An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Magnesium Ammonium Phosphate Cement (MAPC)

- Manufactured Limestone Sand

2.2. Preparation of MAPC Mortar

2.3. Properties of MAPC Mortar with Limestone Sand

- The Properties of Fresh Mortar

- Mechanical Strength

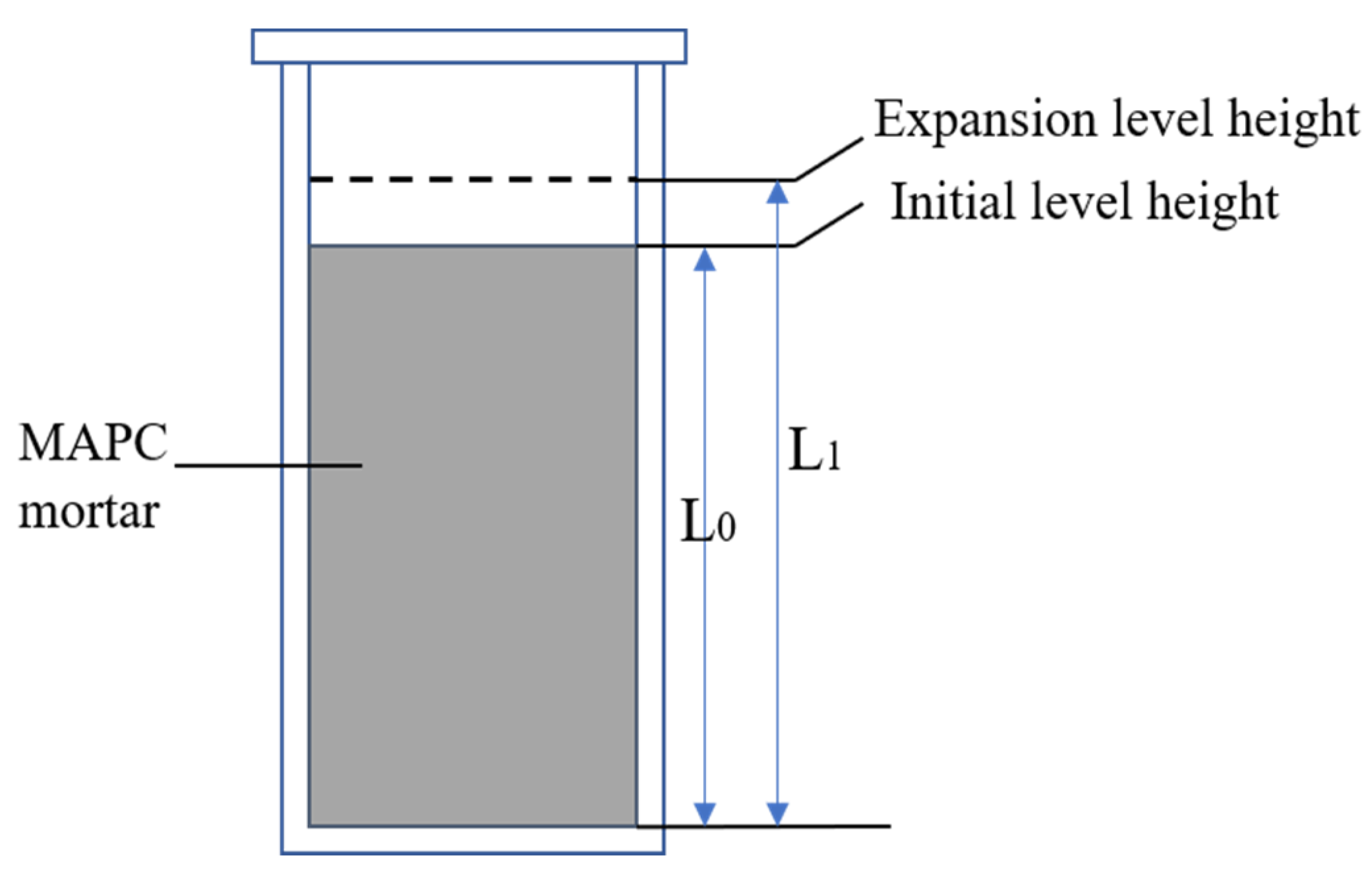

- Volume Stability

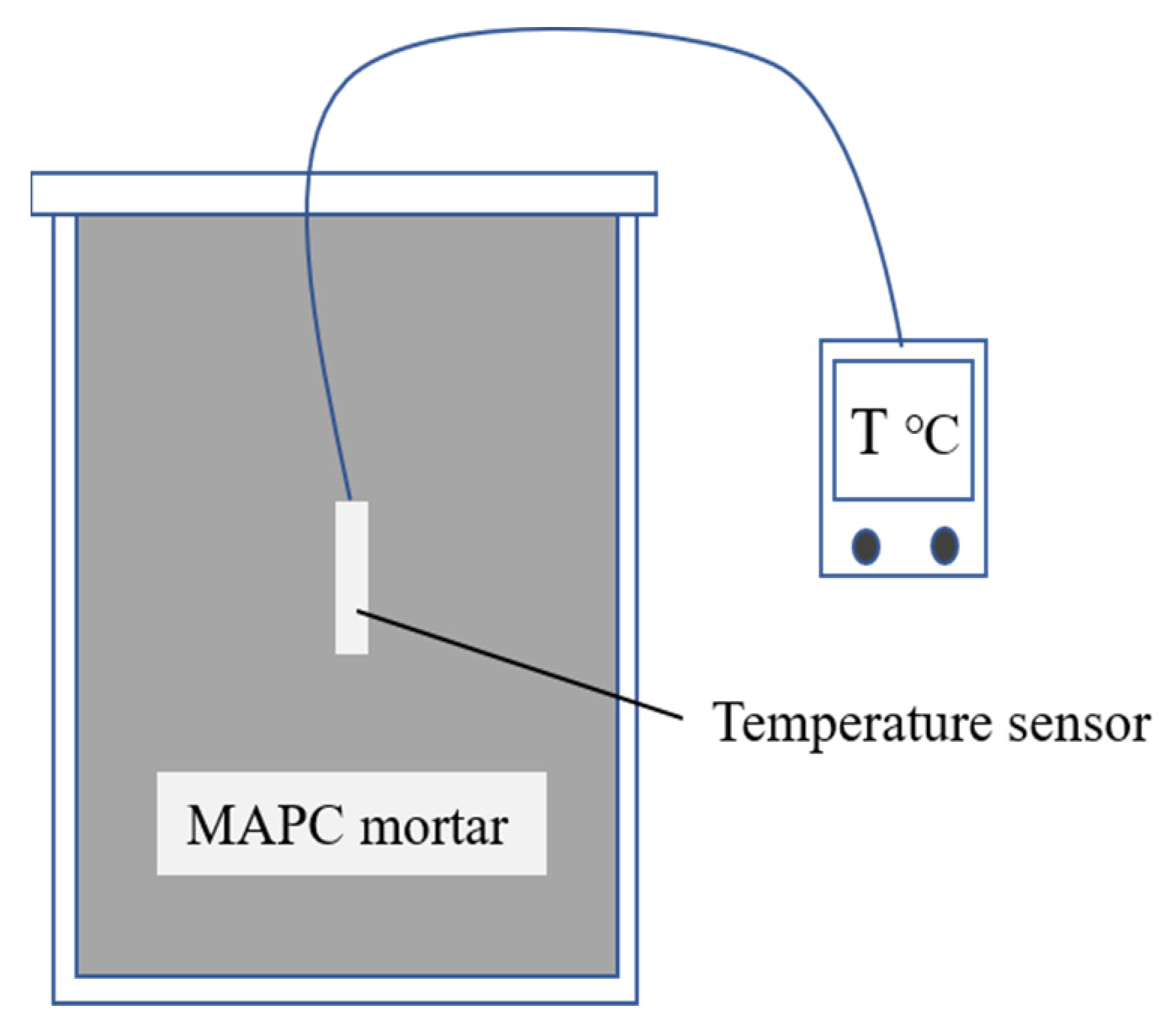

- Hydration Temperature

- Microstructure Analysis

3. Results and Discission

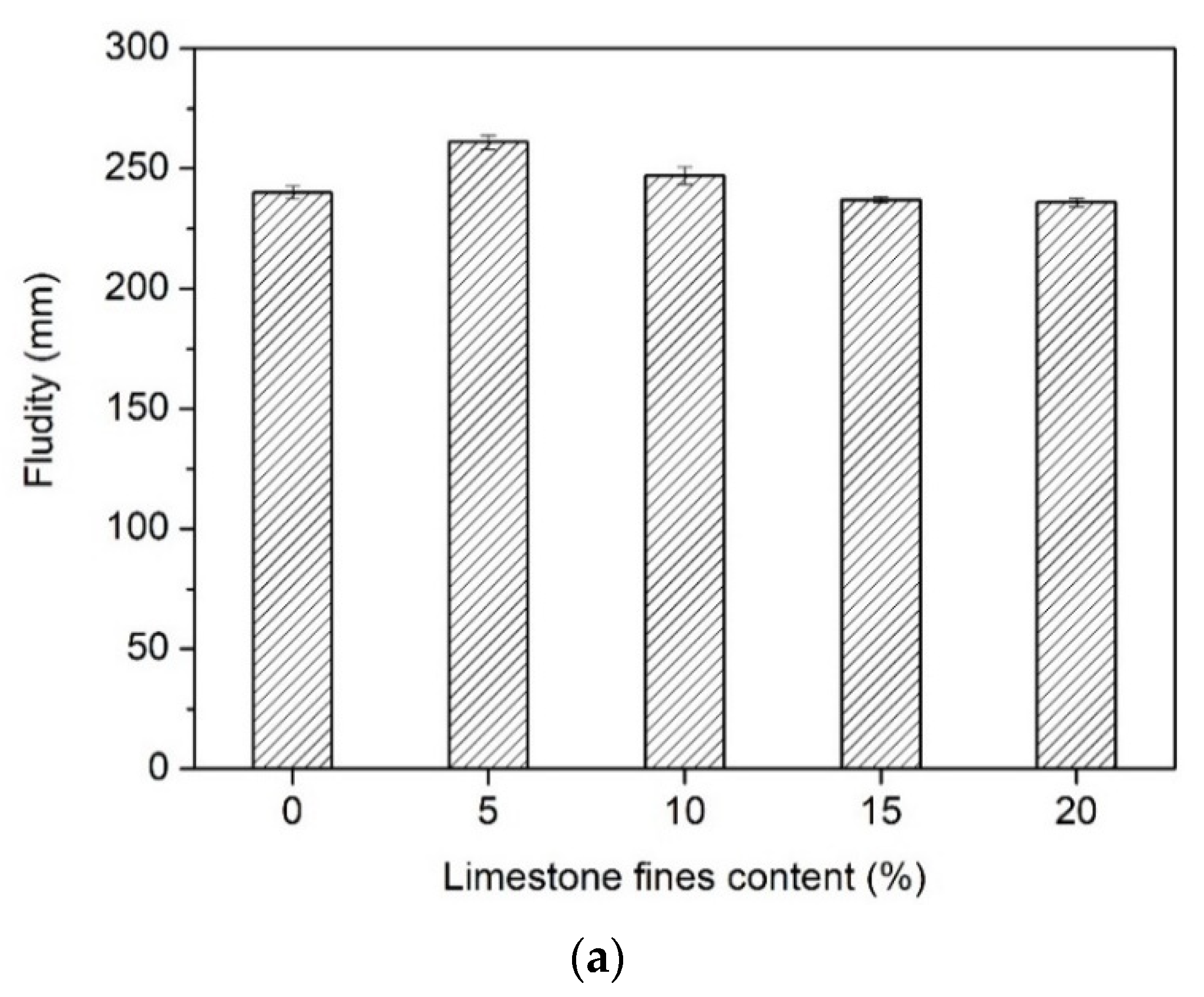

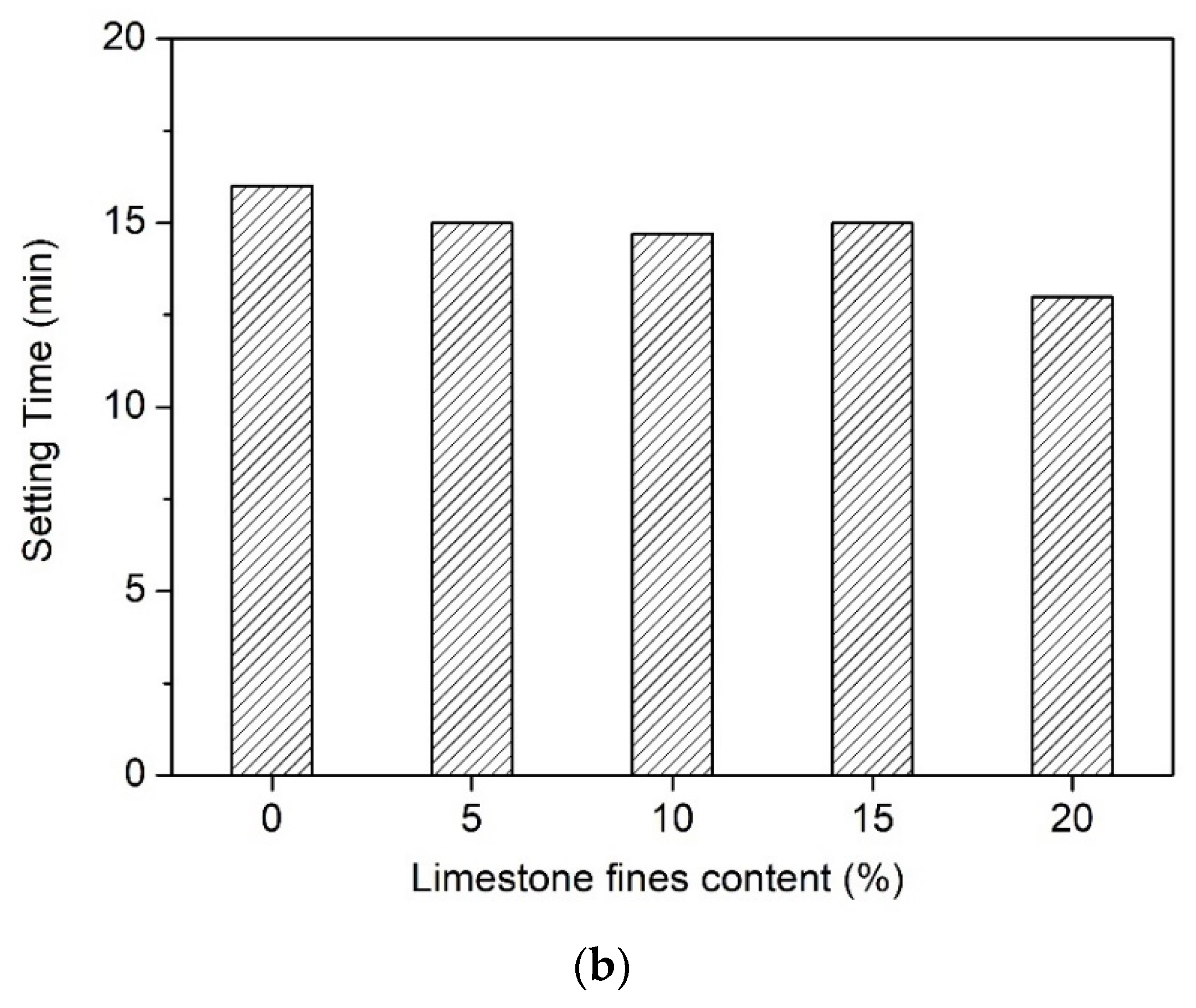

3.1. Properties of Fresh MAPC Mortar

