Calculation of Energy Consumption and Carbon Emissions in the Construction Stage of Large Public Buildings and an Analysis of Influencing Factors Based on an Improved STIRPAT Model

Abstract

1. Introduction

2. Research Methods

- (1)

- Large scale and volume. The construction process requires more materials, machinery, and equipment than other buildings. Therefore, more attention should be paid to the selection of construction equipment, fuel loss, and other factors in the construction process.

- (2)

- High construction management difficulty. There are more cross-construction problems in the construction of large public building projects, and the management of their construction process is more important as it directly affects the completion qualities of green construction.

- (3)

- Complex structure. Large public buildings usually adopt relatively new architectural shapes, often with complex curved shapes, large spans of steel structures, and other characteristics. This is achieved using assembled structures and other ways to reduce the construction of required floor space and reduce pollution, and it has become an important focus of green construction.

- (4)

- The construction period is long, generally lasting more than two years; this length of time has a larger environmental impact.

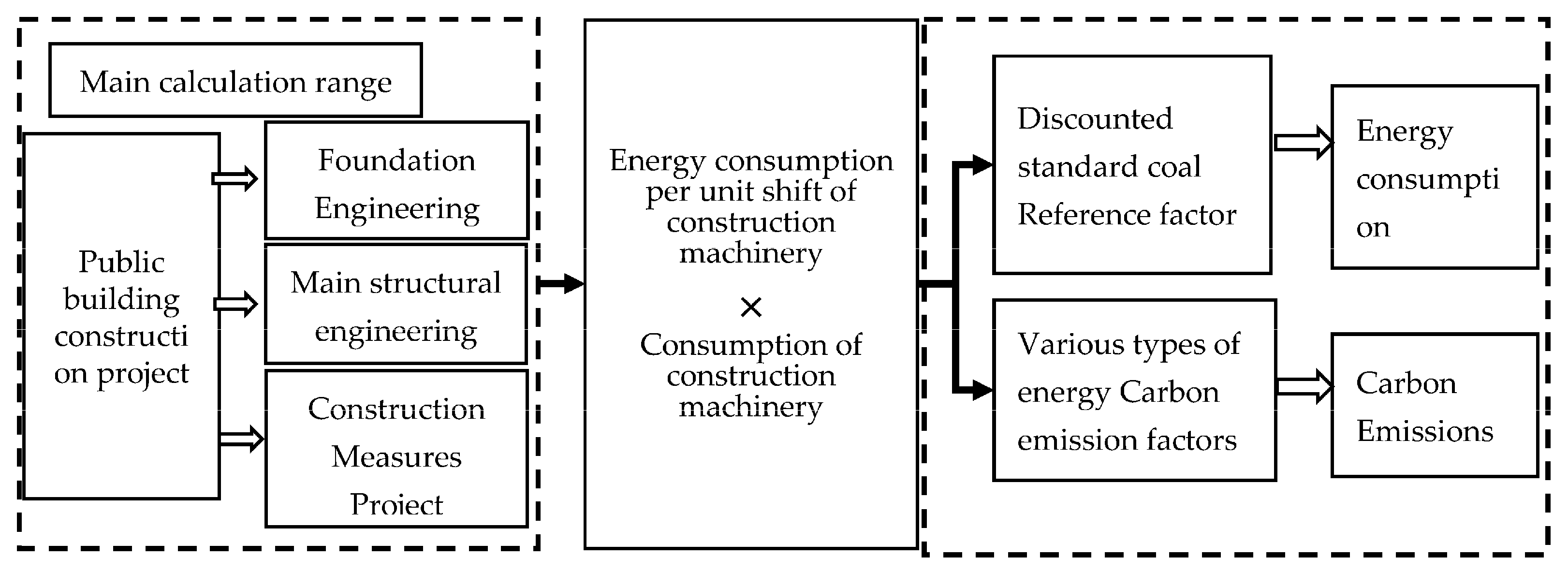

2.1. Determination of Calculation Boundary

2.2. Calculation Method

2.2.1. Calculation Basis

2.2.2. Energy Consumption Calculation Method

2.2.3. Carbon Emissions Calculation Method

2.3. Determination of Carbon Emission Factors

2.4. Influencing Factors Analysis Method

- (1)

- The population factor is expressed as the year-end resident population of the prefecture-level city where the terminal building is located. In order to achieve the goal of “energy saving and emission reduction”, government departments have also introduced a large number of measures and have continued to increase investment in the annual government budget. Such an approach also reduces carbon emissions to a certain extent, so this paper decomposes the economic development level factor into local GDP and local financial expenditure on energy savings and environmental protections.

- (2)

- We decompose the technical factors into construction machinery shift consumption, type and performance specifications of construction machinery, and energy type. Performance specification is expressed by unit shift energy consumption, and energy type is expressed by the carbon emission factor and the reference coefficient of discounted standard coal.

