Super Insulation Materials—An Application to Historical Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Materials

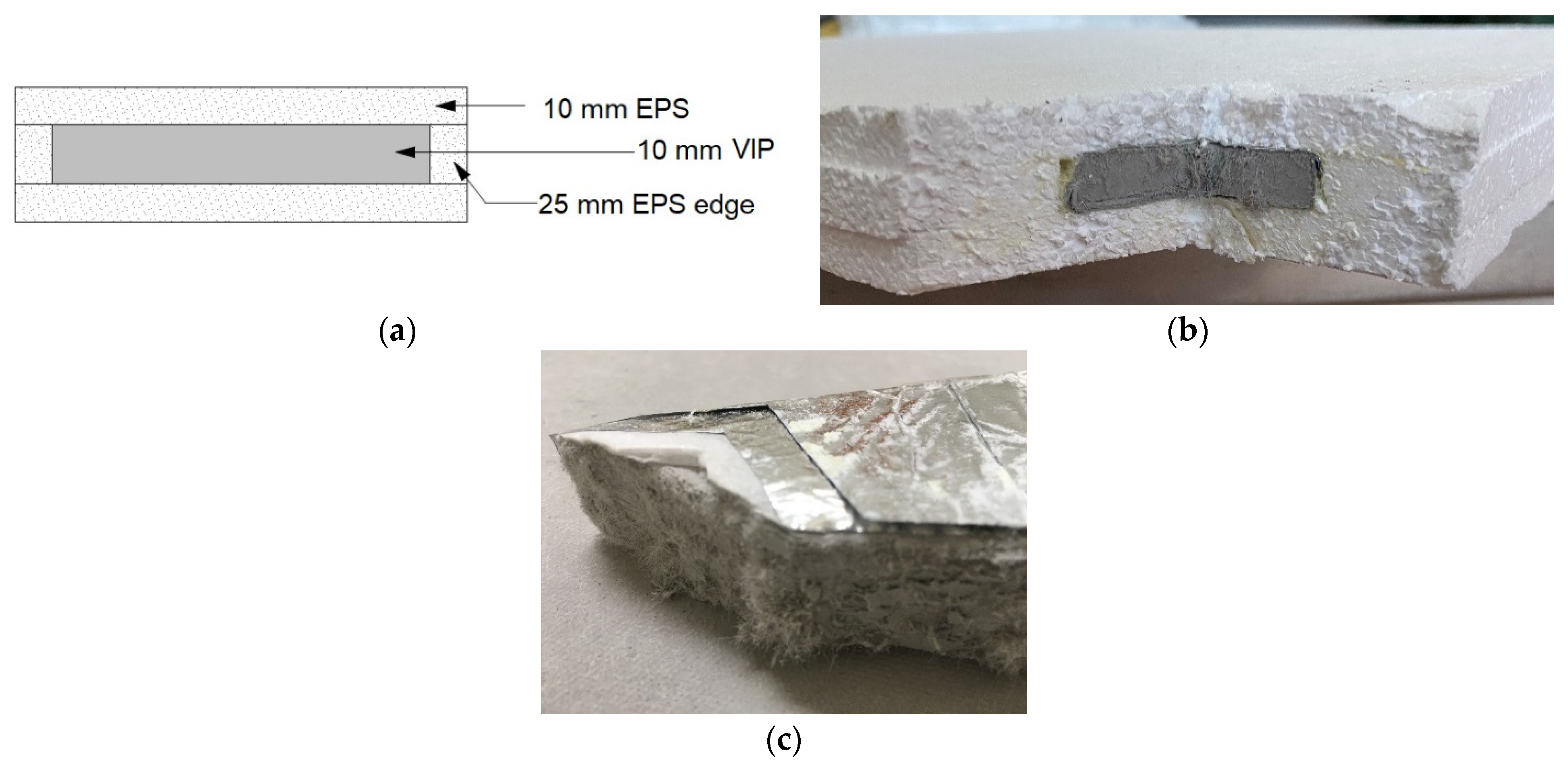

2.1.1. Vacuum Insulation Panel

2.1.2. Aerogel Insulations

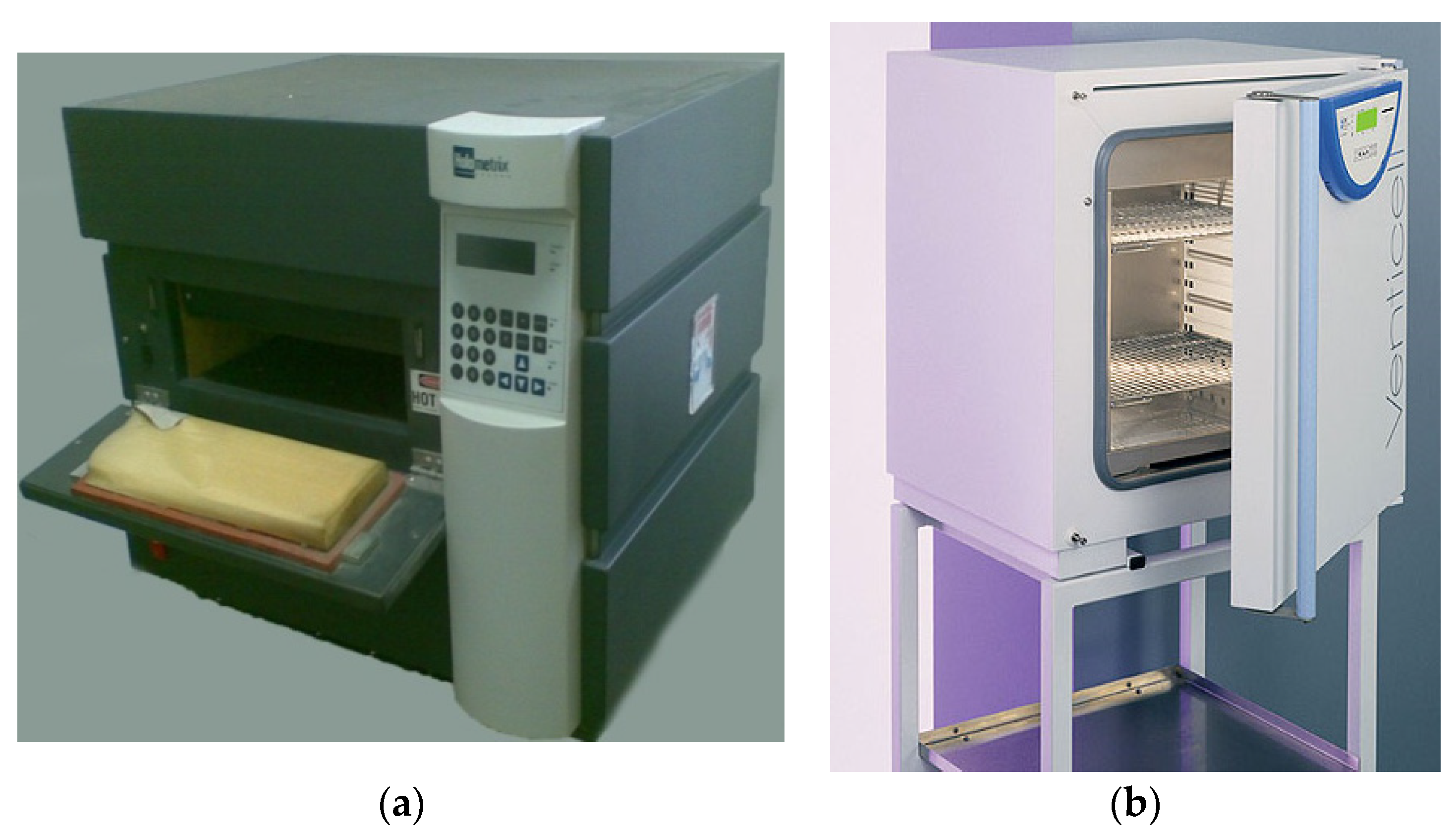

2.1.3. Thermal Conductivity Measurements

3. Results

3.1. Measurement Results

3.1.1. Slentex Insulation Results

3.1.2. Vacuum Panel Results

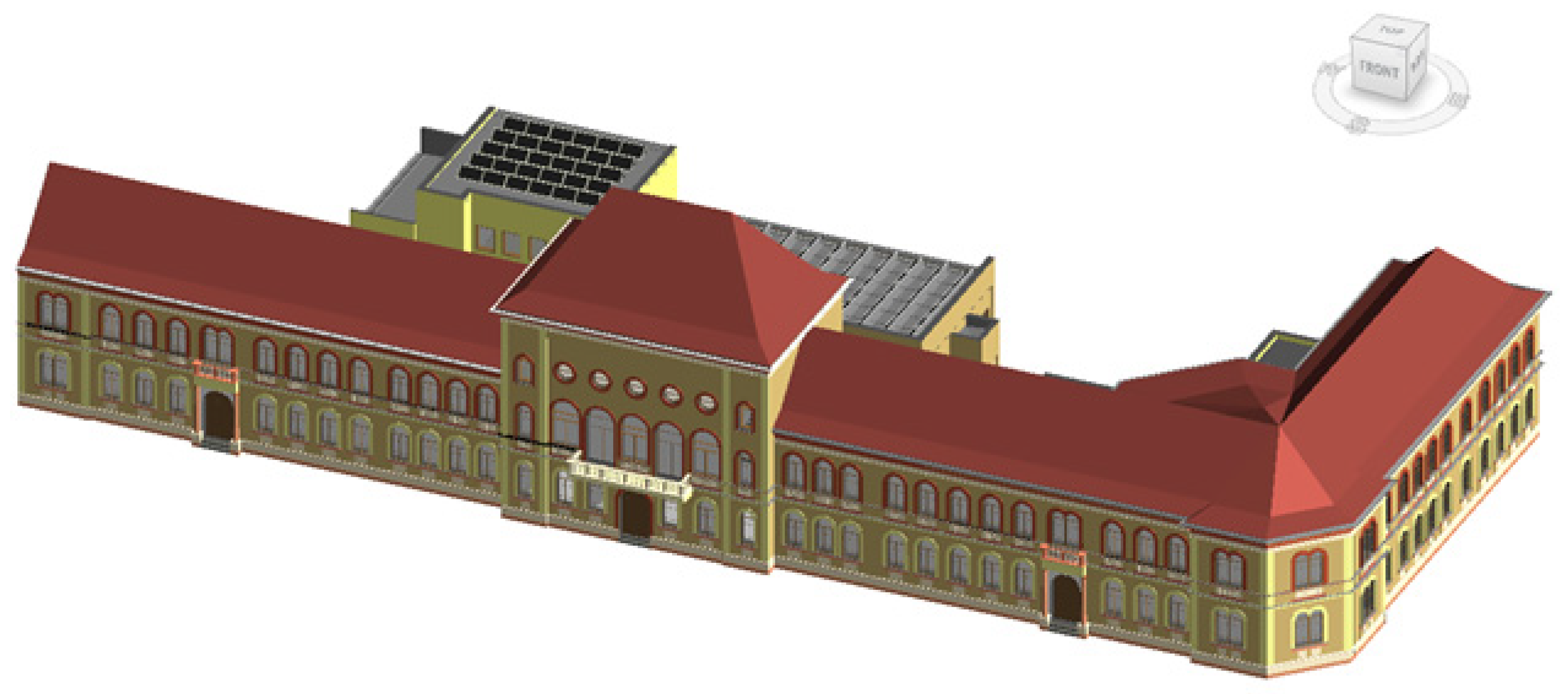

3.2. The Model Building

3.2.1. BIM (Building Information Modeling) of the Building

3.2.2. Calculation Results on the U-Values of the Building

3.2.3. Cost Calculations—Use of Natural Gas

3.2.4. Cost of Renovation—Thermal Insulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Building Element | Information |

|---|---|

| External wall: | 50 cm thick solid brick with 1.5 cm thick plaster at both sides. |

| Internal walls between internal heated spaces: | brick walls with 10 to 20 cm thicknesses |

| Windows: | Uw = 1.15 W/m2K, glazing ratio 80%, g-value of glazing: 0.87. |

| Doors: | Ud = 1.15/1.45 W/m2K. |

| Attic floor: | 0.55/0.876 W/m2K |

| Floor: | 0.554 W/m2K |

| Heating and hot water system: | Condensing gas boilers (VIESSMANN Vitodens 200-W—3 pieces) with two round radiators (60/40 °C). |

| Electricity: | 120 db KYOCERA KD 245GH-2PB 245Wp solar panel, produces 32,340 kWh/year electric energy |

