Review of Digital Twins for Constructed Facilities

Abstract

1. Background

2. The Digital Twin Paradigm

- Static twin (Level 100): a BIM model with no integration between the physical and virtual assets.

- Detailed twin (Level 200): a detailed as-built BIM model with semi-unidirectional integration between the physical and virtual assets.

- As-built twin (Level 300): more detailed than the previous type and enables unidirectional integration between the physical and virtual assets)

- Responsive twin (Level 350): a higher level than the previous one and provides limited bi-directional integration between the physical and virtual assets

- Adaptive twin (Level 400): a higher level that provides semi-bi-directional integration between both assets and a higher degree of data flow.

- Intelligent twin: or digital twin with full bi-directional integration between both assets and a fully autonomous data flow.

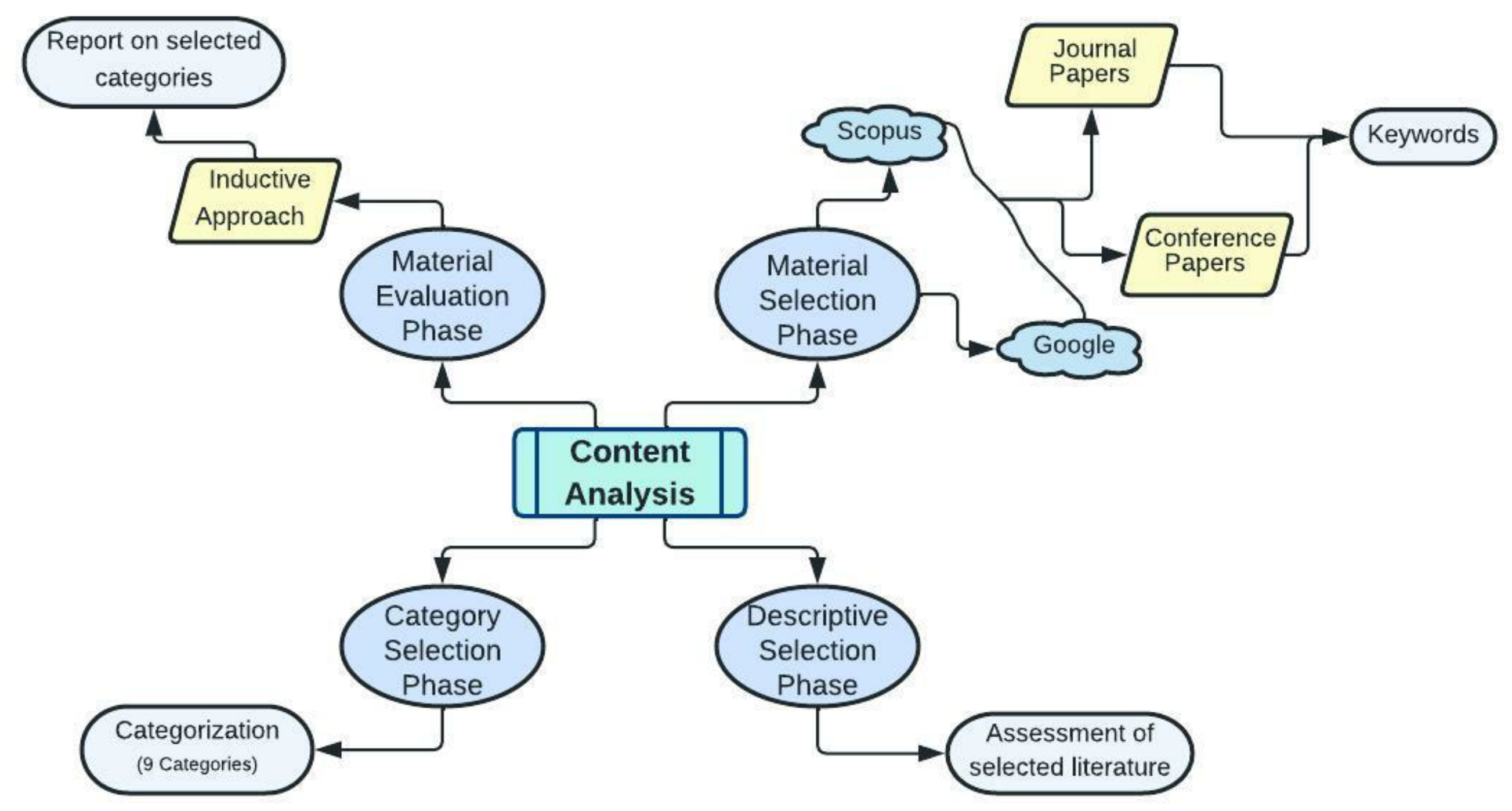

3. Materials and Methods

- (1)

- Identify the research questionsIn this step, the research questions to be carried out are identified as follows:RQ1. What are the applications of digital twins in construction?RQ2. How can we classify digital twin applications?To address these questions, all literature on digital twins in construction was collected. RQ1 required the collection and tabulation of all previous research to visualize it. RQ2 involved content analysis on the previously collected literature to identify methods of classification.

