1. Introduction

Offsite construction (OSC) has been in existence for centuries, and it has evolved through different terminologies and taxonomies [

1]. Technological evolution has triggered the simultaneous advancement of OSC techniques and terms [

2]. Since the prefabricated pavilion roof constructed in 1772, and Manning’s Portable Colonial Cottage constructed in 1833 [

3], OSC has been an integral element of industrialization [

4], modularization [

5], mechanization [

6], and digitalization [

7]. The broad definition—“manufacturing buildings or functional elements of buildings in a factory to be transported and erected onsite” [

1,

8,

9]—was used to refer to several terms, including OSC. Once OSC was differentiated from traditional onsite construction, several OSC types emerged with distinct characteristics [

10].

Gibb [

11] introduced component manufacture and sub-assembly, non-volumetric pre-assembly, volumetric pre-assembly, and modular/complete building under the umbrella term of OSC. Subsequently, various researchers adopted this OSC classification to match their research purposes. However, these published classifications are based on industry practices and theoretical assumptions rather than a rigorous systematic evaluation.

The uniqueness of OSC types and thresholds that distinguish them are imperceptible in the current body of the literature due to the myriad terms used to refer to them [

10]. The inability to accurately differentiate OSC types is a challenge for OSC operations [

12], OSC design [

13], and procurement processes [

14], causing time and cost inefficiencies [

15]. Therefore, the development of a succinct OSC typology assists in enhanced product specification [

5], process improvement [

16], minimized operational risk [

17], efficient procurement process [

14], multi-skilling for optimal process integration [

18], skill prediction [

19], and increased levels of automation [

7,

20]. Such operational benefits can escalate production by incorporating the technological advancements evident in distinct OSC types. Accordingly, both onsite and offsite processes can be improved to embed the features of different OSC types [

10].

It is proven that operational advancements in OSC can contribute to the Gross Domestic Product (GDP) under macroeconomic terms [

6,

21,

22]. A longitudinal study by Taylor [

6], with reference to Farmer [

20], reveals the criticality of different OSC types and their categorical value addition to the United Kingdom (UK) economy. As such, the development of an OSC typology results in both organizational and macroeconomic benefits by improving the overall industrial output.

The rapid evolution of Industry 4.0 technologies is impacting construction, changing the way building components and buildings are constructed. This, in turn, affects OSC methods and the advancement of materials. Consequently, the existing OSC classifications no longer support new types of OSC. Hence, the research addresses the following research question: what are the distinct characteristics of unique OSC types that have emerged through the adoption of Industry 4.0-based technological advancements? This research aims to develop an OSC typology by structuring and validating the pre-identified OSC classifications. A comprehensive literature review is conducted to recognize the current state of OSC and identify the knowledge gap. It is found that a validated OSC typology with defined distinct features of OSC types, integrating modern technological advancements, is non-existent in the current body of knowledge. As such, the OSC typology is developed through a rigorous research process incorporating a case study and an expert forum guided by the Delphi methodology. The outcomes of this research contribute to improved communications related to distinct OSC types. The OSC typology will generate organizational benefits in terms of product specification in OSC design, comprehensible procurement processes, and improved production processes. Subsequently, such operational benefits can result in macroeconomic benefits through OSC productivity enhancement.

2. Literature Review

A thorough literature review was conducted to analyze the existing OSC classifications. This analysis resulted in recognizing the knowledge gaps evidenced in the current body of literature and developing a preliminary OSC typology. The rationale for developing a validated OSC typology was derived based on the literature findings.

2.1. A Plethora of OSC Classifications

The construction industry and academia employ numerous taxonomies and terminologies in discussing OSC types, causing blurring boundaries between different systems [

23]. These terms often overlap, making it hard for readers and users to choose the appropriate ones [

24].

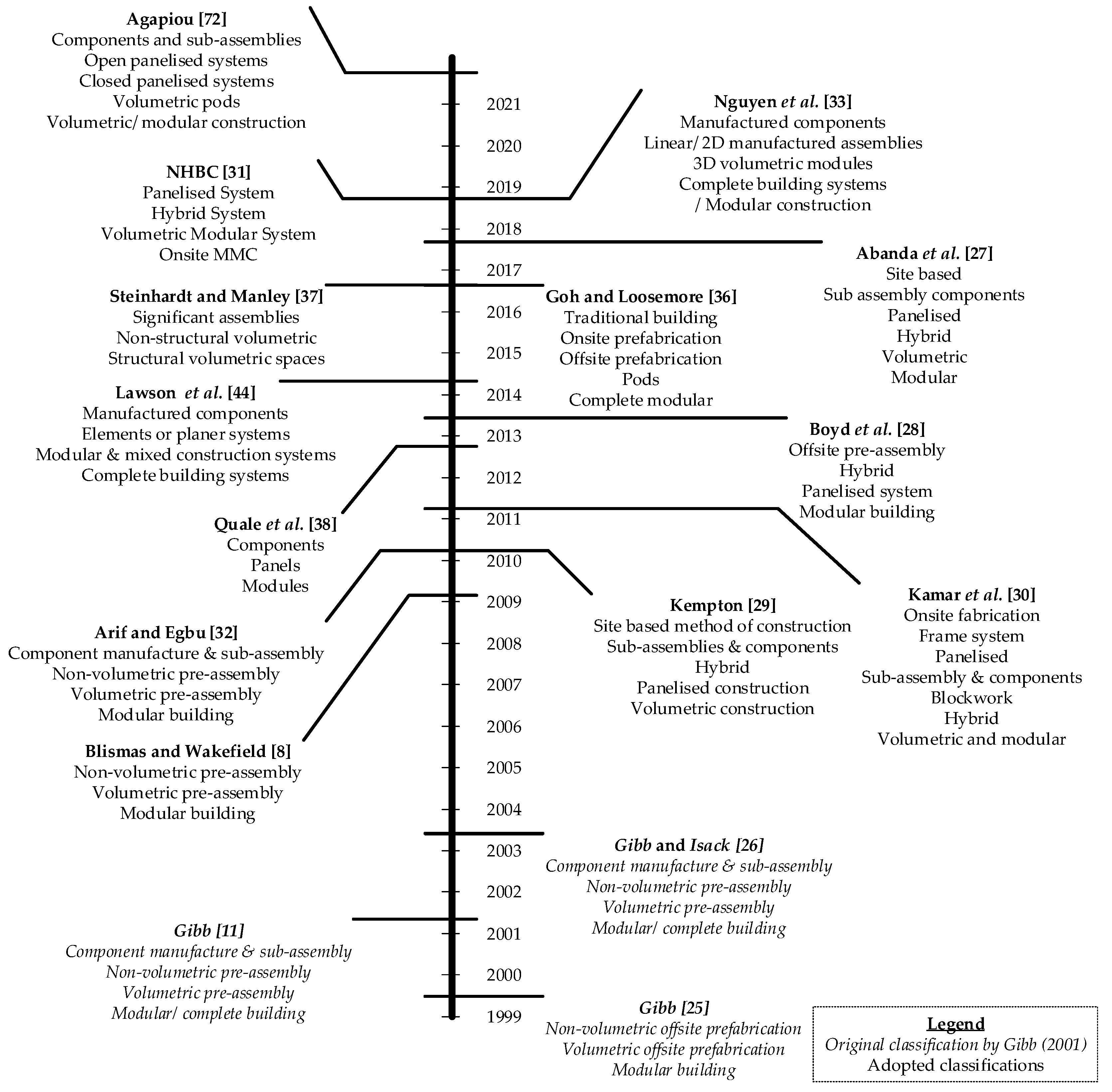

Figure 1 captures a timeline of OSC types in the published literature. Owing to technological advancements with increasing OSC techniques and types, the 21st century has witnessed accelerated OSC evolution [

17,

20]. Although some OSC classifications capture the holistic nature of OSC products, many classifications fail to define the distinct features of OSC types. For example, the difference between volumetric pods, modules, and complete buildings are not defined in the previous classifications.

