The Effect of GFRP Wrapping on Lateral Performance of Double Shear Lap Joints in Cross-Laminated Timber as a Part of Timber Bridges

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood

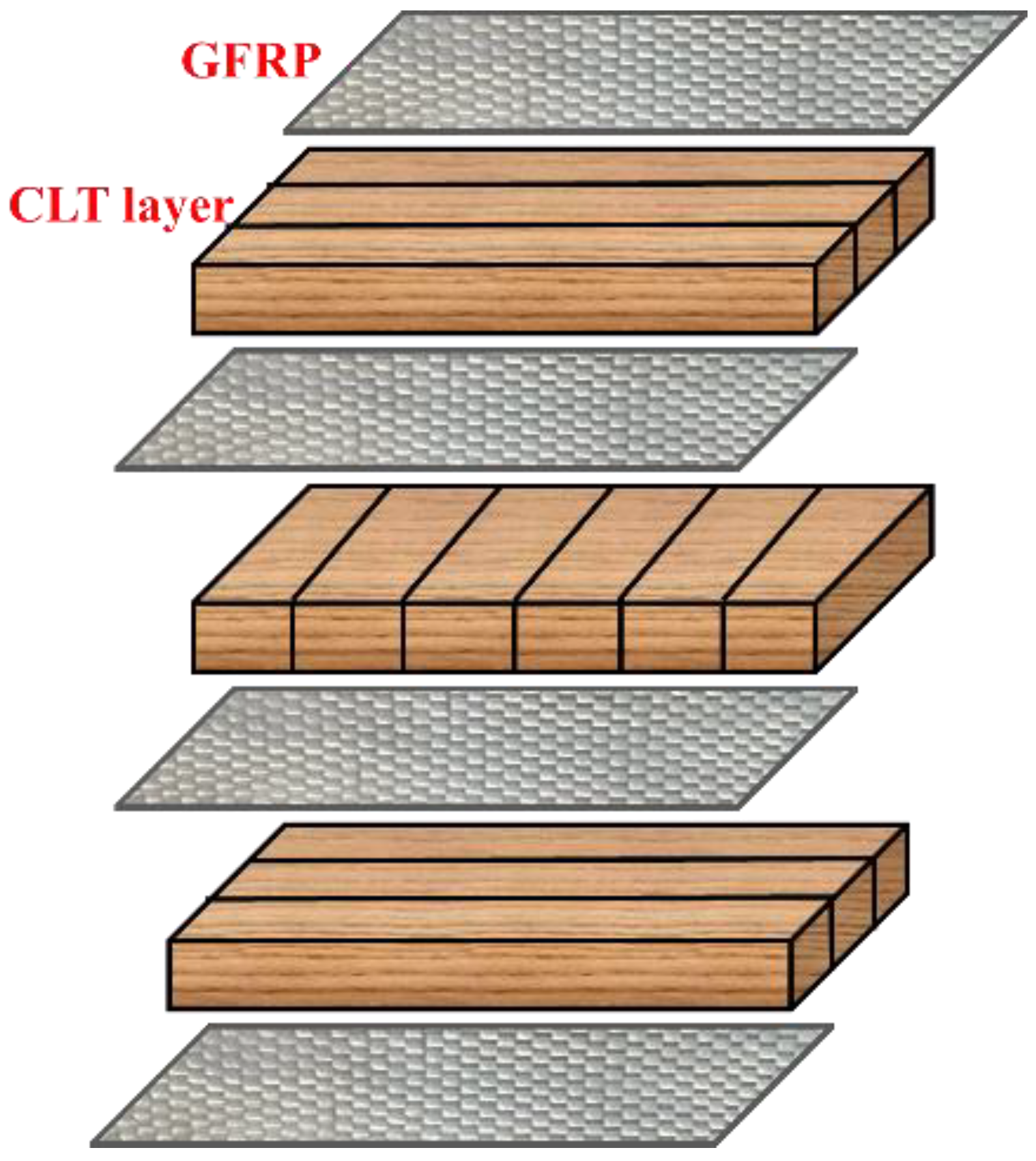