- (2)

- Identify the search process and inclusion/exclusion criteriaTo obtain as many articles as possible, several iterations of searches were conducted. The Scopus database was first used followed by a secondary search on Google Scholar. Additional searches were made in relevant journals, such as the Journal of Computing in Civil Engineering, Automation in Construction, and ASCE Journals (Journal of Construction Engineering and Management, Journal of Management in Engineering, etc.), to ensure the inclusion of all high-quality relevant research. Several search engines and databases were searched to provide a more accurate and comprehensive picture. A keyword search was used due to its popularity in systematic research. The search string consisted of primary and secondary keywords which were combined to collect all literature on DT applications in construction. The primary keyword was ‘digital twin’ while the secondary keywords were one of the following: ‘construction’, ‘engineering’, OR ‘infrastructure’. Additional papers from conference proceedings with the same keywords were also included. The publication year was limited between 2017 and 2021. As a result, a total of 145 papers were identified. A secondary screening was conducted for the abstracts and conclusion to eliminate unrelated articles. Eliminated articles fell under one or more of the following areas: manufacturing sector, discussion of the software/hardware aspects of DT rather than an application/framework, and literature review articles that did not provide an application/framework. Other eliminated articles were those in a language other than English. This resulted in 53 articles that were incorporated into the analysis. Figure 2 shows the distribution of articles over the years, from 2017 to 2021. The two most common journals were ‘Automation in Construction’ with six articles followed by the ‘Journal of Management in Engineering’ with five articles.

- (3)

- Conduct data collectionData collected from the studies include authors, year of publication, the objective of the research, type of application of digital twin, research findings, limitations, and recommendations for future work. This data was used to tabulate the results for better visualization. Two authors reviewed the literature and performed the tabulation of the results, which were then reviewed by the remaining two authors to ensure the high quality of the results.

- (4)

