that this technology helped construction firms reduce wastage in time by 18.4% and the time to survey a site by 98%, translating into money savings in the long term [

8]. Lastly, this smart system gives construction professionals access to real time data, which allows organizations to keep track of their inventory plan and better plan their construction site in general, making room for any adjustments needed as soon as possible [

26].

Another data acquisition tool that could be well integrated and utilized in the construction industry, as mentioned earlier, is RFID. Radio Frequency Identification (RFID) technology allows for automated tracking of equipment and materials in storage or during delivery and makes information readily available for the personnel who handle material tracking and delivery processes [

27]. Furthermore, laser scanning technologies are powerful data acquisition tools that have the capability of capturing complex geometries, angles, and distances [

28]. While laser scanning technologies require expert operators to run, these technologies provide a great value, as the output of these technologies can be used as the basis to develop as-built BIM models of a building [

28].

Table 1 shows some of the potential applications of RFID, drones, and laser scanning technologies in the construction industry.

2.2. Data Processing

The second stage that ultimately comes after data collection is data processing. A virtual innovation that facilitates such a task is Building Information Modeling (BIM). BIM is defined by the US National Institute of Building Sciences as a “digital representation of physical and functional characteristics of a facility creating a shared knowledge resource for information about it forming a reliable basis for decisions during its life cycle, from earliest conception to demolition” [

33]. Kaner et al. [

34] revealed that BIM enables the design and detail processing of complex 3D geometric shapes to a high level of accuracy with error-free drawings. Additionally, through features of clash detection and early error identification, the probability of disputes and claims is greatly minimized due to the utilization of BIM [

35]. Besides this, other features of BIM include automated quantity takeoff that enables users to avoid the traditional error-prone method of measuring elements of a project and assigning related costs to each. This feature also allows stakeholders to know costs early in the design phase so that more informed decisions can be made [

36,

37].

Lastly, there exist tools/software that process schedule-related and cost-related data, such as Primavera P6 and Esti-mate, respectively. Primavera P6, for instance, is a very commonly used scheduling and resource-planning tool in the AEC industry. “P6” has the capacity to allow users to develop complex and large-scale programs, forecast scenarios using what-if analysis, and track resources and costs through the project life cycle [

38]. Comparably, “Esti-mate” is an estimation tool that could be utilized by quantity surveyors, project managers, contract managers, and vendors to process and coordinate Bills of Quantities (BoQs), subcontractor and material inquiries, and tender adjudications, allowing for accurate and timely project cost tracking [

39].

Table 2 illustrates some applications of data processing tools.

2.3. Data Communication

As far as communication is concerned, some tools provide features such as discussion boards, work sharing, project websites, and videoconferencing with data sharing as well as real time data manipulation and exchange through virtual teaming [

41].

Furthermore, a virtual platform that has a huge potential to transform coordination in the construction industry is cloud computing. According to Mell and Grance [

42], clouding computing is a model for “enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources that can be rapidly provisioned and released with minimal management effort or service provider interaction”. In a recent study by Du et al. [

43], they proposed a cloud-based multiuser virtual reality headset system, which is an innovation that collects BIM metadata and translates them into a multiuser virtual communication environment. The technology allows remote project stakeholders to interact and connect simultaneously, thus improving collaboration. Cloud computing software (e.g: Dropbox) can also provide the necessary features to complement intelligent contracts, or “icontracts”. An icontract is an advanced smart contract that utilizes computer codes to automate the execution of contractual clauses between project parties [

44]. For instance, an icontract connected to a BIM model would enable the release of payments to a design consultant upon completion of a pre-specified BIM milestone in the contract. Through Dropbox and other cloud computing technologies, data sources such as models and emails, which may be linked to icontracts, can be stored, accessed, and updated by various project stakeholders [

44]. In a similar manner, blockchain-based intelligent contracts are envisaged to upgrade the supply chain financing industry through “smart factoring” [

45].

Furthermore, Google Meet and Zoom calls, along with the utilization of Dropbox and e-mail communication, are a few of several communication technologies that are adopted in the AEC industry. Due to the ongoing pandemic, video conferencing platforms have now become embedded into the day-to-day AEC work life in the UAE [

46]. Despite their current recognized benefits, video conferencing mediums have the potential to be further optimized to ensure high productivity, which would be especially beneficial for countries that adopt a four- or a four-and-a-half-day work week, such as Iceland and the UAE [

47].

Table 3 identifies the applications of these technologies.

To explore the levels of use of communication technologies in the Nigerian construction industry, a questionnaire [

48] revealed that different positions within an AEC firm utilize electronic communications at different levels of sophistication, based on the position’s need. The questionnaire revealed that email systems were the most frequently used tools to achieve effective information management [

48]. Oliver [

49] stated that current communication platforms provide the necessary features to allow for higher levels of interactivity, intimacy, and immediacy for AEC stakeholders to experience better social and technical communications. Thus, digital communication technologies may ease cost pressures and technical complexities [

50]. For instance, there is a high potential for video conferencing ICTs to solve corporate difficulties in an international market through overcoming lack of expertise and lowering travel expenses [

11]. It is worth noting that Computer-Mediated Communication (CMC) processes have existed for years. However, such communication technologies may not be well-integrated into existing industries to improve their efficacy [

51], meaning that they are underutilized.