2.2. Manufacture of CLT

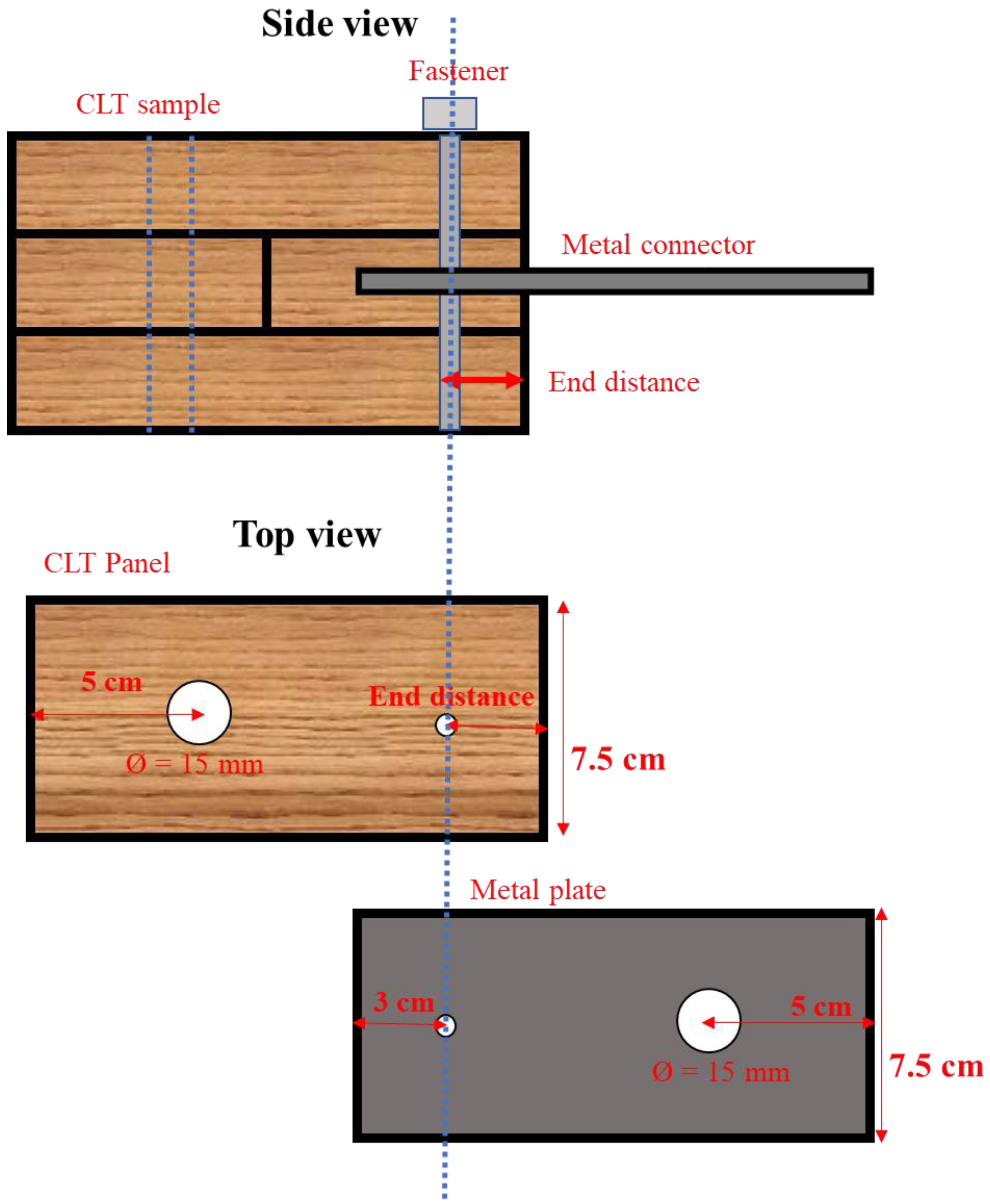

2.3. Lateral Test

2.4. Statistical Analysis

3. Results and Discussion

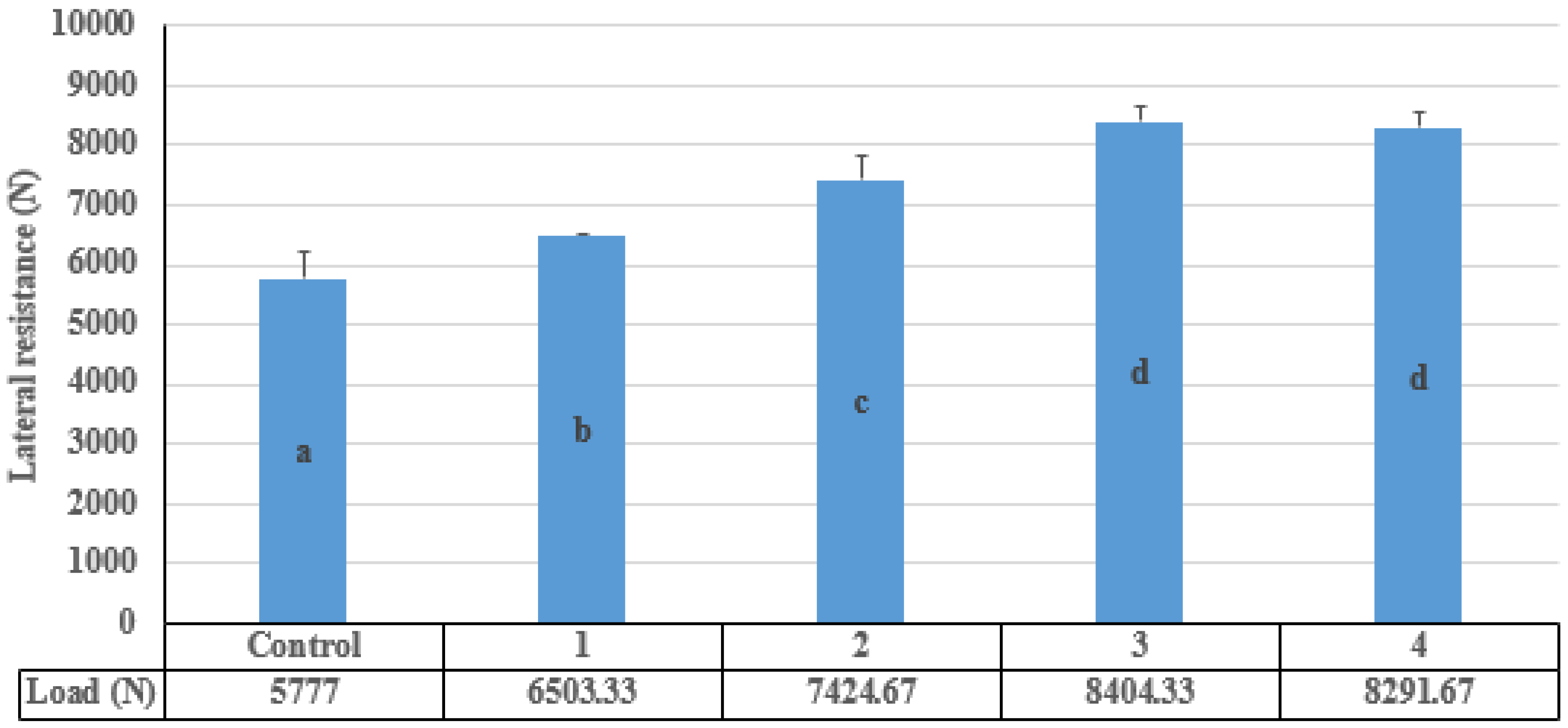

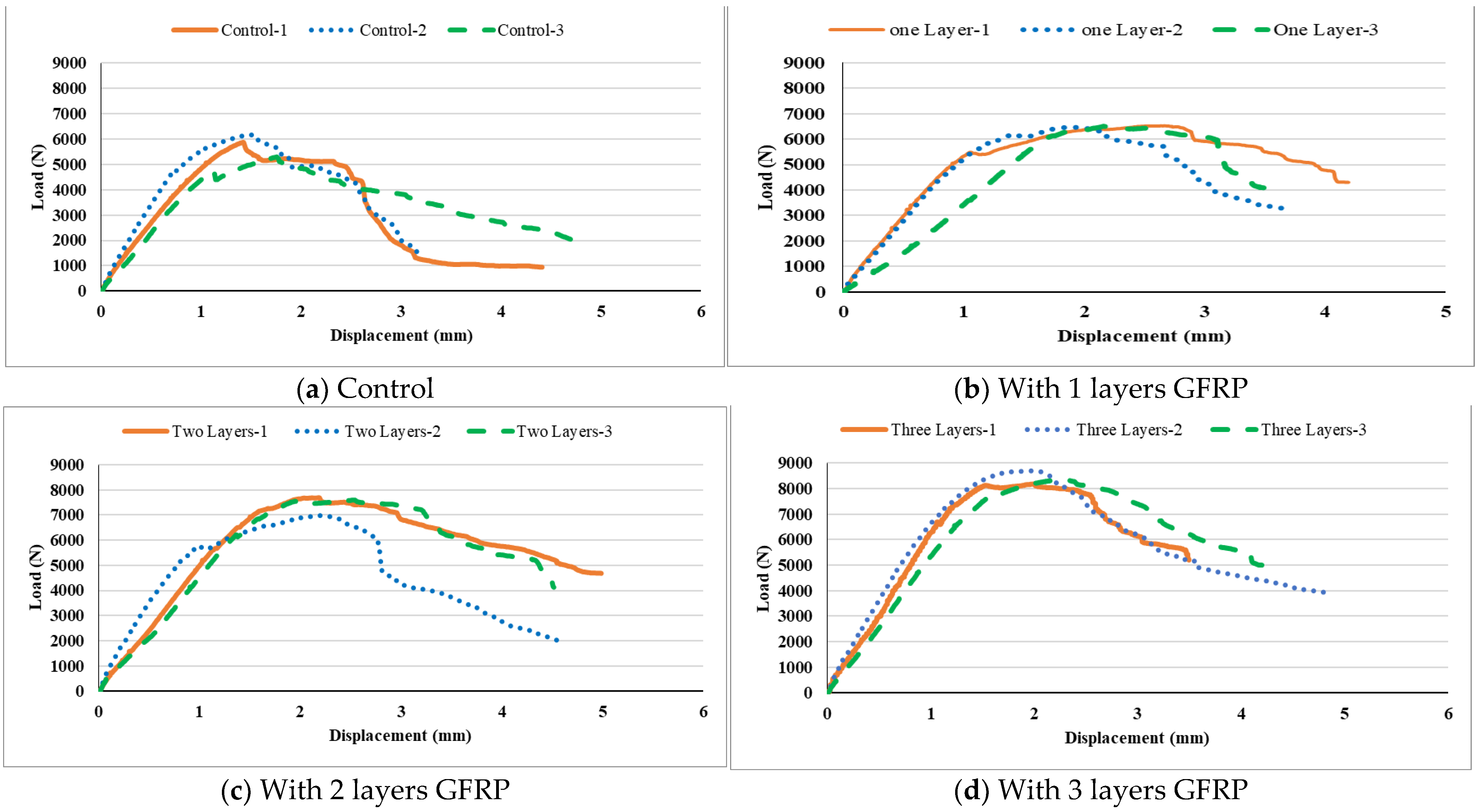