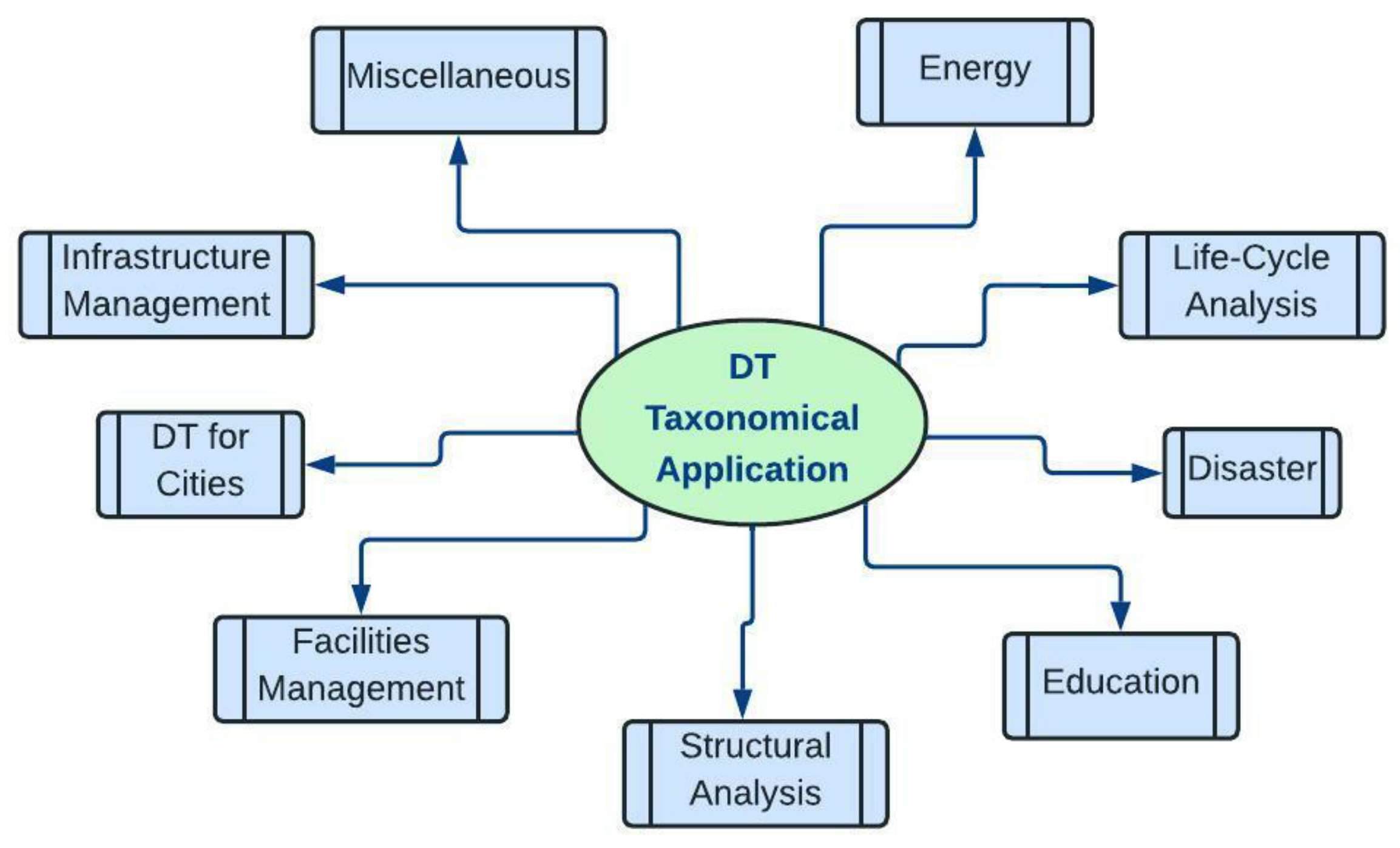

- Perform descriptive analysisAn assessment of the collected literature was conducted to understand the current state of research on DTs (RQ1). Additionally, it involved examining the studies to identify classifications of DT applications and delineate the categories (RQ2). These categories were chosen based on a content analysis of the identified studies and grouped into nine areas as discussed in the upcoming section. Finally, the selected papers were examined and a discussion on the identified areas was reported. This inductive approach enables objective assessment and reporting on a chosen topic.

4. Analysis

4.1. Energy

4.1.1. Growing Interest in Energy

4.1.2. DT Energy Applications

4.2. Life Cycle Analysis (LCA)

4.2.1. Importance of LCA

4.2.2. DT Applications

4.3. Disaster Management

4.3.1. Significance of Research on Disaster Management

4.3.2. Issues in Disaster Management

4.3.3. DT Applicability

4.3.4. Disaster Applications

4.3.5. Emerging Issues/Gaps

4.4. Education

4.4.1. Research on Education

4.4.2. DT Applications in Education

4.5. Structural Health Monitoring (SHM)

4.5.1. Interest in Structural Health Monitoring

4.5.2. Structural Health Monitoring DT Applications

4.6. Facility Management

4.6.1. Facility Management (FM) in Construction Projects

4.6.2. DT Applications for Facility Management

4.7. Digital Twins for Cities

4.7.1. DT Use for Cities

4.7.2. DT Applications for Cities

4.8. Infrastructure Management

4.8.1. Importance of DT for Infrastructure Management

4.8.2. DT Applications for Infrastructure Management

4.9. Miscellaneous DT Application Areas

5. Discussion

5.1. Digital Twin Applications in Construction

5.2. Enabling Technologies for Digital Twins in Infrastructure

6. Recommendations

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khallaf, R.; Khallaf, M. Classification and analysis of deep learning applications in construction: A systematic literature review. Autom. Constr. 2021, 129, 103760. [Google Scholar] [CrossRef]

- Opoku, D.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Mêda, P.; Calvetti, D.; Hjelseth, E.; Sousa, H. Incremental digital twin conceptualizations targeting data-driven circular construction. Buildings 2021, 11, 554. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication. White Paper. 2014. Available online: http://www.apriso.com/library/Whitepaper_Dr_Grieves_DigitalTwin_ManufacturingExcellence.php (accessed on 15 August 2022).