Since the introduction of major OSC categories [

11,

25,

26], OSC classifications appear to be based on industry examples without scientific evidence of the classification process. In the absence of an OSC typology that matches the technological advancements in the 21st century, previous literature has adopted the original classification of Gibb [

11] and any other relevant literature to match their research purposes. None of these researchers who adopted OSC classifications developed an OSC typology, creating a deficiency of an updated typology. As such, in the current OSC research context, the development of an updated OSC typology is long overdue, since the most recent typology is more than two decades old.

OSC classifications have been transformed to include “hybrid” as an OSC type [

27,

28,

29,

30,

31]. However, any construction project is bound to be hybrid if it has various prefab products that fall under different OSC types [

32]. Nguyen, et al. [

33] replaced non-volumetric with 2D and volumetric with 3D in their OSC classification. Another categorization of 2D (panelized) and 3D (volumetric) OSC types recognized the complexity and scale of occurrence [

34]. A similar variation of 2D and 3D primary structural systems is visible in the Modern Methods of Construction (MMC) classification by the MMC Working Group [

35], which also includes non-systemized primary structures, additive manufacturing, non-structural assemblies, and sub-assemblies. Although this classification provides a location-based categorization for offsite, near-site, and onsite MMC methods, the rationale for considering all volumetric OSC types under one category is not apparent. This MMC classification does not recognize the repetitive and non-repetitive nature of volumetric elements. The classification claims a spectrum of five MMC products under offsite and near-site pre-manufacturing. Two of these products include 2D/3D variations, two products relate to structural/non-structural variations, and another refers to non-systemized structures. Having such variations in the five products does not demonstrate a strong rationale for developing a spectrum of MMC products.

Some studies present relatively simple and straightforward OSC types by omitting the terms “sub-assembly” and “pre-assembly” [

36,

37,

38]. Blismas, Arif and Wakefield [

8] removed “component manufacture and sub-assembly” from the original classification of Gibb [

11] and considered the remaining three types to represent different OSC levels. However, the basis for claiming that the types represent different OSC levels was not provided.

Many other literature sources provide various bases for levels of OSC classification, viz. the value of the work [

39], the nature of the work [

40], the material used [

15], the level of pre-design [

41], the value addition before onsite installation [

42], and the location of the work [

43]. Nevertheless, a determining factor for categorizing OSC products is the product complexity [

34] and the value percentage of the product out of the total project value [

44]. As such, instead of vague OSC classifications without a solid scientific background, there is a need for a validated OSC typology. In order to develop the OSC typology, this study adopted the typology with non-volumetric (components, panels, flat-pack) and volumetric (pods, modules, complete buildings) OSC types [

10].

2.2. Rationale for Developing a Validated OSC Typology

OSC is ubiquitous and has different shapes and forms. These OSC products are characterized as OSC types. Many researchers have attempted to summarize OSC from different perspectives, such as “people, process, technology” [

1], “people, process, product” [

45], and the “production and complexity scale” of modular construction [

34]. These classifications and various other product-based categories have significant similarities due to their focus on the study by Gibb [

11], which was exceptionally comprehensive of all OSC types at that time. Since there have been significant developments in the OSC sector, making the original classifications rather outdated, there is a need for the development of a new typology that represents the present state of OSC. The rationale behind these developments is discussed below.

2.2.1. Deficiencies in the Original Classification

Gibb [

11] introduced a comprehensive OSC classification consisting of component manufacture and sub-assembly, non-volumetric pre-assembly, volumetric pre-assembly, and modular building to match the OSC practices at the beginning of the 21st century. However, this classification does not recognize the current trends in OSC or the variations of volumetric OSC that have emerged in the past 20 years. Emerging trends in OSC portray how buildings can be folded together using hinges to simply unfold and fix onsite [

46,

47,

48]. Modular construction in the current context has evolved to incorporate lean manufacturing processes, where 3D building elements are repeatedly produced in assembly lines using advanced robotics [

34,

49]. Further, there are single module buildings that encompass the entire building structure in a 3D unit. Although the original classification includes volumetric pre-assembly and modular building, it does not accurately differentiate the various OSC types in the current context. Other existing classifications are derivatives of Gibb [

11] and hence portray similar deficiencies. OSC has evolved to greater extents, incorporating the technologies that emerged through Industry 4.0 [

50]. Therefore, the original classification requires a revision to match with the current industrial context.

2.2.2. Incorporation of Modern Technologies

Product-based OSC classification was introduced by Gibb [

11], referring to the industry examples available at the time. However, technology has moved on since 2001, and the relevance of technologies to OSC products need to be modified. Followed by the two-decade old classification, other OSC categorizations were adopted by many researchers, yet most of these classifications are simply a re-shuffle of the original OSC types with different terms (

Figure 1). Compared to the technologies and innovations available at the beginning of the 21st century, Industry 4.0-based technologies have re-shaped the construction industry [

7], especially addressing OSC [

36].

Many technologies, such as advanced robotics, 3D printing, extensive digitalization, and cyber-physical integration, resulted from Industry 4.0 [

4], along with blockchain, the Internet of Things, and big data analysis [

51]. Further, innovative design technologies like Building Information Modelling (BIM) and procurement methods like Design for Manufacture and Assembly (DfMA) can benefit from the OSC classification. BIM and DfMA can be effectively used depending on the OSC type. The DfMA processes that incorporate volumetric OSC types would not be the same as DfMA processes that incorporate non-volumetric OSC types. Therefore, a distinct understanding of OSC types advances the use of BIM and DfMA for the effective design and procurement of OSC.

The current industrial practice is influenced by the push for digitalization, and automation through remote work, to accommodate new normal conditions in the post-COVID era [

52]. Although the prevailing technologies may also become redundant in a few years, the current context portrays completely different OSC techniques to those that were obtainable 20 years before. Therefore, developing an OSC typology that incorporates smart and modern technologies supersedes the previous classification, as it captures the state of OSC products in the 21st century.

2.2.3. Addressing Skill Variations

The current state of OSC is primarily affected by industrialization and the increasing shift from onsite construction to factory-based prefabrication [

1]. Hence, onsite works are minimal and focus only on assembling buildings or building elements performed by advanced self-directed work package gangs [

19]. Depending on the OSC type, the requirement for skilled workers and professionals, both onsite and offsite, varies [

53]. Hence, a unique classification of modern technology-based OSC types helps determine the OSC skill requirements for various OSC types.

2.2.4. Incorporation of Simple Taxonomies

The available OSC types include complex and lengthy terms, such as “sub-assembly”, “pre-assembly”, and “building systems”. Although these terms have specific meanings and a purpose for their inclusion in OSC taxonomies, they complicate a simple product reference. Subject to the original classification, various other researchers have tried to include or exclude these terms (

Figure 1), yet have failed to provide a reasonable justification for such inclusion or exclusion. Apart from these findings, the industry terminologies vary from one person to another, making it quite confusing to identify each OSC type distinctly. Therefore, there is the need for a simple classification that portrays the unique features of OSC types.

2.2.5. Validation through a Scientific Process

Jacoby [

54] identifies a typology to be different from basic types and defines a type to be a group of items with shared features. A typology is a systematic classification of types, analyzed through a scientific notion [

54]. According to Neuman [

55], a typology or a taxonomy is a theoretical classification developed by cross-classifying or combining two or more simple concepts to form a set of interrelated subtypes. Hence, this research develops a typology of OSC based on Gibb [

11], confirming it through actual case studies and, finally, validating it through an expert forum. No previous study in the literature has followed such a rigorous scientific process to identify OSC types in a single classification, as their intention was not to develop a typology, but to create a variation of Gibb [

11] to suit their research. Therefore, the research methodology used for OSC typology development in the current study is a firm reason to signify the need for a simple, unique OSC typology that matches modern technologies.

2.3. Materials and Skills for OSC Types

Additive manufacturing or 3D printing is a modern method of construction used to fabricate building elements offsite [

6,

20]. Similar applications are available in the market as business models of manufacturing OSC types [

56]. There is no consensus on predominant materials and relevant skills for different OSC types due to the lack of research on OSC typologies. Therefore, this study identifies predominant materials and prominent skills for different OSC types by seeking expert opinions. A detailed predictive analysis of the OSC skills required for different OSC types has been carried out in a parallel study [

19].

The literature review recognized the deficiencies in the original OSC classification and the need to develop a future-proof OSC typology using a scientifically accepted research method.