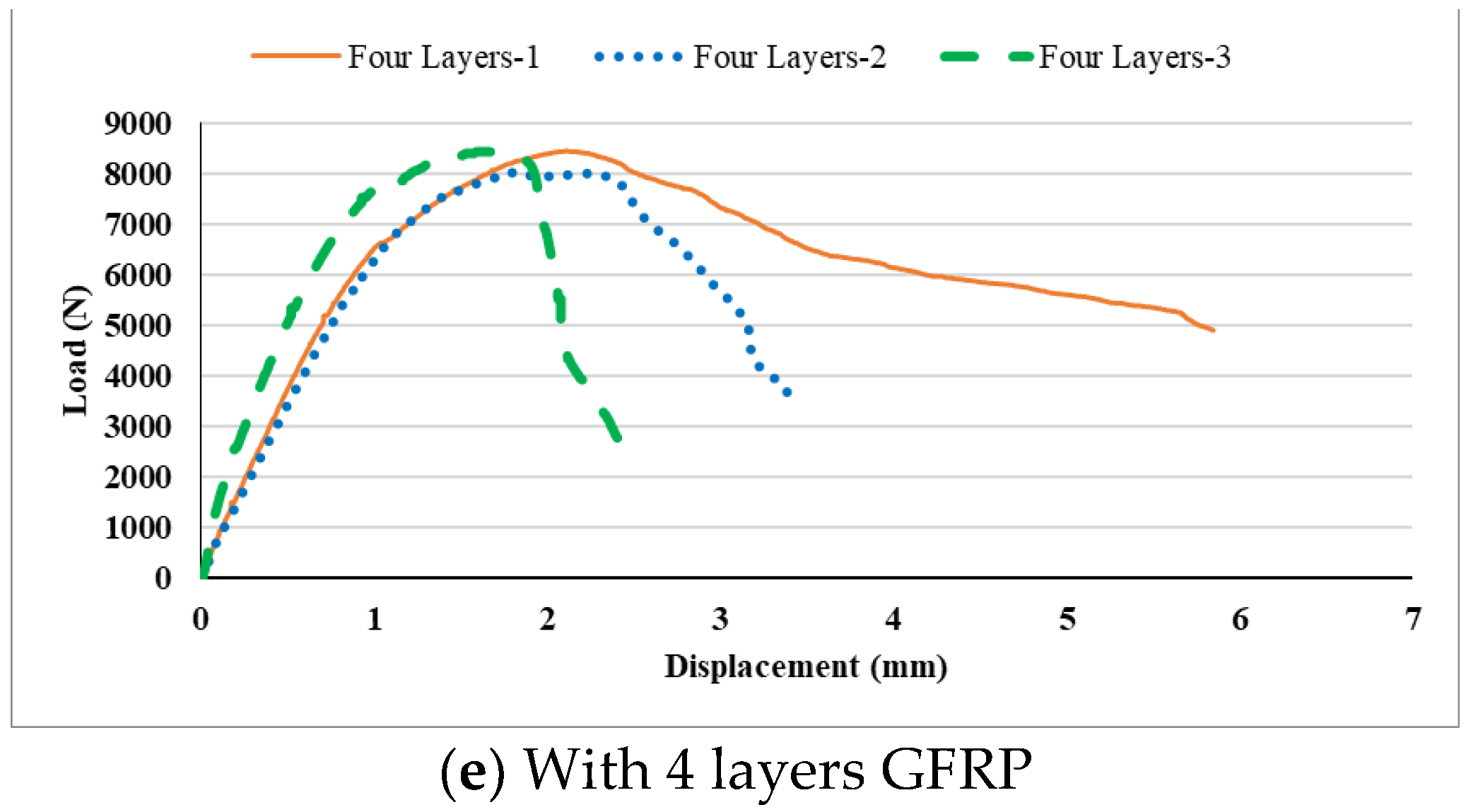

3.1. Effect of GFRP Layer Number on Lateral Resistance

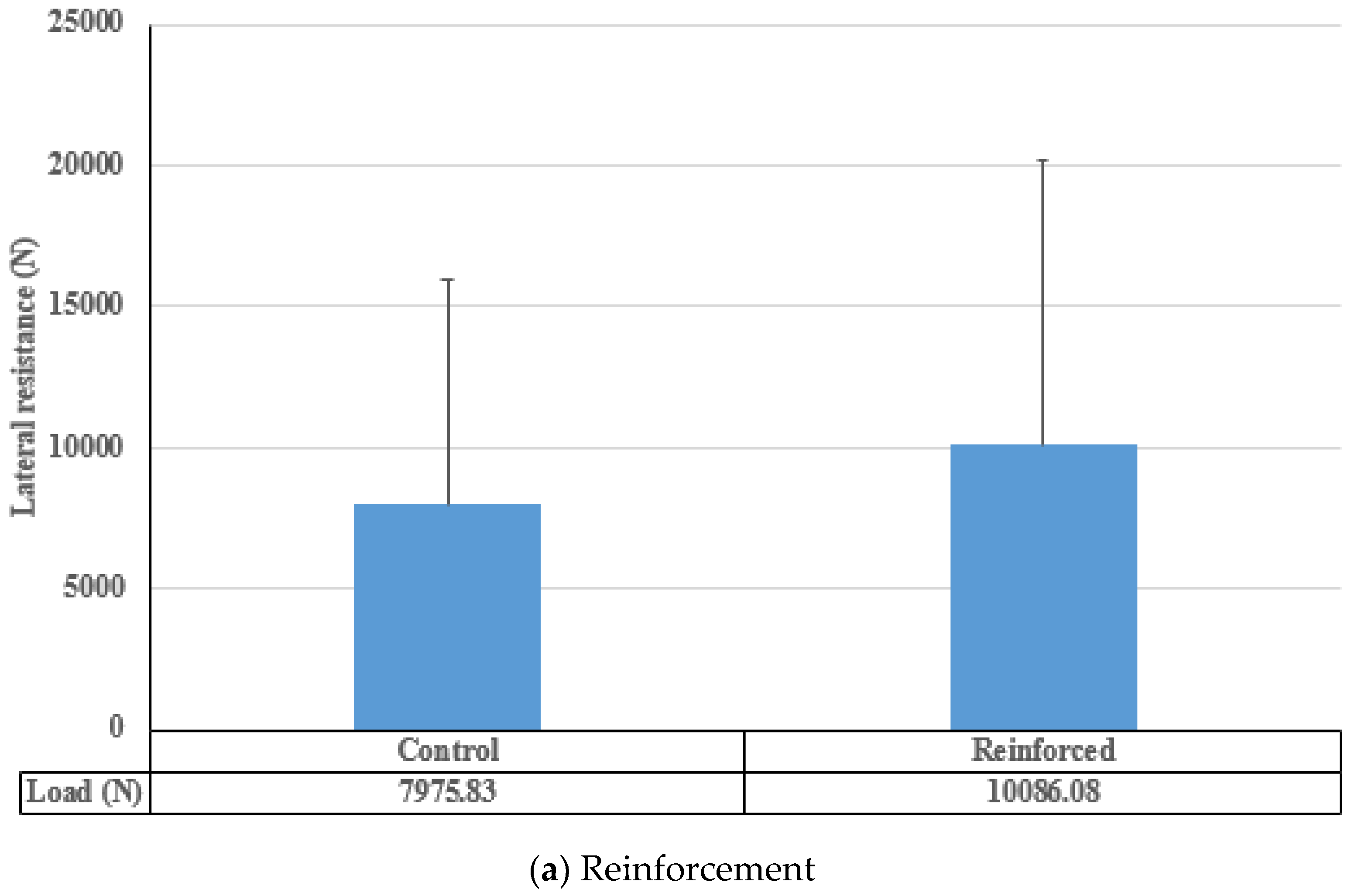

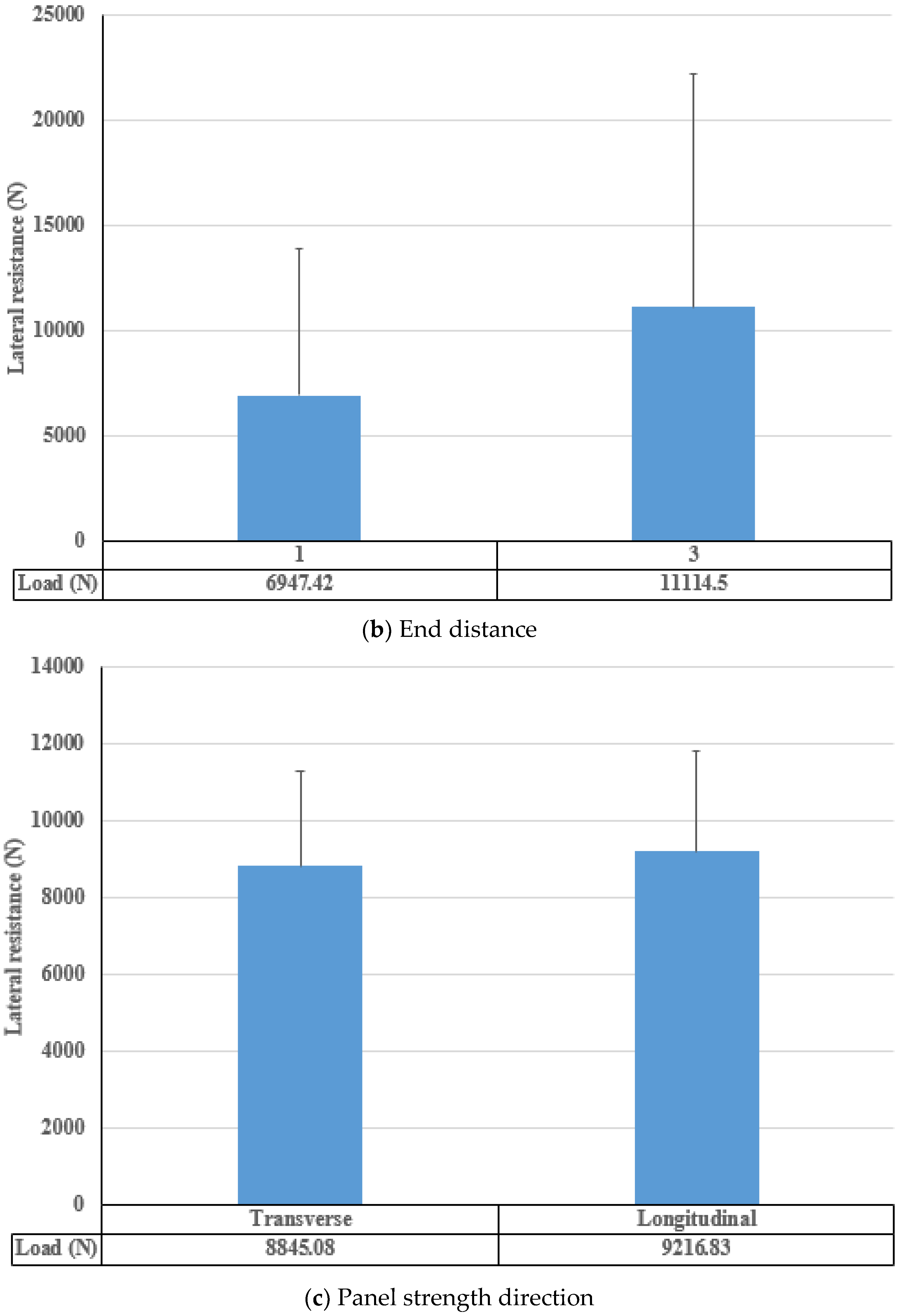

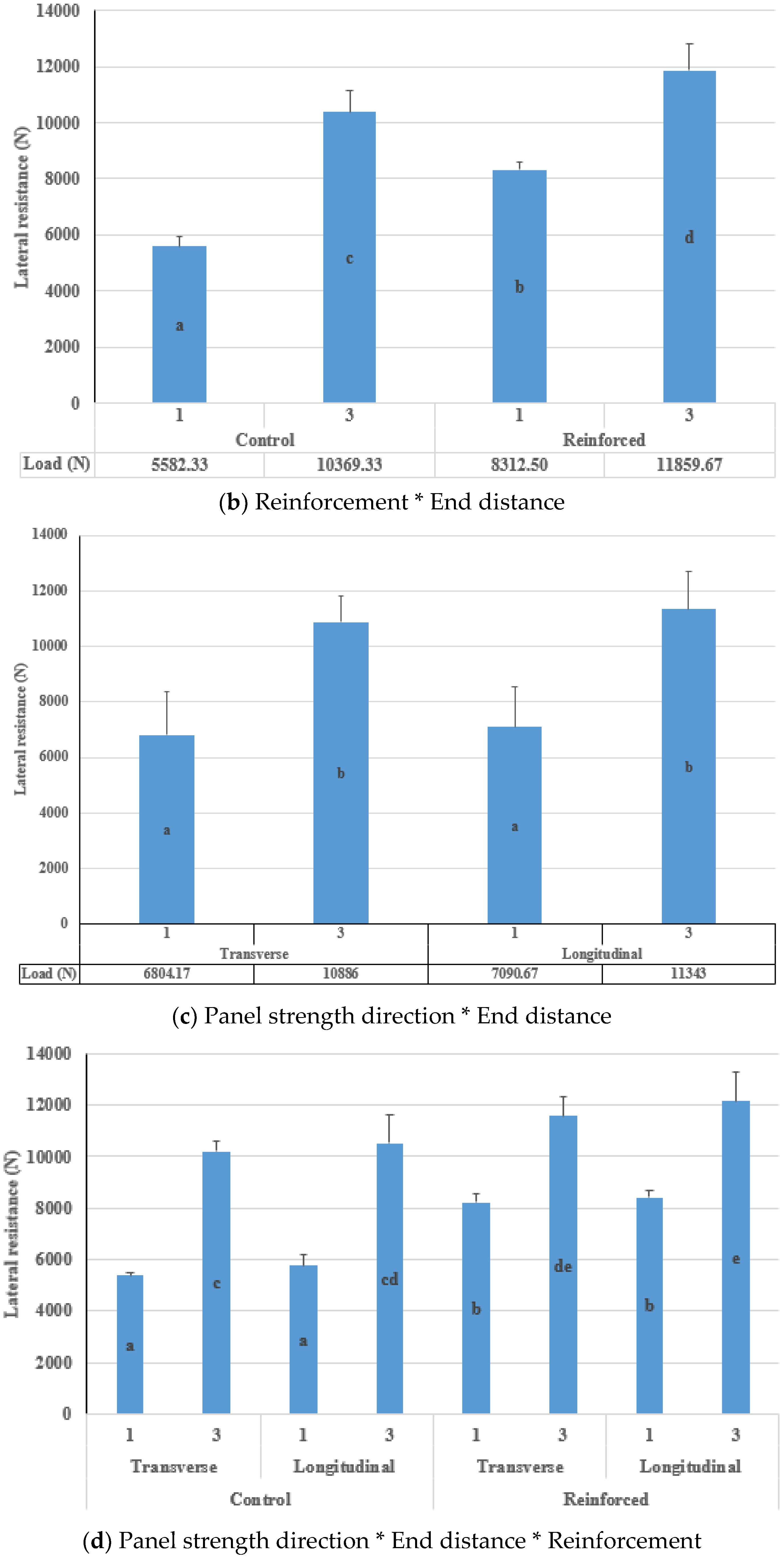

