Correlation between Numerical and Experimental Structural Resistance of a Safety Relevant Aluminum Automotive Component

Abstract

1. Introduction

2. Materials and Methods

2.1. Geometry, Materials and Process Description

2.2. Experimental and Numerical Setups

- (i)

- FEA performed with standard load cases is used to verify the structural behaviour of a re-designed component under standard operating conditions. For example, in order to find the lightest geometry that is sufficiently resistant under the operating conditions, these structural simulations can be used to define a lightweight design, which can be achieved after many iterations of the component shape.

- (ii)

- A selection of physical durability tests is carried out on protypes to confirm that the physical component meets the requirements in terms of mechanical resistance. In this phase, a higher precision can be introduced using real data obtained from experimental investigation of the application (e.g., mission profiles and experimental mechanical properties of components).

- (iii)

- Identification of an efficient method to numerically evaluate the testing outputs in order to provide a correlation with the FEA simulation. For example, strain gauges can be introduced in the most representative areas evaluated following FEA examination.

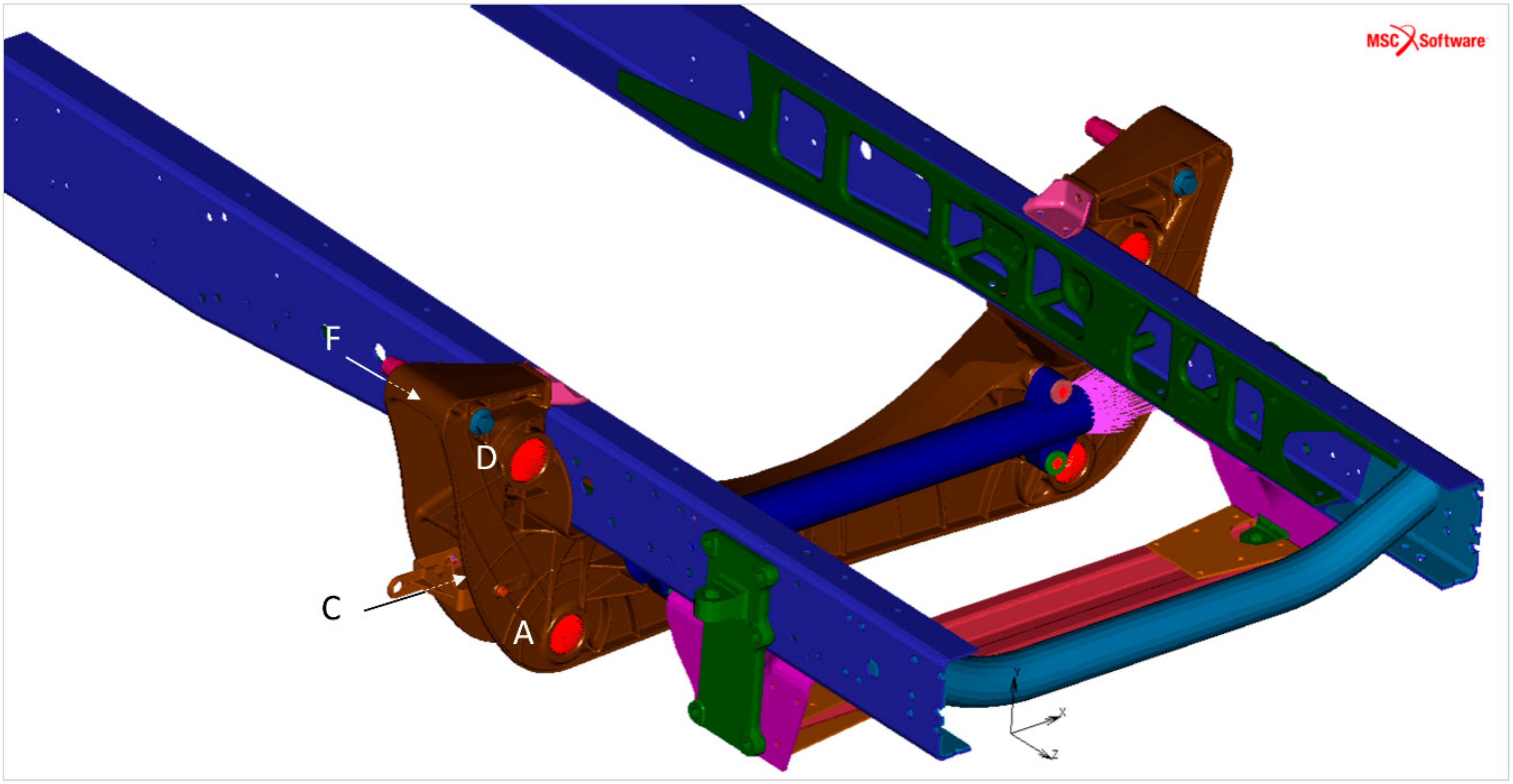

2.2.1. Finite Element Analysis (FEA)

- (i)

- the loads acting on the cross beam due to load at the wheels inputs, as derived from MSC AdamsCar,

- (ii)

- a relevant load case related to the steering of a stationary vehicle (Fx = 0 kN, Fy = 29 kN, Fz = 0 kN). This is a misuse condition representing the maximum load transmittable by the steering arms. For this load case, the force was applied based on a realistic representation of the connection between the hydraulic steering system and the cross beam, which were the main components of the subsystem.

