Polyethylene (PE) Waste Minimization Study of Cement Mortar with Adding PE Content under Different W/B Ratios

Abstract

:1. Introduction

2. Experiment Plan

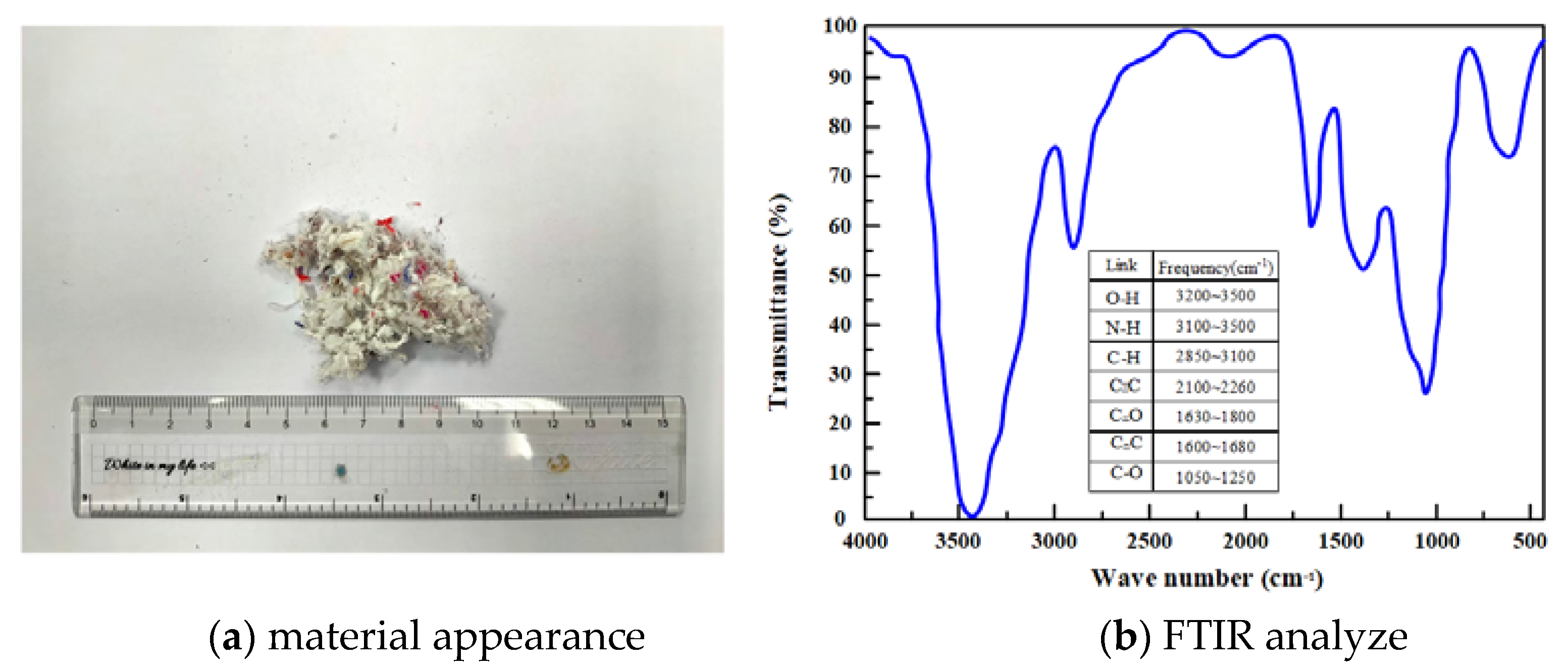

2.1. Experimental Materials

2.2. Test Variables and Mix Proportions

3. Results and Discussion

3.1. Slump

3.2. Flow

3.3. Setting Time

3.4. Compressive Strength

3.5. Flexural Strength

3.6. Tensile Strength

3.7. Ultrasonic Pulse Velocity

3.8. Water Absorption Rate

3.9. Resistivity

3.10. Resistance to Sulfate Attack

3.11. Microscopic Analysis

4. Conclusions

- The slump and flow properties of a specimen decrease as the waste PE content is increased so that the overall workability is degraded; the slump is increased with increasing W/B ratio.

- The setting time is shortened as the waste PE content is increased. When the W/B ratio is increased, the water consumption is increased so that the overall setting time is increased.

- The compressive strength, flexural strength, and tensile strength decrease as the waste PE content is increased. For a waste PE content of 2%, the waste can be eliminated most effectively; meanwhile, the strength is decreased with increasing W/B ratio and increased with increasing age.

