In this section, we collected cases and conducted a CBA to determine whether Scan-vs-BIM-based quality management through the introduction of TLS and BIM was economically helpful for a construction project. The case data were collected through expert interviews with Dongyang Structural Engineers Group—an organization that provides integrated construction services such as structural design and engineering, construction, safety diagnosis, and maintenance.

4.1. Project Description

Dongyang Structural Engineers Group is a Korean company that was established in 1995 and specializes in the field of building structures. Currently, it is a structural engineering design office that performs various tasks, such as structural design and engineering, construction quality control, the revamping of aged facilities, safety diagnosis, and repair reinforcement for fire-damaged buildings, through digital transformation. The company’s capabilities have advanced from basic visual inspection methods to BIM, TLS, and Scan-to-BIM methods. The data measurement process was automated by digital transformation, but the data processing was still manpower-centered. Therefore, Dongyang Structural Engineers Group tried to directly compare the results by conducting the existing visual inspection method together after the introduction of digital conversion to increase the reliability of Scan-vs-BIM.

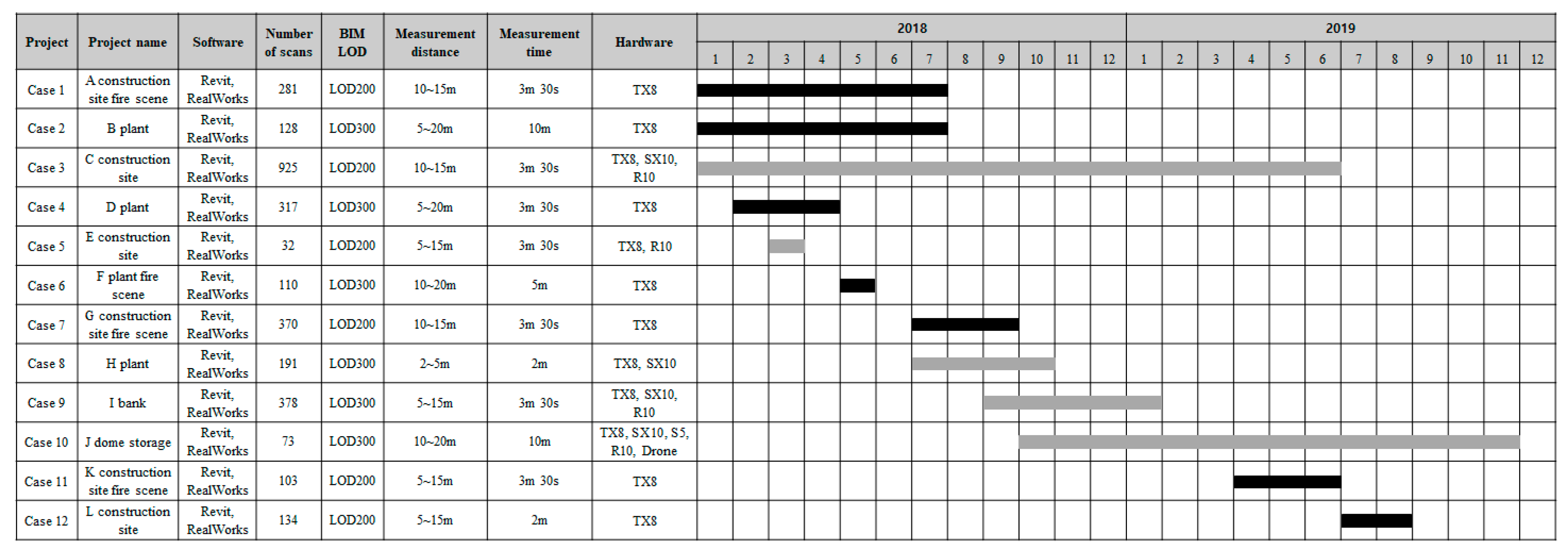

Figure 2 is a diagram of twelve reverse-engineering projects conducted by Dongyang Structural Engineers Group through Scan-vs-BIM. In this study, seven projects with the same software and hardware used were selected from the twelve projects to increase the accuracy of the results.