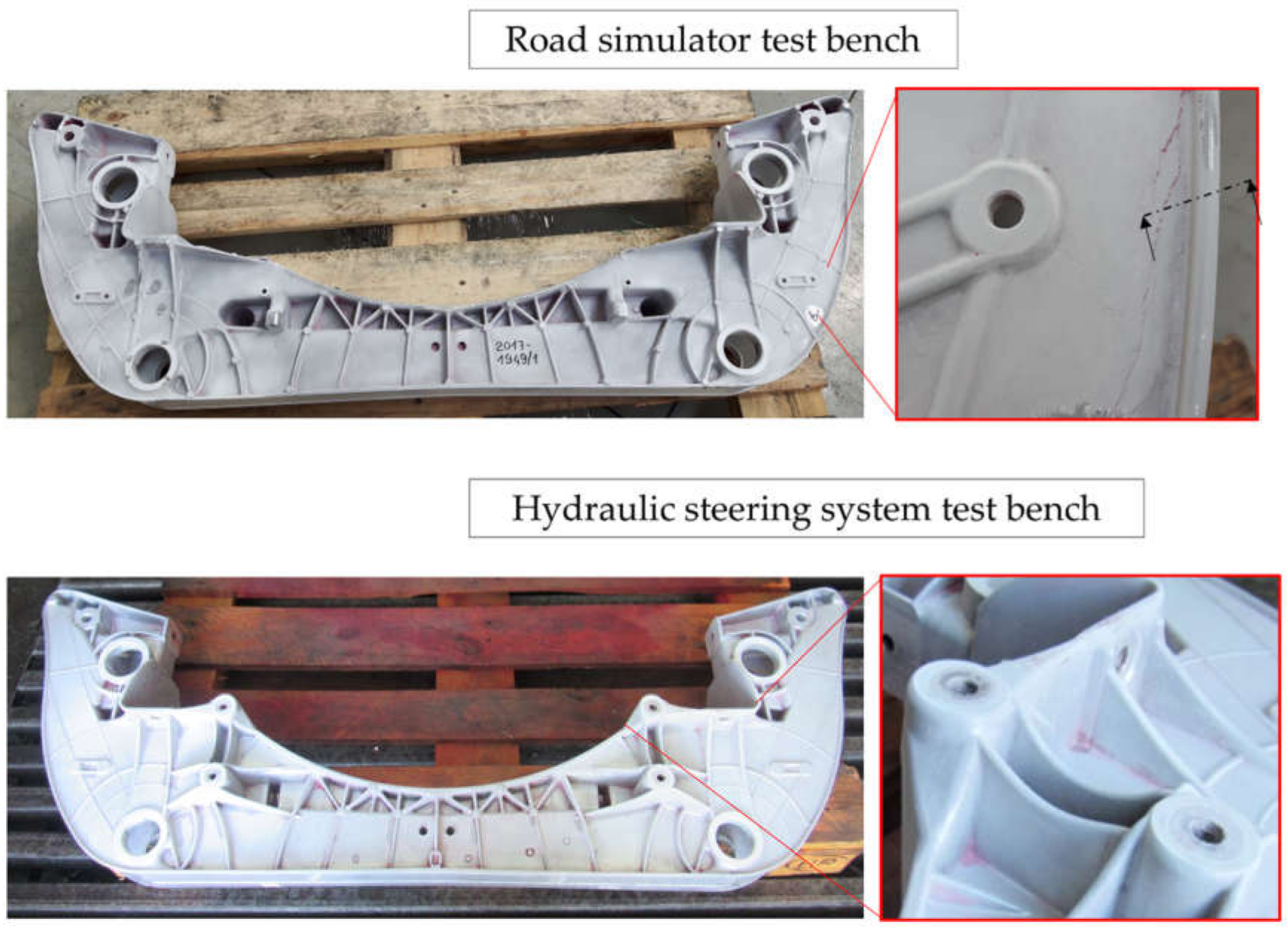

2.2.2. Road Simulator Testing

2.2.3. Fatigue Testing of Cross Beam Resistance under Hydraulic Steering System Load

2.2.4. FEA and Testing Correlation

- (i)

- Identification of the testing load inputs (real data based on WTF acquisition) with all three components (Fx, Fy, Fz) as close as possible to those of the FEA load cases,

- (ii)

- Micro-strain acquisition with strain gauges located in regions identified based on the evaluation of FEA results,

- (iii)

- Calculation of testing stresses using empirical Young’s modulus and Hooke’s law.

2.2.5. End-of-Testing Observations: Liquid Penetrant Testing and Microstructure

3. Results and Discussion

3.1. FEA Results

3.2. Road Simulator Testing

3.3. Fatigue Testing of Cross Beam Resistance under Hydraulic Steering System Loads

3.4. End-of-Testing Observations: Liquid Penetrant Testing and Microstructure

4. Conclusions

- The mechanical solicitations were generally below the safety threshold for all load cases analysed, which confirms the resistance of the innovative re-designed aluminium at the elevated operation loads.

- Some local compressive peaks (maximum stress ~100 MPa) were observed corresponding to the following cross beam interfaces: shock absorber, frame and hydraulic steering system. Note that the values calculated in these areas could be affected by the presence of rigid links used for the simulation of the connection.

- The greatest overall stresses were obtained for the vertical load case, while the highest local mechanical solicitation (~100 MPa local peak) was caused by the steering system forces.

- The 250,000 km road simulator test bench was successfully completed. The stress values measured (maximum peaks ~50 MPa) were always lower than the fatigue limit (σFAF = 89 MPa).

- The testing of the hydraulic steering system was successfully completed. The higher loads registered were ~30 MPa, with similar values for tension and compression state.

- The reliability of the traditional load cases used during FEA was confirmed. Indeed, the maximum loads used during the road simulator test were comparable to the simulated ones. It was also confirmed that FEA guarantees a safety margin, since these loads were slightly higher than the values calculated on the basis of in-field acquisition.

- The FEA and testing results were aligned. The average discrepancies were limited to only about 14 MPa and 6 MPa for the road simulator test bench and the hydraulic steering system test, respectively. The difference registered was lower for the latter experiment due to the simpler structure of this test bench.

- The demonstration of the fulfilment of the resistance limits is an excellent result for this kind of component. Indeed, it was verified that the hollowed shape of the innovative cross beam endured at the elevated mission loads typical for this class of vehicle. These results can also be extended to the redesign of other safety-relevant components belonging to this class of vehicle.

