Abstract

The amount of ground olive stone available in Spain surpasses the needs of the construction industry for lightweight aggregate. The objective herein is to generate a material, lightweight mortar, with different percentages of ground olive stone, and then evaluate the mechanical performance and viability of these materials for the manufacture of lightweight elements used in the construction sector. To this end, an experiment was designed with nine different dosages of ground olive stone and three types of cement. In all, 378 test pieces were produced to assess the material, its handling while fresh, and its performance. Based on an analysis of consistency, density, compressive strength, and flexural strength, we were able to determine how much ground olive stone can be successfully incorporated into the material: 30% ground olive stone achieved a decrease in density of 15% compared to mortar without ground olive stone. The compressive strength of the different dosages studied remained above 70% of that of the mortar without ground olive stone. Bending behavior was more severely compromised, the values being around 50%. Cements with a more robust strength performance proved capable of assimilating a higher percentage of ground olive stone. This study shows the technical viability of the materials produced.

1. Introduction

Owing to climate and soil conditions, the most important olive oil producers are located in the Mediterranean basin and represent about 95% of the world’s production [1]. More than 20 million tons of olives are produced around the world per year, and Spain, as the world’s largest producer of olives, accounts for 35% of that total. Olive stones constitute a significant percentage of the total weight of this fruit (20–28%) and are considered a by-product of olive oil extraction and manufacturing of pitted table olives. There are currently two ways to valorize olive stones: thermochemical (energy source by combustion, gasification, or pyrolysis) and biochemical (ethanol and xylitol production) conversion [2]. Among the thermochemical treatments, its use as biofuel in biomass boilers has demonstrated great potential. Using olive stones as pellets requires specialized treatment before the by-product exits the oil mill [3]. Other applications of ground olive stone (GOS) can be found in the chemical sector. Pyrolysis-derived activated carbons were used as adsorbents to investigate their removal efficiency for oxidation products and polar compounds from used sunflower and corn cooking oils [4]. It has also been found that activated carbon prepared from olive stones by physical activation using water vapor at 750 °C can be used as an efficient adsorbent for NO2 removal [5]. Furthermore, using olive stones as a biosorbent, in fixed-bed columns, to treat industrial wastewater has proven effective in eliminating nickel ions [6] and in the remediation of electroplating wastewater [7].

A significant amount of research has been conducted on fired clay bricks. For example, wet pomace has been incorporated as a pore-forming additive [8], and biomass ashes [9] and olive stones can also be easily ground to obtain a suitable particle size [10]. Incorporating ground olive stone into fired clay bricks reduces their compressive strength; meanwhile, thermal conductivity decreases as does density, and porosity increases [11]. A correlation has been observed between brick performance and the particle size of the olive stone incorporated [12,13].

In the manufacture of adobe bricks, there have been two different experiments with GOS. In one study, six by-products were evaluated as additives in adobe bricks to examine the variability of their mechanical properties through a three-level design of experiments and, thereby, determine optimal formulations. The weakest results were obtained with olive stones as an additive (0.1640 N/mm2) [14]. However, in another study, a new type of ecological compressed-earth brick incorporating ground olive pit (GOS) was presented. Substituting up to 30% with GOS generates a decrease in compressive strength and thermal conductivity of approximately 38.38% and 50.64%, respectively [15].

In the case of this study, the focus is on cement-based matrices. The incorporation of various materials is a current issue, for example, crumb rubber [16], wood waste [17], sawdust [18], diatomaceous earth [19], or polyvinyl chloride waste [20]. In all cases, it is important to assess the mechanical performance of the new materials. Olive-stone biomass ash has already been utilized in a variety of ways and in varying amounts in such materials. For example, various studies have analyzed the effect of olive-stone biomass ash on the activation of blast furnace slag and have demonstrated the viability of using this type of ash as an activating reagent for Portland cement [21,22,23]. This same line of research has also investigated applications in concrete. A study investigating the use of fly ash from the combustion of agricultural olive residue pellets as filler in self-compacting concrete found that biomass fly ash concrete had a compressive strength equal to or greater than that of the reference concrete [24]. An innovative one-part ecocellular concrete (ECC-OP) has also been developed and studied. Olive-stone biomass ash (OBA) was the alkali source, along with other improved components. A 96% reduction in the kgCO2eq per m3 of material was achieved with the new proposed ECC-OP, as compared to that with traditional manufacturing [25].