An overview of the seven selected cases is presented below.

Case 1 involved a fire that occurred during the construction of an office tower located in Suwon, Korea. The tower had five stories underground and forty-one stories above the ground, with a maximum height of 175 m. The scope of the scanning was the first basement floor and the second basement floor where the fire occurred. The contractor requested a status analysis of the fire site. The service period was January 2018 to July 2018 (7 months). The data collection comprised 3 days of scanning using Trimble TX8 and 15 days of data processing using Revit and RealWorks. Through scanning, the soot, microcracks in the concrete, explosion, and exposure and warpage of the rebar were analyzed.

Case 2 involved the displacement analysis of a large-scale plant located in Ulsan, Korea. The total scale of the site was 5,000,000 m2, and the site included five finished car factories, a transmission factory, and an export-only pier. Built from 1968 to 1975, it is the world’s largest single plant, producing an average of 6000 vehicles per day. Thus, it was necessary to conduct a structural safety diagnosis for the aging facilities. However, the safety diagnosis could not be performed because the previously designed design drawings differed from the current factory conditions at the time of the work. The scope of the displacement analysis via TLS and BIM was the main pipe rack onsite. The service period was January 2018 to July 2018 (7 months). The data collection comprised 7 days of scanning using Trimble TX8 and 20 days of data processing using Revit and RealWorks.

Case 4 was a reverse drawing example of a plant located in Mokpo, Korea. The contractor requested preservation through reverse drawing of the plant. Therefore, the entire factory was scanned. The area was 13,715 m2. The plant is a production facility for refractory materials, which has been needed as the steel industry has developed since the 1930s. It consists of three factory buildings, three chimneys, office buildings, residential buildings, and five industrial facilities. Mechanical equipment and ancillary facilities from the 1950s to the 1970s remain, and the working process of fire-resistant materials can be seen, so it is valuable as a modern heritage site. The service period was from February 2018 to April 2018 (3 months). The data collection comprised 4 days of scanning using Trimble TX8 and 20 days of data processing using Revit and RealWorks.

Case 6 involved a fire at a plant located in Miryang, Korea. The contractor requested an analysis of the current state of the fire damage on the site, structural safety diagnosis, and design for repair and reinforcement. The plant had two stories above the ground. The service period was May 2018 (1 month). The data collection comprised 2 days of scanning using Trimble TX8 and 4 days of data processing using Revit and RealWorks. A 3D BIM model was created using 3D scan data, and a drawing was created that was more accurate than the existing 2D drawing. Additionally, using the scan data for repair and reinforcement design, a preliminary review was conducted to prevent interference.

Case 7 involved a fire that occurred during the construction of a residential complex located in Sejong, Korea. The contractor requested an analysis of the fire damage status and a calculation of the repair and reinforcement quantities. The building had two basement floors and twenty-four floors above the ground. The fire damage ranged from the second basement floor to the second floor above the ground. The service period was from July 2018 to September 2018 (3 months). The data collection comprised 4 days of scanning using Trimble TX8 and 10 days of data processing using Revit and RealWorks. Through this process, the concrete explosion, exfoliation, rebar exposure, and damages to the members were analyzed. In addition, damage such as early cracks in the concrete and soot was analyzed in the periphery.

Case 11 involved a fire that occurred at the new construction site of a multipurpose building containing a shopping mall and an apartment in Yongin, Korea. The contractor requested an analysis of the fire damage status. The building had seven stories below the ground and twenty-two stories above the ground. The scanning range was from the fourth floor to the twentieth floor. The service period was from April 2019 to June 2019 (3 months). The data collection comprised 2 days of scanning using Trimble TX8 and 10 days of data processing using Revit and RealWorks.

