Pragmatic Design Decision Support for Additive Construction Using Formal Knowledge and Its Prospects for Synergy with a Feedback Mechanism

Abstract

:1. Introduction

2. Background and Related Works

2.1. AM Technologies for Construction

2.2. Design Decision Support System

2.3. The Importance of Early Design Stages

2.4. Use of Semantic Web in AEC

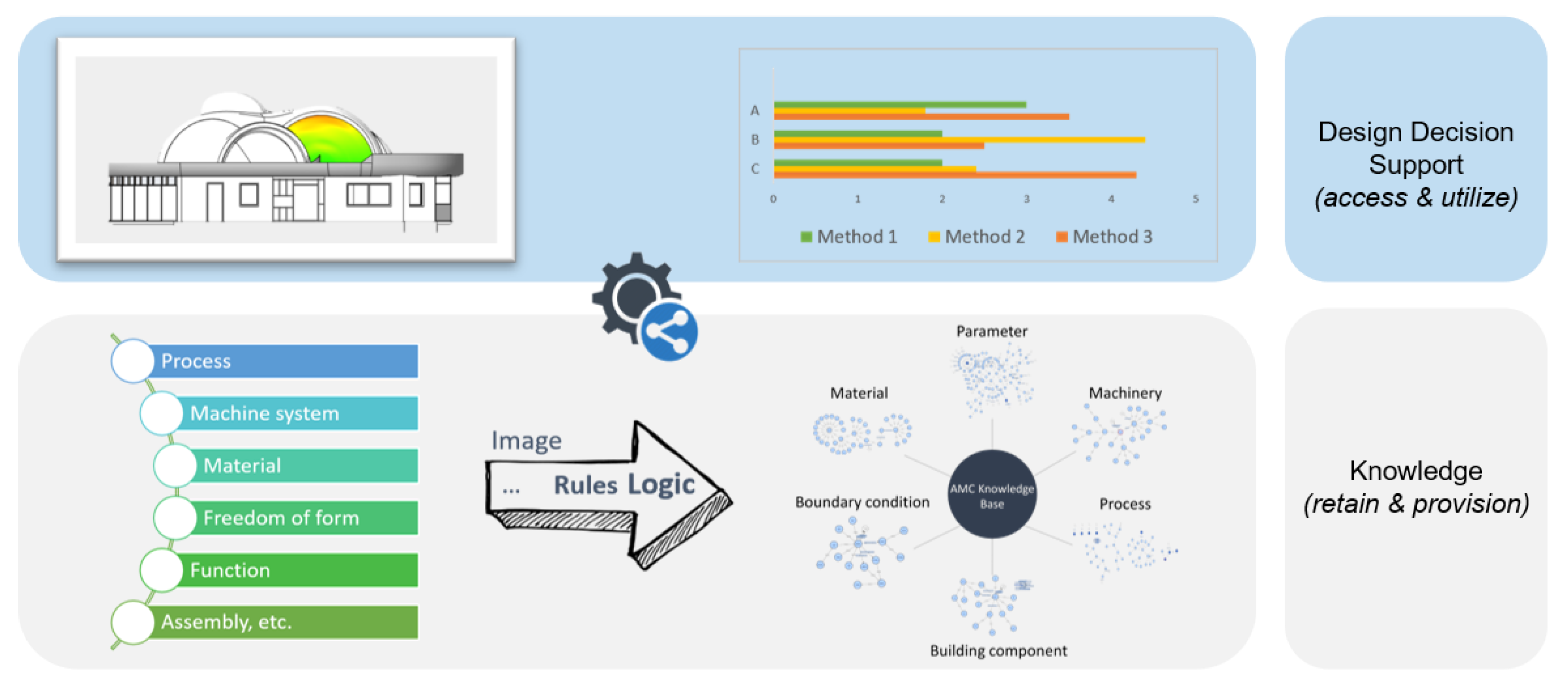

3. Knowledge-Driven Decision Support with a Feedback Mechanism

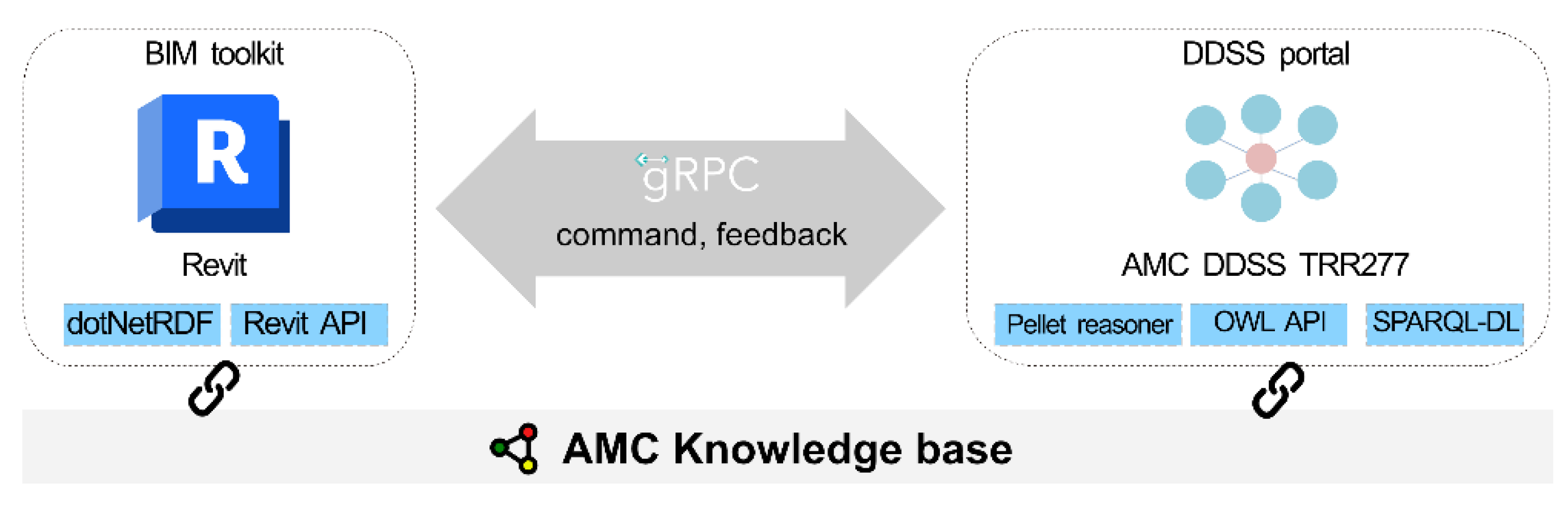

3.1. AMC Knowledge Formalization and BIM Integration: Principle and Methodology

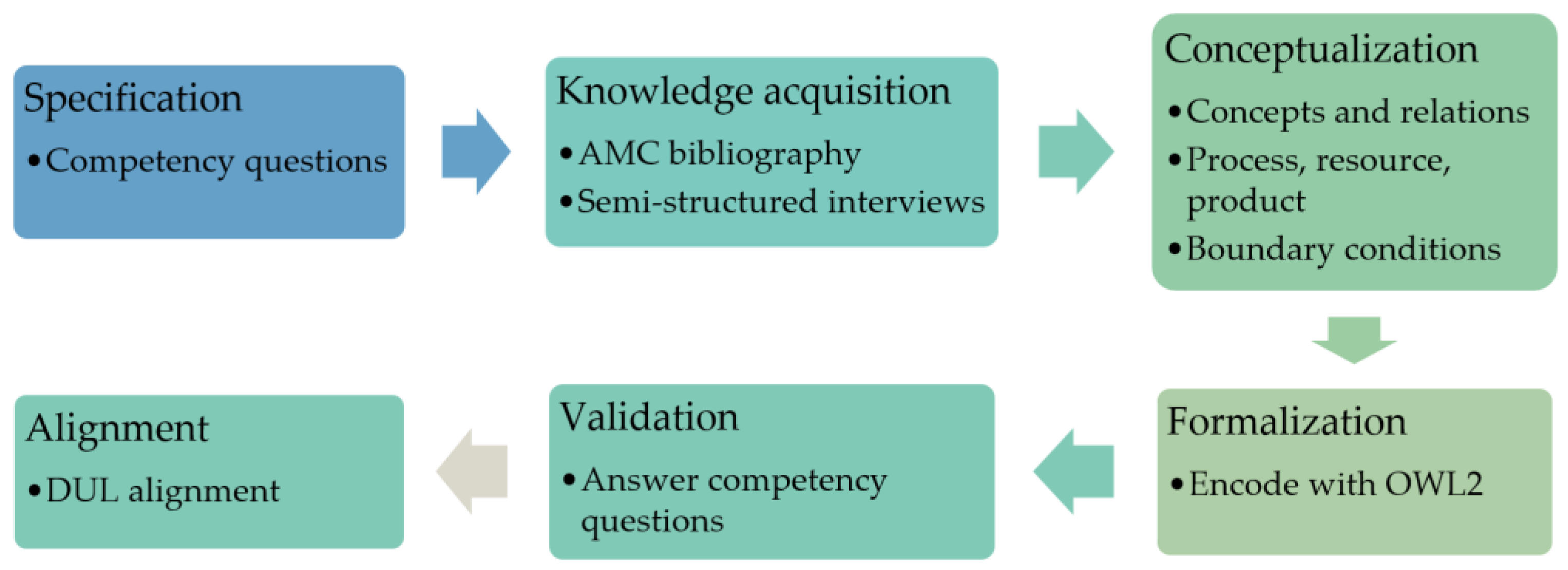

3.2. Ontology Building Processes

3.2.1. Specification

3.2.2. Knowledge Acquisition

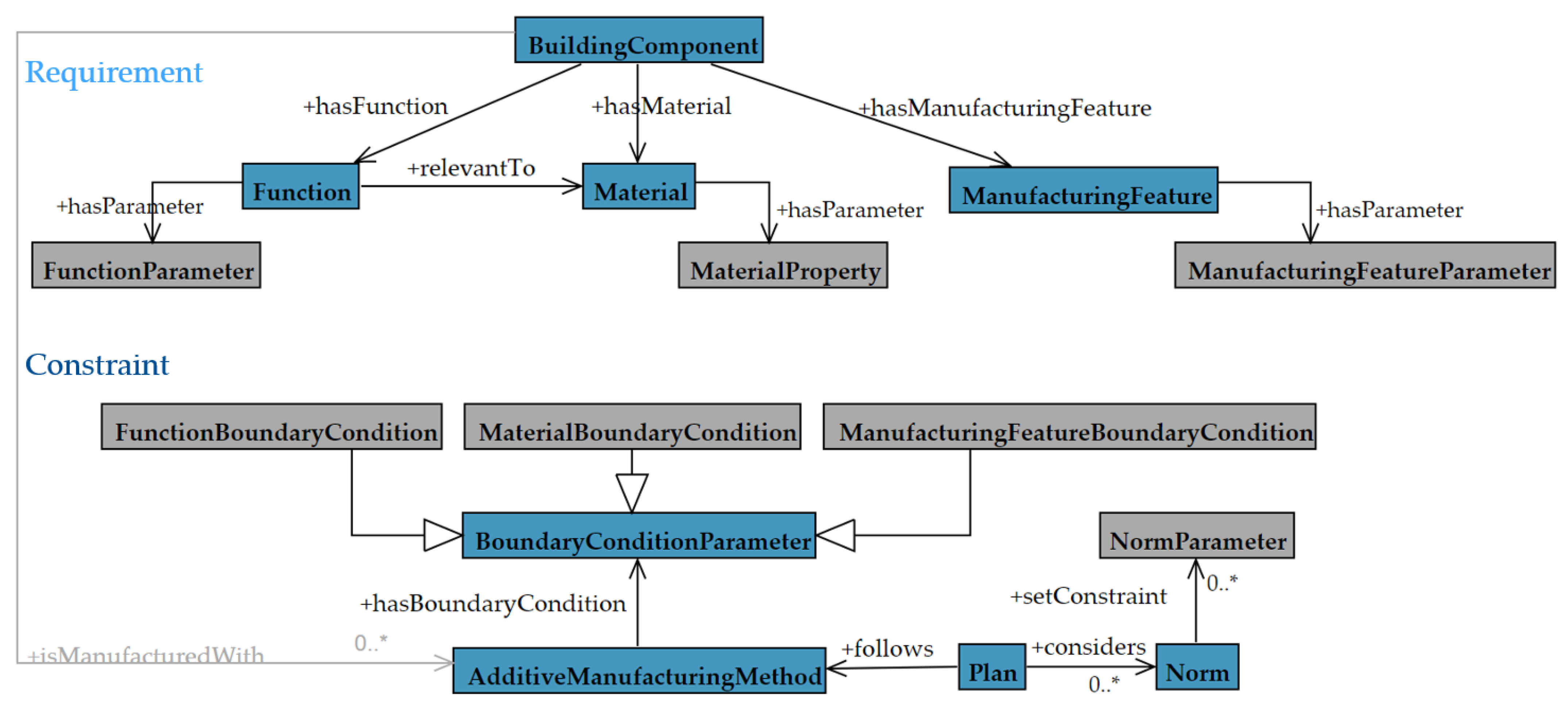