- Warke, V.; Kumar, S.; Bongale, A.; Kotecha, K. Sustainable Development of Smart Manufacturing Driven by the Digital Twin Framework: A Statistical Analysis. Sustainability 2021, 13, 10139. [Google Scholar] [CrossRef]

- Sacks, R.; Girolami, M.; Brilakis, I. Building information modeling, artificial intelligence, and construction tech. Dev. Built Environ. 2020, 4, 100011. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Liu, J.; Liu, X.; Liu, Q.; Qu, T.; Hu, T.; Zhang, Z.; Xiang, F.; Xu, W.; et al. Digital Twin and its potential application exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges, and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and cyber-physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital twin shop-floor: A new shop-floor paradigm towards smart manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Annals 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Fjeld, T.M.B. Digital Twin-towards a Joint Understanding within the AEC/FM Sector. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2020. [Google Scholar]

- Ke, S.; Xiang, F.; Zhang, Z.; Zuo, Y. An enhanced interaction framework based on VR, AR, and MR in digital twin. Procedia CIRP 2019, 83, 753–758. [Google Scholar] [CrossRef]

- Du, J.; Zhu, Q.; Shi, Y.; Wang, Q.; Lin, Y.; Zhao, D. Cognition Digital Twins for Personalized Information Systems of Smart Cities: Proof of Concept. J. Manag. Eng. 2020, 36, 04019052. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.; Tan, Y.; Wang, X. Literature Review of Digital Twins Applications in Construction Workforce Safety. Appl. Sci. 2021, 11, 339. [Google Scholar] [CrossRef]

- Madubuike, O.C.; Anumba, C.J.; Khallaf, R. A review of digital twin applications in construction. J. Inf. Technol. Constr. (ITcon) 2022, 27, 145–172. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Feng, H.; Chen, Q.; de Soto, B.G. Application of digital twin technologies in construction: An overview of opportunities and challenges. In Proceedings of the International Symposium on Automation and Robotics in Construction (ISARC) 2021, Dubai, United Arab Emirates, 2–4 November 2021; IAARC Publications: London, UK, 2021; Volume 38, pp. 979–986. [Google Scholar]

- Kor, M.; Yitmen, I.; Alizadehsalehi, S. An investigation for integration of deep learning and digital twins towards Construction 4.0. Smart Sustain. Built Environ. 2022. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Conducting content-analysis based literature reviews in supply chain management. Supply Chain. Manag. Int. J. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Inhaltanalyse—Grundlagen und Techniken (Qualitative Content Analysis); Beltz Verlag: Weinheim, Germany, 2008. [Google Scholar]

- International Renewable Energy Agency. Renewable Energy Outlook: Egypt. 2018. Available online: https://www.irena.org/publications/2018/Oct/Renewable-Energy-Outlook-Egypt (accessed on 19 November 2020).

- European Commission. Clean Energy for All Europeans Package. Available online: https://ec.europa.eu/energy/topics/energy-strategy/clean-energy-all-europeans_en (accessed on 19 November 2020).

- Francisco, A.; Mohammadi, N.; Taylor, J.E. Smart City Digital Twin–Enabled Energy Management: Toward Real-Time Urban Building Energy Benchmarking. J. Manag. Eng. 2020, 36, 04019045. [Google Scholar] [CrossRef]

- Srinivasan, R.S.; Manoharan, B.; Issa, R.R.A. Urban Building Energy CPS (UBE-CPS): Realtime Demand Response using Digital Twin. In CPS in the Built Environment; Anumba, C.A., Roofigari, N., Eds.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. The Potential of Digital Twin Model Integrated with Artificial Intelligence Systems. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A Digital-Twin Evaluation of Net Zero Energy Building for Existing Buildings. Sustainability 2019, 11, 159. [Google Scholar] [CrossRef]

- Alonso, R.; Borras, M.; Koppelaar, R.H.E.M.; Lodigiani, A.; Loscos, E.; Yöntem, E. SPHERE: BIM Digital Twin Platform. Proceedings 2019, 20, 9. [Google Scholar]

- Ham, Y.; Kim, J. Participatory sensing and digital twin city: Updating virtual city models for enhanced risk-informed decision-making. J. Manag. Eng. 2020, 36, 04020005. [Google Scholar] [CrossRef]

- Macchi, M.; Roda, I.; Negri, E.; Fumagalli, L. Exploring the role of Digital Twin for Asset Lifecycle Management. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Sai, Y.; Zhang, T.; Huang, X.; Ding, C. Analysis of digital twins and application value of power engineering based on BIM. In Proceedings of the International Conference on Big Data Analytics for Cyber-Physical-Systems, Shanghai, China, 28–29 December 2020; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 550–558. [Google Scholar]

- Küsel, K. Model-Based System Engineering for Life Cycle Development of Digital Twins of Real Estate. In INCOSE International Symposium; Wiley: Hoboken, NJ, USA, 2020; Volume 30, pp. 715–730. [Google Scholar]

- Kaewunruen, S.; Lian, Q. Digital Twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Karlsson, P.; Götz, C. Blockchain-Based Digital Twin for Smart Asset Lifecycle Management. Jönköping University, Jönköping, Sweden. 2020. Available online: http://hj.diva-portal.org/smash/record.jsf?pid=diva2%3A1441568&dswid=-3693 (accessed on 10 July 2022).