Lastly, regarding mortars, adding vegetable fibers, for example, in a study on coconut fibers, has demonstrated their viability in the production of lightweight, nonstructural building materials based on their values of compressive strength (3.97–4.35 MPa) and low bulk density (0.99–1.26 g/cm3) [26]. The crack resistance and durability are important factors in certain applications, solved by the application of fibers [27,28]. Another interesting study concluded that replacing expanded clay with olive-stone waste is viable: mortar density decreases by up to 30%, and compression strength also improves by up to 20% as compared to lightweight expanded-clay mortars [29]. Working with a combination of olive stones and pumice stones to obtain lightweight mortars requires a superplasticizing additive [30]. Another study evaluated the relationships between thermal conductivity, density, and water absorption for each different percentage of olive stone incorporated [31].

As the aforementioned studies have illustrated, olive stones are being utilized in a variety of fields. At present, the amount of olive-stone waste generated is double that needed for the lightweight aggregates used in the construction sector (0.7 million tons/year). This by-product does not undergo any type of chemical transformation, that is, it is simply ground olive stone (GOS) obtained when olives are ground in the oil extraction process. In terms of the sustainability of any product or system, the three pillars must be considered: economic, social, and environmental. Thus, regarding the economic aspect, it should be noted that the market price of this vegetable aggregate is similar to the market price of lightweight aggregates made from expanded clay. What is more, using this vegetable aggregate also fosters environmental sustainability given that a CO2 scavenger (GOS, a vegetable aggregate) is replacing a CO2 emitter (the mineral aggregate traditionally used). Future research will focus on further examining this environmental balance. Utilizing GOS also represents a socially responsible strategy as its exploitation is less aggressive than obtaining mineral aggregates.

The objective of this study is to create a lightweight mortar that incorporates olive-stone residue (in different percentages), without requiring additional treatments (thereby achieving a lower environmental impact). This study also aims to assess the materials’ mechanical performance in comparison with the reference material and its viability in the manufacture of elements for enclosures and facades. To conduct this study, the ground olive stones (GOS) were obtained from the company Trujal 5 Valles located in Arnedo, La Rioja, Spain.

2. Materials and Methods

The primary objective of this study is to determine the mechanical properties of mortars dosed with different percentages of GOS and, more specifically, to determine the compression strength capacity and flexural characteristics of the different mortar mixtures. These data inform the evaluation of the possibility of substituting a fraction of the mineral aggregates used in mortar manufacture with ground olive stone, thereby repurposing this waste product. Not only can lighter-weight materials be obtained by incorporating olive stone into mortars, but this strategy also constitutes an interesting way to take advantage of waste generated by olive production. Bearing in mind the expected decrease in mechanical performance, the different dosages were incorporated into various types of cement. The materials used are outlined in the following sections.

2.1. Raw Materials

The laboratory experiments used the same materials as and storage conditions similar to those in lightweight precast factories.

2.1.1. Cement

ASTM-type Portland cement with a density of 3150 kg/m3 was used to prepare the mortar mixes. The chemical properties of the cements provided by Cementos Portland Valderrivas, S.A., are listed in Table 1.

Table 1.

Chemical composition of cementitious materials.

2.1.2. Fine Aggregate

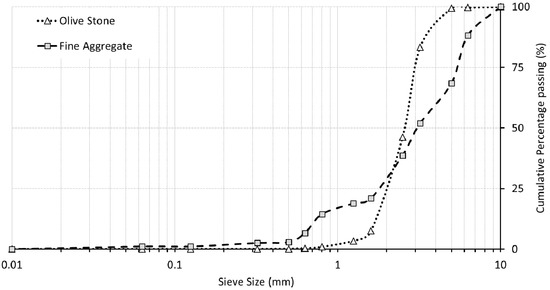

The fine aggregate utilized in this study ranged in size from 0 to 10 mm. The relative density was 1634 kg/m3, and its fineness modulus was 3.16. Figure 1 shows the cumulative percentage of aggregate passing after sieve analysis according to standard EN 933-1 [32]. The source of fine aggregate was crushed limestone from a local quarry (VRESA, Navarra, Spain). Upon reception, the limestone aggregate was stored under stable ambient moisture and temperature conditions (20 ± 2 °C and 55% humidity).

