Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete

Abstract

:1. Introduction

2. Experimental Program

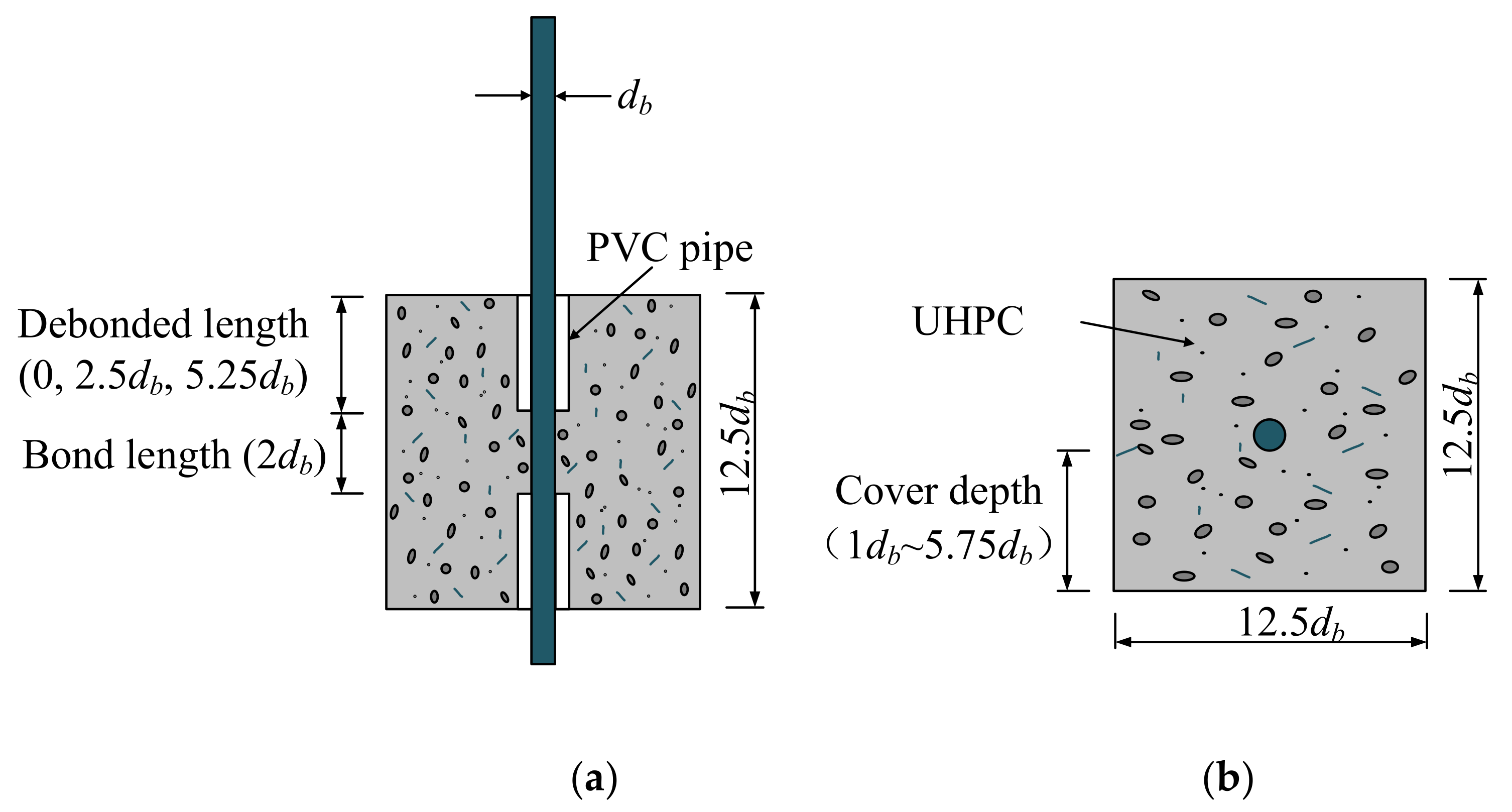

2.1. Specimen Details

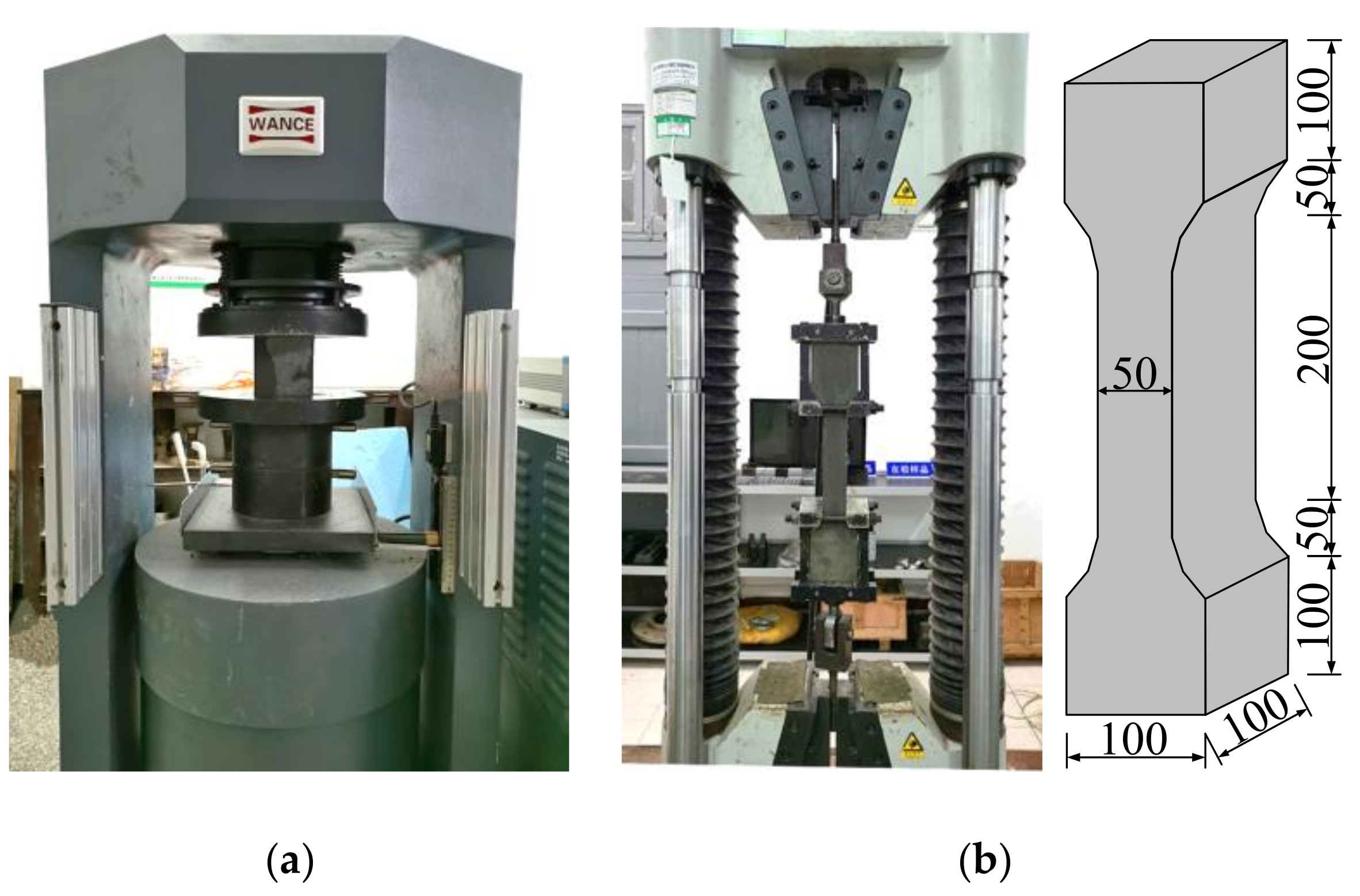

2.2. Materials Properties

2.3. Test Setup and Loading Scheme

3. Results and Discussion

3.1. Bond Capacity Parameters

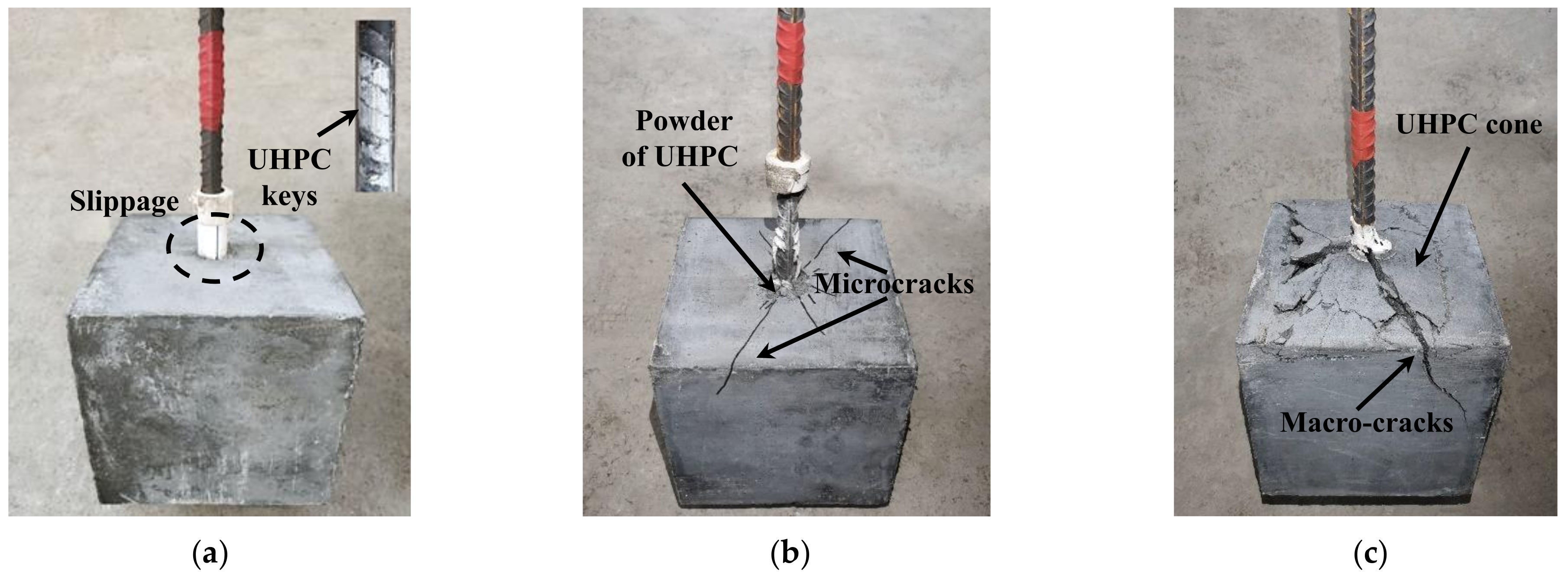

3.2. Failure Mode

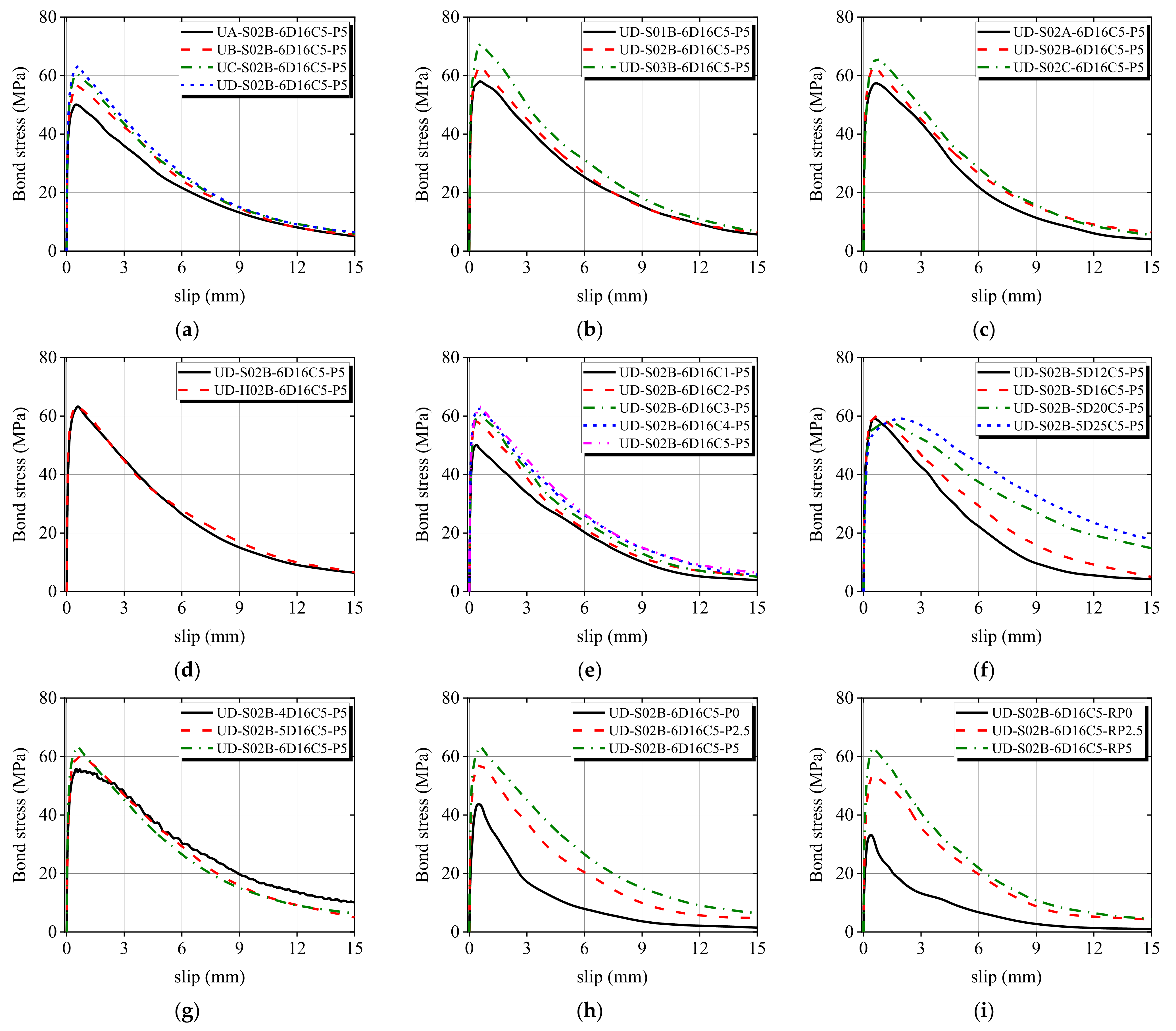

3.3. Bond Stress-Slip Curves

3.4. The Effects of Parameters on Bond Behavior

3.4.1. Compressive Strength

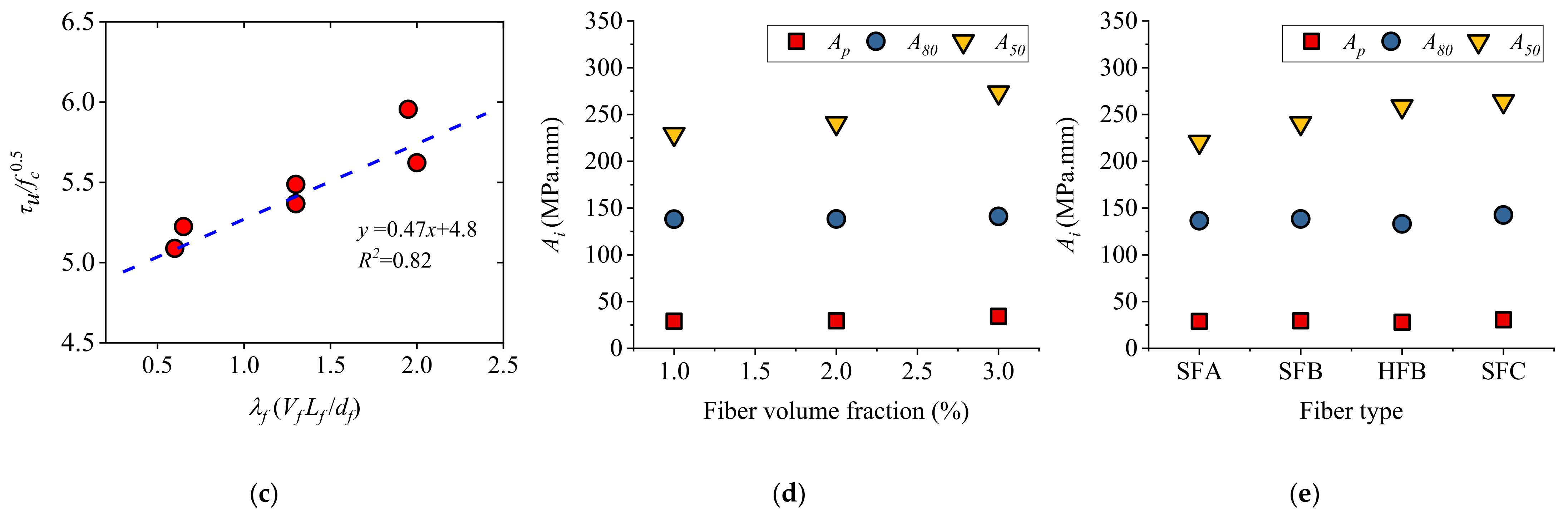

3.4.2. Steel Fiber

3.4.3. Cover Thickness

3.4.4. Rebar Diameter

3.4.5. Rebar Yield Strength

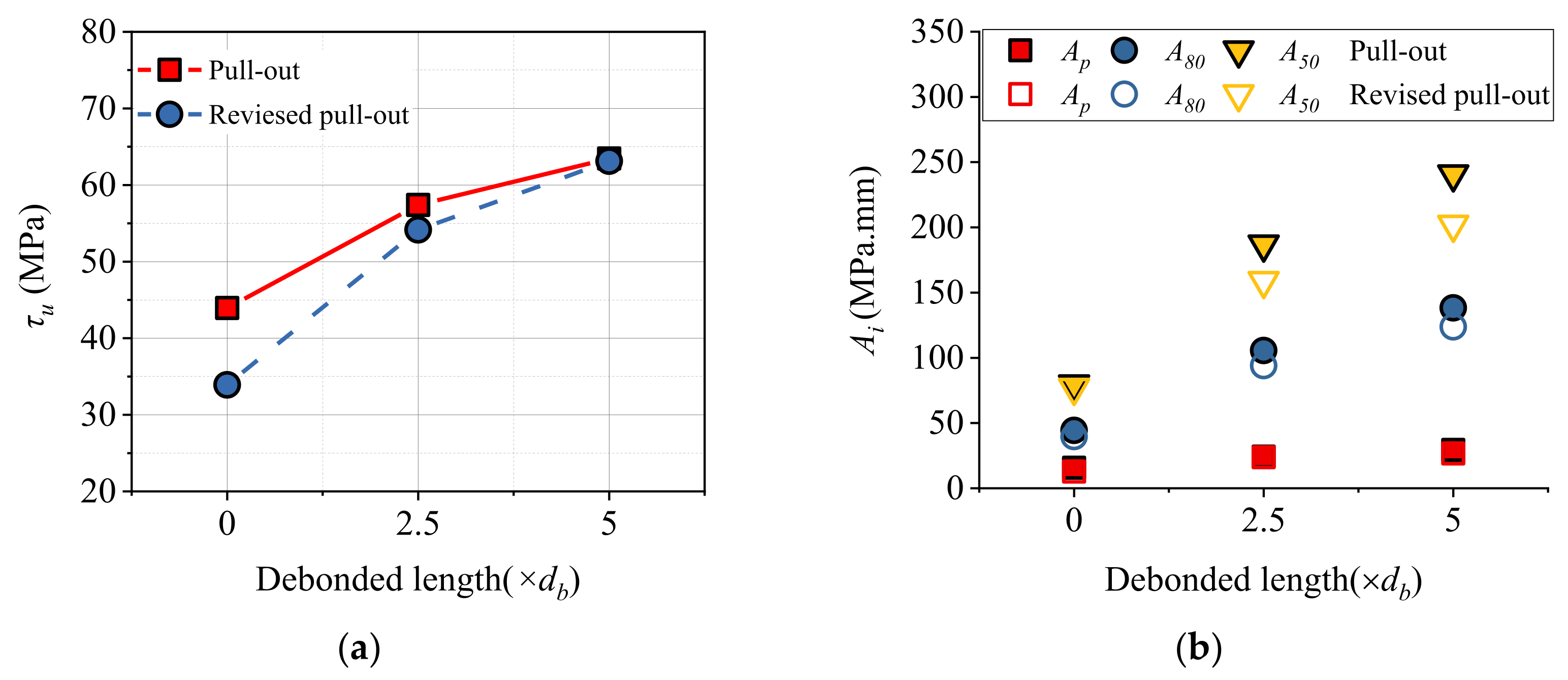

3.4.6. Loading Method and Debonded Length

4. Analytical Model

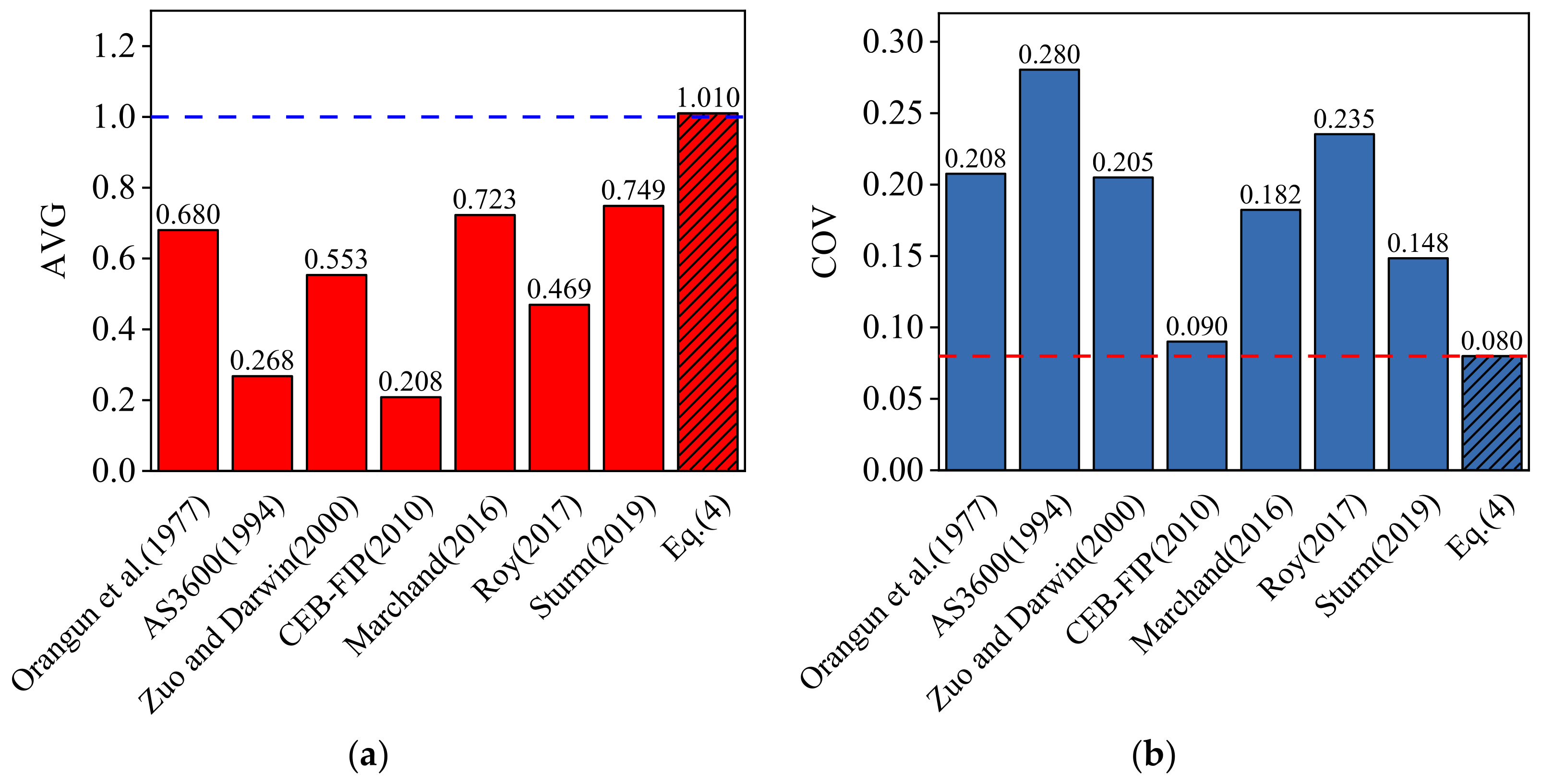

4.1. Bond Strength Model

4.2. Bond Stress-Slip Relationship Model

4.2.1. The Peak Slip su

4.2.2. Bond-Slip Relationship Model

5. Conclusions

- (1)

- The UHPC effectively increases the bond strength of the rebars. The bond strength is linearly related to the square root of UHPC compressive strength in MPa;

- (2)