- Peng, Y.; Zhang, M.; Yu, F.; Xu, J.; Gao, S. Digital twin hospital buildings: An exemplary case study through continuous lifecycle integration. Adv. Civ. Eng. 2020, 2020, 8846667. [Google Scholar] [CrossRef]

- Mitsova, D.; Esnard, A.M.; Sapat, A.; Lamadrid, A.; Escaleras, M.; Velarde-Perez, C. Effects of infrastructure service disruptions following hurricane Irma: Multilevel analysis of Postdisaster recovery outcomes. Nat. Hazards Rev. 2021, 22, 1–15. [Google Scholar] [CrossRef]

- Ford, D.N.; Wolf, C.M. Smart Cities with Digital Twin Systems for Disaster Management. J. Manag. Eng. 2020, 36, 04020027. [Google Scholar] [CrossRef]

- Fan, C.; Jiang, Y.; Mostafavi, A. Social sensing in disaster city digital twin: Integrated textual–visual–geo framework for situational awareness during built environment disruptions. J. Manag. Eng. 2020, 36, 04020002. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, C.; Yahja, A.; Mostafavi, A. Disaster City Digital Twin: A vision for integrating artificial and human intelligence for disaster management. Int. J. Inf. Manag. 2019, 56, 102049. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Digital Twin and Web-Based Virtual Gaming Technologies for Online Education: A Case of Construction Management and Engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Liljaniemi, A.; Paavilainen, H. Using digital twin technology in engineering education–course concept to explore benefits and barriers. Open Eng. 2020, 10, 377–385. [Google Scholar] [CrossRef]

- Chacón, R.; Codony, D.; Toledo, Á. From physical to digital in structural engineering classrooms using digital fabrication. Comput. Appl. Eng. Educ. 2017, 25, 927–937. [Google Scholar] [CrossRef]

- Lin, K.; Xu, Y.-L.; Lu, X.; Guan, Z.; Li, J. Digital twin-based collapse fragility assessment of a long-span cable-stayed bridge under strong earthquakes. Autom. Constr. 2021, 123, 103547. [Google Scholar] [CrossRef]

- Shim, C.; Dang, N.; Lon, S.; Jeon, C. Development of a bridge maintenance system for prestressed concrete bridges using 3D digital twin model. Struct. Infrastruct. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Gardner, P.; Dal Borgo, M.; Ruffini, V.; Zhu, Y.; Hughes, A. Towards the development of a digital twin for structural dynamics applications. In Model Validation and Uncertainty Quantification; Springer: Cham, Switzerland, 2020; Volume 3, pp. 165–179. [Google Scholar]

- Haag, S.; Anderl, R.; Schützer, K.; Zancul, E. Motion-Structural Analysis of Systems Using Digital Twins. In Proceedings of the IFIP International Conference on Product Lifecycle Management, Moscow, Russia, 8–12 July 2019; Springer: Cham, Switzerland, 2019; pp. 243–249. [Google Scholar]

- Revetria, R.; Tonelli, F.; Damiani LDemartini MBisio, F.; Peruzzo, N. A Real-Time Mechanical Structures Monitoring System Based on Digital Twin, IoT, and Augmented Reality. In Proceedings of the IEEE 2019 Spring Simulation Conference (SpringSim), Tucson, AZ, USA, 29 April–2 May 2019; pp. 1–10. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Fogerty, D.; Wu, L.O.; Li, Z.; Sepasgozar, S.M.E.; Zhang, K.; Sepasgozar, S.; Marroquin, F.A. Numerical analysis of the creep and shrinkage experienced in the Sydney Opera House and the rise of digital twin as future monitoring technology. Buildings 2019, 9, 137. [Google Scholar] [CrossRef]

- Ye, C.; Butler, L.; Bartek, C.; Iangurazov, M.; Lu, Q.; Gregory, A.; Girolami, M. A Digital Twin of Bridges for Structural Health Monitoring. In Proceedings of the 12th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 10–12 September 2019. [Google Scholar]

