Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review

Abstract

1. Introduction

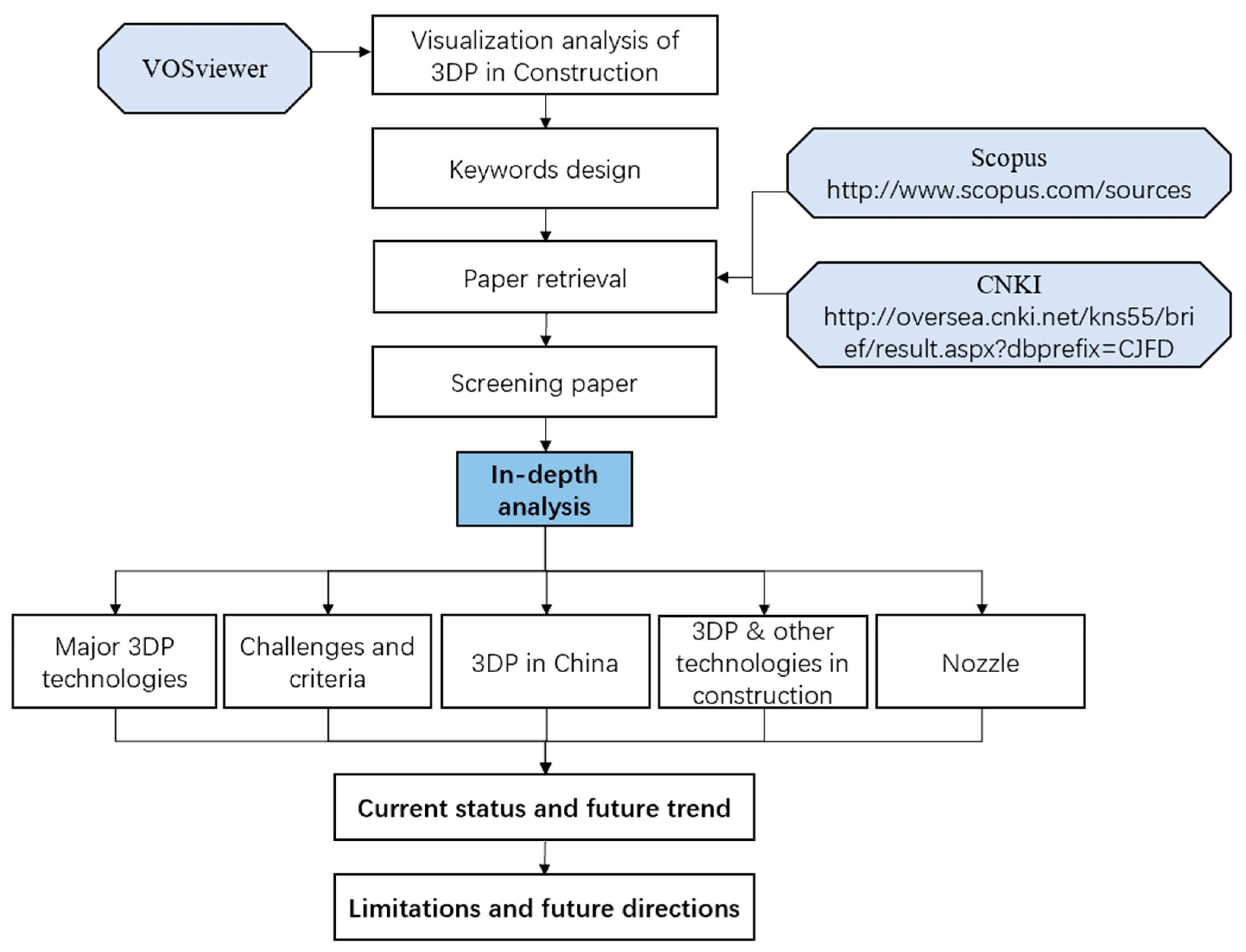

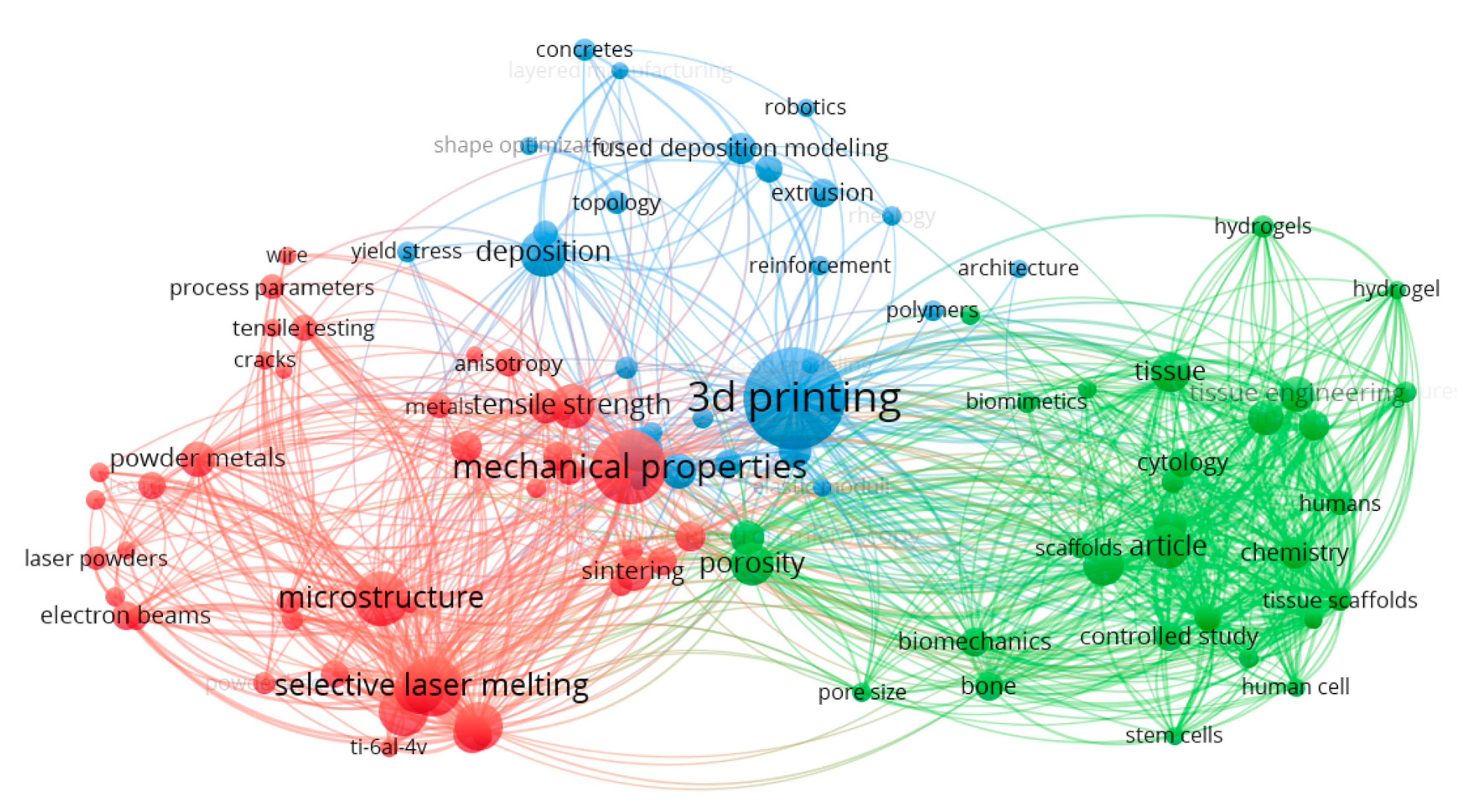

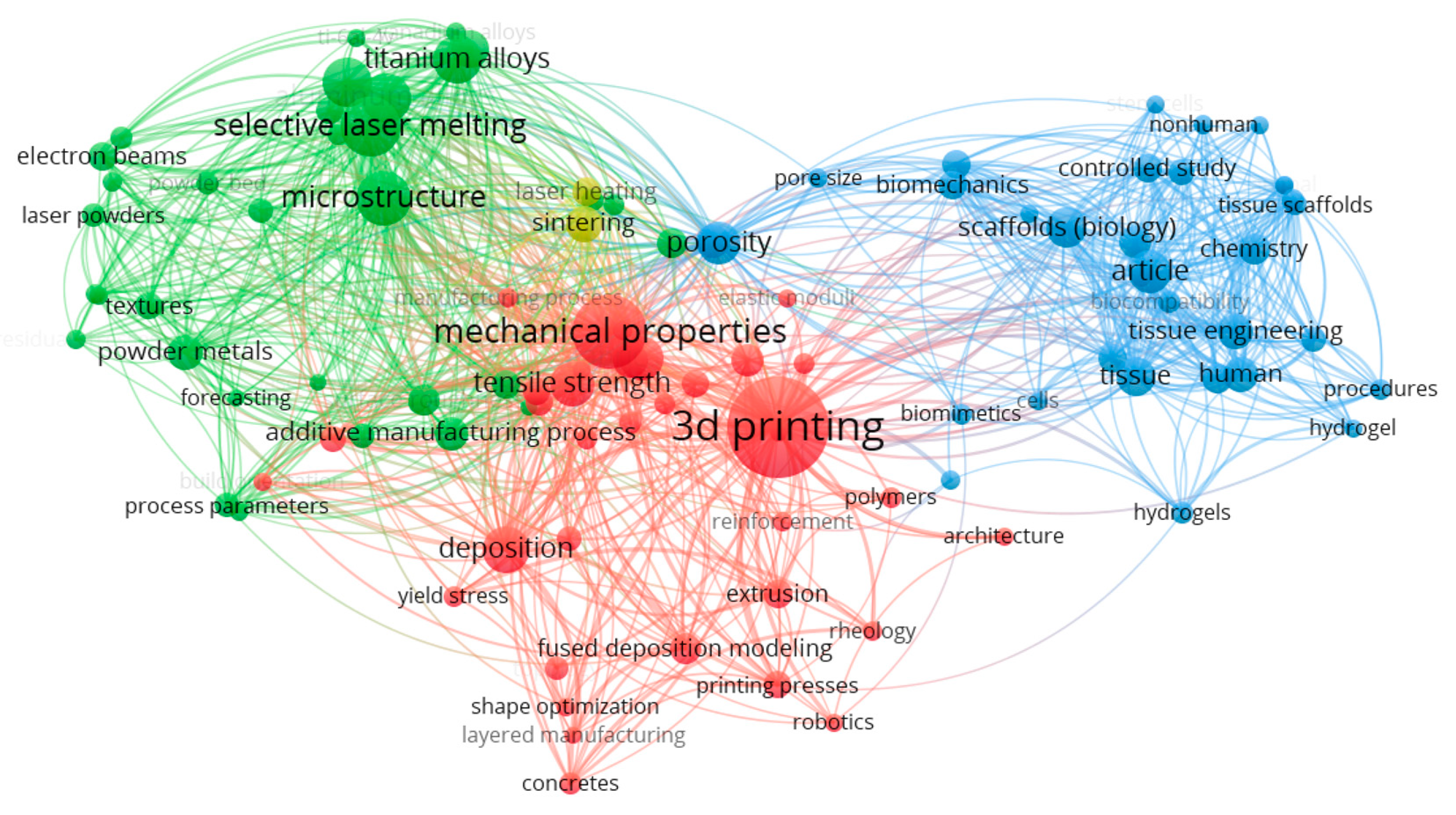

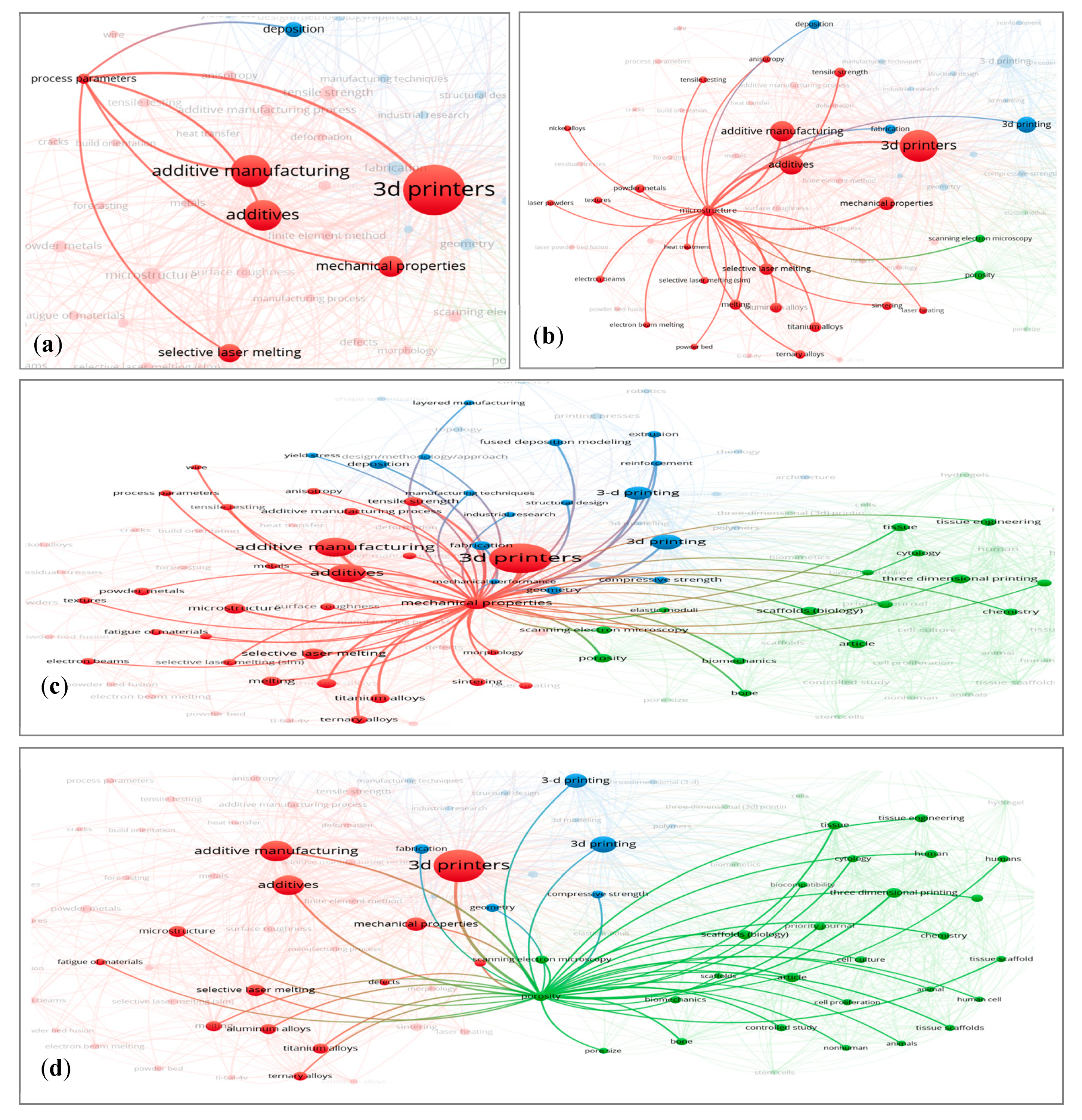

2. Research Method

3. Results

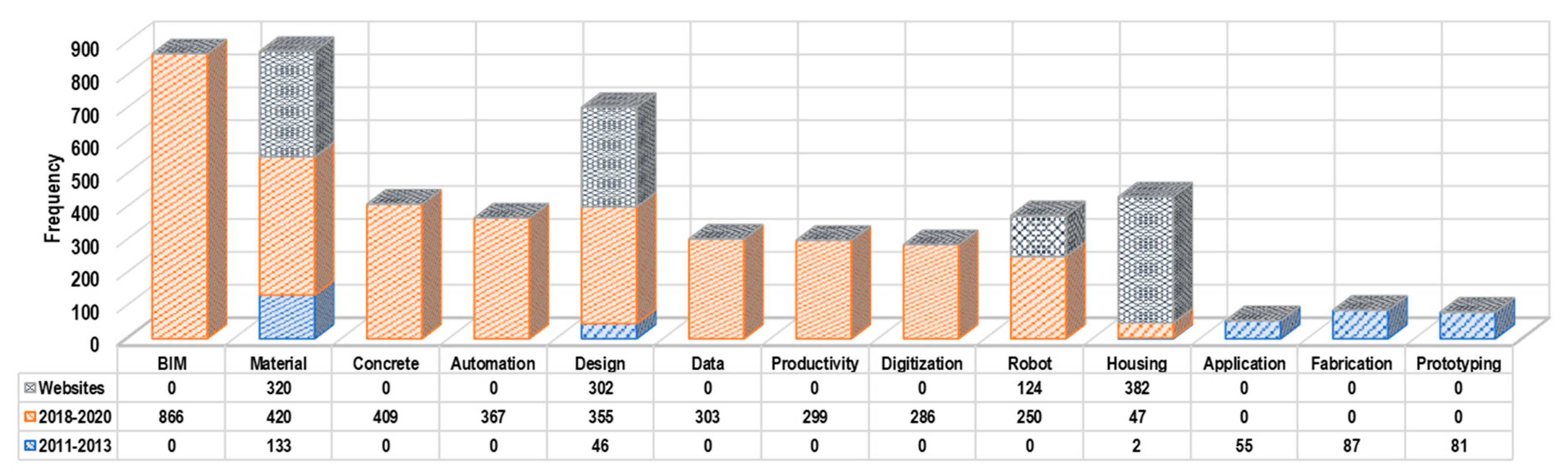

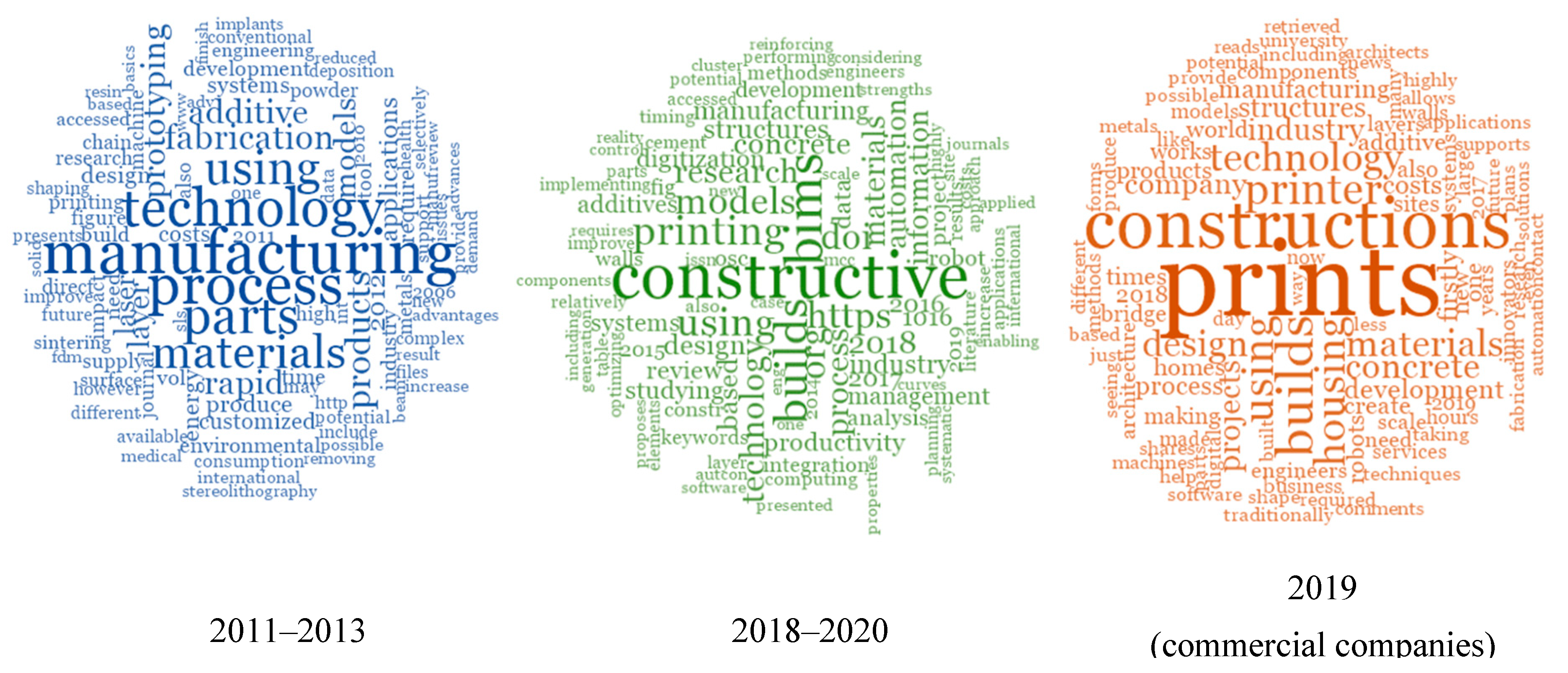

3.1. Content Analysis

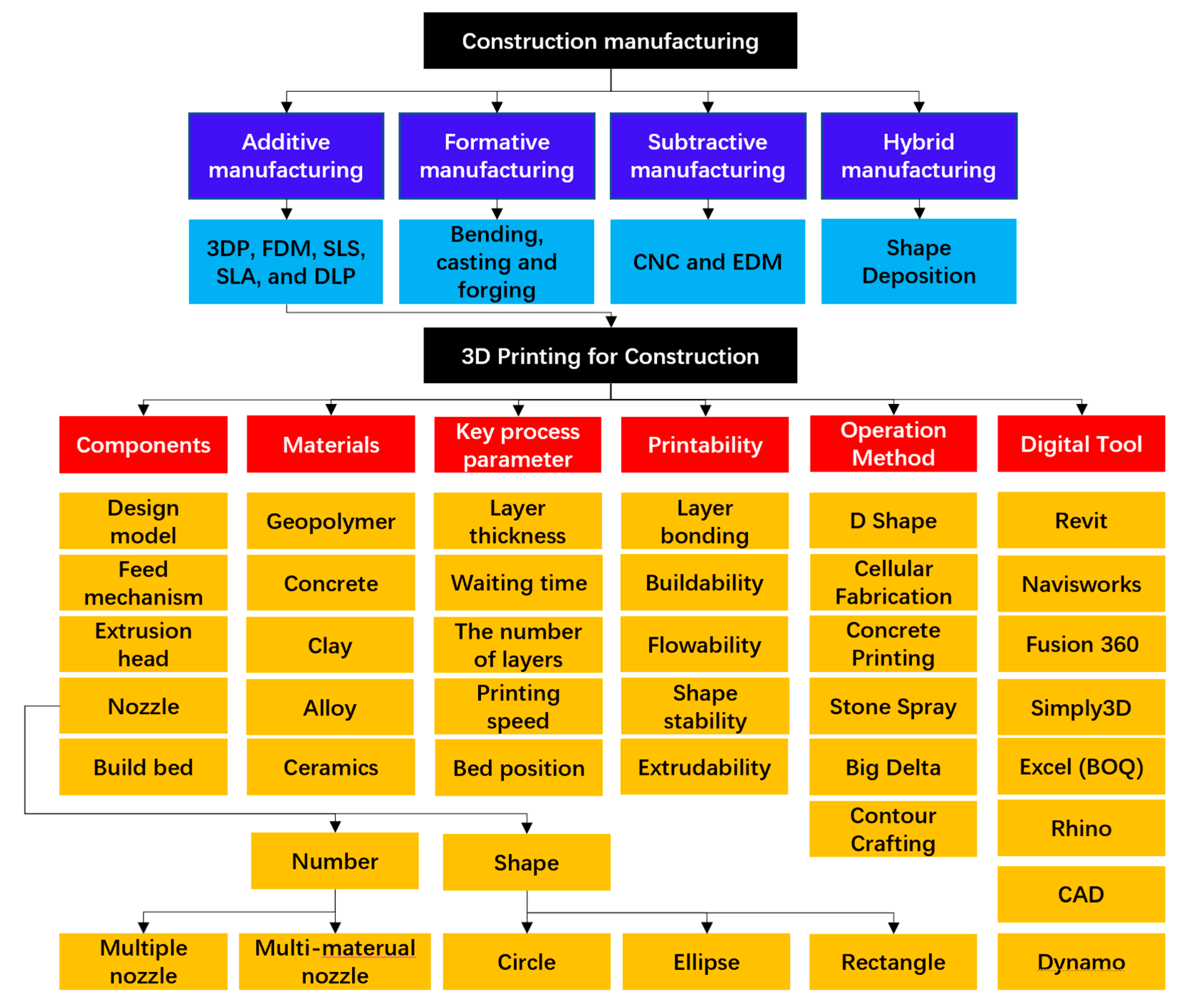

3.2. Major 3DP Technologies

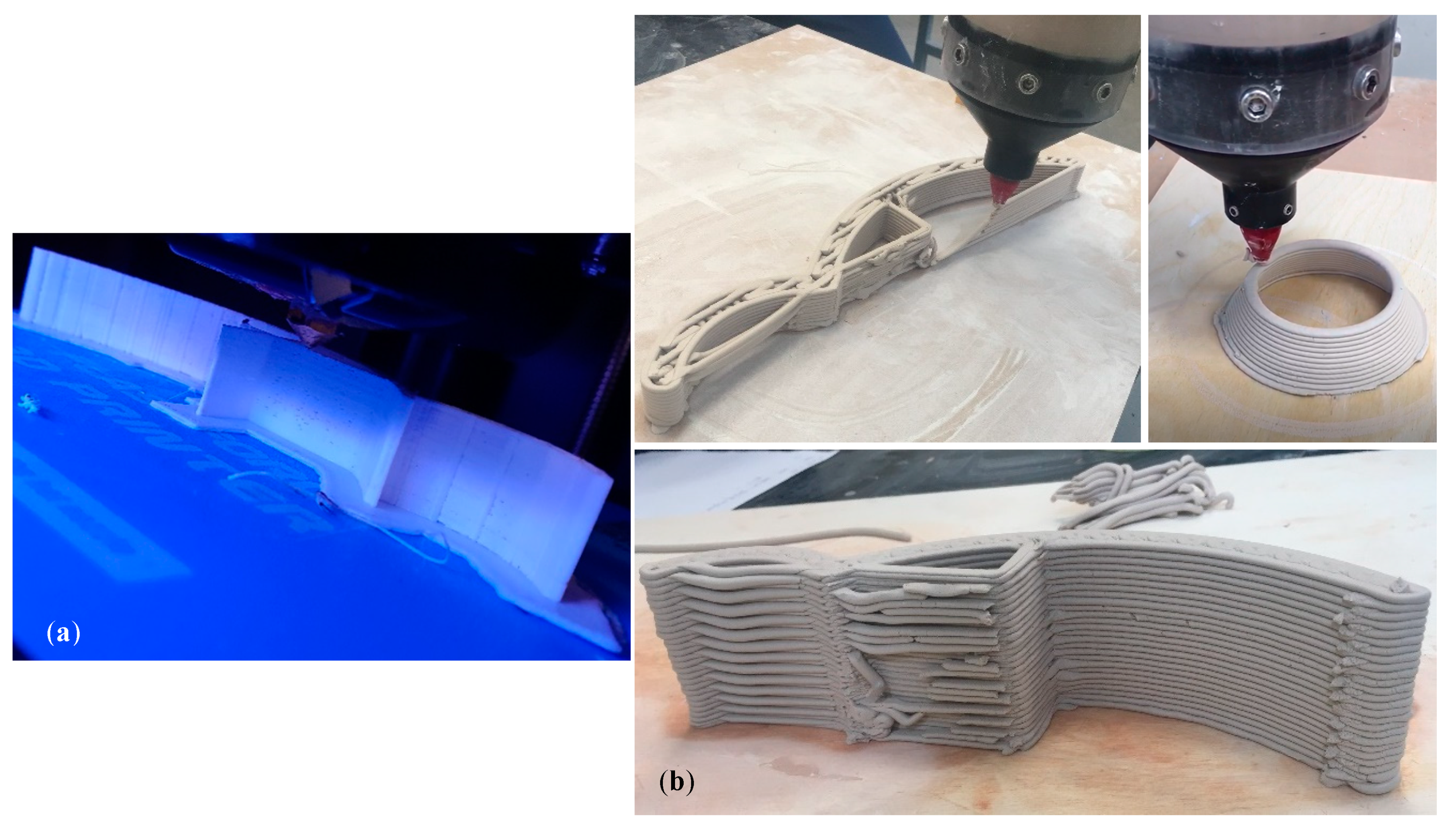

3.3. Development and Challenges of Largescale Printing

3.4. Criteria of 3DP Material Discussed in the Literature

3.5. Environmental, Social and Economic Benefits Reported in the 3DP Database

3.6. Review of Industry Practices

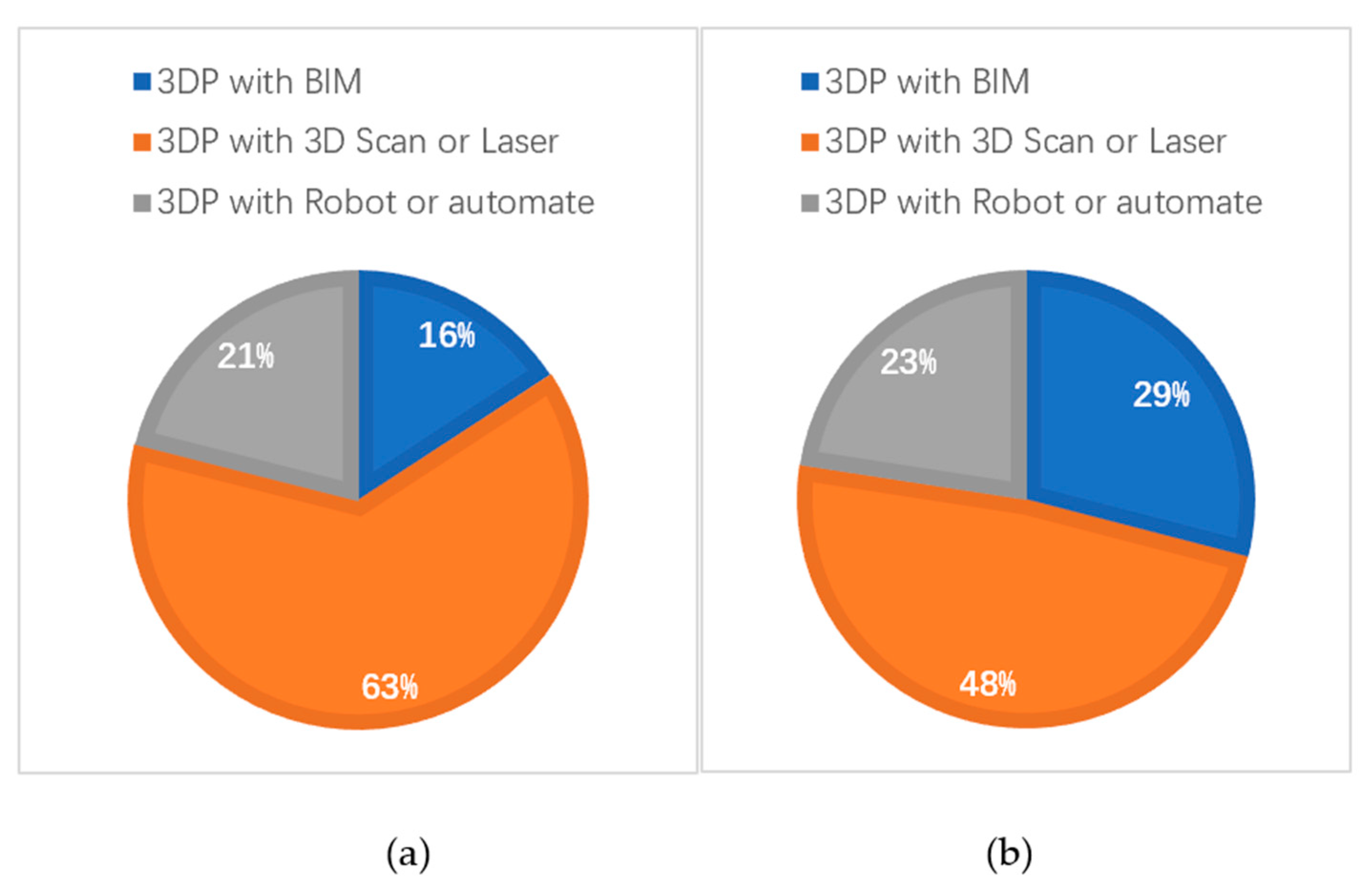

3.7. The Benefits for Construction Applications of 3DP, 3D Scanners and BIM Reported in the Dataset

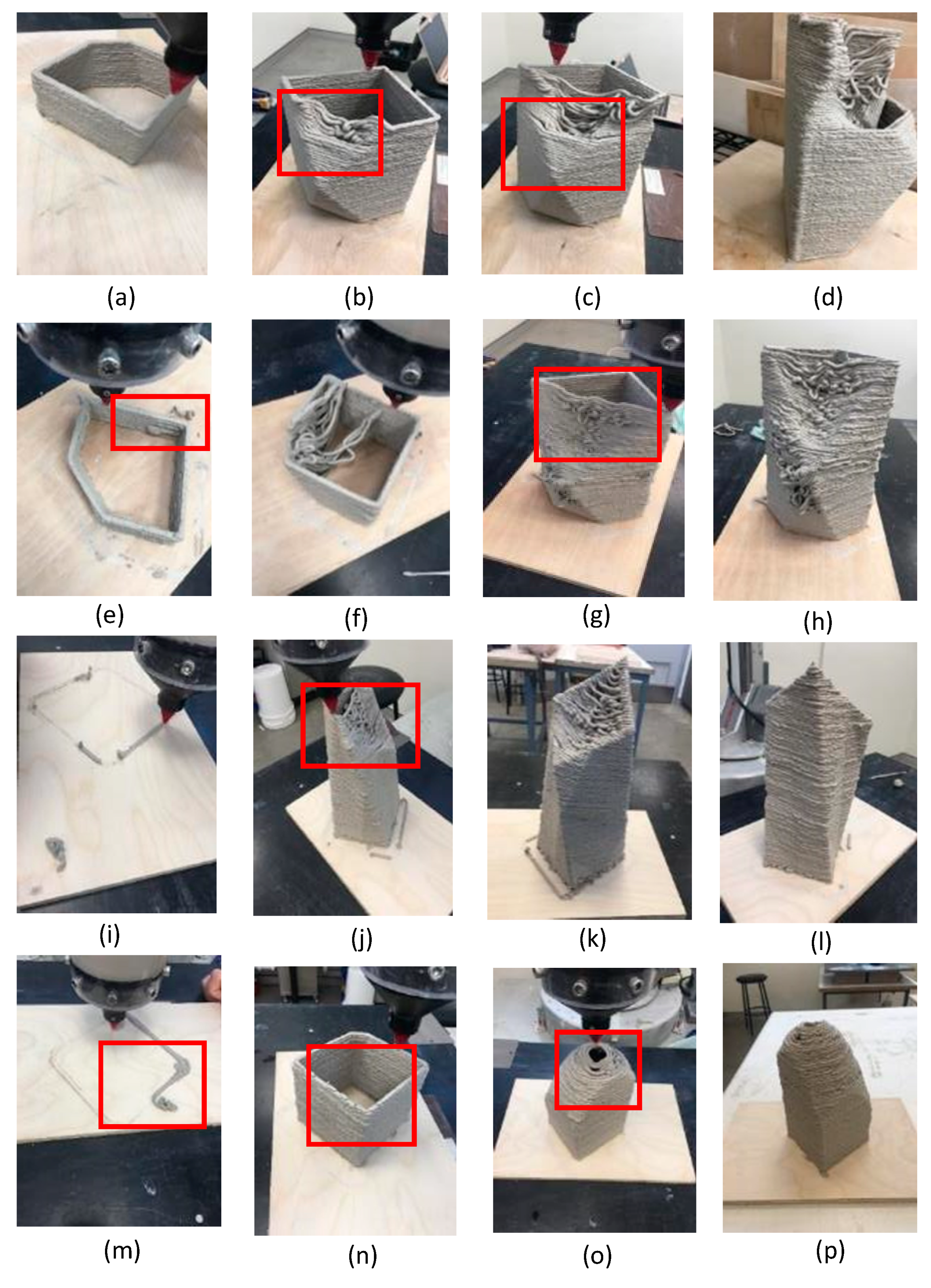

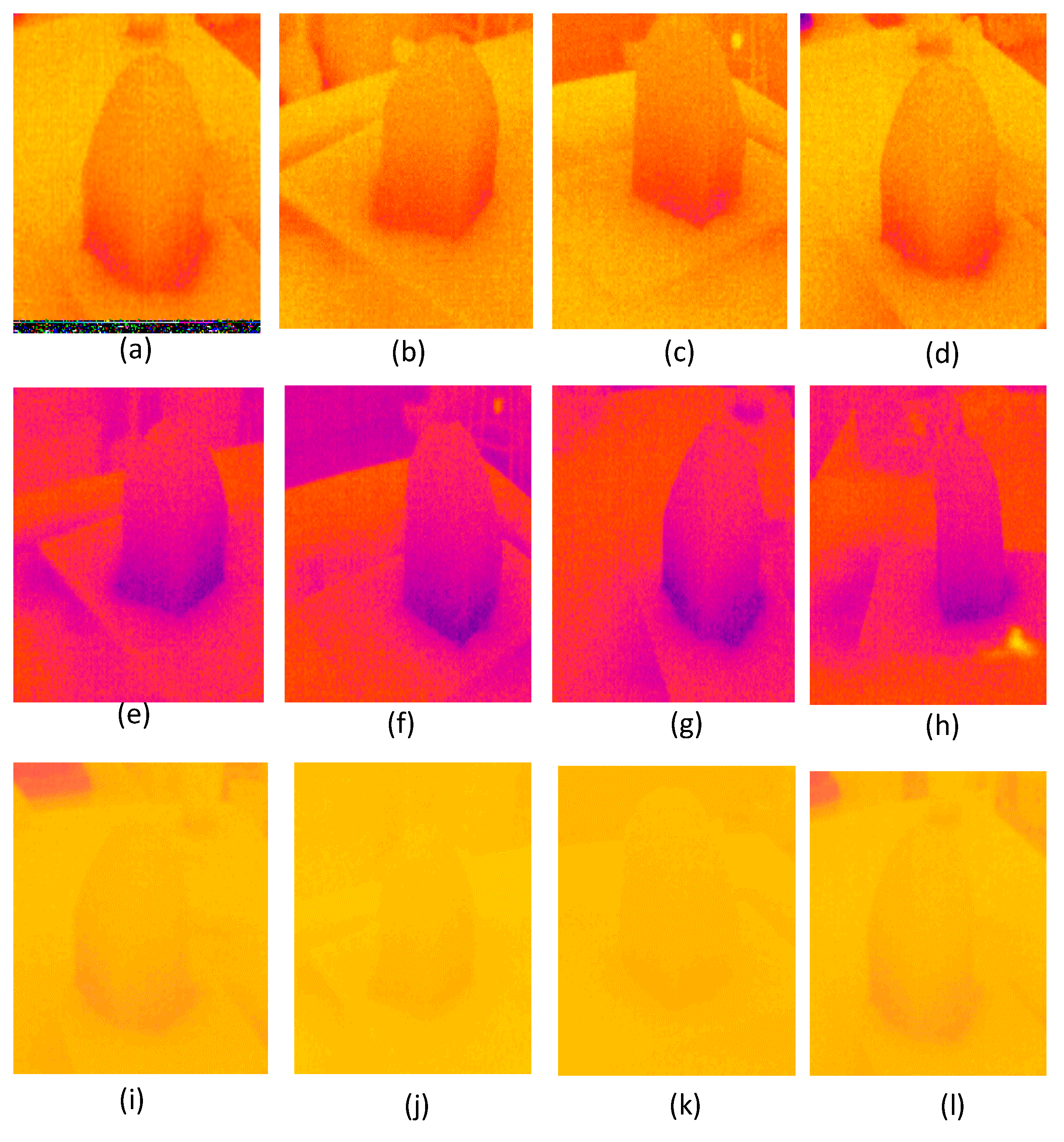

3.8. The Shape and Size of the Nozzle

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| 3DP | Three-dimensional printing |

| BIM | Building information modeling |

| FDM | Fused deposition modeling |

| CC | Contour crafting |

| AM | Additive manufacturing |

| SLS | Selective laser sintering |

| SLM | Selective laser melting |

| EBM | Electron beam melting |

| MJ | Material jetting |

