Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction

Abstract

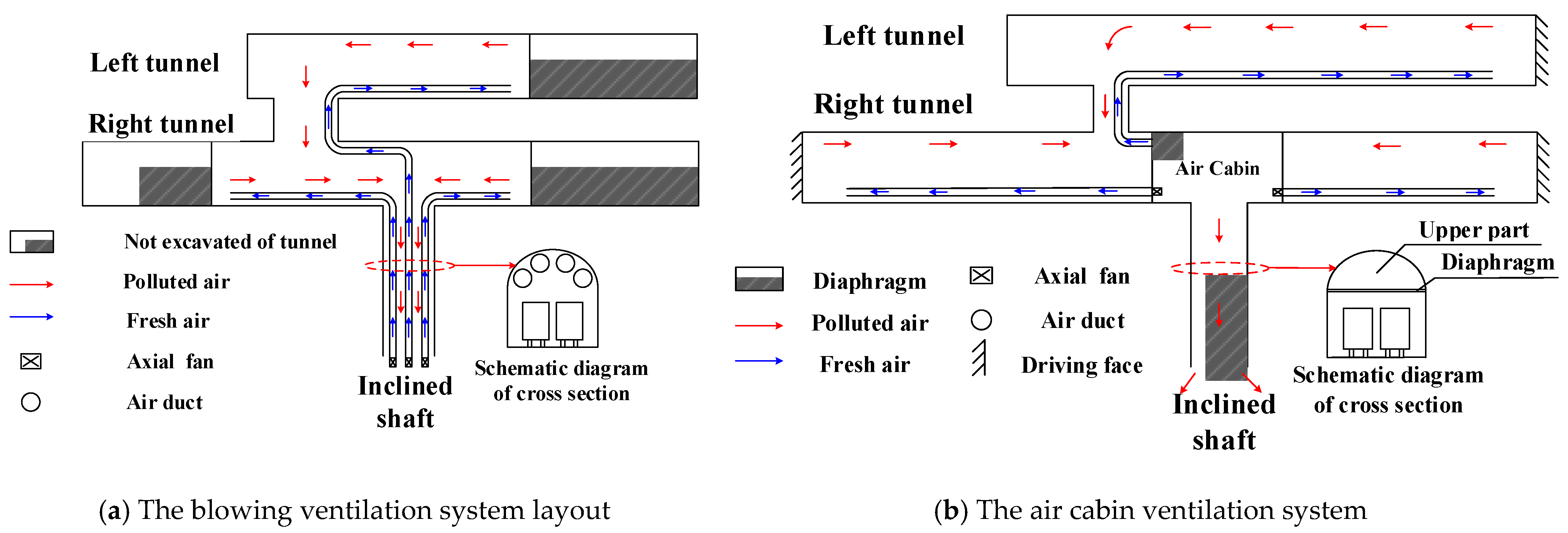

:1. Introduction

2. Calculation of Air Demand and Energy Consumption

2.1. Air Demand for Driving Face

- (1)

- Air demand of workers breathing:

- (2)

- Air demand for blasting operation:

- (3)

- Air demand of the minimum air velocity:

- (4)

- Air demand for diluting mechanical exhaust gas:

2.2. Ventilation Energy Consumption

2.2.1. Calculation Principle

- (1)

- Air volume of the forced draft fan

- (2)

- Ventilation resistance

- (3)

- Power calculation:

2.2.2. Calculation of Ventilation Energy Consumption

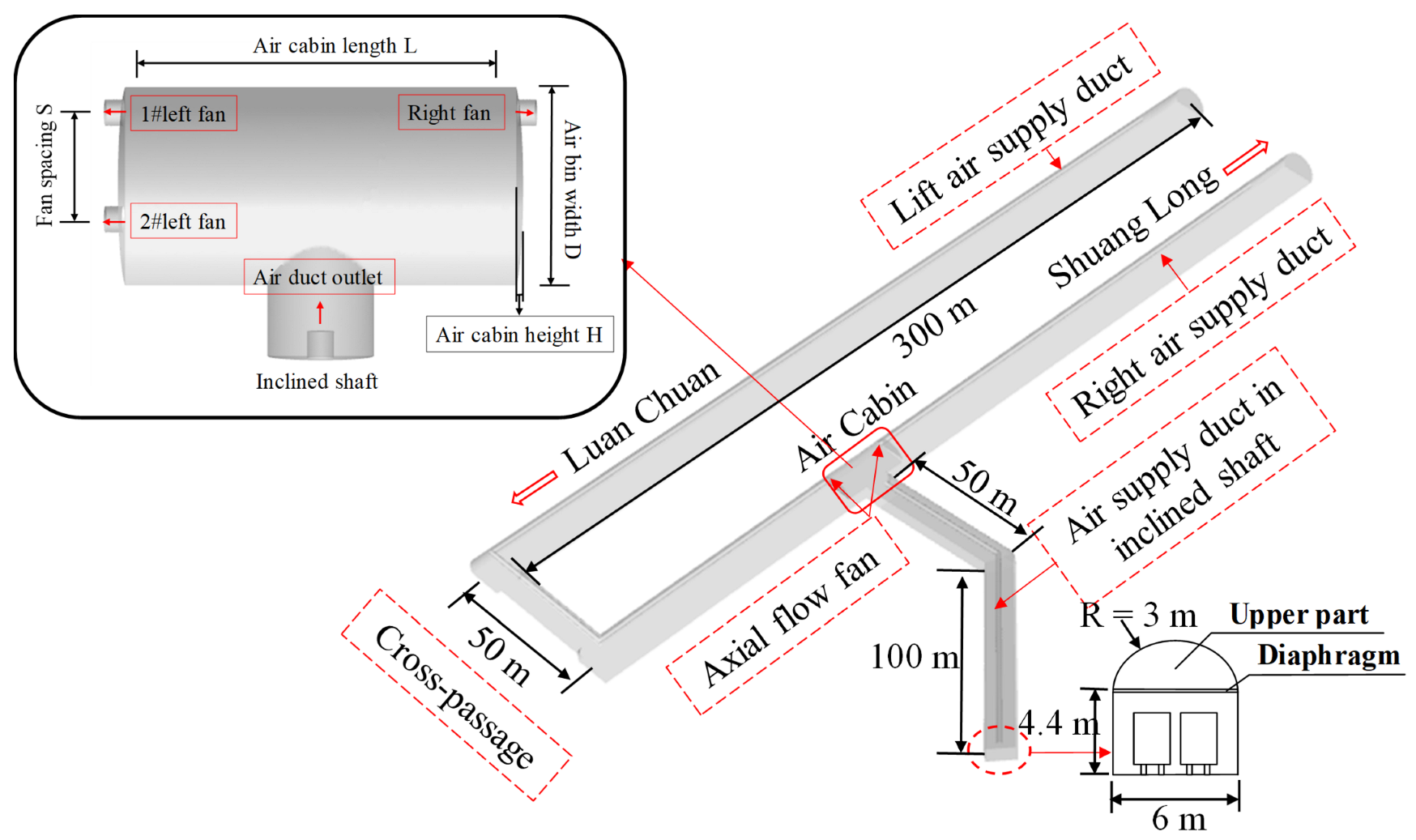

3. Numerical Simulation of the Air Cabin

3.1. Numerical Computational Control Model

3.2. Physical Model

3.3. Mesh Independence

3.4. Boundary Conditions

- (1)

- The air cabin and duct wall were set as the wall, the roughness constant Re was 0.57, and the average roughness height Rh was 0.09.

- (2)

- The left and right fans in the air cabin outlets were set as the velocity inlet, with a wind speed of −15.6 m/s and −14.6 m/s, respectively, where “-” represents the direction, and in this paper, −15.6 m/s represents a velocity of 15.6 m/s in the negative direction of the X-axis.

- (3)

- The air supply outlet of the inclined shaft air duct was set as the velocity inlet, with a wind speed of 25 m/s.

- (4)

- The air inlet is set as the pressure inlet, and the inlet pressure (relative to atmospheric pressure) is defined as 0.

- (5)

- All walls were set as non-slip walls.