3. Research Methodology

This research was conducted in three consecutive steps. In step 1, a literature review was carried out to evaluate the current context of OSC classifications. A lack of a systematically validated OSC typology was evident in literature. The literature review helped with developing the preliminary OSC typology. Step 2 was a case study review of different OSC projects. The selected projects represent the current OSC context and the practicality of the preliminary OSC types. The final step was an expert forum to validate the preliminary OSC typology. The steps of the expert forum, conducted in the form of a Delphi study, are as follows: expert consultation, data analysis, consensus evaluation, and iteration of the above steps until consensus is achieved.

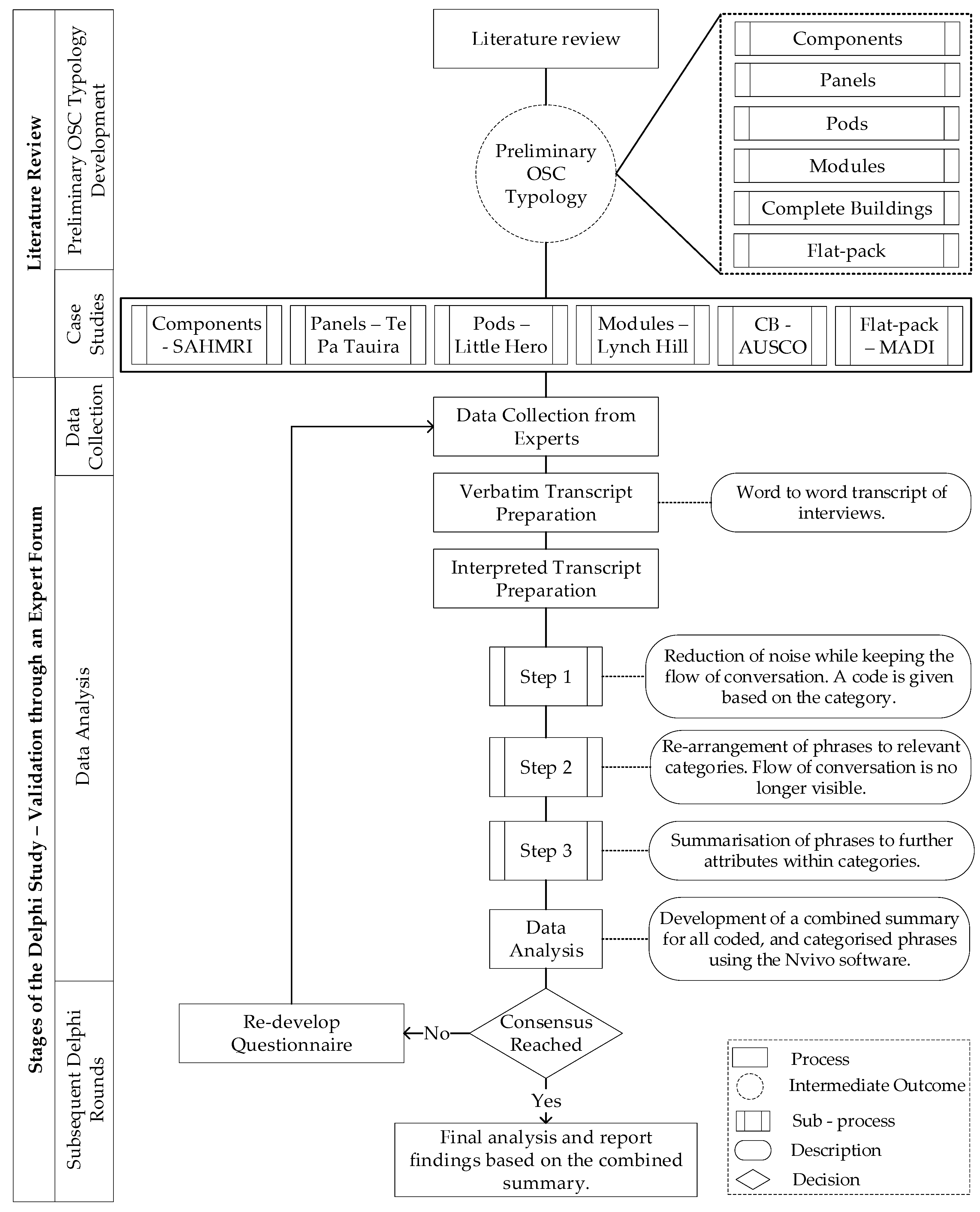

Five OSC experts participated in the Delphi study, achieving a consensus in the findings at the second round. A qualitative research method was adopted while achieving triangulation of observation via multiple methods. A step-by-step breakdown of the applied research methodology is shown in

Figure 2. Succeeding sections discuss the key stages, case studies, and the expert forum in detail.

3.1. Case Studies

After the preliminary typology development, it was necessary to understand the industry practice concerning OSC types. Therefore, case studies were reviewed using detailed project data available to the research team from multiple sources. Published project reports, website content, and news articles on OSC projects were referred to in order to identify possible case studies under each OSC type. The case studies were selected through convenience sampling to demonstrate features of OSC types. Convenience sampling makes the data collection process simple and efficient [

57]. Thus, it was easy to match the preliminary OSC types with actual project data from various sources.

3.2. Expert Forum through Delphi Study

The third and decisive step was presenting the preliminary OSC typology to industry experts to prove its validity in the current industrial context. The expert forum was designed to be a Delphi study. A Delphi study is a structured, critical, academically rigorous, and scientific technique [

58]. Recent studies on OSC have adopted the Delphi method to obtain expert opinions [

18,

59]. The Delphi method controls bias in technology and innovation-based construction management research [

58]. Moreover, the Delphi study has the advantage of conducting a review with geographically dispersed experts [

60]. The iterative process of the expert forum, guided through the Delphi study, initiated with expert selection and then expert consultation. The first round of the expert forum included a series of expert interviews. In alignment with the Delphi study method, the individual interviews held with each expert were confidential and the experts were unaware about the other experts who took part in the expert forum. As presented in

Figure 2, the data collected from expert interviews were subjected to an extensive data analysis procedure. The process included the development of a verbatim transcript that was then converted into a series of interpreted statements resulting in a combined summary of coded and categorized phrases. Consensus statements were derived based on the interview findings.

Several Delphi rounds can include a combination of interviews and questionnaire surveys until a consensus is reached [

57]. The second round of the expert forum was conducted in the mode of a questionnaire survey. The statements that were yet to receive consensus from experts were returned to all five experts individually. The Delphi study was to be continued until a unanimous consensus was reached among all experts. As the consensus was reached after two rounds, this iterative process of the expert forum concluded after the second round. Purposive or judgmental sampling was utilized to select and recruit experts for the forum. This ensured that the experts were selected based on prior decided selection criteria relevant to their subject matter expertise [

60]. Five experts were selected for the expert forum, and their profile summary is presented in

Table 1.

The expert selection criteria are in line with the criteria introduced by Hallowell and Gambatese [

58] for the rigorous implementation of a Delphi study. All selection criteria were fulfilled by a minimum of three experts. Two experts (E3 and E4) were not affiliated to any professional body. E2, being a regulator, did not have hands-on OSC project experience. However, all experts had vast exposure to OSC practices, each with more than 20 years of experience in the industry.

3.2.1. Content Analysis

The Delphi round one data were analyzed using content analysis, a methodical data analysis approach to identify qualitative data in a text format [

55]. NVivo is one of the most used software for qualitative data analysis in various disciplines [

8]. NVivo software was used to manage, code, and analyze the data.

3.2.2. Likert Scale

Several 5-point Likert scale questions were raised in the Delphi round one. The questions aimed to capture the level of agreement of each expert to a given statement. Likert scale measures are ordinal, without a justifiable meaning between the scale intervals, and they display a set of ordered categories [

55]. All responses were qualitatively evaluated by re-sending the answers to Likert scale questions to all of the experts to achieve consensus.

4. OSC Typology Development

The literature review initially identified the preliminary OSC types. These were verified using a case study review. The preliminary OSC typology was then subjected to a comprehensive expert forum involving a Delphi process. This validation exercise enabled the development of the OSC typology. The OSC typology development process is discussed in detail in the following sub-sections.