- Increasing the fiber volume content and aspect ratio can increase the bond strength. A fiber characteristic factor λf (λf =Vf × Lf/df) is used to evaluate the effects of fiber volume content and aspect ratio. The bond strength of the specimens with the hook steel fiber has no significant difference from the straight steel fiber;

- (3)

- As the cover thickness increases from 1db to 2db, the bond strength increases by 17.6%. The bond strength remains unchanged when the cover thickness is greater than 2db. The peak slip increases by 43.6% when the cover thickness changes from 1db to 5.75db;

- (4)

- The influence of rebar diameter on bond strength is negligible since bond strength remains almost constant as rebar diameter increases. When the rebar diameter raises from 12 to 25 mm, the peak slips improve by 276.4%. The bond strength increases with the rebar grade;

- (5)

- The impact of the loading methods on the bond strength can be neglected when the debonded length is greater than the bond length;

- (6)

- A simplified bond strength formula is suggested, fitting well with the test results in this paper and the collected results from previous literature. The average ratio of the calculated value to the experimental value is 1.010, with the coefficient of variation being 0.080. The peak slip expression is developed for the rebar-UHPC interface, which has significant consequences for cover thickness and rebar diameter;

- (7)

- A two-branch bond stress-slip constitutive model is proposed to describe the bond behavior of rebar in UHPC. The predicted bond-slip curves are in suitable agreement with the test curves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Li, T.; Deng, M. Mechanical behavior of RC columns strengthened with thin UHPC jacket under cyclic loads. J. Build. Eng. 2022, 49, 104065. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, X.; Chen, J.; Cao, J.; Deng, S. UHPC-based strengthening technique for orthotropic steel decks with significant fatigue cracking issues. J. Constr. Steel Res. 2021, 176, 106393. [Google Scholar] [CrossRef]

- Graybeal, B.; Crane, C.K.; Perry, V.; Corvez, D.; Ahlborn, T.M. Advancing Ultra-High-Performance Concrete. Concr. Int. 2019, 41, 41–45. [Google Scholar]

- Kim, J.J.; Yoo, D.Y. Effects of fiber shape and distance on the pullout behavior of steel fibers embedded in ultra-high-performance concrete. Cem. Concr. Compos. 2019, 103, 213–223. [Google Scholar] [CrossRef]

