Abstract

Prefabricated construction (PC) is an increasingly popular method of construction utilized globally due to its high productivity and efficient performance. PC as an advanced building technique is susceptible to problems such as the immaturity of the PC industry’s development, inability to realize production benefits, and application-related risks and uncertainties. The management of PC (MPC) can be applied to resolve these difficulties and generally enhance performance. Reviews pertinent to the MPC are scarce, making it challenging to concentrate and comprehensively summarize the research situation of the MPC. The MPC review was conducted by Li et al. in 2014. However, there has been a lot of change in the MPC research field. Therefore, this study is an extension of the work of Li et al. (2014). This article aims to analyze and summarize the current research situation and future trends of the MPC, employing a bibliometric search and scientometric analysis from MPC-related publications between 2011 and 2021. This paper outlines current research topics, gaps, and future development from four perspectives based on publications gathered: (1) PC development, (2) PC performance management, (3) PC life cycle management, and (4) technological applications in the MPC. Based on the discussion of these four performance indexes, the following future research directions are proposed: (1) PC industry development considering a combination of Industry–University–Research, (2) the performance impact of management methods and technologies, (3) the rationality of management methods and technologies. This study is vital for scholars to understand MPC research and to conduct further research.

1. Introduction

1.1. PC and MPC

Prefabrication, mechanization, automation, robotics, and reproduction are all aspects of industrialized construction. Prefabricated construction (PC) is a strategy to realize industrial buildings by transferring the building construction procedure away from the construction site to a specialized factory [1]. There has been increasing recognition in the last decade that prefabricated technology can improve productivity while being eco-friendly. This has spawned an impressive number of PC-related studies. However, as a novel construction method, many countries still have prefabricated buildings in the initial developmental stage [2,3,4,5]. PC applications are characterized by multiple production interconnections, cross-organization, and cross-worksite coordination involving multiple subjects, which are prone to uncertainties and constraints in the construction cycle [6].

Furthermore, PC management is more complex due to the integration of numerous technologies and the collaboration between multiple stakeholders [7]. The management of PC (MPC) refers to management activities that adopt various strategies and methods to achieve the success of the PC project and fulfill its objectives. The primary contents of the MPC include: (1) macro level: the development and promotion of the PC industry, which investigates the barriers and drivers of the development as well as the policies and guidance of PC [8]; (2) micro level: life-cycled management, performance management, and information technology application all focus on the objective and the success of the PC project and complement each other [9,10]. The concept of MPC promotes the systematic management of problems existing in the PC industry in order to reduce process uncertainty and constraints while increasing the efficiency and productivity of PC.

1.2. Literature Review

The research community considers the literature review as a key approach for examining research status and advancement. Lu et al. [11] reviewed the design for manufacturing and assembly (DfMA). Hu et al. [12] examined the sustainability of off-site manufacturing. Masood et al. [13] investigated supply chain management intervention for managing prefabricated construction from a supplier perspective. These reviews are all explored from relevant perspectives and do not focus on the MPC comprehensively. There are not many reviews of the MPC. Li et al. [14], in a critical review of the MPC, adopted the method of text analysis to summarize and condense the topics of some journals; they only analyzed the articles and did not utilize scientific mapping for the analysis of the sample articles from designated journals. Jin et al. [15] adopted scientific mapping to comprehensively investigate the research status and trend of off-site buildings. However, he does not consider prefabricated building project management and industrial development. Therefore, it is necessary to supplement the defects of previous review studies on the MPC and review the MPC systematically.

There are two major challenges of PC: (1) Uncertainty and constraint. PC construction entails both off-site and on-site construction, which includes the design and manufacturing phase, transportation, construction, operation, and “grave” stages. Prefabricated buildings are associated with several uncertainties and constraints due to the multi-stage and production site fragmentation of prefabricated buildings from the design to the construction stage [16]. (2) The practice of PC is still in its initial phase. The benefits of PC are not fully realized as it is an emerging technology in many countries [17]. This study proposes that the MPC can help mitigate these challenges. The MPC has quality, cost, schedule, and sustainability as its goal, analyzes the industry macro environment and project conditions, and uses relevant technology or management tools to reduce project uncertainty and constraints and improve project efficiency from the perspective of the whole life cycle [14]. The quality of the MPC is one of the key success factors for a PC project. The review of the MPC can be beneficial to its development and promote the progress of PC [10,17,18]. Therefore, a review of the MPC can summarize the current research status, explore research limitations to promote the development of future research, and it is also an effective way to explore solutions to PC problems.

1.3. Research Objectives

This study, therefore, conducts a scientometric analysis and discussion. The objectives are to (1) know the MPC research situation by scientometric mapping, (2) summarize research topics in the MPC domain, (3) explore the MPC challenges, and (4) identify future research directions. This paper can help scholars comprehend the MPC, understand the research status, and identify future research directions.

2. Background of PC

Prefabrication, a manufacturing industry concept, refers to the transfer of the manufacturing process to a specialized facility which produces components for final installation. Building industrialization has become a trend in the construction sector due to the necessity to improve the performance of the construction industry [15,19,20]. In the construction industry, the application of the prefabrication concept in construction industry incorporates PC methods, panelized construction, and hybrid construction. Meanwhile, PC refers to the process of designing and manufacturing prefabricated products in specialized factories and transporting the sections for on-site installation to finally form a building structure [14]. PC can be classified into the following types: non-volumetric PC (a PC method in which the prefabrication does not enclose useful space); volumetric PC (a PC method that incorporates units that enclose useful space but does not constitute an entire structure); and modular building (a PC method consisting of modules that form an integrated building or part of a building, including the structure and envelope. Modules are usually nearly finished). Different types of PC can also be used in the same project. For example, non-volumetric PC and volumetric PC are often used in the same project [1,21,22].

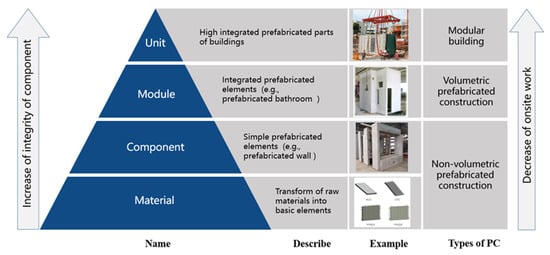

The objective of developing prefabricated buildings and the three categories of PC is to gradually move on-site work to manufacturing industries with increasing integration of prefabricated components. This advancement can increase production specialization while decreasing the risk and uncertainty on the project site [1,6]. Bock and Liner proposed a hierarchical modular framework comprising units, modules, components, and materials [23]. Figure 1 shows the differences between the various types of PC [22]. The figure demonstrates the increasing complexity and integration of PC components. Figure 1 shows that prefabricated components are gradually changing towards a highly integrated direction. From bottom to top, the first level is prefabricated materials (such as steel cages, precast concrete, etc.). The second level is prefabricated components, which can be seen as independent components (such as prefabricated bay windows, roofs, etc.) that are joined together by prefabricated materials. The third layer is the module. At this level, the preproducts are independent units with functions, but they are usually relatively small and not load-bearing (such as prefabricated toilets, kitchens, etc.). The top floor is the unit, which is prefabricated with the highest integration degree. The unit is a space with complete functions, and the building can be directly used after it is assembled with reliable technology, which is also the most integrated architectural form of PC. The prefabricated components used by different types of PC are also different. Due to the continuous improvement of the integration degree of prefabricated components adopted by different PC types, the on-site construction work is gradually reduced, which reduces the uncertainty and interference on the site and is conducive to the improvement of production efficiency. Understanding the types of PCs will enable readers to learn more about the MPC’s managed objects and scope.

Figure 1.

Prefabrication structure.