Case 12 involved an office tower new construction site located in Pohang, Korea. The contractor requested a structural safety diagnosis and safety evaluation of the construction site. The building had six stories below the ground and twenty-two stories above the ground. The scope of the safety diagnosis was from the fourth basement floor to the first floor. The service period was from July 2019 to August 2019 (2 months). The data collection comprised 2 days of scanning using Trimble TX8 and 10 days of data processing using Revit and RealWorks. Through this process, it was confirmed that the cantilever beam was damaged and deformed and that the steel column was pushed.

Table 2 presents details of the projects, including the purposes, scan areas, and main structures. The projects consisted of seven cases with the same input equipment selected from twelve projects conducted from 2018 to 2019. The purposes of the projects included fire scene analysis, displacement analysis, and conversion design through reverse engineering using TLS and BIM. The main structures included a reinforced-concrete (RC) structure, a steel frame, a steel-frame reinforced-concrete (SRC) structure, and a wooden structure.

4.2. Data Collection

In this study, a CBA of the method of quality management was performed through the introduction of Scan-vs-BIM. The employees used in this study were workers at Dongyang Structural Engineers Group. They had no knowledge of TLS. They did not conduct training on TLS separately but proceeded until the performance of TLS-based measurement was the same as or higher than that of visual-inspection-based measurement. Therefore, the standard of CBA conducted in this study meant a financial analysis of the costs and benefits required for generating and analyzing information at the same level as or higher level than when using the existing visual inspection method. These cost and benefit factors were defined through expert interviews, and the monetary value of each factor was considered.

Table 3 provides the cost and benefit factors that were obtained through expert interviews.

Cost factors may vary depending on the size and function of the organization, as well as the main work content. In this study, we established a general standard by developing a model of basic cost factors through expert interviews. A CBA should establish a general basis by presenting a model of basic cost components. Common cost factors for Scan-vs-BIM-based quality management include the initial costs and maintenance costs of hardware, software, and human resources. However, the capabilities of Dongyang Structural Engineers Group have advanced from the visual inspection method to the Scan-vs-BIM method through continuous digital transformation. Therefore, in this study, CBA was conducted only on cost factors (e.g., software and hardware investment cost, insurance cost) that were additionally used for Scan-vs-BIM-based quality management. The benefit factors were classified into quantitative factors that could be measured in monetary units and qualitative factors that could not be measured in monetary units. CBA should be performed in terms of monetary units. Therefore, in this study, the reduction in work time, which could be converted into monetary units, and the reduction in manpower input were measured as benefit factors. The data used in this study were prepared by extracting only onsite data measurement and data processing tasks during the work of each case. Data collection was measured through the visual inspection method and the TLS method. Dongyang Structural Engineers Group assigned both the conventional visual inspection team and the TLS team to the reverse-engineering case project.

