Quantifying Advantages of Modular Construction: Waste Generation

Abstract

:1. Introduction

2. Literature Review

2.1. Waste Definition

2.2. Modular Construction Benefit Quantification

2.3. Conventional Construction Waste Rates

2.4. Modular Construction Waste Rates

3. Methodology

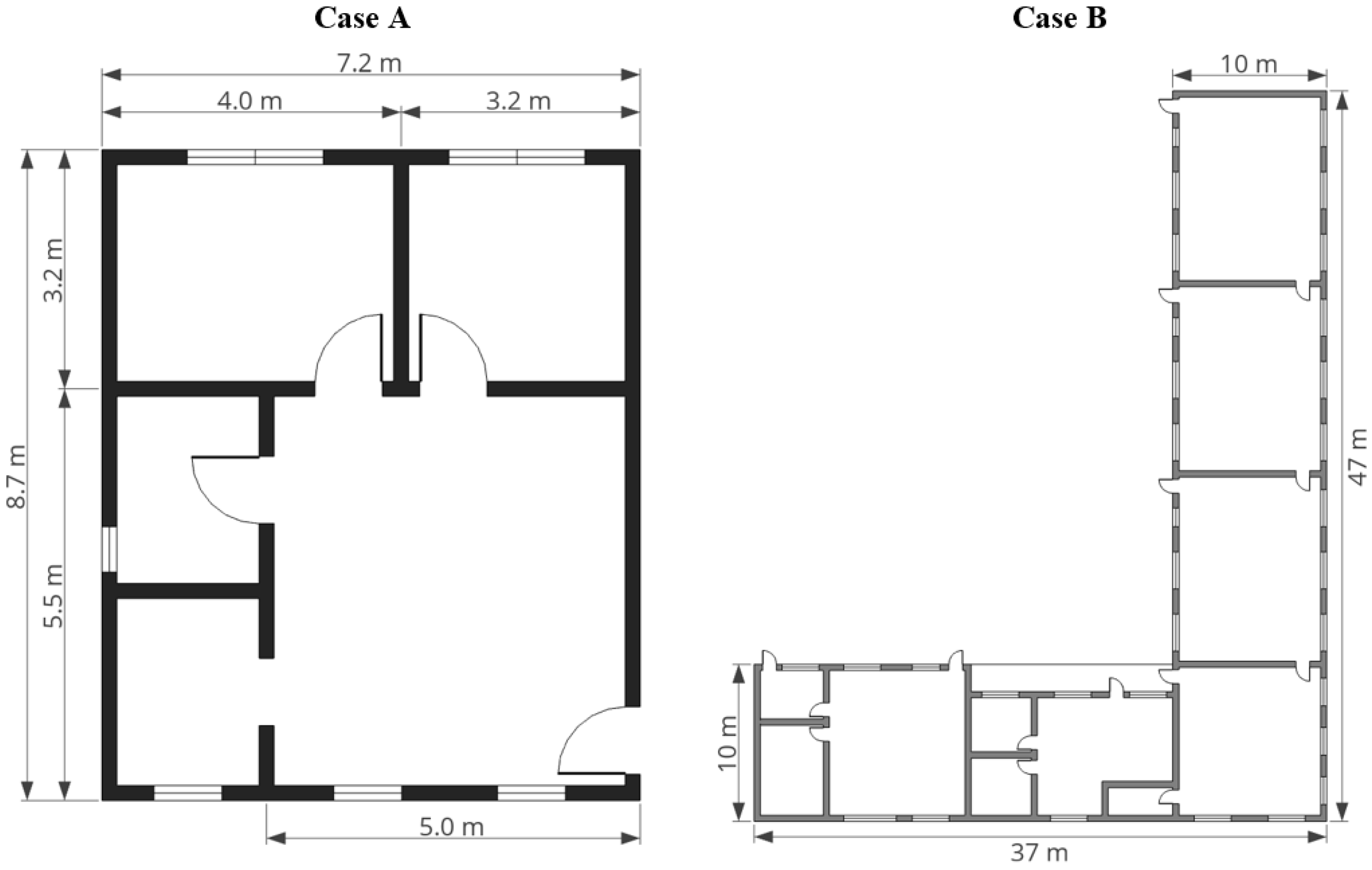

3.1. Case Studies

3.2. Data Analysis

4. Result Analysis

4.1. Conventional Waste Generation

4.2. Modular Waste Generation

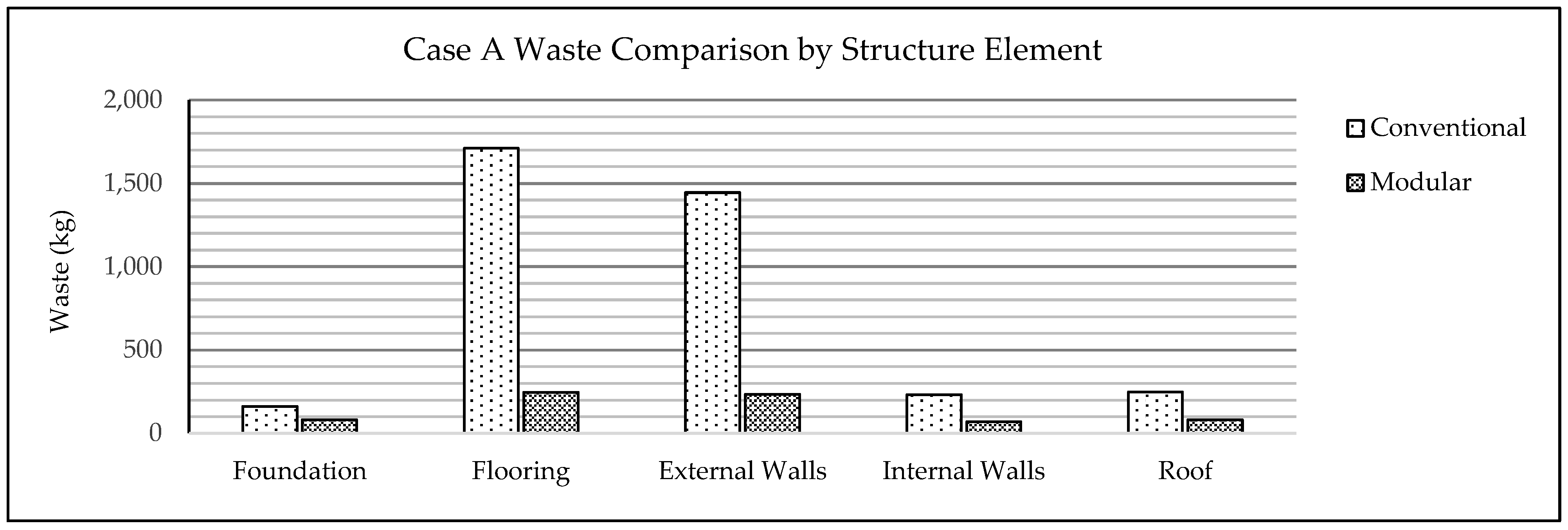

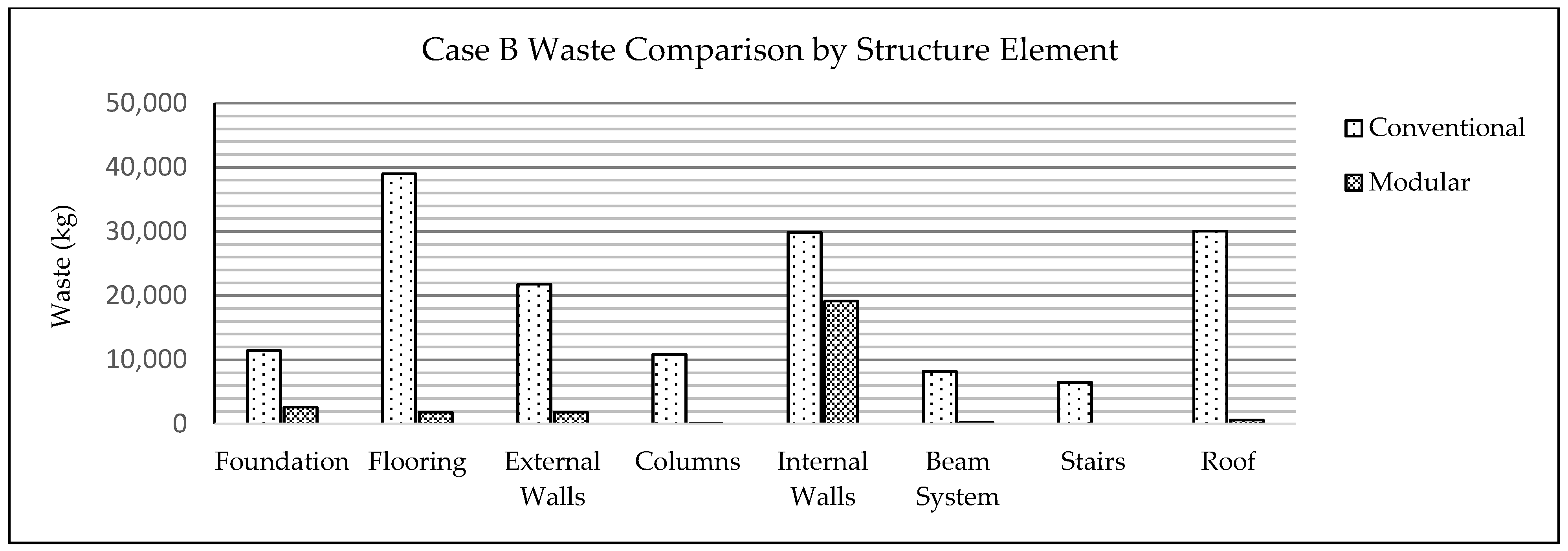

4.3. Waste Comparison

5. Discussion

5.1. Waste and Weight

5.2. Cost of Weight

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Category | Material | Guerra et al. [39] | Bakshan et al. [40] Lower Bound | Bakshan et al. [40] | Bakshan et al. [40] Upper Bound | Li et al. [17] | Li et al. [17] typical | Malia et al. [41] Residential Lower Bound | Malia et al. [41] Residential Upper Bound | Lu et al. [42] | Kim [27] | Treloar et al. [43] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete | Poured concrete | 1767.1 | 207.3 | 548.1 | 2526.3 | 896.9 | 1349.8 | 1121.4 | 2072.7 | 1198.8 | - | 4440.0 |