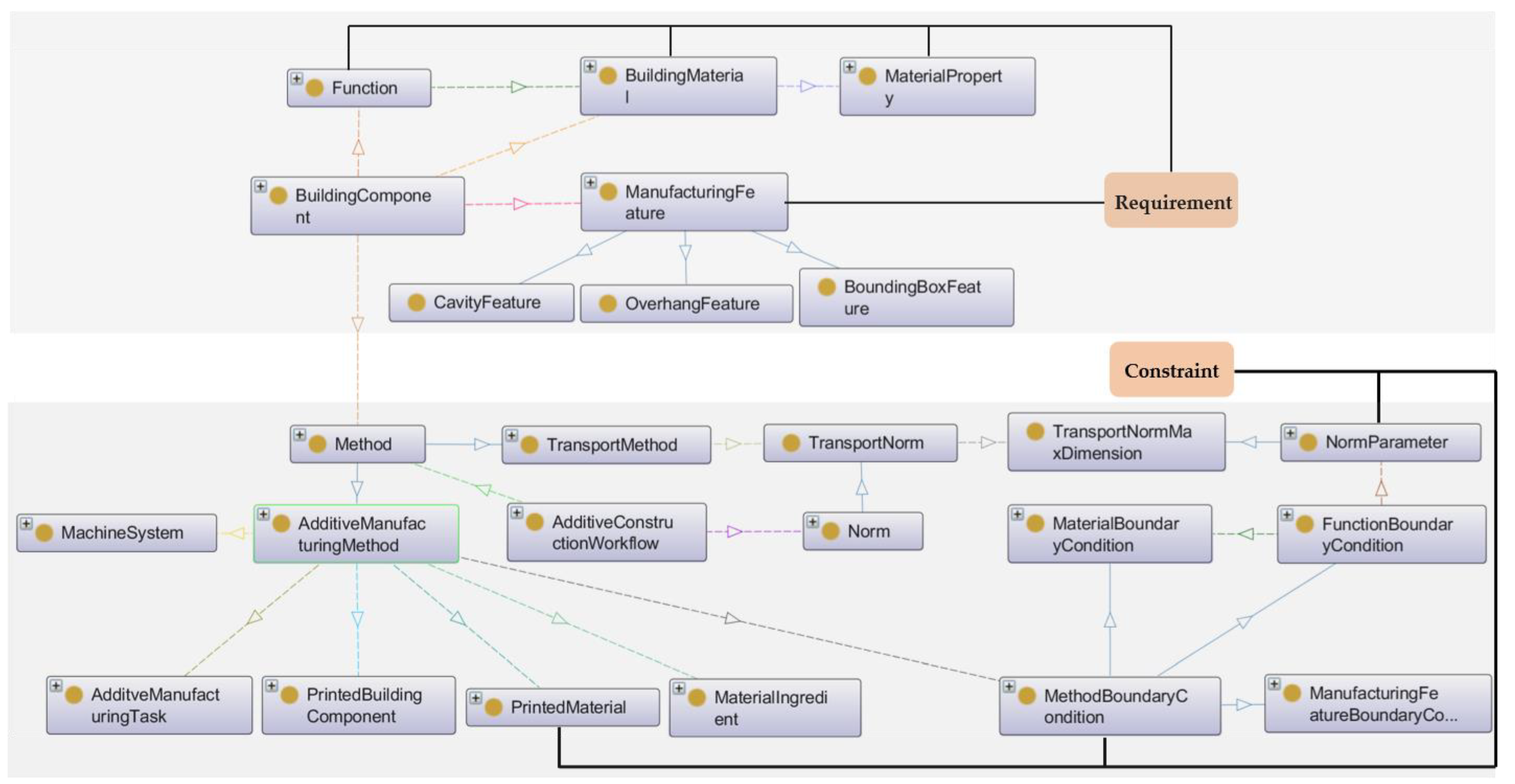

3.2.3. Conceptualization

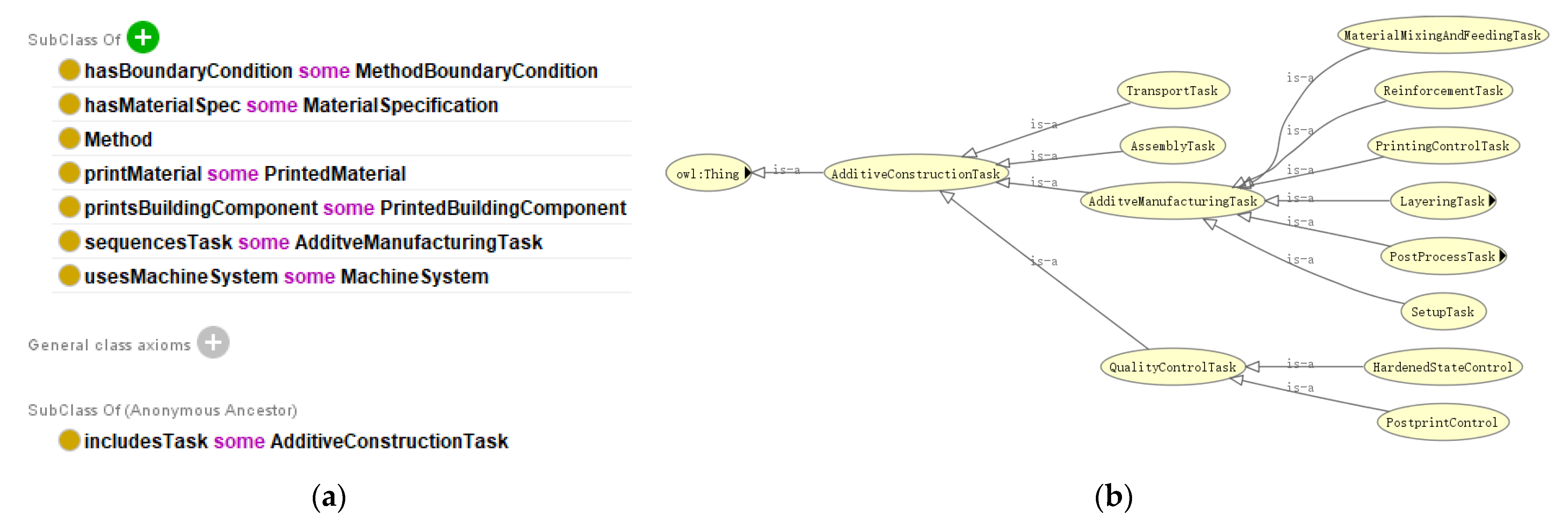

3.2.4. Formalization

3.2.5. Validation

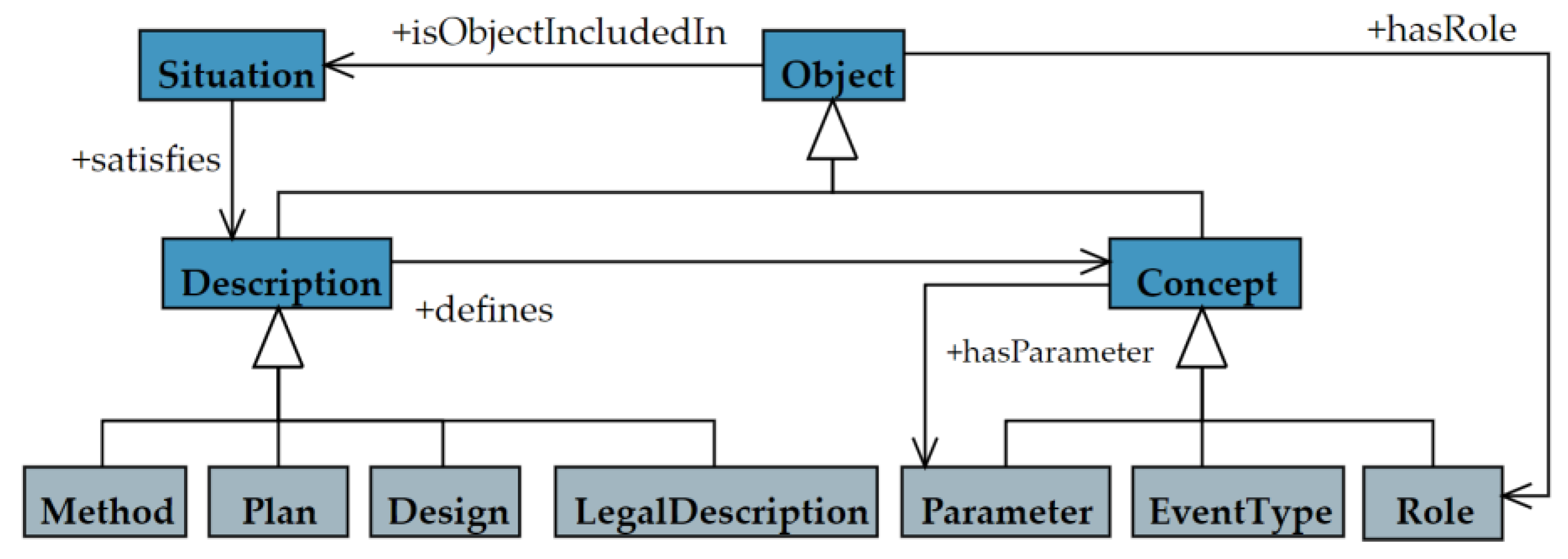

3.2.6. Alignment to DUL Upper Ontology

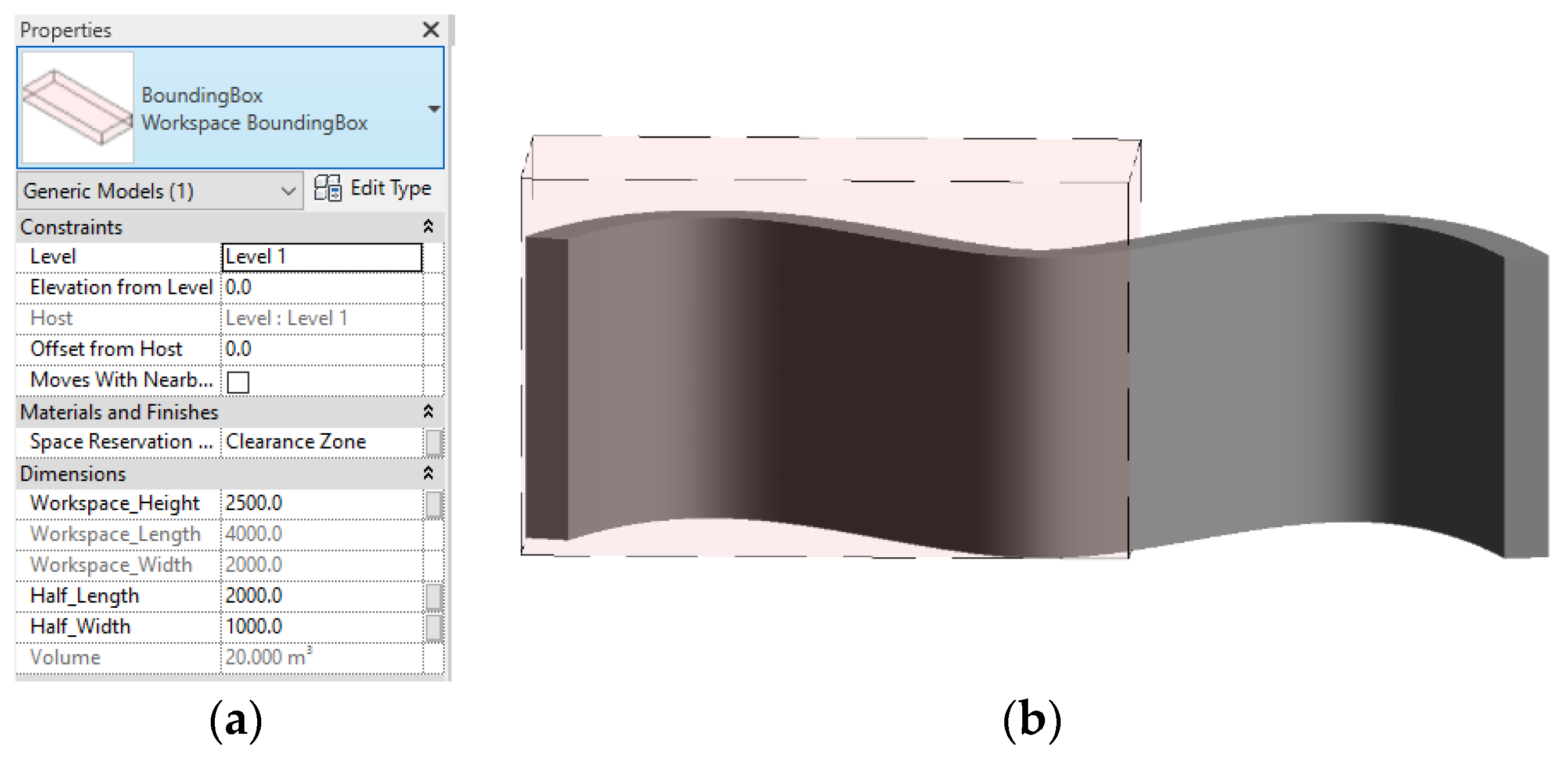

3.3. BIM Integration and Intuition of Design Adaptation

3.4. Feedback Mechanism for AMC

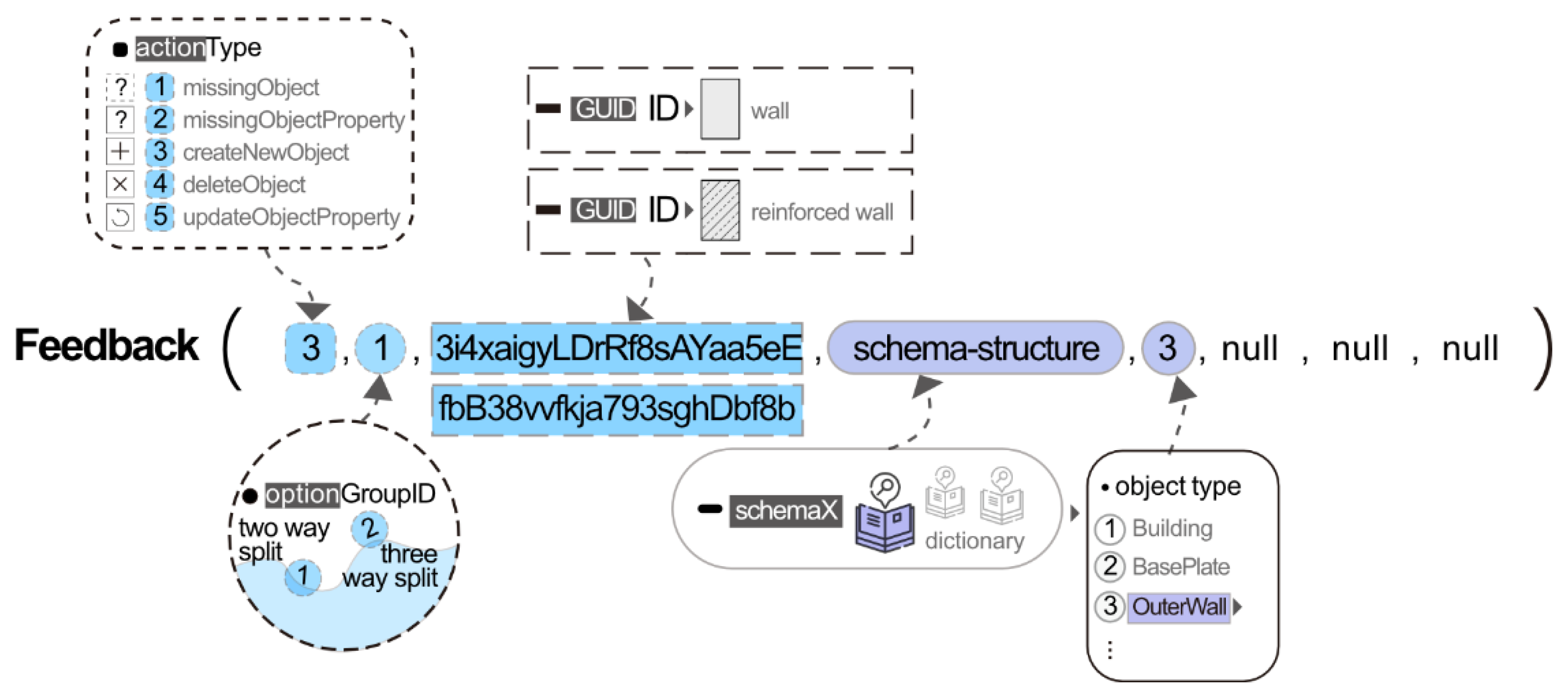

3.4.1. Introduction of the Feedback Mechanism

- Missing details in the design model which are critical for analysis

- Suggested options that meet the design requirements or fulfill the shortcomings

- Related results of simulations or analysis

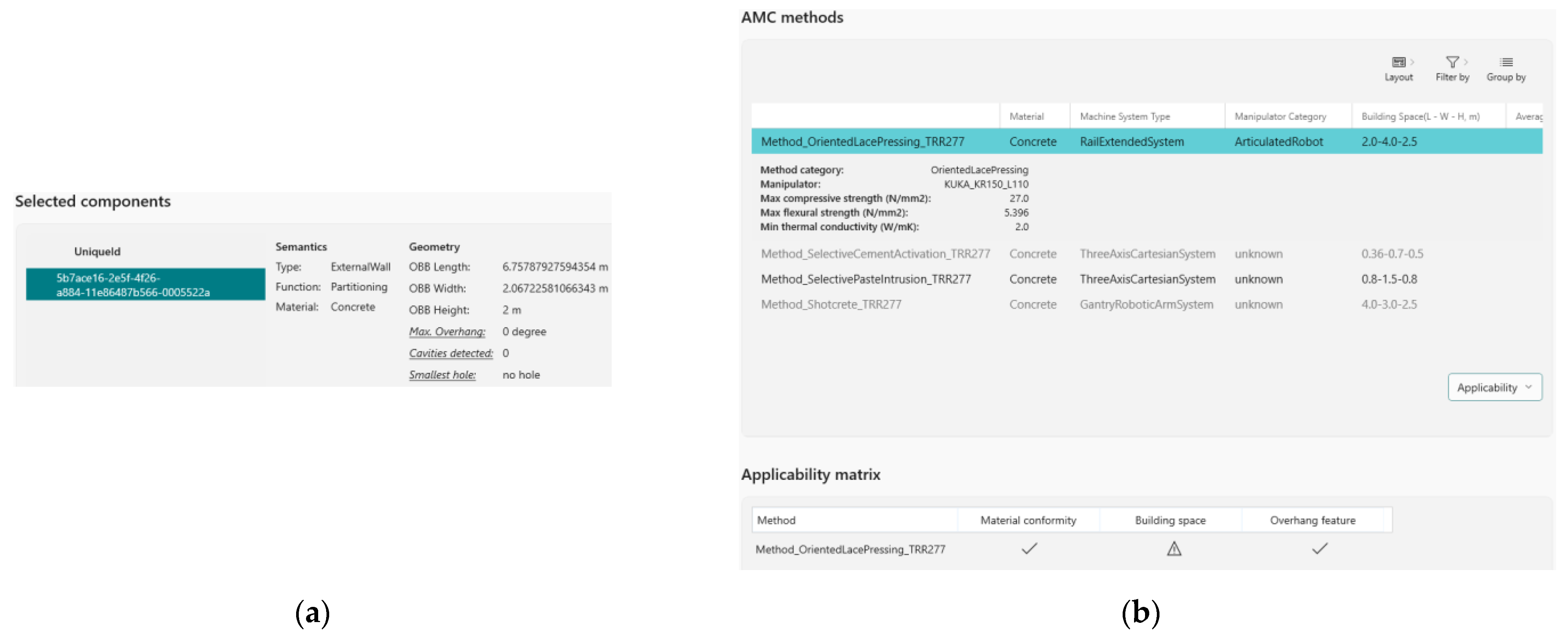

3.4.2. Use Case

4. Discussion

5. Conclusions