Figure 1.

Raw material granulometry.

2.1.3. Olive Stone (GOS)

The mortar samples contained GOS obtained from Trujal 5 Valles. The GOS was produced by mechanically crushing olive pits. As shown in Figure 1, only one type of GOS with a particle size in the range of 1 to 4 mm in diameter was used as a substitute for fine aggregate. The standard chemical composition of this type of waste is summarized in Table 2.

Table 2.

Chemical composition of olive stones.

The crushed olive stones and fine aggregate utilized had the granulometry depicted in Figure 1.

The relative density and the fineness modulus of GOS were 580.07 kg/m3 and 3.41, respectively. The materials were obtained directly from the supplier and, in order to simulate factory conditions, they were not screened or pretreated in the laboratory.

2.1.4. Potable Water

Regular tap water, without any special treatment, was utilized in the mixtures. The water’s pH and sulfate content were 7.9 and 590 ppm, respectively. The water was conditioned at 22 ± 3 °C for all the mixtures in the laboratory experiments.

2.1.5. Release Agent

The internal surfaces of the laboratory molds were coated with the release agent Renocast DES 20L, provided by Fuchs Lubricantes S.A.U. The use of this product facilitated the removal of the samples from the molds.

2.2. Mixed Design

To conduct a comprehensive analysis of the mortar dosing, nine types of mortar were manufactured. The untreated mortar was used as a reference to make comparisons with the mortars with dosages. The treated mortars were differentiated from each other according to the percentage of GOS they contained. This amount was inversely proportional to the amount of sand per volume, that is, the greater the amount of GOS, the smaller the amount of sand. The exact amounts of each of these materials are listed in Table 3, according to the percentage of GOS incorporated. In addition, three types of cements with different resistance categories were utilized: 32.5, 42.5, and 52.5 MPa. The amount of cement incorporated remained consistent throughout the experiment.

Table 3.

Type and quantity of materials used in each mixture.

The mixtures were designed to prepare mortars with a total settlement of less than 90 mm, which corresponds to a fresh consistency of class S2, according to EN 12350-2 [33].

2.3. Mixing and Casting Process

A total of 378 mortar samples were fabricated in the laboratory. Subsequently, 14 test pieces were made of each mixture: 8 cubic specimens of 100 × 100 × 100 mm and 6 prismatic specimens of 150 × 150 × 600 mm. Half of the pieces were cured for 7 days, while the other half were cured for 28 days.

The elaboration of the different mixes began with dry premixing of the fine aggregate, cement, and GOS in the mixer for three minutes. After a two-minute standing period, water was progressively added to the mixture, and mechanical mixing continued. During kneading, the homogeneous distribution of the particles and the uniformity of the mixture were monitored. Then, after a two-minute rest period, the consistency was checked and adjusted. Next, the fresh mortar was poured into the molds. The internal surface of the molds was coated beforehand with a release agent.

The process for making and curing the laboratory samples was conducted in accordance with EN 12390-2 standard [34]. The samples were first cured at room temperature in the laboratory for 24 h without removing them from the molds. Then, air pressure was used to remove the hardened samples from the plastic molds. The samples were collected and cured in limewater at a temperature of 20 ± 1 °C for seven or 28 days depending on the predicted age of failure.

Given that the test pieces are stored for a period of time, it is of vital importance to accurately label each piece so as to avoid unintentional mix-ups or confusion during the experiment. Labels were attached to their respective test piece as soon as it was removed from the mold, and the label remained attached until the piece underwent its corresponding test. The labels were made of plastic so as to be waterproof and capable of withstanding the storage period in the water tanks.

The flexural and compression specimens used for each test are identified by the following nomenclature: A-B-Z, which represent the following:

A: time elapsed from the manufacture of the test piece until it breaks. This period can be R7 or R28 days.

B: M signifies mortar, followed by the % of GOS included in the mixture. This indicates the amount of GOS contained in each mixture relative to the total volume of aggregate.

Z: type of cement used.