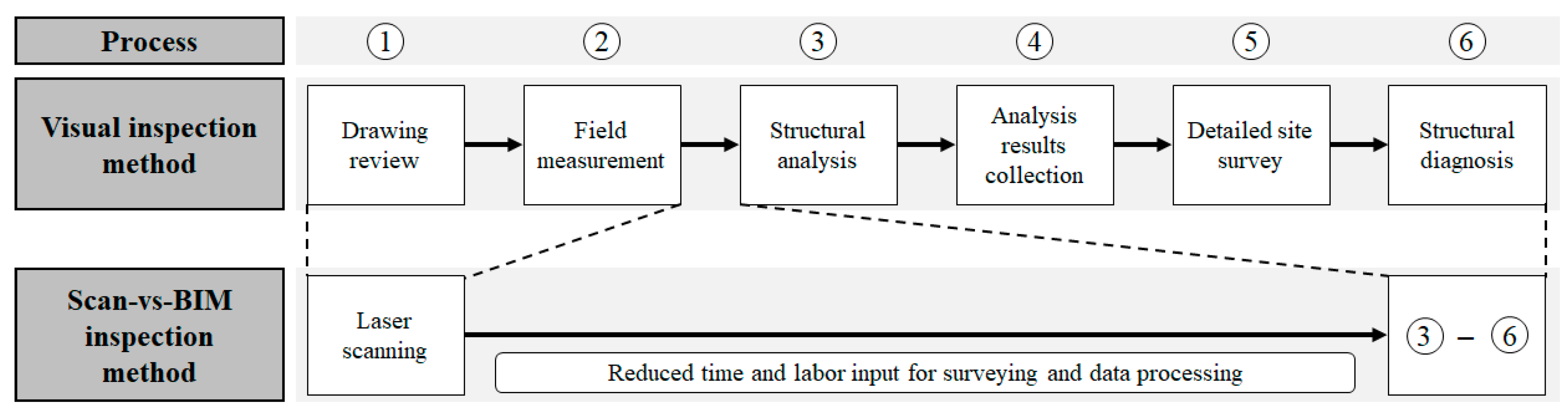

The visual inspection team’s onsite investigation process was as follows. The first step of reverse engineering for structural displacement analysis, field analysis, and conversion design was to conduct a preliminary investigation through a review of design documents and related data before measuring the structure. During the operation of the building, if there was insufficient information, such as the absence of drawings, inconsistency with the drawings, or deterioration, information was supplemented through onsite measurements. For the visual inspection method, at least two onsite inspections are required in this process. Additionally, more time, money, and personnel are invested compared with the case where TLS equipment is used, because the inspection is conducted with the naked eye. Furthermore, in the case of current status analysis through reverse engineering, accurate data cannot be calculated, and economic loss may occur because the entire result is inferred by sampling from a severely damaged area.

The Scan-vs-BIM team’s onsite investigation process was as follows. To determine the purpose, scope, and method of scanning and to efficiently measure point-cloud data, a preliminary investigation of the site was conducted. Three-dimensional scanning data were acquired after establishing the scanning equipment usage plan, scanning interval, and arrangement plan according to the site conditions. In this case, more accurate information could be obtained by scanning at various locations. Through this process, the problem of deriving the entire result from partial measurements in the visual inspection method is mitigated.

Figure 3 presents a comparison of the conventional method and the TLS method.

The Scan-vs-BIM-based quality management had software and hardware that were shared with the existing method. Therefore, in this study, only the newly added software and hardware were considered for the CBA factor of the Scan-vs-BIM-base quality management. Dongyang Structural Engineers Group purchased Trimble’s RealWorks (software) and Trimble’s TX8, SX10, R10, S5, and Drone (hardware) for digital transformation. There were also management costs (e.g., insurance) for the purchased software and hardware. In the process of digital transformation from the existing visual inspection method through TLS and BIM, there were no additional costs, such as training costs, for smooth use. In this study, we analyzed seven cases in which identical software and hardware were used. Therefore, the purchase cost and management cost of RealWorks and TX8 were selected as the cost factors.

After digital transformation, the manpower-oriented method was applied at the same time to produce results similar to the level of work of the conventional method, and thus, the reliability of Scan-vs-BIM was enhanced. By using both methods at the same time, Dongyang Structural Engineers Group had the effect of reducing the manpower input and input time. In addition, there were advantages such as the long-distance measurement of places that people could not enter (e.g., pipelines of the plant) or places that were dangerous for humans to directly measure in the existing manpower-centered survey method. These qualitative benefits could not be measured in terms of quantitative monetary value in the CBA. Therefore, in this study, the reductions in manpower and time were selected as the benefit factors.

Table 4 presents the manpower input and time for the visual inspection method (as-is) and Scan-vs-BIM method (to-be) for each project. These data were compiled by collecting the number of people and time taken for the visual inspection team and the Scan-vs-BIM team involved in each project. Through the data measurement of each project, it was confirmed that the time required for measurement work and data post-processing was reduced when TLS was used.