3. Empirical Analysis

3.1. Basic Information of the Case

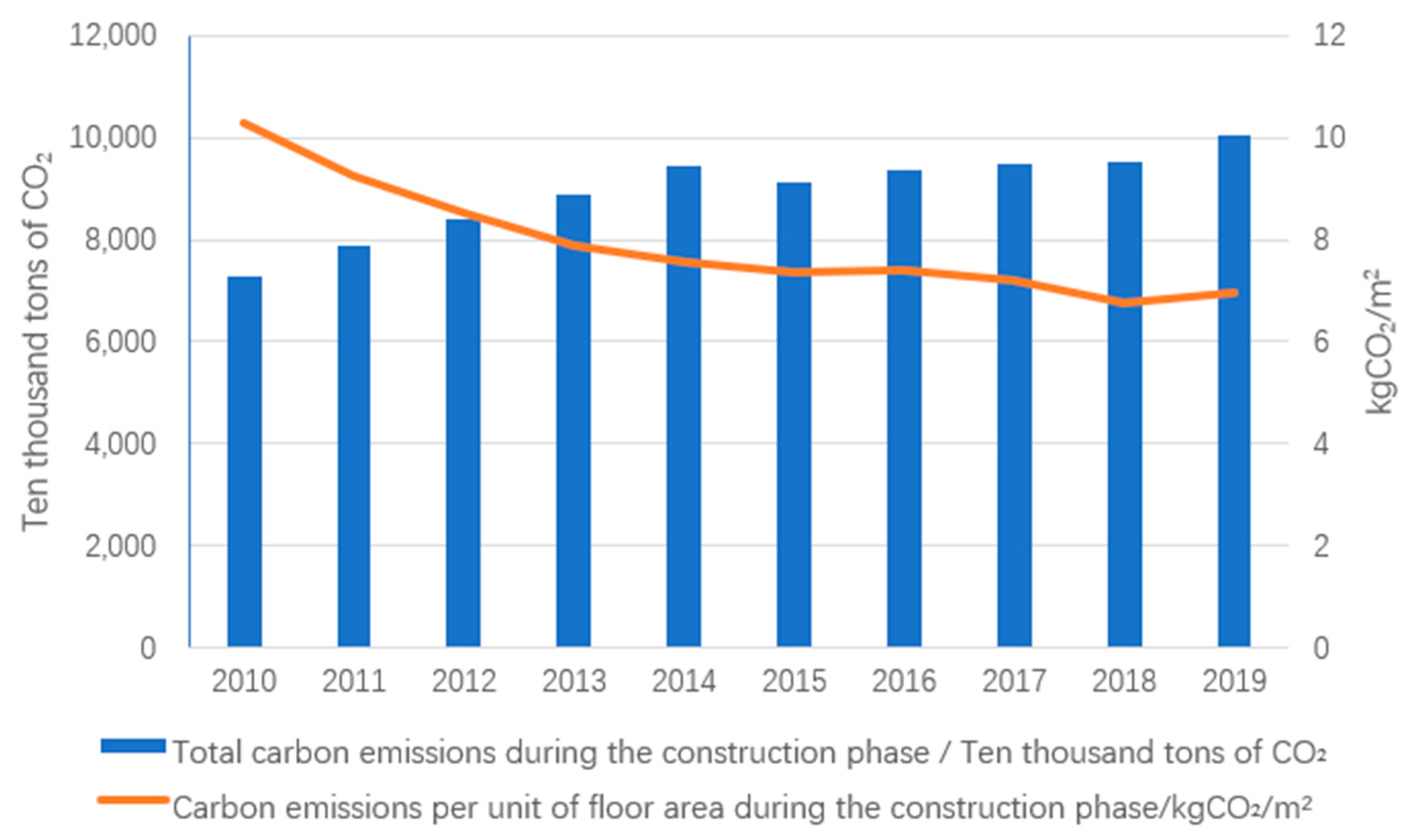

3.2. Project Inventory and Carbon Emission Calculation

- (1)

- Energy consumption and carbon emissions per unit area

- (2)