4.1. Secondary Case Study Review

Six case studies were reviewed to show the practicality of OSC types in the construction industry using project data obtained from different sources.

Table 2 presents the comparative analysis of the selected case studies. A structured analysis of the factors is presented to determine how each selected case study was considered under the developed OSC type. These factors are the scale of the building, technology used, and onsite labor usage, which provide insights into the distinct features of OSC types and their applicability in actual construction projects.

Components found at the South Australian Health and Medical Research Institute (SAHMRI) building include an external façade, an internal wall system, and a steel staircase [

68]. The façade consists of 14,000 individual steel and glazed triangles fabricated in China and installed onsite [

69]. Moreover, 30,000 m

2 of a finished circular wall system made of fiber-reinforced gypsum boards were manufactured in a factory and fixed onsite. An in-situ concrete structure was added to the building at each story, resulting in simultaneous staircase installation onsite [

68]. Features of the SAHMRI building indicate a typical construction project with 300 daily workers onsite, while the related offsite activities were limited to the component OSC type.

“Te Pa Tauira”, a cross-laminated timber (CLT) panelized building, is a five-story student accommodation facility at the Otago Polytechnic University, Dunedin, New Zealand, that includes 231 rooms [

64,

70]. The wall panels of the building were installed onsite with just-in-time delivery practices, followed by intermediate floor cassettes, roofing cassettes, and external walls [

70]. This building is a sound example of CLT panel usage, where non-volumetric 2D elements are transported for onsite assembly.

“Little Hero” is an apartment complex in Melbourne, Australia, incorporating 63 apartment pods [

71]. Each pod was completed offsite and includes natural timber floors, carpets, built-in wardrobes, and full-length balconies [

63]. This project signifies the level of finishing and completion associated with pods that are repetitive in nature.

The Lynch Hill Academy school building in the UK encompasses 146 15.6-m long steel-framed modules over three stories [

67]. The modules were pre-clad, as well as the internal walls, doors, windows, ironmongery, and building services, resulting in 65% of the project work happening offsite [

67]. The building was delivered 17 weeks ahead of schedule, while school operations continued with minimal disruptions from onsite work [

65].

The range of complete buildings offered by the selected manufacturer, AUSCO Modular, varies among project offices, site sheds, commercial offices, lunchrooms, kitchens, diners, toilets, laundries, and accommodation buildings [

61]. They are fully kitted out, single-unit buildings to be fixed onsite within a matter of days. Finally, a collapsible house is considered a flat-pack/foldable structure, with integrated wiring, plumbing, finishes and solar panels included in the structure [

47]. Similar developments of foldable structures are currently available in the market [

46,

48].

The summary of the case study review outcomes is as follows:

Subsequently, an expert forum was conducted to validate the preliminary OSC typology with expert opinions.

4.2. Expert Forum

The summary of findings from the expert forum (a two-round Delphi study) is presented in

Table 3. There were eight sections, where the first six sections were on the six OSC types. The remaining sections covered the overall stance of OSC types and OSC skills.

5. Discussion

The systematic approach validated the preliminary OSC typology via literature sources, industry usage, and expert opinions. In this section, the validated OSC typology is explained to provide comprehensive details on all OSC types.

5.1. Significance of the Validated OSC Typology

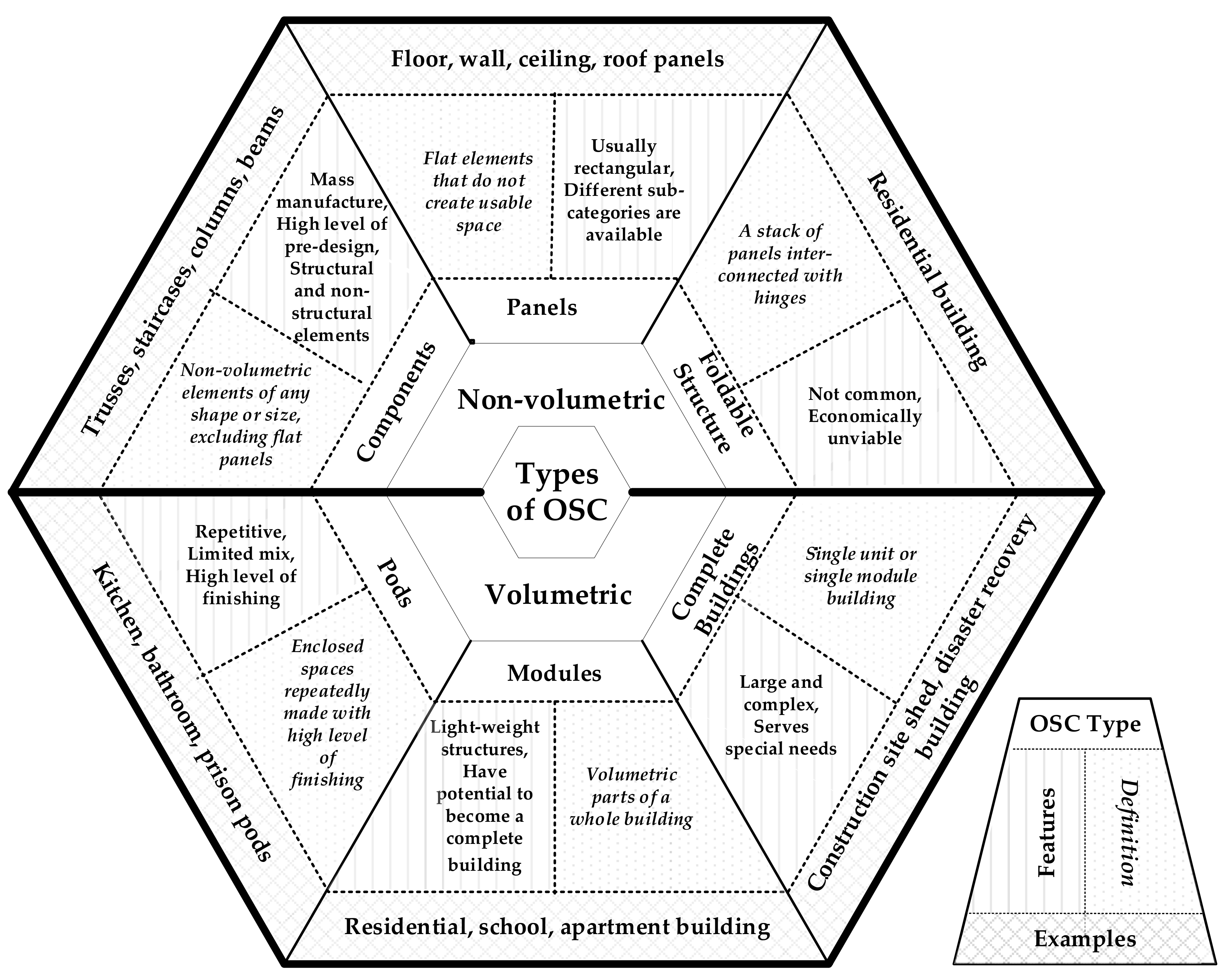

The validated OSC typology is presented in

Figure 3, which shows the definitions, features, and examples of all OSC types. It includes six unique OSC types whose features are distinct from each other. These OSC types are classified under non-volumetric (components, panels, foldable structure) and volumetric (pods, modules, complete buildings) categories.

Compared to the original classification by Gibb [

11], the validated OSC typology represents the holistic nature of OSC. A rigorous research method was followed to develop the OSC typology, including a multi-level expert forum via the Delphi method, to achieve an unbiased consensus through expert opinion. However, the previous classifications adopted Gibb [

11] to suit their research purposes, and hence a validated OSC typology that matches Industry 4.0-driven technologies in the 21st century is long overdue.