Conventional construction refers to the entire on-site construction process, including the use of cast-in-place technologies. Compared with conventional construction, PC may decrease project duration and capital cost significantly, while contributing to enhanced construction quality, environmental sustainability, and safety performance based on predictability and reliability in fabrication [20,24,25,26,27]. PC can also reduce on-site noise pollution and carbon emissions while decreasing labor demand and wastage. Because of PC’s high productivity, it has garnered significant interest and recognition in academia and industry in developed and developing countries, such as China, the United States, Australia, and Singapore [28]. Non-volumetric PC and volumetric PC are construction methods that combine prefabrication with cast-in-site, and they are commonly utilized in many countries. Given the increasing importance of prefabrication integration, several countries have focused on the development of various concepts of modular buildings. This includes (1) modular-integrated construction (MiC) from Hong Kong, China, referring to a construction method for manufacturing 3D volumetric modules (completed with finishes, fixtures, and fittings) at specialized factories off-site and transporting them to the construction site for assembly [29]. (2) Prefabricated, prefinished volumetric construction (PPVC) is a Singaporean construction procedure in which fully finished modules (with finishes) are manufactured at off-site specialized factories then transported to the site for assembly [30]. (3) Modular construction (MC) is dependent on the use of panelized members or full volumetric units manufactured off-site in factories and transported to the construction site for installation. Modular buildings have the highest integration level in PC [31]. As mentioned above, MiC, PPVC, and MC are PC approaches with similar concepts but may have different names in diverse countries.

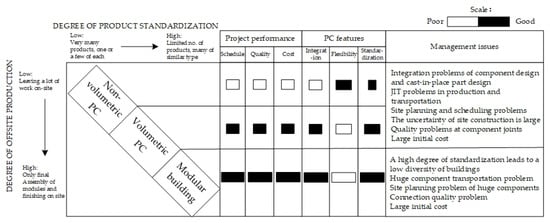

Due to differences in features, different types of PC may result in varying project performances in terms of schedule, quality, and cost. This paper refers to Henric et al.’s matrix for variegated production systems for construction with chemical degrees of industrialization [32]. The framework for classifying PC production systems, project performance, PC features, and management issues is illustrated in Figure 2. Project performance includes the schedule, quality, and cost of a project (full life-cycle cost). The Features of different PC types are described in terms of integration, flexibility, and standardization. Since non-volumetric PC and volumetric PC are frequently utilized in the same project, their management issues are discussed together. The management issues of different types of PC are directly related to their project performance and features. The solution to management issues may result in increased project performance. However, some PC features may generate management issues. For example, the high integration of MC would limit the diversity and versatility of PC buildings, as well as the flexibility of the construction process.

Figure 2.

Framework for classifying PC production systems, project performance, PC features, and management issues.

3. Research Methodology

This holistic review of the MPC provides a framework connecting existing research to near-future research, projecting future research on MPC-related trends, and encouraging interdisciplinarity, such as information technology, manufacturing, and other relevant research areas. Regarding the method of literature collection, this review adopted a collection approach with a combination of keyword search and two-round screening, derived from the review of Jin et al. [15]. This approach is integrated with the previous review steps in PC, including Li et al. [14], Mostafa et al. [33], and Hosseini et al. [34]. Secondly, the two-round screening in Jin et al.’s study ensures that the literature sample is relevant to the review topic, which makes the subsequent analysis more convincing [15].

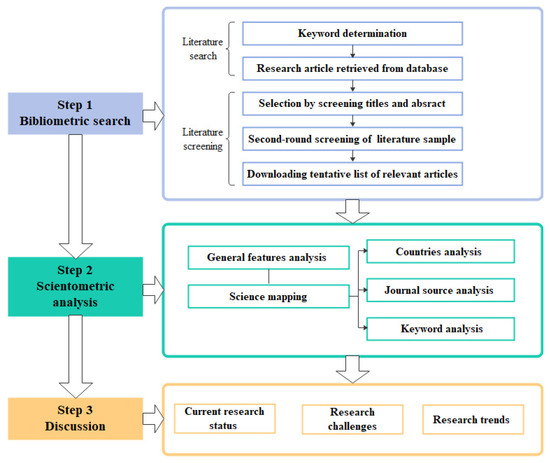

The workflow of the review-based approach is illustrated in Figure 3. The bibliometric search was used to determine articles in the scope of MPC research. According to the selected literature sample, scientometric analysis (statistics and science mapping), aided by literature analysis software (e.g., VOSviewer), was adopted to analyze important findings (e.g., the main trend of research and main research keywords) in the literature. Finally, new research questions were discussed based on the results of the bibliometric search and analysis. A detailed description of the three sections is illustrated in the following subsections.

Figure 3.

Workflow of the MPC review in this study.

3.1. Bibliometric Search

3.1.1. Literature Search

The keywords in this study were based on the frequently searched keywords in previous relevant MPC review papers [14,15,29,35]. The search phrase is as follows: Topic And Title = (“industrialized building*” OR “industrialized housing” OR “industrialized building system” OR “prefabricated construction” OR “prefabricated building*” OR “prefabrication construction “OR “panelized construction “OR “tilt*up construction “ OR “modular construction “ OR “modular integrated construction “OR “MiC” OR “prefabricated prefinished volumetric construction “ OR “PPVC” OR “modular home “ OR “modular building*” OR “modular building system” OR “off-site construction” OR “off-site construction” OR “prefabricated “ OR “prefab” OR “pre-fab” OR “pre-fabrication” OR “pre-assembly” OR “pre-fabricated” OR “prefabrication housing production” OR “PHP” OR “Precast Production System”) AND TS = (“off-site construction” OR “off-site construction” OR “prefabricated “OR “prefab” OR”pre-fab”OR”pre-fabrication”OR”pre-assembly”OR”pre-fabricated”) NOT Topic = (organic, molecular, atomic, chemistry, chemical reaction, nuclear, paper fluidics, medicine, and surgery).

The Web of Science (WOS) and Scopus databases were adopted in the bibliometric search of the PC literature, and many excellent review articles are based on these databases. L. Hou et al. used these databases to review off-site construction from the point of technology [36]. X. Hu et al. indicated that WOS and Scopus are popular engines in the research field [19].

The purpose of this study is to identify the significant topics and research trends in the MPC. Secondly, over the last decade, journal publications on the MPC have gained scholarly attention. This is illustrated through a scientometric analysis in the next section. Therefore, the range of years under review can achieve the aims of this research, which can accurately identify the future trend in the MPC. Conference papers are published in large quantities but with fewer details than journal papers. Therefore, conference papers, both peer-reviewed and non-peer-reviewed, were excluded from the sample. Removing conference papers from literature reviews is generally accepted [15]. Therefore, additional conditions are required in the literature search: (1) articles published between 2011 and 2021 October; (2) excludes conference papers; and (3) the language of articles is English. After eliminating duplication, 602 articles were obtained.

3.1.2. Literature Screening

There is still some unrelated literature retrieved from the database. Two rounds of screening were used to obtain the final literature sample. The first round is to screen the title and abstract of the articles, which can initially filter out the articles unrelated to the PC field and some articles unrelated to the MPC. The second round is to screen the article sample. Articles focusing on the MPC are screened out, and articles related to PC technology or design (such as material technology of prefabricated components, design methods, etc.) are eliminated. After two rounds of screening, 376 articles were finally obtained. Finally, the article are downloaded and used as the basis for subsequent scientometric analysis and discussion.

3.2. Scientometric Analysis

After the bibliometric search, literature samples were selected from WOS and Scopus. A result analysis consists of general feature analysis and science mapping. General features analysis refers to statistics on the data of the literature samples (publication year, annual publication volume, etc.). The scientific mapping includes country analysis, journal source analysis, and keyword analysis using VOSviewer, a text mining tool commonly used for scientometric analysis [15].