- The correlation method presented in this paper was proven to be reliable, since it enabled not only the numerical evaluation of the testing output, but also the validation of the calculation tools. The three-step method presented in this paper could be systematically applied for the analysis of other complex systems, not limited to suspension assemblies, in order to validate innovative projects in a reliable and verifiable way. It is worthwhile to remember that a rigorous evaluation of the results is a relevant item for safety-critical components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Helms, H.; Lambrecht, U. The potential contribution of light-weighting to reduce transport energy consumption. Int. J. Life Cycle Assess. 2007, 12, 58–64. [Google Scholar]

- Modaresi, R.; Pauliuk, S.; Lovik, A.N.; Muller, D.B. Global carbon benefits of material substitution in passenger cars until 2050 and the impact on the steel and aluminum industries. Environ. Sci. Technol. 2014, 48, 10776–10784. [Google Scholar] [CrossRef] [PubMed]

- Das, S. Life Cycle Energy and Environmental Assessment of Aluminum-Intensive Vehicle Design. SAE Int. J. Mater. Manuf. 2014, 7, 588–595. [Google Scholar] [CrossRef]

- Bertram, M.; Buxmann, K.; Furrer, P. Analysis of greenhouse gas emissions related to aluminium transport applications. Int. J. Life Cycle Assess. 2009, 14, 62–69. [Google Scholar] [CrossRef]

- Dioni, D.; Cecchel, S.; Cornacchia, G.; Faccoli, M.; Panvini, A. Effects of artificial aging conditions on mechanical properties of gravity cast B356 aluminum alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1035–1042. [Google Scholar] [CrossRef]

- Cecchel, S.; Chindamo, D.; Turrini, E.; Carnevale, C.; Cornacchia, G.; Gadola, M.; Panvini, A.; Volta, M.; Ferrario, D.; Golimbioschi, R. Impact of reduced mass of light commercial vehicles on fuel consumption, CO2 emissions, air quality, and socio-economic costs. Sci. Total Environ. 2018, 613–614, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Cecchel, S.; Ferrario, D.; Panvini, A.; Cornacchia, G. Lightweight of a cross beam for commercial vehicles: Development, testing and validation. Mater. Des. 2018, 149, 122–134. [Google Scholar] [CrossRef]

- Chindamo, D.; Gadola, M. Reproduction of real-world road profiles on a four-poster rig for indoor vehicle chassis and suspension durability testing. Adv. Mech. Eng. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Chindamo, D.; Lenzo, B.; Gadola, M. On the vehicle sideslip angle estimation: A literature review of methods, models and innovations. Appl. Sci. 2018, 8, 355. [Google Scholar] [CrossRef]

- Azrulhisham, E.A.; Asri, Y.M.; Dzuraidah, A.W.; Nik Abdullah, N.M.; Shahrum, A.; Che Hassan, C.H. Evaluation of Fatigue Life Reliability of Steering Knuckle Using Pearson Parametric Distribution Model. Int. J. Qual. Stat. Reliab. 2010, 8. [Google Scholar] [CrossRef][Green Version]

- Lee, D.C.; Han, C.S. CAE (Computer Aided Engineering) driven durability model verification for the automotive structure development. Finite Elem. Anal. Des. 2009, 45, 324–332. [Google Scholar] [CrossRef]

- Bladh, K. Virtual Full Vehicle Durability Testing of a Coach. Master’s Science Thesis MMK 2012:17 MKN 055, KTH Industrial Engineering and Management, Stockholm, Sweden, 2012. [Google Scholar]

- Dressler, K.; Speckert, M.; Bitsch, G. Virtual durability test rigs for automotive engineering. Veh. Syst. Dyn. 2009, 47, 387–401. [Google Scholar] [CrossRef]

- Magalhaes, R.R.; Fontes, C.H.; Vieira de Melo, S.A.B. Failure analysis and design of a front bumper using finite element method along with durability and rig tests. Int. J. Veh. Des. 2012, 71–83. [Google Scholar] [CrossRef]

- Uberti, S.; Gadola, M.; Chindamo, D.; Romano, M.; Galli, F. Design of a double wishbone front suspension for an orchard/vineyard tractor: A kinematic analysis. J. Terramech. 2015, 57, 23–39. [Google Scholar] [CrossRef]

- Mattetti, M.; Molari, G.; Vertua, A. New methodology for accelerating the four-post testing of tractors using wheel hub displacements. Biosyst. Eng. 2015, 129, 307–314. [Google Scholar] [CrossRef]