3.5. Field Test Verification

4. Results and Discussion

4.1. Effect of Length–Width Ratio R of Air Cabin on Fan Efficiency

4.2. Effect of Fan Spacing S on Fan Efficiency

4.3. Effect of Middle Diaphragm Length on Fan Efficiency

4.4. Effect of Angle of the Middle Diaphragm in “Y” Shape on Fan Efficiency

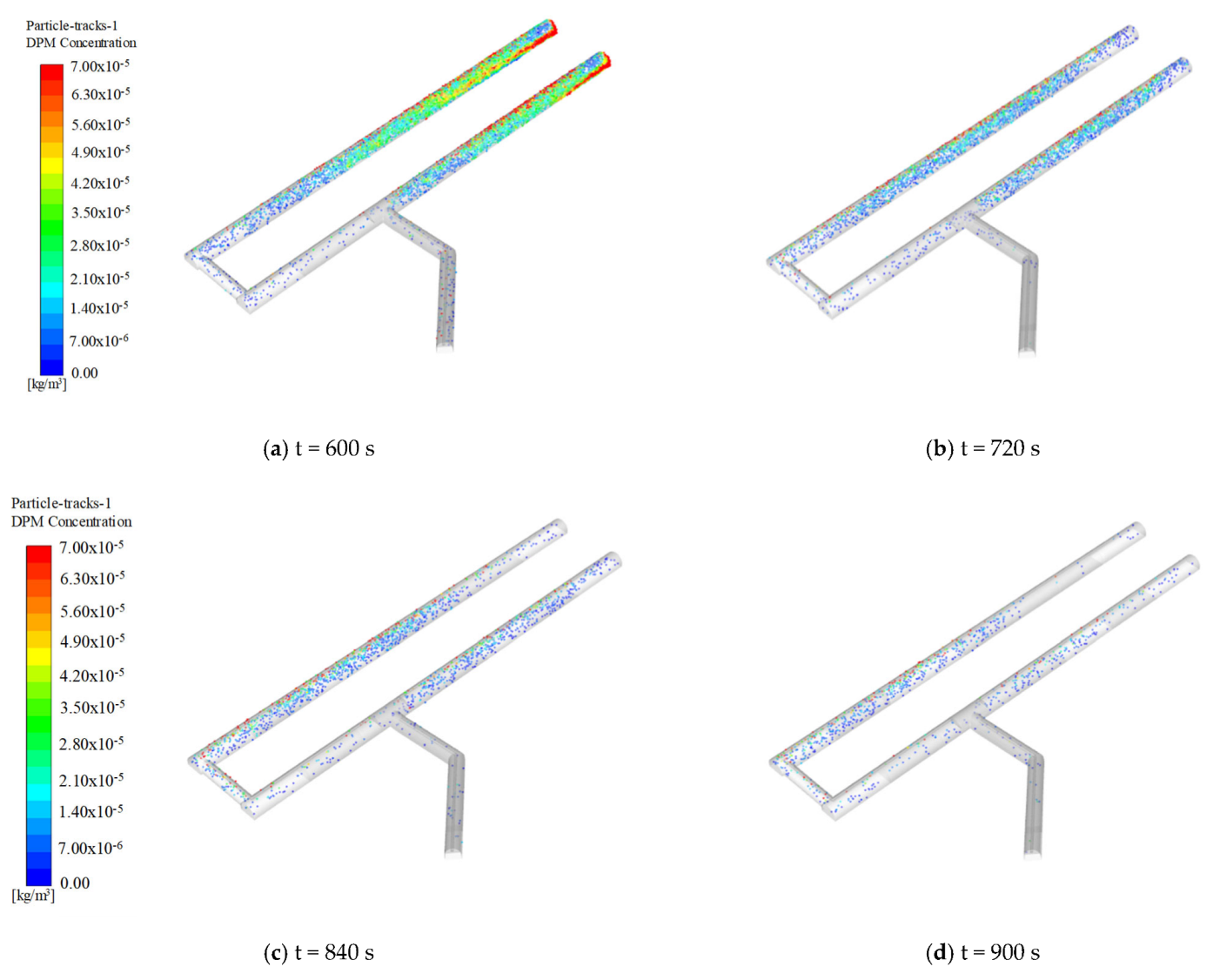

4.5. Effect Evaluation of Air Cabin Ventilation System

5. Conclusions

- (1)

- The air cabin ventilation system reduces the ventilation energy consumption and fully uses the inclined shaft’s clearance section. A numerical model was developed to simulate the air cabin ventilation system. The model’s simulation results are reliable, as verified by the actual measurement data in the field. The ventilation system has a good dust removal effect and ensures a healthy construction environment.