- Fan, L.; Meng, W.; Teng, L.; Khayat, K.H. Effects of lightweight sand and steel fiber contents on the corrosion performance of steel rebar embedded in UHPC. Constr. Build. Mater. 2020, 238, 117709. [Google Scholar] [CrossRef]

- El-Joukhadar, N.; Pantazopoulou, S.J. Effectiveness of UHPFRC cover in delaying bar corrosion. Constr. Build. Mater. 2021, 269, 121288. [Google Scholar] [CrossRef]

- Ma, F.; Deng, M.; Ma, Y.; Lue, H.; Yang, Y.; Sun, H. Experimental study on interior precast concrete beam-column connections with lap-spliced steel bars in field-cast RPC. Eng. Struct. 2021, 228, 111481. [Google Scholar] [CrossRef]

- Bae, B.I.; Choi, H.K.; Choi, C.S. Bond stress between conventional reinforcement and steel fibre reinforced reactive powder concrete. Constr. Build. Mater. 2016, 112, 825–835. [Google Scholar] [CrossRef]

- Holschemacher, K.; Weiße, D.; Klotz, S. Bond of reinforcement in ultra high strength concrete. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 375–387. [Google Scholar]

- Yoo, D.Y.; Shin, H.O.; Yang, J.M.; Yoon, Y.S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Fehling, E.; Lorenz, P.; Leutbecher, T. Experimental Investigations on Anchorage of Rebars in UHPC. In Proceedings of the Hipermat 2012 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012; pp. 533–540. [Google Scholar]