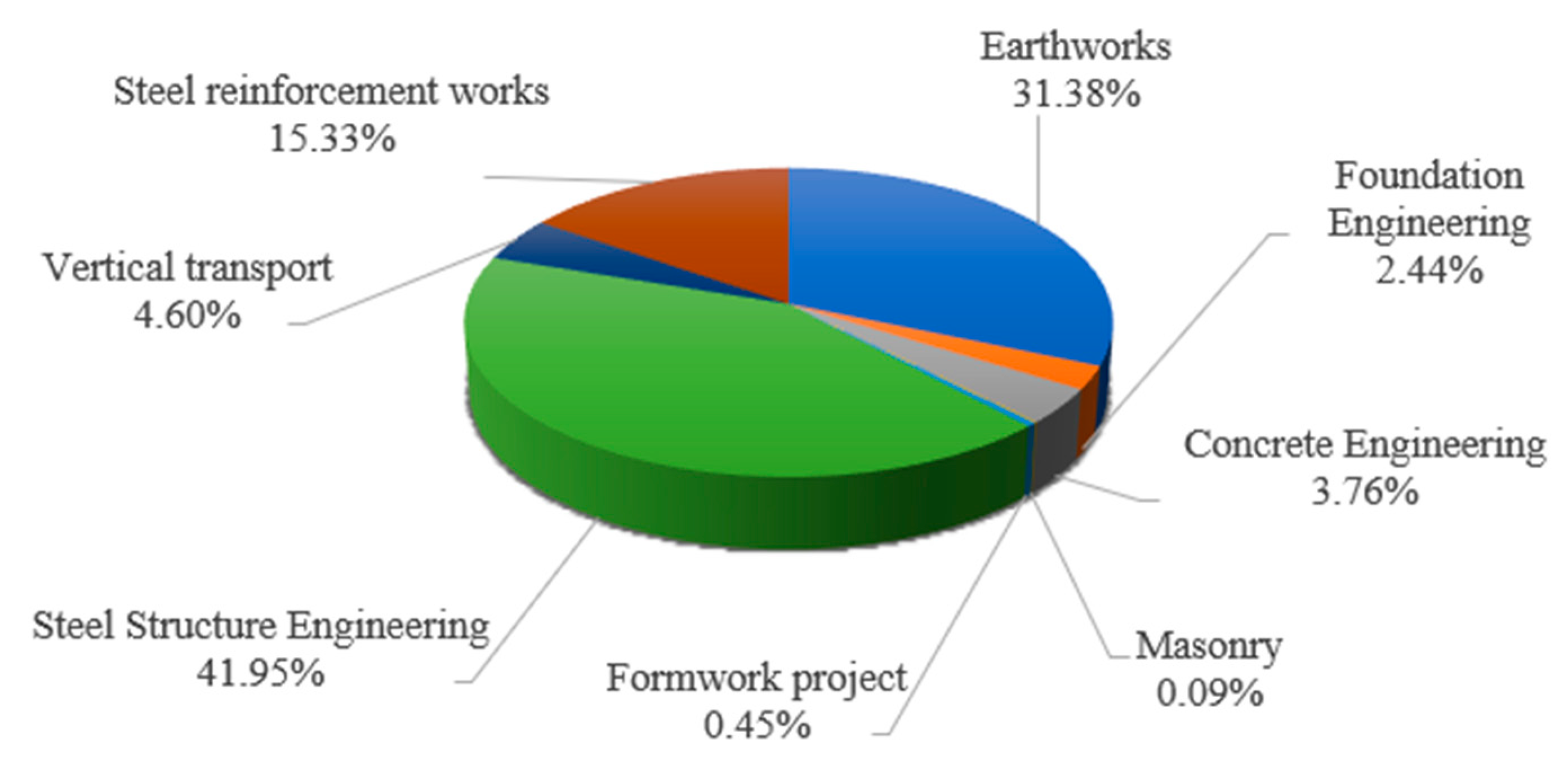

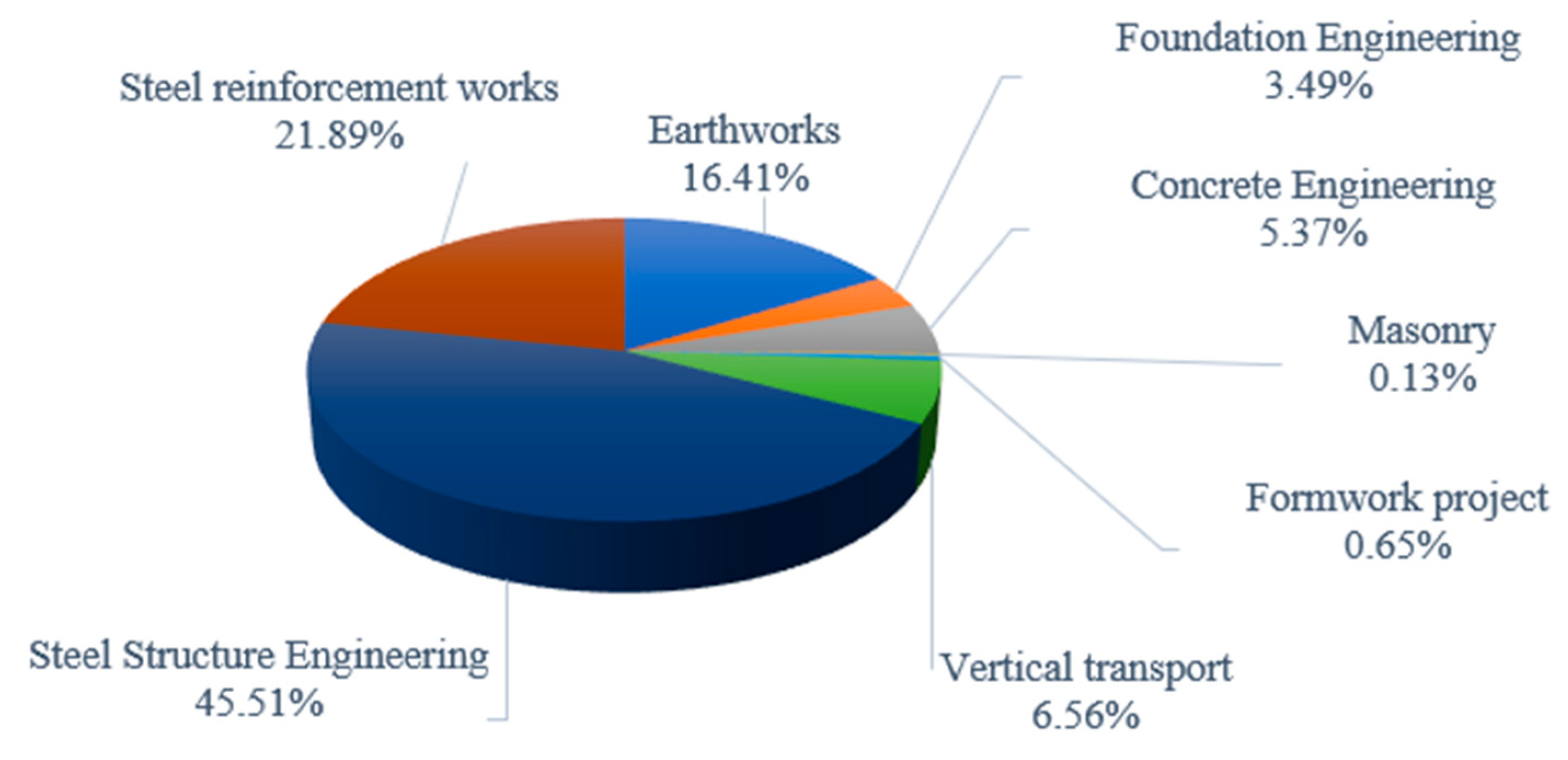

- Energy consumption and carbon emissions of each part of the project

- (3)

- Energy consumption and carbon emissions of different construction machinery

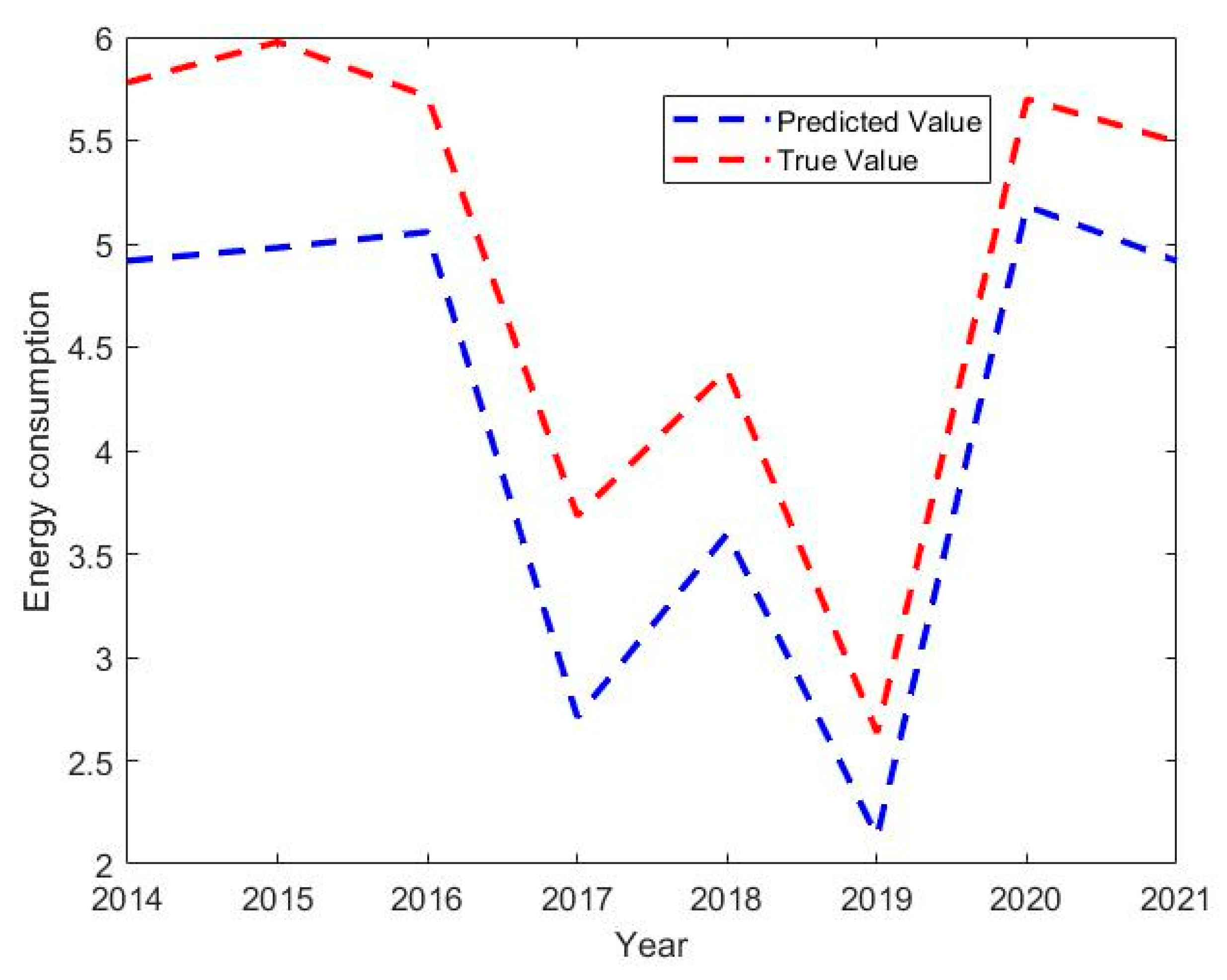

4. Analysis of Energy Consumption and Carbon Emission Influencing Factors

5. Discussions and Conclusions

- (1)

- The impact of construction machinery shift consumption on energy consumption is large, and the impact on carbon emissions is relatively small. To reduce shift consumption, on the one hand, we should improve the utilization rate of machinery and equipment; on the other hand, we also need to ensure and codify the operating hours of construction machinery and equipment.