3. Materials and Methods

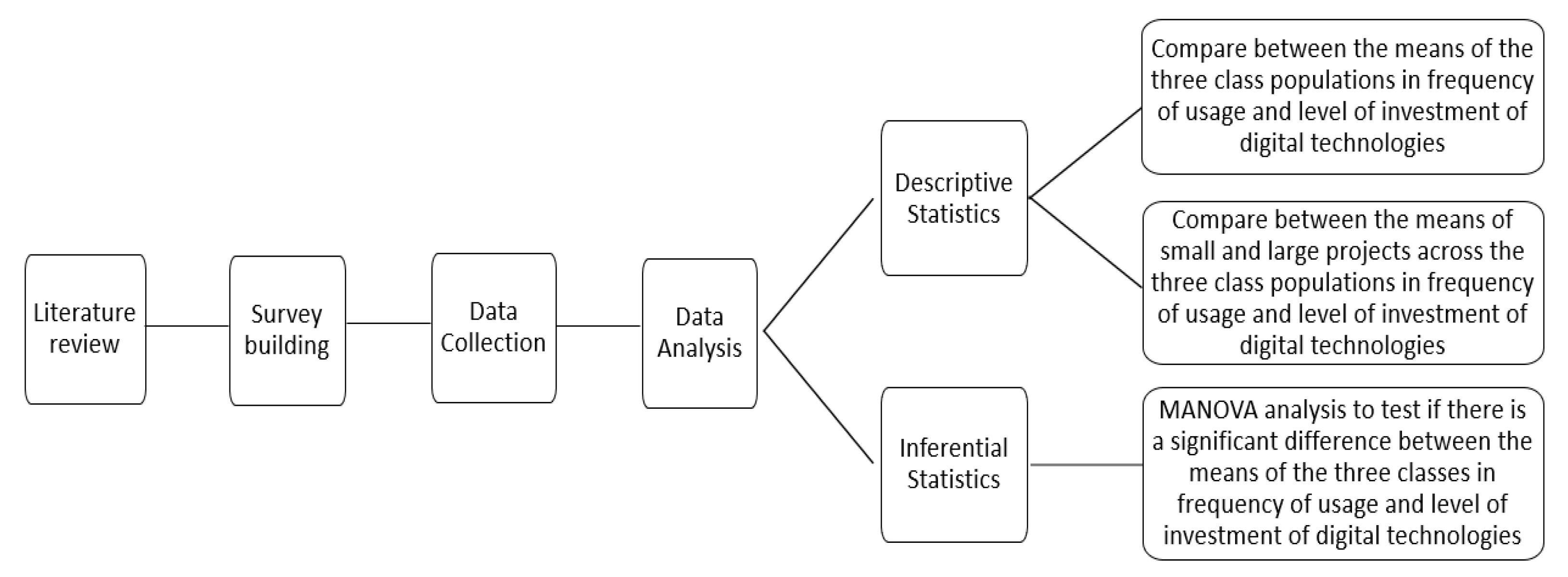

The study used a quantitative approach to differentiate between the level of usage and investment in three digital technology categories (data acquisition, processing, and communication) across three classes (phases)—pre-COVID, during COVID, and post-COVID. In order to select the frequently used digital technology for the purpose of this research study, a thorough literature survey of published materials was conducted. This included journal articles, periodicals, and books that discuss the leading digital technologies currently in use in the construction industry. In the next stage, a questionnaire survey was developed and distributed to construction professionals (owners, consultants, contracts, and project managers) in the UAE using online means. The survey was sent to 100 construction professionals, and 39 responses were collected in the end, representing a 39 percent rate. The survey consisted of 21 questions, and the duration of the survey was approximately 10 min. The questions were developed in a clear manner, where examples from the literature review about the different digital technologies in each category were given to make the questions comprehensible and easy to follow for the respondents. The questionnaire questions are presented in

Appendix A. The first section of the survey consisted of general information about the respondents’ companies or organizations. These included years of experience, respondents’ role, and whether the organizations or companies are local or international. The remaining sections of the survey were designed to elicit the perceptions of the respondents on the frequency of usage and level of investment of the three digital technology categories across the three classes: pre-COVID, during COVID and post-COVID. The questions related to the level of usage of all three digital technology categories pre-COVID and during COVID followed a Likert scale of 1–5, where 5 represented “almost always” and 1 represented “never”. The level of investment of all three digital technology categories pre-COVID and during COVID followed a Likert scale of 1–5, where 5 represented “very high” and 1 represented “very little”. All questions related to the class post-COVID, as being a future state, followed a Likert scale of 1–5, where 5 represented “strongly agree-will increase greatly” and 1 represented “strongly disagree-will return to pre-pandemic level”. We focus on the different digital technology (DT) categories rather than the specific technologies. The paper intentionally states only 3–4 examples within each DT category. The respondents are able to identify the example technologies within each category, as they were included in the survey questions. The survey questions are provided in

Appendix A.

The data were then analyzed using both descriptive statistics and inferential statistics. The descriptive statistics mainly consisted of comparing the means of the three class populations in the frequency of usage and level of investment of the digital technologies. Additionally, the means of the small projects were compared against those of the large projects across the three class populations in frequency of usage and level of investment of the three digital technology categories, while for the inferential statistics, multivariate analysis of variance (MANOVA) was conducted, as the data comprised multiple dependent variables, namely, the level of investment in, and frequency of usage of the three digital technology categories, and a single independent qualitative variable designated as classes: pre-COVID, during COVID, and post-COVID. MANOVA is used to determine whether there is a difference between the level of investment and frequency of usage of the three digital technologies across these classes. In particular, the researchers were interested in determining whether, during COVID, a peak in the level of usage and investment in digital technology is evident, as expected in order to meet the demands imposed by the pandemic. The statistical analysis mainly examined whether or not the average of the dependent variables differs between the three categories of the class variable. MANOVA is an extension of the analysis of variance (ANOVA) in order to incorporate more than one dependent variable by combining the multiple dependent variables into a single optimum value to maximize the difference between the classes. Furthermore, MANOVA is also more appropriate than ANOVA, because it provides additional insights into the effects of the independent variables on the dependent variable [

52,

53].