- The alignment of the current AMC ontology to DUL needs to proceed and must consider important terms of Function, ManufacturingFeature (even Feature), BoundaryCondition, etc. Some modifications may be made to the current AMC ontology, and DUL will be referenced as a design pattern once inconsistencies are found during the alignment process.

- The aligned ontology could be used to organize heterogeneous information including digital resources, linguistics, robot mechanics, etc.

- Efficient feature extraction algorithms should be explored in order to take the flexible slicing directions and the robot’s high DOF into account.

- Explanation functionality for the inference results would greatly improve the comprehensibility of the DDSS and should be further developed.

- More task-specific communication schemas must be identified with domain experts familiar with conventional construction methods and AM optimization. Last but not least, a framework incorporating the knowledge base and feedback mechanisms should be implemented in the future such that the architects and engineers are engaged in a smooth and productive design workflow.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonisation. e-Prime-Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Arifin, N.A.M.; Saman, M.Z.M.; Sharif, S.; Ngadiman, N.H.A. Sustainability Implications of Additive Manufacturing; Springer: Singapore, 2022. [Google Scholar]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- 3D Printing. Available online: https://d-shape.com/3d-printing/ (accessed on 3 April 2022).

- Kloft, H.; Krauss, H.-W.; Hack, N.; Herrmann, E.; Neudecker, S.; Varady, P.A.; Lowke, D. Influence of process parameters on the interlayer bond strength of concrete elements additive manufactured by Shotcrete 3D Printing (SC3DP). Cem. Concr. Res. 2020, 134, 106078. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Boton, C.; Rivest, L.; Ghnaya, O.; Chouchen, M. What is at the Root of Construction 4.0: A Systematic Review of the Recent Research Effort. Arch. Comput. Methods Eng. 2021, 28, 2331–2350. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Industry Foundation Classes (IFC)–buildingSMART Technical. Available online: https://technical.buildingsmart.org/standards/ifc/ (accessed on 6 April 2022).