- (2)

- With the development of society and the continuous growth of regional GDP, the local government’s requirements for the scale and function of buildings will also increase, and the corresponding requirements will be implemented in the construction process, resulting in greater total energy consumption and carbon emissions.

- (3)

- The increase in population also leads to an increase in public demand and a higher demand for public buildings, which leads to higher energy consumption and carbon emissions. However, the influence of demographic factors on energy consumption and carbon emissions can also be reduced through corresponding measures, and studies have found that the higher a population’s education level, the more people tend to live an environmentally friendly lifestyle; using this approach, carbon emissions will gradually decrease as the proportion of the population with higher education increases [34].

- (4)

- The same category of construction machinery, its old and new models, different specifications for energy consumption and unit carbon emissions is more significant, in the construction process for the use of construction machinery, should be timely elimination of high energy consumption, low efficiency of the old equipment to improve the overall efficiency.

- (5)

- As the government continues to invest in energy conservation and environmental protection, it has had a suppressive effect on energy consumption and carbon emissions. That said, the effect of this factor is the least significant among all indicators, because not all government investment in energy conservation and environmental protection is applied to the construction field, and there is a certain lag between the introduction of policies and related standards and their implementation in actual construction. However, government investment in this field is not only effective but also has much room for growth.

6. Research Implications and Recommendations

6.1. Research Implications

6.2. Recommendations

- (1)

- The government should play a leading role, pay full attention to the carbon reduction work of large public buildings, reasonably plan the scale of relevant buildings, appropriately give policy guidance, and encourage enterprises to use low-carbon construction technology. At the same time, it should also promote the research and application of various new building materials to enhance the service life of building materials.

- (2)

- Improving the electrification level of the construction site and optimizing the energy consumption structure in the construction process are the most obvious approaches to reducing energy consumption and carbon emissions. Reasonable arrangements for the use of construction machinery powered by fossil fuels, without delaying the construction schedule arrangement, should be given priority when it comes to the selection of construction machinery powered by electricity; this will effectively reduce total energy consumption. Priority should also be given to the selection of construction machinery, according to its performance specifications, to meet construction needs; smaller models and specifications of construction equipment should be implemented to appropriately reduce carbon emissions in the construction phase on the provision that work efficiency is guaranteed.

- (3)

- The government should strengthen the level of site management, pay attention to the rational use of energy, reduce night operations, encourage more applications of renewable energy in site lighting, and carefully consider domestic water through the use of photovoltaic power generation, wind power, solar water heaters, etc.

- (4)

- Construction plans should be optimized, and the surrounding environment and terrain should be examined in advance. Compared to conventional buildings, the construction period of large public buildings such as terminals is longer, so it is important to design a construction plan in a simple and efficient manner to improve construction efficiency and avoid reworking problems as much as possible.

- (5)

- Assembly construction should be promoted by prefabricating all kinds of building components and accessories in advance in the factory. Standardizing and processing the stacking, lifting, and connecting of all kinds of parts and components at the construction site would thus reduce cast-in-place and manual work at the site. Assembly construction reduces not only the use of various construction machinery but also the consumption of scaffolding, baffles, safety nets, and other turnover materials, thus effectively lowering carbon emissions.

- (6)

- Local governments should make great efforts to hire talents, increase investment in education, and optimize the proportion of local higher education populations by increasing the number of years of education per capita. In addition, the government can also vigorously encourage green and low-carbon travel and energy conservation to continuously improve the overall health quality of the population.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- CHINADAILY. Statement by H.E. Xi Jinping President of the People’s Republic of China At the General Debate of the 75th Session of The United Nations General Assembly. Available online: http://www.chinadaily.com.cn/a/202009/24/WS5f6c08aca31024ad0ba7b776.html (accessed on 22 September 2020).

- UNEP. Global Status Report for Buildings and Construction; UNEP: Nairobi, Kenya, 2019. [Google Scholar]

- Hussain, S.; Maqbool, R.; Hussain, A.; Ashfaq, S. Assessing the Socio-Economic Impacts of Rural Infrastructure Projects on Community Development. Buildings 2022, 12, 947. [Google Scholar] [CrossRef]

- Guggemos, A.A.; Horvath, A. Decision support tool for assessing the environmental effects of constructing commercial buildings. J. Archit. Eng. 2006, 12, 187–195. [Google Scholar] [CrossRef]

- Wang, T. Building Greenhouse Gas Emission Reduction Accounting, Barrier, Strategy, Policy; Economic Science Press: Beijing, China, 2014. [Google Scholar]

- Zhang, S.; Guo, M.; Management, S.O. The Research Trading of on Public Buildings Carbon Emissions. Ecol. Econ. 2016, 32, 80–83. [Google Scholar]

- Liu, X.F. Innovative research on regional low-carbon planning for large public buildings. China Equip. Eng. 2018, 199–200. [Google Scholar]

- Ma, M.; Shen, L.; Ren, H.; Cai, W.; Ma, Z. How to Measure Carbon Emission Reduction in China’s Public Building Sector: Retrospective Decomposition Analysis Based on STIRPAT Model in 2000–2015. Sustainability 2017, 9, 1744. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Paris, France, 1997. [Google Scholar]

- Leontief, W. The Structure of American Economy 1919–1939: An Empirical Application of Equilibrium Analysis; Oxford University Press: New York, NY, USA, 1951. [Google Scholar]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IGES: Kanagawa, Japan, 2006. [Google Scholar]