3.3. Discussion

The discussion was conducted following the bibliometric study and scientometric analysis of the literature that provided a science mapping related to the MPC. The aims were to summarize the research focus in this area, explore the challenges in the MPC and illustrate the MPC from research topics. The authors attempted to utilize VOSviewer for keyword clustering analysis and discovered that the clustering effect is not obvious. Therefore, the authors summarized these discussion topics after reading the literature samples. Based on these topics, current research status, research challenges, and research trends are discussed.

This section may be divided into subheadings to provide a concise and precise description of the experimental data, their interpretation, and the experimental conclusions.

4. Result of Scientometric Analysis

4.1. General Features of the Literature

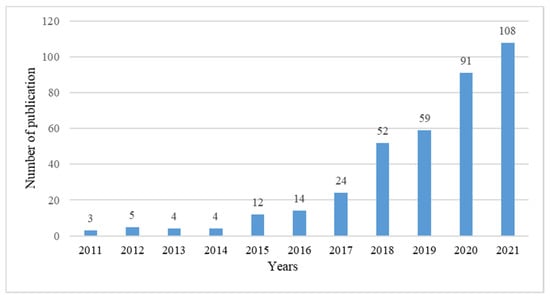

To establish the characteristics of the sample, 376 publications were selected for analysis. The bibliometric search method was conducted, and the literature sample consisted of 40 review articles (11%). Figure 4 shows the annual research articles published in specified literature. The figure revealed the following findings: (1) The number of publications increased between 2011 and 2021, indicating that MPC research has attracted greater attention. (2) The number of research articles has evolved significantly since 2017, with over half of the sample published after 2017. This demonstrates that the MPC has steadily gained scholarly interest and has gradually become a point of discussion for research. It also demonstrates that with the advancement and innovative application of technology, there will be more topics worthy of research in the MPC.

Figure 4.

Yearly research articles related to MPC from 2011 to 2020.

4.2. Active Countries Analysis

The threshold values employed in the analysis in VOSviewer are described. Although there is no standard for determining threshold values, the authors selected these threshold values for the following reasons. First, many existing studies have adopted these values for scientific mapping. Second, after experimenting with different threshold values in VOSviewer, it was discovered that these threshold values are the most suitable for establishing a satisfactory range of sources. The same criteria were applied while selecting the threshold values in this paper. The following analytical procedure also selects threshold values according to the aforementioned principles.

The researchers defined the minimum number of papers and citations of a country to be 5 and 15, respectively, resulting in the selection of 17 out of 43 countries. The countries and contributions of MPC-related journal papers were identified.Figure 5 and Table 1 show the result of the countries’ analysis of the MPC-related papers. Each node refers to the region or country in which an author’s institution is located. Authors from different countries or regions may contribute to an article; the links reflect collaboration across countries or regions (a collaboration between authors often represents cooperation between countries or regions). The thickness of the connecting line indicates the frequency of cooperation. The following conclusions were obtained from Figure 5 and Table 1: (1) China has the most publications, 193 (including papers from Hong Kong and mainland China), indicating that China is at the stage of development in the MPC, and further research targeted at China is required. Hong Kong’s PC research has likewise advanced. In recent years, institutions such as the Hong Kong Polytechnic University (PolyU) and the University of Hong Kong (HKU) have contributed immensely to PC research. Therefore, the number of publications in China exceeds that in Western developed countries. (2) China has the potential and needs to accomplish industrialized construction in the next few decades. (3) China was followed by Australia, the United States, Canada, and the United Kingdom (UK), which published 86, 37, 33, and 27 articles, respectively. (4) The number of publications in China exceeds half of the total publication, indicating that Chinese researchers are particularly active in leading or participating in MPC research and making contributions to this discipline. (5) Combining with the associated number of “Total link strength” and “Citation” shows the state of research in the areas of influence. It can be illustrated in Table 1; China, Australia, Canada, the USA, the United Kingdom, and Singapore have a higher level of “Total link strength” and “Citation”, indicating that these countries have a stronger influence in the MPC research area.

Figure 5.

Mapping of active countries in MPC research.

Table 1.

Country analysis (descending order according to Documents).

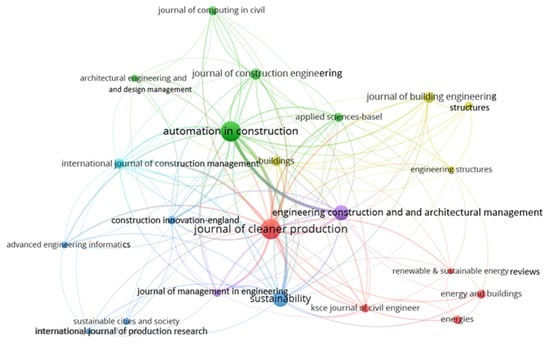

4.3. Journal Source Analysis

The sources of MPC-related journal papers were identified using VOSviewer. The clusters and inter-relations among these journals are illustrated in Figure 6. Consequently, a total of 22 out of 123 sources satisfied these thresholds. In Figure 6, larger font and node size refer to cases with relatively more articles published from the given source. The connection lines among the given sources refer to mutual citation. The thicker the connection lines, the more frequent the mutual citation among the specified sources. For example, Figure 6 illustrates that in the MPC, The Journal of Cleaner Production has a relatively strong relationship with Sustainability, The International Journal of Construction Management, The Journal of Management in Engineering, and Automation in Construction. Table 2 illustrates the detailed results of the journal source analysis. As shown in the table, Journal of Cleaner Production and Automation in Construction have higher levels of “Citation” and “Total link strength”, indicating that MPC-related publications under their journals have better quality and influence. “Avg. citation” refers to the number of citations divided by the document, indicating the average number of citations per article. A high level of “Avg. citation” indicates that the quality of MPC-related papers in this journal is high, except for The Journal of Cleaner Production and Automation in Construction, The Journal of Management in Engineering, Engineering Structures, and The International Journal of Production Research all have high “Avg citation levels”. By ranking and comparing the indicators in the table, it proposes that The Journal of Cleaner Production, Automation in Construction, and The Journal of Management in Engineering have a prominent influence in the field of the MPC.

Figure 6.

Mapping of influential journals in MPC research.

Table 2.

Journal source (descending order according to Documents).

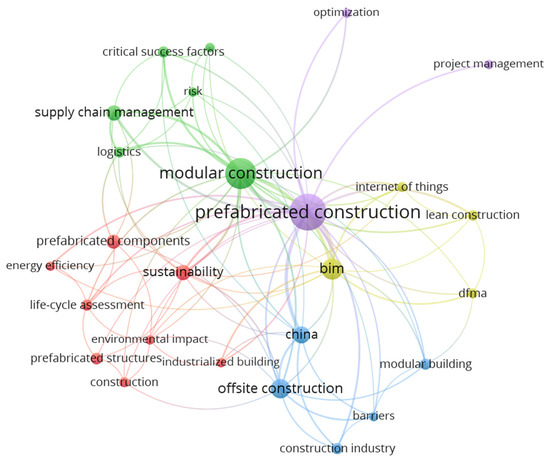

4.4. Keyword Analysis

Keywords can reflect the topic of articles and the core of research. The keyword co-occurrence analysis of the sample articles can assist researchers to master the boundaries of the knowledge area and research on the MPC. The co-occurrence of keywords can highlight the relationships between keywords and the trend of the research discipline. The pattern shown in Figure 7 demonstrates the topics in the PC domain. “Co-occurrence” analysis and “author keyword” were selected in VOSviewer. The occurrence threshold was set to 5, and 34 keywords out of 1265 were selected for analysis after accumulating repeated words (such as OSC with off-site construction). The words of research methods are excluded because the objective of keyword analysis is to show current research topics and the interrelations among them. The result of the analysis is shown in Figure 7 and Table 3.