For example: R7-M10-32.5 identifies a test piece tested seven days after its manufacture, made of mortar with 10% GOS volume replacing the aggregate, and the cement used has a nominal resistance 32.5 MPa.

2.4. Testing Procedures

Once the laboratory samples had been cured for seven or 28 days, they were removed from the tank and placed on a steel wire rack to drain at 23 ± 3 °C for 30 min. Their underside was dried manually with a cloth. The wet density or saturated weight content was measured immediately thereafter. In Figure 2a, the weight of the test pieces can be observed. To determine the weight of each mixture, the average weight of the 14 specimens was used.

Figure 2.

(a) A test piece being weighed. (b) Detail of the surface of the mortar with GOS. Scale bar: 10 mm.

The average weight was used to calculate the density value corresponding to each percentage of incorporated GOS. This non-destructive test was carried out prior to breaking the test pieces. The surface finish is shown in Figure 2b. The incorporation of GOS provides cavities in the mortar mass.

Compressive strength tests were performed on the laboratory samples on days seven and 28. This test was conducted with a sample of four test pieces for each age in accordance with standard EN 12390-3 and a constant rate of loading of 0.5 MPa/s [35]. The flexural strength tests were performed in the same manner, but in this case, three specimens were used for each measurement. The flexural test guidelines followed standard EN 12390-5, with a constant rate of loading of 0.05 MPa/s [36].

The machines used for the compression and bending tests were the Pilot Pro model and the high-rigidity flexural frame Duplex, both made by Controls. Figure 3 shows the test pieces used in each of the stress tests: compression and bending.

Figure 3.

Compression and bending tests.

3. Results and Discussion

Once the tests were completed, a significant limitation was identified regarding the amount of waste product that could be added to the mixtures. A 50% addition proved difficult to handle, and the strength performance suffered greatly. Thus, the decision was made to limit the study of results to dosages between 0% and 30% GOS as they provided the most promising results.

With this consideration in mind, the evolution of mortar density is plotted as a function of the % GOS incorporated in Figure 4.

Figure 4.

Density of dry mixtures; % relative to reference material.

The upper and lower limits correspond to the mortar mixtures that incorporated 0% (2080 kg/m3) and 100% (1226 kg/m3) of GOS, respectively. The graph between these limits depicts the evolution of density as a function of the % addition of GOS. The minimum density for mixtures incorporating GOS was around 1800 kg/m3. Below this value, the mixtures were unstable and difficult to handle.

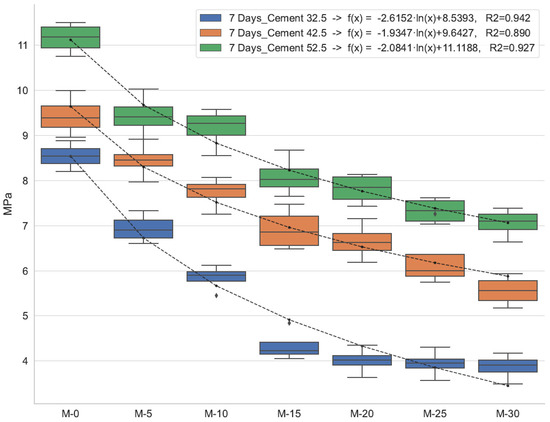

The results of the compression breakage tests conducted on day seven are key to determining the feasibility of producing lightweight precast materials with these mortar mixtures. Therefore, these tests were completed, and the results are presented in Figure 5. The three lines correspond to the three types of cements used.

Figure 5.

Evolution of compressive strength.

The continuous functions represent the estimation of the mixtures’ intermediate values. This estimation was achieved using logarithmic trend lines, which present an adequate fit in all cases, providing an R2 above 0.9. This response can be observed in the strength performances evaluated as a function of the percentage of GOS incorporated.

If 6 MPa is considered the limit, it can be observed that Cement 32.5 is constrained to incorporating 10% GOS, while the mixtures of other cements are capable of assimilating up to 30% GOS. In the case of Cement 32.5, the percentage loss of strength is more pronounced, as it decreases by 45% compared to the reference strength when 30% GOS is added. The mixtures that use better-performing cement maintain a strength value of around 60% of the reference strength, with the same percentage of GOS used.