MANOVA is a very effective statistical tool that has been previously used in the construction context in literature. For instance, Zhao et al. [

54] have used MANOVA analysis to test whether or not different factors such as construction type, technology level, climate, and conditioned floor area significantly affect energy use and whether or not the effect changes over time. The authors tested the “between-subject” effect to analyze the factor’s effect across all building units and used the “within-subject” effects to test the factor’s effect over time. The authors modeled the “between-subject” effect by fitting the sum of the repeated measures to the model effect, while the “within-subject” effect was modeled using a function that fits differences in the repeated measures.

There are three main assumptions when conducting MANOVA analysis. First, the data should be multivariate normally distributed, while the second assumption is concerned with the equality of the covariance matrices for all treatments in the study. The third and last assumption states that all observations must be independent of each other, as this will affect the significance level reported in results later on [

55]. Furthermore, Wilk’s Lambda test statistic (Λ) is used in MANOVA to test whether there are differences between the means of the three classes on the frequency of usage and on the level of the investment of the three digital technologies or, in other words, to test the two-null hypothesis H

0 shown below.

where µ

ip, i = (1,2,3) is the number of the three classes’ populations (pre-COVID, during COVID, post-COVID), while “p” is the number of dependent variables, which, in this study, is three, since there are three digital technology categories (acquisition, processing, and communication) for the variable frequency of usage and the variable level of investment. Furthermore, to test whether there is no difference between the three population mean vectors, Λ will be used according to Equation (3) [

55], as it is the test statistic preferred for MANOVA, where H

0 will be rejected if Λ is small. Lambda is a value that ranges between zero and one; a null hypothesis would be rejected if Lambda was close to zero, but it should be considered in conjunction with a small

p-value as well, where the

p-value here represents the probability that measures the consistency between the data and the hypothesis being tested [

51]. The alpha level that the

p-value will be compared against in this study is 0.1, indicating a level of confidence of 90%. Wilk’s Lambda test statistic is defined as:

where

Serror is the variation of the residual within the matrix of sum of squares cross product and

Seffect is the variation of the treatment between the matrices of sum of squares cross product.

Figure 1 below further illustrates the methodology that will be adopted in this research.

4. Results

A total of 39 responses were received from the online survey. The respondents’ profiles showed that 15% of them worked in international offices, while 85% worked in local offices. Moreover, 13% of the respondents had more than 20 years of experience. Thus, a majority of the respondents were local contractors in the building industry with less than 5 years in business. In addition, it was observed that 56.4% of the respondents were involved in projects with an average project size of AED 50 million (considered large) or more, while 43.6% of respondents’ average project size was less than AED 50 million (considered small). In this research, these two groups’ (large and small) responses were further analyzed to gain important insights.

Descriptive analysis was conducted to compute the mean of the three populations in each variable (

Table 4). The results show that the mean of frequency of using the three digital technologies (y1, y3, y5) in class 0 (pre-COVID) population is 3.29, while the mean of the level of investment (y2, y4, y6) in class 0 was 3.30. Similar calculations were performed for class 1 (during COVID) population, and the mean of frequency of usage and level of investment are 4.03 and 3.75, respectively, whereas the mean of frequency of usage in class 2 population (post-COVID) is 4.26, and the mean of the level of investment is 4.23. This indicates that there is in fact an increasing trend from pre-COVID to post-COVID in terms of mean frequency of usage and level of investment in digital technology for data gathering, processing, and communication. The results are summarized in

Table 4.

In addition, the questionnaire contained three questions related to “project success”. The questionnaire statements and the weighted average of responses, indicating a high degree of agreement, are listed below:

Use of digital technology for data and information gathering contributes towards project success—4.36 (out of 5).

Use of digital technology for data and information processing contributes towards project success—4.59 (out of 5).

Use of digital technology for communication of data and information contributes towards project success—4.28 (out of 5).

Thus, it is substantiated by the above findings that the digital technologies do indeed contribute to overall success of construction projects. Furthermore, the results presented in

Table 4 also indicate that the frequency of using digital technology for communication was at its peak (variable y5 with a value of 4.49) during COVID, as the demands imposed by the pandemic were higher than they were before the pandemic, indicated by a value of 3.21, and decreased somewhat from the peak to 4.28 in the post-COVID phase, as in-person communication is expected to return back somewhat but probably not at the pre-COVID level. This is because it is expected that the professionals in the industry will retain some of the communication technologies and conveniences, as they will be increasingly more familiar and comfortable with the technology. It was noticed that there was a slight drop in the use of communication technology from during COVID to post-COVID, apparently as some of the functions and operations are expected to return to “normalcy” after the pandemic. The results also indicate, predictably, that investment in communication technologies (variable y6) had increased during the pandemic, to 3.97 from 3.44 (pre-COVID), and is higher after the pandemic, at 4.26.

In an effort to compare between the responses based on the project size, two groups were created, as noted earlier: small projects with sizes less than 50 million AED and large projects with sizes 50 million AED or more. These two groups were almost equally represented in the survey.

In general, it should be noted that, while in class 0 (pre-COVID), both the average of the frequency of usage and level of investment were both greater in larger organizations than the smaller ones. The difference shrinks in both when compared to class 1 (during COVID) and class 2 (post-COVID), as the data in the last two rows of

Table 5 indicate. This is a significant observation, as it substantiated two facts—(1) overall, there has been an increase in both the usage and investment in digital technologies in construction during pandemic, and the trend will continue after the pandemic; and (2) the extent of both usage and investment is significantly greater in smaller organizations than the larger ones at the during and post-COVID stages. This underscores the notion that benefits of digital technologies remained largely unknown or unexperienced by the smaller organizations, and once known they can become increasingly more acceptable in the industry.