- Slepicka, M.; Vilgertshofer, S.; Borrmann, A. Fabrication information modeling: Interfacing building information modeling with digital fabrication. Constr. Robot. 2022, 6, 87–99. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Smarsly, K.; Peralta, P.; Luckey, D.; Heine, S.; Ludwig, H.M. BIM-Based Concrete Printing. Lect. Notes Civ. Eng. 2021, 98, 992–1002. [Google Scholar] [CrossRef]

- Borrmann, A.; König, M.; Koch, C.; Beetz, J. (Eds.) Building Information Modeling: Technology Foundations and Industry Practice; Springer: Cham, Switzerland, 2018; pp. 235–314. [Google Scholar]

- Nowak, P.; Ksiązek, M.; Draps, M.; Zawistowski, J. Decision Making with Use of Building Information Modeling. Procedia Eng. 2016, 153, 519–526. [Google Scholar] [CrossRef] [Green Version]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Rezaee, R.; Brown, J.; Augenbroe, G.; Kim, J. Assessment of uncertainty and confidence in building design exploration. Artif. Intell. Eng. Des. Anal. Manuf. 2015, 29, 429–441. [Google Scholar] [CrossRef]

- Abualdenien, J.; Schneider-Marin, P.; Zahedi, A.; Harter, H.; Exner, H.; Steiner, D.; Singh, M.M.; Borrmann, A.; Lang, W.; Petzold, F.; et al. Consistent management and evaluation of building models in the early design stages. J. Inf. Technol. Constr. 2020, 25, 212–232. [Google Scholar] [CrossRef] [Green Version]

- An, S.; Martinez, P.; Al-Hussein, M.; Ahmad, R. BIM-based decision support system for automated manufacturability check of wood frame assemblies. Autom. Constr. 2020, 111, 103065. [Google Scholar] [CrossRef]

- Cao, J.; Vakaj, E.; Soman, R.K.; Hall, D.M. Ontology-based manufacturability analysis automation for industrialized construction. Autom. Constr. 2022, 139, 104277. [Google Scholar] [CrossRef]

- Buswell, R.A.; da Silva, W.L.; Bos, F.; Schipper, H.; Lowke, D.; Hack, N.; Kloft, H.; Mechtcherine, V.; Wangler, T.; Roussel, N. A process classification framework for defining and describing Digital Fabrication with Concrete. Cem. Concr. Res. 2020, 134, 106068. [Google Scholar] [CrossRef]

- Contour Crafting Corporation|Construction 3D Printing|California. Available online: https://www.contourcrafting.com/ (accessed on 30 September 2022).

- Lowke, D.; Dini, E.; Perrot, A.; Weger, D.; Gehlen, C.; Dillenburger, B. Particle-bed 3D printing in concrete construction–Possibilities and challenges. Cem. Concr. Res. 2018, 112, 50–65. [Google Scholar] [CrossRef]

- HiRes Concrete-dbt: 3D-Printed Formwork for the NEST HiLo. Available online: https://dbt.arch.ethz.ch/project/3d-printed-formwork-for-hires-concrete-slab/ (accessed on 27 September 2022).

- Endres, E.; Mehnert, J.; Hildebrand, L.; Schweiker, M.; Roswag-Klinge, E.; Knaack, U. State of the art and potentials of additive manufactured earth (AME). In Proceedings of the 9th PowerSKIN Conference, Munich, Germany, 9 April 2021; Auer, T., Knaack, U., Schneider, J., Eds.; TU Delft Open: Delft, The Netherlands; pp. 203–212. [Google Scholar]

- Buschmann, B.; Henke, K.; Talke, D.; Saile, B.; Asshoff, C.; Bunzel, F. Additive manufacturing of wood composite panels for individual layer fabrication (Ilf). Polymers 2021, 13, 3423. [Google Scholar] [CrossRef] [PubMed]

- Dielemans, G.; Dörfler, K. Mobile Additive Manufacturing: A robotic system for cooperative on-site construction. In Proceedings of the International Conference of Intelligent Robots and Systems (IROS), Workshop Robotic Fabrication: Sensing in Additive Construction, Prague, Czech Republic, 27 September–1 October 2021. [Google Scholar]

- Tan, Y.; Dahlenburg, M.; Kessler, S.; Fottner, J. Virtual Prototyping mit DEM zur Entwicklung eines Near-Nozzle-Mixing Verfahrens für den additiven 3D Betondruck für den Roboter Einsatz. In Proceedings of the 25. Fachtagung Schüttgutfördertechnik, Magdeburg, Germany, 22–23 September 2021. [Google Scholar]

- Hack, N.; Kloft, H. Shotcrete 3D Printing Technology for the Fabrication of Slender Fully Reinforced Freeform Concrete Elements with High Surface Quality: A Real-Scale Demonstrator. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, online, 6–9 July 2020; Springer: Cham, Switzerland, 2020; Volume 28, pp. 1128–1137. [Google Scholar] [CrossRef]

- Lanwer, J.-P.; Weigel, H.; Baghdadi, A.; Empelmann, M.; Kloft, H. Jointing Principles in AMC—Part 1: Design and Preparation of Dry Joints. Appl. Sci. 2022, 12, 4138. [Google Scholar] [CrossRef]

- Matthäus, C.; Kofler, N.; Kränkel, T.; Weger, D.; Gehlen, C. Interlayer Reinforcement Combined with Fiber Reinforcement for Extruded Lightweight Mortar Elements. Materials 2020, 13, 4778. [Google Scholar] [CrossRef] [PubMed]

- Freund, N.; Dressler, I.; Lowke, D. Studying the Bond Properties of Vertical Integrated Short Reinforcement in the Shotcrete 3D Printing Process. In Second RILEM International Conference on Concrete and Digital Fabrication; Springer: Cham, Switzerland, 2020; Volume 28, pp. 612–621. [Google Scholar]

- de Witte, D.; de Klijn-Chevalerias, M.L.; Loonen, R.C.G.M.; Hensen, J.L.M.; Knaack, U.; Zimmermann, G. Convective concrete: Additive manufacturing to facilitate activation of thermal mass. J. Facade Des. Eng. 2017, 5, 107–117. [Google Scholar] [CrossRef]

- Dielemans, G.; Briels, D.; Jaugstetter, F.; Henke, K.; Dörfler, K. Additive Manufacturing of Thermally Enhanced Lightweight Concrete Wall Elements with Closed Cellular Structures. J. Facade Des. Eng. 2021, 9, 59–72. [Google Scholar] [CrossRef]

- Bos, F.; Menna, C.; Pradena, M.; Kreiger, E.; da Silva, W.L.; Rehman, A.; Weger, D.; Wolfs, R.; Zhang, Y.; Ferrara, L.; et al. The realities of additively manufactured concrete structures in practice. Cem. Concr. Res. 2022, 156, 106746. [Google Scholar] [CrossRef]

- Weger, D.; Gehlen, C.; Korte, W.; Meyer-Brötz, F.; Scheydt, J.; Stengel, T. Building rethought – 3D concrete printing in building practice. Constr. Robot. 2021, 5, 203–210. [Google Scholar] [CrossRef]

- Xu, W.; Huang, S.; Han, D.; Zhang, Z.; Gao, Y.; Feng, P.; Zhang, D. Toward automated construction: The design-to-printing workflow for a robotic in-situ 3D printed house. Case Stud. Constr. Mater. 2022, 17, e01442. [Google Scholar] [CrossRef]

- About AMC TRR 277–Additive Manufacturing in Construction–Additive Manufacturing in Construction (AMC) TRR277. Available online: https://amc-trr277.de/trr-277-mission/ (accessed on 22 September 2022).