- Marchand, P.; Baby, F.; Khadour, A.; Battesti, T.; Rivillon, P.; Quiertant, M.; Nguyen, H.H.; Généreux, G.; Deveaud, J.P.; Simon, A. Bond behaviour of reinforcing bars in UHPFRC. Mater. Struct. 2016, 49, 1979–1995. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S. Factors affecting bond development between Ultra High Performance Concrete (UHPC) and steel bar reinforcement. Constr. Build. Mater. 2017, 144, 412–422. [Google Scholar] [CrossRef]

- Sturm, A.B.; Visintin, P. Local bond slip behavior of steel reinforcing bars embedded in ultra high performance fibre reinforced concrete. Struct. Concr. 2019, 20, 108–122. [Google Scholar] [CrossRef]

- Hu, A.X.; Liang, X.W.; Shi, Q.X. Bond Characteristics between High-Strength Bars and Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2020, 32, 1–14. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lim, A.R.; Kim, J.; Kim, J. Bond behaviour of GFRP bars in high-strength concrete: Bar diameter effect. Mag. Concr. Res. 2017, 69, 541–554. [Google Scholar] [CrossRef]

- Metelli, G.; Plizzari, G.A. Influence of the relative rib area on bond behaviour. Mag. Concr. Res. 2014, 66, 277–294. [Google Scholar] [CrossRef] [Green Version]

- Bamonte, P.F.; Gambarova, P.G. High-bond bars in NSC and HPC: Study on size effect and on the local bond stress-slip law. J. Struct. Eng. 2007, 133, 225–234. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Sener, S. Size effect in pull-out tests. ACI Mater. J. 1988, 85, 347–351. [Google Scholar]

- Seo, J.; Lee, G.C.; Liang, Z.; Dargush, G.F. Configuration and Size Effects on Bond Stress-Slip and Failure Modes of RC Connections. J. Eng. Mech. 2014, 140, 04014082. [Google Scholar] [CrossRef]

- Kook, K.H.; Shin, H.O.; Kwahk, I.J.; Yoon, Y.S. Bond Characteristics of Ultra High Performance Concrete. J. Korea Concr. Inst. 2010, 22, 753–760. [Google Scholar] [CrossRef] [Green Version]

- Lagier, F.; Massicotte, B.; Charron, J.P. Bond strength of tension lap splice specimens in UHPFRC. Constr. Build. Mater. 2015, 93, 84–94. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kwon, K.Y.; Park, J.J.; Yoon, Y.S. Local bond-slip response of GFRP rebar in ultra-high-performance fiber-reinforced concrete. Compos. Struct. 2015, 120, 53–64. [Google Scholar] [CrossRef]

- Yuan, J.; Graybeal, B.A. Bond Behavior of Reinforcing Steel in Ultra-High Performance Concrete; US Department of Transportation, Federal Hifhway Administartion: McLean, VA, USA, 2014.

- Firas, S.A.; Gilles, F.; Robert, L. Bond between carbon fibre-reinforced polymer (CFRP) bars and ultra high performance fibre reinforced concrete (UHPFRC): Experimental study. Constr. Build. Mater. 2011, 25, 479–485. [Google Scholar] [CrossRef]

- Lin, H.W.; Zhao, Y.X.; Ozbolt, J.; Feng, P.; Jiang, C.; Eligehausen, R. Analytical model for the bond stress-slip relationship of deformed bars in normal strength concrete. Constr. Build. Mater. 2019, 198, 570–586. [Google Scholar] [CrossRef]

- Delso, J.M.; Stavridis, A.; Shing, P. Bond Strength and Cyclic Bond Deterioration of Large-Diameter Bars. ACI Struct. J. 2013, 110, 659–670. [Google Scholar]

- Chao, S.-H.; Naaman, A.E.; Parra-Montesinos, G.J. Local Bond Stress-Slip Models for Reinforcing Bars and Prestressing Strands in High-Peformance Fiber-Reinforced Cement Composites. ACI Special Publication 2010, 272, 151–172. [Google Scholar]

- Wu, Y.F.; Zhao, X.M. Unified Bond Stress-Slip Model for Reinforced Concrete. J. Struct. Eng. 2013, 139, 1951–1962. [Google Scholar] [CrossRef]

- Xu, Y.L. Experimental Study of Anchorage Properties for Deformed Bars in Concrete; Tsinghua University: Beijing, China, 1990. (In Chinese) [Google Scholar]

- Zhao, W.P.; Zhu, B.R. Theoretical model for the bond-slip relationship between ribbed steel bars and confined concrete. Struct. Concr. 2018, 19, 548–558. [Google Scholar] [CrossRef]

- Lee, Y.H.; Joo, Y.T.; Lee, T.; Ha, D.H. Mechanical properties of constitutive parameters in steel–concrete interface. Eng. Struct. 2011, 33, 1277–1290. [Google Scholar] [CrossRef]

- Chao, S.-H. Bond Characterization Of Reinforcing Bars and Prestressing Strands in High Performance Fiber Reinforced Cementitious Composites under Monotonic and Cyclic Loading. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2005. [Google Scholar]

- CEB-FIP. Fib Model Code for Concrete Structures 2010; Comité Euro international du Béton/Federation Internationale de la Precontrainte: Lausanne, Switzerland, 2013. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- Harajli, M.H.; Hamad, B.S.; Rteil, A.A. Effect of confinement of bond strength between steel bars and concrete. ACI Struct. J. 2004, 101, 595–603. [Google Scholar]

- Huang, L.; Chi, Y.; Xu, L.; Chen, P.; Zhang, A. Local bond performance of rebar embedded in steel-polypropylene hybrid fiber reinforced concrete under monotonic and cyclic loading. Constr. Build. Mater. 2016, 103, 77–92. [Google Scholar] [CrossRef]

- Gao, X.L.; Li, N.K.; Ren, X.D. Analytic solution for the bond stress-slip relationship between rebar and concrete. Constr. Build. Mater. 2019, 197, 385–397. [Google Scholar] [CrossRef]

- Bravo, M.; Duarte, A.P.C.; de Brito, J.; Evangelista, L. Tests and Simulation of the Bond-Slip between Steel and Concrete with Recycled Aggregates from CDW. Buildings 2021, 11, 40. [Google Scholar] [CrossRef]

- Zhou, Z.D.; Qiao, P.Z. Bond behavior of epoxy-coated rebar in ultra-high performance concrete. Constr. Build. Mater. 2018, 182, 406–417. [Google Scholar] [CrossRef]

- GB/T 31387-2015; Reactive Powder Concrete. China Standard Press: Beijing, China, 2015.

- Li, W.; Huang, Z.; Hu, G.; Hui Duan, W.; Shah, S.P. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Constr. Build. Mater. 2017, 131, 767–774. [Google Scholar] [CrossRef]

- GB/T 1499.2-2018; Steel for the Reinforcement of Concrete-Part 2: Hot Rolled Ribbed Bars. China Standard Press: Beijing, China, 2018.