The results show that in class 2 (post-COVID), as illustrated in

Table 5, the average of the frequency of usage and the level of investment were equal to each other in the large projects, but in small projects the average of the frequency of usage was higher than the average of the level of investment. Furthermore, it can be seen that both the averages were greater in small projects than in large projects in class 2, and that could be due to the fact that large projects were ahead of small projects in terms of digital technology usage before the pandemic and, therefore, will not need to invest as much as the small projects to keep up with the demands created by the pandemic. Another observation that can be drawn is the fact that in class 1 the averages of the frequency of digital technology usage were almost the same in both small and large projects—in data gathering (variable y1, 3.69—small to 3.61—large) and communication (variable y5, 4.63—small to 4.40—large) technologies but not so different in processing technologies (variable y3, 3.69—small versus 4.13—large). Again, it is not surprising, as data/information processing technologies are more capital-intensive (high initial investment cost) compared to the other two—acquisition and communication technologies—and organizations dealing with smaller projects would not have investment capital available to them during the pandemic. This observation naturally leads to a closer look at what happens to expected investment responses after the pandemic. Results in

Table 5 show that it is expected that organization with smaller projects would increase their investments significantly—in data acquisition (y2) from pre-COVID response of 3.00 to 4.38; in data processing (y4) from 3.00 to 4.18; and, lastly, in data communication (y6) from 3.25 from 4.25. The average of all three variables shows an increase in responses from 3.08 to 4.27. For organizations with larger projects, the extent of this difference in investment level between pre-COVID and post-COVID is much lower—from 3.45 to 4.23—although higher as predicted. These results are shown in

Table 5.

To gain further insight, the responses from the survey were then analyzed using SAS statistical software as per the methodology explained in the earlier section. The MANOVA test was conducted using F approximation to test the hypothesis of no significant difference between the means of the three classes’ populations (pre-, during, and post-COVID) on the frequency of usage and level of investment of the three digital technologies as shown in

Table 6 and

Table 7, respectively.

Table 6 shows that the

p-value is less than alpha (0.1) for the null hypothesis of “no overall class difference”; therefore, it can be rejected, and it can be concluded with 90% confidence that there is in fact a significant difference between the means of the three class populations on the frequency of usage of the three digital technologies. Therefore, the analysis was taken a step further to conduct pairwise comparisons between the means of class 0 (pre-COVID) and class 1 (during COVID), class 0 (pre-COVID) and class 2 (post-COVID), and class 1 (during COVID) and 2 (post-COVID). The results have shown that in all three MANOVA tests, the

p-values were less than alpha (0.1), which leads to the rejection of the null hypothesis and the conclusion with 90% confidence that there is a significant difference between the means of class 0 and class 1 and between the means of class 0 and 2 as well as between the means of class 1 and 2 on the frequency of usage of the three digital technology categories. Similar conclusions were drawn when MANOVA was conducted to compare between the means of the three class populations on the level of investment of the three digital technology categories, and the results are shown in

Table 7.

The first row in the tables above shows the value of Wilk’s Lambda (refer to Equation (3)) in each MANOVA test. It measures how well each category of the independent variable (class) contributes to the model. The scale ranges from 0 to 1 as mentioned earlier, where 0 means total discrimination and 1 means no difference. Since all the Lambda values are less than 1 and are associated with a small p-value (significant at the 0.1 level), it can be concluded with 90% confidence that there is in fact a difference between the means of the three classes on both the frequency of usage and level of investment of the three digital technology categories. The p-value represents the probability that measures the consistency between the data and the hypothesis being tested. The null hypothesis that there is no overall class effect and no difference between the classes in pairwise comparisons is evaluated with regard to this p-value. For a given alpha level, if the p-value is less than alpha then this null hypothesis is rejected. The alpha level used in this study is 0.1, and the tables show that all p-values are less than 0.1. It should be noted that some of the p-values are slightly higher for “no difference between classes 1 and 2” and “no difference between classes 0 and 1” in the level of investment, they are still less than 0.1. Therefore, it is safe to reject all the null hypotheses and conclude with 90% confidence that there is in fact a significant difference between the means of the three classes on both the frequency of usage and level of investment of the three digital technology categories. Future studies can focus on testing a larger sample size in order to achieve a smaller p-value and a higher confidence level.

5. Discussion

The study on COVID-19 and its impact in the construction industry are fairly new. Nevertheless, the following paragraph compares the results of this study with recently published papers. The results of this study are in line with the conclusions of the research done by Cheshmehzang [

56], who reported on the impact of COVID-19 on boosting digitalization in the built environment. The author stated that COVID-19 was a driver for the built environment to utilize available technological toolkits even further and formulate new policies on the use of digital technologies. Similarly, Ebekozien and Aigbavboa [

57] have highlighted the role of the fourth industrial revolution technologies in curtailing the impacts of COVID-19 in Nigerian construction sites. The authors explained how the use of AI technologies such as RFID have compensated for the absence of workforces and the use of BIM has helped construction professionals to comply with the pandemic rules, such as physical distancing, and still be able to simulate construction site activities.

The study was conducted using a carefully crafted questionnaire survey in the UAE construction industry. The survey instrument (

Appendix A) was designed to elicit responses from the professionals. Although it is common knowledge that digital technology contributes towards project success, the findings of this study confirmed the observation across all three categories of digital technology. Importance of data acquisition and processing technologies were rated at a higher level by the respondents than communication, indicating that in-person communication will continue to be used with less dependence on technology as compared with the other two. The study showed that smaller organizations will be using and investing in digital technologies at a greater extent than the larger ones.