- Li, C.; Petzold, F. Integrating Digital Design and Additive Manufacturing Through Bim-Based Digital Support. In Proceedings of the 26th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Hong Kong, China, 29 March–1 April 2021; Volume 1, pp. 263–270. [Google Scholar]

- Li, C.; Petzold, F. Towards Informed Design Decision Support of Additive Manufacturing in Construction: The Use of Integrated Knowledge in BIM-Based Architectural Design. In Proceedings of the 10th Arab Society for Computer Aided Architectural Design (ASCAAD), Beirut, Lebanon, 12–13 October 2022; Volume 1, pp. 237–252. [Google Scholar]

- Østergård, T.; Jensen, R.L.; Maagaard, S.E. Early Building Design: Informed decision-making by exploring multidimensional design space using sensitivity analysis. Energy Build. 2017, 142, 8–22. [Google Scholar] [CrossRef]

- Leary, M. Chapter 3—Digital Design for AM. In Additive Manufacturing Materials and Technologies, Design for Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2020; pp. 33–90. [Google Scholar]

- Zeiler, W.; Savanovic, P.; Quanjel, E. Design decision support for the conceptual phase of the design process. In Proceedings of the International Association of Societies of Design Research: Emerging Trends in Design Research Conference 2007 (IASDR 2007), Hung Hom, Kowloon, Hong Kong, China, 12–15 November 2007; 15 November 2007; pp. 1–5. [Google Scholar]

- Abualdenien, J.; Borrmann, A. A meta-model approach for formal specification and consistent management of multi-LOD building models. Adv. Eng. Inform. 2019, 40, 135–153. [Google Scholar] [CrossRef]

- Zahedi, A.; Petzold, F. Utilization of simulation tools in early design phases through adaptive detailing strategies. In Proceedings of the 23rd International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Beijing, China, 17–19 May 2018; Volume 2, pp. 11–20. [Google Scholar] [CrossRef]

- Zahedi, A.; Abualdenien, J.; Petzold, F.; Borrmann, A. Minimized communication protocol based on a multi-LOD meta-model for adaptive detailing of BIM models. CEUR Workshop Proc. 2019, 2394, 1–10. [Google Scholar]

- Pauwels, P.; Terkaj, W. EXPRESS to OWL for construction industry: Towards a recommendable and usable ifcOWL ontology. Autom. Constr. 2016, 63, 100–133. [Google Scholar] [CrossRef]

- Building Topology Ontology. Available online: https://w3c-lbd-cg.github.io/bot/ (accessed on 17 May 2022).

- w3c-lbd-cg/Product: Product Ontology. Available online: https://github.com/w3c-lbd-cg/product (accessed on 31 October 2022).

- Digital Construction Ontologies (DiCon). Available online: https://digitalconstruction.github.io/v/0.5/index.html (accessed on 3 May 2022).

- ISO/IEC 21838-2; Information Technology—Top-Level Ontologies (TLO)—Part 2: Basic Formal Ontology (BFO). ISO: Geneva, Switzerland, 2021.

- Pauwels, P.; Zhang, S.; Lee, Y.C. Semantic web technologies in AEC industry: A literature overview. Autom. Constr. 2017, 73, 145–165. [Google Scholar] [CrossRef]

- Kalemi, E.V.; Cheung, F.; Tawil, A.R.; Patlakas, P.; Alyania, K. ifcOWL-DfMA a new ontology for the offsite construction domain. In Proceedings of the 8th Linked Data in Architecture and Construction Workshop, Dublin, Ireland, 17–19 June 2020; Volume 2636, pp. 105–117. [Google Scholar]

- Polanyi, M. The Tacit Dimension; University of Chicago Press: Chicago, IL, USA, 2009. [Google Scholar]

- Roith, J.; Langenhan, C.; Petzold, F. Supporting the building design process with graph-based methods using centrally coordinated federated databases. Vis. Eng. 2017, 5, 20. [Google Scholar] [CrossRef] [Green Version]

- Menolli, A.; Pinto, H.S.; Reinehr, S.; Malucelli, A. An incremental and iterative process for ontology building. CEUR Workshop Proc. 2013, 1041, 215–220. [Google Scholar]

- Liaw, S.; Rahimi, A.; Ray, P.; Taggart, J.; Dennis, S.; de Lusignan, S.; Jalaludin, B.; Yeo, A.; Talaei-Khoei, A. Towards an ontology for data quality in integrated chronic disease management: A realist review of the literature. Int. J. Med. Inform. 2013, 82, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Pinto, H.S.; Martins, J.P. Ontologies: How can They be Built? Knowl. Inf. Syst. 2004, 6, 441–464. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Lepuschitz, W.; Hoebert, T.; Merdan, M.; Schwentenwein, M.; Strasser, T.I. Knowledge-Driven Manufacturability Analysis for Additive Manufacturing. IEEE Open J. Ind. Electron. Soc. 2021, 2, 207–223. [Google Scholar] [CrossRef]

- Hagedorn, T.J.; Krishnamurty, S.; Grosse, I.R. A Knowledge-Based Method for Innovative Design for Additive Manufacturing Supported by Modular Ontologies. J. Comput. Inf. Sci. Eng. 2018, 18, 021009. [Google Scholar] [CrossRef] [Green Version]

- Dinar, M.; Rosen, D.W. A design for additive manufacturing ontology. J. Comput. Inf. Sci. Eng. 2017, 17, 021013. [Google Scholar] [CrossRef]

- Li, C.; Petzold, F. Formal knowledge as a basis for BIM-based design decision support in additive manufacturing. In Proceedings of the 33.Forum Bauinformatik, Munich, Germany, 7–9 September 2022; pp. 412–420. [Google Scholar]

- González, E.; Piñeiro, J.D.; Toledo, J.; Arnay, R.; Acosta, L. An approach based on the ifcOWL ontology to support indoor navigation. Egypt. Inform. J. 2020, 22, 1–13. [Google Scholar] [CrossRef]

- Sanfilippo, E.M.; Terkaj, W.; Borgo, S. Ontological modeling of manufacturing resources. Appl. Ontol. 2021, 16, 87–109. [Google Scholar] [CrossRef]

- Pauwels, P.; Roxin, A. SimpleBIM: From full ifcOWL graphs to simplified building graphs. In eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2016; pp. 11–18. [Google Scholar]

- Borgo, S.; Sanfilippo, E.M.; Šojić, A.; Terkaj, W. Ontological Analysis and Engineering Standards: An Initial Study of IFC. In Ontology Modeling in Physical Asset Integrity Management; Ebrahimipour, V., Yacout, S., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 17–43. [Google Scholar]

- Ocker, F.; Paredis, C.J.J.; Vogel-Heuser, B. Applying knowledge bases to make factories smarter. Automatisierungstechnik 2019, 67, 504–517. [Google Scholar] [CrossRef] [Green Version]

- Compton, M.; Barnaghi, P.; Bermudez, L.; García-Castro, R.; Corcho, O.; Cox, S.; Graybeal, J.; Hauswirth, M.; Henson, C.; Herzog, A.; et al. The SSN ontology of the W3C semantic sensor network incubator group. J. Web Semant. 2012, 17, 25–32. [Google Scholar] [CrossRef]

- IEEE Std 1872.2-2021; IEEE Standard for Autonomous Robotics (AuR) Ontology. IEEE: Piscatway, NJ, USA, 2021.