3.2. Effects of Reinforcement, End Distance, and Panel Strength Directions on Lateral Resistance

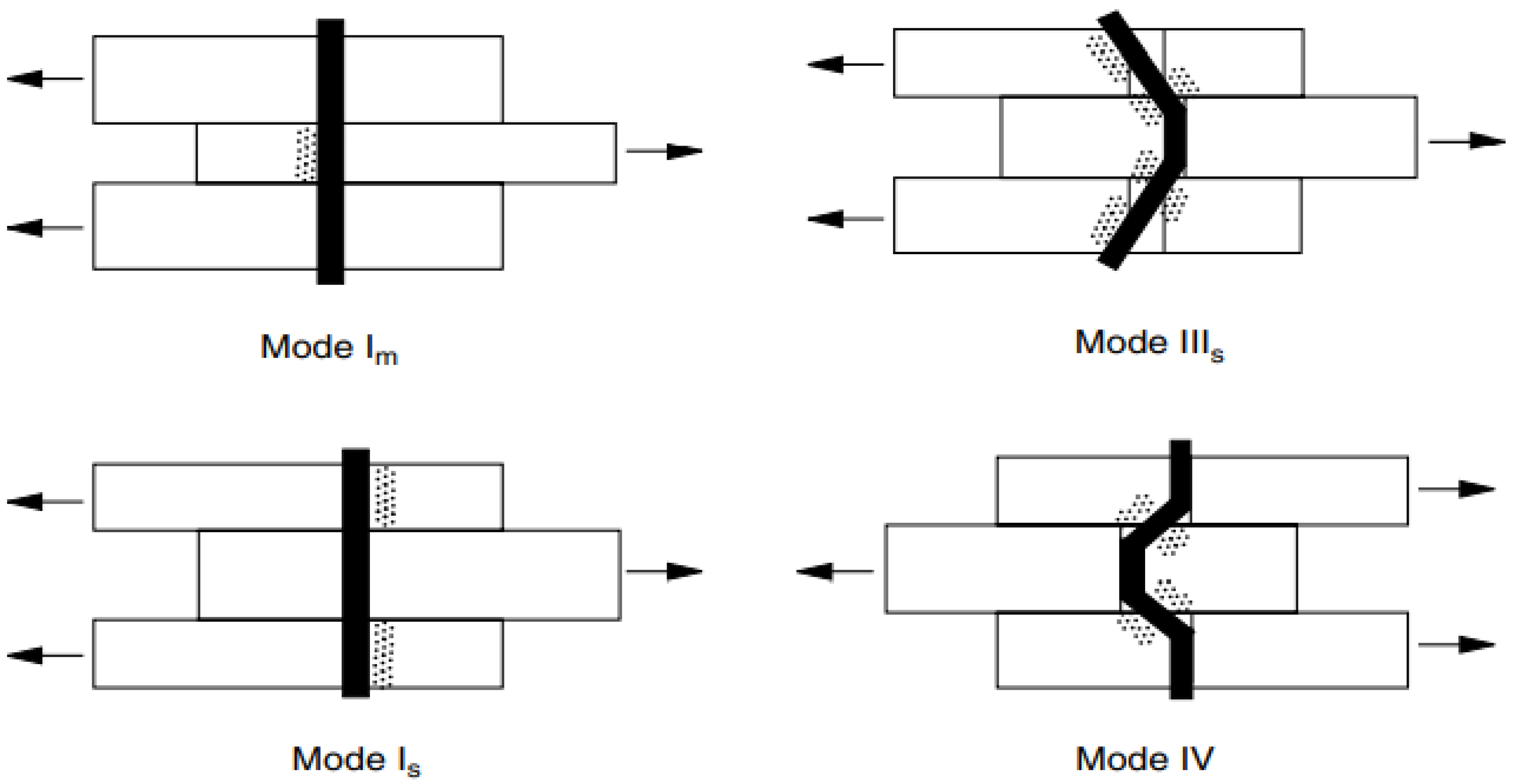

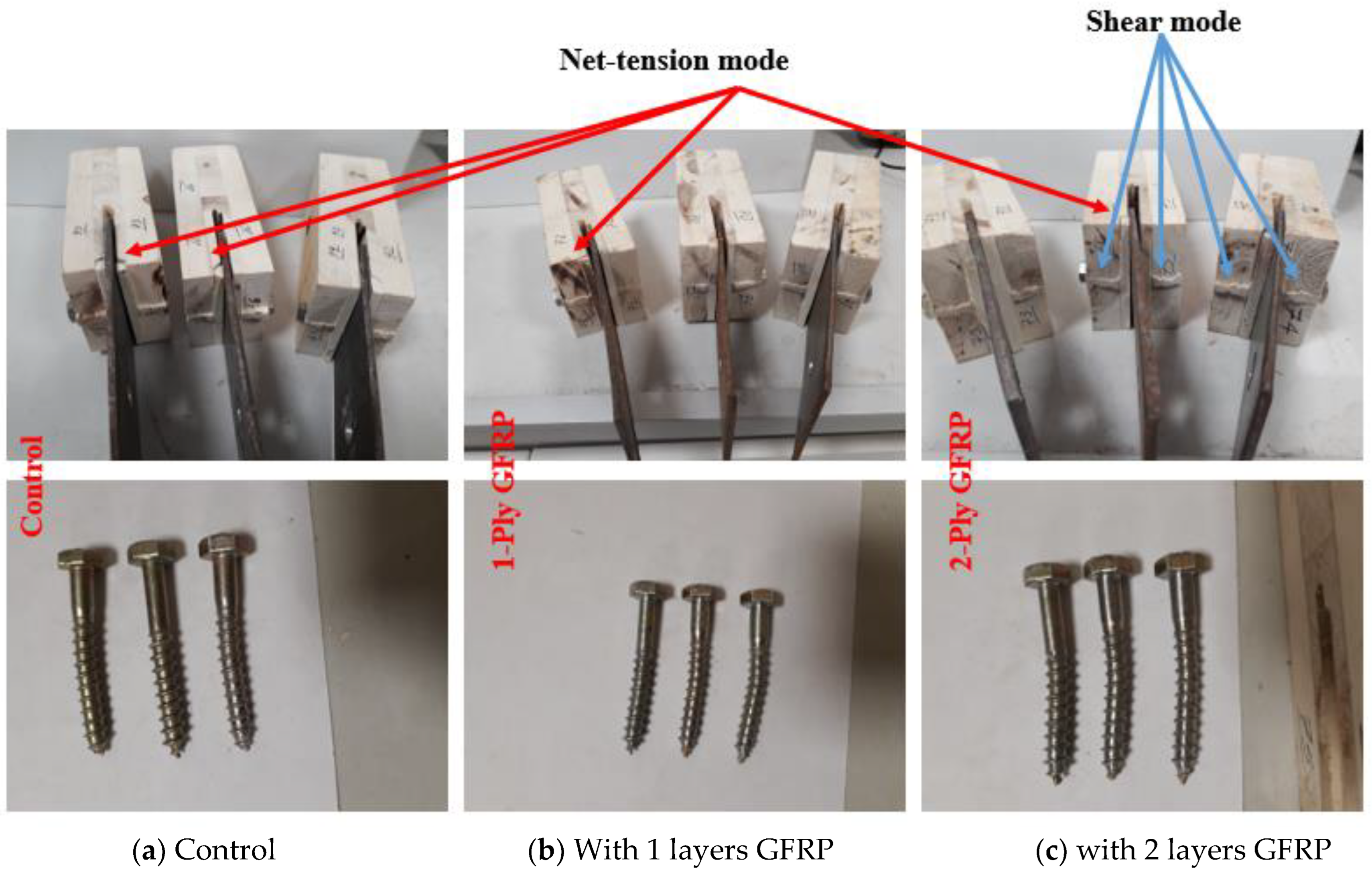

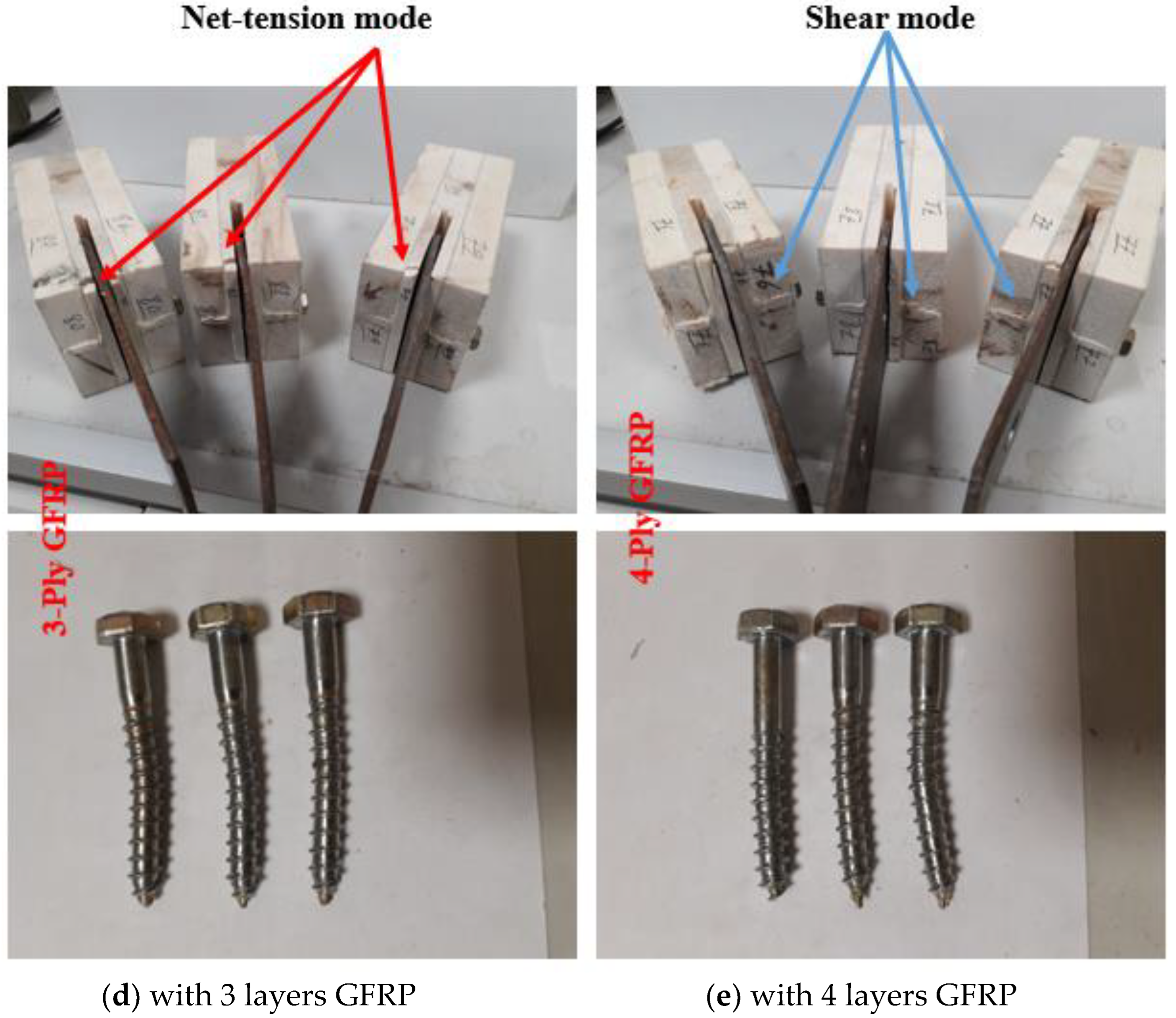