Figure 7.

Co-occurrence of keywords in MPC research.

Table 3.

Keyword co-occurrence analysis (descending order according to Total link strength).

The connecting lines between keywords (refers to link) indicate a correlation. The thickness of links signifies the strength of correlation (refers to link strength). Therefore, the thicker the connection lines, the stronger the correlation amongst keywords. Modular construction, prefabricated construction, and off-site construction are used in the literature selection. These keywords consequently have more links and greater link strength. In addition, BIM, China, and sustainability also have more links and greater link strength. China is the country with the most publications in the literature samples. BIM application in the MPC and the concept of sustainability are constantly the key topics in the MPC discipline. The average publication year of these keywords (sustainability, supply chain management, critical success factors, Internet of Things, and optimization) is 2020. These topics are key research issues and future research trends.

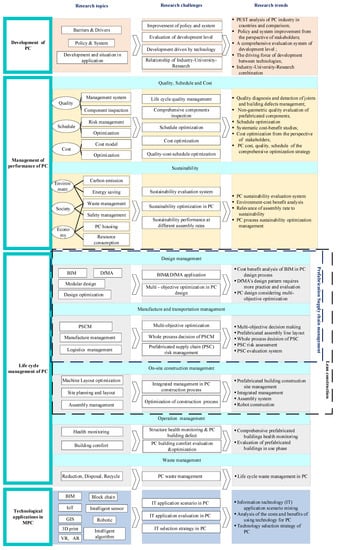

5. Discussion

After discussions on the number of publications, sources, countries, institutions, researchers, and keywords in the PC domain, the following conclusions were highlighted: (1) outlining the major research topics, (2) investigating research challenges, and (3) forecasting future research trends. A classification based on research topics was created, as shown in Figure 8. This includes (1) development of PC, (2) management of performance of PC, (3) life-cycle management of PC, and (4) technological applications in the MPC. If there are articles covering more than one category, divide according to the corresponding category covered by the article, which means that an article can be classified into more than one category. For example, a study that focused on a quality traceability system examining blockchain is classified as quality management and information technology about the MPC. Finally, it is classified into the categories of “Management of Performance of PC” and “Technological applications in MPC”.

Figure 8.

Framework for connecting current research topics, research challenges, and trends in PC.

5.1. MPC-Related Research Topics

5.1.1. Development of PC

The development of PC focuses on the development of the prefabricated construction industry.

- Application Background and Evaluation

This research area focuses on the development level of PC. The current background of PC development must be evaluated in order to conduct effective research. Scholars use qualitative analysis methods (such as SWOT) to evaluate the current status of the PC industry and analyze the advantages and disadvantages of PC development [37]. Identifying the present state of the industry is a prerequisite for development. The application of PC in developing countries is still in the preliminary stage, and the development direction needs to be determined in accordance with the existing development situation. Citing China as an example, scholars use big data mining to analyze and describe the status of the PC construction industry, providing a basis for development planning [5]. MC is also gaining popularity in regions where the construction industry is transitioning to industrialization. According to academics, continued MC development requires further governmental assistance, particularly on technical supervision and innovation [38]. This study shows that the application and innovation of information technology would be a key factor in the development level of PC, which is also one of the evaluation indicators of the development level.

- 2.

- Limitations of PC Development

To further promote prefabricated buildings, the influencing factors of the development process should be defined and analyzed [39]. High cost has always been a significant barrier to PC development. Studies have shown that the incremental cost increases with the prefabrication rate, but from the perspective of the whole life cycle, the overall costs are reduced and the benefits are improved [40]. PC development will have greater support if it can effectively resolve the problem of production process cost [41,42,43,44]. With the continuous development of assembly, increasing research has been conducted on promoting MC technology with a high integration degree. Sun et al. analyzed the challenges associated with constructing modular buildings. The findings of the research showed that “lack of coordination and communication amongst stakeholders”, “high cost”, “lack of government support”, “lack of knowledge and expertise”, “lack of building codes and standards”, “poor supply chain integration”, and “complexity of connection” are all significant limitations to PC development [45]. Among these challenges, most of them are related to stakeholders. Therefore, finding the mechanism to promote the development of PC from the perspective of stakeholders is also a focused research issue [41,46,47].

- 3.

- Policy and System Research

The high cost of PC often inhibits the industry’s growth, necessitating additional governmental support. Governments have gradually implemented a variety of measures to encourage the adoption of PC technology by multiple stakeholders. Policymakers are required to examine the policies to adopt and their effectiveness. Policy research has consistently focused on the policy considerations of incentive and regulation on the usage of prefabricated buildings, predominantly discussing the choice of incentive and regulation mode from the relationship between different stakeholders [8,48,49]. In addition to promoting the development of the PC industry through policies, it is also necessary to build relevant management systems within PC projects to promote coordination and cooperation among stakeholders [44,50]. Solving the problem of cooperation, coordination, and integration among PC stakeholders [46] is conducive to the success of prefabricated construction projects, making the development of PC gradually mature. Although a cost and benefit analysis is essential to policy or system improvement and development, policy or system formation and examination are achieved over a long period [48].

5.1.2. Management of the Performance of PC

This research examines PC performance based on sustainability, quality, schedule, and cost. This paper is divided into two parts, as shown in Figure 8. Sustainability, according to Landman, is defined as building design and construction using methods and materials that are resource efficient without prejudice to environmental health, health, and the well-being of building occupants, construction workers, the public, or future generations. Sustainability is a measure of a building’s social, economic, and environmental impacts, which is discussed in the initial part of this research. The subsequent section discusses the performance of PC from the project level, mainly: quality, cost, and schedule.

- Quality, Schedule, and Cost

Professional production methods and personnel enable PC to achieve quality performance. However, the separation between onsite and off-site makes tracing the quality issues difficult. Based on blockchain technology, Zhang et al. proposed a quality traceability system framework that can accurately track the quality of prefabricated components and guarantee that the quality information is transparent and absolute [51]. This study enhances the MPC application of blockchain technology, indicating that there are blockchain technology application scenarios for performance management. In the production process, the quality of prefabricated components directly affects the operation of the subsequent processes. According to David Watt, “Building defects refer to a shortcoming or failure in the function, performance, statutory or user requirements of a building, which may be detected in the structure, fabric, services or other facilities of the affected building” [52]. PC building defects include these shortcomings or failures, which may be regarded as potential risks affecting PC quality. Helena J. and John H. M. studied PC building defects and discussed the building defects of PC and conventional construction. The findings concluded that PC had a higher quality and a relatively shorter construction duration, however, there could be the risk of a delayed schedule [53]. In the study of schedule management, the factors leading to schedule delay are usually identified first and then optimized. Li et al. identified the risks of schedule delay and quantified the extent to which each risk affects the schedule. Finally, schedule optimization is carried out by taking measures against the risks [54]. Meanwhile, Ji et al. and Li et al. focused on schedule factors. Through the identification and evaluation of these factors, corresponding measures are finally taken for optimization [54,55]. According to Xie et al., schedule planning is adopted in optimizing the project schedule by identifying relevant constraints. Optimization models were then established to optimize the project schedule while giving the schedule optimization a more intelligent framework [56]. On cost management, Lin and Lu adopted an improved neural network model to forecast the budget of prefabricated building projects to increase the accuracy of cost prediction [57]. The accurate budgeting of costs can improve the effectiveness of cost management. The performance of prefabricated buildings must be evaluated by combining cost and benefit. The benefit generated by prefabricated buildings cannot be determined solely by economic income. Therefore, ensuring that benefits are realized while reducing cost is essential to the study of cost [40].

- 2.