- RILEM TC. RC6: Bond Test for Reinforcement Steel: 2: Pull-Out Test, 1983. In RILEM Recommendations for the Testing and Use of Construction Materials; E & FN SPON: London, UK, 1994; pp. 218–220. [Google Scholar]

- Saikali, E.R. Bond Behaviour of Steel Reinforcing Bars Embedded in Ultra-High-Performance Steel Fiber Reinforced Concrete. Master’s Thesis, York University, Toronto, ON, Canada, 2019. [Google Scholar]

- ACI Committee 408. ACI 408R-03: Bond and Development of Straight Reinforcing Bars in Tension; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Yao, Y.; Zhang, H.; Zhang, X.; Ren, F.; Li, Y.; Yang, Z. Experimental, Analytical and Numerical Studies of Interfacial Bonding Properties between Silane-Coated Steel Fibres and Mortar. Buildings 2021, 11, 398. [Google Scholar] [CrossRef]

- Harajli, M.H.; Mabsout, M.E. Evaluation of Bond Strength of Steel Reinforcing Bars in Plain and Fiber-Reinforced Concrete. ACI Struct. J. 2002, 99, 509–517. [Google Scholar]

- Zhao, M.; Liu, G.; Liu, L.; Zhang, Y.; Shi, K.; Zhao, S. Bond of Ribbed Steel Bar in High-Performance Steel Fiber Reinforced Expanded-Shale Lightweight Concrete. Buildings 2021, 11, 582. [Google Scholar] [CrossRef]

- Qi, J.; Cheng, Z.; John Ma, Z.; Wang, J.; Liu, J. Bond strength of reinforcing bars in ultra-high performance concrete: Experimental study and fiber–matrix discrete model. Eng. Struct. 2021, 248, 113290. [Google Scholar] [CrossRef]

- Bonacci, J.F. Bar Yield Penetration in Monotonically Loaded Anchorages. J. Struct. Eng. 1994, 120, 965–986. [Google Scholar] [CrossRef]

- Ma, F.; Deng, M.; Fan, H.; Yang, Y.; Sun, H. Study on the lap-splice behavior of post-yield deformed steel bars in ultra high performance concrete. Constr. Build. Mater. 2020, 262, 120611. [Google Scholar] [CrossRef]

- Chu, S.H.; Kwan, A.K.H. A new method for pull out test of reinforcing bars in plain and fibre reinforced concrete. Eng. Struct. 2018, 164, 82–91. [Google Scholar] [CrossRef]

- Deng, Z.C.; Cheng, S.K. HRB 500 high-strength reinforced and reactive power concrete bond-slip constitutive relations research. Concrete 2015, 303, 25–31. (In Chinese) [Google Scholar]

- Jungwirth, J.; Muttoni, A. Structural behavior of tension members in Ultra High Performance Concrete. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004. [Google Scholar]

- Orangun, C.; Jirsa, J.O.; Breen, J. The Strength of Anchor Bars: A Reevaluation of Test Data on Development Length and Splices; University of Texas: Austin, Texas, USA, 1975. [Google Scholar]

- AS3600; Australian Standard for Concrete Structures. Standards Australia Limited: Sydney, Australia, 1994.

- Zuo, J.; Darwin, D. Bond slip of high relative rib area bars under cyclic loading. ACI Struct. J. 2000, 97, 331–334. [Google Scholar]

- Roy, M.; Hollmann, C.; Wille, K. Influence of volume fraction and orientation of fibers on the pullout behavior of reinforcement bar embedded in ultra high performance concrete. Constr. Build. Mater. 2017, 146, 582–593. [Google Scholar] [CrossRef]

- Wang, D.; Han, L.; Ju, Y.; Zeng, C.; Li, Z. Bond behavior between reinforcing bar and reactive powder concrete. Struct. Concr. 2021, 1–13. [Google Scholar] [CrossRef]

- Khaksefidi, S.; Ghalehnovi, M.; de Brito, J. Bond behaviour of high-strength steel rebars in normal (NSC) and ultra-high performance concrete (UHPC). J. Build. Eng. 2021, 33, 101592. [Google Scholar] [CrossRef]

- Amini Pishro, A.; Feng, X.; Ping, Y.; Dengshi, H.; Shirazinejad, R.S. Comprehensive equation of local bond stress between UHPC and reinforcing steel bars. Constr. Build. Mater. 2020, 262, 119942. [Google Scholar] [CrossRef]

| Design Variables | Variation Range |

|---|---|

| Compressive strength fc | UA, UB, UC, UD |

| Fiber volume content Vf | 1%, 2%, 3% |

| Fiber type | SFA, SFB, SFC, HFB |

| Cover thickness c | 1db, 2db, 3db, 4db, 5.75db |

| Rebar diameter db | 12 mm, 16 mm, 20 mm, 25 mm |

| Rebar yield strength fy | 422 MPa, 542 MPa, 680 MPa |

| Loading method | P, RP |

| Debonded length (The distance between the bonded part and the specimen loading surface) | 0, 2.5db, 5.25db |

| Test Variable | Specimen | fc (MPa) | ft (MPa) | c (mm) | db (mm) | Vf (%) | Fiber Type | Loading Method | Debonded Length (mm) | Rebar Yield Strength (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| Control group | UD-S02B-6D16C5-P5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Pull-out | 84 | 680 |

| Compressive strength | UA-S02B-6D16C5-P5 | 98.34 | 6.86 | 92 | 16 | 2 | SFB | Pull-out | 84 | 680 |

| UB-S02B-6D16C5-P5 | 109.64 | 7.24 | 92 | 16 | 2 | SFB | Pull-out | 84 | 680 | |

| UC-S02B-6D16C5-P5 | 116.10 | 8.50 | 92 | 16 | 2 | SFB | Pull-out | 84 | 680 | |

| Fiber volume content | UD-S01B-6D16C5-P5 | 125.18 | 8.24 | 92 | 16 | 1 | SFB | Pull-out | 84 | 680 |

| UD-S03B-6D16C5-P5 | 144.97 | 9.57 | 92 | 16 | 3 | SFB | Pull-out | 84 | 680 | |

| Fiber type | UD-S02A-6D16C5-P5 | 129.93 | 8.27 | 92 | 16 | 2 | SFA | Pull-out | 84 | 680 |

| UD-S02C-6D16C5-P5 | 141.89 | 9.72 | 92 | 16 | 2 | SFC | Pull-out | 84 | 680 | |

| UD-H02B-6D16C5-P5 | 133.82 | 9.05 | 92 | 16 | 2 | HFB | Pull-out | 84 | 680 | |

| Cover thickness | UD-S02B-6D16C1-P5 | 139.82 | 9.38 | 16 | 16 | 2 | SFB | Pull-out | 84 | 680 |

| UD-S02B-6D16C2-P5 | 139.82 | 9.38 | 32 | 16 | 2 | SFB | Pull-out | 84 | 680 | |

| UD-S02B-6D16C3-P5 | 139.82 | 9.38 | 48 | 16 | 2 | SFB | Pull-out | 84 | 680 | |

| UD-S02B-6D16C4-P5 | 139.82 | 9.38 | 64 | 16 | 2 | SFB | Pull-out | 84 | 680 | |

| Rebar diameter | UD-S02B-5D12C5-P5 | 139.82 | 9.38 | 92 | 12 | 2 | SFB | Pull-out | 84 | 520 |

| UD-S02B-5D16C5-P5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Pull-out | 84 | 542 | |

| UD-S02B-5D20C5-P5 | 139.82 | 9.38 | 92 | 20 | 2 | SFB | Pull-out | 84 | 539 | |

| UD-S02B-5D25C5-P5 | 139.82 | 9.38 | 92 | 25 | 2 | SFB | Pull-out | 84 | 534 | |

| Rebar yield strength | UD-S02B-4D16C5-P5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Pull-out | 84 | 422 |

| Loading method and debonded length | UD-S02B-6D16C5-P0 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Pull-out | 0 | 680 |