| BJ | Binder jetting |

| SLA | Stereo lithography appearance |

| DED | Directed energy deposition |

| C-Fab | Cellular fabrication technology |

| VMA | Viscosity modifying agent |

| FRP | Fiberglass reinforced plastics |

| GDP | Gross domestic product |

| HUST | Huazhong University of Science and Technology |

| DMLS | Direct metal laser sintering |

| HIPS | Polystyrene |

| PA | Polyamide |

| SEM | Scanning electron microscope |

| AECO | Architecture, engineering, construction and operations |

| PS | Polymer blend of polystyrene |

| NASA | National Aeronautics and Space Administration |

| EOS | Electro-optical systems |

Appendix A. Keywords and Eligibility

| Combinations of Keywords | Limitations (Scopus Copy not Finishes) | No of Result Paper | Total |

|---|---|---|---|

| 3dp* or ‘3D print*’ + construction or build* or architectur* + chin* or ‘hong kong’ or taiwan or macao + All (BIM or ‘Building information model*’) | Exclude Conference Paper, Conference Review. Exlude Conference Proceedings and Book Series. | 1 (English) 1 (Chinese) | 20 |

| 3dp* or ‘3D print*’ + construction or build* or architectur* + chin* or ‘hong kong’ or taiwan or macao + All (‘3D scan*’ or laser or scan*) | Exclude 2019. Exclude Physics and Astronomy, Medicine, Agricultural and Biological Sciences, Biochemistry, Genetics