- Gerilla, G.P.; Teknomo, K.; Hokao, K. An environmental assessment of wood and steel reinforced concrete housing construction. Build. Environ. 2007, 42, 2778–2784. [Google Scholar] [CrossRef]

- Rossi, B.; Marique, A.-F.; Reiter, S. Life-cycle assessment of residential buildings in three different European locations, case study. Build. Environ. 2012, 51, 402–407. [Google Scholar] [CrossRef]

- Moon, H.S.; Hyun, C.T.; Hong, T.H. Prediction model of CO2 emission for residential buildings in South Korea. J. Manag. Eng. 2014, 30, 1–7. [Google Scholar] [CrossRef]

- Jonathan, N.; Heather, L.M. Comparing high and low residential density: Life cycle analysis of energy use and greenhouse gas emissions. Journey Urban Plan. Dev. 2006, 132, 10–19. [Google Scholar]

- Winkelman, S.; Bishins, A.; Kooshian, C. Planning for economic and environmental resilience. Transp. Res. Part A Policy Pract. 2010, 44, 575–586. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Zhang, P. Application of green construction material saving measures in engineering. Low Carbon World 2018, 1, 239–240. [Google Scholar]

- Du, Z.; Liu, Y.; Zhang, Z. Spatiotemporal Analysis of Influencing Factors of Carbon Emission in Public Buildings in China. Buildings 2022, 12, 424. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, W.; Wang, S. Research on carbon emission calculation method of building construction process. Build. Sci. 2014, 30, 5. [Google Scholar]

- York, R.; Rosa, E.A.; Dietz, T. STIRPAT, IPAT and ImPACT: Analytic tools for unpacking the driving forces of environmental impacts. Ecol. Econ. 2003, 46, 351–365. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F.; Zhang, X.; Yang, Y.; Su, Y.; Ye, Y.; Zhang, H. Examining the driving factors of energy related carbon emissions using the extended STIRPAT model based on IPAT identity in Xinjiang. Renew. Sustain. Energy Rev. 2017, 67, 51–61. [Google Scholar] [CrossRef]

- Ehrlich, P.R.; Holdren, J.P. Impact of Population Growth. Science 1971, 171, 1212–1217. [Google Scholar] [CrossRef]

- Dietz, T.; Rosa, E.A. Rethinking the Environmental Impacts of Population, Affluence and Technology. Hum. Ecol. Rev. 1994, 1, 277–300. [Google Scholar]

- Hu, S.; Zhang, Y.; Yan, D.; Guo, Y.; Liu, Y.; Jiang, Y. Defining and accounting for energy consumption and carbon emissions in China’s building sector. Build. Sci. 2020, 2, 10. [Google Scholar]

- GB/T 51366-2019; Standard for building carbon emission calculation. MOHURD: Beijing, China, 2019.

- TY 01-31-2015; Housing construction and decoration project consumption quota. MOHURD: Beijing, China, 2015.

- National Bureau of Statistics. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2021.

- Yan, H.; Shen, Q.P.; Linda, C.H.; Wang, Y.; Zhang, L. Greenhouse gas emission in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Chen, G.Q.; Chen, H.; Chen, Z.M.; Zhang, B.; Shao, L.; Guo, S.; Zhou, S.Y.; Jiang, M.M. Low-carbon building assessment and multi-scale input–output analysis. Commun. Nonlinear Sci. Numer. Simul. 2011, 16, 583–595. [Google Scholar] [CrossRef]

- Ma, M.; Yan, R.; Cai, W. An extended STIRPAT modelbased methodology for evaluating the driving forces affecting carbon emissions in existing public building sector: Evidence from China in 2000–2015. Nat. Hazards 2017, 89, 741–756. [Google Scholar] [CrossRef]

- Niu, S.; Ding, Y.; Li, Y.; Luo, G.; Niu, Y. The association between energy consumption, economic growth and carbon emissions: An empirical study based on panel data of eight Asia-Pacific countries. China Soft Sci. 2010, 5, 12–19+80. [Google Scholar]

- Chai, N.; Zhao, T.; Lin, T. Gray correlation analysis of energy consumption and carbon emissions in China’s industries. Ecol. Econ. 2012, 9, 105–107. [Google Scholar]

- Xu, Z.; Wei, J.; Tian, W. The influence of demographic factors on carbon emissions from the perspective of urbanization--an empirical study based on the improved STIRPAT model. Xinjiang Agric. Reclam. Econ. 2018, 6, 56–63. [Google Scholar]

- Al-Mulali, U. Factors affecting CO2 emission in the Middle East: A panel data analysis. Energy 2012, 44, 564–569. [Google Scholar] [CrossRef]

- Lu, J.; Zhong, Z.; Huang, X. Decomposition of carbon emission evolution characteristics and LMDI influence factors in China’s construction industry. Constr. Econ. 2017, 38, 81–88. [Google Scholar]

- Xu, S.C.; He, Z.X.; Long, R.Y. Factors that influence carbon emissions due to energy consumption based on different stages and sectors in China. J. Clean. Prod. 2015, 115, 139–148. [Google Scholar] [CrossRef]