| Steel | Reinforcement | - | 6.9 | 78.8 | 453.6 | 25.6 | 39.1 | 12.6 | 163.8 | 24.7 | 76.1 | 83.0 |

| Battens | - | 3.1 | 4.7 | 3.0 | 9.1 | 9.9 | ||||||

| Bitumen | Bitumen | - | - | - | - | - | - | 25.2 | 163.8 | - | - | - |

| Masonry | Bricks | 214.2 | 1098.7 | 3691.8 | 1092.2 | 423.6 | 1209.6 | 3691.8 | 1561.5 | - | 1038.3 | |

| Timber | Formwork | - | - | - | - | 81.3 | 101.7 | - | - | 5.3 | 12.5 | - |

| Internal walls | - | 62.4 | 274.1 | 478.8 | - | - | 157.5 | 403.2 | - | 60.3 | 72.9 | |

| Joists | - | - | 73.5 | 88.8 | ||||||||

| Tiling | Roof tiles | - | 20.8 | 126.0 | 201.6 | 154.5 | 75.6 | 107.1 | 201.6 | - | - | - |

| Plaster-board | Plasterboard | 127.3 | 22.1 | 19.5 | 378.0 | - | - | 170.1 | 478.8 | - | 47.6 | 79.7 |

| Insulation | Type 1, roof insulation and vapour barrier | - | - | - | - | - | - | 6.3 | 75.6 | - | - | - |

| Category | Material | Guerra et al. [39] | Bakshan et al. [40] Lower Bound | Bakshan et al. [40] | Bakshan et al. [40] Upper Bound | Li et al. [17] | Li et al. [17] Typical | Malia et al. [41] Residential Lower Bound | Malia et al. [41] Residential Upper Bound | Lu et al. [42] | Kim [27] | Treloar et al. [43] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete | Poured concrete | 50,244 | 7304 | 19,314 | 89,022 | 25,500 | 38,377 | 40,626 | 89,022 | 34,085 | 126,240 | |

| Screed | 16,788 | 8520 | 12,823 | 11,389 | 42,180 | |||||||

| 10 mm CFC | 101,952 | 777 | 688 | 13,320 | 5772 | 13,986 | 38,152 | 63,800 | ||||

| Steel | Reinforcement | - | 244 | 2775 | 15,984 | 2236 | 3408 | 2220 | 15,984 | 2149 | 6634 | 7235 |

| Bitumen | Bitumen | - | - | - | - | - | - | 1554 | 14,652 | - | - | - |

| Masonry | Bricks | - | 7548 | 38,717 | 130,092 | 9612 | 3728 | 34,632 | 120,546 | 13,741 | - | 9137 |

| Other | - | 11,796 | 4575 | 16,865 | - | 11,213 | ||||||

| Timber | Formwork | - | - | - | - | 31,030 | 38,788 | - | - | 2040 | 4782 | - |

| Insulati-on | Wall insulation | - | - | - | - | - | - | 222 | 3330 | - | - | - |

| Roof insulation | - | - | - | - | - | - | - | - | - |

References

- Thirunavukkarasu, K.; Kanthasamy, E.; Gatheeshgar, P.; Poologanathan, K.; Rajanayagam, H.; Suntharalingam, T.; Dissanayake, M. Sustainable Performance of a Modular Building System Made of Built-Up Cold-Formed Steel Beams. Buildings 2021, 11, 460. [Google Scholar] [CrossRef]

- Almahmoud, E.; Doloi, H.K. Identifying the Key Factors in Construction Projects That Affect Neighbourhood Social Sustainability. Facilities 2020, 38, 765–782. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of Performance Criteria for Sustainability Evaluation of Modular versus Conventional Construction Methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life Cycle Performance of Modular Buildings: A Critical Review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Chen, Y.; Okudan, G.E.; Riley, D.R. Sustainable Performance Criteria for Construction Method Selection in Concrete Buildings. Autom. Constr. 2010, 19, 235–244. [Google Scholar] [CrossRef]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of Parametric Design into Modular Coordination: A Construction Waste Reduction Workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Pickin, J.; Randell, P.; Trinh, J.; Grant, B. National Waste Report 2018; Department of the Environment and Energy: Canberra, Australia, 2018. [Google Scholar]

- Osmani, M. Chapter 15—Construction Waste. In Waste: A Handbook for Management; Letcher, T.M., Vallero, D.A.B.T.-W., Eds.; Academic Press: Boston, MA, USA, 2011; pp. 207–218. ISBN 978-0-12-381475-3. [Google Scholar]

- Wang, J.; Li, Z.; Tam, V.W.Y. Critical Factors in Effective Construction Waste Minimization at the Design Stage: A Shenzhen Case Study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Jaques, R. Construction Site Waste Generation—The Influence of Design and Procurement. Archit. Sci. Rev. 2000, 43, 141–145. [Google Scholar] [CrossRef]