- Sustainability

This section focuses exclusively on the sustainability of PC and how to improve it. Regarding environmental impact, the use of PC can reduce energy consumption [58], construction waste, material waste, and carbon emissions [49]. Given the variations between experiments and data, scholars have discovered that the carbon emissions of PC are comparable to those of traditional construction. According to some studies, the lowest possible carbon emissions can be achieved with the appropriate use of PC technology [59]. These studies motivated people to embrace PC technology (or the degree of prefabrication) to achieve optimal performance. With its social impact, PC can reduce on-site work and waste generation [31], thus impacting the site’s surrounding environment. This characteristic, however, does not imply that PC will not interfere with the surrounding environment. Relevant studies are required to discuss the reduction in the adverse effects of PC pertinent to the surrounding environment. PC has good safety performance. Although it can reduce the frequent occurrence of accidents, the new construction method still poses new safety risks. Fard et al. conducted a statistical analysis of the most common accidents and their causes based on the data from PC safety accidents in the United States [60]. On economic impact, despite the increase in construction costs, the life-cycle cost of a PC project is low [61]. During the construction process, the construction duration and labor hours are reduced, as well as material usage and wastage [31].

5.1.3. Life Cycle Management of PC

This section discusses the MPC based on Figure 8, the entire life cycle of PC, design, manufacturing and transportation, construction operation, and waste management. The aim is to examine the problems associated with the process and the corresponding research and propose a future research direction.

- Design Management

DfMA is a popular term and methodology in prefabricated building design [11]. Building defects enable the design process to be nearly accurately matched with downstream manufacturing and assembly processes. From interviews with senior engineers and managers, Trinder revealed that the significance of DfMA to PC is mainly evident in off-site modularization and standardization [62]. The Royal Institute of British Architects regards DfMA as a tool and technology to promote PC. Consequently, DfMA-related research is becoming more prevalent in the PC domain. For instance, Lu et al. reviewed the background, development, and current state of DfMA in construction, demonstrating that its concept has been in existence. However, with advancements in assembly technology, DfMA provides an opportunity to improve the productivity of construction [11]. For implementing the coupling of DfMA and BIM, Alfieri et al. explored and developed prefabricated components based on family templates and the DfMA creation process guided by the DfMA BIM development process and DfMA-oriented prefabricated BIM optimization process to implement the connection between DfMA and BIM [63]. Furthermore, extensive research has focused on the intelligent design of PC.; Sharafi et al., particularly, introduced a unified matrix approach to automatically identify the optimal spatial design for modular buildings [64].

- 2.

- Manufacture and Transportation Management

One of the key differences between PC and traditional construction is the manufacturing process, which is often carried out in specialized prefabrication facilities, usually off-site. Just-in-time (JIT) delivery of PC is heavily dependent on the production schedule. An efficient and effective production scheduling of prefabricated components is a subject that requires attention. Wang and Hu developed a two-stage rearrangement model of prefabricated production with multiple production lines to achieve a dynamic response to demand changes [65,66]. The coordination between production and subsequent processes is considered while researching this topic. Prefabrication supply chain management is a novel area, since the manufacturing, storage, and transportation of prefabricated components are closely inter-related. Luo et al. investigated the production, transportation, and assembly of prefabricated building projects in Hong Kong to quantitatively review their supply chain management [67]. Zhai et al. proposed a coordinated plan to provide pre-production hedging for potential delayed production delivery in the prefabrication supply chain, which reduces the amount of PLTH [68].

In PC systems, delivering the required prefabricated components to the construction site is challenging. The process of transportation is not only a large part of the cost of prefabricated buildings but also generates additional carbon emissions compared with conventional construction. Li et al. proposed the use of an improved artificial bee colony algorithm to solve the cross-synchronization process in logistic optimization to resolve vehicular routing restrictions [69]. Ahn et al. recommended a spatial and temporal data filtering and abstracting approach to estimate transportation costs using fleet GPS data. The method adopted in this paper extracts equipment activities from the GPS data and accordingly forecasts the transportation demands required for specific projects. The estimation result is accurate and beneficial to the management of transportation costs [69].

- 3.

- On-Site Construction Management

The on-site construction process for prefabricated buildings mainly includes on-site logistics, hoisting, and the assembly of prefabricated components. The site may be congested due to the change in the site’s production schedule. The layout of the construction site should therefore be reasonable. Scholars investigate dynamic coordination and buffer management as approaches to effective on-site construction management [70,71]. On-site construction management is also extremely critical for the crane position [72]. Some academics have conducted crane simulations [73] and an automatic inspection of their path [74]. The geometry of prefabricated components must be considered during the assembly process because a plausible assembly schedule can maximize the efficiency of assembly. Enshassi et al. proposed a component order and arrangement optimization framework for the geometric dimensional variation problem of prefabricated components to reduce the impact of geometric variation on the assembly [75].

- 4.

- Operation Management

Structural health has always been a predominant issue in the operation and maintenance phase of prefabricated buildings. Prefabricated buildings should therefore be monitored for safety and health. This is because prefabricated buildings are easily damaged by joints and structural cracks or flaws which may be difficult to identify. Tsangouri et al. employed acoustic emission technology to accurately monitor the internal damage of prefabricated building structures and described the structural damage [76]. M.V. et al. proposed the integration of structural health monitoring with BIM, such that the loss or damage of buildings’ prefabricated parts could be visualized [77]. Building health status can be discovered and identified in time with the combination of health monitoring and BIM, although this technology fusion still needs further research. Research on the thermal comfort of prefabricated buildings during usage can reflect the potential for energy savings. Furthermore, there is scope for improvement and optimization to consider incorporating heat reduction techniques into the design, manufacturing, and construction process [78,79].

- 5.

- Waste Management

PC waste management refers to the disposal, reduction, and recycling of PC waste in its whole life cycle. Although some studies have shown that PC technology can minimize the generation of construction waste by producing prefabricated components in a professional factory [80], the disposal of waste after the demolition of a PC building is still being studied. Some scholars indicate that applying circular economy theory to PC waste management can effectively utilize the waste of prefabricated components and improve the sustainability of prefabricated buildings [81]. Few research articles exist on the waste management of prefabricated buildings. The reason might be that prefabricated buildings are still in their development phase and cases or data for research are insufficient. There are two trends worth studying in the future, these include reducing the waste generated in the process of assembly and recycling the waste from prefabricated buildings effectively.

- 6.

- Precast Supply Chain Management (PSCM) and Lean Construction Principle

Compared with traditional construction projects, PC projects are more integrated with modern technologies and may require the collaboration of numerous stakeholders, which increases project management risks and uncertainties [82]. Many scholars have introduced the concept of production management into the manufacturing sector and the building construction assembly process, notably PSCM and lean construction principles. PSCM provides a perspective on MPC research. Some scholars have studied PSC as a system. Luo L. et al. observed the supply chain of an assembly-type building project to reveal the real situation of the supply chain, which is conducive to the in-depth understanding of PSCM [67]. Luo L. et al. studied the risks in PSC and identified the critical risks in PSCM and its corresponding strategies [47].

Lean Construction (LC) refers to the continuous process of satisfying or exceeding client needs, eliminating waste, and pursuing perfection while centering on the value stream during the implementation of a project [83]. The application of the LC principle in PC can improve production efficiency and the performance of prefabricated buildings [84,85]. The LC principle with BIM, RFID, and other emerging technologies has been the focus of MPC research [22]. B. Barkokebas et al. established a BIM–LC integrated application framework to optimize PC design and planning stages [86]. Additionally, S.G. Brissi et al. investigated the interaction between robotic systems and LC through a literature review to promote the development of automated architecture [87]. It demonstrates that LC can promote the use of information technology in the MPC, and information technology is also the foundation for implementing the LC production concept.