and Molecular Biology, Pharmacology, Toxicology and Pharmaceutics. Exclude Conference Paper. Exclude Conference Proceedings and Trade Publications. | 5 (English) 7 (Chinese) | Laser (E): 3 repeated with Robot (E). 1 repeated with BIM and Robot (E). |

| 3dp* or ‘3D print*’ + construction or build* or architectur* + chin* or ‘hong kong’ or taiwan or macao + All (robot* or automat*) | Exclude 2019. Exclude Agricultural and Biological Sciences, Biochemistry, Genetics and Molecular Biology, Physics and Astronomy. Exclude Conference Paper, Editorial. Exclude Conference Proceedings. | 4 (English) 2 (Chinese) | Robot (E): 3 repeated with Laser (E). 1 repeated with BIM and Laser (E). 1 repeated with BIM. |

| 3dp* or ‘3D print*’ + construction or build* or architectur* + nozzle +shape or size | Exclude Medicine, Physical and Astronomy, Biochemistry, Genetics and Molecular Biology, Agricultural and Biological Science, Pharmacology Toxicology and Pharmaceutics, Immunology and Microbiology. Exclude 2019. Exclude Conference Paper, Conference Review, Editorial. Exclude Russian. Exclude Conference Proceedings, Trade Publications, Book Series. | 34 (English) | 34 |

| Combinations of Keywords | Limitations | No of Result Paper | Total |

|---|---|---|---|