Table 5 presents the time and cost reductions for the scan-vs-BIM method (to-be) relative to the visual inspection method (as-is) for each case. The workers involved were paid workers. Therefore, it was not possible to calculate the amount of manpower input and the reduced time as monetary value. For the convenience of analysis and comparison, the calculation of the benefit increment for each case was based on 292,249 KRW/d, which is the labor cost of an express engineer based on the Korea 2020 engineering fee. Assuming an 8 h workday, the labor cost was 36,531 KRW per hour. This indicated the reduced cost per unit time when using TLS instead of the visual inspection method.

4.3. Data Analysis

The factors included in the CBA were analyzed for the cost increment (∆C) and benefit increment (∆B) when switching from the conventional visual inspection method to the Scan-vs-BIM method. Before analyzing the data, Dongyang Structural Engineers Group’s work ability was assumed for seven cases conducted in 2018. Therefore, a CBA was conducted assuming that the seven selected projects were conducted for one year.

Table 6 presents a CBA for the seven selected projects. As cost factors for the method of Scan-vs-BIM-based quality management, there were software and hardware investment costs. The investment cost was 25,000,000 KRW for software and 110,000,000 KRW for hardware, and the annual management cost was 135,000,000 KRW, i.e., 10% of the total investment cost. For the software and hardware, only the cost of annual maintenance (e.g., insurance), without additional costs after the initial input cost, was used.

The seven cases analyzed previously were classified into reverse drawing, displacement analysis, and fire scene analysis according to the purpose of the work. A CBA was conducted assuming that the project was conducted for one year based on the average value of the cases according to the purpose.

Table 7 presents the CBA for a single project conducted for one year based on the purpose.