- (2)

- Increasing the length of the air cabin makes the wind flow develop more fully, which is the same as the results of other scholars. The pressure difference of the fan is the maximum when the length–width ratio R of the air cabin is 1:2, which satisfies the wind flow wind development demand.

- (3)

- The change of fan spacing has less effect on the pressure difference between the two fans arranged in axisymmetry. As the spacing between two fans on the same side increases, the vortex area increases, and the greater the impact on the differential pressure of the 2# fan. As S increases from 2 m to 4 m, the differential pressure of the 2# fan increases slightly by 0.2%. The fan spacing S is taken as 2−4 m to ensure the ventilation efficiency of the three fans.

- (4)

- When the difference in air demand between the two sides of the air cabin is large, the distribution of the flow field is not uniform, and the phenomenon of suction of fans occurs. The average wind speed on the left side was 53.28% higher than on the right. The middle diaphragm can reduce the phenomenon while generating a larger local pressure loss. The difference in wind speed between the left and right sides was reduced to 35.84%. A “Y”−shaped middle diaphragm with an angle can reduce local loss. When the angle is 30°, the local pressure loss sharply decreased by 59.40%.

- (5)

- This paper uses the control variable method to study each factor’s effect on the fan’s efficiency without considering the interaction between the factors. Therefore, subsequent research can design orthogonal experiments to improve the final combination of air cabin design parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Notes |

| A | The sectional area of the driving face |

| d | The equivalent diameter of the air passage section |

| D | The width of the air cabin |

| G | Total explosive mass |

| hg | The friction resistance of the air duct |

| hg11 | The local resistance of the air duct |

| hv | The dynamic pressure loss at the air duct outlet |

| H | The height of the air cabin |

| Ht | The total pressure of the ventilation system |

| The acceleration of gravity in direction i | |

| The term for the generation of turbulent kinetic energy k due to the mean velocity gradient | |

| k | The air demand per unit power of machinery |

| k1 | The effective utilization coefficient of mechanical power |

| k2 | The working coefficient of mechanical power |

| L | Duct length |

| L0 | Ventilation length |

| The maximum number of people | |

| Ni | The power of machinery operating |

| Nt | The total power of the ventilation system |

| P | The static pressure |

| p1 | The ambient air pressure of the fan |

| p0 | The standard atmospheric pressure |

| pa | The total pressure of the air cabin inlet |

| Pf | The total pressure of the fan inlet |

| ptot | Fan full-pressure |

| q | The air volume required per person per minute |

| Q0 | Air demand |

| Qa | Fan flow |

| Qb | Air demand for discharging the dust produced by blasting |

| Qf | The air volume of the forced draft fan |

| Qs | The total air demand for diluting mechanical exhaust gas |

| Qv | The total air demand to meet the minimum air velocity |

| Air demand for workers’ breathing | |

| R | The length–width ratio of an air cabin |

| S | The fan spacing in the air cabin |

| The turbulent momentum source term | |

| SKW | The mechanical motor power |

| t | Ventilation time |

| T0 | Standard temperature |

| T1 | Ambient temperature |

| v | The minimum air velocity |

| v1 | The wind speed of the air duct outlet |

| The component of flow velocity in the direction | |

| The right angle coordinates | |

| The component mass fraction | |

| ρ | Air density |

| β | The average value of 100 m air leakage rate |

| The Prandtl number of the K equation | |

| The Prandtl number of the equation | |

| The turbulent energy dissipation rate | |

| The laminar viscosity coefficient | |

| λ | Friction coefficient |

| η | Fan efficiency |

| Local resistance coefficient |

References

- Jiang, S.; Lin, Z.; Wang, S. Development of highway tunnels in China in 2018. Tunn. Constr. 2019, 39, 1217–1220. [Google Scholar]