- Bertman, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey & Company: New York, NY, USA, 2019; pp. 1–34. [Google Scholar]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an Optimal Level of Prefabrication in Construction: An Analytical Framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Dave, M.; Watson, B.; Prasad, D. Performance and Perception in Prefab Housing: An Exploratory Industry Survey on Sustainability and Affordability. Procedia Eng. 2017, 180, 676–686. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X. Sustainability Perceptions of Off-Site Manufacturing Stakeholders in Australia. J. Clean. Prod. 2019, 227, 346–354. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical Evaluation of Off-Site Construction Research: A Scientometric Analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Johanson, B. Prefab and the Australian Building Sector. Available online: https://builtoffsite.com.au/emag/issue-01/prefab-australian-building-sector/ (accessed on 4 December 2020).

- Li, J.; Ding, Z.; Mi, X.; Wang, J. A Model for Estimating Construction Waste Generation Index for Building Project in China. Resour. Conserv. Recycl. 2013, 74, 20–26. [Google Scholar] [CrossRef]

- Hammad, A.W.A.; Akbarnezhad, A.; Wu, P.; Wang, X.; Haddad, A. Building Information Modelling-Based Framework to Contrast Conventional and Modular Construction Methods through Selected Sustainability Factors. J. Clean. Prod. 2019, 228, 1264–1281. [Google Scholar] [CrossRef]

- Al-Hussein, M.; Manrique, J.; Mah, D. North Ridge CO2 Analysis Report: Com Parison between Modular and on Site Construction; University of Alberta: Edmontom, AB, Canada, 2009; pp. 1–20. [Google Scholar]

- Baldwin, A.; Poon, C.-S.; Shen, L.-Y.; Austin, S.; Wong, I. Designing out Waste in High-Rise Residential Buildings: Analysis of Precasting Methods and Traditional Construction. Renew. Energy 2009, 34, 2067–2073. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life Cycle Greenhouse Gas Emissions and Energy Analysis of Prefabricated Reusable Building Modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An Embodied Carbon and Energy Analysis of Modern Methods of Construction in Housing: A Case Study Using a Lifecycle Assessment Framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters: Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Dabirian, S.; Han, S.H.; Lee, J. Stochastic-Based Noise Exposure Assessment in Modular and off-Site Construction. J. Clean. Prod. 2020, 244, 118758. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New Advancements, Challenges and Opportunities of Multi-Storey Modular Buildings—A State-of-the-Art Review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of Modular Construction in High-Rise Buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Kim, D. Preliminary Life Cycle Analysis of Modular and Conventional Housing in Benton Harbor, MI. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2008. [Google Scholar]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life Cycle Design and Prefabrication in Buildings: A Review and Case Studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable Construction Aspects of Using Prefabrication in Dense Urban Environment: A Hong Kong Case Study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the Waste Reduction Potential of Using Prefabrication in Building Construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Chan, J.K.W.; Ng, W.C.Y. Use of Prefabrication to Minimize Construction Waste-a Case Study Approach. Int. J. Constr. Manag. 2005, 5, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the Impact of Prefabrication on Construction Waste Reduction: An Empirical Study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I. The foundations of lean construction. In Design and Construction: Building in Value; Routledge: London, UK, 2002; pp. 211–226. [Google Scholar]

- Demirkesen, S.; Bayhan, H.G. A Lean Implementation Success Model for the Construction Industry. Eng. Manag. J. 2020, 32, 219–239. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A.; Ennadi, A.; El Hammoumi, M. The Practical Relationships between Lean Construction Tools and Sustainable Development: A Literature Review. J. Eng. Sci. Technol. Rev. 2017, 10, 170–177. [Google Scholar] [CrossRef]

- Hosseini, S.A.A.; Nikakhtar, A.; Wong, K.Y.; Zavichi, A. Implementing lean construction theory into construction processes’ waste management. In ICSDC 2011: Integrating Sustainability Practices in the Construction Industry; ASCE: Reston, VA, USA, 2012; pp. 414–420. [Google Scholar]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-Based Automated Construction Waste Estimation Algorithms: The Case of Concrete and Drywall Waste Streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M. A Field Based Methodology for Estimating Waste Generation Rates at Various Stages of Construction Projects. Resour. Conserv. Recycl. 2015, 100, 70–80. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and Demolition Waste Indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H.; Li, J.; Hao, J.J.L.; Mi, X.; Ding, Z. An Empirical Investigation of Construction and Demolition Waste Generation Rates in Shenzhen City, South China. Waste Manag. 2011, 31, 680–687. [Google Scholar] [CrossRef] [Green Version]

- Treloar, G.J.; Gupta, H.; Love, P.E.D.; Nguyen, B. An Analysis of Factors Influencing Waste Minimisation and Use of Recycled Materials for the Construction of Residential Buildings. Manag. Environ. Qual. An Int. J. 2003, 14, 134–145. [Google Scholar] [CrossRef]

- Australian Institute of Building Volume 1 NCC- National Construction Code; Australian Institute of Building: Canberra, Australia, 2016.