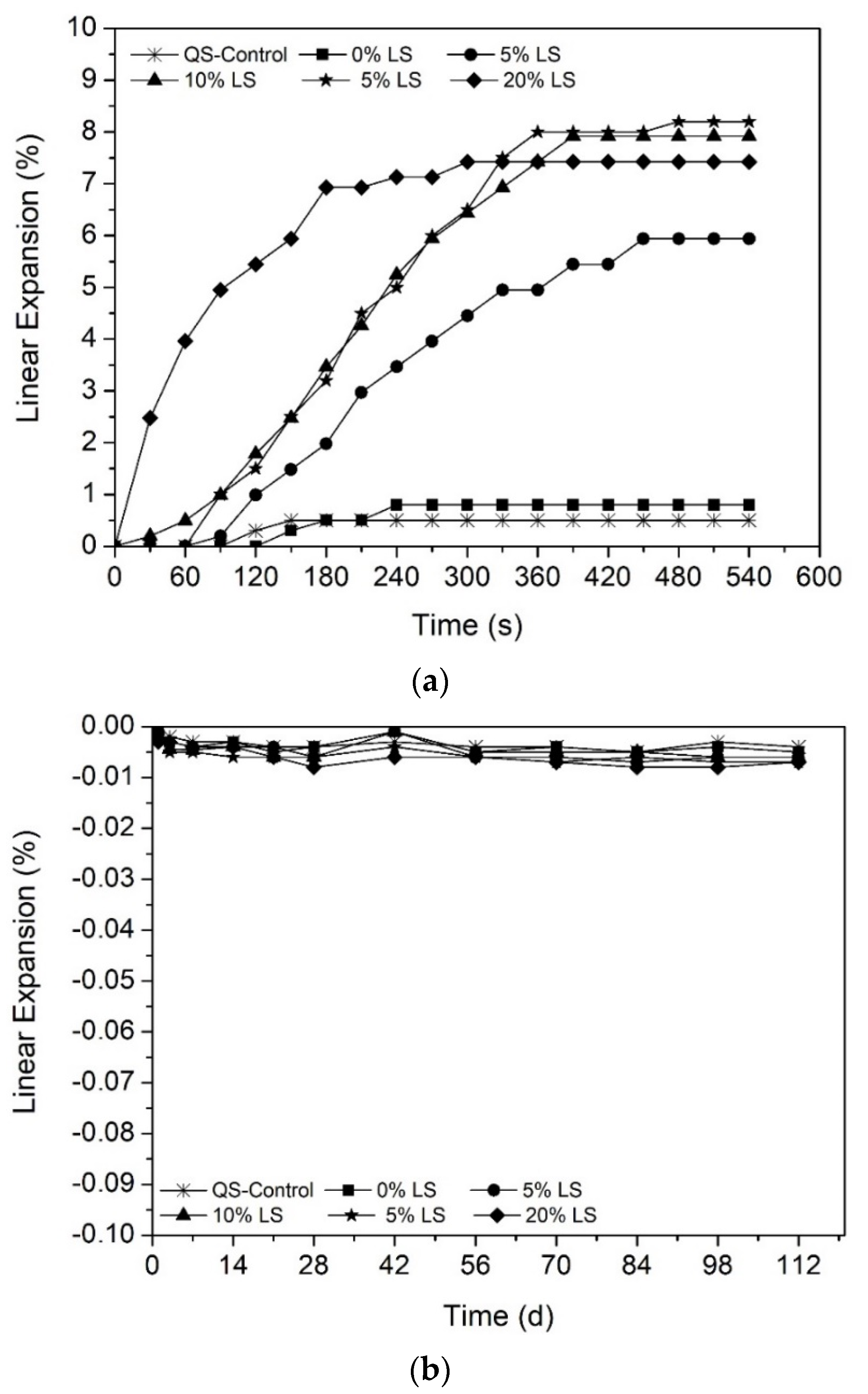

3.2. Volume Stability of MAPC Mortar with Limestone Sand

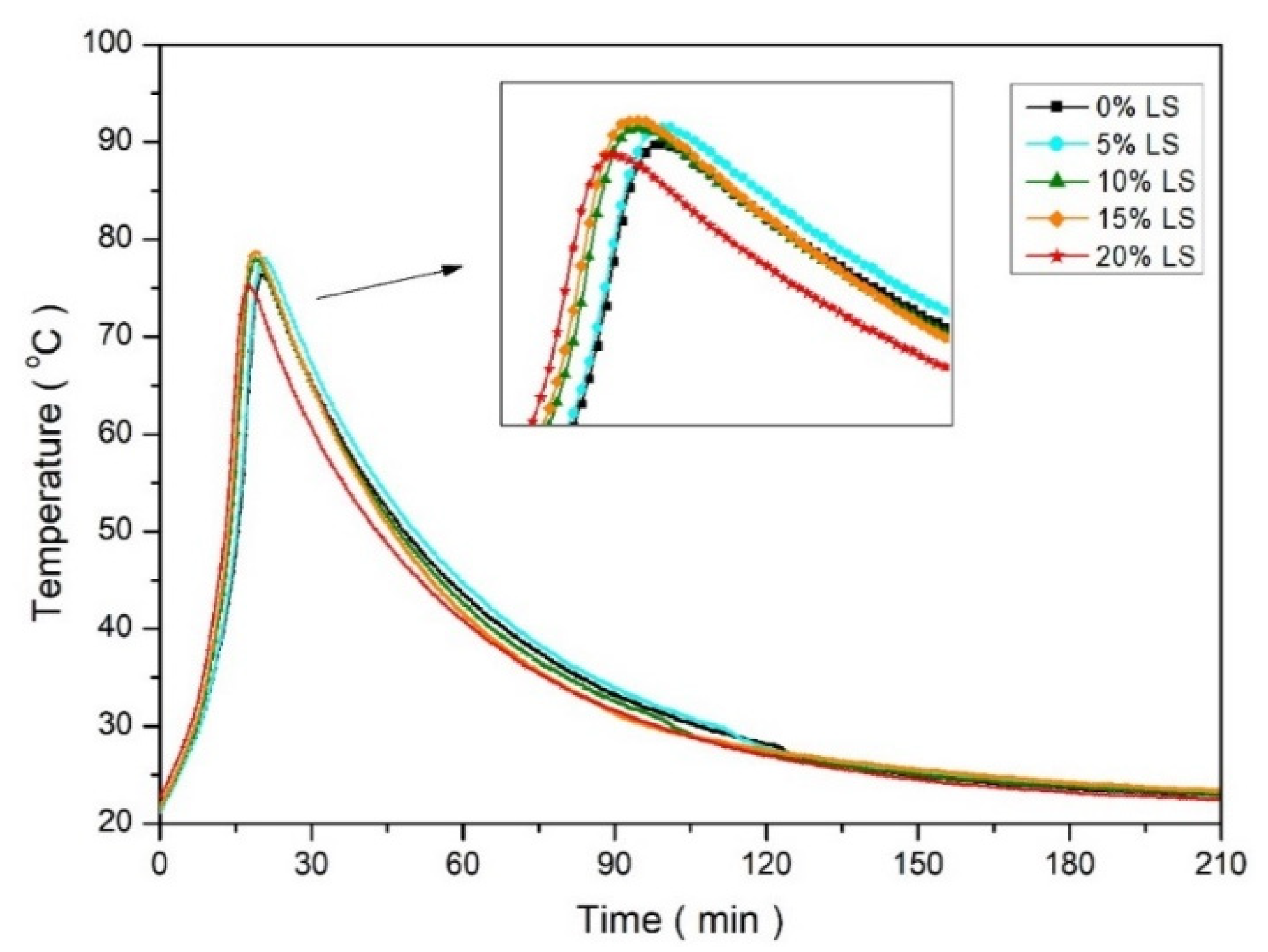

3.3. Hydration Temperature of MAPC

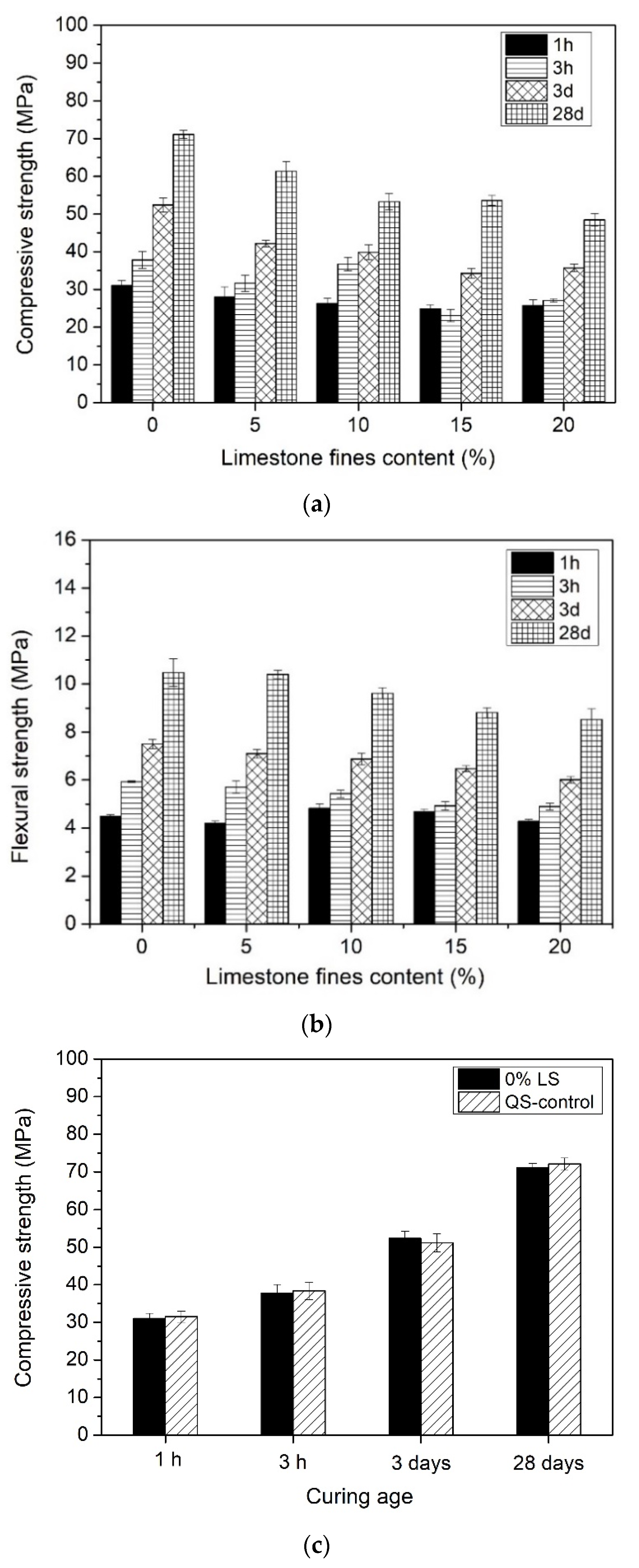

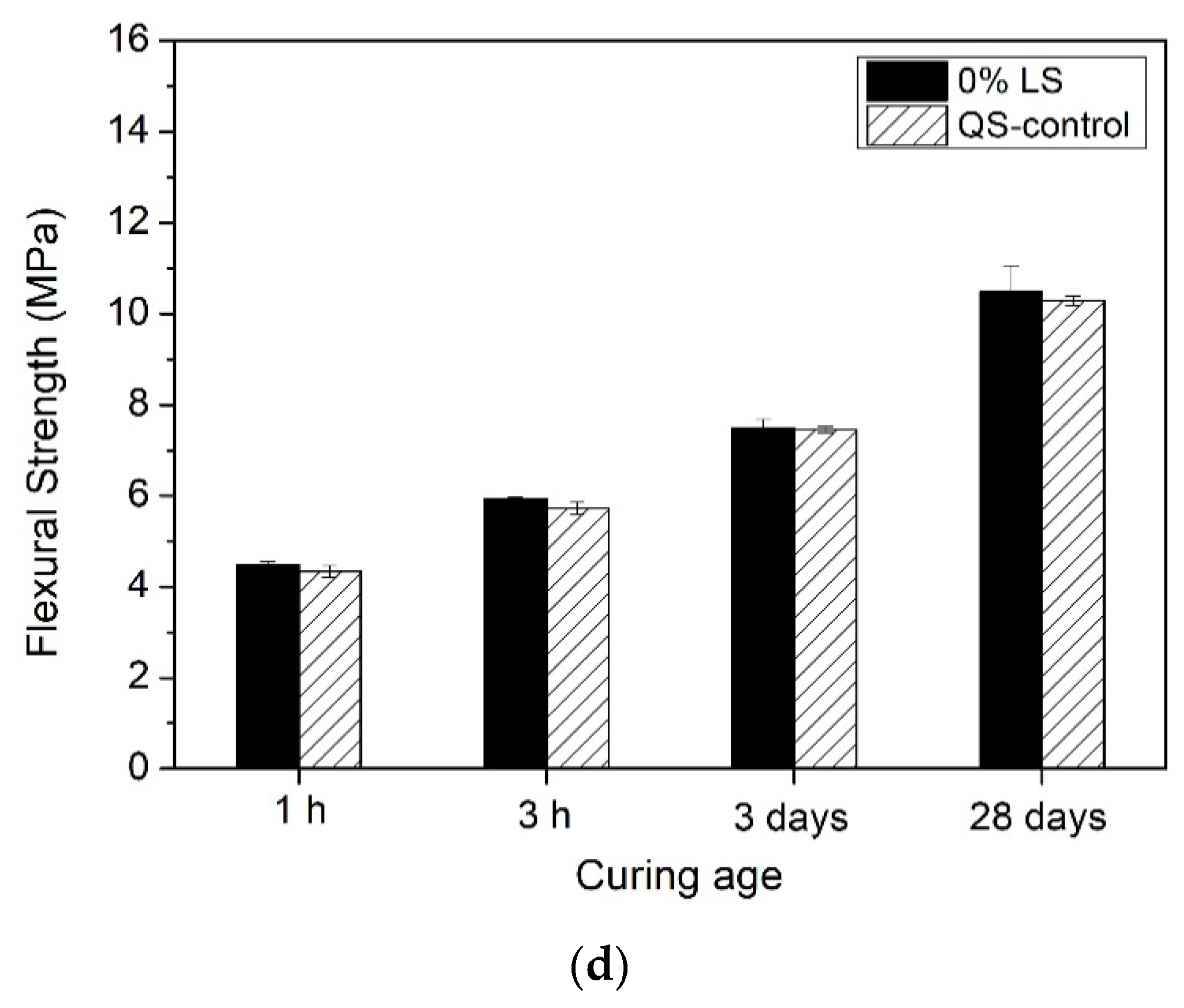

3.4. Mechanical Strength of MAPC

3.5. Microstructure Analysis

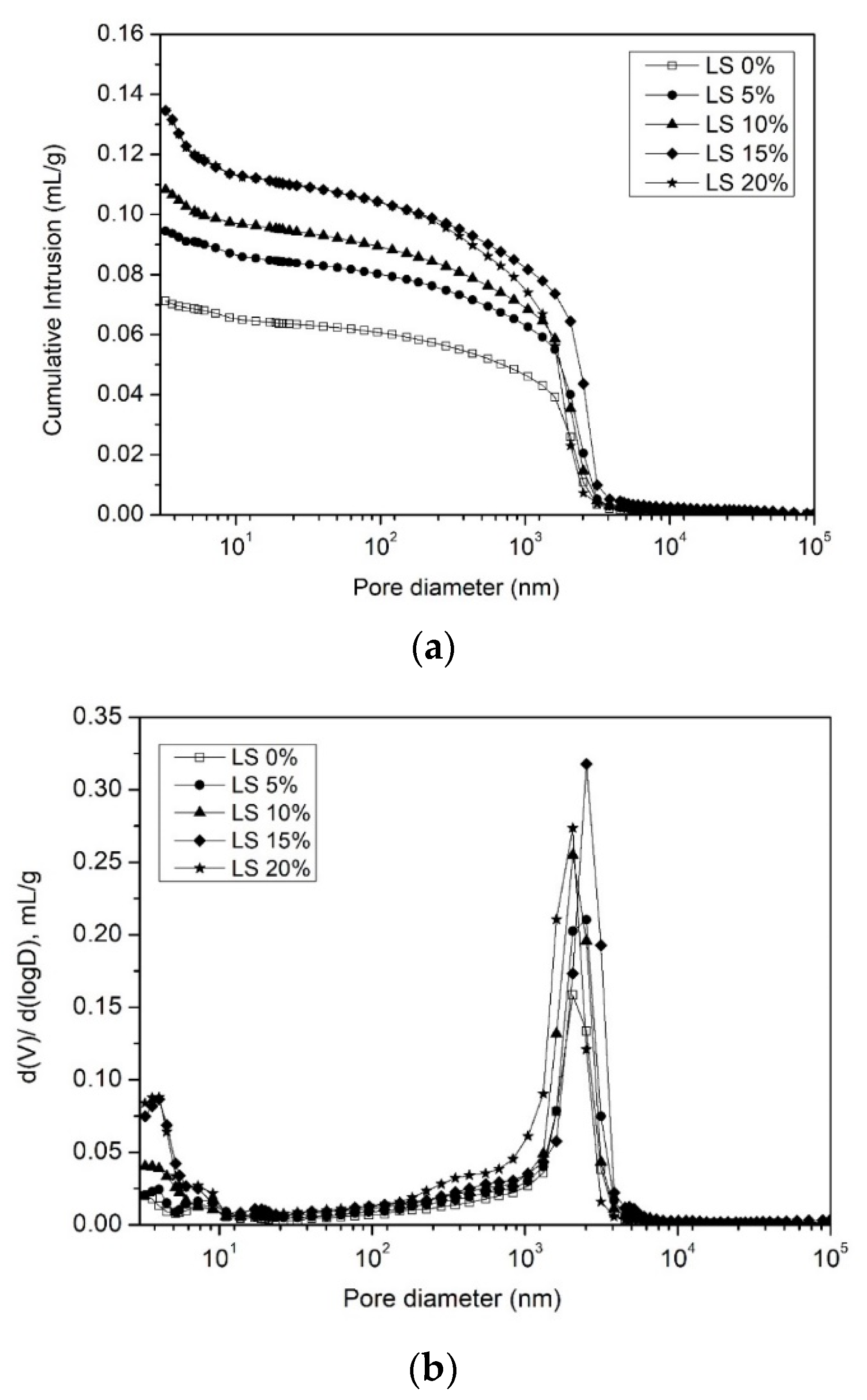

- MIP

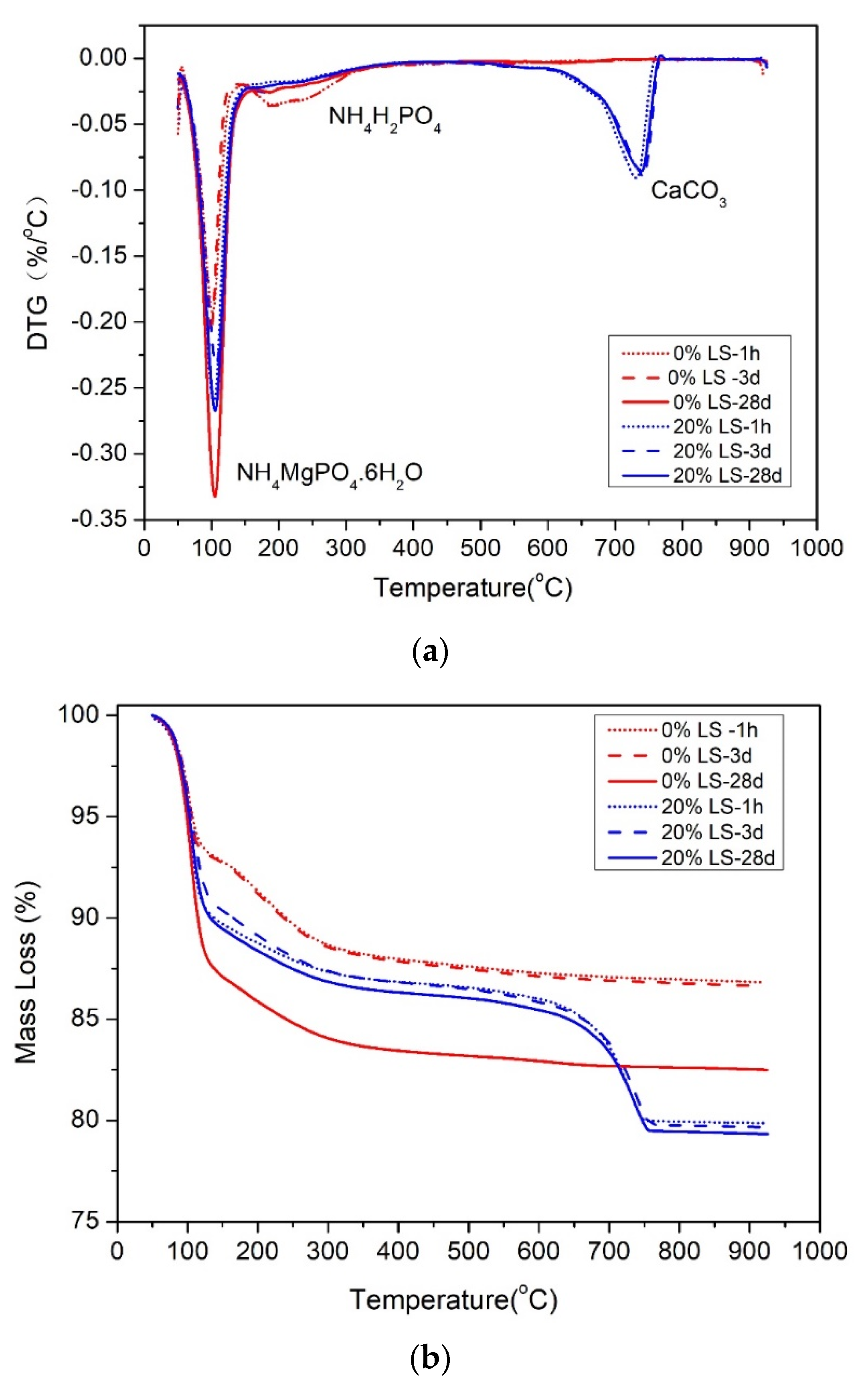

- TGA

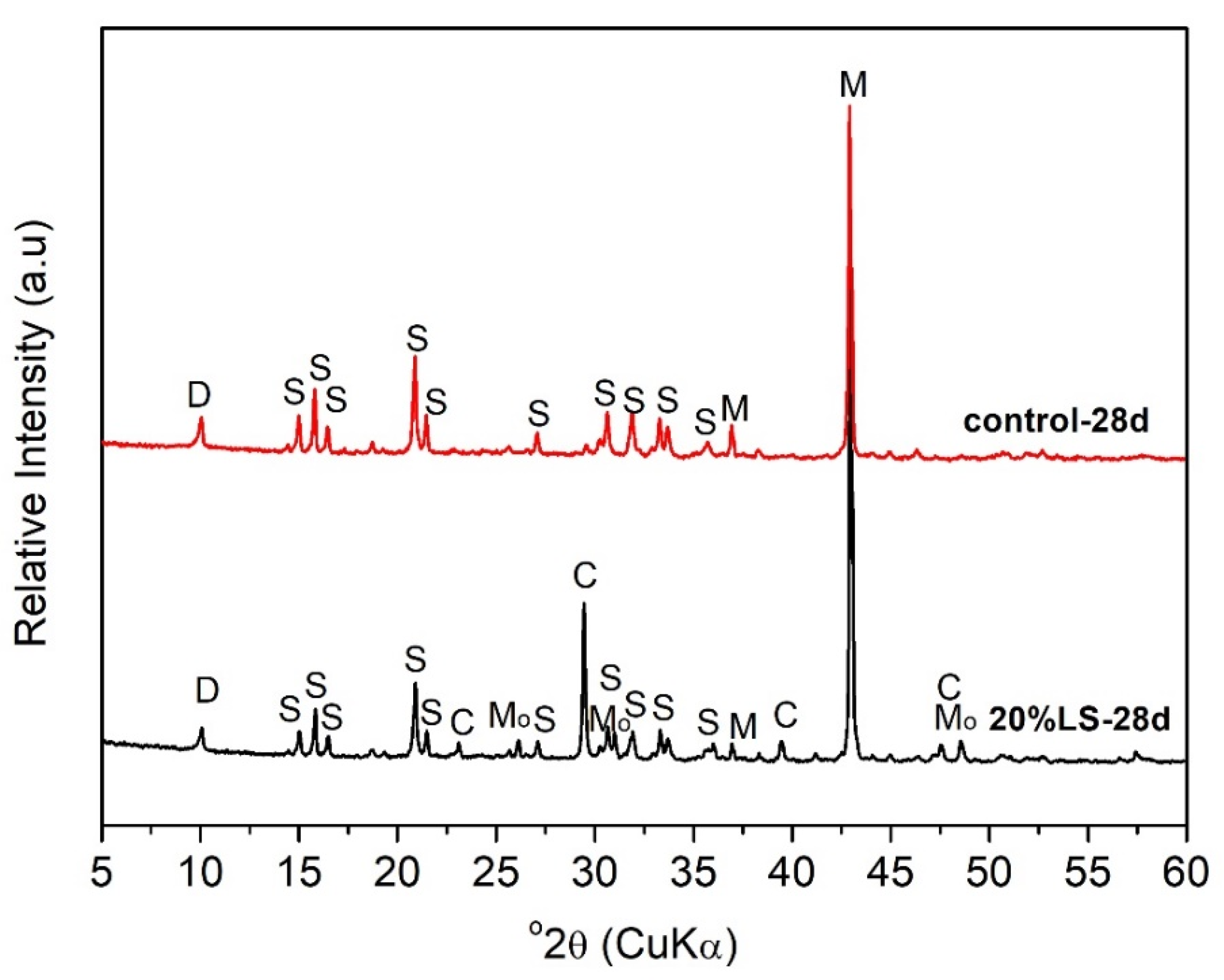

- XRD

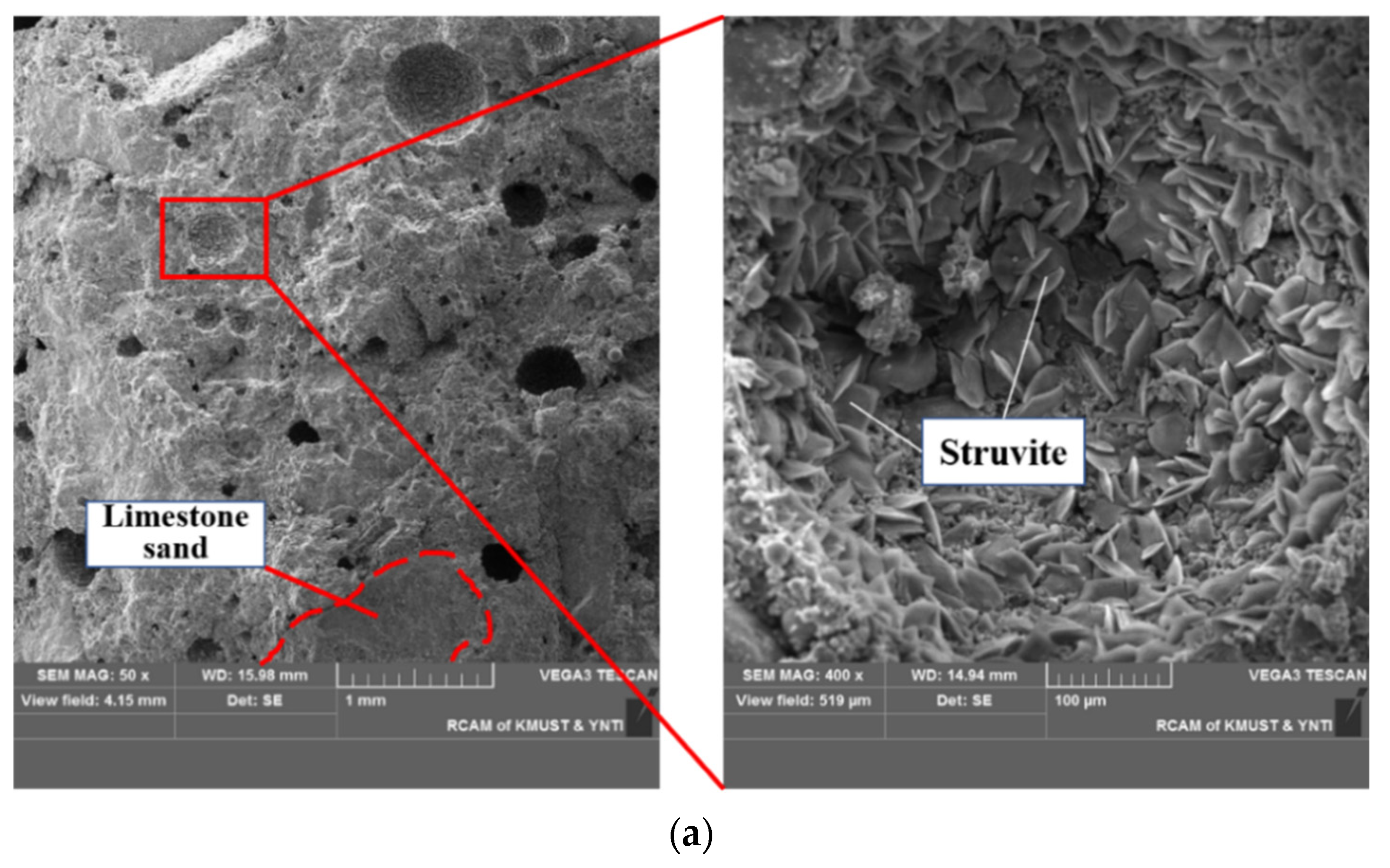

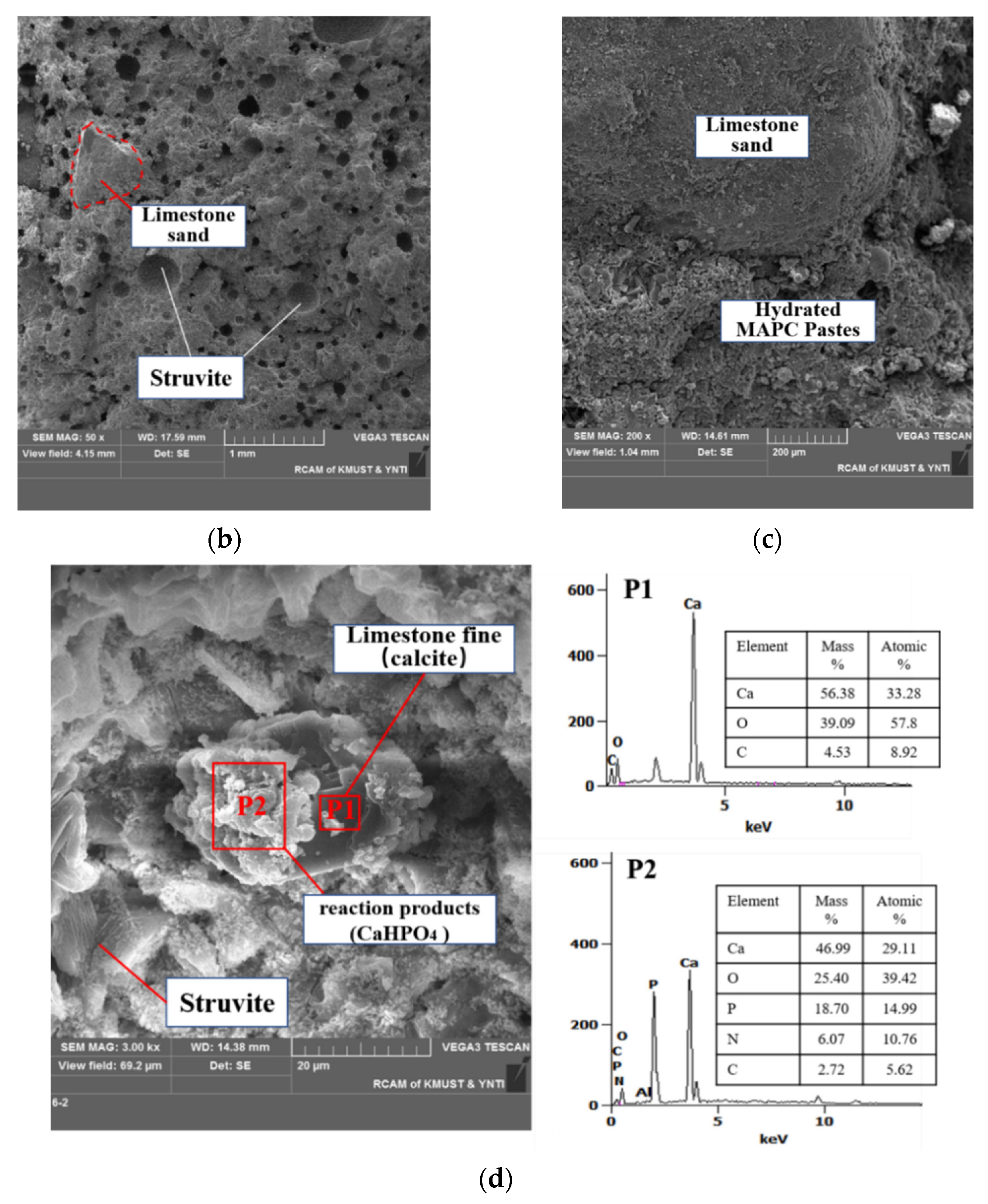

- SEM

4. Conclusions