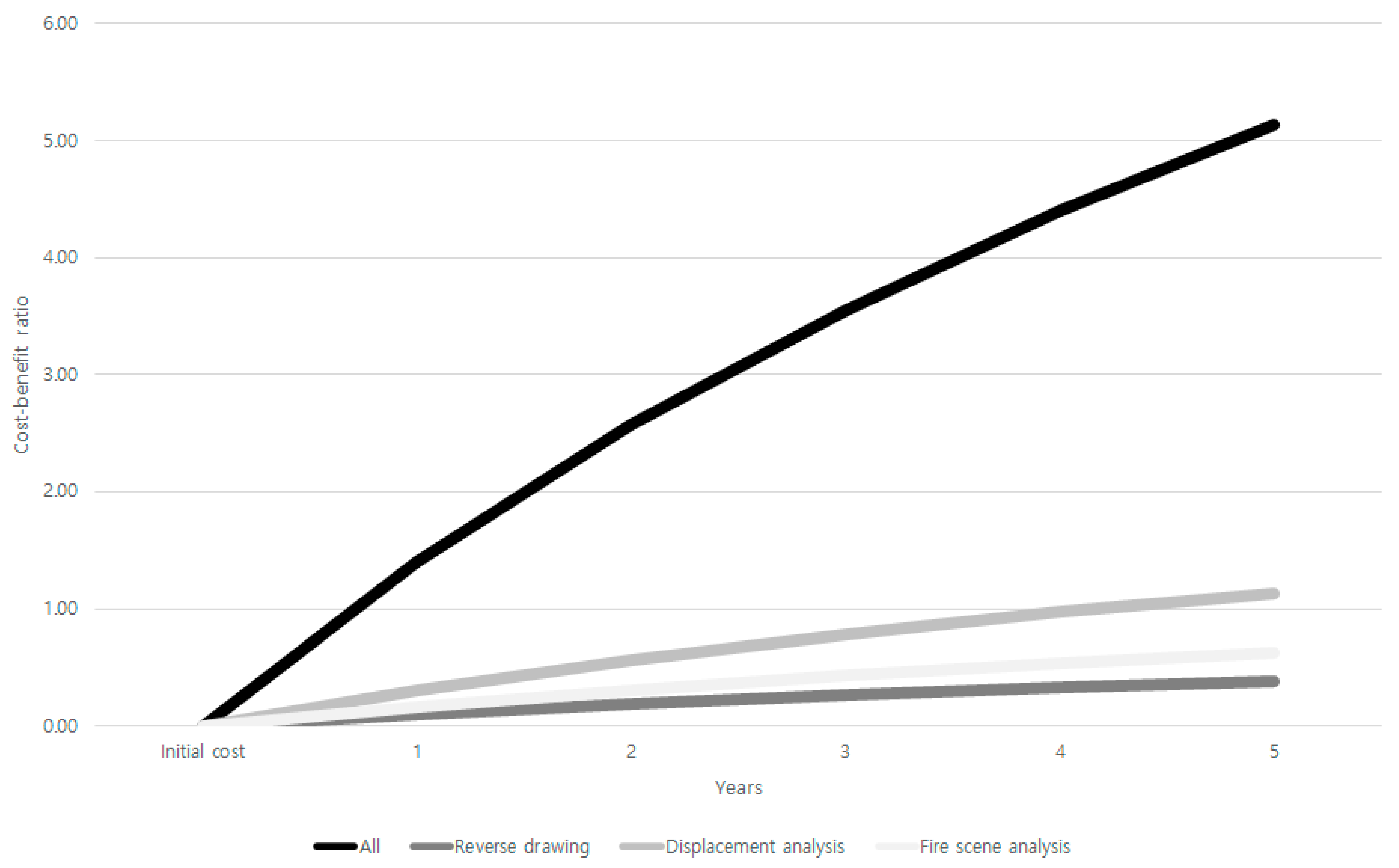

A CBA was performed by dividing the accumulated amount by applying a social discount rate (∆B/∆C) by calculating the costs and benefits of the seven selected projects. The operating period was set as the average equipment lifespan of 5 years. It was assumed that the residual value of the equipment after the average equipment lifespan of 5 years was the same. The CBA for one year (from

Table 7) was used as the analysis standard. A social discount rate of 4.5% was applied according to the guideline for conducting a preliminary feasibility study set by the Ministry of Strategy and Finance of Korea. It was confirmed that the reverse drawing and fire scene analysis fields were not economical because the NPV did not exceed 0 even after 5 years, which is the average life cycle. However, the displacement analysis was able to provide an economic benefit as the NPV exceeded zero in its fifth year.

Table 8 presents the CBA for 5 years, i.e., the average lifespan of the equipment.

The results of the CBA for single project and multi-project by purpose through TLS and BIM are shown in

Figure 4. According to the results, it was possible to see economic benefits when carrying out multiple projects as opposed to when carrying out a single project. The result of the CBA for the single case of reverse engineering was 0.10 in the 1st year and 0.38 in the 5th year. The result of the CBA for the single case of a fire site was 0.17 in the 1st year and 0.62 in the 5th year. These results indicated that the introduction of reverse engineering through TLS and BIM for short-term use in the fire site and reverse engineering work could not be cost-effective. For the displacement analysis, the result of the CBA for a single case was 0.31 in the 1st year and 1.13 in the 5th year, indicating economic advantages even for a single project. When Scan-vs-BIM-based quality management for a multi-project was used for 1 year, the cost–benefit ratio was 1.40, indicating economic feasibility due to the benefits outweighing the investment cost. The cost–benefit ratio at the 5th year—corresponding to the average lifespan of the equipment—was 5.14. The ratio could bring greater economic benefits when used longer than the average lifespan of the equipment due to user maintenance. These results can provide a quantitative basis in terms of monetary units for Scan-vs-BIM-based quality management. They are also useful for engineering firms making investment decisions, e.g., regarding whether to continue a project.