| UD-S02B-6D16C5-P2.5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Pull-out | 40 | 680 | |

| UD-S02B-6D16C5-RP0 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Revised pull-out | 0 | 680 | |

| UD-S02B-6D16C5-RP2.5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Revised pull-out | 40 | 680 | |

| UD-S02B-6D16C5-RP5 | 139.82 | 9.38 | 92 | 16 | 2 | SFB | Revised pull-out | 84 | 680 |

| Cement | Quartz Sand | Silica Flour | Silica Fume | Fly Ash | Water/Binder Ratio |

|---|---|---|---|---|---|

| 1.0 | 1.1 | 0.3 | 0.25 | 0.1 | 0.18 |

| Steel Fiber ID | Form | Lf (mm) | df (mm) | Lf/df | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| SFA | Straight | 6 | 0.2 | 30 | ≥2850 |

| SFB | Straight | 13 | 0.2 | 65 | ≥2850 |

| SFC | Straight | 20 | 0.2 | 100 | ≥2850 |

| HFB | Hooked | 13 | 0.2 | 65 | ≥2850 |

| Type of Steel Bars | HRB400-D16 | HRB500-D12 | HRB500-D16 | HRB500-D20 | HRB500-D25 | HRB600-D16 |

|---|---|---|---|---|---|---|

| Nominal diameter db (mm) | 16 | 12 | 16 | 20 | 25 | 16 |

| Core diameter d1 (mm) | 15.4 | 11.5 | 15.4 | 19.3 | 24.2 | 15.4 |

| Average rib depth h1 (mm) | 1.5 | 1.0 | 1.5 | 1.7 | 2.0 | 1.5 |

| Rib inclination β (°) | 60.5 | 60 | 60.5 | 65.2 | 76.3 | 60.5 |

| Rib spacing C (mm) | 10 | 7.9 | 10.0 | 11.0 | 12.5 | 10 |

| Yield strength fy (MPa) | 422 | 520 | 542 | 539 | 534 | 680 |

| Ultimate strength fu (MPa) | 583 | 695 | 716 | 714 | 708 | 861 |

| Specimen | τu (MPa) | Mean | su (mm) | Mean | Ap (MPa.mm) | Mean | A80 (MPa.mm) | Mean | A50 (MPa.mm) | Mean | Failure Modes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UD-S02B-6D16C5-P5-1 | 61.36 | 63.46 | 0.52 | 0.56 | 23.39 | 29.45 | 141.02 | 138.26 | 238.40 | 240.72 | PO |