- Tao, Y.; Hu, H.; Zhang, H.; Zhang, G.; Hao, Z.; Wang, L. A new ventilation system for extra-long railway tunnel construction by using the air cabin relay: A case study on optimization of air cabin parameters length. J. Build. Eng. 2022, 45, 103480. [Google Scholar] [CrossRef]

- Li, K.; Mao, S.; Yang, H.; Zhang, F.; Guo, C. Study on Optimization of Mixed Construction Ventilation for Super Long Tunnel. Mod. Tunn. Technol. 2020, 57 (Suppl. S1), 686–692. [Google Scholar]

- Wang, F.; Luo, F.; Xu, H.; Wang, Y. Calculation method of air temperature in tunneling section of open-type TBM construction. China Railw. Sci. 2019, 40, 64–70. [Google Scholar]

- Zeng, Y.; Tao, L.; Ye, X.; Zhou, X.; Fang, Y.; Fan, L.; Liu, X.; Yang, Z. Temperature reduction for extra-long railway tunnel with high geotemperature by longitudinal ventilation. Tunn. Undergr. Space Technol. 2020, 99, 103381. [Google Scholar] [CrossRef]

- Chen, Y.; He, X.; Lin, G.; Ping, W. Research on safety risk early warning of tunnel construction based on BIM and RFID Technology. E3S Web Conf. EDP Sci. 2021, 293, 02048. [Google Scholar]

- Yu, H.; Cheng, W.; Xie, Y.; Pengm, H. Micro-scale pollution mechanism of dust diffusion in a blasting driving face based on CFD-DEM coupled model. Environ. Sci. Pollut. Res. 2018, 25, 21768–21788. [Google Scholar] [CrossRef]

- Zhou, W.; Nie, W.; Liu, C.; Liu, Q.; Hetang, W.; Wei, C.; Yan, J.; Yin, S.; Xiu, Z.; Xu, C. Modelling of ventilation and dust control effects during tunnel construction. Int. J. Mech. Sci. 2019, 160, 358–371. [Google Scholar] [CrossRef]

- Chang, X.; Chai, J.; Luo, J.; Qin, Y.; Xu, Z.; Cao, J. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 2020, 177, 106902. [Google Scholar] [CrossRef]

- Li, Z.; Xie, W.; Wang, M.; Yu, L. Ventilation energy saving technology for Hongtiguan extra-long highway tunnel construction. J. Railw. Sci. Eng. 2016, 13, 760–766. [Google Scholar]

- Zhang, H.; Sun, J.; Lin, F.; Wang, L. Optimization on energy saving ventilation of gallery-type combined construction shaft exhaust in extra long tunnel. Procedia Eng. 2017, 205, 1777–1784. [Google Scholar] [CrossRef]

- Chang, X.; Chai, J.; Liu, Z.; Qin, Y.; Xu, Z. Comparison of ventilation methods used during tunnel construction. Eng. Appl. Comput. Fluid Mech. 2020, 14, 107–121. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; He, Y.; Zhao, Y.; Jiang, X.; Ren, S. Tunnel construction ventilation frequency-control based on radial basis function neural network. Autom. Constr. 2020, 118, 103293. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, Y.; Jiang, C.; Ren, Z.; Li, X.; Yu, K. Numerical study on fine dust pollution characteristics under various ventilation time in metro tunnel after blasting. Build. Environ. 2021, 204, 108111. [Google Scholar]

- Cao, Z.; Yang, Q.; Guo, C. Optimization of clapboard with wind box type construction ventilation in super-long railway tunnel. In Civil Engineering and Urban Planning III; CRC Press: Boca Raton, FL, USA, 2014; p. 267. [Google Scholar]

- Torno, S.; Toraño, J. On the prediction of toxic fumes from underground blasting operations and dilution ventilation. Conventional and numerical models. Tunn. Undergr. Space Technol. 2020, 96, 103194. [Google Scholar] [CrossRef]

- Toraño, J.; Torno, S.; Menéndez, M.; Gent, M. Auxiliary ventilation in mining roadways driven with roadheaders: Validated CFD modelling of dust behaviour. Tunn. Undergr. Space Technol. 2011, 26, 201–210. [Google Scholar] [CrossRef]