5.1.4. Technological Applications in the MPC

This subsection discusses the information technology used in the MPC. Informatization is a step in the process of building industrialization. With the increasing size and complexity of building projects, informatization has been the focus of scholars to use information technology flexibly and effectively to manage building projects. As shown in Table 4, this study lists BIM, the Internet of Things, blockchain, and intelligent algorithms for discussion. Although these information technologies are prevalent in the literature samples, they are not the only methods employed in the MPC. The table mainly includes technology types, topics, co-emerging technologies, and references. Where Technology refers to specific technologies under technology types and Co-emergence technology refers to the combination of technologies.

According to Table 4, BIM is the most extensively utilized technology and is frequently coupled with other information technologies. From the previous analysis, BIM is widely used in PC communities and enables the visualization of prefabricated buildings. Buildings’ geometrical information can be understood by a platform constructed using the Internet of Things technology, which can also determine the spatial information and status of buildings, allowing for collaborative management. Blockchain technology is a relatively cutting-edge information technology adopted by the PC community. It can provide an open, tamper-free, and traceable information platform, which is conducive to managing decentralized processes, such as prefabricated supply chain management. As artificial intelligence advances, intelligent algorithms are constantly incorporated into the PC industry to address a series of optimization problems, such as path optimization [88,89], space optimization [89,90], and production planning optimization [91]. Thus, automated guided vehicles [92] and robotics [93] may gradually become the focus of future research and the intelligent construction process of PC. Meanwhile, He R et al. explored the flexible production scheme of 3D printing modules or components through robot simulation of 3D printing and described the process and future work in BIM design and prefabrication automation [94].

Table 4.

Technology application in MPC.

Table 4.

Technology application in MPC.

| Types of Technology | Topics | Coemerging Technologies | Reference |

|---|---|---|---|

| BIM | Application environment in PC BIM+ Planning and schedule control Energy consumption Construction site management Operations management CO2 emission | Internet of Things (IoT) Intelligent sensor LiDAR 3D printing | [77,94,95,96,97,98,99,100,101,102,103] |

| Internet of Things (IoT) | Application environment in PC Planning and schedule control Logistics management Construction site management Operations management CO2 emission | BIM The cloud GPS | [77,96,104,105,106,107,108,109,110] |

| Blockchain | Quality management Supply chain management | [25,51,111] | |

| Intelligent algorithm | Coordination optimization Planning and schedule control Logistics management Construction site management Risk management | [65,66,88,89,91,112,113,114,115] |

5.2. Research Challenges and Future Developments in Research

5.2.1. PC Industry Development Challenges and Future Research Developments

This section discusses ineffective industrial management policy systems. There are still issues with incentives, regulations, and policies in many countries, and these factors have an impact on the development of the PC industry [9,116,117]. Developing a system to encourage PC stakeholders to embrace and advance this new construction method is a challenge [7]. There is potential to study PC policy improvement and project management system improvement from the perspective of stakeholders, but there are also some challenges, such as how to integrate, coordinate, and manage various stakeholders. Moreover, the policies and strategies of countries and regions with relatively high development of their PC industries (such as the United States, Japan, Singapore, and Hong Kong) are a strong reference to countries with relatively low levels of development [39]. The construction industry in each country is different and knowing how to efficiently learn and develop is essential. The cost–benefit analysis of policies and guidance can determine if the development of the PC industry can be promoted, revised, and improved based on the existing policies and guidelines [8,118]. However, there is still insufficient relevant research in this area.

There is a lack of comprehensive research on industrial development Focus on only the development of the PC industry is limited. The advancement of one technology may have an impact on other technologies and management concepts [36,119,120]. The relationship between the development and popularity of PC-related technologies and concepts (such as BIM, IoT, lean construction, etc.) and the development of the PC industry is rarely discussed [121]. Although few studies have focused on the dialectical relationship between the three, an effective combination of Industry–University–Research would foster the growth of technological innovation such as the PC method.

The development of the driving factors of the industry may be identified by comparing the policy framework and development level of the PC industry in different countries, which is essential to the formulation of a comprehensive industrial policy system. In future studies, PEST in countries with a higher development level can be analyzed and compared to summarize the experience and improve the system [122,123,124,125,126]. The quality of the policy and system needs objective evaluation to facilitate modification and improvement.

Future research on the development of PC can be carried out in the following directions: (1) compare the development of PC in different countries to find the development mechanism of PC; (2) improve PC policies and project management systems from the perspective of stakeholders; (3) improve the evaluation system of the development level of PC, including policy, supervision, technology, talent, etc.; (4) technology is a powerful driver for the development of PC. Thus, explore the mechanism of technological innovation in the development of the industry and explore the application of technological innovation in the field of PC; and (5) the development of the PC industry cannot be separated from the integration of Industry–University–Research. Studying the dialectical relationship and interaction mechanism among the three is critical in promoting the PC industry’s development.

5.2.2. Management of the Performance of PC Challenges and Future Research Trends

This section discusses quality, schedule, and cost. The quality diagnosis objects are not comprehensive, and they are required to thoroughly investigate the diagnosis of geometric and non-geometric quality prefabricated components [127,128]. Quality management should focus not only on the manufacturing stage but also on the post-production stage. Therefore, PC buildings’ defect management and health monitoring are required throughout the life cycle. There are few studies on the component connection quality evaluation and diagnosis for partial or fully prefabricated buildings [52]. Moreover, the risk induction and summary of prefabricated construction project schedules have been studied. Some researchers adopted intelligent scheduling to optimize project schedules [129], which has a limited relationship among schedule, quality, and cost. Research on schedule optimization should consider quality, which increases the scope and challenges of the study. Cost is of crucial concern to all stakeholders [40]; thus, it is worthwhile exploring the perspectives of all stakeholders on PC cost management. The high cost of PC is unavoidable, and the cost optimization research must be constantly enhanced and improved.

Regarding sustainability, although PC technology can improve the sustainability of buildings, it remains a challenge for PC projects to achieve sustainability benefits. The basis for improving sustainability is the establishment of a sustainability evaluation system for PC projects [130]. In addition, a comprehensive and reasonable evaluation system still needs to be studied further. Studies show that a high prefabrication rate does not guarantee high project sustainability, and the relationship between prefabrication rate and sustainability still needs to be explored. Despite being a complex task, finding the appropriate level of prefabrication rate for a project can efficiently eliminate risks and uncertainties.

5.2.3. MPC and Future Research Developments

This section discusses the design stage. The introduction of the concept of DfMA enables the design of prefabricated buildings to integrate the requirements of the subsequent stage, increasing the accuracy of PC design [11]. There are many studies on the establishment of the DfMA framework, but research on the application practice and benefits of DfMA is still insufficient [131]. With the emergence of research on automatic design, the optimization of project performance objectives in the design process has become achievable but a challenge for researchers.

Concerning the manufacturing and transportation stages, the production and transportation of prefabricated components have both benefited from multi-objective optimization. However, there is still a gap between the optimization model and the actual work. Furthermore, the aim and challenge of this kind of optimization research have always been the establishment of a workable algorithm model. Production and transportation are the core of the precast supply chain [35]. Meanwhile, the prefabricated supply chain is an intricate system, and more research is needed to determine how to maximize its efficiency.

As for the on-site construction stage, a prefabricated building site entails the assembly of prefabricated components [132], cast-in-place construction, measure installation, site material transportation, and other works [133]. The management of the construction site is the biggest challenge in the construction stage.

For the operation stage, though the concerns of energy consumption [134], thermal comfort [135], and healthy construction practices [76] are primarily addressed, there is limited available research on these subjects, which presents substantial difficulties for the operation and maintenance management of prefabricated structures.