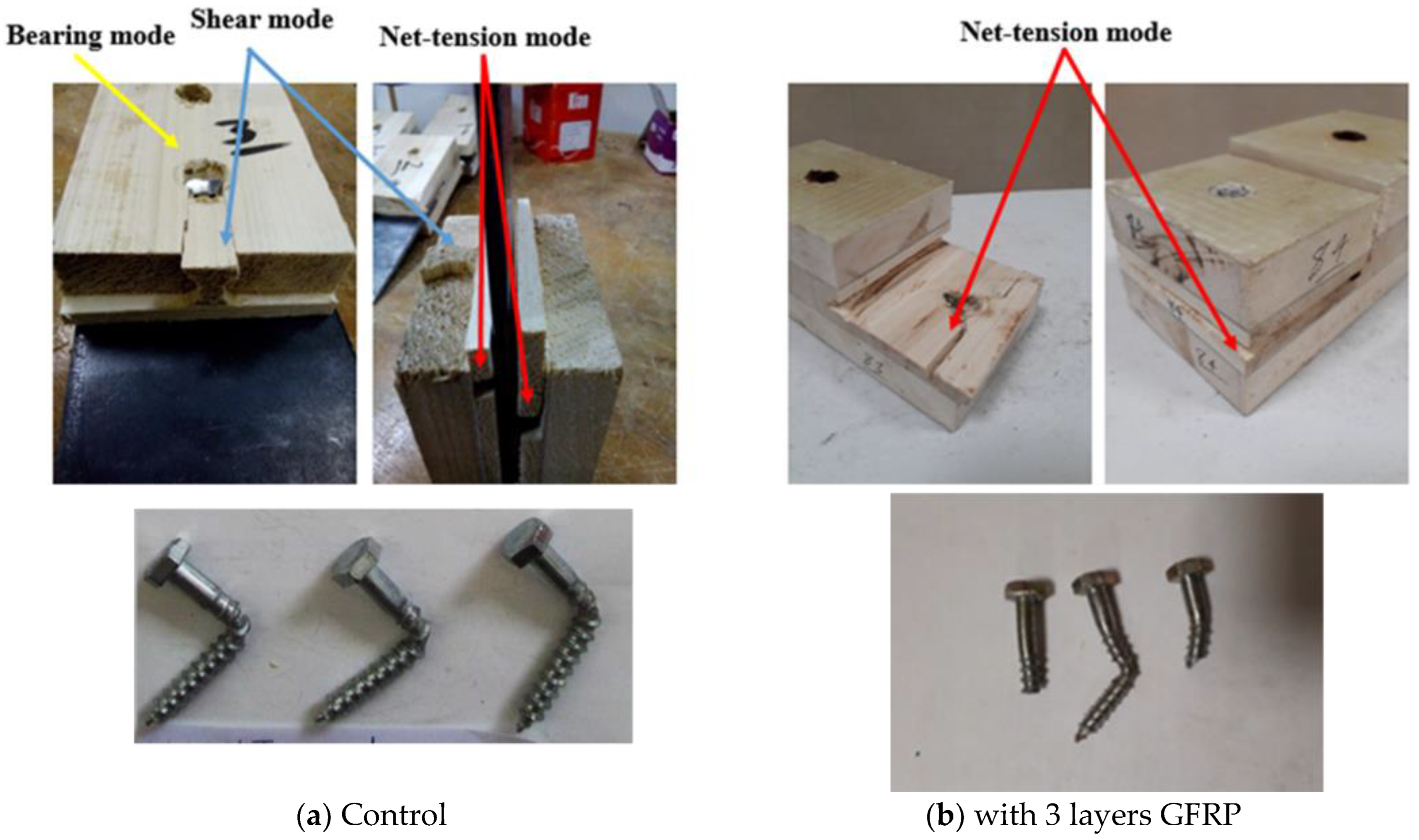

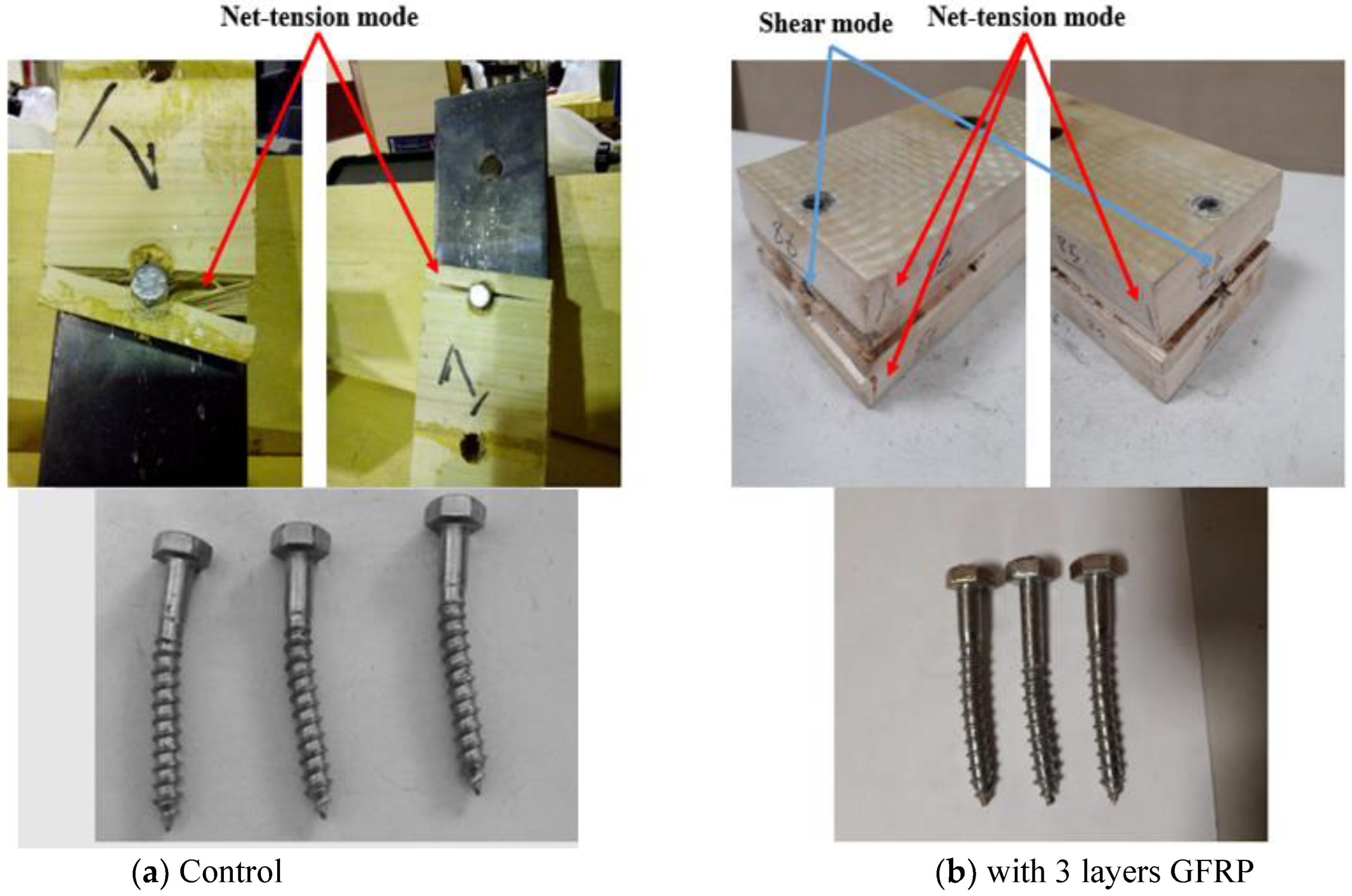

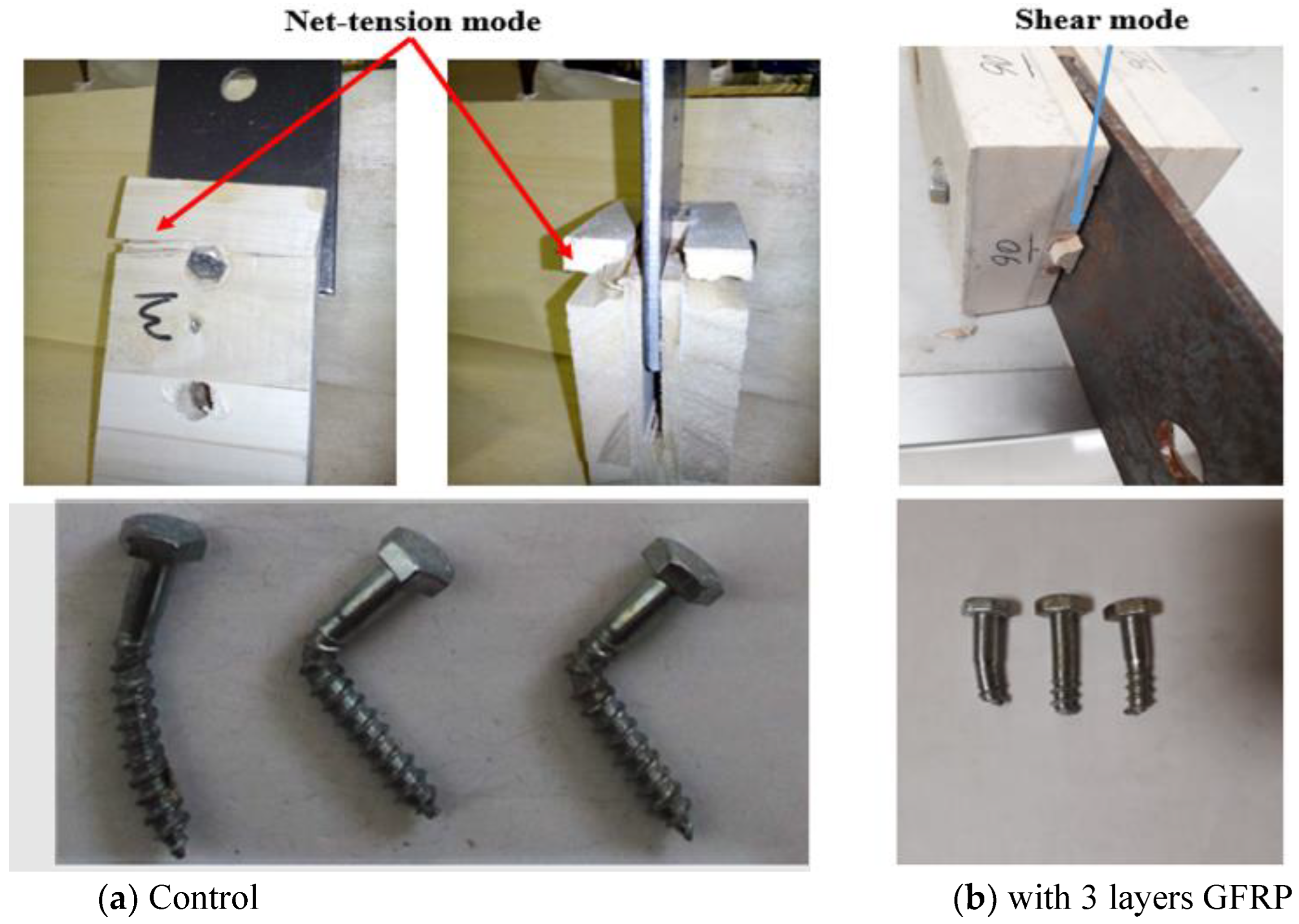

4. Failure Modes

5. Conclusions

- -

- As the number of layers to reinforce the CLT increased from one to three, the lateral resistance of the fastener increased significantly. However, the lateral resistance of the fastener decreased as the number of layers to reinforce the CLT increased from three to four.