References

- Riahinezhad, M.; Hallman, M.; Masson, J.-F. Critical Review of Polymeric Building Envelope Materials: Degradation, Durability and Service Life Prediction. Buildings 2021, 11, 299. [Google Scholar] [CrossRef]

- Sajjadian, S.M. Performance Evaluation of Well-Insulated Versions of Contemporary Wall Systems—A Case Study of London for a Warmer Climate. Buildings 2017, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Török, L. Industry 4.0 from a few aspects, in particular, in respect of the decision making of the Management, /Will the new industrial revolution change the traditional management functions. Int. Rev. Appl. Sci. Eng. 2020, 11, 140–146. [Google Scholar]

- Moga, L.M.; Bucur, A.; Iancu, I. Current Practices in Energy Retrofit of Buildings. In Springer Tracts in Civil Engineering; Springer Nature Switzerland AG: Cham, Switzerland, 2021; pp. 1–41. [Google Scholar]

- Heinemann, U.; Adl-Zarrabi, B.; Brunner, S.; Foray, G.; Johansson, P.; Kono, J.; Kücükpinar, E.; Milow, B.; Quénard, D.; Sprengard, C.; et al. IEA Annex 65 International Energy Agency (IEA)—Energy in Buildings and Communities (EBC) Annex 65 “Long-Term Performance of Super-Insulating-Materials (SIM) in Building Components and Systems”—Report of Subtask I: State of the Art and Case Studies; IEA. 3 January 2020. Available online: https://www.iea-ebc.org/projects/project?AnnexID=65 (accessed on 23 August 2020).

- Aegerter, A.; Leventis, N.; Koebel., M. (Eds.) Aerogels Handbook; Springer: New York, NY, USA, 2011; pp. 537–564. [Google Scholar]

- Lakatos, Á.; Csík, A.; Csarnovics, I. Experimental verification of thermal properties of the aerogel blanket. Case Studies Thermal Eng. 2021, 25, 100966. [Google Scholar] [CrossRef]

- Galliano, R.; Wakili, K.G.; Stahl Th Binder, B.; Daniotti, B. Performance evaluation of aerogel-based and perlite-based prototyped insulations for internal thermal retrofitting: HMT model validation by monitoring at demo scale. Energy Build. 2016, 12, 275–286. [Google Scholar] [CrossRef]

- Cannavale, A.; Martellotta, F.; Berardi, U.; Rubino, C.; Liuzzi, S.; De Carlo, V.; Ayr, U. Modeling of an Aerogel-Based “Thermal Break” for Super-Insulated Window Frames. Buildings 2020, 10, 60. [Google Scholar] [CrossRef] [Green Version]

- Buratti, C.; Moretti, E.; Zinzi, M. High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions. Buildings 2017, 7, 8. [Google Scholar] [CrossRef] [Green Version]

- Fantucci, S.; Fenoglio, E.; Grosso, G.; Serra, V.; Perino, M.; Marino, V.; Dutto, M. Development of an aerogel-based thermal coating for the energy retrofit and the prevention of condensation risk in existing buildings. Sci. Technol. Built Environ. 2019, 25, 1178–1186. [Google Scholar] [CrossRef] [Green Version]

- Cornaro, C.; Basciano, G.; Puggioni, V.A.; Pierro, M. Energy Saving Assessment of Semi-Transparent Photovoltaic Modules Integrated into NZEB. Buildings 2017, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Basińska, M.; Kaczorek, D.; Koczyk, H. Economic and Energy Analysis of Building Retrofitting Using Internal Insulations. Energies 2021, 14, 2446. [Google Scholar] [CrossRef]