- Nikolaev, S.; Gusev, M.; Padalitsa, D.; Mozhenkov, E.; Mishin, S.; Uzhinsky, I. Implementation of “Digital Twin” Concept for Modern Project-Based Engineering Education. IFIP Advances in Information and Communication Technology. Product Lifecycle Management to Support Industry 4.0. In Proceedings of the 15th IFIP WG 5.1 International Conference, PLM 2018, Turin, Italy, 2–4 July 2018; Chapter 18. Volume 540, pp. 193–203. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Xue, F.; Chen, K.; Lu, W. Understanding unstructured 3D point clouds for creating digital twin city: An unsupervised hierarchical clustering approach. In Proceedings of the CIB World Building Congress, Hong Kong SAR, 17–21 June 2019. [Google Scholar]

- Nochta, T.; Parlikad, A.; Schooling, J.; Badstuber, N.; Wahby, N. The Local Governance of Digital Technology—Implications for the City-Scale Digital Twin. 2019. Available online: https://www.repository.cam.ac.uk/bitstream/handle/1810/296276/cdbb_ecr_project_final_report_tn_10july_timea_nochta_.pdf?sequence=1&isAllowed=y> (accessed on 5 April 2022).

- Mohammadi, N.; Taylor, J. Devising a game theoretic approach to enable smart city digital twin analytics. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Honolulu, HI, USA, 1 August 2019. [Google Scholar]

- Austin, M.; Delgoshaei, P.; Coelho, M.; Heidarinejad, M. Architecting Smart City Digital Twins: Combined Semantic Model and Machine Learning Approach. J. Manag. Eng. 2020, 36, 04020026. [Google Scholar] [CrossRef]

- Olszewski, R.; Cegiełka, M.; Wesołowski, J. The Concept and Development of a Serious Game Alter Eco as Part of Creating a Digital Twin of a Smart City. In Proceedings of the Joint International Conference on Entertainment Computing and Serious Games, Arequipa, Peru, 11–15 November 2019; Springer: Cham, Switzerland, 2019; pp. 426–430. [Google Scholar]

- Ruohomaki, T.; Airaksinen, E.; Huuska, P.; Kesaniemi, O.; Martikka, M.; Suomisto, J. Smart City Platform Enabling Digital Twin. In Proceedings of the IEEE 2018 International Conference on Intelligent Systems (IS), Funchal, Madeira, Portugal, 25–27 September 2018; pp. 155–161. [Google Scholar] [CrossRef]

- Al-Sehrawy, R.; Kumar, B.; Watson, R. Digital Twin Uses Classification System for Urban Planning & Infrastructure Program Management. In Enabling the Development and Implementation of Digital Twins. Proceedings of the 20th International Conference on Construction Applications of Virtual Reality, Middlesbrough, UK 30 September–2 October 2020; Dawood, N., Rahimian, F., Seyedzadeh, S., Sheikhkhoshkar, M., Eds.; Teesside University Press: Middlesbrough, UK, 2021. [Google Scholar]

- Lu, R.; Brilakis, I. Digital twinning of existing reinforced concrete bridges from labeled point clusters. Autom. Constr. 2019, 105, 102837. [Google Scholar] [CrossRef]

- Shim, C.S.; Kang, H.R.; Dang, N.S. Digital Twin Models for Maintenance of Cable-Supported Bridges. In Proceedings of the ICE Publishing International Conference on Smart Infrastructure and Construction 2019 (ICSIC), Cambridge, UK, 8–10 July 2019; pp. 737–742. [Google Scholar] [CrossRef]

- Sofia, H.; Anas, E.; Faiz, O. Mobile Mapping, Machine Learning and Digital Twin for Road Infrastructure Monitoring and Maintenance: Case Study of Mohammed VI Bridge in Morocco. In Proceedings of the IEEE 2020 International conference of Moroccan Geomatics (Morgeo), Casablanca, Morocco, 11–13 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Zhao, H.; Tan, C.; OBrien, E.J.; Zhang, B.; Uddin, N.; Guo, H. Developing Digital Twins to Characterize Bridge Behavior Using Measurements Taken under Random Traffic. J. Bridge Eng. 2022, 27, 04021101. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Peng, S.; Phil-Ebosie, O. Digital Twin aided sustainability and vulnerability audit for subway stations. Sustainability 2020, 12, 7873. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.; Woodall, P.; Don Ranasinghe, G.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a dynamic digital twin at building and city levels: A case study of the West Cambridge campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Barat, S.; Kulkarni, V. An Actor-Based Simulation Driven Digital Twin for Analyzing Complex Business Systems. In Proceedings of the 2019 Winter Simulation Conference, National Harbor, MD, USA, 8–11 December 2019. Tata Consultancy Services Research. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the void: Digital twins for construction site logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Li, M.; Lu, Q.; Bai, S.; Zhang, M.; Tian, H.; Qin, L. Digital twin-driven virtual sensor approach for safe construction operations of trailing suction hopper dredger. Autom. Constr. 2021, 132, 103961. [Google Scholar] [CrossRef]