- -

- Examining the effect of reinforcement with GFRP, end distance, and panel strength direction on the lateral resistance revealed that the end distance has a meaningful effect. By reinforcing the CLT with the GFRP, increasing the end distance, and changing the panel strength direction, the values of lateral resistance changed to 26.45, 60, and 4.2%, respectively.

- -

- In reinforcement CLT panels, lateral resistance of joints was changed slightly by increasing end distance; however, it was increased drastically in unreinforced CLT with the increase in end distance.

- -

- The failure modes study indicated that specimens in which the fastener did not have a plastic deformation but the CLT member failed more severely showed less resistance. With the reinforcement of the CLT, the fracture intensity in the CLT member decreased, which indicated their excellent resistance. Those specimens showed very high resistance in which the screw was sheared in the interface between wood and steel plate, which was observed mainly in reinforced specimens, especially those with higher end distance. Consequently, GFRP is recommended for reinforcing CLTs under the lateral load, especially in the connection spots.

- -

- These findings could be useful in designing the connectors, such as angle brackets, since these types of connectors are exposed to the lateral loads when they apply to the timber structures.

Author Contributions

Funding

Conflicts of Interest

References

- Rashidi, M.; Hoshyar, A.N.; Smith, L.; Samali, B.; Siddique, R. A comprehensive taxonomy for structure and material deficiencies, preventions and remedies of timber bridges. J. Build. Eng. 2021, 34, 101624. [Google Scholar] [CrossRef]

- North, M. Spreading the load: The management of heritage timber truss bridges in the NSW road network. Aust. J. Multi-Discip. Eng. 2012, 9, 79–85. [Google Scholar] [CrossRef]

- Rashidi, M.; Zhang, C.; Ghodrat, M.; Kempton, S.; Samali, B.; Akbarnezhad, A.; Zhu, L. Bridge abutment movement and approach settlement—A case study and scenario analysis. Int. J. Struct. Stab. Dyn. 2018, 18, 1840011. [Google Scholar] [CrossRef]

- Franke, S.; Franke, B.; Harte, A.M. Failure modes and reinforcement techniques for timber beams–State of the art. Constr. Build. Mater. 2015, 97, 2–13. [Google Scholar] [CrossRef]

- Canbek, C.; Mirmiran, A.; Chowdhury, A.G.; Suksawang, N. Development of fiber-reinforced polymer roof-to-wall connection. J. Compos. Constr. 2011, 15, 644–652. [Google Scholar] [CrossRef]

- Lukaszewska, E.; Fragiacomo, M.; Johnsson, H. Laboratory tests and numerical analyses of prefabricated timber-concrete composite floors. J. Struct. Eng. 2010, 136, 46–55. [Google Scholar] [CrossRef]

- Saribiyik, M.; Akguuml, T. GFRP bar element to strengthen timber connection systems. Sci. Res. Essays 2010, 5, 1713–1719. [Google Scholar]

- Nie, Y.; Valipour, H. Experimental and numerical study of long-term behaviour of timber-timber composite (TTC) connections. Constr. Build. Mater. 2021, 304, 124672. [Google Scholar] [CrossRef]

- Miotto, J.L.; Dias, A.A. Evaluation of perforated steel plates as connection in glulam–concrete composite structures. Constr. Build. Mater. 2012, 28, 216–223. [Google Scholar] [CrossRef]

- Clouston, P.; Bathon, L.A.; Schreyer, A. Shear and bending performance of a novel wood–concrete composite system. J. Struct. Eng. 2005, 131, 1404–1412. [Google Scholar] [CrossRef]

- Otero-Chans, D.; Estévez-Cimadevila, J.; Suárez-Riestra, F.; Martin-Gutierrez, E. Experimental analysis of glued-in steel plates used as shear connectors in Timber-Concrete-Composites. Eng. Struct. 2018, 170, 1–10. [Google Scholar] [CrossRef]

- Chybiński, M.; Polus, Ł. Mechanical behaviour of aluminium-timber composite connections with screws and toothed plates. Materials 2021, 15, 68. [Google Scholar] [CrossRef] [PubMed]

- Morales-Conde, M.; Rodríguez-Liñán, C.; Rubio-de Hita, P. Bending and shear reinforcements for timber beams using GFRP plates. Constr. Build. Mater. 2015, 96, 461–472. [Google Scholar] [CrossRef]

- Raftery, G.M.; Whelan, C. Low-grade glued laminated timber beams reinforced using improved arrangements of bonded-in GFRP rods. Constr. Build. Mater. 2014, 52, 209–220. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Teng, J.-G. Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Karbhari, V.M. Introduction: The use of composites in civil structural applications. In Durability of Composites for Civil Structural Applications; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–10. [Google Scholar]

- Madhoushi, M.; Ansell, M.P. Effect of glue-line thickness on pull-out behavior of glued-in GFRP rods in LVL: Finite element analysis. Polym. Test. 2017, 62, 196–202. [Google Scholar] [CrossRef][Green Version]

- Song, X.; Ma, Y.; Gu, X.; Wang, M. Carbon fiber–reinforced polymer reinforcement for rotational behavior of bolted glulam beam-to-column connections. J. Compos. Constr. 2017, 21, 04016096. [Google Scholar] [CrossRef]

- Gómez, S.; Svecova, D. Behavior of split timber stringers reinforced with external GFRP sheets. J. Compos. Constr. 2008, 12, 202–211. [Google Scholar] [CrossRef]

- Hay, S.; Thiessen, K.; Svecova, D.; Bakht, B. Effectiveness of GFRP sheets for shear strengthening of timber. J. Compos. Constr. 2006, 10, 483–491. [Google Scholar] [CrossRef]

- Skinner, J.; Salisbury, E.; Harris, R. GFRP connectors for thin topping timber-concrete composites. Eur. J. Wood Wood Prod. 2016, 74, 477–479. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, Z.; Tam, L.-h.; Feng, P.; He, L. Group effect of GFRP-timber bolted connections in tension. Compos. Struct. 2021, 262, 113637. [Google Scholar] [CrossRef]

- Hadigheh, S.; McDougall, R.; Wiseman, C.; Reid, L. Evaluation of composite action in cross laminated timber-concrete composite beams with CFRP reinforcing bar and plate connectors using Digital Image Correlation (DIC). Eng. Struct. 2021, 232, 111791. [Google Scholar] [CrossRef]

- Joyce, T.P. Connections for CLT Diaphragms in Steel-Frame Buildings; University of New Brunswick: Fredericton, NB, Canada, 2014. [Google Scholar]

- Ringhofer, A.; Brandner, R.; Blaß, H.J. Cross laminated timber (CLT): Design approaches for dowel-type fasteners and connections. Eng. Struct. 2018, 171, 849–861. [Google Scholar] [CrossRef]

- Hossain, A.; Danzig, I.; Tannert, T. Cross-laminated timber shear connections with double-angled self-tapping screw assemblies. J. Struct. Eng. 2016, 142, 04016099. [Google Scholar] [CrossRef]

- Wadi, H.; Amziane, S.; Taazount, M. The lateral load resistance of unclassified cross-laminated timber walls: Experimental tests and theoretical approach. Eng. Struct. 2018, 166, 402–412. [Google Scholar] [CrossRef]

- Oh, J.-K.; Kim, G.-C.; Kim, K.-M.; Lee, J.-J.; Hong, J.-P. End distance of single-shear screw connection in cross laminated timber. J. Korean Wood Sci. Technol. 2017, 45, 746–752. [Google Scholar] [CrossRef]

- Brown, J.R.; Li, M. Structural performance of dowelled cross-laminated timber hold-down connections with increased row spacing and end distance. Constr. Build. Mater. 2021, 271, 121595. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Z.; Wang, F.; Huang, H.; Que, Z. Effect of arrangement distances on stiffness of shear-tension mode in timber-to-timber connections with inclined screws. Constr. Build. Mater. 2022, 314, 125592. [Google Scholar] [CrossRef]

- Ruan, G.; Filz, G.H.; Fink, G. Shear capacity of timber-to-timber connections using wooden nails. Wood Mater. Sci. Eng. 2022, 17, 20–29. [Google Scholar] [CrossRef]

- Fonseca, E.M.; Leite, P.A.; Silva, L.D.; Silva, V.S.; Lopes, H.M. Parametric Study of Three Types of Timber Connections with Metal Fasteners Using Eurocode 5. Appl. Sci. 2022, 12, 1701. [Google Scholar] [CrossRef]

- Bhat, J. Improved strength and stiffness characteristics of cross-laminated poplar timber columns. Int. J. Eng. 2021, 34, 803–810. [Google Scholar]

- Karacabeyli, E.; Gagnon, S. Canadian CLT Handbook, 2019th ed.; Digital; FPInnovations: Pointe-Claire, QC, Canada, 2019. [Google Scholar]

- Abdoli, F.; Rashidi, M.; Rostampour-Haftkhani, A.; Layeghi, M.; Ebrahimi, G. Withdrawal Performance of Nails and Screws in Cross-Laminated Timber (CLT) Made of Poplar (Populus alba) and Fir (Abies alba). Polymers 2022, 14, 3129. [Google Scholar] [CrossRef] [PubMed]

- ASTM, D. 1037; Standard Methods of Evaluating the Properties of Wood-Base Fiber and Particle Panel Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 1999.