The results of the compression tests conducted on day 28 are shown in Figure 5. The drop in performance is less marked than in the case of the day seven tests. The 28-day data are used to describe the strength performance of prefabricated products on the market.

If materials with a compressive strength above 10 MPa are considered valid, the Cement 32.5 mixtures once again present the same limitation (10%) in terms of the amount of GOS they are capable of incorporating. However, the mixtures with other types of cement incorporating 30% GOS maintain a strength performance of around 70% of that of the reference material.

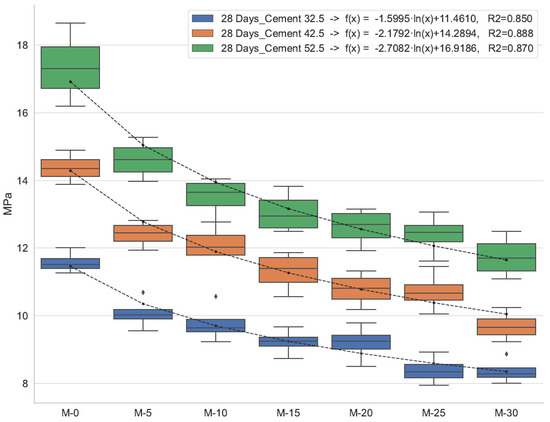

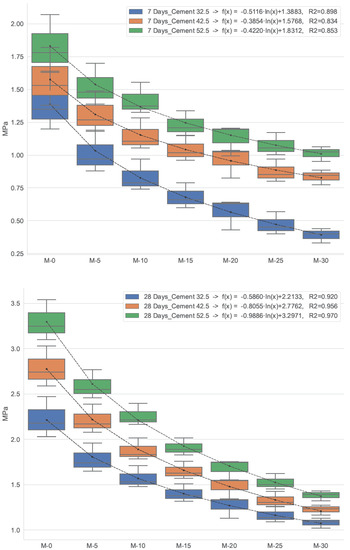

Both sets of results (day 7 and day 28) of the bending tests are tabulated in the graph in Figure 6. The continuous line indicates the 7-day results, and the dashed line, the 28-day results.

Figure 6.

Evolution of flexural strength.

The various percentage losses in flexural strength are greater than the decreases in compressive strength. For the mixtures incorporating a larger quantity of GOS, in the case of Cement 32.5, at seven days, its flexural strength dropped 30%, and in the other two cements, strength reduced by 55% compared to the reference strength. In the case of 28 days, the results were the same for all the types of cements, with performance stabilizing at around 45% for all the mixtures.

4. Conclusions

The results reveal that the strength performance of those materials made with Cement 32.5 is compromised early on. This finding represents a determining factor when it comes to utilizing these mixtures in common industrial processes. In such cases, if the objective is to utilize a mixture that incorporates more than 10% GOS, the options are Cement 42.5 and Cement 52.5.

The compressive strength performance of the mixtures fared better than flexural strength performance. That is, for the highest quantity of GOS (30%), compressive strength held steady around 70%, while flexural strength dropped to below 50%, in both cases in comparison with the reference material.

Let us consider the following as a market reference: strength performance, compression at 28 days, 10 MPa, and the mortar made with Cement 32.5 (see Figure 5). Thus, it can be concluded that, in order to maintain strength performance in elements made with GOS mixtures, Cement 42.5 must be used when GOS additions of 0% to 10% are incorporated. To add a greater percentage of GOS, up to 30%, Cement 52.5 must be utilized. Working with lower-performing cement is ruled out given that the amount of GOS that can be assimilated is minimal.

The decision to launch these new materials on the market must be examined alongside their increase in thermal performance. Another possible use for GOS is in enclosure and lightening elements for floor slabs, rather than using it as biomass. If the flexural strength of a material is a determining factor, and Cement 32.5 mix 0 is the reference, then the amount of GOS that can be incorporated into the mixtures is limited to 10%. To achieve a 15% decrease in density, up to 30% GOS must be incorporated.

Green aggregates, such as GOS, whose economic cost is similar to that of expanded clay, are CO2 scavengers capable of offsetting emissions generated by obtaining the rest of a material’s components. Using green aggregates also represents a more socially responsible activity since their exploitation is less aggressive than obtaining mineral aggregates.