- Stratco. Stratco Roofing Battens. Available online: https://www.stratco.com.au/siteassets/pdfs/steel_framing_roof_batten.pdf (accessed on 10 March 2021).

- Spanman. Weights of Building Materials. Available online: https://www.spanman.net/Members/Technical/Weight-Of-Building-Materials (accessed on 8 March 2021).

- MPW. Wall and Ceiling Panels. Available online: http://www.misterplywood.com.au/Products/Wall-and-Ceiling-Panels (accessed on 15 April 2021).

- Pavertrend. Pavertrend Asphalt/Hot Mix Tonnage Calculator. Available online: https://www.pavertrend.com.au/asphalt/asphalt-calculator (accessed on 9 March 2021).

- Knauf. Knauf External Stud Wall Framing Systems. Available online: https://knauf.solutions/products/metal-framing-systems/knauf-external-stud-wall-framing-systems/ (accessed on 9 March 2021).

- Millform. C-Section Purlin. Available online: https://millform.com.au/c-section-purlins (accessed on 8 March 2021).

- Fletcher Insulation. Pink Soundbreak High Performance Accoustic Insulation Technical Data Sheet. Available online: https://insulation.com.au/wp-content/uploads/2016/04/pink-soundbreak-technical-data-sheet.pdf (accessed on 10 March 2021).

- Insulfoam. Roof Insulation Systems Consistently Predictable Value. Available online: https://www.insulfoam.com/wp-content/uploads/2014/04/2016-Roofing_Manual_10-10-16-web.pdf (accessed on 10 March 2021).

- AustubeMills. Design Capacity Tables for Structural Steel Hollow Sections. Available online: https://www.libertygfg.com/media/164047/design-capacity-tables-for-structural-steel-hollow-sections.pdf (accessed on 8 March 2021).

- hySPAN. Span Guide for Residential Framing. Available online: https://www.dindas.com.au/f.ashx/pdf/dindas-hyspan-span-tables-oct13.pdf (accessed on 10 March 2021).

- HardiePanel. Certificate of Physical Properties Hardiepanel Compressed Sheets. Available online: http://www.bigrivergroup.com.au/wp-content/uploads/2016/05/HardiPanel-Physical-Properties.pdf (accessed on 8 March 2021).

- Johnston, M.P. Secondary Data Analysis: A Method of Which the Time Has Come. Qual. Quant. methods Libr. 2017, 3, 619–626. [Google Scholar]

- Boslaugh, S. An Introduction to Secondary Data Analysis. In Secondary Data Sources for Public Health: A Practical Guide; Cambridge University Press: New York, NY, USA, 2007; pp. 2–10. [Google Scholar]

- MacInnes, J. An Introduction to Secondary Data Analysis with IBM SPSS Statistics; Sage: Thousand Oaks, CA, USA, 2016; ISBN 1473986958. [Google Scholar]

- Busse, C. A Procedure for Secondary Data Analysis: Innovation by Logistics Service Providers. J. Supply Chain Manag. 2010, 46, 44–58. [Google Scholar] [CrossRef]

- Liew, J.Y.R.; Chua, Y.S.; Dai, Z. Steel Concrete Composite Systems for Modular Construction of High-Rise Buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef] [Green Version]

- Cameron, P.J.; Di Carlo, N.G. Piecing Together Modular: Understanding the Benefits and Limitations of Modular Construction Methods for Multifamily Development. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

| Researcher(s) | Results |

|---|---|

| Dabirian et al. [24] | Prefabrication facilities produce more noise than on-site construction. |

| Bertman et al. [11] | Construction times can be reduced by 50%. Reduced labour costs can outweigh increased material costs and reduce overall cost by 20%. |

| Ferdous et al. [25] | Modular construction results in better integration of supply chains; however, requires high investment costs as well as additional project planning. The modular industry in Australia will grow form 3% of construction in 2016 to 5–10% by 2030. |

| Hammad et al. [18] | Modular construction reduces embodied energy by 56% and 26% in small and large structures, respectively, and decreases construction time and speeds up the return on investment. |

| Kamali and Hewage [4] | Modular construction increases material consumption, reduces construction time, reduces labour cost and delivers a higher quality and more durable structure. |

| Aye et al. [21] | A steel prefabrication system can reduce material consumption by up to 78% when compared to conventional reinforced concrete construction; however, a 50% increase in embodied energy was observed. |

| Lawson et al. [26] | Modular construction reduces safety incidents by up to 80%, noise by 30–50%, delivery vehicle frequency by up to 70%, and embodied energy, while also improving acoustic insulation and thermal performance. |

| Quale et al. [23] | Modular construction increases water usage and eutrophication, and decreases greenhouse gas emissions, acidification, carcinogens, non-carcinogens, criteria pollutants, ecotoxicity, smog, and ozone depletion. |

| Monahan and Powell [22] | Modular construction reduces embodied carbon by 34% cradle to site. |