- The ultrasonic pulse velocity is reduced by 6.9%~8.7% as the age and the waste PE content are increased. Since the waste PE fiber material absorbs the free water in cement mortar, it causes voids after cement mortar hardening and reduces the density of the specimen. Therefore, in the ultrasonic test, the ultrasonic wave speed showed a decreasing trend with the addition of PE material from 1% to 4%, and the decrease increased from 6.9% to 8.7%. With the addition of 20% GGBFS, which has the property of delaying the reaction of the Portland, the ultrasonic wave speed can exceed 4500 m/s at the age of 28 days only if the W/B ratio is 0.4. With the increase in the W/B ratio, the test results show that at the age of 56 days and 91 days, the amount of waste PE material added within 2%, although the density of the cement mortar specimen will be reduced, it can still meet the ultrasonic wave speed of 4500 m/s. The density requirement of wave speed is over 4500 m/s. The addition of 2% of waste PE material can be used as a reference for concrete mixture proportioning design, which is helpful to remove the waste PE material.

- As the W/B ratio and waste PE content are increased, pores are formed inside the specimen, and the water absorption rate is increased. The specimen has a better density due to hydration at a later age, so the water absorption rate is decreased. Regardless of whether the cement mortar specimen has added waste PE fiber material or not, its water absorption rate will show a decreasing trend with the development of age, and because of the addition of 20% GGBFS, at a late age, it delays the hydration reaction of the Brahmin, so that the specimen shows a better dense condition internally at a late age. At the same age, for the series with a W/B ratio of 0.4, the effect of the addition of waste PE fiber material on the water absorption was minimal, and the same was true for W/B ratios of 0.5 and 0.6. The correlation between water absorption and the reaction time of hydration, i.e., the development of age, indicates that the addition of waste PE material is feasible as long as the hydration reaction is developed until the cement mortar meets the requirement of density.

- The resistivity is decreased as the waste PE content and W/B ratio are increased. The resistivity shows the same trend as that for the ultrasonic pulse velocity. At the age of 28 days, the durability resistance test values of all specimens exceeded 20 kΩ-cm, indicating that although the addition of 20% GGBFS delayed the hydration effect, the resistance values met the requirement of compactness. Compared with the age of 28 days, the difference in resistance values between the PE materials added to the specimens at the same W/B was more minor. Still, at the late age of 91 days, the difference in resistance values between the PE materials added to the specimens at the same W/B was more significant. With the addition of PE materials, the resistance values decreased, indicating that the waste PE materials could not produce hydration. After a complete hydration reaction, the voids were formed. In addition, microscopic analysis by an electron microscope revealed that the PE fibers in the specimen made tangled masses, which was also the reason for the increase in voids.

- The resistance to sulfate attack is degraded for increasing W/B ratio and waste PE content; however, with the pozzolanic reaction, as the specimen pores are filled with hydrates, the specimen has a better density, and the decrease in weight loss rate is not obvious at a later stage.

- Under the condition of a W/B ratio of 0.4, the addition of 2% waste PE and 20% GGBFS in the mix proportion leads to better hardening properties and durability to achieve the goal of waste reuse. In addition, it suggests the appropriate PE addition ratio for the reference of concrete mixture proportioning design, so as to achieve waste minimization by recycling PE film on the surface of disposable containers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhaurova, M.; Soukka, R.; Horttanainen, M. Multi-criteria evaluation of CO2 utilization options for cement plants using the example of Finland. Int. J. Greenh. Gas Control 2021, 112, 103481. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Jang, J.G.; Kim, G.M.; Kim, H.J.; Lee, H.K. Review on recent advances in CO2 utilization and sequestration technologies in cement-based materials. Constr. Build. Mater. 2016, 127, 762–773. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Havukainen, J.; Horttanainen, M. How environmentally sustainable are fibre reinforced alkali-activated concretes. J. Clean. Prod. 2019, 236, 117601. [Google Scholar] [CrossRef]

- Islam, M.J.; Islam, K.; Shahjalal, M.; Khatun, E.; Islam, S.; Razzaque, A.B. Influence of different types of fibers on the mechanical properties of recycled waste aggregate concrete. Constr. Build. Mater. 2022, 337, 127577. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production and use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and fragmentation of plastic debris in global environments. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1526. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al-Khateeb, G.G.; Qasem, Y. Rheological properties of polyethylene/modified asphalt binder. Athens J. Τechnol. Eng. 2015, 2, 75–88. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Triantafillopoulos, N.; Koukoulas, A.A. The future of single-use paper coffee cups: Current progress and outlook. BioResources 2020, 15, 7260–7287. [Google Scholar] [CrossRef]