- Cecchel, S.; Collotta, M.; Cornacchia, G.; Panvini, A.; Tomasoni, G. A comparative cradle-to gate impact assessment: Primary and secondary aluminum automotive components case. La Metall. Ital. 2018, 2, 46–55. [Google Scholar]

- Cecchel, S.; Cornacchia, G.; Panvini, A. Cradle-to-Gate Impact Assessment of a High-Pressure Die-Casting Safety-Relevant Automotive Component. JOM 2016, 8, 2443–2448. [Google Scholar] [CrossRef]

- Cecchel, S.; Cornacchia, G.; Gelfi, M. Corrosion behavior of primary and secondary AlSi High Pressure Die Casting alloys. Mater. Corros. 2017, 68, 961–969. [Google Scholar] [CrossRef]

- Cecchel, S.; Chindamo, D.; Collotta, M.; Cornacchia, G.; Panvini, A.; Tomasoni, G.; Gadola, M. Lightweighting in light commercial vehicles: Cradle-to-grave life cycle assessment of a safety relevant component. IJLCA 2018, 1–12. [Google Scholar] [CrossRef]

- Cornacchia, G.; Cecchel, S.; Panvini, A. A comparative study of mechanical properties of metal inert gas (MIG)-cold metal transfer (CMT) and fiber laser-MIG hybrid welds for 6005A T6 extruded sheet. Int. J. Adv. Manuf. Technol. 2017, 94, 2017–2030. [Google Scholar] [CrossRef]

- Cecchel, S.; Ferrario, D. Numerical and experimental analysis of a high pressure die casting Aluminum suspension cross beam for light commercial vehicles. La Metall. Ital. 2016, 6, 41–44. [Google Scholar]

- Cecchel, S.; Cornacchia, G.; Gelfi, M. A study of a non-conventional evaluation of results from salt spray test of aluminum High Pressure Die Casting alloys for automotive components. Mater. Corros. 2019, 70, 70–78. [Google Scholar] [CrossRef]

- Cecchel, S.; Cornacchia, G.; Panvini, A. Low temperature T6 heat treatment of AlSi9Cu3(Fe) high pressure die casting actual automotive components. J. Mater. Eng. Perform. 2018, 27, 3791. [Google Scholar] [CrossRef]

- Primary Aluminium Alloys for Pressure die Casting. Available online: http://rheinfelden-alloys.eu/wp-content/uploads/2016/01/05-HB-DG_Ci_Sf_Cm_Td_Ma_RHEINFELDEN-ALLOYS_2015_EN.pdf (accessed on 1 August 2019).

- Uni ente Italiano di Normazione. UNI 10478-4:1998, Prove non Distruttive-Controllo Mediante Estensimetri Elettrici a Resistenza-Circuiti di Misura, Elaborazione e Presentazione dei Risultati; Uni ente Italiano di Normazione: Milano, Italy, 1998. [Google Scholar]

- Dong, Z.; Wang, X.; Lou, W.; Huang, Y.; Zhong, M.; Fan, H.; Peng, L. Simulation of the Spindle Coupled Multi-Axial Loading Fatigue Test of a Minivan Rear Axle. Strength Mater. 2017, 49, 872–896. [Google Scholar] [CrossRef]

- Palma, E.S.; Dos Santos, E.S. Fatigue damage analysis in an automobile stabilizer bar. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 865–871. [Google Scholar] [CrossRef]

- Casari, D.; Merlin, M.; Garagnani, G.L. Influence of injection parameters on the final surface quality of Al-Si-Cu die cast components. Metall. Sci. Technol. 2012, 30, 12–18. [Google Scholar]