| ABSTRACT (3d printing and engineering) + ABSTRACT (architectur) + ALL (BIM) | Include Mathematics, Mechanics, Physics, Resources Science; Architecture/Energy/traffic/electromechanics, etc; Macro-economic Management and Sustainable Development; Theory of Industrial Economy; Economy of Traffic and Transportation; Culture Economy; Information and Post Economy; Market Research and Information and Management Science. | 3 (English) 15 (Chinese) | 62 |

| ABSTRACT (3d printing and engineering) + ABSTRACT (architecture) + ALL (3D scan OR laser OR scan) | Include Mathematics, Mechanics, Physics, Resources Science; Architecture/Energy/traffic/electromechanics, etc; Macro-economic Management and Sustainable Development; Theory of Industrial Economy; Economy of Traffic and Transportation; Culture Economy; Information and Post Economy; Market Research and Information and Management Science. | 5 (English) 25 (Chinese) | Laser: 1 repeated with BIM |

| ABSTRACT (3d printing and engineering) + ABSTRACT (architecture) + ALL (robot OR automat) | Include Mathematics, Mechanics, Physics, Resources Science; Architecture/Energy/traffic/electromechanics, etc; Macro-economic Management and Sustainable Development; Theory of Industrial Economy; Economy of Traffic and Transportation; Culture Economy; Information and Post Economy; Market Research and Information and Management Science. | 2 (English) 12 (Chinese) | Robot: 4 repeated with BIM |