- Dele, R. Application of plastics and paper as food packaging materials—An overview. Emir. J. Food Agric. 2013, 25, 177–188. [Google Scholar]

- Islam, J.; Shahjalal, M. Effect of polypropylene plastic on concrete properties as a partial replacement of stone and brick aggregate. Case Stud. Constr. Mater. 2021, 15, e00627. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, M.; Kumar, I.; Srivastava, D. A review on utilization of plastic waste materials in bricks manufacturing process. Mater. Today Proc. 2021, 46, 6775–6780. [Google Scholar] [CrossRef]

- Chanhoun, M.; Padonou, S.; Adjovi, E.C.; Olodo, E.; Doko, V. Study of the implementation of waste wood, plastics and polystyrenes for various applications in the building industry. Constr. Build. Mater. 2018, 167, 936–941. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Han, R.; Yu, B.; Wei, Y.M. Accounting process-related CO2 emissions from global cement production under Shared Socioeconomic Pathways. J. Clean. Prod. 2018, 184, 451–465. [Google Scholar] [CrossRef]

- Adina, B.; Masek, O.; Oakey, J.E. CO2 capture technologies for cement industry. Energy Procedia 2009, 1, 133–140. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Yesilata, B.; Yusuf, I.; Paki, T. Thermal insulation enhancement in concretes by adding waste PET and rubber pieces. Constr. Build. Mater. 2009, 23, 1878–1882. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.; Levett, P. Evaluation of concrete performance with different types of recycled plastic waste for kerb application. J. Build. Eng. 2021, 293, 123477. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Wang, C.H.; Lin, H.T. Quantification of food packaging generation and material loss from major retailers in Taipei, Taiwan. Waste Manag. 2022, 137, 139–149. [Google Scholar] [CrossRef]

- Taerwe, L.; Van Gysel, A. Influence of steel fibers on design stress-strain curve for high-strength concrete. J. Mech. Eng. 1996, 122, 695–704. [Google Scholar] [CrossRef]

- Kakemi, M.; Hannant, D.J. Effect of autoclaving on cement composites containing polypropylene, glass and carbon fibres. Cem. Concr. Compos. 1996, 18, 61–66. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Wang, W.; Wu, S.; Dai, H. Fatigue behaviour and life prediction of carbon fiber reinforced concrete under cyclic flexural loading. Mater. Sci. Eng. A 2006, 434, 347–351. [Google Scholar] [CrossRef]

- Hsie, M.; Tu, C.; Song, P.S. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Rumšys, D.; Bačinskas, D.; Spudulis, E.; Meškėnas, A. Comparison of material properties of lightweight concrete with recycled polyethylene and expanded clay aggregates. Procedia Eng. 2017, 172, 937–944. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, M.J. High energy absorbent ultra-high-performance concrete with hybrid steel and polyethylene fibers. Constr. Build. Mater. 2019, 209, 354–363. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Waste polyethylene terephthalate as an aggregate in concrete. Mat. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernadez, M.; Matheus, A.; Gutierrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Chung, J.S.; Cho, S.K. Effect of waste PET bottles aggregate on properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Hanna, T.H.; Mosa, I.H. Effect of using waste polyethelene production on mechanical properties of concrete. J. Duhok Univ. 2012, 15, 37–42. [Google Scholar]

- Irwan, J.M.; Asyraf, R.M.; Othman, N.; Koh, H.B.; Annas, M.M.K.; Faisal, S.K. The mechanical properties of PET fiber reinforced concrete from recycled bottle wastes. Adv. Mat. Res. 2013, 795, 347–351. [Google Scholar] [CrossRef]

- Juki, M.I.; Muhamad, K.; Mahamad, M.K.A.; Boon, K.H.; Othman, N.; Kadir, A.A.; Roslan, M.A.; Khalid, F.S. Development of concrete mix design nomograph containing polyethylene terephthalate (PET) as fine aggregate. Adv. Mat. Res. 2013, 701, 12–16. [Google Scholar]

| Materials | Chemical Contents (%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | TiO2 | P2O5 | f-CaO | C3S | C2S | C3A | C4AF | L.O.I | |

| Cement | 19.6 | 4.4 | 3.1 | 62.5 | 4.9 | 2.2 | - | - | 0.5 | 0.11 | 0.7 | 56 | 14 | 7 | 9 | 2.5 |