- Dembski, F.; Wössner, U.; Letzgus, M. The Digital Twin Tackling Urban Challenges with Models, Spatial Analysis and Numerical Simulations in Immersive Virtual Environments. In Proceedings of the eCAADe + SIGraDI Conference—Architecture in the Age of the 4th Industrial, Porto, Portugal, 11–13 September 2019. [Google Scholar] [CrossRef]

- Saroj, A.J.; Roy, S.; Guin, A.; Hunter, M. Development of a Connected Corridor Real-Time Data-Driven Traffic Digital Twin Simulation Model. J. Transp. Eng. Part A Syst. 2021, 147, 04021096. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Lin, Y.H. Digital twins for managing railway maintenance and resilience. Open Res. Eur. 2021, 1, 91. [Google Scholar] [CrossRef]

- Hamarat, M.; Papaelias, M.; Kaewunruen, S. Fatigue damage assessment of complex railway turnout crossings via Peridynamics-based digital twin. Sci. Rep. 2022, 12, 14377. [Google Scholar] [CrossRef] [PubMed]

- O’Dwyer, E.; Pan, I.; Charlesworth, R.; Butler, S.; Shah, N. Integration of an energy management tool and digital twin for coordination and control of multi-vector smart energy systems. Sustain. Cities Soc. 2020, 62, 102412. [Google Scholar] [CrossRef]

- Fathy, Y.; Jaber, M.; Nadeem, Z. Digital twin-driven decision-making and planning for energy consumption. J. Sens. Actuator Netw. 2021, 10, 37. [Google Scholar] [CrossRef]

- Khallaf, R.; Hastak, M. A System-of-Systems Framework for Public-Private Partnership Projects. In Proceedings of the European and Mediterranean Structural Engineering and Construction Conference, Beirut, Lebanon, 23–28 July 2018. [Google Scholar]

- Schrotter, G.; Hürzeler, C. The digital twin of the city of Zurich for urban planning. PFG–J. Photogramm. Remote Sens. Geoinf. Sci. 2020, 88, 99–112. [Google Scholar] [CrossRef]

- Heaton, J.; Parlikad, A.K. Asset Information Model to support the adoption of a Digital Twin: West Cambridge case study. IFAC-PapersOnLine 2020, 53, 366–371. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges, and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

| Criteria | Content |

|---|---|

| Search engine | Scopus and Google Scholar |

| Article Type | Peer-reviewed journal and conference articles |

| Search string | “Digital twin” AND “construction”, or “engineering” or “infrastructure” |

| Screening process | Initial screening of abstract followed by reading the paper |

| Author | Methodology/Aim | Findings |

|---|---|---|

| [28] | Developed a DT energy management platform using various benchmarks for occupied and unoccupied periods throughout the year for near real-time management. | The proposed method is more accurate in efficiency measurement than a building’s overall benchmark. It can aid in the creation of platforms for energy management using digital twin. |

| [29] | Develops a framework that combines a DT with energy models to manage and automate buildings. | The framework can control and automate building energy demand. |

| [30] | Proposes the use of DT to automate building energy management systems. | The proposed method can automate and optimize building energy systems. |

| [31] | Proposes a hierarchy-flow chart and DT-based model to evaluate net zero energy building for existing buildings. | A 23-year payback period was reached using solar (PV) and wind turbines for renewable energy. |

| [32] | Proposes an energy-focused model for buildings’ lifecycle based on: (1) DT; (2) Integrated Design and Delivery Solutions (IDDS) framework; and (3) System of Systems infrastructure. | The proposed model can reduce construction time as well as energy demand and emissions during operation. |

| Author | Methodology/Aim | Findings |

|---|---|---|

| [35] | Proposes power engineering digital twins using IoT and Big Data. | The proposed model can be used by the design, construction, and supervision companies for real-time information sharing and management of a project. |

| [36] | Proposes a framework for DTs of real estate through model-based system engineering. | Significant savings can be obtained from the use of DTs for lifecycle management. |

| [37] | Proposes 6D BIM for managing railway turnout systems throughout their lifecycle. | The most expensive phase in the lifecycle is the reconstruction phase. |