Neither the original classification nor any of the adopted classifications (

Figure 1) have used a rigorous research method to justify the development process of OSC classifications. In contrast, this research deploys a systematic scientific process to develop an OSC typology that depicts the holistic nature of OSC types. Existing classifications strongly represent the subjective judgments and independent expert opinions of the researchers to derive OSC categorizations that match their research purposes. These classifications also portray the influence of industry practices where multiple terms are used to refer to similar OSC products without a clear distinction between their features and the definitions. For example, as per

Figure 1, the terms volumetric [

27,

29,

72], volumetric and modular [

30], volumetric pre-assembly [

8,

11,

26,

32], volumetric offsite prefabrication [

25], modular [

11,

26,

27,

72], modular building [

8,

25,

28], modular construction [

33], modules [

38], 3D volumetric modules [

33], complete modular [

36], pods [

36], volumetric pods [

72], structural volumetric spaces [

37], volumetric modular system [

31], complete building [

11,

26], complete building systems [

44,

44], and modular and mixed construction systems [

44] have been used to refer to any volumetric element. Similar complexities are evidenced for non-volumetric elements as well. The existing classifications do not present a clear distinction between the terms used to refer to OSC products. Many of them fail to capture the holistic nature of OSC products [

8,

25,

27,

28,

29,

30,

31,

32,

38,

72]. Therefore, the developed OSC typology (

Figure 3) resolves the complications surrounding OSC types and indicates their distinct features.

The first OSC type, component, is a constant in many previous classifications [

11,

26,

27,

29,

30,

32,

33,

38,

44,

72], and the current typology represents them as factory-made, non-volumetric building elements. Panels are also recognized in the literature [

8,

11,

25,

26,

27,

28,

29,

30,

31,

32,

33,

44,

72], yet the definition, features, and differentiation from other OSC types were not given consideration in previous studies. Foldable structures are not evidenced in any of the existing classifications. Among the many terms used to refer to volumetric building elements, pods [

36,

72], modules [

38,

72], and complete buildings [

11,

25,

33,

36,

44] are interchangeably used to refer to anything that comes in a box. Therefore, the differentiation of these three volumetric OSC types assists the industry with operational and, subsequently, macroeconomic benefits. The developed typology is accompanied by a building classification process (

Figure 4), which provides a decision matrix to match various OSC projects with building elements manufactured offsite.

5.2. OSC Building Classification Process

The process to be followed for OSC building classification is presented in

Figure 4. The purpose of the building classification process is to have a better understanding of the distribution of various OSC types in a project. Building construction projects are complex [

34] and, thus, most of them do not fall into one distinct OSC type. Every project includes an onsite element [

73], while the rest of the building structure can incorporate more than one OSC type. As such, classifying a construction project under one unique OSC type can be done by considering the predominant OSC type.

Buildings that belong to the component OSC type are recognized by considering the non-availability of other OSC types (Decision 1.0). If the building does not have panels, pods, modules, a complete building, or a foldable structure, it belongs to the component OSC type and has close resemblance to a traditionally constructed building. Components are common in many buildings irrespective of whether the buildings are constructed traditionally or offsite. Examples for components vary from pre-manufactured fittings, fixtures, columns, beams, staircases, trusses, and façades to building services that include site-intensive construction [

33].

Furthermore, due to their wide variety and abundance, the chances of components having a higher total value percentage than other OSC types are exceptionally high (E2 and E5). Jaillon and Poon [

74] evaluated 11 prefabricated elements frequently used in Hong Kong, out of which five were components, while the rest were either panels or volumetric elements. Therefore, the subsequent steps in OSC building classification exclude components. As such, if a building only has a single OSC type (panels, pods, modules, a complete building, or a foldable structure) besides components, it is recognized under the relevant OSC type (Decision 2.0).

When a building has more than one OSC type, the OSC type with a higher value percentage is considered (Decision 3.0). If a building involves the same OSC percentages for two OSC types in value terms, the OSC type with the higher complexity is considered the relevant OSC type. The complexity of OSC types can be decided based on the nature of the products and the manufacturing processes involved. For example, compared to a panelized project, pods can be far more complex to manufacture. As such, the decision process considers the predominant usage of a specific OSC type.

5.3. Non-Volumetric OSC Types

5.3.1. Components

Since the first reference to “component manufacture and sub-assembly”, components have been considered in many classifications as the simplest OSC type [

29,

33,

44]. Components have been stereotyped as non-structural building elements, with examples such as doors, windows, light fixtures [

11], and pre-assembled mechanical services [

29]. Boyd, Khalfan and Maqsood [

28] renamed components as “offsite pre-assembly” to incorporate trusses and staircases. Gosling, Pero, Schoenwitz and Towill [

23], with reference to the OSC sub-component classification by Schoenwitz, et al. [

75], consider beams and columns as sub-components, but this is critically questioned by da Rocha and Kemmer [

12] due to the inadequate rationale behind the consideration.

Although earlier classifications recognize the volume-based differentiation in OSC types, none of them consider the structural-based differentiation of non-volumetric elements. Therefore, the validity of considering beams and columns as structural components was questioned (Q1.2 in

Table 3), to which all experts agreed. As such, this study suggests a rearrangement of components, including both structural and non-structural building elements.

5.3.2. Panels

All five experts unanimously considered panels as a valid OSC type, and several sub-sets of panels were suggested, viz.: sandwich, co-op (E5), open, and closed panels (E3). This finding is in accordance with open and closed panels [

34,

43], concrete, and structural insulated panels [

31] in the literature. A detailed evaluation of the sub-categories of OSC types is a further research area beyond the scope of the current study.

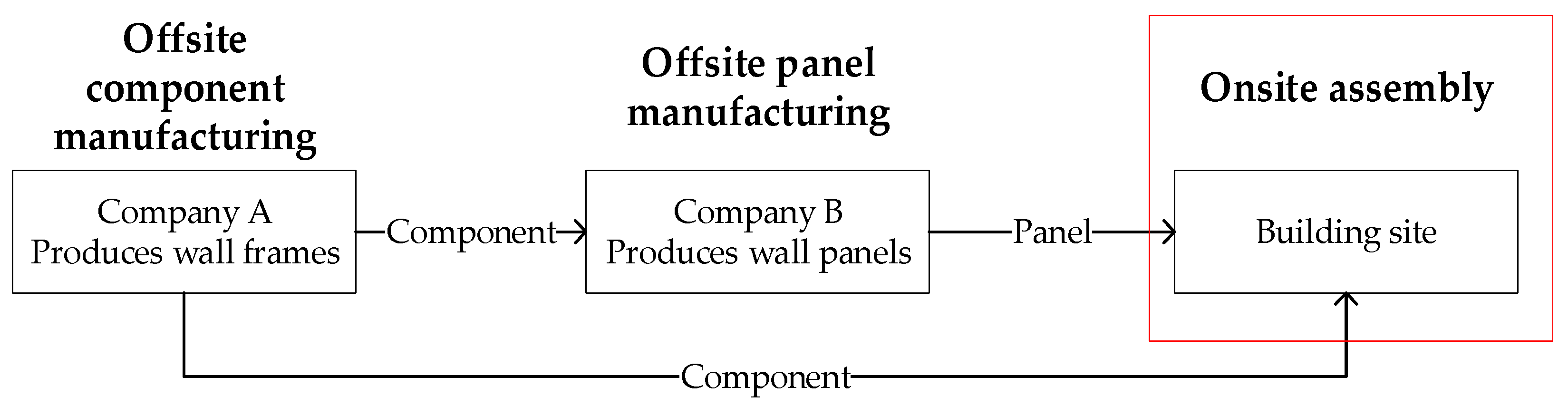

Whilst agreeing for components and panels to be distinct OSC types, E3 highlighted the nexus between them (

Figure 5). According to E3, some manufacturers (Company A) solely focus on components (e.g., wall frames) to be re-manufactured by a different entity (Company B) to produce panels (e.g., wall panels). However, as shown by the “red box” in

Figure 5, the OSC type is decided based on the point of delivery to the construction site. Once the element is delivered to the building site for onsite assembly (shown within the red box), the OSC type is decided.

This opinion provided the possibility of merging several OSC types on an organizational basis. However, as per the definition, any manufacturing activity within a factory before transportation to the site is OSC. Therefore, both “A” and “B” produce valid types, yet “A” also acts as a supplier to “B”. The scenario is similar to the sub-contracting process in traditional construction [

1]. As such, several OSC types can always be incorporated within a much more complex type. However, OSC types in this study are developed from a building construction project perspective rather than from an organizational perspective. Therefore, the OSC types are differentiated within the project scope based on the final delivery for onsite assembly, and not on delivery for re-manufacturing.