- Sharos, P.A. Efficient Load Distribution Analysis and Strength Prediction of Bolted Composite Joints at Various Loading Rates. Ph.D. Thesis, University of Limerick, Limerick, Ireland, 2016. [Google Scholar]

- Williamson, T.G. APA Engineered Wood Handbook; McGraw Hill Professional: New York, NY, USA, 2002. [Google Scholar]

- Chen, G.; Jiang, H.; Yu, Y.-f.; Zhou, T.; Wu, J.; Li, X. Experimental analysis of nailed LBL-to-LBL connections loaded parallel to grain. Mater. Struct. 2020, 53, 1–13. [Google Scholar] [CrossRef]

- Mohamadzadeh, M.; Haftkhani, A.R.; Ebrahimi, G.; Yoshihara, H. Numerical and experimental failure analysis of screwed single shear joints in wood plastic composite. Mater. Des. 2012, 35, 404–413. [Google Scholar] [CrossRef]

- Haftkhani, A.R.; Ebrahimi, G.; Tajvidi, M.; Layeghi, M.; Arabi, M. Lateral resistance of joints made with various screws in commercial wood plastic composites. Mater. Des. 2011, 32, 4062–4068. [Google Scholar] [CrossRef]

| Statistical Design | Panel Direction | GFRP Layer Number | End Distance (cm) | Replicate |

|---|---|---|---|---|

| Completely random | Major axis | Unreinforced | 1 | 3 |

| Major axis | 1 | 1 | 3 | |

| Major axis | 2 | 1 | 3 | |

| Major axis | 3 | 1 | 3 | |

| Major axis | 4 | 1 | 3 |

| Statistical Design | CLT | Panel Direction | End Distance (cm) | Replicate |

|---|---|---|---|---|

| Two-level factorial | Reinforced with 3 GFRP layers | Major axis | 1 | 3 |

| Reinforced with 3 GFRP layers | Major axis | 3 | 3 | |

| Reinforced with 3 GFRP layers | Minor axis | 1 | 3 | |

| Reinforced with 3 GFRP layers | Minor axis | 3 | 3 | |

| Unreinforced | Major axis | 1 | 3 | |

| Unreinforced | Major axis | 3 | 3 | |

| Unreinforced | Minor axis | 1 | 3 | |

| Unreinforced | Minor axis | 3 | 3 |

| Thickness (mm) | Weight (gr/m2) | Modulus of Elasticity (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 0.236 | 600 | 90 | 2300 |

| Lag screw (8 mm) |  |

| Neck length (mm) | 65.5 |

| Major diameter (mm) | 7.75 |

| Minor diameter (mm) | 5.6 |

| Pre-drilled hole diameter (mm) | 5 |

| Metal connector hole diameter (mm) | 8 |

| Panel Direction | GFRP Layer Number | End Distance (cm) | Lateral Load (N) | Ductility δ (mm/mm) | Failure Mode of Screw |

|---|---|---|---|---|---|

| Major axis | Unreinforced | 1 | 5871 | 1.37 | Is (common) and IIIs |

| Major axis | Unreinforced | 1 | 6161 | 1.881 | |

| Major axis | Unreinforced | 1 | 5299 | 1.439 | |

| Major axis | 1 | 1 | 6526 | 2.438 | Is (common) and IIIs |

| Major axis | 1 | 1 | 6472 | 1.802 | |

| Major axis | 1 | 1 | 6512 | 1.46 | |

| Major axis | 2 | 1 | 7691 | 1.763 | IIIs |

| Major axis | 2 | 1 | 6980 | 2.216 | |

| Major axis | 2 | 1 | 7603 | 2.118 | |

| Major axis | 3 | 1 | 8183 | 2.114 | IIIs |

| Major axis | 3 | 1 | 8696 | 2.242 | |

| Major axis | 3 | 1 | 8334 | 1.876 | |

| Major axis | 4 | 1 | 8439 | 2.019 | Is and IIIs (common) |

| Major axis | 4 | 1 | 8013 | 1.711 | |

| Major axis | 4 | 1 | 8423 | 2.124 |

| Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 15,512,230 | 4 | 3,878,057 | 41.15 | 0.000 ** |

| Within Groups | 942,427 | 10 | 94,243 | ||

| Total | 16,454,656 | 14 |

| CLT | Direction | End Distance (cm) | Lateral Load (N) | Failure Mode of Screw |

|---|---|---|---|---|

| Unreinforced | Major | 1 | 5871 | IIIs |

| Unreinforced | Major | 1 | 6161 | |

| Unreinforced | Major | 1 | 5299 | |

| Unreinforced | Major | 3 | 11,110 | IIIs with higher deformation than those in minor axis |

| Unreinforced | Major | 3 | 9286 | |

| Unreinforced | Major | 3 | 11,220 | |

| Unreinforced | Minor | 1 | 5468 | Is |

| Unreinforced | Minor | 1 | 5299 | |

| Unreinforced | Minor | 1 | 5396 | |

| Unreinforced | Minor | 3 | 10,230 | IIIs with lower deformation than those in minor axis |

| Unreinforced | Minor | 3 | 10,560 | |

| Unreinforced | Minor | 3 | 9810 | |

| Reinforced | Major | 1 | 8183 | IIIs |

| Reinforced | Major | 1 | 8696 | |

| Reinforced | Major | 1 | 8334 | |

| Reinforced | Major | 3 | 12,627 | IV |

| Reinforced | Major | 3 | 10,831 | |

| Reinforced | Major | 3 | 12,984 | |

| Reinforced | Minor | 1 | 8362 | Is Is Is |

| Reinforced | Minor | 1 | 7842 | |

| Reinforced | Minor | 1 | 8458 | |

| Reinforced | Minor | 3 | 12,157 | IV |

| Reinforced | Minor | 3 | 11,830 | |

| Reinforced | Minor | 3 | 10,729 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| reinforcement | 2,6718,930.375 | 1 | 26,718,930.375 | 59.520 | 0.000 ** |

| Panel strength direction | 829,188.375 | 1 | 829,188.375 | 1.847 | 0.193 ns |

| End distance | 104,187,501.042 | 1 | 104,187,501.042 | 232.091 | 0.000 ** |

| reinforcement * Panel strength direction | 360.375 | 1 | 360.375 | 0.001 | 0.978 ns |

| reinforcement * End distance | 2,305,780.042 | 1 | 2,305,780.042 | 5.136 | 0.038 * |

| Panel strength direction * End distance | 43,605.375 | 1 | 43,605.375 | 0.097 | 0.759 ns |

| reinforcement * Panel strength direction * End distance | 73,372.042 | 1 | 73,372.042 | 0.163 | 0.691 ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rostampour Haftkhani, A.; Rashidi, M.; Abdoli, F.; Gerami, M. The Effect of GFRP Wrapping on Lateral Performance of Double Shear Lap Joints in Cross-Laminated Timber as a Part of Timber Bridges. Buildings 2022, 12, 1678. https://doi.org/10.3390/buildings12101678

Rostampour Haftkhani A, Rashidi M, Abdoli F, Gerami M. The Effect of GFRP Wrapping on Lateral Performance of Double Shear Lap Joints in Cross-Laminated Timber as a Part of Timber Bridges. Buildings. 2022; 12(10):1678. https://doi.org/10.3390/buildings12101678

Chicago/Turabian StyleRostampour Haftkhani, Akbar, Maria Rashidi, Farshid Abdoli, and Masood Gerami. 2022. "The Effect of GFRP Wrapping on Lateral Performance of Double Shear Lap Joints in Cross-Laminated Timber as a Part of Timber Bridges" Buildings 12, no. 10: 1678. https://doi.org/10.3390/buildings12101678

APA StyleRostampour Haftkhani, A., Rashidi, M., Abdoli, F., & Gerami, M. (2022). The Effect of GFRP Wrapping on Lateral Performance of Double Shear Lap Joints in Cross-Laminated Timber as a Part of Timber Bridges. Buildings, 12(10), 1678. https://doi.org/10.3390/buildings12101678