| [38] | Proposes a blockchain-based Digital Twin for asset lifecycle management | Several prerequisites are needed to enable this: BIM Level 3, scalable blockchains, and implementation manuals. |

| [39] | Proposed a case study for continuous lifecycle integration of a hospital. | Several benefits were observed including a reduction in energy consumption and requested repairs as well as improved quality of the maintenance work. |

| Author | Methodology/Aim | Findings |

|---|---|---|

| [47] | Proposes a method for collapse fragility assessment using DT. | The proposed model was able to determine the seismic collapse resistance and the bridge’s vulnerable areas. |

| [49] | Develops a digital twin for structural dynamics systems. | The DT was able to update and improve the model and learn from observed data. |

| [50] | Develops a DT demonstrator for structural simulation. | A bending beam bench test was applied to demonstrate the system. The calculation time was over half a minute, which hinders real-time capabilities. |

| [51] | Proposes a system using AR, IoT, digital twin, and simulation to monitor stresses. | The stresses can be calculated and observed for the entire lifecycle. |

| [52] | Analyzes the effect of creep and shrinkage on the Sydney Opera House. | Proposed the integration of BIM and finite element to create a digital twin. |

| [53] | Proposes a framework for structural health monitoring of bridges using digital twins. | Two bridges were used as a case study and four different approaches were utilized. |

| Author | Methodology/Aim | Findings |

|---|---|---|

| [48] | Proposes a DT model for bridge maintenance. | The proposed model combined 3D information with a digital inspection system and applied it to prestressed concrete systems. |

| [62] | Proposes a “DT Uses Classification System” for infrastructure program management. | The terminology developed here will contribute to the National Digital Twin strategy in the UK. |

| [63] | Proposes a DT of a reinforced concrete bridge. | The proposed model used a ‘slicing-based object fitting method’. |

| [64] | Proposes a DT-based bridge management system. | The proposed model showed the behavior and future performance of cable-supported bridges. |

| [65] | Proposes an integration of DT with geospatial data for bridge infrastructure modeling. | The proposed model aided in creating a bridge maintenance system for a case study in Morocco. |

| Author | Methodology/Aim | Findings |

|---|---|---|

| [67] | Proposes a life cycle assessment for a subway station using digital twin. | The carbon footprint is calculated throughout the life cycle and found to be highest during operation and maintenance. |

| [68] | Proposes a semi-automatic method to create a DT based on images and CAD drawings. | The proposed model was able to achieve LOD 300, which can aid in the operation and maintenance phases. |

| [69] | Proposes a method to control complex business enterprises using digital twins. | The proposed method enables the quantitative assessment of operations in business enterprises. |

| [70] | Proposes a DSS for construction site logistics using DTs. | Using sensors enables silo tracking and threshold-based filling. The DT enables the collection of data on orders, silos, and trucks. |

| [71] | Proposes a DT framework using BIM, IoT, and data mining for advanced project management. | The proposed model enables the assessment of workflows, workloads, and worker tasks. |

| [72] | Develops a DT-driven sensor that ensures construction safety in the process of dredging. | Using a deep learning-based model to create the DT model provided environmentally friendly results while maintaining high accuracy in its predictions. |

| [73] | Uses DT with VR to involve citizens in the urban planning process. | Using 3D modeling, urban mobility simulation and other tools enabled the decision-making process while involving the public. |

| [74] | Develops a DT model that uses traffic data to provide feedback about traffic and environmental performance | The proposed model can be used to monitor real-time transportation system technologies. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khallaf, R.; Khallaf, L.; Anumba, C.J.; Madubuike, O.C. Review of Digital Twins for Constructed Facilities. Buildings 2022, 12, 2029. https://doi.org/10.3390/buildings12112029

Khallaf R, Khallaf L, Anumba CJ, Madubuike OC. Review of Digital Twins for Constructed Facilities. Buildings. 2022; 12(11):2029. https://doi.org/10.3390/buildings12112029

Chicago/Turabian StyleKhallaf, Rana, Lama Khallaf, Chimay J. Anumba, and Obinna C. Madubuike. 2022. "Review of Digital Twins for Constructed Facilities" Buildings 12, no. 11: 2029. https://doi.org/10.3390/buildings12112029

APA StyleKhallaf, R., Khallaf, L., Anumba, C. J., & Madubuike, O. C. (2022). Review of Digital Twins for Constructed Facilities. Buildings, 12(11), 2029. https://doi.org/10.3390/buildings12112029