E4 questioned the difference between the terms “flat-pack” and “panels”. The term “flat-pack” was claimed to be misleading, as it refers to the stacking and transportation of panels in a single flattened package. The literature also refers to 2D panelized structures as flat-pack [

34], as opposed to a whole building of panels connected with hinges [

46,

47,

48]. Therefore, the experts suggested a different term, “foldable structure”, to be used instead of flat-pack.

5.3.3. Flat-Pack/Foldable Structure

“Foldable structure” refers to building panels (floors, walls, ceilings) connected using hinges, to be folded, transported, and finally unfolded at the site [

46,

47,

48]. None of the experts claimed foldable structure to be a common OSC type due to its limited use in the industry. E1 identified it as rare and hardly economical for any offsite manufacturer. E4 stated that its usage in the industry was less than 1%. Based on the findings in the current industrial context, the foldable structure is visible as an OSC type that has not yet gained sufficient market interest or economic viability. As technology is rapidly evolving, attraction for this type of semi-temporary buildings is also incrementing. Apart from the comments received about the limited use of foldable structures, none of the experts disagreed for this to be a valid OSC type. Given these comments, to future-proof the OSC typology, the foldable structure is kept as a part of the OSC typology.

5.4. Volumetric OSC Types

5.4.1. Pods

Despite the unanimous consensus that pods are a valid OSC type, several concerns were raised about their inflexibilities and stringent maintenance requirements (E2). However, studies comparing in-situ and prefabricated bathrooms demonstrated better maintenance for prefab bathrooms in regard to cost and performance [

76,

77].

E4, unlike other experts, was of the view that “it is not a must for pods to be repetitive” (Delphi round one), and that “pods can be repetitive from an economic point of view but not from a typology point of view” (Delphi round two). Thus, an 80% agreement was achieved for the consensus statement that pods are repetitive in nature (Q3.2 in

Table 3). Goh and Loosemore [

36] also acknowledge the repetitive tasks involved in pod manufacturing, as pods are entirely completed in a factory to install building services and finishes similar to an assembly line.

5.4.2. Modules

Modules were confirmed as a valid OSC type with unanimous consensus. Moreover, it was noted that several modules could be used to build a complete building (E1), which is the concept behind modules in the OSC typology. Although the OSC typology identifies pods, modules, and complete buildings under the umbrella term “volumetric”, several comments were received about using the terms “module” and “volumetric”. Both modules and volumetrics can be referred to as modes (E4); they are common terminologies to refer to anything that comes in a box (E3). “Module” can be misleading, as OSC operations are also called modular construction (E3). However, the term “modular” is a broad concept that spans several disciplines, referring to the breaking up of a particular system into various parts [

23]. Such inconsistencies in an industrial context reveal the need to develop a validated typology to ease OSC communications and subsequently improve the operational benefits of OSC.

A question was raised to understand whether there are differences between pods and modules. The responses in the Delphi round one were mostly inclined towards an agreement. E3 stated that the only difference between pods and modules was related to size. As per E4, pods are parts of modules, and there can be occasions where a pod becomes a module. A consensus was reached in the Delphi round two by differentiating pods and modules as repetitive and non-repetitive volumetric types, respectively.

The entire building can be made up of modules, while pods have a limited mix of possibilities (E2). E1 proposed another view on modules, which is illustrated in

Figure 6.

There can be three different buildings (Buildings A, B, C) in a single project, and each building needs unique modules (Modules 1–9), resulting in nine unique modules (E1). However, the pods for the three buildings are similar (Pod x). This interpretation further aligns with the consideration of repetitive, finished pods. It shows how modules are not repeated building elements due to the uniqueness of building projects, while pods are repetitive as they are manufactured based on mass manufacturing principles. Several modules make up a building, while pods are finished components that need to be incorporated into a building (E1). In addition, modules possess a lower finishing level than pods, as modules need to be joined onsite for interior finishes (E1).

5.4.3. Complete Buildings

A complete building is a single unit or a single module building. The experts unanimously agreed that it is a valid OSC type with practical differences and unique features compared to modules. Moreover, complete buildings can be business models (E4). Referring to one of their projects, E1 stated that a police station in New South Wales, Australia, is 18 m × 4.8 m in size, including a fully furnished and cladded reception area, interview rooms, lock-up, and gun sites. E1 revealed that onsite tasks were limited to foundation construction and fixing of the delivered building. E1 also compared complete buildings with pods due to the level of finishes completed offsite, yet confirmed that complete buildings would never be called pods in the current industrial context.

Examples of complete buildings are fully fitted out telecommunications bases, fully kitted out infrastructure buildings, and health buildings, particularly in developing countries or remote locations, refugee camps, and disaster recovery areas (E2). These findings reveal a particular purpose of complete buildings, which are also considered a proven OSC solution to build back communities efficiently as a convenient disaster relief building model [

1].

5.5. Overall Position of OSC Types

Responding to the questions on the overall stance of the preliminary OSC typology and the practical usage/applicability of the OSC types, all experts agreed that the developed preliminary typology paints a holistic picture of OSC. According to the experts, even the items that are not very common, such as foldable structures, are taken into consideration.

The OSC types are dispersed among various sectors, such as residential offices, school buildings, hotels, switch rooms, and police stations (E1). E3 opined that the practical usage of each type reduced with the complexity level. This finding implies that most OSC activities will be limited to non-volumetric/2D types rather than volumetric/3D building elements.

Additionally, the typology was identified as a means of expressing the construction mode and the degree of completion (E4, E5). It confirms the aim of developing the OSC typology: to remove confusion and have a unique identity for each OSC type, resulting in operational and macroeconomic benefits.

5.6. Materials Used in OSC Types

The experts mentioned relevant materials for each OSC type in the Delphi round one. All responses were circulated in the Delphi round two, and the materials with more than or equal to 60% consensus (minimum 3/5 experts agreed) are presented in

Table 4. The materials that received more than or equal to 60% consensus are presented with “√” symbol. The materials with less than 60% consensus are shown with “- “symbol.

Steel and timber stud frames are significant materials for all OSC types. Despite the consensus on the use of timber in all OSC types, OSC in Australia is mostly made from pre-cast concrete, while timber contributes only 1% of the materials (E2). Furthermore, timber pod construction is common in other countries, whereas there is a limited number of timber pod manufacturers in Australia (E1). Steel frames are commonly used with a solid concrete base for pod manufacturing (E4, E5). A primary concern related to the materials used for volumetric OSC is the requirement of lightweight structures, resulting in CLT, steel, and timber frames being the typical materials.

5.7. Offsite Construction Skills

The experts were required to provide their opinions on various skills used in the OSC types. E1 observed a gradual increase in skills when the complexity of the OSC type increased. The complex OSC types (modules and complete buildings) are project-oriented and require an OSC project team, including an architect, a mechanical engineer, and technical staff to manage the building services (E1). These views specify how skill needs vary significantly among the OSC types, primarily due to mass manufacturing as opposed to project-based manufacturing.

The experts stated various skills, such as planning, designing, manufacturing, logistics and assembly processes, as important skills in OSC compared to traditional onsite construction (Q8.2 in

Table 3). Both E2 and E3 mentioned the need for architects with computer-aided designing (CAD) skills to suit a manufacturing environment (DfMA) and how OSC design must begin with a simple approach like AutoCAD. Moreover, E2 suggested how BIM is not in line with DfMA. However, this finding is against the promising synergy between BIM and DfMA [

16].

Further, E4 highlighted the critical need for increased design time and decreased production time in OSC. Similar OSC skill needs are also acknowledged by Hairstans and Smith [

43]. These findings signal the possible skill quantity variations for different OSC tasks compared to traditional construction. The references to production-based skills (E1), technology-driven skills (E3), and logistics-based skills (E4) signify how OSC skills differ from the usual trade-based construction skills.