| PE | 42.5 | 36 | 1.1 | 11.2 | 2.9 | - | 0.4 | 0.7 | 5.2 | - | - | - | - | - | 42 | |

| GGBFS | 33.5 | 14.7 | 0.4 | 41.2 | 6.4 | 0.6 | 0.3 | 0.2 | 0.5 | 0.01 | - | - | - | - | - | 0.6 |

| W/B | GGBFS (%) | GGBFS | Cement | PE (%) | PE | Sand | Water |

|---|---|---|---|---|---|---|---|

| 0.4 | 20 | 172 | 749 | 0 | 0 | 2302 | 375 |

| 1 | 13.8 | ||||||

| 2 | 27.7 | ||||||

| 3 | 41.5 | ||||||

| 4 | 55.4 | ||||||

| 0.5 | 151 | 658 | 0 | 0 | 411 | ||

| 1 | 13.8 | ||||||

| 2 | 27.7 | ||||||

| 3 | 41.5 | ||||||

| 4 | 55.4 | ||||||

| 0.6 | 135 | 586 | 0 | 0 | 439 | ||

| 1 | 13.8 | ||||||

| 2 | 27.7 | ||||||

| 3 | 41.5 | ||||||

| 4 | 55.4 |

| No. | Test Items | Test Regulations |

|---|---|---|

| 1 | Slump | ASTM C143 |

| 2 | Flow | ASTM C230 |

| 3 | Setting time | ASTM C403 |

| 4 | Compressive strength | ASTM C109 |

| 5 | Flexural strength | ASTM C348 |

| 6 | Tensile strength | ASTM C190 |

| 7 | Water absorption rate | ASTM C1585 |

| 8 | Ultrasonic velocity | ASTM C597 |

| 9 | Resistivity | ASTM C876 |

| 10 | Resistance to sulfate attack | ASTM C1012 |

| RM (%) | AM (%) | W/B | |||||

|---|---|---|---|---|---|---|---|

| GGBFS | PE | 0.4 | 0.5 | 0.6 | |||

| Slump | SR * | Slump | SR * | Slump | SR * | ||

| 20 | 0 | 1.9 | 1.00 | 2.8 | 1.00 | 4.1 | 1.00 |

| 1 | 1.5 | 0.79 | 2.6 | 0.93 | 3.8 | 0.92 | |

| 2 | 1.3 | 0.68 | 2.5 | 0.89 | 3.7 | 0.90 | |

| 3 | 1.3 | 0.68 | 2.3 | 0.82 | 3.5 | 0.85 | |

| 4 | 1.2 | 0.63 | 2.1 | 0.75 | 3.4 | 0.83 | |

| RM (%) | AM (%) | W/B | |||||

|---|---|---|---|---|---|---|---|

| GGBFS | PE | 0.4 | 0.5 | 0.6 | |||

| Flow | FR * | Flow | FR * | Flow | FR * | ||

| 20 | 0 | 15.6 | 1.00 | 19.9 | 1.00 | 21.7 | 1.00 |

| 1 | 15.2 | 0.97 | 19.7 | 0.99 | 21.3 | 0.98 | |

| 2 | 14.7 | 0.94 | 19.4 | 0.97 | 21.2 | 0.98 | |

| 3 | 14.4 | 0.92 | 18.9 | 0.95 | 21.0 | 0.97 | |

| 4 | 14.2 | 0.91 | 18.7 | 0.94 | 20.9 | 0.96 | |

| W/B | RM (%) | AM (%) | Initial Setting | Final Setting |

|---|---|---|---|---|

| GGBFS | PE | min | min | |

| 0.4 | 20 | 0 | 324 | 394 |

| 1 | 315 | 382 334 | ||

| 2 | 302 | 365 | ||

| 3 | 284 268 | 347 | ||

| 4 | 268 | 334 | ||

| 0.5 | 20 | 0 | 401 | 518 |

| 1 | 387 356 | 505 474 | ||

| 2 | 375 | 496 | ||

| 3 | 367 | 488 | ||

| 4 | 356 | 474 | ||

| 0.6 | 20 | 0 | 479 | 633 |

| 1 | 468 | 625 | ||

| 2 | 460 | 617 | ||

| 3 | 447 439 | 609 598 | ||

| 4 | 439 | 589 |

| W/B | GGBFS (%) | PE (%) | 3 Days | 7 Days | 28 Days | 56 Days | 91 Days |

|---|---|---|---|---|---|---|---|