References

- Wohlers, T. Wohlers Report 2016; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Gerbert, P.; Castagnino, S.; Rothballer, C.; Renz, A.; Filitz, R. The transformative power of building information modeling. In Digital in Engineering and Construction; Boston Consulting Group: Boston, MA, USA, 2016. [Google Scholar]

- Tahmasebinia, F.; Sepasgozar, S.M.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Ko, Z.M.K.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0. Constr. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]

- Sepasgozar, S.M. Digital technology utilisation decisions for facilitating the implementation of Industry 4.0 technologies. Constr. Innov. 2020. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: An Innovation Platform for the Built Environment; Routledge: London, UK, 2020. [Google Scholar]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing–Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Teh, K.S. Additive direct-write microfabrication for MEMS: A review. Front. Mech. Eng. 2017, 12, 490–509. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Niemelä, M.; Sepasgozar, S.M.E.; Lai, T.Y.; Su, W.; Reddy, K.R.; Shirowzhan, S.; Sepasgozar, S.M.E.; Marroquin, F.A. Three-Dimensional Printing Using Recycled High-Density Polyethylene: Technological Challenges and Future Directions for Construction. Buildings 2018, 8, 165. [Google Scholar] [CrossRef]

- Lee, D.; Kim, H.; Sim, J.; Lee, D.; Cho, H.; Hong, D. Trends in 3D Printing Technology for Construction Automation Using Text Mining. Int. J. Precis. Eng. Manuf. 2019, 20, 871–882. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Davis, S. Digital Construction Technology and Job-site Equipment Demonstration: Modelling Relationship Strategies for Technology Adoption. Buildings 2019, 9, 158. [Google Scholar] [CrossRef]

- Freire, T.; Brun, F.; Mateus, A.; Gaspar, F. 3D Printing Technology in the Construction Industry. In Frontiers in Water-Energy-Nexus—Nature-Based Solutions, Advanced Technologies and Best Practices for Environmental Sustainability; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2020; pp. 157–167. [Google Scholar]

- Sepasgozar, S.M.; Lim, S.; Shirowzhan, S.; Kim, Y. Implementation of As-Built Information Modelling UsingMobile and Terrestrial Lidar Systems. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC), Sydney, Australia, 9–11 July 2014; pp. 876–883. [Google Scholar]

- Sepasgozar, S.M.E.; Forsythe, P.; Shirowzhan, S. Evaluation of Terrestrial and Mobile Scanner Technologies for Part-Built Information Modeling. J. Constr. Eng. Manag. 2018, 144, 04018110. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.; Li, H.; Trinder, J. Spatial compactness metrics and Constrained Voxel Automata development for analyzing 3D densification and applying to point clouds: A synthetic review. Autom. Constr. 2018, 96, 236–249. [Google Scholar] [CrossRef]

- Sepasgozar, S.; Lim, S.; Shirowzhan, S.; Kim, Y.; Nadoushani, Z.M. Utilisation of a New Terrestrial Scanner for Reconstruction of As-Built Models: A Comparative Study. In Proceedings of the 32nd ISARC, Oulu, Finland, 15–18 June 2015; pp. 1–9. [Google Scholar]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0–organizing routines or innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Andelfinger, U. An investigation into the technology adoption paradox. In Proceedings of the Third AIS SIGSAND European Symposium on Analysis, Design, Use and Societal Impact of Information Systems (SIGSAND-EUROPE 2008), Marburg, Germany, 12–13 June 2008. [Google Scholar]

- Feng, P.; Meng, X.; Chen, J.-F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2017, 61, 475–495. [Google Scholar] [CrossRef]

- Wen, S.; Yan, C.; Wei, Q.; Zhang, L.; Zhao, X.; Zhu, W.; Shi, Y. Investigation and development of large-scale equipment and high performance materials for powder bed laser fusion additive manufacturing. Virtual Phys. Prototyp. 2014, 9, 213–223. [Google Scholar] [CrossRef]

- Koslow, T. 35 Greatest 3D Printed Houses & Structures All3DP 2017. Available online: http://www.dongoubag.com/listing/35-greatest-3d-printed-houses-structures-of-2017-all3dp-466b-623518 (accessed on 15 November 2019).

- Lao, W.; Li, M.; Tjahjowidodo, T. Variable-Geometry Nozzle for Surface Quality Enhancement in 3D Concrete Printing. Addit. Manuf. 2020, 101638. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Camacho, D.D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry–A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G. A Study into the Effect of Different Nozzles Shapes and Fibre-Reinforcement in 3D Printed Mortar. Materials 2019, 12, 1708. [Google Scholar] [CrossRef]

- Roussel, N.; Spangenberg, J.; Wallevik, J.; Wolfs, R. Numerical simulations of concrete processing: From standard formative casting to additive manufacturing. Cem. Concr. Res. 2020, 135, 106075. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.; Liu, C. Monitoring physical progress of indoor buildings using mobile and terrestrial point clouds. In Proceedings of the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Preferred reporting items for systematic reviews and meta analyses: The PRISMA statement. PLoS Med. 2009, 151, 6. [Google Scholar]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Zhong, B.; Wu, H.; Li, H.; Sepasgozar, S.; Luo, H.; He, L. A scientometric analysis and critical review of construction related ontology research. Autom. Constr. 2019, 101, 17–31. [Google Scholar] [CrossRef]

- Sepasgozar, S.; Karimi, R.; Shirowzhan, S.; Mojtahedi, M.; Sepasgozar, S.M.E.; McCarthy, D. Delay Causes and Emerging Digital Tools: A Novel Model of Delay Analysis, Including Integrated Project Delivery and PMBOK. Buildings 2019, 9, 191. [Google Scholar] [CrossRef]

- Leonidou, L.C.; Katsikeas, C.S.; Coudounaris, D.N. Five decades of business research into exporting: A bibliographic analysis. J. Int. Manag. 2010, 16, 78–91. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Li, H.; Shirowzhan, S.; Tam, V.W.Y. Methods for monitoring construction off-road vehicle emissions: A critical review for identifying deficiencies and directions. Environ. Sci. Pollut. Res. 2019, 26, 15779–15794. [Google Scholar] [CrossRef] [PubMed]

- Sepasgozar, S.M.E.; Karimi, R.; Farahzadi, L.; Moezzi, F.; Shirowzhan, S.; Sepasgozar, S.M.E.; Hui, F.K.P.; Aye, L. A Systematic Content Review of Artificial Intelligence and the Internet of Things Applications in Smart Home. Appl. Sci. 2020, 10, 3074. [Google Scholar] [CrossRef]

- Murcia, D.H.; Genedy, M.; Taha, M.R. Examining the significance of infill printing pattern on the anisotropy of 3D printed concrete. Constr. Build. Mater. 2020, 262, 120559. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened properties of layered 3D printed concrete with recycled sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Seyedkanani, A.; Niknam, H.; Akbarzadeh, A.H. Bending behavior of optimally graded 3D printed cellular beams. Addit. Manuf. 2020, 35, 101327. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; Van Zijl, G. A rheology-based quasi-static shape retention model for digitally fabricated concrete. Constr. Build. Mater. 2020, 254, 119241. [Google Scholar] [CrossRef]

- Kruger, J.; Cho, S.; Zeranka, S.; Viljoen, C.; Van Zijl, G. 3D concrete printer parameter optimisation for high rate digital construction avoiding plastic collapse. Compos. Part B Eng. 2020, 183, 107660. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef]

- Abeykoon, C.; Abeykoon, C.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Light. Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Huang, B.; He, H.; Meng, S.; Jia, Y. Optimizing 3D printing performance of acrylonitrile-butadiene-styrene composites with cellulose nanocrystals/silica nanohybrids. Polym. Int. 2019, 68, 1351–1360. [Google Scholar] [CrossRef]

- Hassani, V.; Khabazi, Z.; Raspall, F.; Banon, C.; Rosen, D. Form-Finding and Structural Shape Optimization of the Metal 3D-Printed Node. In Proceedings of the CAD’19, Singapore, 24–26 June 2019; pp. 24–28. [Google Scholar]

- Ashrafi, N.; Nazarian, S.; Meisel, N.A.; Duarte, J.P. Experimental prediction of material deformation in large-scale additive manufacturing of concrete. Addit. Manuf. 2020, 101656. [Google Scholar] [CrossRef]

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Cai, L.; Zhang, L.; Luo, H.; Qin, W. Volume-forming 3D concrete printing using a variable-size square nozzle. Autom. Constr. 2019, 104, 95–106. [Google Scholar] [CrossRef]

- Dakshinamurthy, D.; Gupta, S. A Study on the Influence of Process Parameters on the Viscoelastic Properties of ABS Components Manufactured by FDM Process. J. Inst. Eng. Ser. C 2016, 99, 133–138. [Google Scholar] [CrossRef]

- Mitterberger, D.; Derme, T. Digital soil: Robotically 3D-printed granular bio-composites. Int. J. Arch. Comput. 2020, 18, 194–211. [Google Scholar] [CrossRef]

- Yassin, A.; Hamzeh, F.; Al Sakka, F. Agent based modeling to optimize workflow of robotic steel and concrete 3D printers. Autom. Constr. 2020, 110, 103040. [Google Scholar] [CrossRef]

- Nicholas, P.; Rossi, G.; Williams, E.; Bennett, M.; Schork, T. Integrating real-time multi-resolution scanning and machine learning for Conformal Robotic 3D Printing in Architecture. Int. J. Arch. Comput. 2020. [Google Scholar] [CrossRef]

- Mick, S.; Lapeyre, M.; Rouanet, P.; Halgand, C.; Benois-Pineau, J.; Paclet, F.; Cattaert, D.; Oudeyer, P.-Y.; De Rugy, A. Reachy, a 3D-Printed human-like robotic arm as a testbed for human-robot control strategies. Front. Neurorobotics 2019, 13, 65. [Google Scholar] [CrossRef] [PubMed]

- Fok, W.W.; Picon, A. The Ownership Revolution. Arch. Des. 2016, 86, 6–15. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Leung, A.K.; Davies, S.; Ching, S.H. When new technology joins old documents and east meets west: Virtually reconstructing the Fisher Island Pagoda Lighthouse (China). Virtual Archaeol. Rev. 2018, 9, 12–27. [Google Scholar] [CrossRef]

- Leach, N. Size matters: Why architecture is the future of 3D printing. Arch. Des. 2017, 87, 76–83. [Google Scholar] [CrossRef]

- Kan, W.; Lin, J. Research progress on fabrication of TiAl alloys fabricated by additive manufacturing. Mat. China 2015, 34, 111–119. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, Y.; Chen, Y.; Wang, W.; Tong, L. prospective applications of 3d printing technology in civil, engineering. Steel Constr. 2014. [Google Scholar] [CrossRef]

- Guo, J.; Wang, H.; Guo, Z.; Lu, Z. Application of BIM and 3D Printing Technology in Architectural. Decor. Eng. 2018. [Google Scholar] [CrossRef]

- Yu, W. Principle and Prospect on the 3D Printing Construction Technology. J. Beijing Univ. Civ. Eng. Archit. 2015, 4. Available online: https://en.cnki.com.cn/Article_en/CJFDTotal-JZJI201512006.htm (accessed on 5 September 2020).