One of the limitations of this study was the small size of data, as represented by only 39 respondents. It should be pointed out, however, that the respondents were drawn from a very specific population—the UAE construction professionals. Thus, the value of their responses was considered significant qualitatively for this study despite the small sample size. The second limitation was that the study was conducted in a specific country (UAE), and, thus, the results are difficult to generalize. While this is a shortcoming, the fact is that the UAE is a vibrant economy in the Middle East with a high projected growth rate in the construction sector and is considered a representative example in the global construction industry. Nevertheless, the results and findings derived from this study conducted in the UAE provide valuable future directions and insights for further research on this topic.

The methodology developed and adopted in this study can be replicated in a larger country with a major economy and high volume of construction spending. A similar study can be undertaken with bigger sample sizes derived from different professional groups in the AEC industry. The variations and correlations between the regions and the professional groups will provide valuable insights regarding the use of digital technologies. Moreover, specific digital technologies can be investigated further, in addition to the three broad categories of digital technologies as conducted in this study. Nevertheless, this study provided a framework for future investigations on the use and investment in digital technologies in construction in the wake of catastrophic disasters, such as COVID-19.

The findings of this study can be useful from a practical standpoint by several measures. First, the study highlights the importance of digital technology in improving construction productivity. Second, this study differentiates between data acquisition, information processing, and communication technologies; this differentiation is helpful to identify and prioritize technologies for investing. Finally, and most importantly, this study underscores the importance of ‘virtualization’ in construction enabled by digital technology in the wake of catastrophes such as COVID-19. While the findings are general in nature in the context of the construction sector, the implications at the project level are imperative and indicative.

6. Conclusions

It is common knowledge that overall productivity increases in the construction sector, both regional and global, are minimal and significantly lower than the manufacturing and the service sectors. One reason frequently cited by the researchers and the practitioners alike is the slow adoption of technology, digital in particular, in construction. This study takes a deep look into this issue of adoption (usage and investment) of digital technology in construction in the context of the prevalent pandemic caused by COVID-19 since early 2020. COVID-19, ironically, presented an opportunity to investigate the status of use of digital technology adoption in the construction industry. Thus, this study is undertaken to determine the status in three levels, pre-COVID, during COVID, and post-COVID. The premise of the study is that digital technologies in three major categories—data acquisition, processing, and communication of data and information—are all impacted by the pandemic. There was a noticeable increase in the use of, and investment in, these digital technologies in the industry since early 2020 as a reaction to the restrictions put in place to reduce the spread of the COVID-19 virus. This crisis caused by the COVID-19 pandemic imposed a de facto mandate by instilling a sense of urgency among the construction professionals for digitalization of many processes and operations in construction and to perform them virtually. Digital technology, although not new and having existed for some time, was not utilized extensively prior to the “lockdown” situation caused by the pandemic. Oddly, COVID-19 provided the necessary impetus for digitalization in the construction industry. This crisis, as unexpected and undesirable as it is, offers a window of opportunity to improve and make the industry better positioned for the future.

This research study, despite the limitations, identified several significant facts and provided important insights. The most significant among them are that COVID-19 revealed that the use of digital technology, although remaining underutilized, is gaining wider acceptance in the industry. It also showed that the benefits of digital technology, once realized, will continue to be used. As a consequence, investment in digital technology in the construction industry will continue to increase. This will have long-term transformational and beneficial impacts on productivity in the construction sector. The methodology developed and employed in this study can be utilized to investigate certain selected technologies for use and investment decisions. A decision-making model for use in the industry can be developed using the categories as outlined in this study.

Author Contributions

Conceptualization, I.A. and S.E.-S.; methodology, O.E., S.A., I.A. and S.E.-S.; software, S.A.; validation, O.E., S.A., I.A. and S.E.-S.; formal analysis, O.E., S.A., I.A. and S.E.-S.; investigation, O.E., S.A., I.A. and S.E.-S.; resources, O.E., S.A., I.A. and S.E.-S.; data curation, O.E. and S.A.; writing—original draft preparation, O.E. and S.A.; writing—review and editing, I.A. and S.E.-S.; visualization, O.E. and S.A.; supervision, I.A. and S.E.-S.; project administration, I.A. and S.E.-S.; funding acquisition, I.A. and S.E.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The American University of Sharjah, grant number FRG21-M-E71. The work in this paper was supported, in part, by the Open Access Program from the American University of Sharjah, and the APC was funded through Grant number: OAPCEN-1410-E00060.

Institutional Review Board Statement

The study was approved by the Institutional Review Board of the AMERICAN UNIVERSITY OF SHARJAH (protocol # 20-072 on 5 May 2021).

Informed Consent Statement

Written informed consent was waived for this study.

Data Availability Statement

Data are available upon request.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results. This paper represents the opinions of the author(s) and does not mean to represent the position or opinions of the American University of Sharjah.

Appendix A. Survey Instrument

Appendix A.1. General Information

In this section, you will be asked about your general information.

Appendix A.2. Data and Information Gathering Technologies

In this section, you will be asked to rate the level of usage, investment decisions, and the success potential for data and information gathering technologies (e.g., RFID, Barcode, Drones, GPS, laser scanning).

Do you believe that the use of digital technology (such as drones) for data and information gathering contributes towards project success?

- □

Strongly Agree

- □

Agree

- □

Neutral

- □

Disagree

- □

Strongly Disagree

Prior to the COVID-19 Pandemic, how frequently your company have used digital technology for data and information gathering?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

During the COVID-19 Pandemic (after March 2020), how frequently your company have used digital technology for data and information gathering?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the usage of digital technology will increase beyond the level reached during COVID-19 Pandemic for data and information gathering.