- Luo, Y.; Han, J.; Wen, Z.; Wen, Z.; Luo, Y.; Liu, F. Optimization of Ventilation Scheme of Jinjiazhuang Extra-long Spiral Tunnel. Tunn. Constr. 2019, 39 (Suppl. S1), 385–391. [Google Scholar]

- Zhang, H.; Zhang, J.; Zhou, S.; Sun, J.C.; Wu, J. Deciding and determination of the key parameters of the relay ventilation based on the air cabin and its effect in the ultra-long tunnel. J. Saf. Environ. 2019, 19, 795–803. [Google Scholar]

- Song, J.; Wan, X.; Guo, C. Study on Construction Ventilation Scheme of Air Cabin for An′ding Tunnel on Yumo Railway. Mod. Tunn. Technol. 2020, 57, 232–238. [Google Scholar]

- Han, X.M.; Sun, M.L.; Zhu, Y.Q. Application of combined clapboard and vent-pipe ventilation techniques in the construction of extra-long tunnels on a plateau. Mod. Tunn. Technol. 2016, 5, 208–215. [Google Scholar]

- Liu, G. An Application of Relay Ventilation in the Construction of a Water-conveyance Tunnel. Tunn. Constr. 2013, 33, 785–790. [Google Scholar]

- Zhou, S. Numerical analysis on air cabin construction ventilation effect in extra long railway tunnel. Sichuan Archit. 2018, 38, 222–225. [Google Scholar]

- Liu, X.; Yang, Q.; Jiang, Y.; Cao, Z. The Simulation Computing Research on Air Cabin Construction Ventilation in Underground Storage Caverns. Chin. J. Undergr. Space Eng. 2015, 11, 462–468. [Google Scholar]

- Chen, H. Study of Optimization of Construction Ventilation of Wanhua Yantai Underground Liquefied Hydrocarbon Water-sealed Cavern Group. Tunn. Constr. 2017, 37, 230–235. [Google Scholar]

- Luo, G.; Liu, C.; Jia, H.; Zhang, Y.; Wang, H. Study on Optimization of Ventilation Parameters of Air Cabin in Long Highway Tunnel. Constr. Technol. 2020, 49, 57–60. [Google Scholar]

- Atinc, G.; Simmering, M.J.; Kroll, M.J. Control variable use and reporting in macro and micro management research. Organ. Res. Methods 2012, 15, 57–74. [Google Scholar] [CrossRef]

- Bernerth, J.B.; Aguinis, H. A critical review and best-practice recommendations for control variable usage. Pers. Psychol. 2016, 69, 229–283. [Google Scholar] [CrossRef]

- JTG/T 3600-2020; Technical Specifications for Construction of Highway Tunnel. Ministry of Communications of PRC: Beijing, China, 2020.

- Niu, J.; Zheng, Q.; Lv, D.; Wang, Y. Numerical simulation of the effect of air-intake on the indoor flow field of a dedusting equipment cabin used in tunnel construction. Alex. Eng. J. 2022, 61, 12405–12416. [Google Scholar] [CrossRef]

- Caliendo, C.; Genovese, G.; Russo, I. A 3D CFD modeling for assessing the effects of both longitudinal slope and traffic volume on user safety within a naturally ventilated road tunnel in the event of a fire accident. IATSS Res. 2022, 46, 547–558. [Google Scholar] [CrossRef]

- Bogdan, S.; Birgmajer, B.; Kovačić, Z. Model predictive and fuzzy control of a road tunnel ventilation system. Transp. Res. Part C Emerg. Technol. 2008, 16, 574–592. [Google Scholar] [CrossRef]