| 0.4 | 20 | 0 | 26.5 | 36.3 | 54.1 | 59.8 | 65.3 |

| 1 | 25.1 | 35.6 | 52.4 | 59.0 | 64.4 | ||

| 2 | 24.3 | 34.2 | 51.0 | 58.1 | 61.9 | ||

| 3 | 23.6 | 33.7 | 50.4 | 57.3 | 62.5 | ||

| 4 | 22.5 | 32.4 | 48.9 | 55.6 | 60.0 | ||

| 0.5 | 20 | 0 | 24.7 | 33.3 | 48.5 | 53.5 | 59.1 |

| 1 | 23.0 | 33.1 | 47.8 | 52.5 | 57.9 | ||

| 2 | 21.6 | 30.0 | 46.8 | 50.0 | 55.5 | ||

| 3 | 21.0 | 29.4 | 45.9 | 51.1 | 56.9 | ||

| 4 | 20.3 | 28.6 | 44.9 | 49.3 | 53.8 | ||

| 0.6 | 20 | 0 | 20.0 | 27.1 | 37.2 | 45.7 | 50.4 |

| 1 | 19.0 | 25.4 | 35.3 | 44.0 | 50.2 | ||

| 2 | 18.4 | 24.7 | 35.1 | 42.6 | 48.2 | ||

| 3 | 17.6 | 24.2 | 34.6 | 42.0 | 47.6 | ||

| 4 | 17.0 | 23.5 | 34.7 | 40.3 | 46.6 |

| W/B | GGBFS (%) | PE (%) | 3 Days | 7 Days | 28 Days | 56 Days | 91 Days |

|---|---|---|---|---|---|---|---|

| 0.4 | 20 | 0 | 11.7 | 15.8 | 26.6 | 35.6 | 39.0 |

| 1 | 11.0 | 15.4 | 26.8 | 34.8 | 38.8 | ||

| 2 | 10.4 | 14.4 | 25.2 | 34.0 | 37.3 | ||

| 3 | 9.6 | 14.0 | 24.6 | 33.8 | 36.4 | ||

| 4 | 8.9 | 13.2 | 24.0 | 33.3 | 35.7 | ||

| 0.5 | 20 | 0 | 10.0 | 14.7 | 26.3 | 35.5 | 38.9 |

| 1 | 9.5 | 14.2 | 25.4 | 34.5 | 37.3 | ||

| 2 | 9.1 | 13.7 | 24.9 | 34.0 | 36.2 | ||

| 3 | 8.6 | 13.4 | 24.0 | 33.6 | 36.3 | ||

| 4 | 8.0 | 12.2 | 23.3 | 32.6 | 33.8 | ||

| 0.6 | 20 | 0 | 8.4 | 13.2 | 21.6 | 32.8 | 35.4 |

| 1 | 8.0 | 12.1 | 20.9 | 33.2 | 35.2 | ||

| 2 | 7.7 | 12.1 | 20.9 | 32.6 | 34.9 | ||

| 3 | 7.2 | 11.5 | 20.0 | 31.8 | 33.8 | ||

| 4 | 6.9 | 11.6 | 19.4 | 30.9 | 32.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, S.-L.; Lin, K.-T.; Hung, C.-C.; Wang, H.-Y.; Wen, F.-L. Polyethylene (PE) Waste Minimization Study of Cement Mortar with Adding PE Content under Different W/B Ratios. Buildings 2022, 12, 2117. https://doi.org/10.3390/buildings12122117

Tsai S-L, Lin K-T, Hung C-C, Wang H-Y, Wen F-L. Polyethylene (PE) Waste Minimization Study of Cement Mortar with Adding PE Content under Different W/B Ratios. Buildings. 2022; 12(12):2117. https://doi.org/10.3390/buildings12122117

Chicago/Turabian StyleTsai, Shen-Lun, Keng-Ta Lin, Chang-Chi Hung, Her-Yung Wang, and Fu-Lin Wen. 2022. "Polyethylene (PE) Waste Minimization Study of Cement Mortar with Adding PE Content under Different W/B Ratios" Buildings 12, no. 12: 2117. https://doi.org/10.3390/buildings12122117

APA StyleTsai, S.-L., Lin, K.-T., Hung, C.-C., Wang, H.-Y., & Wen, F.-L. (2022). Polyethylene (PE) Waste Minimization Study of Cement Mortar with Adding PE Content under Different W/B Ratios. Buildings, 12(12), 2117. https://doi.org/10.3390/buildings12122117