6. Conclusions

This research aimed to develop a comprehensive OSC typology consisting of distinct OSC types. The preliminary typology (components, panels, pods, modules, complete buildings, flat-pack/foldable structure) was initially developed based on a literature review. A case study review was conducted using publicly available project data to confirm the applicability of the preliminary typology in actual OSC projects. Primary data analysis of the typology was then performed through an expert forum. The expert forum consisted of five experienced professionals with vast exposure to OSC in Australia and Europe. The expert forum followed a Delphi process, and the consensus on OSC types was reached in the second round. The first round of the Delphi process was conducted using semi-structured interviews, while the second round was a questionnaire survey.

The study concludes OSC types to be non-volumetric (components, panels, foldable structure) and volumetric (pods, modules, complete buildings). Components are non-volumetric elements of any shape or size that fall under structural and non-structural building elements, except flat panels. Panels are flat elements that do not create usable space. Foldable structures are flat panels interconnected using hinges. Pods are enclosed spaces repeatedly made with a high level of finishing. Modules are the volumetric parts of a building. Complete buildings are large and complex single-module units.

These OSC types share common materials: lightweight steel and timber frames. CLT plays a vital role in panel and complete building manufacturing. In addition, it is verified that the skills needed for each OSC type vary, especially according to the level of complexity of the type. Components are mass-manufactured and require production-specific skills, whilst more project-specific types depend on OSC skills. This knowledge sheds light on OSC skill development, depending on the specific OSC type and its demand in a particular market.

The research has practical implications in terms of developing a common language to refer to distinct OSC types. The research enhances communication about OSC products by removing the ambiguous and complex terms. The OSC typology creates a strong theoretical basis for future research to accommodate distinct OSC types in OSC research. It is also accompanied by a decision matrix that enables the classification of OSC projects to relevant OSC types. The research implications include developing a uniform categorization that captures the existing technological advancements emerging through MMC and Industry 4.0. The clear distinction between OSC types offers operational benefits. The typology can be utilized for skill prediction and procurement method development, and to formulate the level of automation (both onsite and offsite) in OSC projects. Subsequently, it will improve the contribution of the OSC industry to the GDP and enhance efficiency and productivity. Earlier studies on OSC have adopted the original classification of Gibb [

11] to suit different research purposes, but this study validates the OSC typology through a rigorous systematic review process to capture the smart and modern technologies in the 21st century. It contributes to the OSC knowledge base by developing the first systematically developed OSC typology. Further, the research incorporates a three-fold research methodology, where literature findings are confirmed through case study review and then validated using observations by multiple experts. Despite the consensus on the OSC typology, the five experts in the expert forum may be a limitation of the study, and hence expansion of the number of experts can be an approach used on future research. The research has the limitations of a qualitative study, and hence the findings may be difficult to generalize. As follow-up research, a quantitative study needs to be undertaken.

Author Contributions

Conceptualization, B.G., S.P., Y.F. and P.R.; methodology, B.G., S.P., Y.F. and P.R.; software, B.G.; validation, B.G.; formal analysis, B.G.; investigation, B.G.; resources, B.G. and S.P.; data curation, B.G.; writing—original draft preparation, B.G.; writing—review and editing, S.P., Y.F. and P.R.; visualization, B.G., S.P., Y.F. and P.R.; supervision, S.P., Y.F. and P.R.; project administration, S.P., Y.F. and P.R.; funding acquisition, S.P., Y.F. and P.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Centre for Smart Modern Construction (c4SMC), Western Sydney University.

Institutional Review Board Statement

Ethical approval for this research has been granted by the Western Sydney University Human Research Ethics Committee (HREC). This HREC is constituted and operates in accordance with the National Statement on Ethical Conduct in Human Research 2007 (Updated 2018). (HREC approval number: H13515; HREC approval date: 11 October 2019).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to ethics-related restrictions.

Acknowledgments

The authors are grateful for the time and effort expended by the experts who took part in the expert forum.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Goulding, J.S.; Pour Rahimian, F. Offsite Production and Manufacturing for Innovative Construction: People, Process and Technology; Routledge: Oxford, UK; New York, NY, USA, 2020. [Google Scholar]

- Liu, G.; Nzige, J.H.; Li, K. Trending topics and themes in offsite construction (OSC) research. Constr. Innov. 2019, 19, 343–366. [Google Scholar] [CrossRef]

- Herbert, G. The portable colonial cottage. J. Soc. Archit. Hist. 1972, 31, 261–275. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum Geneva: Geneva, Switzerland, 2016. [Google Scholar]

- Johnsson, H. Production strategies for pre-engineering in house-building: Exploring product development platforms. Constr. Manag. Econ. 2013, 31, 941–958. [Google Scholar] [CrossRef]

- Taylor, M.D. A definition and valuation of the UK offsite construction sector: Ten years on. Int. J. Constr. Manag. 2020, 1–9. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Blismas, N.; Arif, M.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 2009, 9, 72–83. [Google Scholar] [CrossRef] [Green Version]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef] [Green Version]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P. Typologies of offsite construction. In Proceedings of the 8th World Construction Symposium, Colombo, Sri Lanka, 8–10 November 2019; pp. 567–577. [Google Scholar]

- Gibb, A.G.F. Standardization and pre-assembly- distinguishing myth from reality using case study research. Constr. Manag. Econ. 2001, 19, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Da Rocha, C.G.; Kemmer, S. Integrating product and process design in construction. Constr. Manag. Econ. 2018, 36, 535–543. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Agapiou, A. Factors influencing the selection of a procurement route for UK off-site housebuilding. Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 1–13. [Google Scholar] [CrossRef]

- Pan, W.; Sidwell, R. Demystifying the cost barriers to offsite construction in the UK. Constr. Manag. Econ. 2011, 29, 1081–1099. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Lee, E.W.M.; Chan, R.; Hosseini, M.R. Analysis of interacting uncertainties in on-site and off-site activities: Implications for hybrid construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Abbasi, B.; Arashpour, M.; Hosseini, M.R. Optimal process integration architectures in off-site construction: Theorizing the use of multi-skilled resources. Archit. Eng. Des. Manag. 2018, 14, 46–59. [Google Scholar] [CrossRef]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Rahnamayiezekavat, P. Offsite construction skills evolution: An Australian case study. Constr. Innov. 2021, 22, 41–56. [Google Scholar] [CrossRef]

- Farmer. The Farmer Review of the UK Construction Labour Model; Construction Leadership Council (CLC): London, UK, 2016. [Google Scholar]

- Taylor, M.D. A definition and valuation of the UK offsite construction sector. Constr. Manag. Econ. 2010, 28, 885–896. [Google Scholar] [CrossRef]

- Ahmad, S.B.S.; Mazhar, M.U.; Bruland, A.; Andersen, B.S.; Langlo, J.A.; Torp, O. Labour productivity statistics: A reality check for the Norwegian construction industry. Int. J. Constr. Manag. 2020, 20, 39–52. [Google Scholar] [CrossRef] [Green Version]

- Gosling, J.; Pero, M.; Schoenwitz, M.; Towill, D. Defining and categorizing modules in building projects: An international perspective. J. Constr. Eng. Manag. 2016, 142. [Google Scholar] [CrossRef]

- Nawi, M.N.M.; Pozin, M.A.A.; Kamar, K.A.M.; Lee, A.; Harun, A.N. The Global Adoption of Industrialised Building System (IBS): Lessons Learned. J. Soc. Sci. Res. 2018, 6, 1272–1278. [Google Scholar] [CrossRef] [Green Version]

- Gibb, A.G.F. Off-Site Fabrication: Prefabrication, Pre-Assembly and Modularisation; John Wiley and Sons Incorporation: New York, NY, USA; Toronto, ON, Canada, 1999. [Google Scholar]

- Gibb, A.G.F.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef] [Green Version]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Boyd, N.; Khalfan, M.M.A.; Maqsood, T. Off-site construction of apartment buildings. J. Archit. Eng. 2013, 19, 51–57. [Google Scholar] [CrossRef]

- Kempton, J. Modern methods of construction and RSL asset management: A quantitative study. Struct. Surv. 2010, 28, 121–131. [Google Scholar] [CrossRef]

- Kamar, K.A.M.; Hamid, Z.A.; Azman, M.N.A.; Ahmad, M.S.S. Industrialised Building System (IBS): Revisiting issues of definition and classification. Int. J. Emerg. Sci. 2011, 1, 120–132. [Google Scholar]

- NHBC. Modern Methods of Construction Who’s Doing What? 978-1-9995997-1-3; NHBC: Buckinghamshire, UK, 2018. [Google Scholar]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Archit. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Nguyen, Q.C.; Perera, S.; Jin, X. The status of offsite construction in Vietnam. In Proceedings of the 42nd AUBEA Conference 2018: Educating Building Professionals for the Future in the Globalised World, Singapore, 26–28 September 2018; pp. 68–77. [Google Scholar]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey & Company: Zurich, Switzerland, 2019. [Google Scholar]

- MMC Working Group. Modern Methods of Construction Working Group: Developing a Definition Framework. Available online: https://www.gov.uk/government/publications/modern-methods-of-construction-working-group-developing-a-definition-framework (accessed on 16 November 2021).