| UD-S02B-6D16C5-P5-2 | 61.72 | 0.61 | 34.58 | 143.09 | 257.13 | PO | |||||

| UD-S02B-6D16C5-P5-3 | 67.31 | 0.54 | 30.37 | 130.66 | 226.65 | PO | |||||

| UA-S02B-6D16C5-P5-1 | 52.72 | 50.45 | 0.55 | 0.53 | 20.63 | 23.08 | 109.46 | 100.47 | 214.63 | 192.66 | PO |

| UA-S02B-6D16C5-P5-2 | 51.17 | 0.42 | 19.43 | 89.54 | 183.30 | PO | |||||

| UA-S02B-6D16C5-P5-3 | 47.44 | 0.61 | 29.19 | 102.41 | 180.04 | PO | |||||

| UB-S02B-6D16C5-P5-1 | 60.82 | 57.21 | 0.57 | 0.56 | 29.29 | 27.07 | 122.92 | 131.42 | 213.38 | 236.70 | PO |

| UB-S02B-6D16C5-P5-2 | 59.61 | 0.53 | 27.56 | 131.70 | 244.02 | PO | |||||

| UB-S02B-6D16C5-P5-3 | 51.20 | 0.57 | 24.37 | 139.63 | 252.70 | PO | |||||

| UC-S02B-6D16C5-P5-1 | 60.24 | 61.12 | 0.55 | 0.54 | 28.12 | 27.71 | 129.25 | 132.21 | 212.37 | 231.20 | PO |

| UC-S02B-6D16C5-P5-2 | 64.80 | 0.53 | 27.39 | 128.37 | 230.00 | PO | |||||

| UC-S02B-6D16C5-P5-3 | 58.31 | 0.53 | 27.63 | 139.01 | 251.23 | PO | |||||

| UD-S01B-6D16C5-P5-1 | 59.48 | 58.45 | 0.60 | 0.56 | 32.86 | 29.07 | 135.03 | 138.05 | 223.88 | 229.08 | PO |

| UD-S01B-6D16C5-P5-2 | 58.18 | 0.47 | 23.36 | 148.28 | 249.11 | PO | |||||

| UD-S01B-6D16C5-P5-3 | 57.69 | 0.62 | 30.99 | 130.85 | 214.24 | PO | |||||

| UD-S03B-6D16C5-P5-1 | 74.57 | 71.71 | 0.58 | 0.55 | 38.48 | 34.25 | 149.06 | 141.09 | 294.69 | 273.54 | PO |

| UD-S03B-6D16C5-P5-2 | 67.92 | 0.48 | 26.18 | 143.51 | 274.47 | PO | |||||

| UD-S03B-6D16C5-P5-3 | 72.63 | 0.60 | 38.09 | 130.70 | 251.46 | PO | |||||

| UD-S02A-6D16C5-P5-1 | 60.37 | 58.00 | 0.56 | 0.58 | 27.46 | 28.82 | 135.71 | 136.43 | 226.62 | 220.71 | PO |

| UD-S02A-6D16C5-P5-2 | 58.85 | 0.68 | 35.87 | 127.27 | 202.79 | PO | |||||

| UD-S02A-6D16C5-P5-3 | 54.78 | 0.49 | 23.13 | 146.29 | 232.73 | PO | |||||

| UD-S02C-6D16C5-P5-1 | 63.23 | 66.97 | 0.58 | 0.57 | 33.67 | 30.48 | 142.19 | 142.54 | 245.16 | 264.08 | PO |

| UD-S02C-6D16C5-P5-2 | 67.67 | 0.50 | 23.52 | 139.04 | 261.71 | PO | |||||

| UD-S02C-6D16C5-P5-3 | 70.00 | 0.62 | 34.25 | 146.38 | 285.38 | PO | |||||

| UD-H02B-6D16C5-P5-1 | 62.74 | 63.47 | 0.64 | 0.51 | 34.80 | 27.98 | 138.50 | 133.05 | 283.90 | 258.65 | PO |

| UD-H02B-6D16C5-P5-2 | 63.33 | 0.46 | 25.62 | 129.01 | 243.27 | PO | |||||

| UD-H02B-6D16C5-P5-3 | 64.35 | 0.42 | 23.51 | 131.64 | 248.78 | PO | |||||

| UD-S02B-6D16C1-P5-1 | 49.63 | 50.32 | 0.40 | 0.39 | 17.29 | 17.01 | 102.03 | 94.02 | 194.66 | 179.02 | PO |

| UD-S02B-6D16C1-P5-2 | 54.46 | 0.43 | 19.42 | 85.17 | 157.38 | PO | |||||

| UD-S02B-6D16C1-P5-3 | 46.86 | 0.35 | 14.31 | 94.85 | 185.02 | PO | |||||

| UD-S02B-6D16C2-P5-1 | 59.79 | 59.16 | 0.40 | 0.44 | 20.55 | 22.61 | 98.98 | 109.40 | 187.73 | 197.50 | PO |

| UD-S02B-6D16C2-P5-2 | 58.54 | 0.48 | 23.67 | 121.03 | 204.28 | PO | |||||

| UD-S02B-6D16C2-P5-3 | 59.14 | 0.43 | 23.61 | 108.20 | 200.50 | PO | |||||

| UD-S02B-6D16C3-P5-1 | 60.15 | 60.73 | 0.39 | 0.46 | 20.09 | 22.94 | 120.69 | 112.88 | 210.43 | 206.13 | PO |

| UD-S02B-6D16C3-P5-2 | 61.36 | 0.43 | 20.71 | 106.01 | 216.18 | PO | |||||

| UD-S02B-6D16C3-P5-3 | 60.68 | 0.55 | 28.01 | 111.95 | 191.77 | PO | |||||

| UD-S02B-6D16C4-P5-1 | 62.66 | 63.16 | 0.45 | 0.52 | 22.39 | 28.72 | 107.15 | 115.87 | 225.69 | 218.61 | PO |

| UD-S02B-6D16C4-P5-2 | 67.71 | 0.60 | 36.54 | 128.52 | 216.01 | PO | |||||

| UD-S02B-6D16C4-P5-3 | 59.12 | 0.50 | 27.22 | 111.92 | 214.11 | PO | |||||

| UD-S02B-5D12C5-P5-1 | 62.85 | 59.59 | 0.48 | 0.51 | 21.10 | 23.26 | 123.47 | 128.19 | 204.27 | 216.46 | PO |

| UD-S02B-5D12C5-P5-2 | 60.54 | 0.56 | 29.48 | 126.43 | 226.02 | PO | |||||

| UD-S02B-5D12C5-P5-3 | 55.38 | 0.48 | 19.20 | 134.68 | 219.10 | PO | |||||

| UD-S02B-5D16C5-P5-1 | 59.42 | 60.42 | 0.54 | 0.54 | 26.16 | 27.16 | 135.51 | 137.82 | 268.31 | 270.49 | PO |

| UD-S02B-5D16C5-P5-2 | 58.51 | 0.54 | 26.43 | 130.40 | 262.15 | PO | |||||

| UD-S02B-5D16C5-P5-3 | 63.33 | 0.55 | 28.88 | 147.54 | 281.00 | PO | |||||

| UD-S02B-5D20C5-P5-1 | 59.78 | 58.02 | 1.31 | 1.32 | 70.97 | 70.28 | 253.84 | 256.72 | 394.06 | 399.93 | PO |

| UD-S02B-5D20C5-P5-2 | 57.25 | 1.34 | 69.70 | 261.77 | 404.21 | PO | |||||

| UD-S02B-5D20C5-P5-3 | 57.02 | 1.31 | 70.18 | 254.56 | 401.52 | PO | |||||

| UD-S02B-5D25C5-P5-1 | 56.06 | 59.31 | 1.80 | 1.92 | 96.62 | 103.04 | 286.18 | 276.36 | 478.71 | 458.97 | PO |

| UD-S02B-5D25C5-P5-2 | 60.41 | 1.98 | 103.95 | 269.87 | 441.41 | PO | |||||

| UD-S02B-5D25C5-P5-3 | 61.46 | 2.00 | 108.55 | 273.02 | 456.78 | PO | |||||

| UD-S02B-4D16C5-P5-1 | 57.78 | 56.85 | 0.52 | 0.54 | 24.71 | 25.35 | 165.72 | 167.97 | 295.26 | 293.59 | PO |

| UD-S02B-4D16C5-P5-2 | 55.58 | 0.65 | 30.65 | 162.79 | 277.03 | PO | |||||

| UD-S02B-4D16C5-P5-3 | 57.19 | 0.44 | 20.69 | 175.39 | 308.49 | PO | |||||

| UD-S02B-6D16C5-P0-1 | 45.04 | 43.95 | 0.47 | 0.47 | 15.30 | 15.78 | 33.14 | 44.36 | 62.03 | 79.73 | SP + PO |

| UD-S02B-6D16C5-P0-2 | 47.73 | 0.43 | 16.48 | 57.12 | 99.32 | SP + PO | |||||

| UD-S02B-6D16C5-P0-3 | 39.07 | 0.52 | 15.57 | 42.83 | 77.86 | SP + PO | |||||

| UD-S02B-6D16C5-P2.5-1 | 54.10 | 57.40 | 0.61 | 0.51 | 21.54 | 24.30 | 94.49 | 105.60 | 170.10 | 186.90 | PO |

| UD-S02B-6D16C5-P2.5-2 | 57.37 | 0.48 | 27.47 | 115.83 | 208.87 | PO | |||||

| UD-S02B-6D16C5-P2.5-3 | 60.72 | 0.43 | 23.91 | 106.47 | 181.73 | PO | |||||

| UD-S02B-6D16C5-RP0-1 | 36.88 | 33.91 | 0.44 | 0.45 | 13.15 | 12.77 | 49.55 | 39.65 | 92.41 | 77.04 | Cone |

| UD-S02B-6D16C5-RP0-2 | 32.26 | 0.52 | 14.30 | 40.67 | 73.01 | Cone | |||||

| UD-S02B-6D16C5-RP0-3 | 32.58 | 0.40 | 10.86 | 28.73 | 65.70 | Cone | |||||

| UD-S02B-6D16C5-RP2.5-1 | 49.50 | 54.15 | 0.55 | 0.55 | 25.39 | 23.78 | 94.94 | 94.00 | 136.41 | 158.96 | PO |

| UD-S02B-6D16C5-RP2.5-2 | 55.28 | 0.57 | 19.37 | 86.55 | 166.65 | PO | |||||

| UD-S02B-6D16C5-RP2.5-3 | 57.67 | 0.52 | 26.58 | 100.52 | 173.82 | PO | |||||

| UD-S02B-6D16C5-RP5-1 | 64.17 | 63.12 | 0.44 | 0.51 | 22.16 | 26.62 | 111.18 | 123.69 | 177.08 | 202.12 | PO |

| UD-S02B-6D16C5-RP5-2 | 60.73 | 0.60 | 30.71 | 125.76 | 211.36 | PO | |||||

| UD-S02B-6D16C5-RP5-3 | 64.45 | 0.51 | 27.00 | 134.13 | 217.92 | PO |

| Type | Reference | Equations |

|---|---|---|

| NC | Orangun et al. [57] | |

| AS3600 [58] | ||

| CEB-FIP [35] | ||

| Zuo and Darwin [59] | ||

| UHPC | Marchand [13] | |

| Roy [60] | ||

| Sturm [15] |

| Coefficient | Mean | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| sr | 0.112 | 0.034 | 0.301 |

| α | 0.805 | 0.178 | 0.221 |

| β | 0.157 | 0.029 | 0.183 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, R.; Huang, Y.; Xu, Z. Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete. Buildings 2022, 12, 460. https://doi.org/10.3390/buildings12040460

Liang R, Huang Y, Xu Z. Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete. Buildings. 2022; 12(4):460. https://doi.org/10.3390/buildings12040460

Chicago/Turabian StyleLiang, Rui, Yuan Huang, and Zhenming Xu. 2022. "Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete" Buildings 12, no. 4: 460. https://doi.org/10.3390/buildings12040460

APA StyleLiang, R., Huang, Y., & Xu, Z. (2022). Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete. Buildings, 12(4), 460. https://doi.org/10.3390/buildings12040460