Author Contributions

Conceptualization, J.F.-C. and E.F.-G.; methodology, E.F.-G.; software, J.F.-C.; validation, J.F.-C., E.F.-G. and A.P.-E.; formal analysis, J.F.-C.; investigation, F.J.M.-d.-P.; resources, F.J.M.-d.-P.; data curation, A.P.-E.; writing—original draft preparation, J.F.-C.; writing—review and editing, J.F.-C. and E.F.-G.; visualization, A.P.-E.; supervision, F.J.M.-d.-P.; project administration, J.F.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would also like to express their gratitude for the support of the University of La Rioja and the company Trujal 5 Valles.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Boufi, S. Biocomposites from olive-stone flour. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 387–408. [Google Scholar]

- Cuevas, M.; Sánchez, S.; García, J.F. Thermochemical and biochemical conversion of olive stones. In Agricultural Wastes: Char-acteristics, Types and Management; Nova Science Publishers: Hauppauge, NY, USA, 2015; pp. 61–85. [Google Scholar]

- Fokaides, P.A. Energy recovery alternatives of the olive oil industry byproducts. In European Biomass Conference and Exhibition Proceedings; ETA Florence Revewable Energies: Florence, Italy, 2018; Volume 2018, no. 26thEUBCE; pp. 83–87. [Google Scholar]

- Alshuiael, S.M.; Al-Ghouti, M.A. Multivariate analysis for FTIR in understanding treatment of used cooking oil using activated carbon prepared from olive stone. PLoS ONE 2020, 15, e0232997. [Google Scholar] [CrossRef] [PubMed]

- Ghouma, I.; Jeguirim, M.; Dorge, S.; Limousy, L.; Ghimbeu, C.M.; Ouederni, A. Activated carbon prepared by physical activa-tion of olive stones for the removal of NO2 at ambient temperature. Comptes Rendus Chim. 2015, 18, 63–74. [Google Scholar] [CrossRef]

- Corral Bobadilla, M.; Lostado Lorza, R.; Somovilla Gómez, F.; Escribano García, R. Adsorptive of Nickel in Wastewater by Olive Stone Waste: Optimization through Multi-Response Surface Methodology Using Desirability Functions. Water 2020, 12, 1320. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Blázquez, G.; Trujillo, M.C.; Pérez, A.; Calero, M. New treatment of real electroplating wastewater containing heavy metal ions by adsorption onto olive stone. J. Clean. Prod. 2014, 81, 120–129. [Google Scholar] [CrossRef]

- La Rubia-García, M.D.; Yebra-Rodríguez, Á.; Eliche-Quesada, D.; Corpas-Iglesias, F.A.; López-Galindo, A. Assessment of olive mill solid residue (pomace) as an additive in lightweight brick production. Constr. Build. Mater. 2012, 36, 495–500. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Felipe-Sesé, M.A.; Infantes-Molina, A. Evaluation of fly and bottom ash of different biomass combustion as raw materials in clay-based ceramics. In Ceramic Materials: Synthesis, Performance and Applications; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2017; pp. 1–32. [Google Scholar]

- Quaranta, N.E.; Caligaris, M.G.; Unsen, M.A.; López, H.A.; Pelozo, G.G.; Cristóbal, A.A. Residual biomass of the agricultural industry as pore forming material in ceramics. In Municipal and Industrial Waste: Sources, Management Practices and Future Challenges; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2018; pp. 249–264. [Google Scholar]

- Arezki, S.; Chelouah, N.; Tahakourt, A. The effect of the addition of ground olive stones on the physical and mechanical proper-ties of clay bricks. Mater. Construcción 2016, 66, e082. [Google Scholar] [CrossRef]

- Djadouf, S.; Chelouah, N.; Tahakourt, A. Influence de la distribution en taille (broyat de noyaux d’olive) sur les propriétés de la brique. Matériaux Tech. 2019, 107, 403. [Google Scholar] [CrossRef]

- Bories, C.; Aouba, L.; Vedrenne, E.; Vilarem, G. Fired clay bricks using agricultural biomass wastes: Study and characterization. Constr. Build. Mater. 2015, 91, 158–163. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Cabeza, L.F. Use of by-products as additives in adobe bricks: Mechanical properties characterisation. Constr. Build. Mater. 2016, 108, 105–111. [Google Scholar] [CrossRef]