- Goh, E.; Loosemore, M. The impacts of industrialization on construction subcontractors: A resource based view. Constr. Manag. Econ. 2016, 35, 288–304. [Google Scholar] [CrossRef]

- Steinhardt, D.A.; Manley, K. Adoption of prefabricated housing–the role of country context. Sustain. Cities Soc. 2016, 22, 126–135. [Google Scholar] [CrossRef] [Green Version]

- Quale, J.D.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Sutrisna, M.; Cooper-Cooke, B.; Goulding, J.S.; Ezcan, V. Investigating the cost of offsite construction housing in Western Australia. Int. J. Hous. Mark. Anal. 2019, 12, 5–24. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Smith, R.E.; Quale, J.D. Offsite Architecture: Constructing the Future; Routledge: Oxford, UK; New York, NY, USA, 2017. [Google Scholar]

- Ritchie, L. Fundamentals of Prefabrications Costing and Considerations; AIQS: Sydney, Australia, 2019; pp. 46–49. [Google Scholar]

- Hairstans, R.; Smith, R.E. Offsite HUB (Scotland): Establishing a collaborative regional framework for knowledge exchange in the UK. Archit. Eng. Des. Manag. 2018, 14, 60–77. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Ayinla, K.O.; Cheung, F.; Tawil, A.-R. Demystifying the concept of offsite manufacturing method. Constr. Innov. 2019, 20, 223–246. [Google Scholar] [CrossRef]

- Boxabl. Available online: https://www.boxabl.com/ (accessed on 12 October 2021).

- MADI. MADI home. Available online: https://www.madihome.com/ (accessed on 16 November 2021).

- Ten Fold Technology. Available online: https://www.tenfoldengineering.com/ (accessed on 19 March 2021).

- Ribeirinho, M.J.; Mischke, J.; Strube, G.; Sjödin, E.; Blanco, J.L.; Palter, R.; Biörck, J.; Rockhill, D.; Andersson, T. The Next Normal in Construction; McKinsey & Company: Madrid, Spain, 2020. [Google Scholar]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in off-site construction: Current status and future direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Perera, S.; Nanayakkara, S.; Rodrigo, M.N.N.; Senaratne, S.; Weinand, R. Blockchain technology: Is it hype or real in the construction industry? J. Ind. Inf. Integr. 2020, 17. [Google Scholar] [CrossRef]

- World Economic Forum. Future of Jobs Report 2020; World Economic Forum: Geneva, Switzerland, 2020. [Google Scholar]

- Southern, J. Smart Construction—How Offsite Manufacturing Can Transform Our Industry; Klynveld Peat Marwick Goerdeler (KPMG) International: Amstelveen, The Netherlands, 2016. [Google Scholar]

- Jacoby, S. Type versus typology introduction. J. Archit. 2016, 20, 931–937. [Google Scholar] [CrossRef]

- Neuman, W.L. Social Research Methods: Qualitative and Quantitaive Approaches, 7th ed.; Pearson: Boston, MA, USA, 2011. [Google Scholar]

- Mason, H. 3D-Printed Prefab Homes Aim to Disrupt Construction Market. Available online: https://www.compositesworld.com/articles/3d-printed-prefab-homes-aim-to-disrupt-construction-market (accessed on 16 November 2021).

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill-Building Approach, 7th ed.; John Wiley & Sons Ltd.: Chichester, UK, 2016. [Google Scholar]

- Hallowell, M.R.; Gambatese, J.A. Qualitative research: Application of the Delphi method to CEM research. J. Constr. Eng. Manag. 2010, 136, 99–107. [Google Scholar] [CrossRef]

- Nasirian, A.; Arashpour, M.; Abbasi, B.; Zavadskas, E.; Akbarnezhad, A. Skill set configuration in prefabricated construction: Hybrid optimization and multicriteria decision-making approach. J. Constr. Eng. Manag. 2019, 145. [Google Scholar] [CrossRef]

- Collis, J.; Hussey, R. Business Research: A Practical Guide for Undergraduate and Postgraduate Students, 8th ed.; Palgrave Macmillan: Basingstoke, UK, 2014. [Google Scholar]

- AUSCO Modular. Buildings. Available online: http://ausco.com.au/buildings (accessed on 16 November 2021).

- SAHMRI. Australian National Construction Review; SAHMRI: Gosford, Australia, 2019; p. 6. [Google Scholar]

- Chua, G. Nine Storey Melbourne Apartment Goes up in just Five Days. Available online: https://www.architectureanddesign.com.au/news/nine-storey-melbourne-apartment-goes-up-in-just-fi# (accessed on 28 December 2021).

- Mason and Wales. Te Pa Tauira—OP Student Village. Available online: https://www.masonandwales.com/projects/multi-residential/Otago-Polytechnic-Student-Village (accessed on 16 October 2019).

- Mcavoy. Lynch Hill Enterprise Academy. Available online: https://www.mcavoygroup.com/newcasestudies/lynchhill/ (accessed on 23 February 2021).

- OC Bristo. Little Hero Steel Container Apartments- Melbourne, Australia. Available online: https://ocbristo.com/little-hero-steel-container-apartments-melbourne-australia/ (accessed on 1 September 2019).

- The Irish News. McAvoy Completes One of UK’s Largest Ever Off-Site Education Projects 17 Weeks Early. Available online: https://www.irishnews.com/business/2018/01/06/news/mcavoy-completes-one-of-uk-s-largest-ever-off-site-education-projects-17-weeks-early-1225917/ (accessed on 22 February 2021).

- Woods Bagot. Heart of Innovation. Available online: https://www.woodsbagot.com/projects/south-australian-health-and-medical-research-institute/ (accessed on 20 August 2019).

- Aurecon. South Australian Health and Medical Research Institute (SAHMRI), Australia. Available online: https://www.aurecongroup.com/projects/property/sahmri (accessed on 20 August 2019).

- Otago Polytechnic. Otago Polytechnic Student Village—Accommodation; Otago Polytechnic University: Dunedin, New Zealand, 2019; p. 20. [Google Scholar]

- Gunawardena, T.; Tuan, N.; Mendis, P.; Aye, L.; Crawford, R.H.; Jose, A. A holistic model for designing and optimising sustainable prefabricated modular buildings. In Proceedings of the ICSBE 2012—International Conference on Sustainable Built Environment 2012, Kandy, Sri Lanka, 16 December 2012. [Google Scholar]

- Agapiou, A. An exploration of the best value perceptions of small housebuilding developers towards offsite construction. Sustainability 2021, 13, 4054. [Google Scholar] [CrossRef]

- Eastman, C.M.; Sacks, R. Relative productivity in the AEC industries in the United States for on-site and off-site activities. J. Constr. Eng. Manag. 2008, 134, 517–526. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Schoenwitz, M.; Naim, M.; Potter, A. The nature of choice in mass customized house building. Constr. Manag. Econ. 2012, 30, 203–219. [Google Scholar] [CrossRef]

- Pan, W.; Arif, M.; Gibb, A.G.F. Maintenance performance evaluation of offsite and in situ bathrooms. Constr. Innov. 2009, 9, 7–21. [Google Scholar] [CrossRef] [Green Version]

- Pan, W.; Gibb, A.G.F.; Sellars, A.B. Maintenance cost implications of utilizing bathroom modules manufactured offsite. Constr. Manag. Econ. 2008, 26, 1067–1077. [Google Scholar] [CrossRef] [Green Version]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).