- Limestone fines are the key factor that influences the properties of MAPC mortar. The MAPC mortar prepared by manufactured sands without limestone fines showed comparable properties with the one prepared by quartz sands.

- The limestone fines (<0.075mm) of manufactured sands caused an intense bubbling phenomenon and significant volume expansion in the system of MAPC before hardening. The higher the content of limestone fines, the larger the volume expansion. It is noted that the volume expansion occurred only before hardening while the volume of hardened MAPC mortar remained stable in the long term.

- As the content of limestone fines increased, the MAPC mortar showed decreased fluidity. The limestone fines also showed an acceleration effect on the hydration of MAPC mortar at early age. As a result, the setting time of MAPC mortar became shorter, especially with a higher content (>15%) of limestone fines. TGA results confirmed that more struvite was generated in MAPC mortar with limestone fines.

- The limestone fines showed significant negative effects on the mechanical strength of MAPC mortar, especially for the compressive strength. As the content of limestone fines increased from 0 to 20%, the compressive strength at 28 days decreased by 31.8%. By contrast, the development of flexural strength was less affected by the limestone fines.

- According to MIP results, the incorporation of limestone fines led to increased porosity of MAPC mortar due to the bubbling reaction, thus decreasing the mechanical strength.

- Based on the microstructure analysis, including TGA, XRD, and SEM, it is inferred that the bubbling phenomenon was mainly caused by the reaction between limestone fines (CaCO3) and NH4H2PO4 (ADP), which generated NH3 and CO2 gases. This reaction mainly occurred during a short period before setting. Most limestone fines were not involved in the hydration process of MAPC and remained unreactive in the hardened MAPC matrix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Walling, S.A.; Provis, J.L. Magnesia-Based Cements: A Journey of 150 Years, and Cements for the Future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Long, X.; Qu, W.; Li, L.; Jiang, H.; Zhong, Z. Influence of sulfuric acid corrosion on concrete stress-strain relationship under uniaxial compression. Measurement 2021, 187, 110318. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.X.; Yang, H.M.; Wang, Y.; Tang, S.W. Comparison of FLY ASH, PVA Fiber, MgO and Shrinkage-reducing Admixture on the Frost Resistance of Face Slab Concrete via Pore Structural and Fractal Analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Qian, J. 4—Magnesium Phosphate Cement; Shand, M.A., Al-Tabbaa, A., Qian, J., Mo, L., Jin, F., Cements, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 85–170. ISBN 9780123919250. [Google Scholar] [CrossRef]