- Djadouf, S.; Chelouah, N.; Tahakourt, A. The influence of the addition of ground olive stone on the thermo-mechanical behavior of compressed earth blocks. Matériaux Tech. 2020, 108, 203. [Google Scholar] [CrossRef]

- Sodupe-Ortega, E.; Fraile-Garcia, E.; Ferreiro-Cabello, J.; Sanz-Garcia, A. Evaluation of crumb rubber as aggregate for auto-mated manufacturing of rubberized long hollow blocks and bricks. Constr. Build. Mater. 2016, 106, 305–316. [Google Scholar] [CrossRef]

- Adelusi, E.; Ajala, O.; Afolabi, R.; Olaoye, K. Strength and dimensional stability of cement-bonded wood waste-sand bricks. J. For. Sci. 2021, 67, 545–552. [Google Scholar] [CrossRef]

- El-Nadoury, W.W. Production of sustainable concrete using sawdust. Mag. Civ. Eng. 2021, 105, 66–74. [Google Scholar] [CrossRef]

- Hasan, M.; Saidi, T.; Afifuddin, M. Mechanical properties and absorption of lightweight concrete using lightweight aggre-gate from diatomaceous earth. Constr. Build. Mater. 2021, 277, 122324. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; Balaji, K.V.G.D.; Chilukoti, S. Influence of PVC waste powder and silica fume on strength and microstructure prop-erties of concrete: An experimental study. Case Stud. Constr. Mater. 2021, 15, e00610. [Google Scholar] [CrossRef]

- De Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-stone biomass ash (OBA): An alternative alkaline source for the blast furnace slag activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; de Moraes Pinheiro, S.M.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Design and properties of 100% waste-based ternary alkali-activated mortars: Blast furnace slag, olive-stone bio-mass ash and rice husk ash. J. Clean. Prod. 2020, 243, 118568. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Moraes, J.; Tashima, M.; Monzó, J.; Borrachero, M.; Payá, J. A 100% waste-based alkali-activated material by using olive-stone biomass ash (OBA) and blast furnace slag (BFS). Mater. Lett. 2017, 203, 46–49. [Google Scholar] [CrossRef]

- Cuenca, J.; Rodríguez, J.; Martín-Morales, M.; Sánchez-Roldán, Z.; Zamorano, M. Effects of olive residue biomass fly ash as filler in self-compacting concrete. Constr. Build. Mater. 2013, 40, 702–709. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. One-part eco-cellular concrete for the precast industry: Functional features and life cycle assessment. J. Clean. Prod. 2020, 269, 122203. [Google Scholar] [CrossRef]

- Brasileiro, G.A.M.; Vieira, J.A.R.; Barreto, L.S. Use of coir pith particles in composites with Portland cement. J. Environ. Manag. 2013, 131, 228–238. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab con-crete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.A.N.; Tang, S. Comparison of fly ash, PVA fiber, MGO and shrinkage-reducing admix-ture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 1–18. [Google Scholar] [CrossRef]

- Del Río Merino, M.; Rodríguez, J.G.; Martínez, F.F.; Astorqui, J.S.C. Viability of using olive stones as lightweight aggregate in construction mortars. Rev. Constr. 2017, 16, 431–438. [Google Scholar] [CrossRef]

- MAbdulkarem, A.; Rasool, D.A.; Nabhan, B.J. Utilization of olive and pumice stones to improve the thermal properties of cement mortar. Int. J. Nanoelectron. Mater. 2020, 13, 181–188. [Google Scholar]

- Barreca, F.; Fichera, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- AEN/CTN 146-ÁRIDOS, UNE-EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. AENOR: Madrid, Spain, 2012.

- AEN/CTN 83, EN 12350-2; Testing Fresh Concrete—Part 2: Slump-Test. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN, UNE-EN 12390-2; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN. UNE-EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. AENOR: Madrid, Spain, 2020.

- CTN 83-HORMIGÓN. UNE-EN 12390-5; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. AENOR: Madrid, Spain, 2020.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).