| Al-Hussein et al. [19] | Modular construction reduces direct emissions by 43%, minimises injuries due to falls, and causes a 10–30% cost reduction due to productivity increase and reduced maintenance cost due to improved structure ‘tightness.’ |

| Baldwin et al. [20] | There is little difference between modular and conventional overall costs; however, there is potential for cost reduction due to labour cost reduction. |

| Kim [27] | Modular construction produces less waste and uses less energy over its lifespan and during the extraction, production, transport, and construction stages. |

| Material | Guerra et al. [39] | Bakshan et al. [40] | Li et al. [17] | Malia et al. [41] | Lu et al. [42] | Kim [27] | Treloar et al. [43] |

|---|---|---|---|---|---|---|---|

| Steel | - | 1.25 (0.11–7.2 range) | 3.09% (4.71% typical) | 0.2–2.6 (residential) 1–7.2 (non-residential) | 2.97% | 9.17% | 10% |

| Bitumen | - | - | - | 0.4–2.6 (residential) 0.7–6.6 (non-residential) | - | - | - |

| Masonry | - | 17.44 (3.4–58.6 range) | 5.26% (2.04% typical) | 19.2–58.6 (residential) 15.6–54.3 (non-residential) | 7.52% | - | 5% |

| Timber | - | 4.35 (0.99–7.6 range) | - | 2.5–6.4 (residential) 1.7–5.4 (non-residential) | - | 8.28% | 10% |

| Formwork | - | - | 80% (100% typical) | - | 5.26% | 12.33% | - |

| Tiles | - | 2 (0.33–3.2 range) | 4.17% (2.04% typical) | 1.7–3.2 (residential) 0.4–3.2 (non-residential) | - | - | - |

| Plasterboard | 15.98% | 0.31 (0.35–6 range) | - | 3.7–7.6 (residential) 2.6–6.3 (non-residential) | - | 5.98% | 10% |

| Insulation | - | - | - | 0.1–1.2 (residential) 0.1–1.5 (non-residential) | - | - | - |

| Estimation method 1 | MLR | GFA | MLR | GFA | MLR | MLR | MLR |

| Construction Stage | Conventional Case A | Conventional Case B |

|---|---|---|

| Stage 1 | Step 1—Excavation Step 2—Foundation (Steel work, formwork, and concrete pouring) Step 3—Backfill | |

| Stage 2 | Slab on grade (Steel work, formwork, and concrete pouring) | Step 1: Slab on grade (Steel work, formwork, and concrete pouring) Step 2: 1st level columns (Steel work, formwork, and concrete pouring) Step 3: Brickwork |

| Stage 3 | Walls (Brickwork and Insulation) | Step 1: 2nd level slab (Steel work, formwork, and concrete pouring) Step 2: 2nd level columns (Steel work, formwork, and concrete pouring) Step 3: Brickwork |

| Stage 4 | Step 1: Roof (Frame, tiling, and insulation) Step 2: Internal finishes | Step 1: 3rd level slab (Steel work, formwork, and concrete pouring) Step 2: 3rd level columns (Steel work, formwork, and concrete pouring) Step 3: Brickwork Step 4: Internal finishes |

| Material 1 | Bulk Density 2 | Case A | Case B | ||

|---|---|---|---|---|---|

| Conventional | Modular | Conventional | Modular | ||

| Concrete - Poured concrete - Screed - 10 mm CFC | 2400 kg/m3 1900 kg/m3 1595 kg/m3 | 37 m3 - - | 0.6 m3 - - | 1052 m3 444 m3 400 m3 | 25 m3 - 400 m3 |

| Steel - Reinforcement - Roof sheeting - Roof flashing - Battens - C115 Purlin - C181 Purlin - 110 PFC - 140 PFC - 200 PFC - 380 PFC - 400 PFC - 75 mm light steel - 90 mm light steel - Light steel studs - 75 SHS | N/A 10 kg/m2 9 kg/m 0.71 kg/m 3.706 kg/m 5.236 kg/m 9.758 kg/m 15.38 kg/m 22.9 kg/m 55.2 kg/m 58.105 kg/m 1.41 kg/m 1.53 kg/m 1.41 kg/m 10.3 kg/m | 0.83 t - - 140 m - - - - - - - - - - - | 0.04 t 64 m2 30 m 51 m 115 m - 48 m - 63 m - 52 m 86 m - 10.3 m - | 72.35 t - - - - - - - - - - - - - - | 0.642 t 740 m2 210 m 629 m - 2673 m - 288 m 144 m 810 m 52 m - 842 m - 528 m |

| Masonry - Bricks - Other masonry | 830.6 kg/m3 830.6 kg/m3 | 25 m3 - | - - | 220 m3 270 m3 | - - |

| Timber - Formwork - Internal walls - Joists | 10.7 kg/m2 7.59 kg/m2 5.445 kg/m | 9.5 m2 96 m2 163 m | 1.5 m2 - - | 3625 m2 - - | 87 m2 - - |