Regarding waste management, prefabricated buildings can reduce waste and waste on construction sites [136]. However, the treatment and reuse of prefabricated construction wastes such as prefabricated components are a complex subject.

A more integrated MPC is required. Currently, the DfMA, PCSM, and Lean Construction in the MPC indicate that each stage is not independent and must be considered comprehensively. These important subjects should be explored further, and the comprehensive evaluation of the whole life cycle should be expanded. It is worthwhile to develop and improve corresponding technical conditions and management platforms (such as the PC–BIM whole-process management platform).

5.2.4. Technological Application

After reviewing the literature samples, it was observed that GIS technology is rarely used in PC. The wireless location system of construction sites can be developed in future research using the Internet of Things technology to accurately assess the status of construction sites [136]. There are few studies on the application of GIS technology on PC sites, indicating that there are still many new technologies in PC project applications worth exploring. The more information technology there is, the better. It is therefore critical to determine how to match and integrate different information technologies. Similarly, research on the degree of cooperation among information technologies is crucial and necessary. The application of information technology is to efficiently support a PC project rather than increase the workload. The benefits of information technology should be assessed for reasonable decision making on its adoption.

5.3. Change in the Dynamics of MPC Research

Since this study is an extension of the study of Li et al., (2014) [14], the dynamic changes and development direction of MPC research are revealed by comparing the findings of the two papers. This section, according to the topic classification of this paper, compares the topic findings and future trend findings of this study with that of Li et al. (2014), as shown in Table 5. From the research topics, MPC research is growing increasingly comprehensive, rich, and detailed. More in-depth investigations have been conducted in various research directions. For example, the study of the MPC process encompasses the design, manufacturing, transportation, and on-site construction management to full life-cycle management (including design, manufacturing, transportation, on-site construction, operation, and demolition). By comparison, we may determine the development direction of MPC research in recent years:

Table 5.

Comparison with previous MPC review.

- (1)

- More and more countries are exploring how to develop their own PC industry. Many developing countries have conducted qualitative analyses of PC adoption, similar to the predicted trend as described by Li et al. (2014) [14]. Scholars can explore the mechanism of PC industry development, learn from its industry development path, and localize by comparing countries with mature PC industries. Stakeholders have a greater impact on the development of the PC industry, which serves as an effective direction when exploring the policies and systems of the PC industry from the perspective of stakeholders [46].

- (2)

- MPC research traditionally focuses on sustainability, however, quality, schedule, and cost are also important factors which need to be considered for a project. The research on performance evaluation and optimization study will therefore be more systematic and comprehensive.

- (3)

- Integrated management of the whole life cycle of prefabricated buildings becomes the target. The research should not only include the problems of design, production, transportation, and assembly process, but also the problems of the operation and demolition stage.

- (4)

- Advanced production concepts and techniques are constantly introduced into the MPC, such as Lean Construction [33], Prefabricated Supply Chain theory [13], Circular Economy [81], etc. These theories broaden the perspective of the MPC. However, current research seeks to investigate how to integrate and practice the MPC.

- (5)

- Transformation from the MPC to digital. Researchers are continually investigating the scenario of the comprehensive application of information technology, and they are exploring how to efficiently apply it to increase production efficiency.

6. Conclusions

This study conducted a review to re-examine the MPC from the perspective of development. This study was divided into three stages: bibliometric search, scientometric analysis, and discussion. In the process of the bibliometric search procedure, keywords gathered from previous PC research were entered into a database for bibliometric search. A total of 376 literature samples were filtered through the conditions specified in the paper for scientometric analysis. The results show that the number of publications related to PC increased yearly, the peak was in 2021, and the outbreak period was between 2017 and 2021. China was the country where scholars published the largest number of publications, 197, followed by Australia, the United States, and Canada in the second, third, and fourth places, respectively. China, Australia, Canada, the United States, the United Kingdom, and Singapore have a strong influence in the MPC research area. MPC-related publications in The Journal of Cleaner Production, Automation in Construction, and The Journal of Management in Engineering had a significant impact. Modular construction, prefabricated construction and off-site construction, BIM, China, and sustainability are the keywords with more links and higher link strength. Sustainability, supply chain management, critical success factors, Internet of Things, and optimization had an average occurrence time of 2020, which indicated that these are the key topics and trends of recent MPC research.

In the discussion, the article discussed four topics, the research areas, and future research trends. Based on the past literature, possible future research trends were obtained. The major future trend and points related to the MPC are given as follows: (1) Development of PC. From the perspective of this review, PEST (Politics, Economy, Society, and Technology) analysis of the PC industry’s adoption in countries and comparison, a comprehensive assessment system, PC policy and system improvement from the perspective of stakeholders, the driving force of development between technologies, and Industry–University–Research combination can be further researched. (2) Management of PC performance. Additional research into quality, schedule, cost, and sustainability optimization is required, and a holistic performance optimization strategy is worth studying. Furthermore, a study on the relationship between assembly rate and performance can assist engineers in determining the optimum assembly rate. (3) Life cycle management of PC. Management optimization at all stages of the whole life cycle, integrated management, DfMA, PSCM, Lean Construction, and digital management platforms are future trends in the MPC. (4) Technological applications in MPC. Information technology application scenario mining, cost–benefit analysis of using technology for PC, and technology selection strategies of PC are areas that need to be researched.

This study will benefit scholars who are interested in PC to successfully understand the topic and its future trends. This article suggests prospective future research directions and current research flaws in PC. The development of PC is needed to address the combination of Industry–University–Research. To achieve good performance and success, PC projects must adopt management methods and technologies in the life cycle. Performance, management strategies, and technological application in the MPC process must all be considered. One of the most important and challenging concerns in the MPC sector is how to adopt proper management methods and techniques to effectively achieve an increase in MPC performance.

However, due to some rules in the literature collection process, not all publications could be included in the literature sampling. They could be considered in future review studies, statistics yearbooks, policy guidance, and other publications for scientific analysis. This paper reviews PC-related research only from the perspective of management. Many more detailed directions can be reviewed in PC research, which are not explored in depth in this paper. They can be discussed in depth in future research. Nonetheless, this article will help to illuminate the research position on MPC and serve as a reference for most scholars. In addition, this research helps PC practitioners to thoroughly understand the current status of MPC in research and allows them to apply some management methods or techniques in practice.

Author Contributions

Conceptualization, C.Z.L. and S.L.; methodology, S.L.; software, S.L.; validation, C.Z.L., S.L. and H.W.; formal analysis, X.L.; investigation, B.X.; resources, V.W.Y.T.; data curation, S.L.; writing—original draft preparation, S.L.; writing—review and editing, C.A.-K.; visualization, C.A.-K.; supervision, H.W.; project administration, C.Z.L.; funding acquisition, C.Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (NSFC) (Grant No. 52078302), the National Natural Science Foundation of Guangdong Province (Grant No. 2021A1515012204 and 2021A1515110474), the Department of Education of Guangdong Province (Grant No. 2021ZDZX1004), the Shenzhen Science and Technology Innovation Commission (Grant No.JCYJ20190808174409266, No. GJHZ20200731095806017 and No. SGDX20201103093600002) and the funding support from the Fellowship of China Post-doctoral Science Foundation (No. 2021M692169 and No. 2021M702236).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gibb, A.G. Off-Site Fabrication: Prefabrication, Pre-Assembly and Modularisation; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Akmam Syed Zakaria, S.; Amtered El-Abidi, K.M. Economic effects of migrant labor on industrialized building system (IBS) adoption in the Malaysian construction industry. Archit. Eng. Des. Manag. 2021, 17, 50–66. [Google Scholar] [CrossRef]

- Almutairi, Y.; Arif, M.; Khalfan, M.M.A. Moving towards managing offsite construction techniques in the Kingdom of Saudi Arabia: A review. Middle East J. Manag. 2016, 3, 164–178. [Google Scholar] [CrossRef]