- Canalesa, A.A.; Talamantes-Silva, J.; Gloria, D.; Valtierra, S.; Colás, R. Thermal analysis during solidification of cast Al–Si alloys. Thermochim. Acta 2010, 510, 82–87. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Ni | Zn | Sn | Ti | |

|---|---|---|---|---|---|---|---|---|---|

| EN AC-43500 | 9.5–11.5 | 0.15 | 0.03 | 0.5–0.8 | 0.1–0.5 | - | 0.07 | - | 0.15 |

| Loads at Wheels (kN) | |||

|---|---|---|---|

| Load Case | X | Y | Z |

| Vertical | 0 | 0 | 24.7 |

| Brake | 14.19 | 0 | 15.7 |

| Lateral | 0 | 14.5 | 20.6 |

| FX (kN) | FY (kN) | FZ (kN) | |

|---|---|---|---|

| MBS: load case “Vertical” | 0 | 0 | 24.7 |

| Road simulator: mission “rough-terrain” | −1.47 | −2.46 | 19.20 |

| MBS: load case “Brake” | −14.19 | 0 | 15.7 |

| Road simulator: mission “special racetrack - brake” | −10.70 | 0.34 | 15.22 |

| MBS: Load case “Lateral” | 0 | −14.5 | 20.6 |

| Road simulator: mission “special racetrack - steering” | −2.06 | −12.90 | 14.13 |

| Left WFT | Right WFT | |||||

|---|---|---|---|---|---|---|

| FX | FY | FZ | FX | FY | FZ | |

| MBS: Load case “Vertical” | 0 | 0 | 24.7 | 0 | 0 | 24.7 |

| Road simulator: mission “rough-terrain” | −0.71 | −0.55 | 15.30 | 1.00 | −0.11 | 18.10 |

| MBS: Load case “Brake” | −14.19 | 0 | 15.7 | 14.2 | 0 | 15.17 |

| Road simulator: mission “special racetrack - brake” | −7.72 | −0.96 | 12.49 | 7.68 | 1.04 | 12.13 |

| MBS: Load case “Lateral” | 0 | −14.5 | 20.6 | 0 | 0 | 0 |

| Road simulator: mission “special racetrack - steering” | −1.62 | −12.26 | 15.54 | −0.61 | 4.11 | 3.84 |

| ER #1 | ER #2 | ER #3 | ER #4 | |

|---|---|---|---|---|

| Load case “Vertical” | 54.5 | 53.0 | 53.0 | −60.5 |

| Road simulator: mission “rough-terrain” | 46.7 | 27.1 | 28.0 | −32.1 |

| Load case “Brake” | 0.0 | 8.0 | 14.0 | −20.0 |

| Road simulator: mission “special racetrack - brake” | 20.2 | 11.5 | 12.3 | −21.8 |

| Load case “Lateral” | 0.0 | 0.0 | 0.0 | 0.0 |

| Road simulator: mission “special racetrack - steering” | 19.7 | 7.4 | 9.3 | −16.9 |

| ER #5 | ER #6 | |||||

|---|---|---|---|---|---|---|

| Input loads (kN) | +F1 | 29 | Output stresses (MPa) | load case “hydraulic steering system” | 30 | 15 |

| Fatigue testing bench “hydraulic steering system” | 25 | 4 | ||||

| −F1 | −29 | load case “hydraulic steering system” | −30 | −15 | ||

| Fatigue testing bench “hydraulic steering system” | −30 | −9 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cecchel, S.; Ferrario, D.; Mega, F.; Cornacchia, G. Correlation between Numerical and Experimental Structural Resistance of a Safety Relevant Aluminum Automotive Component. Metals 2019, 9, 949. https://doi.org/10.3390/met9090949

Cecchel S, Ferrario D, Mega F, Cornacchia G. Correlation between Numerical and Experimental Structural Resistance of a Safety Relevant Aluminum Automotive Component. Metals. 2019; 9(9):949. https://doi.org/10.3390/met9090949

Chicago/Turabian StyleCecchel, Silvia, Davide Ferrario, Francesco Mega, and Giovanna Cornacchia. 2019. "Correlation between Numerical and Experimental Structural Resistance of a Safety Relevant Aluminum Automotive Component" Metals 9, no. 9: 949. https://doi.org/10.3390/met9090949

APA StyleCecchel, S., Ferrario, D., Mega, F., & Cornacchia, G. (2019). Correlation between Numerical and Experimental Structural Resistance of a Safety Relevant Aluminum Automotive Component. Metals, 9(9), 949. https://doi.org/10.3390/met9090949