| Insulation - Type 1 - Wall insulation - Roof insulation - Vapour barrier - 6 mm PVC lining | 1.44 kg/m2 25 kg/m3 20.023 kg/m3 0.184 kg/m2 8.28 kg/m2 | 96 m2 - 19.5 m3 96 m2 - | - - 33 m3 - 72 m2 | - 990 m3 140 m3 - - | - - 555 m3 - - |

| Other - Bitumen - Roof tiles - Plasterboard | 20.833 kg/m2 57 kg/m2 8.3 kg/m2 | 13 m2 65 m2 96 m2 | 6 m2 - 96 m2 | 740 m2 - - | 93 m2 - - |

| Category/Material | Quantity Take off (kg) | Average Waste (kg) | Total Material (kg) | MLR 1 (%) |

|---|---|---|---|---|

| Concrete (poured concrete) | 88,800.00 | 1674.35 | 90,474.83 | 1.89 |

| Steel | 929.40 | 66.68 | 996.08 | 7.17 |

| 830.00 | 49.70 | 879.70 | 5.99 |

| 99.40 | 5.95 | 105.35 | 5.99 |

| Bitumen | 270.83 | 94.50 | 365.33 | 34.89 |

| Masonry (brick) | 20,765.00 | 1445.11 | 22,210.11 | 6.96 |

| Timber (excluding formwork) | 1717.83 | 226.04 | 1943.87 | 13.99 |

| 728.64 | 66.60 | 795.24 | 9.14 |

| 887.54 | 81.12 | 968.66 | 9.14 |

| Formwork | 101.65 | 50.21 | 151.86 | 49.40 |

| Tiles (roof tiles) | 3705.00 | 132.96 | 3837.96 | 3.59 |

| Plasterboard | 796.80 | 153.85 | 950.65 | 19.31 |

| Insulation | 546.35 | 40.95 | 587.30 | 7.50 |

| 138.24 | No data | N/A | N/A |

| 390.45 | No data | N/A | N/A |

| 17.66 | No data | N/A | N/A |

| Category/Material | Quantity Take off (kg) | Average Waste (kg) | Total Material (kg) | MLR 1 (%) |

|---|---|---|---|---|

| Concrete (excluding CFC) | 3,368,400 | 61,143 | 4,067,543 | 1.82 |

| 2,524,800 | 54,889 | 2,579,689 | 2.17 |

| 843,600 | 18,340 | 861,940 | 2.17 |

| 10 mm CFC | 638,000 | 29,806 | 667,806 | 4.67 |

| Steel (Reinforcement) | 72,350 | 5887 | 78,237 | 8.14 |

| Bitumen | 15,416 | 8103 | 23,519 | 52.56 |

| Masonry | 406,994 | 45,800 | 452,794 | 11.25 |

| 182,732 | 9054 | 191,786 | 4.96 |

| 224,262 | 11,112 | 235,374 | 4.96 |

| Formwork | 38,788 | 19,160 | 57,948 | 49.40 |

| Insulation | 27,553 | 1776 | 29,329 | 6.45 |

| 24,750 | No data | N/A | N/A |

| 2803 | No data | N/A | N/A |

| Category/Material | Quantity Take off (kg) | Average Waste (kg) | Total Material (kg) | MLR 1 (%) |

|---|---|---|---|---|

| Concrete (poured concrete) 2 | 1440.00 | 27.22 | 1467.22 | 1.89 |

| Steel | 6344.94 | 318.12 | 6663.06 | 5.01 |

| 40.00 | 2.87 | 42.87 | 7.17 |

| 36.21 | 1.81 | 38.02 | 5 |

| 640.00 | 32.00 | 672.00 | 5 |

| 426.19 | 21.31 | 447.50 | 5 |

| 468.38 | 23.42 | 491.80 | 5 |

| 1442.70 | 72.14 | 1514.84 | 5 |

| 3021.46 | 151.07 | 3172.53 | 5 |

| 270.00 | 13.50 | 283.5 | 5 |

| Light steel | 4212.38 | 210.62 | 4423.00 | 5 |

| 4197.86 | 209.89 | 4407.75 | 5 |

| 14.52 | 0.73 | 15.25 | 5 |

| Bitumen 2 | 125.00 | 43.61 | 168.61 | 34.89 |

| Formwork 2 | 16.05 | 7.93 | 23.98 | 49.40 |

| Plasterboard | 796.80 | 39.84 | 836.64 | 5 |

| Insulation | 1256.92 | 62.85 | 1319.77 | 5 |

| 660.76 | 33.04 | 693.80 | 5 |

| 596.16 | 29.81 | 625.97 | 5 |

| Category/Material | Quantity Take off (kg) | Average Waste (kg) | Total Material (kg) | MLR 1 (%) |