- Drobnjakovic, M.; Kulvatunyou, B.S.; Ameri, F.; Will, C.; Smith, B. The Industrial Ontologies Foundry (IOF) Core Ontology. In Proceedings of the FOMI 2022: 12th International Workshop on Formal Ontologies Meet Industry, Tarbes, France, 12–15 September 2022. [Google Scholar]

- Mendonça, F.M.; Coelho, K.C.; Andrade, A.Q.; Almeida, M.B. Knowledge acquisition in the construction of ontologies: A case study in the domain of hematology. CEUR Workshop Proc. 2012, 897, 2–6. [Google Scholar]

- Bobillo, F.; Straccia, U. An owl ontology for fuzzy owl 2. In Foundations of Intelligent Systems; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2009; Volume 5722, pp. 151–160. [Google Scholar] [CrossRef]

- Krisnadhi, A.; Maier, F.; Hitzler, P. OWL and rules. In Reasoning Web. Semantic Technologies for the Web of Data; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6848, pp. 382–415. [Google Scholar] [CrossRef]

- DOLCE + DnS Ultralite. Available online: https://databus.dbpedia.org/ontologies/ontologydesignpatterns.org/ont--dul--DUL--owl/2021.02.22-022820 (accessed on 31 October 2022).

- Pisanelli, D.; Gangemi, A.; Geri, S. An ontology of descriptions and situations for Lyee’s hypothetical world. In New Trends in Software Methodologies, Tools and Techniques; IOS Press: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Mika, P.; Sabou, M.; Gangermi, A.; Oberle, D. Foundations for DAML-S: Aligning DAML-S to DOLCE. In Proceedings of the First International Semantic Web Services Symposium (SWS2004), Palo Alto, CA, USA; 2004; Volume 6, pp. 52–59. Available online: https://www.researchgate.net/profile/Marta-Sabou/publication/2928246_Foundations_for_DAML-S_Aligning_DAML-S_to_DOLCE/links/0912f50a7e7d33c8e8000000/Foundations-for-DAML-S-Aligning-DAML-S-to-DOLCE.pdf (accessed on 31 October 2022).

- Merrell, E.; Limbaugh, D.; Koch, P.; Smith, B. Capabilities. PhilPapers. Available online: https://philpapers.org/rec/MERC-14 (accessed on 25 November 2022).

- Guarino, N. BFO and DOLCE: So Far, So Close…. Cosmos + Taxis 2017, 4, 10–18. [Google Scholar]

- Zhang, Y.; Yang, S.; Dong, G.; Zhao, Y.F. Predictive manufacturability assessment system for laser powder bed fusion based on a hybrid machine learning model. Addit. Manuf. 2021, 41, 101946. [Google Scholar] [CrossRef]

- Nickchen, T.; Engels, G.; Lohn, J. Opportunities of 3D Machine Learning for Manufacturability Analysis and Component Recognition in the Additive Manufacturing Process Chain. In Industrializing Additive Manufacturing; Springer: Cham, Switzerland, 2021; pp. 37–51. [Google Scholar]

- Svetashova, Y.; Zhou, B.; Pychynski, T.; Schmidt, S.; Sure-Vetter, Y.; Mikut, R.; Kharlamov, E. Ontology-Enhanced Machine Learning: A Bosch Use Case of Welding Quality Monitoring; Springer: Cham, Switzerland, 2020; Volume 12507. [Google Scholar]

- Kulmanov, M.; Smaili, F.Z.; Gao, X.; Hoehndorf, R. Semantic similarity and machine learning with ontologies. Brief. Bioinform. 2021, 22, bbaa199. [Google Scholar] [CrossRef]

| Index | Competency Question | Reason |

|---|---|---|

| CQ1 | What is the type of a given AMC process? | Aware of the method type and hierarchy |

| CQ2 | What are the tasks executed for the AMC method? | Descriptive workflow of AMC methods. Potentially used for construction planning. |

| CQ3 | What is the material type that the AMC method can print? | Get the catalog of AMC methods’ printed material types. Match the design intent. |

| CQ4 | What are the constraints for the hardened-state properties of AMC methods’ printed specimens? | Reflect AMC methods’ functions; evaluate AMC methods’ material suitability by comparison. |

| CQ5 | What is the type of machine system used for the AMC method? | Describe the machine system category and link to the determination of the building range; potential used for construction planning. |

| CQ6 | What is the building range of the machine system? | Constrain the building components’ geometry; evaluate AMC methods’ geometry suitability by comparison. |

| CQ7 | What are the manufacturing features important for the AMC method? | Get the catalog for geometry constraints; useful for feature extraction. |

| CQ8 | What are the constraints of the manufacturing feature for the AMC method? | Evaluate building components’ manufacturability by comparison. |

| CQ9 | What is the type of building component? | Describe the type of the building component; basic semantics in BIM. |

| CQ10 | What are the values of the building component’s manufacturing features? | Describe the geometry requirements of the building component to AMC methods. |

| CQ11 | What is the material type of the building component? | Describe the material type of the building component as the requirement for AMC methods. |

| CQ12 | What are the material properties of the building component? | Describe the properties of the building component’s material as the requirement for AMC methods. |

| CQ13 | Except for limitations from AMC methods, is there any constraint that impacts the design of the building components? | Bring AMC methods into actual practice; couple AMC methods with other procedures in construction planning. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zahedi, A.; Petzold, F. Pragmatic Design Decision Support for Additive Construction Using Formal Knowledge and Its Prospects for Synergy with a Feedback Mechanism. Buildings 2022, 12, 2072. https://doi.org/10.3390/buildings12122072

Li C, Zahedi A, Petzold F. Pragmatic Design Decision Support for Additive Construction Using Formal Knowledge and Its Prospects for Synergy with a Feedback Mechanism. Buildings. 2022; 12(12):2072. https://doi.org/10.3390/buildings12122072

Chicago/Turabian StyleLi, Chao, Ata Zahedi, and Frank Petzold. 2022. "Pragmatic Design Decision Support for Additive Construction Using Formal Knowledge and Its Prospects for Synergy with a Feedback Mechanism" Buildings 12, no. 12: 2072. https://doi.org/10.3390/buildings12122072

APA StyleLi, C., Zahedi, A., & Petzold, F. (2022). Pragmatic Design Decision Support for Additive Construction Using Formal Knowledge and Its Prospects for Synergy with a Feedback Mechanism. Buildings, 12(12), 2072. https://doi.org/10.3390/buildings12122072