- Andreotti, M.; Bottino-Leone, D.; Calzolari, M.; Davoli, P.; Dias Pereira, L.; Lucchi, E.; Troi, A. Applied Research of the Hygrothermal Behaviour of an Internally Insulated Historic Wall without Vapour Barrier: In Situ Measurements and Dynamic Simulations. Energies 2020, 13, 3362. [Google Scholar] [CrossRef]

- Ganobjak, M.; Brunner, S.; Wernery, J. Aerogel materials for heritage buildings: Materials, properties and case studies. J. Cult. Herit. 2020, 42, 81–98. [Google Scholar] [CrossRef]

- Wakili, K.G.; Stahl Th Heiduk, E.; Schuss, M.; Vonbank, R.; Pont, U.; Sustr, C.; Wolosiuk, D.; Mahdavi, D. High Performance Aerogel Containing Plaster for Historic Buildings with Structured Façades. Energy Proc. 2015, 78, 949–954. [Google Scholar] [CrossRef] [Green Version]

- Lucchi, E.; Becherini, F.; di Tuccio, M.C.; Troi, A.; Frick, J.; Roberti, F.; Hermann, C.; Fairnington, I.; Mezzasalma, G.; Pockelé, L.; et al. Thermal performance evaluation and comfort assessment of advanced aerogel asblown-in insulation for historic buildings. Build. Environ. 2017, 122, 258–268. [Google Scholar] [CrossRef]

- Alam, M.; Singh, H.; Limbachiya, M.C. Vacuum Insulation Panels (VIPs) for building construction industry—A review of the contemporary developments and future directions. Appl. Energy 2011, 88, 3592–3602. [Google Scholar] [CrossRef] [Green Version]

- Sprengard, C.; Holm, A.H. The thermal bridging effects are only reduced by covering layers made of insulating materials on the surfaces of the VIP. Energy Build. 2014, 85, 638–643. [Google Scholar] [CrossRef]

- Fantucci, S.; Garbaccio, S.; Lorenzati, A.; Perino, M. Thermo-economic analysis of building energy retrofits using VIP—Vacuum Insulation Panels. Energy Build. 2019, 196, 269–279. [Google Scholar] [CrossRef]

- Biswas, K.; Desjarlais, A.; Smith, D.; Letts, J.; Jiang, J.Y.T. Development and thermal performance verification of composite insulation boards containing foam-encapsulated vacuum insulation panels. Appl. Energy 2018, 228, 1159–1172. [Google Scholar] [CrossRef]

- Lakatos, Á.; Kovács, Z. Comparison of thermal insulation performance of vacuum insulation panels with EPS protection layers measured with different methods. Energy Build. 2021, 236, 110771. [Google Scholar] [CrossRef]

- Lakatos, Á. Comprehensive thermal transmittance investigations carried out on opaque aerogel insulation blanket. Materials Struct. 2017, 50, 1–12. [Google Scholar]

- Berardi, U.; Nosrati, R.H. Long-term thermal conductivity of aerogel-enhanced insulating materials under different laboratory aging conditions. Energy 2018, 147, 1188–1202. [Google Scholar] [CrossRef]

- Ihara, T.; Jelle, B.P.; Gao, T.; Gustavsen, A. Aerogel granule aging driven by moisture and solar radiation. Energy Build. 2015, 103, 238–248. [Google Scholar] [CrossRef]

- Lakatos, Á.; Csík, A.; Trník, A.; Budai, I. Effects of the Heat Treatment in the Properties of Fibrous Aerogel Thermal Insulation. Energies 2019, 12, 2001. [Google Scholar] [CrossRef] [Green Version]

- Lakatos, A. Investigation of the thermal insulation performance of fibrous aerogel samples under various hygrothermal environment: Laboratory tests completed with calculations and theory. Energy Build. 2020, 214, 109902. [Google Scholar] [CrossRef]

- Available online: https://www.aerogelszigeteles.hu/termekek (accessed on 20 October 2021).