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

Prior to the COVID-19 Pandemic, what is the level of your company’s investment in digital technology for data and information gathering?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

During the COVID-19 Pandemic (after March 2020), what is the level of your company’s investment in digital technology for data and information gathering?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the investment in digital technology will increase beyond the level reached during COVID-19 Pandemic for data and information gathering.

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

Appendix A.3. Data and Information Processing Technologies

In this section, you will be asked to rate the level of usage, investment decisions, and the success potential for data and information processing technologies (e.g., Building Information Modeling or BIM, Scheduling program, such as Primavera, Power Project, Procore, Job Master, CMIC, Estimating software such as Manifest, Esti-mate, FBS-Estimator).

Do you believe that the use of digital technology (such as BIM) for data and information processing contributes towards project success?

- □

Strongly Agree

- □

Agree

- □

Neutral

- □

Disagree

- □

Strongly Disagree

Prior to the COVID-19 Pandemic, how frequently your company have used digital technology for data and information processing?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

During the COVID-19 Pandemic (after March 2020), how frequently your company have used digital technology for data and information processing?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the usage of digital technology will increase beyond the level reached during COVID-19 Pandemic for data and information processing.

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

Prior to the COVID-19 Pandemic, what is the level of your company’s investment in digital technology for data and information processing?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

During the COVID-19 Pandemic (after March 2020), what is the level of your company’s investment in digital technology for data and information processing?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the investment in digital technology will increase beyond the level reached during COVID-19 Pandemic for data and information processing.

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

Appendix A.4. Information and Communications Technologies

In this section, you will be asked to rate the level of usage, investment decisions, and the success potential for information and communication technologies (e.g., Video Conferencing such as google meet and zoom, Dropbox, mail, web-based systems).

Do you believe that the use of digital technology (such as video conferencing and file sharing) for communications of data and information (including virtual meetings) contributes towards project success?

- □

Strongly Agree

- □

Agree

- □

Neutral

- □

Disagree

- □

Strongly Disagree

Prior to the COVID-19 Pandemic, how frequently your company have used digital technology for communication of data and information (including virtual meetings)?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

During the COVID-19 Pandemic (after March 2020), how frequently your company have used digital technology for communication of data and information (including virtual meetings)?

- □

Almost Always

- □

Often

- □

Sometimes

- □

Rarely

- □

Never

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the usage of digital technology will increase beyond the level reached during COVID-19 Pandemic for communication of data and information (including virtual meetings).

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

Prior to the COVID-19 Pandemic, what is the level of your company’s investment in digital technology for communication of data and information (including virtual meetings)?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

During the COVID-19 Pandemic (after March 2020), what is the level of your company’s investment in digital technology for communications of data and information (including virtual meetings)?

- □

Very high

- □

High

- □

Normal

- □

Adequate

- □

Very little

Please indicate your choice related to the statement: After COVID-19 Pandemic is essentially over, the investment in digital technology will increase beyond the level reached during COVID-19 Pandemic for communication of communications of data and information (including virtual meetings).

- □

Strongly Agree—Will greatly increase

- □

Agree—Will slightly increase

- □

Neutral—remain the same as already reached

- □

Disagree—Will slightly decrease

- □

Strongly Disagree—Will return to the pre-Pandemic level

References

- Global Construction Market to Grow $8 Trillion by 2030: Driven by China, US and India. Institution of Civil Engineers (ICE). 2015. Available online: https://myice.ice.org.uk/ICEDevelopmentWebPortal/media/documents/news/ice%20news/global-construction-press-release.pdf (accessed on 29 January 2022).

- Reinventing Construction through a Productivity Revolution|McKinsey. McKinsey Global Institute. 2017. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/reinventing-construction-through-a-productivity-revolution (accessed on 29 January 2022).

- IFS Finds Concerns about Economic Disruption Driving Digital Transformation Spending—Bizness Transform. Business Transformation (BT). 2020. Available online: https://www.biznesstransform.com/ifs-finds-concerns-about-economic-disruption-driving-digital-transformation-spending/ (accessed on 29 January 2022).

- The Essential Eight Technologies. PricewaterhouseCoopers (PwC). 2022. Available online: https://www.pwc.com/us/en/tech-effect/emerging-tech/essential-eight-technologies.html (accessed on 29 January 2022).

- Allan-Blitz, L.-T.; Turner, I.; Hertlein, F.; Klausner, J.D. High Frequency and Prevalence of Community-Based Asymptomatic SARS-CoV-2 Infection. Emerg. Infect. Dis. 2020. [Google Scholar] [CrossRef]

- Dadlani, D. COVID-19 Guidelines for Construction Workers. Construction Week Online. 9 May 2020. Available online: https://www.constructionweekonline.com/business/264880-covid-19-guidelines-for-construction-workers (accessed on 8 November 2021).

- Report: UAE Construction after COVID-19, Middle East Business Intelligence (MEED). 10 August 2020. Available online: https://www.meed.com/report-uae-construction-after-covid-19 (accessed on 22 January 2022).

- The Rise of Drones in UAE Construction. Middle East Business Intelligence (MEED). 15 December 2020. Available online: https://www.meed.com/the-rise-of-drones-in-uae-construction (accessed on 22 January 2022).

- Here’s Why UAE’s Construction Industry Needs to Pick up Pace of Change, Gulf News. 8 January 2021. Available online: https://gulfnews.com/business/property/heres-why-uaes-construction-industry-needs-to-pick-up-pace-of-change-1.1610097889474 (accessed on 22 January 2022).

- Wallett, P. Going Digital in COVID-19: Welcoming Next-Gen Workers on Site. Construction Week Online. 28 June 2020. Available online: https://www.constructionweekonline.com/products-services/266085-going-digital-in-covid-19-welcoming-next-gen-workers-on-site (accessed on 8 November 2021).