- Glaeser, E.L.; Kahn, M.E. The greenness of cities: Carbon dioxide emissions and urban development. J. Urban Econ. 2010, 67, 404–418. [Google Scholar] [CrossRef]

- Khan, S.A.; Alam, T.; Khan, M.S.; Blecich, P.; Kamal, M.A.; Gupta, N.K.; Yadav, A.S. Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements. Buildings 2022, 12, 1944. [Google Scholar] [CrossRef]

| Energy Type | Carbon Content per Unit Calorific Value) tC/TJ _ | Carbon Oxidation Rate (%) | CO2 Emission Factor per Unit Calorific Value (tCO2/TJ) |

|---|---|---|---|

| Crude oil | 20.1 | 0.98 | 72.23 |

| Fuel oil | 21.1 | 0.98 | 75.82 |

| Gasoline | 18.9 | 0.98 | 67.91 |

| Diesel | 20.2 | 0.98 | 72.59 |

| Machine Name | Performance Specifications | Energy Usage | ||

|---|---|---|---|---|

| Diesel (kg) | Electric Power(kWh) | |||

| Crawler bulldozers | Power | 75 kw | 56.50 | |

| Crawler type single bucket Hydraulic excavator | Hopper capacity | 1 m³ | 63.00 | |

| Steel wheel internal combustion Road roller | Quality of work | 15 t | 42.95 | |

| Rebar cutting machine | Diameter | 40 mm | 32.10 | |

| Rebar bending machine | Diameter | 40 mm | 12.80 | |

| DC arc welding machine | Capacity | 32 kV · A | 96.53 | |

| Butt welding machine | Capacity | 75 kV · A | 122.00 | |

| Energy Name | Average Low Level Heat Generation | Reference Factor for Discounted Standard Coal |

|---|---|---|

| Raw coal | 20,908 kJ/kg | 0.7143 kgce/kg |

| Gasoline | 43,070 kJ/kg | 1.4714 kgce/kg |

| Diesel | 42,652 kJ/kg | 1.4571 kgce/kg |

| Electric power | 3600 kJ/kW·h | 0.1229 kgce/kW·h |

| Year | Year-End Resident Population (10,000 People) | Gross Regional Product (CNY Billion) | Local Finance for Energy Saving and Environmental Protection Expenditure (CNY Million) |

|---|---|---|---|

| 2010 | 311.26 | 1338.5 | 62,058 |

| 2011 | 321.21 | 1690.03 | 88,692 |

| 2012 | 335.00 | 2004.1 | 171,655 |

| 2013 | 346.00 | 2202.85 | 200,521 |

| 2014 | 353.00 | 2461.47 | 236,830 |

| 2015 | 355.00 | 2631.64 | 138,728 |

| 2016 | 351.96 | 2458.98 | 118,072 |

| 2017 | 350.40 | 2743.82 | 94,436 |

| 2018 | 350.58 | 3099.77 | 147,140 |

| Division Project Name | Secondary Classification | Energy Consumption (Unit: Tons of Standard Coal) | Carbon Emissions (Unit: Tons of CO2) |

|---|---|---|---|

| Earthworks | Earth excavation, earth backfill | 539.48 | 1140.77 |

| Foundation Engineering | Pouring of matting, formwork installation, etc. | 42.03 | 242.63 |

| Masonry | Mortar production and reinforcement of steel bars in masonry, etc. | 1.57 | 9.08 |

| Formwork project | On-site processing of formwork | 7.81 | 45.07 |

| Steel Structure Engineering | On-site fabrication and lifting of steel components, welding of steel structures, etc. | 721.21 | 3163.60 |

| Concrete Engineering | Concrete pounding and pumping, etc. | 64.64 | 373.16 |

| Steel reinforcement works | Rebar handling, rebar connection, etc. | 263.57 | 1521.49 |

| Vertical transport | Transportation of vertical means of transport such as construction elevators | 79.05 | 456.30 |

| Serial Number | Construction Machinery | Mechanical Parameters | Energy Consumption (Unit: Tons of Standard Coal) | Carbon Emissions (Unit: Tons of CO2) |

|---|---|---|---|---|

| 1 | Crawler bulldozers | Power (kw) 75 | 171.15 | 363.68 |

| 2 | Crawler type single bucket hydraulic excavator | Hopper capacity (m3) 1 | 182.39 | 393.93 |

| 3 | Steel wheel internal combustion road roller | Quality of work (t) 15 | 142.44 | 302.65 |

| 4 | Sprinkler | Tank capacity (L) 4000 | 40.50 | 80.50 |

| 5 | Truck-mounted cranes | Lifting weight (t) 16 | 6.56 | 13.94 |

| 6 | Truck-mounted cranes | Lifting weight (t) 20 | 140.62 | 298.79 |

| 7 | Portal crane | Lifting weight (t) 10 | 122.68 | 708.19 |

| 8 | Forklift | Lifting weight (t) 3 | 122.27 | 243.06 |

| 9 | Rocker drilling machine | Drill hole diameter (mm) 50 | 9.14 | 52.78 |

| 10 | Edge planing machine | Processing length (mm) 12,000 | 17.58 | 101.47 |

| 11 | Semi-automatic cutting machine | Thickness (mm) 100 | 75.65 | 436.71 |

| 12 | Section Steel Shearing Machine | Shear width (mm) 500 | 4.11 | 23.71 |

| 13 | Sandblasting and rust removal machine | Capabilities (m3/min) 3 | 65.79 | 379.80 |