- Yang, N.; Shi, C.; Yang, J.; Chang, Y. Research Progresses in Magnesium Phosphate Cement—Based Materials. J. Mater. Civ. Eng. 2014, 26, 04014071. [Google Scholar] [CrossRef]

- You, C.; Qian, J.; Qin, J.; Wang, H.; Wang, Q.; Ye, Z. Effect of early hydration temperature on hydration product and strength development of magnesium phosphate cement (MPC). Cem. Concr. Res. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; You, C.; Fan, Y.; Li, Z.; Wang, H. Bond behavior and interfacial micro-characteristics of magnesium phosphate cement onto old concrete substrate. Constr. Build. Mater. 2018, 167, 166–176. [Google Scholar] [CrossRef]

- Abdelrazig, B.; Sharp, J.; El-Jazairi, B. The chemical composition of mortars made from magnesia-phosphate cement. Cem. Concr. Res. 1988, 18, 415–425. [Google Scholar] [CrossRef]

- Ma, C.; Wang, F.; Zhou, H.; Jiang, Z.; Ren, W.; Du, Y. Effect of early-hydration behavior on rheological properties of borax-admixed magnesium phosphate cement. Constr. Build. Mater. 2021, 283, 122701. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, X. Factors influencing properties of phosphate cement-based binder for rapid repair of concrete. Cem. Concr. Res. 1999, 29, 389–396. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Wang, Q.; Qian, J.; Qin, J.; You, C.; Wang, H. Effect of ambient temperature on setting time and strength development of magnesia-phosphate cement. J. Chin. Ceram. Soc. 2013, 41, 1493–1498. (In Chinese). Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDHIS2&filename=GXYB201311006&uniplatform=NZKPT&v=DV39cad9uxp6EkVAelxgLK4gk8cOA5MNqWilIORI03BA9NJTpZ1V7a6e5ZZ4l%25mmd2BUv (accessed on 25 December 2021).

- Le Rouzic, M.; Chaussadent, T.; Stefan, L.; Saillio, M. On the influence of Mg/P ratio on the properties and durability of magnesium potassium phosphate cement pastes. Cem. Concr. Res. 2017, 96, 27–41. [Google Scholar] [CrossRef]

- Chauhan, C.K.; Vyas, P.M.; Joshi, M.J. Growth and characterization of Struvite-K crystals. Cryst. Res. Technol. 2011, 46, 187–194. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Liu, S.; Yan, P. Effect of limestone powder on microstructure of concrete. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 328–331. [Google Scholar] [CrossRef]

- Wang, L.; Lu, X.; Liu, L.; Xiao, J.; Zhang, G.; Guo, F.; Li, L. Influence of MgO on the Hydration and Shrinkage Behavior of Low Heat Portland Cement-Based Materials via Pore Structural and Fractal Analysis. Fractal Fract. 2022, 6, 40. [Google Scholar] [CrossRef]

- Yang, J.; Du, B.; Xu, X. Effect of limestone powder on properties of magnesium phosphate cement paste. J. Build. Mater. 2015, 18, 34–38. (In Chinese) [Google Scholar] [CrossRef]

- Chong, L.; Shi, C.; Yang, J.; Jia, H. Effect of limestone powder on the water stability of magnesium phosphate cement-based materials. Constr. Build. Mater. 2017, 148, 590–598. [Google Scholar] [CrossRef]

- ASTM C939-10; Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method). ASTM International: West Conshohocken, PA, USA, 2010.

- ASTMC187-10; Standard Test Method for Normal Consistency of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2010.

- ISO 679:2009; Cement—Test Methods—Determination of Strength. ISO/TC 74. 2009. Available online: https://standards.iteh.ai/catalog/standards/iso/12357ab7-763f-4e77-80f4-8faba1f901b5/iso-679-2009 (accessed on 11 January 2022).

- JTG 3420-2020 (T 0518-2020); Testing Methods of Cement and Concrete for Highway Engineering: Testing Method for Free Bleeding Rate and Free Expansion Rate of Cement Slurry. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- ASTM C596-18; Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Huang, J.; Li, W.; Huang, D.; Wang, L.; Chen, E.; Wu, C.; Wang, B.; Deng, H.; Tang, S.; Shi, Y.; et al. Fractal Analysis on Pore Structure and Hydration of Magnesium Oxysulfate Cements by First Principle, Thermodynamic and Microstructure-Based Methods. Fractal Fract. 2021, 5, 164. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Yang, H.; Lv, X.; Guo, F.; Shi, Y.; Hanif, A. Investigation and Application of Fractal Theory in Cement-Based Materials: A Review. Fractal Fract. 2021, 5, 247. [Google Scholar] [CrossRef]

- Vu, V.-H.; Tran, B.-V.; Le, B.-A.; Nguyen, H.-Q. Prediction of the relationship between strength and porosity of pervious concrete: A micromechanical investigation. Mech. Res. Commun. 2021, 118, 103791. [Google Scholar] [CrossRef]

- Lian, H.; Shi, H. Clarification of a Hypothesis on‘Centroplasm of Cement-based Composite’ Proposed by Wu Zhongwei. J. Chin. Ceram. Soc. 2020, 48, 777. [Google Scholar] [CrossRef]

- Wang, L.; Song, X.; Yang, H.; Wang, L.; Tang, S.; Wu, B.; Mao, W. Pore structural and fractal analysis of the effects of MgO reactivity and dosage on permeability and F–T resistance of concrete. Fractal Fract. 2022, 6, 113. [Google Scholar] [CrossRef]

- Bhuiyan, M.I.H.; Mavinic, D.; Koch, F. Thermal decomposition of struvite and its phase transition. Chemosphere 2008, 70, 1347–1356. [Google Scholar] [CrossRef]

- Paul, I.; Varghese, G.; Ittayachen, M.A. Thermal decomposition studies of struvites. Indian J. Pure Appl. Sci. 2002, 40, 664–669. [Google Scholar]

- Ramlogan, M.V.; Rouff, A.A. An investigation of the thermal behavior of magnesium ammonium phosphate hexahydrate. J. Therm. Anal. 2016, 123, 145–152. [Google Scholar] [CrossRef]

| Sample | Phase 1 (Temperature Range 60–150 °C) | Phase 2 (Temperature Range 150–300 °C) | Phase 3 (Temperature Range 700–760 °C) |

|---|---|---|---|

| 0% LS-1 h | 6.98 | 4.22 | / |

| 0% LS-3 d | 7.08 | 4.02 | / |

| 0% LS-28 d | 12.80 | 3.00 | / |

| 20% LS-1 h | 9.47 | 2.93 | 6.19 |

| 20% LS-3 d | 10.09 | 2.33 | 6.24 |

| 20% LS-28 d | 10.40 | 2.01 | 6.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, W.; Cao, C.; Li, X.; Qian, J.; Dang, Y. An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar. Buildings 2022, 12, 249. https://doi.org/10.3390/buildings12020249

Mao W, Cao C, Li X, Qian J, Dang Y. An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar. Buildings. 2022; 12(2):249. https://doi.org/10.3390/buildings12020249

Chicago/Turabian StyleMao, Wenting, Chunpeng Cao, Xincheng Li, Jueshi Qian, and Yudong Dang. 2022. "An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar" Buildings 12, no. 2: 249. https://doi.org/10.3390/buildings12020249

APA StyleMao, W., Cao, C., Li, X., Qian, J., & Dang, Y. (2022). An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar. Buildings, 12(2), 249. https://doi.org/10.3390/buildings12020249