|---|---|---|---|---|

| Concrete | 698,000 | 20,232 | 718,232 | 2.90 |

| 60,000 | 1092 | 61,092 | 1.82 |

| 638,000 | 19,140 | 657,140 | 3 |

| Steel | 85,318 | 2593 | 87,911 | 3.04 |

| 642 | 52 | 694 | 8.14 |

| 491 | 15 | 506 | 3 |

| 7400 | 222 | 7622 | 3 |

| 13,996 | 420 | 14,416 | 3 |

| 4429 | 133 | 4562 | 3 |

| 3298 | 99 | 3397 | 3 |

| 44,712 | 1341 | 46,053 | 3 |

| 3021 | 91 | 3112 | 3 |

| 5438 | 163 | 5602 | 3 |

| 1890 | 57 | 1947 | 3 |

| Light steel | 58,949 | 1768 | 60,718 | 3 |

| 58,512 | 1755 | 60,267 | 3 |

| 438 | 13 | 451 | 3 |

| Bitumen 2 | 1937 | 1018 | 2956 | 52.56 |

| Formwork 2 | 931 | 460 | 1391 | 49.40 |

| Insulation (roof) | 11,113 | 333 | 11,446 | 3 |

| Structure Element | Case A | Case B | ||||

|---|---|---|---|---|---|---|

| Conventional Waste (kg) | Modular Waste (kg) | % Change | Conventional Waste (kg) | Modular Waste (kg) | % Change | |

| Foundation | 161 | 82 | −49.1 | 11,439 | 2622 | −77.1 |

| Flooring structure (plus chassis for modular) | 1712 | 245 | −85.7 | 38,994 | 1852 | −95.3 |

| External walls | 1445 | 233 | −83.9 | 21,783 | 1822 | −91.6 |

| Columns | N/A | N/A | N/A | 10,838 | 96 | −99.1 |

| Internal walls | 232 | 70 | −69.8 | 29,795 | 19,153 | −35.7 |

| Beam system | N/A | N/A | N/A | 8211 | 232 | −97.17 |

| Stairs | N/A | N/A | N/A | 6520 | - | −100 |

| Roof | 248 | 82 | −66.9 | 30,049 | 627 | −97.9 |

| Sum | 3798 | 712 | −81.3 | 157,629 | 26,404 | −83.2 |

| Construction Method | Quantity Take off (kg) | Total Waste (kg) | Total Material (kg) | Waste Per 100 kg Total Material (kg) | |

|---|---|---|---|---|---|

| Case A | Conventional | 117,531 | 3798 | 121,329 | 3.13 |

| Modular | 14,192 | 712 | 14,904 | 4.78 | |

| Case B | Conventional | 4,567,501 | 157,629 | 4,725,130 | 3.34 |

| Modular | 856,248 | 26,404 | 882,652 | 2.99 |

| Material | Cost/kg 1 (AUD) | Cost of Waste, Case A (AUD) | Cost of Waste, Case B (AUD) | ||

|---|---|---|---|---|---|

| Conventional | Modular | Conventional | Modular | ||

| Concrete - Poured Concrete - Screed - 10 mm CFC | 0.10 1.85 3.78 | 171.62 - - | 2.79 - - | 5626.12 33,929.00 112,664.81 | 111.93 - 72,348.00 |

| Steel - Reinforcement - Roof sheeting - Roof flashing - Battens - C115 Purlin - C181 Purlin - 110 PFC - 140 PFC - 200 PFC - 380 PFC - 400 PFC - 90 mm light steel - Light steel studs - 75 SHS - Walls | 1.52 7.70 0.61 6.38 2.14 2.18 2.70 2.51 2.76 2.48 2.50 8.49 8.34 2.52 21.52 | 75.30 - 37.96 - - - - - - - - - - - | 4.35 246.24 8.30 11.55 45.60 - 63.19 - 199.13 - 377.43 - 6.09 - 4516.08 | 8918.81 - - - - - - - - - - - - - | 78.78 1708.29 35.02 95.70 - 916.84 - 334.06 273.27 3327.72 227.36 110.37 - 411.46 37,761.27 |

| Masonry - Bricks - Other Masonry | 0.59 0.59 | 856.23 - | - - | 5364.50 6583.86 | - - |

| Timber - Formwork - Internal Walls - Joists | 2.48 7.14 3.32 | 124.45 475.33 269.66 | 19.65 - - | 47,488.15 - - | 1140.11 - - |

| Other - Bitumen - Roof tiles - Plasterboard | 1.27 0.56 0.74 | 119.75 75.11 114.37 | 55.26 - 29.62 | 10,268.29 - - | 1290.03 - - |

| Sum | 2319.76 | 5585.27 | 230,843.53 | 120,170.21 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loizou, L.; Barati, K.; Shen, X.; Li, B. Quantifying Advantages of Modular Construction: Waste Generation. Buildings 2021, 11, 622. https://doi.org/10.3390/buildings11120622

Loizou L, Barati K, Shen X, Li B. Quantifying Advantages of Modular Construction: Waste Generation. Buildings. 2021; 11(12):622. https://doi.org/10.3390/buildings11120622

Chicago/Turabian StyleLoizou, Loizos, Khalegh Barati, Xuesong Shen, and Binghao Li. 2021. "Quantifying Advantages of Modular Construction: Waste Generation" Buildings 11, no. 12: 622. https://doi.org/10.3390/buildings11120622

APA StyleLoizou, L., Barati, K., Shen, X., & Li, B. (2021). Quantifying Advantages of Modular Construction: Waste Generation. Buildings, 11(12), 622. https://doi.org/10.3390/buildings11120622