| 14 | AC arc welding machine | Capacity (kV·A) 40 | 25.52 | 147.31 |

| 15 | Carbon dioxide gas shielded welder | Current (A) 250 | 68.09 | 393.04 |

| 16 | Electric welding rod drying box | Capacity (cm3) 45 × 35 × 45 | 35.48 | 204.81 |

| 17 | Electric Air Compressor | Exhaust volume (m³/min) 10 | 32.68 | 188.66 |

| 18 | Concrete transfer pumps | Delivery volume (m³/h) 45 | 73.94 | 426.85 |

| 19 | Woodworking circular sawing machine | Diameter (mm) 500 | 8.05 | 46.46 |

| 20 | Dry mortar tank mixer | Nominal storage capacity (L 20,000 | 1.57 | 9.08 |

| 21 | Rebar cutting machine | Diameter (mm) 40 | 58.07 | 335.23 |

| 22 | Rebar bending machine | Diameter (mm) 40 | 53.24 | 307.38 |

| 23 | Butt welding machine | Capacity (kV·A) 75 | 144.02 | 831.35 |

| 24 | AC arc welding machine | Capacity (kV·A) 32 | 35.76 | 206.43 |

| 25 | Self-lifting tower crane | Lifting weight (t) 400 | 65.09 | 375.71 |

| 26 | Single cage construction elevator | Lifting weight (t) 1 Lift height (m) 75 | 13.96 | 80.59 |

| Linear Regression Analysis Results n = 8 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Non-Standardized Coefficient | Standardization Factor | t | P | VIF | R2 | Adjustment of R2 | F | ||

| B | Standard Error | Beta | |||||||

| Constant | 0.152 | 0.072 | - | 0.113 | 0.102 | - | 0.974 | 0.955 | F = 50.166 p = 0.001 *** |

| Population | 0.89 | 0.421 | 0 | 0.113 | 0.102 | 0 | |||

| Regional GDP | 1.221 | 0.578 | 0 | 0.113 | 0.102 | 0 | |||

| Construction machinery performance specifications | 0.613 | 0.29 | 0 | 0.113 | 0.102 | 0 | |||

| Construction machinery shift consumption | 1.014 | 0.1 | 1 | 0.154 | 0.001 *** | 1.5 | |||

| Energy saving and environmental protection input | −0.07 | 0.265 | −0.026 | 0.266 | 0.804 | 1.49 | |||

| Energy type | 3.043 | 24.172 | −0.192 | 0.153 | 0.098 * | 1.236 | |||

| Dependent variable: energy consumption | |||||||||

| Linear Regression Analysis Results n = 8 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Non-Standardized Coefficient | Standardization Factor | t | p | VIF | R2 | Adjustment of R2 | F | ||

| B | Standard Error | Beta | |||||||

| Constant | −0.328 | 0.145 | - | 0.259 | 0.087 * | - | 0.974 | 0.955 | F = 50.166 p = 0.001 *** |

| Population | 1.923 | 0.851 | 0 | 0.259 | 0.087 * | 0 | |||

| Regional GDP | 2.638 | 1.168 | 0 | 0.259 | 0.087 * | 0 | |||

| Construction machinery performance specifications | 1.324 | 0.586 | 0 | 0.259 | 0.087 * | 0 | |||

| Construction machinery shift consumption | 1.014 | 0.1 | 1 | 0.154 | 0.001 *** | 1.5 | |||

| Energy saving and environmental protection input | −0.07 | 0.265 | −0.026 | 0.0266 | 0.804 | 1.49 | |||

| Energy Type | 4.627 | 3.542 | 0.218 | 0.0435 | 0.072 * | 1.236 | |||

| Dependent variable: carbon emissions | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wu, Y.; Chen, N.; Kang, C.; Du, J.; Luo, C. Calculation of Energy Consumption and Carbon Emissions in the Construction Stage of Large Public Buildings and an Analysis of Influencing Factors Based on an Improved STIRPAT Model. Buildings 2022, 12, 2211. https://doi.org/10.3390/buildings12122211

Chen Y, Wu Y, Chen N, Kang C, Du J, Luo C. Calculation of Energy Consumption and Carbon Emissions in the Construction Stage of Large Public Buildings and an Analysis of Influencing Factors Based on an Improved STIRPAT Model. Buildings. 2022; 12(12):2211. https://doi.org/10.3390/buildings12122211

Chicago/Turabian StyleChen, Yingjie, Yunfeng Wu, Ning Chen, Chaofeng Kang, Jiabin Du, and Cheng Luo. 2022. "Calculation of Energy Consumption and Carbon Emissions in the Construction Stage of Large Public Buildings and an Analysis of Influencing Factors Based on an Improved STIRPAT Model" Buildings 12, no. 12: 2211. https://doi.org/10.3390/buildings12122211

APA StyleChen, Y., Wu, Y., Chen, N., Kang, C., Du, J., & Luo, C. (2022). Calculation of Energy Consumption and Carbon Emissions in the Construction Stage of Large Public Buildings and an Analysis of Influencing Factors Based on an Improved STIRPAT Model. Buildings, 12(12), 2211. https://doi.org/10.3390/buildings12122211