- Bower, D.J.; Hinks, J.; Wright, H.; Hardcastle, C.; Cuckow, H. ICTs, videoconferencing and the construction industry: Opportunity or threat? Constr. Innov. 2002, 1, 129–144. [Google Scholar] [CrossRef]

- Allen, S.; Hinks, A.J. Using Action Research to Compare the Theory and Practice of Managing Housing Information: International Symposium on the Organisation and Management of Construction (W65); International Symposium on the Organization and Management of Construction: Glasgow, UK, 1996; pp. 276–286. [Google Scholar]

- Bigliardi, B.; Galati, F.; Petroni, A. How to effectively manage knowledge in the construction industry. Meas. Bus. Excell. 2014, 18, 57–72. [Google Scholar] [CrossRef]

- Kamal, M. The triple-edged sword of COVID-19: Understanding the use of digital technologies and the impact of productive, disruptive, and destructive nature of the pandemic. Inf. Syst. Manag. 2020, 37, 310–317. [Google Scholar] [CrossRef]

- Alsharef, A.; Banerjee, S.; Uddin, S.M.J.; Albert, A.; Jaselskis, E. Early Impacts of the COVID-19 Pandemic on the United States Construction Industry. Int. J. Environ. Res. Public Health 2021, 18, 1559. [Google Scholar] [CrossRef]

- Oey, E.; Lim, J. Challenges and action plans in construction sector owing to COVID-19 pandemic—A case in Indonesia real estates. Int. J. Lean Six Sigma 2021, 12, 835–858. [Google Scholar] [CrossRef]

- The Construction Labor Shortage: Will Developers Deploy Robotics? Forbes. 2019. Available online: https://www.forbes.com/sites/columbiabusinessschool/2019/07/31/the-construction-labor-shortage-will-developers-deploy-robotics/ (accessed on 8 November 2021).

- Buchanan, J.; Kelley, B.; Hatch, A. Digital Workplace and Culture How Digital Technologies Are Changing the Workforce and How Enterprises Can Adapt and Evolve. Deloitte. 2016. Available online: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/human-capital/us-cons-digital-workplace-and-culture (accessed on 29 January 2022).

- Delgado, J.M.D.; Oyedele, L.O.; Ajayi, A.; Àkànbí, L.; Akinadé, O.O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Kent, D.C.; Becerik-Gerber, B. Understanding Construction Industry Experience and Attitudes toward Integrated Project Delivery. J. Constr. Eng. Manag. 2010, 136, 815–825. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, H.; Yang, Y. Implementation of augmented reality for segment displacement inspection during tunneling construction. Autom. Constr. 2017, 82, 112–121. [Google Scholar] [CrossRef]

- Digital America: A Tale of the Haves and Have-Mores|McKinsey. Available online: https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/digital-america-a-tale-of-the-haves-and-have-mores (accessed on 29 January 2022).

- Delgado, M.D.; Oyedele, L.; Demian, P.; Beach, T. A research agenda for augmented and virtual reality in architecture, engineering and construction. Adv. Eng. Inform. 2020, 45, 101122. [Google Scholar] [CrossRef]

- Kardasz, P.; Doskocz, J. Drones and Possibilities of Their Using. J. Civ. Environ. Eng. 2016, 6, 1–7. [Google Scholar] [CrossRef]

- Xiao, Y.; Kamat, V.R.; Lee, S. Monitoring Excavation Slope Stability Using Drones. In Proceedings of the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018; pp. 169–179. [Google Scholar] [CrossRef]

- Liu, P.; Chen, A.; Huang, Y.-N.; Han, J.-Y.; Lai, J.-S.; Kang, S.-C.; Wu, T.-H.; Wen, M.-C.; Tsai, M.-H. A review of rotorcraft Unmanned Aerial Vehicle (UAV) developments and applications in civil engineering. Smart Struct. Syst. 2014, 13, 1065–1094. [Google Scholar] [CrossRef]

- Ergen, E.; Akinci, B. An Overview of Approaches for Utilizing RFID in Construction Industry. In Proceedings of the 2007 1st Annual RFID Eurasia, Istanbul, Turkey, 5–6 September 2007; pp. 1–5. [Google Scholar] [CrossRef]

- Dinis, F.M.; Sanhudo, L.; Martins, J.P.; Ramos, N.M.M. Improving project communication in the architecture, engineering and construction industry: Coupling virtual reality and laser scanning. J. Build. Eng. 2020, 30, 101287. [Google Scholar] [CrossRef]

- Dziadak, K.; Kumar, B.; Sommerville, J. Model for the 3D Location of Buried Assets Based on RFID Technology. J. Comput. Civ. Eng. 2009, 23, 148–159. [Google Scholar] [CrossRef]

- Chae, S.; Yoshida, T. Application of RFID technology to prevention of collision accident with heavy equipment. Autom. Constr. 2010, 19, 368–374. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Q.; Wu, J.; Zhao, Y. Dimensional accuracy and structural performance assessment of spatial structure components using 3D laser scanning. Autom. Constr. 2018, 96, 324–336. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, J.; Fu, C.Q.; Huang, L.; Ye, H. Characterization of steel reinforcement corrosion in concrete using 3D laser scanning techniques. Constr. Build. Mater. 2020, 270, 121402. [Google Scholar] [CrossRef]

- National Institute of Building Sciences. Frequently Asked Questions About the National BIM Standard-United StatesTM|National BIM Standard—United States. Available online: https://www.nationalbimstandard.org/faqs (accessed on 8 November 2021).