- Ferkl, L.; Meinsma, G. Finding optimal ventilation control for highway tunnels. Tunn. Undergr. Space Technol. 2007, 22, 222–229. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Y.; Zhang, H.; Zhao, Y.; Zhu, X. Experimental and numerical study on the influence of wall roughness on the ventilation resistance coefficient in a tunnel under construction. Tunn. Undergr. Space Technol. 2022, 119, 104198. [Google Scholar] [CrossRef]

| Working Condition | Air Demand (m3/min) |

|---|---|

| The total air demand for breathing of workers | 180 |

| The total air demand for discharging the dust produced by blasting | 1220 |

| The total air demand to meet the minimum air velocity | 738 |

| The total air demand for diluting mechanical exhaust gas | 878.4 |

| 1220 |

| Item | Parameter | |

|---|---|---|

| 100 m air leakage rate of air duct (%) | 1.5 | |

| The friction coefficient of the air duct | 0.02 | |

| Air demand of driving face (m3/min) | 1220 | |

| Ventilation length of the inclined shaft (m) | 1030 | |

| Left tunnel | Ventilation length of small mileage (m) | 1230 |

| Right tunnel | Ventilation length of small mileage (m) | 1793 |

| Ventilation length of large mileage (m) | 100 | |

| Duct diameter (m) | 1.6 | |

| Air density (kg/m3) | 1.004 | |

| Item | Calculated Value | |

|---|---|---|

| Air volume (m3/s) | Small mileage of left tunnel | 28.64 |

| Small mileage of right tunnel | 31.28 | |

| Large mileage of right tunnel | 24.12 | |

| Resistance of air duct (Pa) | Resistance along the air duct | 2863.62 |

| Local resistance at fan inlet | 82.99 | |

| Local resistance at Three bends of air duct | 53.77 | |

| Dynamic pressure loss at the air outlet of the air duct | 51.39 | |

| Resistance at the inclined shaft (Pa) | Friction resistance of the inclined shaft | 99.96 |

| Local resistance of inclined shaft air inlet | 1.03 | |

| Local resistance of inclined shaft air outlet | 8.66 | |

| Total resistance of ventilation system (Pa) | 3161.42 | |

| Total power of ventilation system (kW) | 347 | |

| Item | Calculated Value | |

|---|---|---|

| Air volume (m3/s) | Small mileage of left tunnel | 23.76 |

| Small mileage of right tunnel | 26.66 | |

| Large mileage of right tunnel | 20.64 | |

| Resistance of air duct (Pa) | Resistance along the air duct | 1528.92 |

| Local resistance at two bends of the air duct | 35.85 | |

| Dynamic pressure loss at the air outlet of the air duct | 51.39 | |

| Resistance of diaphragm (Pa) | Friction resistance of the diaphragm | 552.28 |

| Local resistance at the inlet of the inclined shaft fan | 79.09 | |

| Local resistance at the outlet of the inclined shaft fan | 25.7 | |

| Local resistance at the junction of the inclined shaft and tunnel diaphragm | 64.92 | |

| Local resistance at the junction of the right tunnel and cross-passage diaphragm | 3.01 | |

| Local resistance at the junction of tunnel diaphragm and fan | 24.15 | |

| Resistance at the inclined shaft (Pa) | Friction resistance of the inclined shaft | 107.21 |

| Local resistance of inclined shaft air inlet | 18.58 | |

| Local resistance of inclined shaft air outlet | 9.29 | |

| Total resistance of ventilation system (Pa) | 2500.39 | |

| Total power of ventilation system(kW) | 275 | |

| Item | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Length width ratio R | 1:1 | 1:1.5 | 1:2 | 1:3 | 1:4 |

| Fan spacing S | 2 m | 4 m | 6 m | 8 m | ~ |

| Length of the middle diaphragm | 1:1 D | 1:1.5 D | 1:2 D | 1:3 D | 1:4 D |

| The angle of the middle diaphragm | 0° | 30° | 45° | 60° | 90° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Ren, R.; Wang, Y.-Q. Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction. Buildings 2022, 12, 2235. https://doi.org/10.3390/buildings12122235

Yang S, Ren R, Wang Y-Q. Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction. Buildings. 2022; 12(12):2235. https://doi.org/10.3390/buildings12122235

Chicago/Turabian StyleYang, Shuai, Rui Ren, and Ya-Qiong Wang. 2022. "Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction" Buildings 12, no. 12: 2235. https://doi.org/10.3390/buildings12122235

APA StyleYang, S., Ren, R., & Wang, Y.-Q. (2022). Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction. Buildings, 12(12), 2235. https://doi.org/10.3390/buildings12122235