- Lu, Z.; Du, Y.; Yu, Y.; Yang, J. BIM Application in the Porject of Urumchi Inernational Highway-railway Combined Passenger Station and Its North Square Entrance. J. Inf. Technol. Civ. Eng. Archit. 2017. [Google Scholar] [CrossRef]

- Li, R. Research Direction and Progress of Building 3D Pringting Key Technology. Build. Constr. 2017, 39, 248–250. [Google Scholar] [CrossRef]

- Liu, L.; Gao, W. Analysis on utilization of pre-fabricated housing system projects with PC-steel and 3D-print co-construction technologies. China Acad. J. Electron. Publ. House 2017, 12, 26–30. (In Chinese) [Google Scholar]

- Zhang, Y.; Su, Y. Development and prospect of 3D printing architecture. Shanxi Archit. 2015, 41, 6–8. (In Chinese) [Google Scholar]

- Su, Y.; Li, C.; Yang, T.; Yang, K.; Li, J. Study on application of 3d printing concrete technique in architectural engineering. Archit. Technol. 2017, 48, 98–100. (In Chinese) [Google Scholar]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Godbold, O.; Kang, J.; Buswell, R.; Soar, R. Fabrication of acoustic absorbing topologies using rapid prototyping. Can. Acoust. 2008, 36, 144–145. [Google Scholar]

- Lim, S.; Le, T.; Webster, J.; Buswell, R.; Austin, A.; Gibb, A.; Thorpe, T. Fabricating construction components using layered manufacturing technology. In Proceedings of the Global Innovation in Construction Conference, Loughborough, UK, 13–16 September 2009; pp. 512–520. [Google Scholar]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Dutton, R. Innovative rapid prototyping process makes large sized, smooth surfaced complex shapes in a wide variety of materials. Mater. Technol. 1998, 13, 53–56. [Google Scholar] [CrossRef]

- Designboom. Stone Spray Robot Produces Architecture from Soil. Available online: https://www.designboom.com/design/stone-spray-robot-produces-architecture-from-soil (accessed on 20 November 2020).

- Molitch-Hou, M. Branch Technology is 3D Printing the Future of Construction One Wall at a Time. Available online: https://www.3dprintingindustry.com/news/branch-technology-is-3d-printing-the-future-of-construction-one-wall-at-a-time-54149 (accessed on 20 November 2020).

- Colla, V.; Dini, E.; Canessa, E.; Fonda, C.; Zennaro, M. Large Scale 3D Printing: From Deep Sea to the Moon. Low-Cost 3D Printing, for Science, Education & Sustainable Development; Canessa, E., Fonda, C., Zennaro, M., Eds.; ICTP—The Abdus Salam Center for Theoretical Physics: Sant’Anna, Italy, 2013; pp. 127–132. [Google Scholar]

- Xu, F.; Fok, W.W.; Picon, A. VULCAN: Closing the Loop in 3D-Printed Architectural Design. Arch. Des. 2016, 86, 82–91. [Google Scholar] [CrossRef]

- Yu, X.; Yang, J.; Hu, Z. Talking about the Application of 3D Printing Building Technology. Shanghai Build. Mater. 2017, 3, 33–35. (In Chinese) [Google Scholar]

- Shi, A.; Shirowzhan, S.; Sepasgozar, S.M.; Kaboli, A. 5D BIM Applications in Quantity Surveying: Dynamo and 3D Printing Technologies. In Smart Cities and Construction Technologies; IntechOpen: London, UK, 2020. [Google Scholar]

- Huang, Q.; Zhang, J.; Sabbaghi, A.; Dasgupta, T. Optimal offline compensation of shape shrinkage for three-dimensional printing processes. IIE Trans. 2015, 47, 431–441. [Google Scholar] [CrossRef]

- Khalil, N.; Aouad, G.; El Cheikh, K.; Rémond, S. Use of calcium sulfoaluminate cements for setting control of 3D-printing mortars. Constr. Build. Mater. 2017, 157, 382–391. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Zhang, H.; An, Y. Application and prosepct of 3D printing technology in the field of construction engineering. Shanxi Archit. 2016, 42, 17–18. (In Chinese) [Google Scholar]

- Stott, R. Chinese Company Constructs the World’s Tallest 3D Printed Building. 2015. Available online: https://www.archdaily.com/591331/chinese-company-creates-the-world-s-tallest-3d-printed-building (accessed on 5 September 2020).

- Wang, L. Chinese company ‘builds’ 3D-printed villa in less than 3 hours. 2015. Available online: https://inhabitat.com/chinese-company-builds-3d-printed-villa-in-less-than-3-hours/ (accessed on 5 September 2020).

- Morrow, M.a.A. World’s first 3D printed house is completed after just 45 days in China. 2016. Available online: https://www.news.com.au/technology/innovation/design/worlds-first-3d-printed-house-is-completed-after-just-45-days-in-china/news-story/05c819dfc0dc6bf7ec0fd2abfed23edd (accessed on 5 September 2020).

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current progress of 3D concrete printing technologies. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction (ISARC), Taipei, Taiwan, 28 June–1 July 2017; pp. 260–267. [Google Scholar]

- Tess. Two 3D printed Suzhou-style Chinese courtyards are unveiled in Binzhou! Not a single brick was used. 2016. Available online: https://3dprint.com/148637/3d-printed-house-shandong/ (accessed on 20 November 2020).

- Garofalo, F. The world’s first 3D-printed office building is in Dubai. 2016. Available online: https://www.lifegate.com/worlds-first-3d-printed-office-building-dubai (accessed on 5 September 2020).

- Koslow, T. 35 Greatest 3D Printed Houses & Structures 2017. Available online: https://genuinebritishengineer.wordpress.com/2017/03/07/3d-printers-in-the-construction-world-30-greatest-3d-printed-houses-structures-in-the-world/ (accessed on 20 November 2020).

- Fu, C.; Liu, B. Material Saving Optimization of 3D Printed Objects. J. Comput. Aided Des. Comput. Graph. 2017, 29, 742–750. (In Chinese) [Google Scholar]

- Jia, D.; He, P.; Yuan, J.; Wang, R. Development of Geopolymer and Geopolymer-based Composites. Kuei Suan Jen Hsueh Pao 2017, 45, 1721–1737. [Google Scholar] [CrossRef]

- Liu, W.; Ge, Y.; Zhou, Z.; Zhang, S. Multi-source BIM Information Fusion Technology. J. Inf. Technol. Civil Eng. Archit. 2017, 9, 23–28. (In Chinese) [Google Scholar]

- Huang, D.; Yan, B.; Wen, J.; Fan, D.; Zhao, Q.; Li, X. Integrated BIM Application in Construction of Tencent Beijing Headquarter. J. Inf. Technol. Civil Eng. Archit. 2016, 8, 16–22. (In Chinese) [Google Scholar]

- Liu, Z.; Li, M.; Tay, Y.W.D.; Weng, Y.; Wong, T.N.; Tan, M.J. Rotation nozzle and numerical simulation of mass distribution at corners in 3D cementitious material printing. Addit. Manuf. 2020, 34, 101190. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, Z.; Chen, C.; Yang, W. Additive manufacturing of WC-20Co components by 3D gel-printing. Int. J. Refract. Met. Hard Mater. 2018, 70, 215–223. [Google Scholar] [CrossRef]

- Wu, Y.; Hou, H.; Liu, S.; Wen, Q. A Review of FDM Nozzle System for Additional Materials Manufacturing Technology. In Advanced Graphic Communication, Printing and Packaging Technology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 517–522. [Google Scholar]

- Lao, W.; Tay, D.Y.W.; Quirin, D.; Tan, M.J. The Effect of Nozzle Shapes on the Compactness and Strength of Structures Printed by Additive Manufacturing of Concrete. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 80–86. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.A.; Gibb, A.; Thorpe, T. Development of a viable concrete printing process. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, Korea, 29 June–2 July 2011; pp. 665–670. [Google Scholar]

- Kwon, H. Experimentation and Analysis of Contour Crafting (CC) Process Using Uncured Ceramic Materials. Ph.D. Thesis, University of southern California, Los Angeles, CA, USA, 2004. [Google Scholar]

- McGee, W.; Ng, T.Y.; Yu, K.; Li, V.C. Extrusion Nozzle Shaping for Improved 3DP of Engineered Cementitious Composites (ECC/SHCC). In Second RILEM International Conference on Concrete and Digital Fabrication; Springer: Berlin/Heidelberg, Germany, 2020; pp. 916–925. [Google Scholar]

- Triyono, J.; Sukanto, H.; Saputra, R.M.; Smaradhana, D.F. The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material. Open Eng. 2020, 10, 762–768. [Google Scholar] [CrossRef]

- Cameron, T.; Naseri, E.; Maccallum, B.; Ahmadi, A. Development of a disposable single-nozzle printhead for 3D bioprinting of continuous multi-material constructs. Micromachines 2020, 11, 459. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Kowalski, C.; Mulholland, T.; Osswald, T.A. Nozzle flow behavior of aluminum/polycarbonate composites in the material extrusion printing process. J. Appl. Polym. Sci. 2019, 136, 47252. [Google Scholar] [CrossRef]

- Heller, B.; Smith, D.; Jack, D. Effect of extrudate swell, nozzle shape, and convergence zone on fiber orientation in fused deposition modeling nozzle flow. In Proceedings of the Solid Freeform Fabrication, Austin, TX, USA, 10–12 August 2015; pp. 1220–1236. [Google Scholar]

- Song, H.; Martínez, J.; Bedell, P.; Vennin, N.; Lefebvre, S. Colored fused filament fabrication. ACM Trans. Graph. 2019, 38, 1–11. [Google Scholar] [CrossRef]

- Sodupe-Ortega, E.; Garcia-Verdugo, J.M.; Pernía-Espinoza, A.; Escobedo-Lucea, C. Accurate calibration in multi-material 3D Bioprinting for tissue engineering. Materials 2018, 11, 1402. [Google Scholar] [CrossRef]

- Kolesky, D.B.; Truby, R.L.; Gladman, A.S.; Busbee, T.A.; Homan, K.A.; Lewis, J.A. 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv. Mater. 2014, 26, 3124–3130. [Google Scholar] [CrossRef]