- Kaner, I.; Sacks, R.; Kassian, W.; Quitt, T. Case studies of BIM adoption for precast concrete design by mid-sized structural engineering firms. Electron. J. Inf. Technol. Constr. 2008, 13, 303–323. [Google Scholar]

- Marzouk, M.; Othman, A.; Enaba, M.; Zaher, M. Using BIM to Identify Claims Early in the Construction Industry: Case Study. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2018, 10, 5018001. [Google Scholar] [CrossRef]

- Forgues, D.; Iordanova, I.; Valdivesio, F.; Staub-French, S. Rethinking the Cost Estimating Process through 5D BIM: A Case Study. In Proceedings of the Construction Research Congress 2012: Construction Challenges in a Flat World, West Lafayette, Indiana, 21–23 May 2012; pp. 778–786. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, A.; Martins, J. A survey on modeling guidelines for quantity takeoff-oriented BIM-based design. Autom. Constr. 2013, 35, 238–253. [Google Scholar] [CrossRef]

- Oracle. Primavera P6 Enterprise Project Portfolio Management|Oracle United Arab Emirates. Available online: https://www.oracle.com/ae/industries/construction-engineering/primavera-p6/ (accessed on 30 January 2022).

- Esti-Mate. Describe, Measure & Price Jobs|Esti-Mate. Available online: https://estimate.co.uk/ (accessed on 30 January 2022).

- Cadalyst. Cadalyst Labs Review: Autodesk Revit Structure 2-Digital Models for Structural Design|Cadalyst. 2005. Available online: https://www.cadalyst.com/aec/cadalyst-labs-review-autodesk-revit-structure-2-digital-models-structural-design-5397 (accessed on 22 January 2022).

- Chinowsky, P.S.R. Virtual teams: Guide to successful implementation. J. Manag. Eng. 2003, 19, 98–106. [Google Scholar] [CrossRef] [Green Version]

- Mell, P.; Grance, T. The NIST Definition of Cloud Computing. Natl. Inst. Stand. Technol. 2011, 800, 145. [Google Scholar] [CrossRef]

- Du, J.; Shi, Y.; Zou, Z.; Zhao, D. CoVR: Cloud-Based Multiuser Virtual Reality Headset System for Project Communication of Remote Users. J. Constr. Eng. Manag. 2018, 144, 4017109. [Google Scholar] [CrossRef]

- McNamara, A.J.; Sepasgozar, S.M.E. Intelligent contract adoption in the construction industry: Concept development. Autom. Constr. 2021, 122, 103452. [Google Scholar] [CrossRef]

- Zheng, K.; Zhang, Z.; Gauthier, J. Blockchain-based intelligent contract for factoring business in supply chains. Ann. Oper. Res. 2022, 308, 777–797. [Google Scholar] [CrossRef]

- Godinho, V. How Digital Transformation Is Taking Root within the Construction Industry. Gulf Business. 2021. Available online: https://gulfbusiness.com/how-digital-transformation-is-taking-root-within-the-construction-industry/ (accessed on 30 January 2022).

- UAE’s New Workweek: A Bit of Tech and More Creative Thinking Can Get the Job Done. Gulf News. 2022. Available online: https://gulfnews.com/business/analysis/uaes-new-workweek-a-bit-of-tech-and-more-creative-thinking-can-get-the-job-done-1.1641816313034 (accessed on 30 January 2022).

- Ikediashi, D.I.; Ogwueleka, A.C. Assessing the use of ICT systems and their impact on construction project performance in the Nigerian construction industry. J. Eng. Des. Technol. 2016, 14, 252–276. [Google Scholar] [CrossRef]

- Oliver, S. Communication and trust: Rethinking the way construction industry professionals and software vendors utilise computer communication mediums. Vis. Eng. 2019, 7, 1. [Google Scholar] [CrossRef]

- Wong, C.H.; Sloan, B. Use of ICT for E-Procurement in The UK Construction Industry: A Survey of SMEs Readiness. In Proceedings of the ARCOM Proceedings Twentieth Annual Conference, Edinburgh, UK, 1–3 September 2005; pp. 1–3. Available online: https://www.semanticscholar.org/paper/USE-OF-ICT-FOR-E-PROCUREMENT-IN-THE-UK-CONSTRUCTION-Wong-Sloan/9fc85aaac97515ee4115f22a89b1c686eee4e742 (accessed on 8 November 2021).

- Giel, B.; Issa, R.R.A. Quality and Maturity of BIM Implementation in the AECO Industry. Appl. Mech. Mater. 2013, 438–439, 1621. [Google Scholar] [CrossRef]

- Kleinbaum, D.G.; Kupper, L.L.; Nizam, A.; Rosenberg, S.E. Applied Regression Analysis and Other Multivariable Methods, 5th ed.; Cengage Learning: Boston, MA, USA, 2013. [Google Scholar]

- Hair, J.F., Jr.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Zhao, D.; Mccoy, A.; Agee, P.; Mo, Y.; Reichard, G.; Paige, F. Time effects of green buildings on energy use for low-income households: A longitudinal study in the United States. Sustain. Cities Soc. 2018, 40, 559–568. [Google Scholar] [CrossRef]

- Huberty, C.J.; Olejnik, S. Applied MANOVA and Discriminant Analysis, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2006. [Google Scholar]

- Cheshmehzangi, A. From transitions to transformation: A brief review of the potential impacts of COVID-19 on boosting digitization, digitalization, and systems thinking in the built environment. J. Build. Constr. Plan. Res. 2021, 9, 26. [Google Scholar] [CrossRef]

- Ebekozien, A.; Aigbavboa, C. COVID-19 recovery for the Nigerian construction sites: The role of the fourth industrial revolution technologies. Sustain. Cities Soc. 2021, 69, 102803. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).