- ISO 10456:2007. Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Barone, G.; Buonomano, A.; Forzano, C.; Giuzio, G.F.; Palombo, A. Improving the Efficiency of Maritime Infrastructures through a BIM-Based Building Energy Modelling Approach: A Case Study in Naples, Italy. Energies 2021, 14, 4854. [Google Scholar] [CrossRef]

- De Ruggiero, M.; Forestiero, G.; Manganelli, B.; Salvo, F. Buildings Energy Performance in a Market Comparison Approach. Buildings 2017, 7, 16. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Thermal performance of a selection of insulation mate-rials suitable for historic buildings. Build. Environ. 2015, 94 Pt 1, 155–165. [Google Scholar] [CrossRef]

- Wakili, K.G.; Dworatzyk, C.; Sanner, M.; Sengespeick, A.; Paronen, M.; Stahl, T. Energy efficient retrofit of a prefabricated concrete panel building (Plattenbau) in Berlin by applying an aerogel based rendering to its façades. Energy Build. 2018, 165, 293–300. [Google Scholar] [CrossRef]

| Slentex | Protected Vacuum Panel |

|---|---|

| Class A2-s1, d0 | Polystyrene and Fume Silica |

| Entirely mineral-based product | Sandwich panel 3 = core + foil covering (VIP) with aluminium/aluminium and circumferential EPS insert edge band |

| Thermal conductivity declared by the manufacturer: 0.019 W/mK | Thermal conductivity declared by the manufacturer VIPcop: 0.007 W/mK, PS: 0.035 W/mK |

| Open to diffusion | Polystyrene closed cell |

| Sold in rolls | Slabs |

| Non-combustible | Polystyrene is combustible, fume silica non-combustible |

| Measurement Row | Thermal Conductivity (W/mK) | Average Deviance (W/mK) |

|---|---|---|

| 1 | 0.021781 | 0.000197 |

| 2 | 0.021945 | 0.000033 |

| 3 | 0.022027 | 0.000049 |

| 4 | 0.0221 | 0.000132 |

| 5 | 0.022027 | 0.000049 |

| Average | 0.021978~0.022 | 0.000046 |

| Measurement Row | Thermal Conductivity (W/mK) | Average Deviance (W/mK) |

|---|---|---|

| 1 | 0.0206 | 0.0003 |

| 2 | 0.0207 | 0.0002 |

| 3 | 0.0211 | 0.0001 |

| 4 | 0.0210 | 0.0002 |

| 5 | 0.0211 | 0.0001 |

| Average | 0.0209~0.021 | 0.0001 |

| Case | U-Value (W/m2K) |

|---|---|

| U-value before renovation | 1.296 |

| U-vale with the Slentex insulation | 0.741 |

| U-value with VIP | 0.429 |

| State of the Building | Ep Specific Primary Energy Consumption (kWh/m2year) | Energetic Category According to 7/2006 Decree in Hungary | Yearly Use of Natural Gas (MWh/year) | Savings Compared to the Current State (%) |

|---|---|---|---|---|

| Current | 112.87 | DD (up-to-date) | 391.15 | - |

| With Slentex | 93.33 | CC (modern) | 328.48 | 16 |

| With VIP | 75.46 | CC (modern) | 273.44 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vajó, B.; Lakatos, Á. Super Insulation Materials—An Application to Historical Buildings. Buildings 2021, 11, 525. https://doi.org/10.3390/buildings11110525

Vajó B, Lakatos Á. Super Insulation Materials—An Application to Historical Buildings. Buildings. 2021; 11(11):525. https://doi.org/10.3390/buildings11110525

Chicago/Turabian StyleVajó, Brigitta, and Ákos Lakatos. 2021. "Super Insulation Materials—An Application to Historical Buildings" Buildings 11, no. 11: 525. https://doi.org/10.3390/buildings11110525

APA StyleVajó, B., & Lakatos, Á. (2021). Super Insulation Materials—An Application to Historical Buildings. Buildings, 11(11), 525. https://doi.org/10.3390/buildings11110525