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Kłodowski, A.; Eskelinen, H.; Semken, S. Leakage-proof nozzle design for RepRap community 3D printer. Robotica 2015, 33, 721–746. [Google Scholar] [CrossRef]

- Pitayachaval, P.; Masnok, K. Feed rate and volume of material effects in fused deposition modeling nozzle wear. In Proceedings of the 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 27–29 April 2017; pp. 39–44. [Google Scholar]

- Shakor, P.; Nejadi, S.; Paul, G.; Sanjayan, J. Dimensional accuracy, flowability, wettability, and porosity in inkjet 3DP for gypsum and cement mortar materials. Autom. Constr. 2020, 110, 102964. [Google Scholar] [CrossRef]

- Aoki, H.; Mitani, J.; Kanamori, Y.; Fukui, Y. AR based ornament design system for 3D printing. J. Comput. Des. Eng. 2014, 2, 47–54. [Google Scholar] [CrossRef][Green Version]

- Han, D.; Yin, H.; Qu, M.; Zhu, J.; Wickes, A. Technical analysis and comparison of formwork-making methods for customized prefabricated buildings: 3D printing and conventional methods. J. Arch. Eng. 2020, 26, 04020001. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Technol. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Oh, Y.; Zhou, C.; Behdad, S. Part decomposition and assembly-based (Re) design for additive manufacturing: A review. Addit. Manuf. 2018, 22, 230–242. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Colosimo, B.M.; Huang, Q.; Dasgupta, T.; Tsung, F. Opportunities and challenges of quality engineering for additive manufacturing. J. Qual. Technol. 2018, 50, 233–252. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?–Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Chang, Y.N. Lack of Adoption of 3D Printing in Malaysia Construction Industry; Tunku Abdul Rahman University College: Kuala Lumpur, Malaysia, 2020. [Google Scholar]

| Concept | Definition and Associated Key Words |

|---|---|

| Additive manufacturing | A process utilizing an industrial fabrication technique to create solid objects (typically layer upon layer [6]) by using computer-generated models [7] in the absence of human intervention [8]. |

| 3DP, 3D print, 3-D print, 3D printing or 3D concrete print [9] | A production technology [10] sequentially laying down layers of material until the envisaged form of the object has been developed [8] using digital information. Reduces lead time and cost in construction and increases sustainability [3,11]. |

| 3D scanner [12] | Provides massive point clouds to create precise 3D representations of objects and offer dimensional data from construction objects for 3D modeling [13]. Light detection and ranging (lidar) [14], mobile and terrestrial laser scanners [15], drones. |

| Construction technology | Refers to materials, equipment, technical methods, novel construction operation processes, unique formworks, knowledge and tools or any digital hand tools, hardware, heavy equipment or machines [10]. Cranes equipped with programmable system, autonomous haulage system, global positioning system (GPS) and radio frequency identification (RFID). |

| Industry 4.0 (the Fourth Industrial Revolution) [4] | Refers to the use of advanced technologies for mechanization [3,5], which can be based on a network of automation, self-configuring, knowledge-based, or sensor-based [16] systems, including the use of 3DP in the production. |

| Technology adoption | How companies make a decision to accept and utilize technology at the organization level and whether the technology and similar implementation methodologies can be equally successful in any construction project, due to the unique nature of projects or customized technology, known as the ”adoption paradox” [4,17]. |

| Aims and Objectives | Method | Limitations | Outcome |

|---|---|---|---|

| Examine three common largescale 3DP systems and the main challenges they face [19]. | Chinese Winsun Company used CC to create a five-story apartment; ten houses built in Shanghai by gigantic 3DP within 24 h; 3D printed five-story apartment in Jiangsu Province, China. | The 3DP size limited the components’ dimensions; the reinforcement implementation; lack of relevant standards and testing methods for new cementitious material. | Developed some criteria, including shrinkage, for producing an optimized cementitious mixture. |

| Discuss the ownership and legal issues of 3DP [54]. | Feng Xu’s Vulcan project, the largest 3D structure in the world. | Copyright issues as it is too easy for stakeholders to modify and incorporate. | In China, Philip Yuan and Hao Meng introduced the robotic platform. |

| Develop a methodology that combines three-dimensional (3D) scanning and cement mortar-based 3DP [55]. | Combine 3D scanning and cement mortar-based 3DP. The cup-shaped individual plinth is damaged and replicated through 3D scanning, remodeling and re-construction. | New approach for the materials; less control on mechanical motion and a precise and flexible nozzle; lack of the restoration modelling algorithms for alternative or missing elements. | This methodology is a novel approach for replicating a heritage decorative element as the labor cost is expensive and the process is fussy. |

| Develop an SLS and SLM system for large objects [20]. | A multi-layer flexible preheating system according to self-adaptive fuzzy control technique. A non-uniform temperature field is created by the single-large preheating system. | Material limitations. | Suggests a material with high mechanical properties, which is high impact polystyrene. Evaluates the other suitable material for SLS, a mixture of polyamide (PA) and reinforcement particles. |

| Virtually reconstruct the Fisher Island Pagoda Lighthouse (China): repair the historical buildings [56]. | Revit used to rebuild a 3D virtual construction for a 3D printer, using the lighthouse at Penghu, between Xiamen and Taiwan. | Shows 3DP and Revit have benefits for historical building replication. | |

| Size challenges and structural performance [57]. | According to experience, increase the column 10-fold. It uses the facade of Arachne designed by Lei Yu, a Chinese architect (Foshan, China, 2017) as an example. | Size affected structural performance. | 3DP is more suitable for small-scale and customized structures until 2017. |

| Develop a new type of Tial alloy by selective electron beam melting (EBM) [58]. | Evaluates SLM and EMB for manufacturing the metal material. | The material preparation for the Tial alloy; the microstructure evolution process of EBM samples during heat treatment. | Suggests SLM and EMB to be used for manufacturing the metal material. |

| Aims and Objectives | Method | Limitations | Outcome |

|---|---|---|---|

| Evaluate SLS, SLM, SLA, EBM and FDM methods [59]. | Discusses a case study of Oakland Bay Bridge for the earthquake in San Francisco. | Limited material; size; durability of the 3DP; lack of estimation, cost control and benefits maximization when combined with the conventional approaches. | Contribution in the connecting point between components; presents a large casting mold printing manufacture and earthquake resistance. |

| Decoration application using BIM and 3DP [60]. | A case study to conceal fire-hydrant box stone door for a theatre project including scenario simulation. | Limitation to printing object size; higher accuracy requires more time; limited materials. | Successful experiment for the decoration finishes of complex units including model sandboxes. |

| Principle of 3DP: demonstrate 6 ways of 3DP, with benefits and limitations [61]. | A 10-story building developed by Winsun company. | Limited materials; accuracy; lack of required standards. | Presents a cost-effective benchmark, suitable for rapid fabrication of small batches of complex units. |

| BIM 3DP integration for a case project of Urumqi International Highway-railway [62]. | Integrates different tools including Rhino, Catia, Revit, the 3D laser scanner and total station, RealWorks and Naviswork. | Interoperability and lack of functionality in BIM and other tools. | Successful use of BIM with 3DP for design, production, constitution and management phases. |

| Introduced a multi-head printer and developed a self-climbing 3D printer [63]. | A 10-story building, and the VULCAN created by LCD in Beijing’s Parkview Green retail center. | Problem with 3D printing, the building height and low outcome caused by the single printer head-solved in this paper. | Reports successful practice with high safety level; presents a cooperative path plan of multi-printhead printing. |

| Aims and Objectives | Method | Limitations | Outcome |

|---|---|---|---|

| Analysis of the utilization of pre-fabricated housing system projects with PC-steel and 3DP [64]. | Self-supporting floor slab with a space truss support system in the middle of the slab, reducing the slab weight. | Material and reinforcement limitations. | Presents an application for hollow concrete structural units (volumetric modular), such as the entire bathroom or kitchen, which can enhance the flexibility of house space. |

| Develop architectural elements and evaluate limitations [65]. | Develop a self-insulating wall and install the pipes. The alternative method is to print the wall with two-sided formwork and pour concrete. | Limited aggregate size due to nozzle size; limited size of the 3D printer; interoperability issue; difficulty in printing doors, windows and pipes. | Evaluates an architectural practice and presents a large-scale 3DP at Zhangjiang Qingu Science and Technology Park, China. |

| Evaluate the CC method for both 10 and 6-story buildings in China [66]. | Evaluate CC methods by hanging a nozzle on the crane and moving in the X and Y directions. | Limited material type; software issues, hardware facility; lack of relevant standards. | Discussion around earthquake resistance and the ”ink” used for achieving high strength and lightweight concrete. |

| Method | General Information |

|---|---|

| Material jetting (MJ) [61] | Like the inkjet printing approach, the liquid photopolymer or waxy material is selectively sprayed through the nozzle. |

| Binder jetting (BJ) [61] | The adhesive is selectively sprayed onto the powder base layer through the nozzle. |

| Stereo lithography appearance (SLA) [61] | Selectively scans liquid photopolymer with a certain type of light source and solidifies quickly, such as AM created by 3D system companies. |

| Fused deposition modeling (FDM) [61] | Under certain pressure, the filamentous polymer materials are softened by a heating nozzle just above melting point, then stacked to form a 3D structure. |

| Selective laser sintering (SLS) [61] | Like BJ, but SLS uses laser or electron beams. |

| Directed energy deposition (DED) [61] | Uses a laser or other energy to simultaneously melt the “ink”, solidify and stack to form 3D structure. |

| 3DP | Applications | Limitations |

|---|---|---|

| D-shape: Enrico [70] in 2007, sand, salt, and inorganic binding agent [19]. | Applied on very largescale structures [75]; allowed faster construction for the army, such as support and hospitals. It has a high printed performance due to the narrow and precise nozzle. | The approach of deposition may determine the printed dimension. |

| Contour crafting: Khoshnevis in 1998 [72], materials have a shorter setting time and low shrinkage [19]. | Applied on very largescale structures through a multi-axis robotic arm. The printing process is very fast, allowing printing on-site; the faster print speed is due to the single large nozzle, which is applied on low printing performance and large thick layer. | It cannot print roof and window at the same time. |

| Concrete printing, material: cement mortar [19]. | The alternative approach of counter-crafting: better for complicated or freeform structures as no need for formwork and subsequent vibration. The rapid printing speed depends on the individual large nozzle, which is applied to low printing performance and large thick layer. | The approach of deposition and the mechanical fabric determine the printed dimension. |

| Stone Spray—a robotic 3D printer (Institute for Advanced Architecture of Catalonia (Spain) 2012) material: sand and soil with environmental adhesive [19]. | ||

| Cellular fabrication technology (C-Fab): Platt et al. in 2013 [19]. | Used to produce sustenance construction. More suitable for largescale structures. | |

| BigDelta: 12m × 6m gigantic 3D printer, used below 100 W of power [19]. | Used to print sun-dried brick building on-site with environmental materials, such as clay, water and straw and soil. It also used a lift linked with a 3D printer to deliver the material. | |