- Ansari, W.S.; Thaheem, M.J.; Khalfan, M.M.A. Use of offsite construction techniques in Pakistan. Middle East J. Manag. 2016, 3, 218–229. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X.; Wang, Y.; Luo, X.; Shang, S. New media data-driven measurement for the development level of prefabricated construction in China. J. Clean. Prod. 2019, 241, 118353. [Google Scholar] [CrossRef]

- Arashpour, M.; Abbasi, B.; Arashpour, M.; Hosseini, M.R.; Yang, R. Integrated management of on-site, coordination and off-site uncertainty: Theorizing risk analysis within a hybrid project setting. Int. J. Proj. Manag. 2017, 35, 647–655. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Jing, S.; Zhang, Z.; Yan, J. Government Supervision Mode Selection in the Promotion Period of Prefabricated Construction Using Evolutionary Game. Math. Probl. Eng. 2020, 2020, 7105617. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Wu, G.; Li, X. Critical Success Factors for Project Planning and Control in Prefabrication Housing Production: A China Study. Sustainability 2018, 10, 836. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X. Sustainability perceptions of off-site manufacturing stakeholders in Australia. J. Clean. Prod. 2019, 227, 346–354. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.P.; González, V.A.; Roy, K.; Khan, K.I.A. A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings 2022, 12, 40. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Framework for modeling operational uncertainty to optimize offsite production scheduling of precast components. Autom. Constr. 2018, 86, 69–80. [Google Scholar] [CrossRef]

- Jung, S.; Lee, S.; Yu, J. Identification and Prioritization of Critical Success Factors for Off-Site Construction Using ISM and MICMAC Analysis. Sustainability 2021, 13, 8911. [Google Scholar] [CrossRef]

- Zhang, S.; Rong, X.; Bakhtawar, B.; Tariq, S.; Zayed, T. Assessment of Feasibility, Challenges, and Critical Success Factors of MiC Projects in Hong Kong. J. Arch. Eng. 2021, 27, 04020047. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y. Environmental sustainability of off-site manufacturing: A literature review. Eng. Constr. Archit. Manag. 2019, 28, 332–350. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Arashpour, M.; Kamat, V.; Bai, Y.; Wakefield, R.; Abbasi, B. Optimization modeling modeling of multi-skilled resources in prefabrication: Theorizing cost analysis of process integration in off-site construction. Autom. Constr. 2018, 95, 1–9. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Fan, H.; Wu, H.; Teng, Y. RBL-PHP: Simulation of Lean Construction and Information Technologies for Prefabrication Housing Production. J. Manag. Eng. 2018, 34, 04017053. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Robotic Industrialization: Automation and Robotic Technologies for Customized Component, Module, and Building Prefabrication; Cambridge University Press: New York, NY, USA, 2015. [Google Scholar]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A blockchain- and IoT-based smart product-service system for the sustainability of prefabricated housing construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Yuan, Y.; Ye, S.; Lin, L.; Gen, M. Multi-objective multi-mode resource-constrained project scheduling with fuzzy activity durations in prefabricated building construction. Comput. Ind. Eng. 2021, 158, 107316. [Google Scholar] [CrossRef]

- Ahn, S.; Crouch, L.; Kim, T.W.; Rameezdeen, R. Comparison of Worker Safety Risks between Onsite and Offsite Construction Methods: A Site Management Perspective. J. Constr. Eng. Manag. 2020, 146, 05020010. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Tan, Y.; Wang, Y.; Zhang, Y. Exploring a body of knowledge for promoting the sustainable transition to prefabricated construction. Eng. Constr. Arch. Manag. 2020, 28, 2637–2666. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction–Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction. Autom. Constr. 2018, 94, 168–178. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Henric, J.; Martin, R. Classification of production systems for industrialized building: A production strategy perspective. Constr. Manag. Econ. 2014, 32, 53–69. [Google Scholar]

- Mostafa, S.; Chileshe, N.; Abdelhamid, T. Lean and agile integration within offsite construction using discrete event simulation A systematic literature review. Constr. Innov. 2016, 16, 483–525. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J.; Ma, X.; Xiong, W. Precast supply chain management in off-site construction: A critical literature review. J. Clean. Prod. 2019, 232, 1204–1217. [Google Scholar] [CrossRef]

- Hou, L.; Tan, Y.; Luo, W.; Xu, S.; Mao, C.; Moon, S. Towards a more extensive application of off-site construction: A technological review. Int. J. Constr. Manag. 2020, 22, 2154–2165. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Meng, Q.; Hu, X. Barriers to the development of prefabricated buildings in China: A news coverage analysis. Eng. Constr. Arch. Manag. 2020, 28, 2884–2903. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost-benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Factors Affecting the Capital Cost of Prefabrication-A Case Study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Capital Cost Optimization for Prefabrication: A Factor Analysis Evaluation Model. Sustainability 2018, 10, 159. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Wu, J.; Shi, W.; Ji, D.; Wang, X.; Zhao, X. Constraints Hindering the Development of High-Rise Modular Buildings. Appl. Sci. 2020, 10, 7159. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X.; London, K. Understanding Stakeholders in Off-Site Manufacturing: A Literature Review. J. Constr. Eng. Manag. 2019, 145, 03119003. [Google Scholar] [CrossRef]

- Luo, L.; Shen, G.Q.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Jiang, W.; Luo, L.; Wu, Z.; Fei, J.; Antwi-Afari, M.F.; Yu, T. An Investigation of the Effectiveness of Prefabrication Incentive Policies in China. Sustainability 2019, 11, 5149. [Google Scholar] [CrossRef]

- Cheng, B.; Wei, Y.; Zhang, W.; Zhou, X.; Chen, H.; Huang, L.; Huang, J.; Kang, X. Evolutionary Game Simulation on Government Incentive Strategies of Prefabricated Construction: A System Dynamics Approach. Complexity 2020, 2020, 8861146. [Google Scholar] [CrossRef]

- Hamzeh, F.; Ghani, O.A.; Bacha, M.B.S.; Abbas, Y. Modular concrete construction the differing perspectives of designers, manufacturers, and contractors in Lebanon. Eng. Constr. Archit. Manag. 2017, 24, 935–949. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, Z.; Ni, G.; Lin, H.; Lu, Y. The quality traceability system for prefabricated buildings using blockchain: An integrated framework. Front. Eng. Manag. 2020, 7, 528–546. [Google Scholar] [CrossRef]

- Tarekegn, G.A.; Shooshtarian, S.; Mahmood, M.N. Critical Evaluation of Building Defects Research: A Scientometric Analysis. J. Perform. Constr. Facil. 2022, 36, 03122001. [Google Scholar] [CrossRef]

- Helena, J.; John, H.M. Defects in offsite construction: Timber module prefabrication. Constr. Manag. Econ. 2010, 27, 667–681. [Google Scholar]

- Li, C.Z.; Hong, J.; Fan, C.; Xu, X.; Shen, G.Q. Schedule delay analysis of prefabricated housing production: A hybrid dynamic approach. J. Clean. Prod. 2018, 195, 1533–1545. [Google Scholar] [CrossRef]

- Ji, Y.; Qi, L.; Liu, Y.; Liu, X.; Li, H.X.; Li, Y. Assessing and Prioritising Delay Factors of Prefabricated Concrete Building Projects in China. Appl. Sci. 2018, 8, 2324. [Google Scholar] [CrossRef]

- Xie, L.; Chen, Y.; Chang, R. Scheduling Optimization of Prefabricated Construction Projects by Genetic Algorithm. Appl. Sci. 2021, 11, 5531. [Google Scholar] [CrossRef]