| Control Criteria | Definition | Examples |

|---|---|---|

| Shrinkage | The material deforms during the coagulation process, which causes dimensional deflection [79]. | In specimens with the structural nano-synthetic fiber around 0.26 vol %, the crack area reduces 36% from the original [19]. |

| Extrudability | The workability of material to be moved out from the nozzle [80]. | The optimized mixture proportion is 3:2 sand–binder and mixes with 70% cement, 20% fly ash and 10% silica fume [19]. |

| Flowability | The ability of the material to spread from the nozzle; it should be easy to pump out [71]. | Varies in different experimentations. The rate observed varies from 1.1 to 1.4 cm/s for superplasticizer rates of 0.14%, 0.28%, 0.30% and 0.35% [19]. |

| Setting time | Extended setting time requires extrudability and flowability, but should not be too long due to buildability requirements. | Six different retarders are tested. The sodium tetraborate is optimal, and the critical point is from 0.1% to 0.3% [19]. |

| Buildability | Stiffness of material to lay down without collapsing [80]. | The critical point of viscosity modifying agent (VMA) mixed in the paste is from 0.025 to 0.075%. The adhesiveness of the mixture at 0.075% is over four times stronger than at 0.025% [19]. |

| Mechanical properties | These relate to compression, strength, flexibility and physical properties. | The specimen with fiberglass-reinforced plastics (FRP) can achieve 31.5 MPa maximally, as 1729.0% times that of unreinforced specimens [19]. |

| Case/Year of Practice/Company | 3DP Technology and Details | Material | Design Complexity |

|---|---|---|---|

| (1) Ten houses in Shanghai by gigantic 3DP within 24 h/2014/Winsun Company [19]. | Gigantic 3D printer of size 150 m × 10 m × 6 m; CC (method) [19]. | High-grade quick dry cement and glass fiber [19]. | 200 m2 each [19]. |

| (2) 3D printed five-story apartment in Jiangsu Province, China/2014/Winsun Company [19]. | Components of 3DP are pre-printed and assembled on-site (details of 3DP) CC (method) [81]. | Cement, glass fiber, construction waste and hardening agent [81]. | 1100 m2 This house withstands earthquakes [19]. |

| (3) Earthquake-proof modular homes at Xian, China in 15 days/2015/ZhuoDa Group [89]. | Ready-made modules of 3DP are pre-printed and assembled on-site in around three days. The LEGO brick technique is used (details of 3DP) [84]. | The material mix is not published. | 500 m2 two-story villa in Xian. Theoretically resists a level-nine earthquake on the Richter scale [89]. |

| (4) The world’s first 3D printed two-story villa in 45 days/2016/HuaShang Tengda [89]. | The building was printed on-site and required frame and print concrete by custom-built 3DP system (details of 3DP). Custom-built 3DP system (method) [86]. | C30-grade concrete including rough aggregates. The volume of the concrete was 20 tons [89]. | 400 m2 The thickness of the wall is 250 mm. This house should resist a level of eight on the Richter scale [89]. |

| (5) 3D printed Chinese Classical Gardens of Suzhou at Shanghai, China/2016 [89]. | Gigantic 3D printer 150 m × 10 m × 6 m was used (details of 3DP) [87]. | Special concrete ink [87]. | 80 m2 and 130 m2 (both of them are garden-style courtyards in Shanghai, China) [89]. |

| (6) 3D printed office in Dubai, United Arab Emirates/2016/Winsun Company [89]. | The components of 3DP are pre-printed and take around 2 days to assemble on site with a size of 36 m × 12 m × 6 m [88]. | A new kind of construction material [88]. | 240 m2 Winsun Company pre-printed components [89]. |

| Phases | Benefits |

|---|---|

| Concept or pre-development phase [65] | The 3D model clearly shows the merits and deficiencies of the project. |

| Initial design phase [65] | Modeling and site layout planning. |

| Final design and submit phase [65] | Structural elements enhanced against earthquakes [59]; allows freeform architecture [59] and green design. |

| Project technical design and construction phase [65] | Efficient construction and enhances productivity in modular construction [64]; shortens the construction time. |

| Topic | Limitation and/or Positive Impact | Optimization Direction/Aspects to Consider | |

|---|---|---|---|

| Shape | Circular | Low percentage of contact area; low interlayer bonding; low compactness; specimens were easier to break; more freedom and ease to change the nozzle angle [97,98,99]. | 1. Nozzle shape design should consider the shape of specimens and the flowing speed of material [99]. 2. Nozzle shape design should consider the nozzle travel speed and the toolpath curvature radius [48]. 3. The size and shape of the side blades need to be further studied [100]. |

| Elliptical | Lower surface finish than that printed by rectangular nozzle [101]. | ||

| Rectangular | Better compactness and compressive strength [97,101]. | ||

| Nozzle with side blades | Better surface finishes than specimens printed by nozzle without side blades [102]. | ||

| Size | Diameter | A larger nozzle diameter produces better product density and tensile strength, while a smaller diameter leads to poor interlayer bonding but high dimensional accuracy. An increase in diameter leads to a decrease in the material transition distance, while a small diameter can lead to the rheology of material changes [48,103,104]. | Nozzle size design should consider flowability of material, shape and size of specimens, dimensional precision requirements and the printing path of the material [104,105,106]. |

| Nozzle aspect ratio | Decreasing nozzle aspect ratio is beneficial to decreasing uneven mass distribution at corners [94]. | ||

| Special type | A multi-material nozzle | The mutual penetration of different materials, no calibration when depositing material [104,107]. | To eliminate material contamination and waste, to improve calibration accuracy, and to avoid multiple nozzle collision [104,107,108]. |

| Multiple nozzles | Increase in printing time due to replacement of printing material; high precision calibration is required, which will lead to shrinkage of the material; printing filament discontinuity leads to a reduction in the integrity of the printing structure; lack of precision of nozzle due to parallax error [108,109,110]. | ||

| Factor | Current Practice and Limitations | Future Directions and Needs |

|---|---|---|

| Material [77] | The materials used for 3DP are challenging in meeting the optimized standards, such as shrinkage, extrudability, flowability, setting time, buildability, interlayer bonding, mechanical properties and layer-by-layer appearance. Some requirements can also conflict, such as buildability and flowability. However, one of the significant advantages of 3DP is to save materials and cost. The material difficulty meets construction standards. Thermal insulation and energy-saving, earthquake resistance and economy [77]. | Efficient construction methods regarding cost, materials, time, safety and management; potential for customization and freeform construction; reduction of waste during the construction phase; eco-friendly practice; diversity of materials practice; resource consumption; quality control/assurance for the surface finish. |

| Size [77] | In 3DP literature, all components are printed off-site, except for those generated by HuaShang Tengda. There is no detailed information about the off-site printed component dimensions but the highest 3DP residential building is a five-story apartment in Jiangsu Province, China. | Products (quality, size, duration, building height); control budget (high accuracy). |

| Laboratory or on-site practice; modular construction | High production costs and conventional printing materials are still the challenges of 3DP in modular construction [115]. Lack of investigation for post-occupancy satisfaction, and environmental measures. | Present an application for hollow concrete structural units (volumetric modular), such as the entire bathroom or kitchen, which can enhance the flexibility of the house space [64]. |

| Durability | Low corrosion resistance for reinforcement but high earthquake resistance [59]. | Durability indicators need to be measured in different contexts and climates. |

| Software interoperability | Except for the significant software Revit and Navisworks, Rhino and Catia are used for curtain wall and cooperated with Revit. RealWorks is a tool for point cloud data processing. Enovia is a data sharing and transfer platform to provide a ground for a project. | Little information included in the sample articles regarding software compatibility issues. |

| Productivity and cost effectiveness | High dimensional accuracy and the complex shapes of parts leads to a dramatic increase in production time, which limits productivity [116]. To meet the production standards, the decrease in build time leads to an increase in process time. Expensive post-processing is one of the main expenditures [117,118,119]. | Relieves labor intensity on the construction site and also in the office. The market evolution, supply chain management, production, and machinery costs and the reduction of reoccurring costs. Multiple nozzles, to optimize and reduce printing steps. |

| Legal | Lack of standards, guidelines, evaluation criteria, blockchain instructions and standards for 3DP practices. | Copyright/standard applicable for 3DP; unemployment. |

| Heritage applications [55,56] | Leung et al. [56] demonstrate how to use 3DP to repair historical buildings like the lighthouse at Penghu, between Xiamen and Taiwan. It uses state-of-the-art Revit to rebuild 3D virtual construction, save input detail into 3DP and then apply 3DP. | Earthquake resistance after construction. |

| Stakeholders and workers | An overall shortage of appropriately trained workers in AM, and limited opportunities for collaboration and exploitation of ideas [119]. | Knowledge reserve and skill cultivation. |

| Integration with BIM | A significant lack of experimental data and validated models for 3DP parts, lack of compatible conversion files [120]. | Open BIM has the potential to integrate more information and improve workflows for 3DP. |

| Metrology | Fundamentals of optical interrogation of the surface, such as the compromise between spatial resolution and field of view [121]. | High spatial resolution, fast and compatible with the production environment. |

| Binder | Organic binders work well among different binders, however they can affect the plastic parts of 3DP machines during long-term operation, and the residue from binders is difficult to remove during sintering [71]. | Sustainability of material and the continuous effect of binder on the mechanical properties of the material. |

| Calibration | Lack of simulation and calibration models based on a structured framework. The big diversity of shape and size of 3DP products [122]. | Integration of physical knowledge into models based on principles of model calibration. |

| Pump | Delivery segregation of particles; material blockage during high-pressure pumping process; discontinuous material based on slow pumping process [99]. | Insurance of the fluidity and constructability of material. |

| Geometrical imperfection | Prone to produce a layer-by-layer appearance [123]; layer deposition based on gravity, the thickness of the layer and material property [23]. | Development of material to improve the buildability. The improvement of machines, such as adding side flank with a nozzle. |

| Monitor | Difficulty in acquiring fast and accurate measurements of the temperature, cooling rate and residual stress [124]. | Implementation of other optical technology with higher precision, camera and ultrasonic C-scan, and in-process correction to compensate for the defect. |

| Industrial promotion | Lack of incentives for 3DP-transformation in industries; supply chain complexities; lack of skills and knowledge; regulation and liability issues [125]. | Government support and construction market stimulus. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepasgozar, S.M.E.; Shi, A.; Yang, L.; Shirowzhan, S.; Edwards, D.J. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. https://doi.org/10.3390/buildings10120231

Sepasgozar SME, Shi A, Yang L, Shirowzhan S, Edwards DJ. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings. 2020; 10(12):231. https://doi.org/10.3390/buildings10120231

Chicago/Turabian StyleSepasgozar, Samad M. E., Anqi Shi, Liming Yang, Sara Shirowzhan, and David J. Edwards. 2020. "Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review" Buildings 10, no. 12: 231. https://doi.org/10.3390/buildings10120231

APA StyleSepasgozar, S. M. E., Shi, A., Yang, L., Shirowzhan, S., & Edwards, D. J. (2020). Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings, 10(12), 231. https://doi.org/10.3390/buildings10120231